Electrical connector and manufacturing method thereof

A technology of an electrical connector and a manufacturing method, which is applied to the connection, the parts of the connecting device, the protective grounding/shielding device of the connecting part, etc., can solve the problems of the cumbersome manufacturing process of the electrical connector, the high production cost, the low structural strength, and the like, To achieve the effect of simple manufacturing process, reducing production cost and improving sealing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

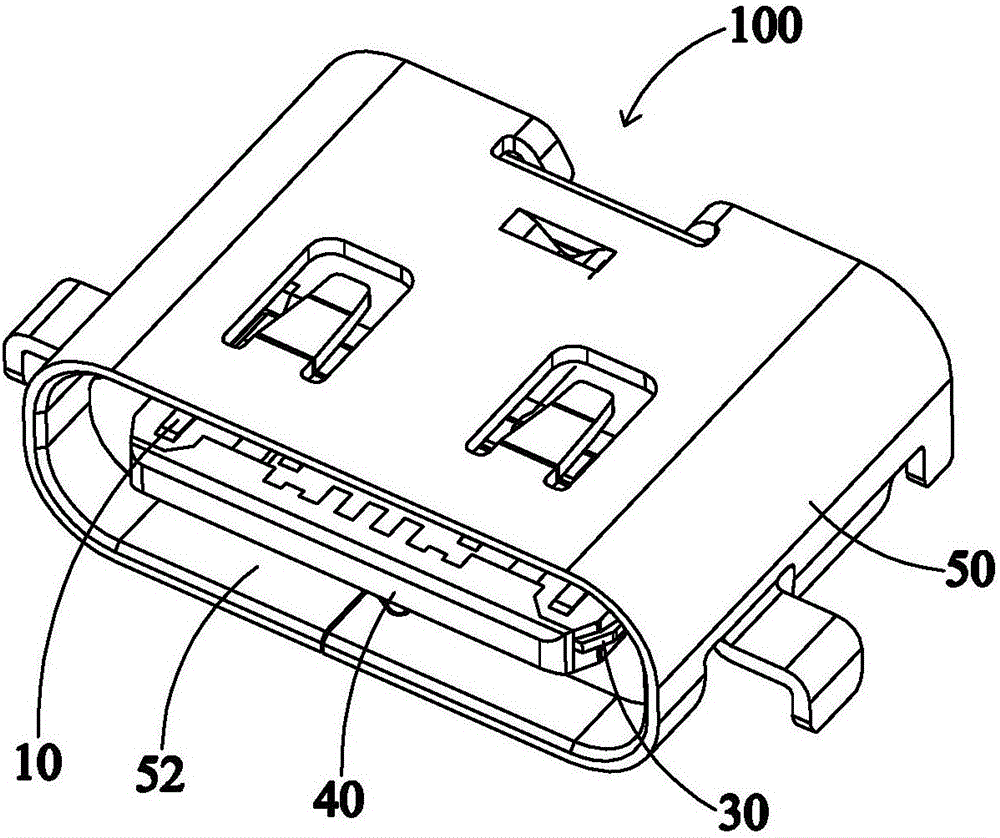

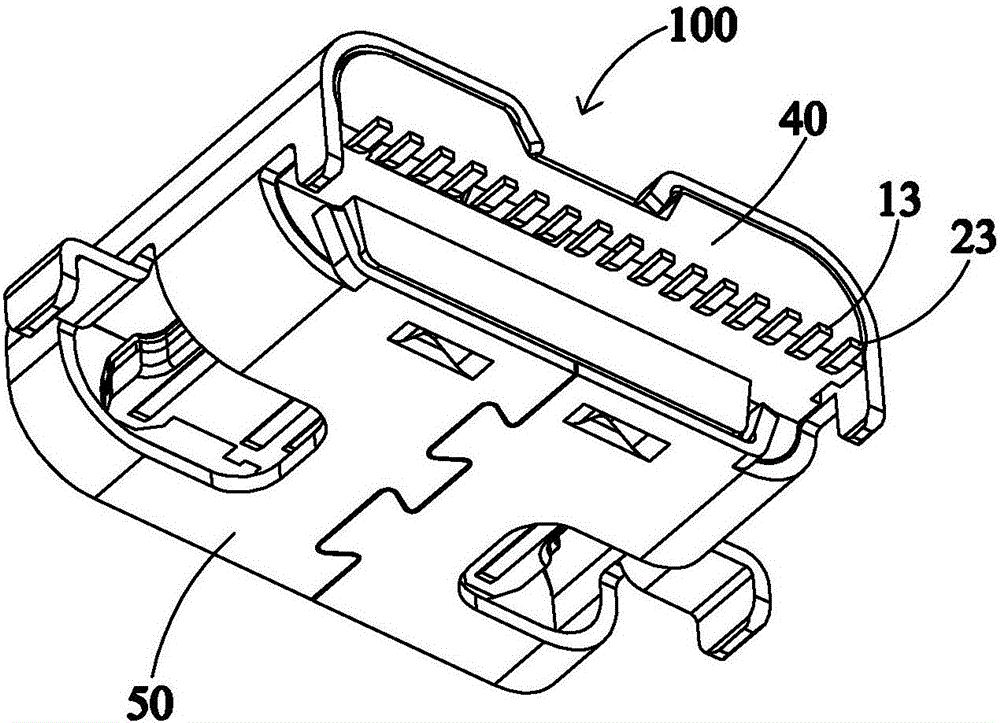

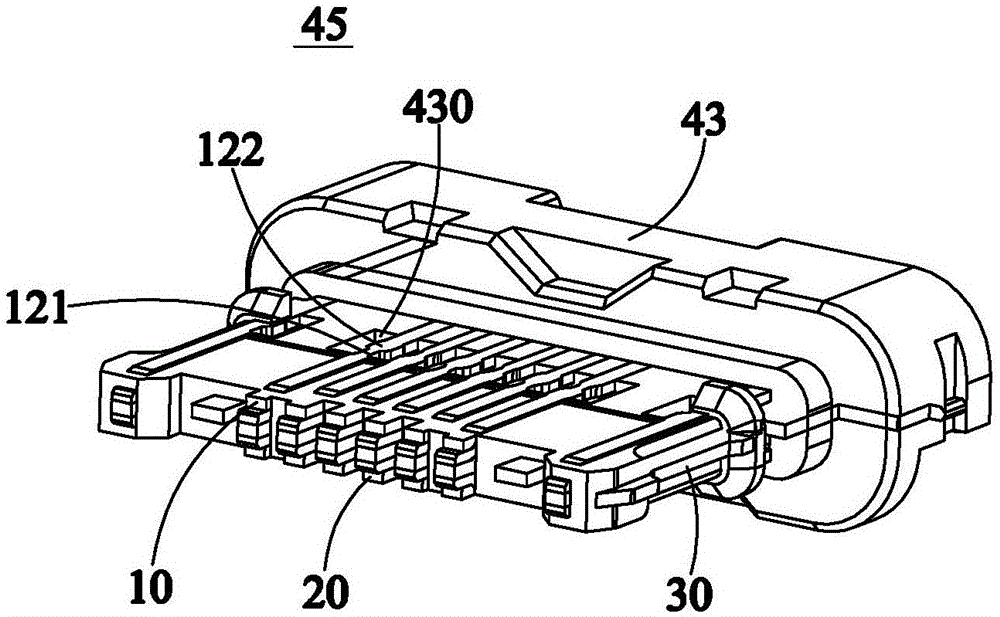

[0029] see Figure 1 to Figure 4 As shown, the electrical connector 100 of the present invention is a USB Type-C receptacle connector with forward and reverse insertion functions, and is used to be welded on a circuit board (not shown) for docking with a plug connector (not shown) , which includes terminals having a first terminal group 10 and a second terminal group 20 , an intermediate shielding sheet 30 , an insulating body 40 and a metal shell 50 .

[0030] Please refer to Figure 1 to Figure 9 As shown, the first terminal group 10 includes a first contact portion 11, a first fixing portion 12 and a first welding portion 13, the first contact portion 11 is located in front of the first welding portion 13, and the first fixing portion 12 is connected to the first contact Between the part 11 and the first welding part 13. The front end of the first fixing part 12 is provided with a wider part 121 and a narrower part 122 close to the first contact part 11. The two sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com