An automatic grinding machine for the sealing surface of a floating oil seal and its grinding process

A technology for floating oil seals and sealing surfaces, which is applied to grinding workpiece supports, machine tools suitable for grinding workpiece planes, grinding machines, etc., can solve problems such as insufficient precision of floating oil seal sealing surfaces, and achieve a wide range of applications, which is conducive to popularization and use convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

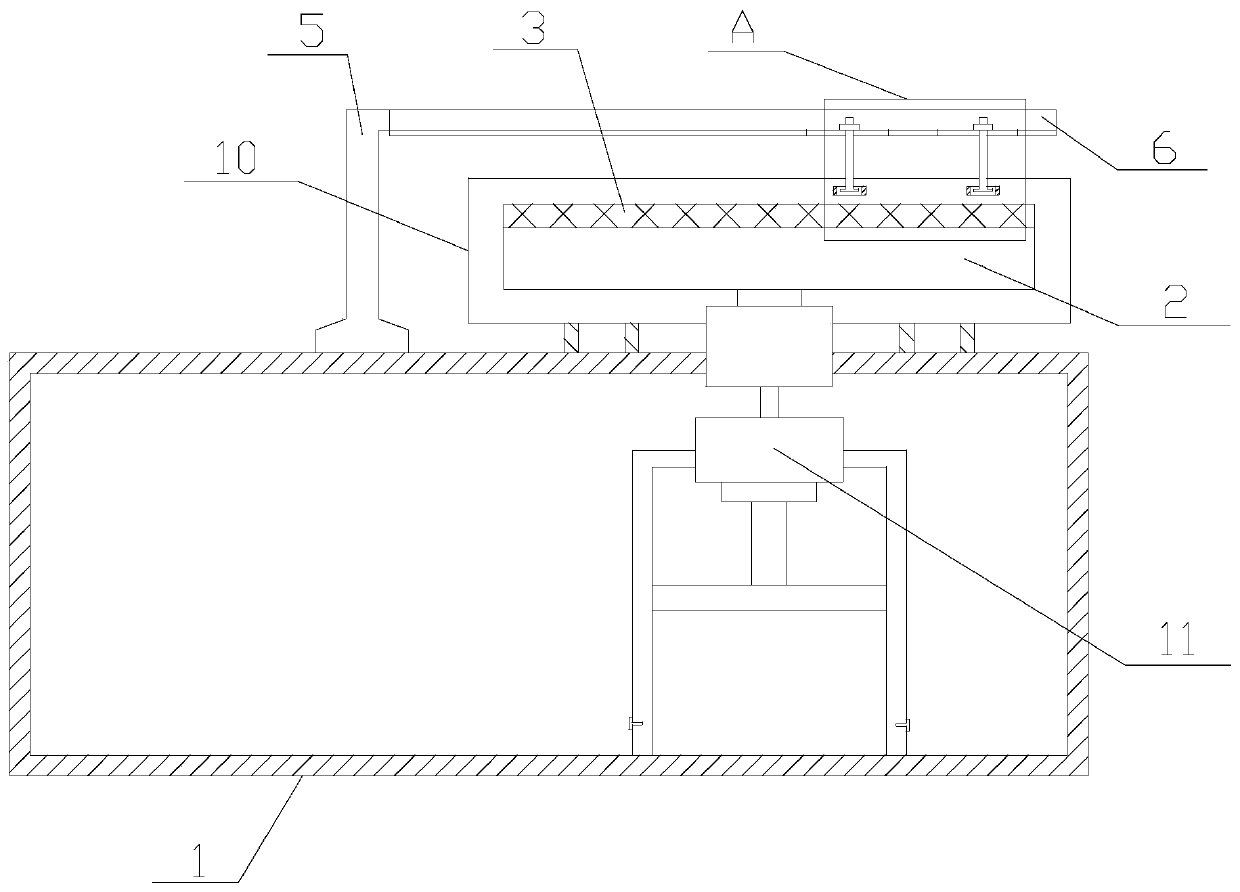

