Continuously variable transmission driving belt with sliding vanes

A technology of continuously variable transmission and transmission belt, which is applied in the direction of transmission belts, belts/chains/gears, mechanical equipment, etc. It can solve the problems of poor anti-overload and anti-shock performance, large sliding rate, and low load-bearing capacity, and achieve anti-overload and anti-shock resistance The effect of poor performance and large slip rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, embodiments of the present invention will be further described with reference to the drawings.

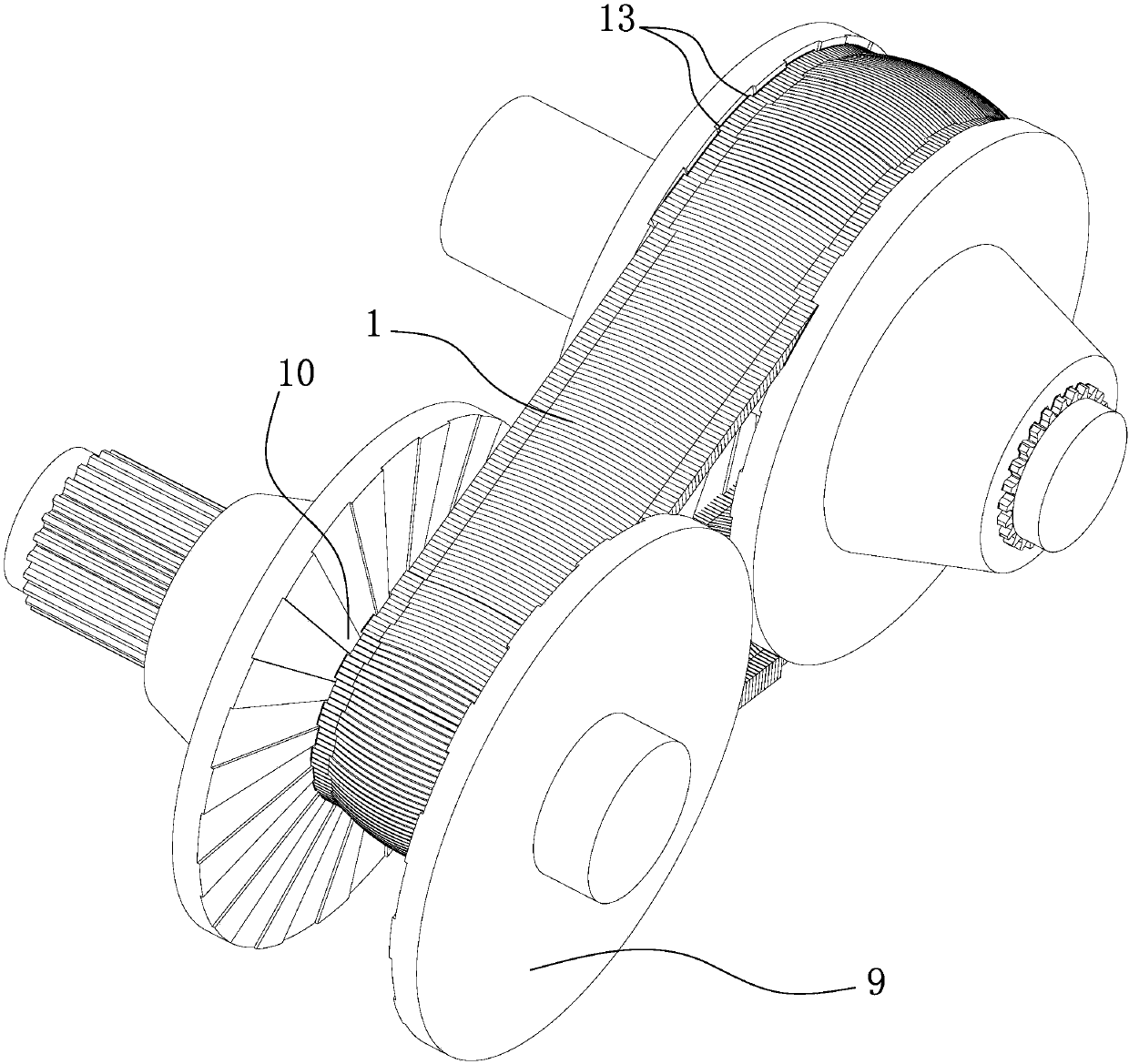

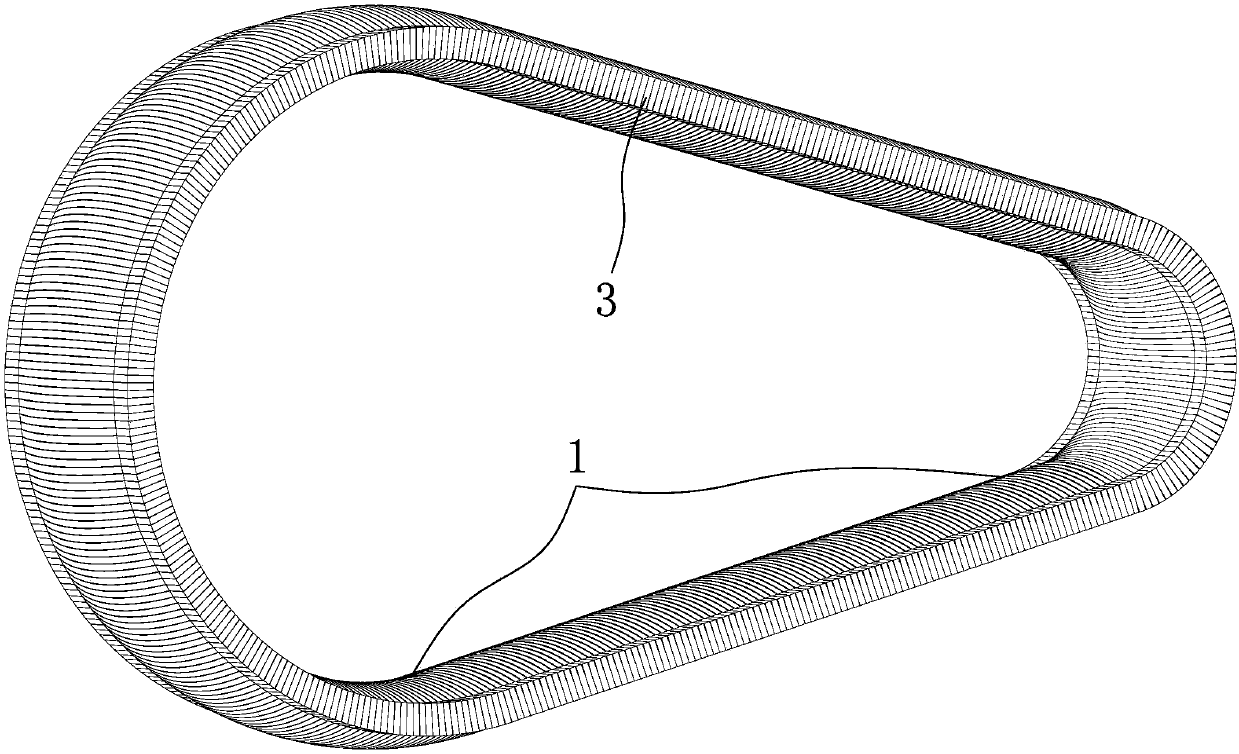

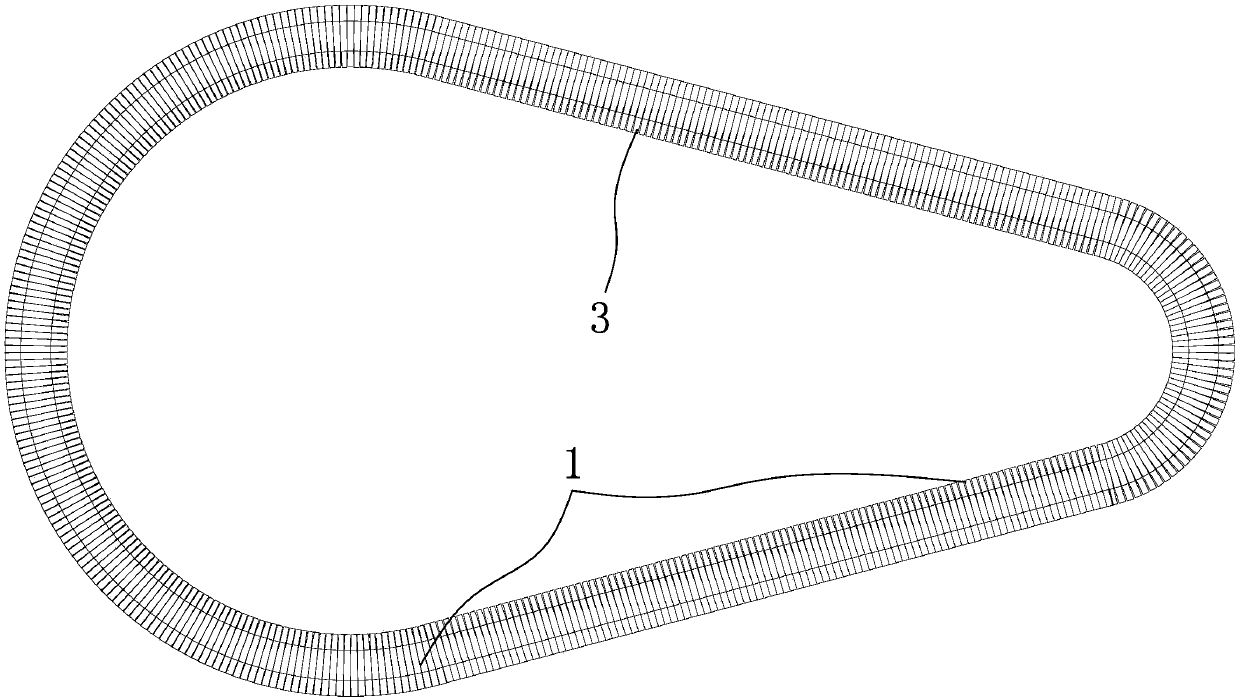

[0025] Such as Figure 1-12 with Figure 15 , 16 As shown, a movable-plate continuously variable transmission belt (1) includes: an annular carrier (2) and a transverse member (3) installed on the annular carrier (2), characterized in that: the transverse member ( 3) Continuously arranged and installed on the annular carrier (2), and can move laterally left and right on the axis of the annular carrier (2), so that the surface of the transmission belt can form a tooth shape of any shape and size, that is, figure 1 Deformed tooth (13) shown.

[0026] Such as Figure 4 , 7 , 10, and 12, the movable-plate continuously variable transmission belt (1) has at least one group of annular bearing bodies (2), and the transverse member (3) is provided with as many ring-shaped bearing bodies as the number of annular bearing bodies (2). The groove of the body (2) is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com