Method and device for automatically sealing two contact surfaces twice for drip injection

A sealing device and injection technology, applied in the field of medical devices, can solve the problems of low sealing precision, loss of sealing, low processing precision of plastic parts, etc., and achieve the effects of high sealing precision, firm sealing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

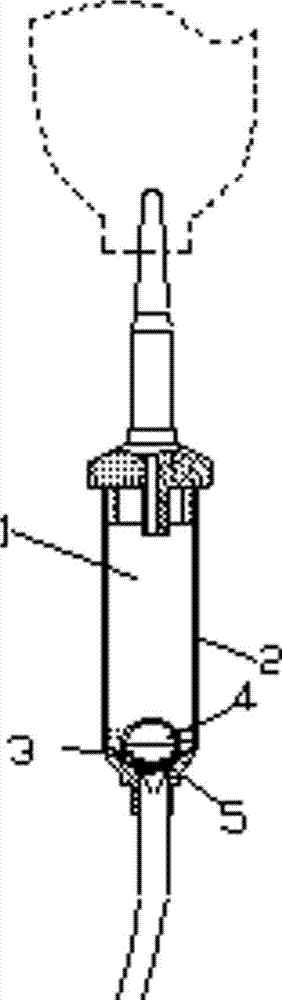

[0019] The method for automatically sealing the two contact surfaces twice with drip injection, the steps are as follows:

[0020] (1) During drip injection, the soft sealing body 3 in the drip funnel in the drip syringe 1 floats up to make the injection go smoothly;

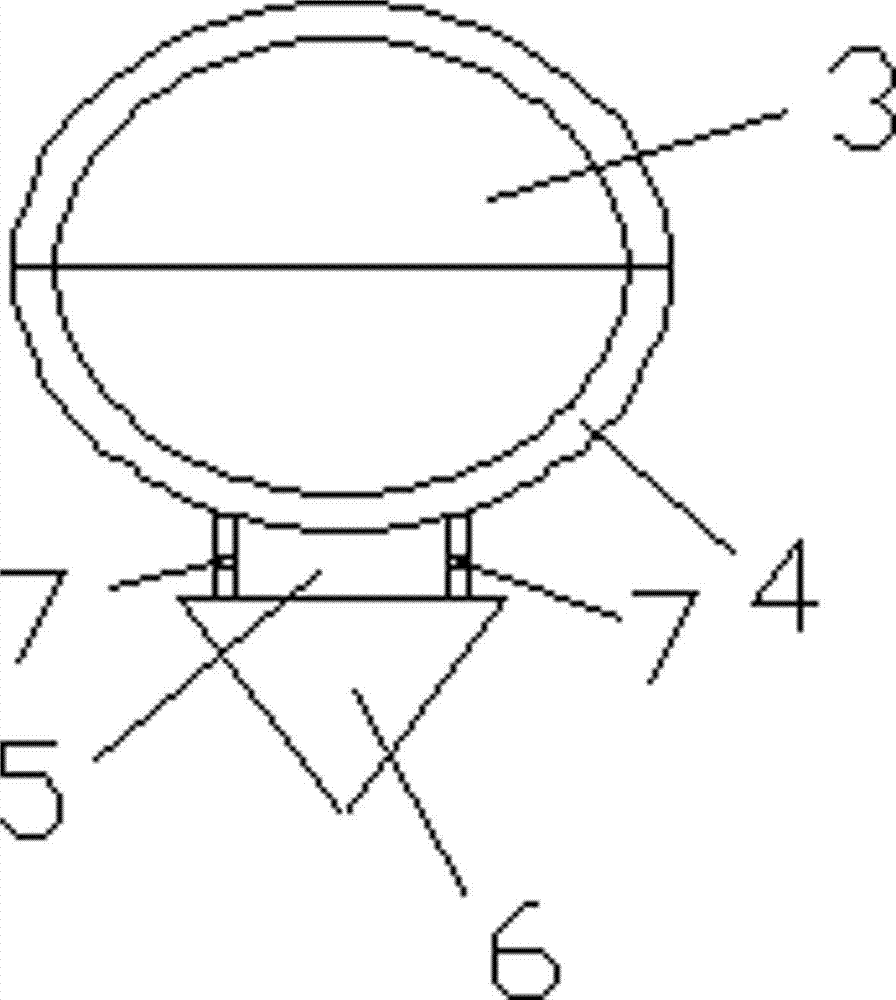

[0021] (2) After the drip injection is injected, the outer surface of the lower part of the thin-walled bag in the soft sealing body 3 seals the inner wall of the liquid outlet of the drip funnel;

[0022] (3) After the inner wall is sealed, the liquid in the thin-walled soft bag is deformed under the double action of the gravity of the floating body 4 and the gravity of the liquid in the bag, and the liquid in the soft bag is discharged from the water inlet and outlet 7 at the lower part of the floating body 4 Outflow, the outer surface of the thin-walled soft bag covers the end face of the water outlet in the drip funnel, thereby achieving two-sided sealing.

[0023] (4) The nurse has time to change the injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com