Spinning stop valve

A globe valve and valve body technology, applied in sliding valves, valve details, valve devices, etc., can solve the problems of high power consumption, sealing leakage, and inability to remove debris on the sealing surface, and achieve low power consumption and reduce transmission torque. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

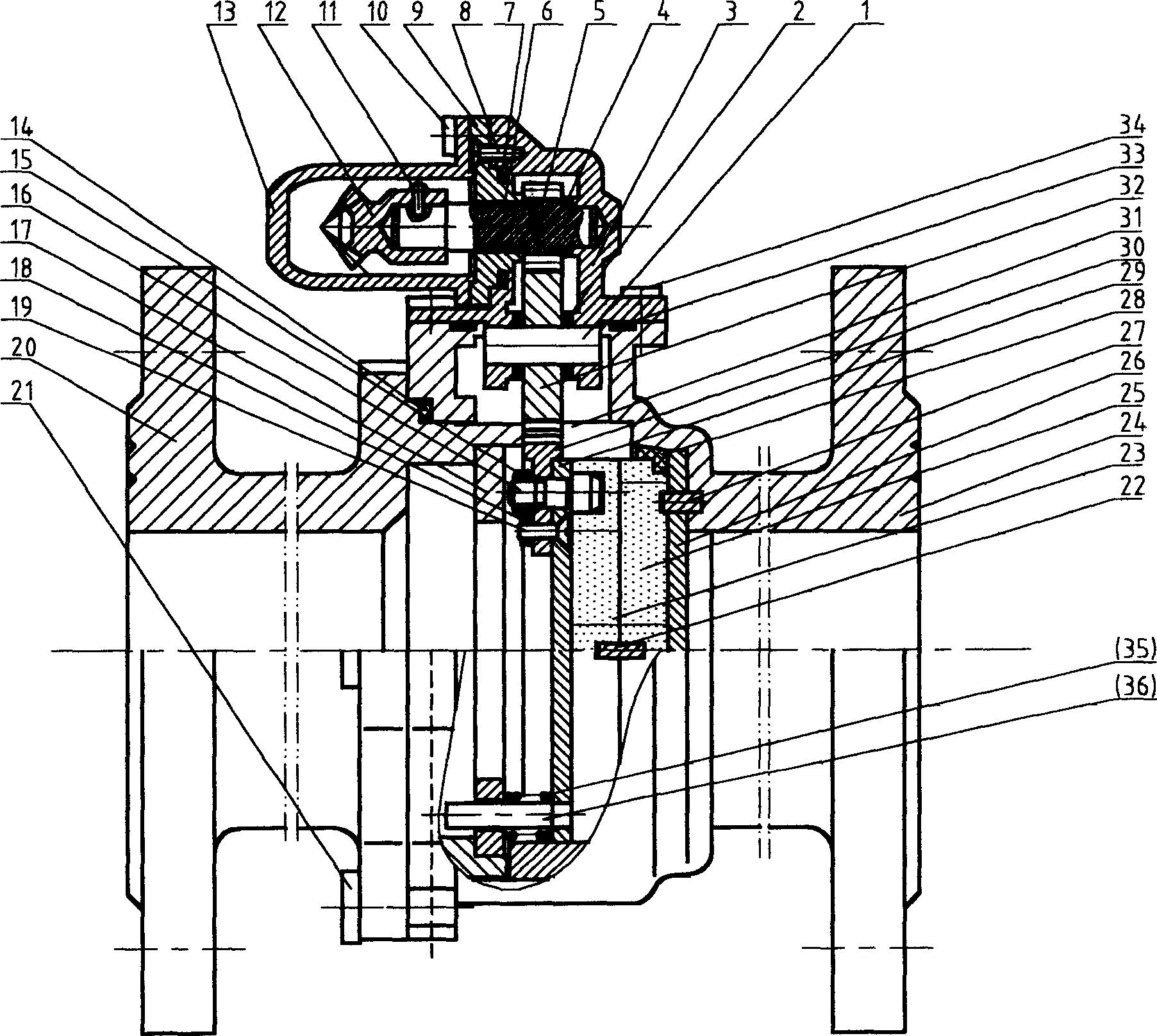

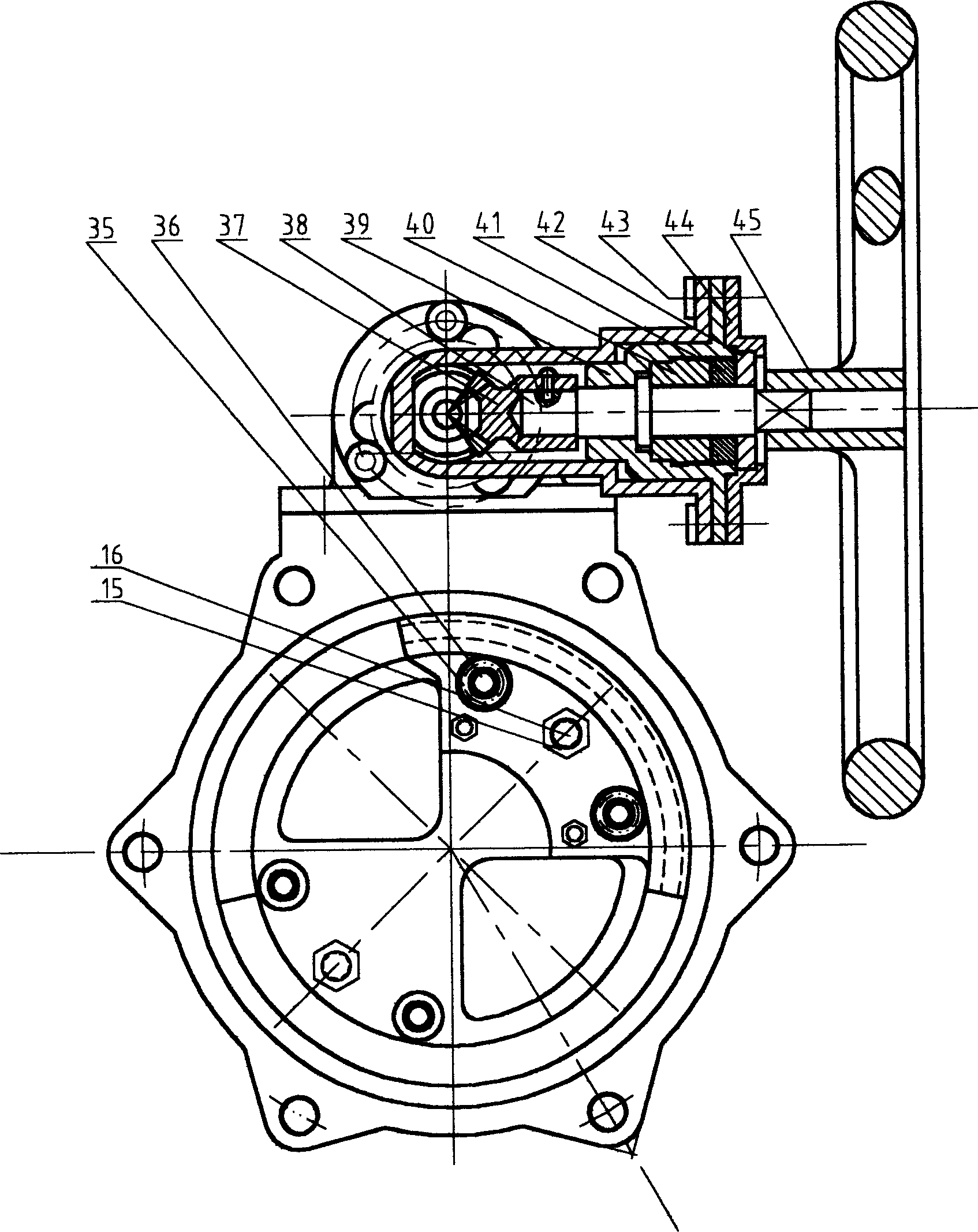

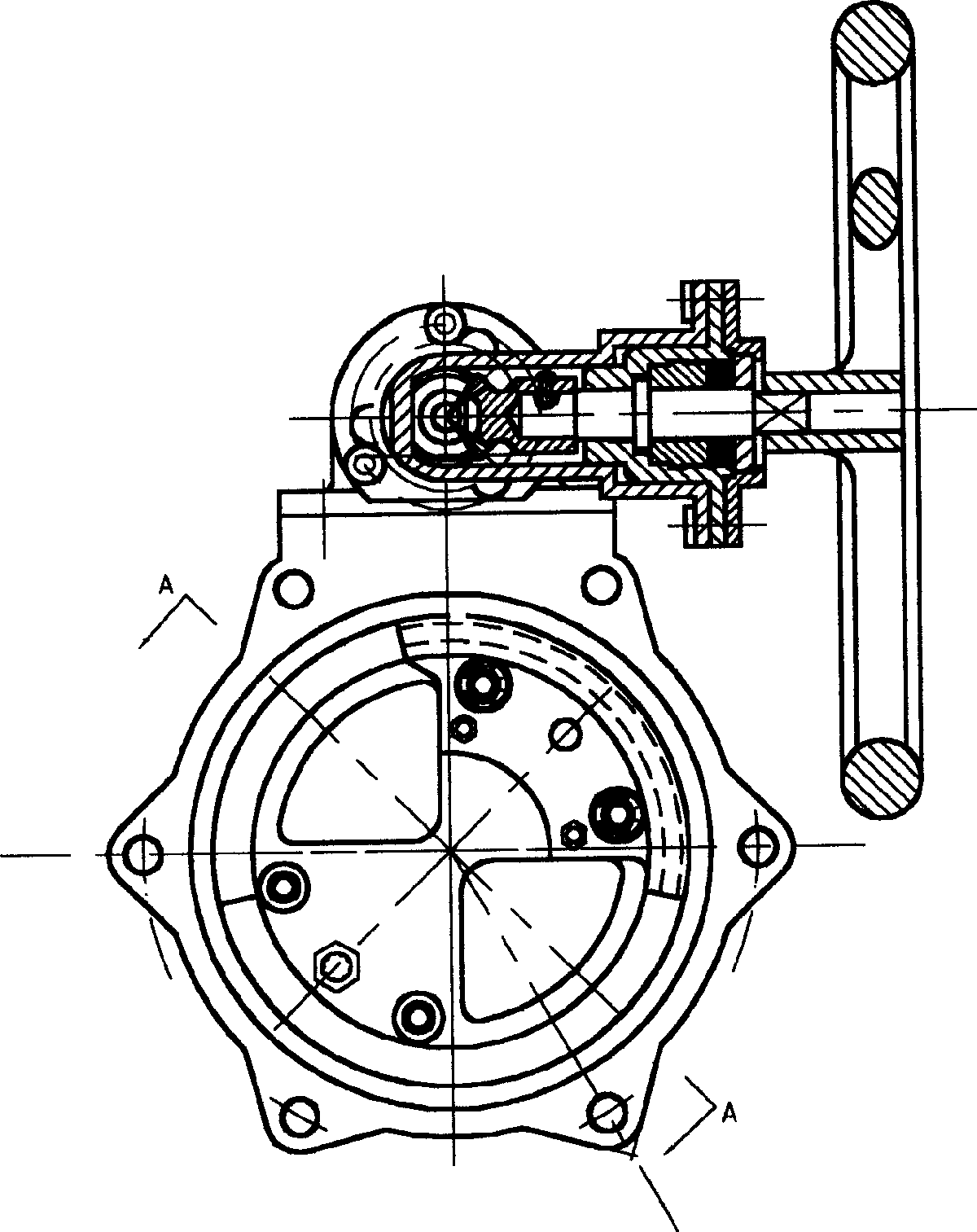

[0018] Refer to attached Figure 1-2 , the spinning type globe valve is composed of a transmission device on the side of the valve body, a pressure compensation device, and a spinning sealing device. The hand wheel 45 is connected to the front end of the transmission shaft 38, and the rear end is connected to the fixed bevel gear 37, which is crimped by the support sleeve 39 and the nut 40. The centering ring sleeve 42 is slidingly fitted, the support sleeve 39 is fixed on the support tube 13, the support tube 13 is fixed on the gear box 3 by the hexagonal bolt 10, and is fixed on the valve body 24 by the hexagonal bolt 34, and the front end of the driving gear shaft 5 is installed The bevel gear 12 meshes with the bevel gear 37. The middle part of the gear shaft 5 is covered with an O-ring 6 and the gear box cover 9 for rotation and sealing cooperation. The gear box cover 9 is fixed on the gear box 3 by the countersunk screw 8. The gear shaft The rear end of 5 is slidingly ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com