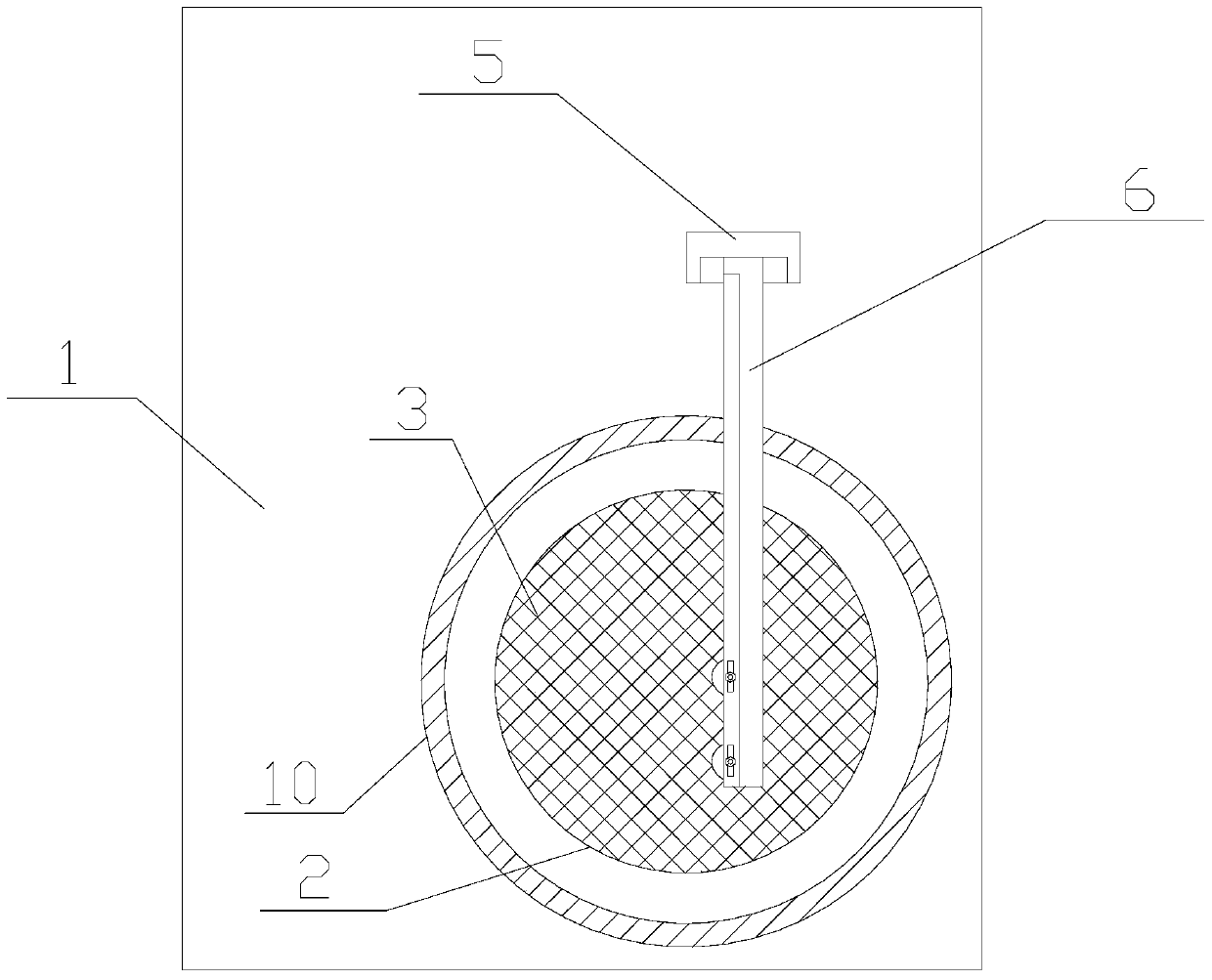

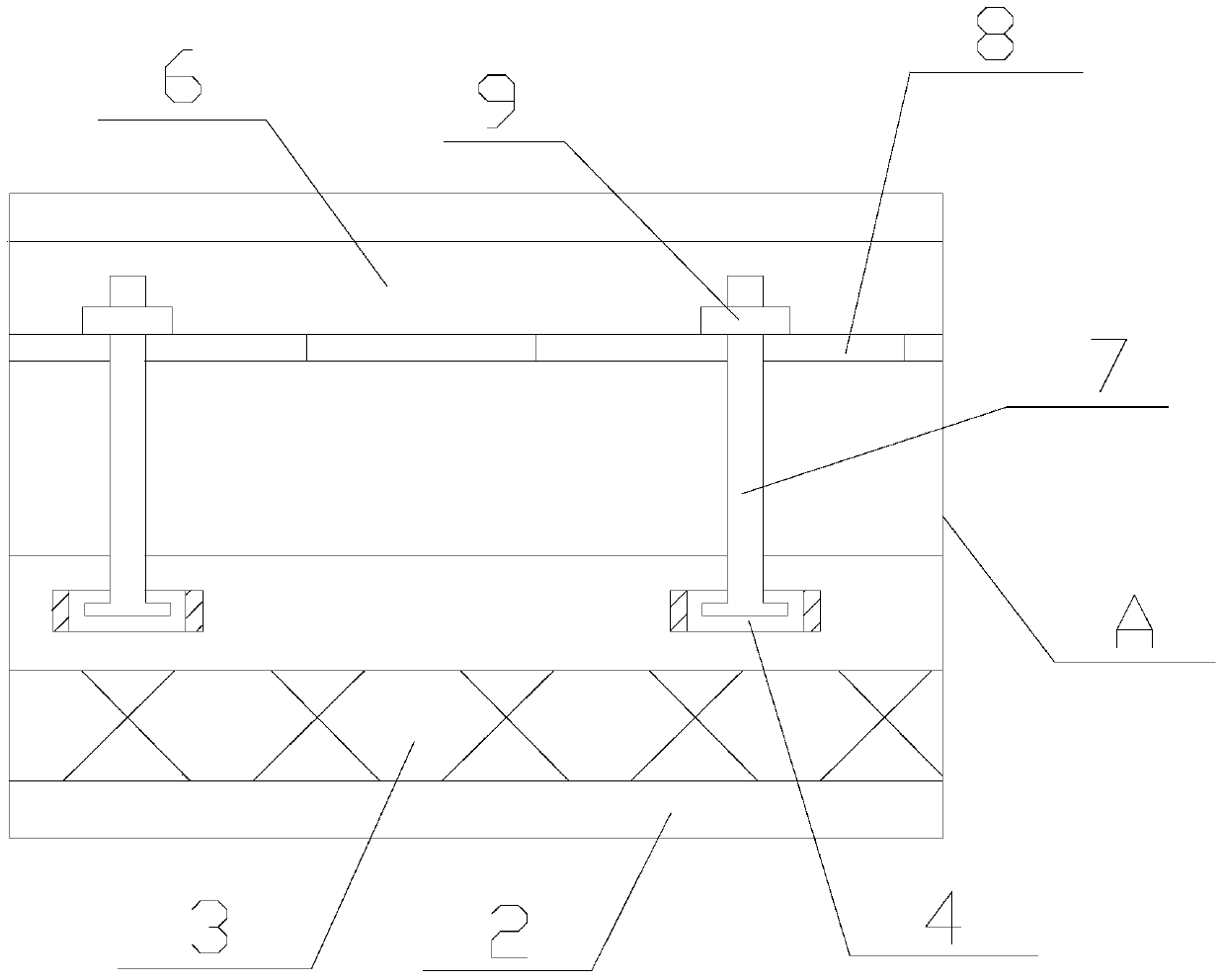

[0023] The present invention will be further described below in conjunction with accompanying drawing:

[0024] Referring to the accompanying drawings: the automatic grinding machine for the sealing surface of the floating oil seal in the present embodiment includes a workbench 1, the surface of the workbench 1 is provided with a grinding disc 2, and the surface of the grinding disc 2 is convexly provided with a pitted surface layer 3, and the pitted surface A pair of rollers 4 are arranged above the layer 3, wherein one roller 4 is positioned at the middle part of the textured layer 3, and the other roller 4 is positioned at the edge of the textured layer 3, and the rolling surface of the rollers 4 is arranged in parallel with the textured layer 3. The roller 4 is connected with the support roller 4 suspended on the support 5 above the pockmarked surface layer 3, the support 5 is positioned above the pockmarked surface layer 3, the support 5 is connected with a pole 6, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com