High-pressure regulation valve and pressure detection device

A technology of verification device and pressure regulating valve, applied in valve device, valve operation/release device, lift valve, etc., can solve the problems of poor sealing effect and reliability, large volume, low pressure resistance, etc., and achieve high sealing accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

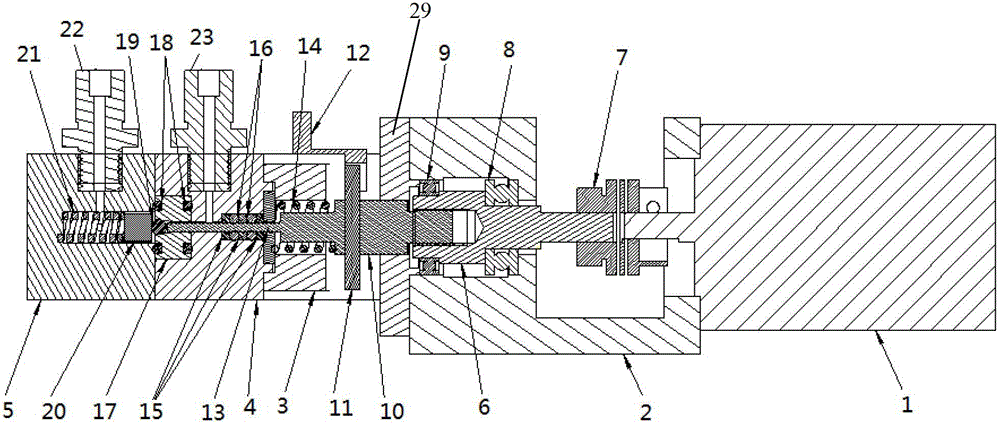

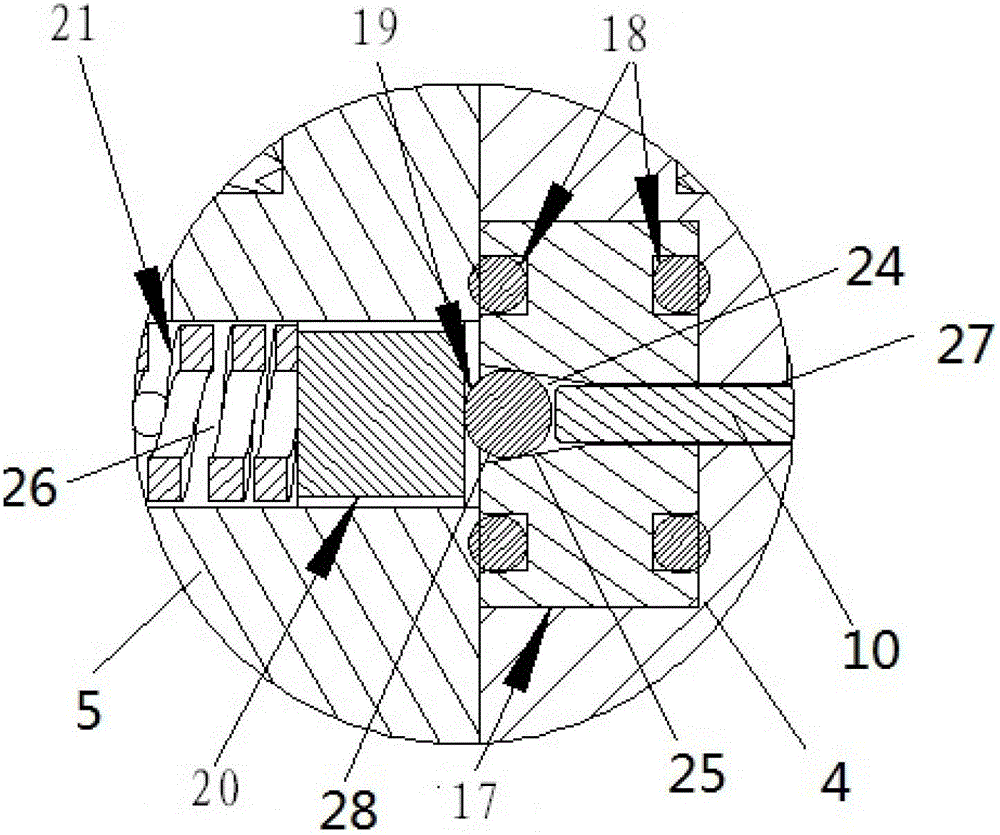

[0032] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0033] like figure 1 and figure 2 As shown, a high-pressure regulator valve includes a valve seat 4, a valve end cover 5, a high-pressure joint 22, a low-pressure joint 23, a thimble 10 and a power source. The low-pressure joint 23 is arranged longitudinally on the valve seat 4 , and the valve seat 4 also has a first valve chamber 27 extending transversely. The low-pressure joint 23 communicates with the first valve chamber 27 . The high-pressure joint 22 is arranged longitudinally on the valve end cover 5 , and the valve end cover 5 also has a second valve cavity 26 extending transversely, and the high-pressure joint 22 communicates with the second valve cavity 26 . The first valve cavity 27 and the second valve cavity 26 are butted, and the butt joint of the first valve cavity 27 is provided with a conical cavity 24 . The ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com