Floor tile laying device for building

A laying device and a technology for using floor tiles, which are applied in the direction of construction and building construction, can solve the problems of unstable manual operation of technical workers, low efficiency of laying tiles on the ground, and high technical content, achieving good application prospects and improving the bonding effect , the effect of good fit precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

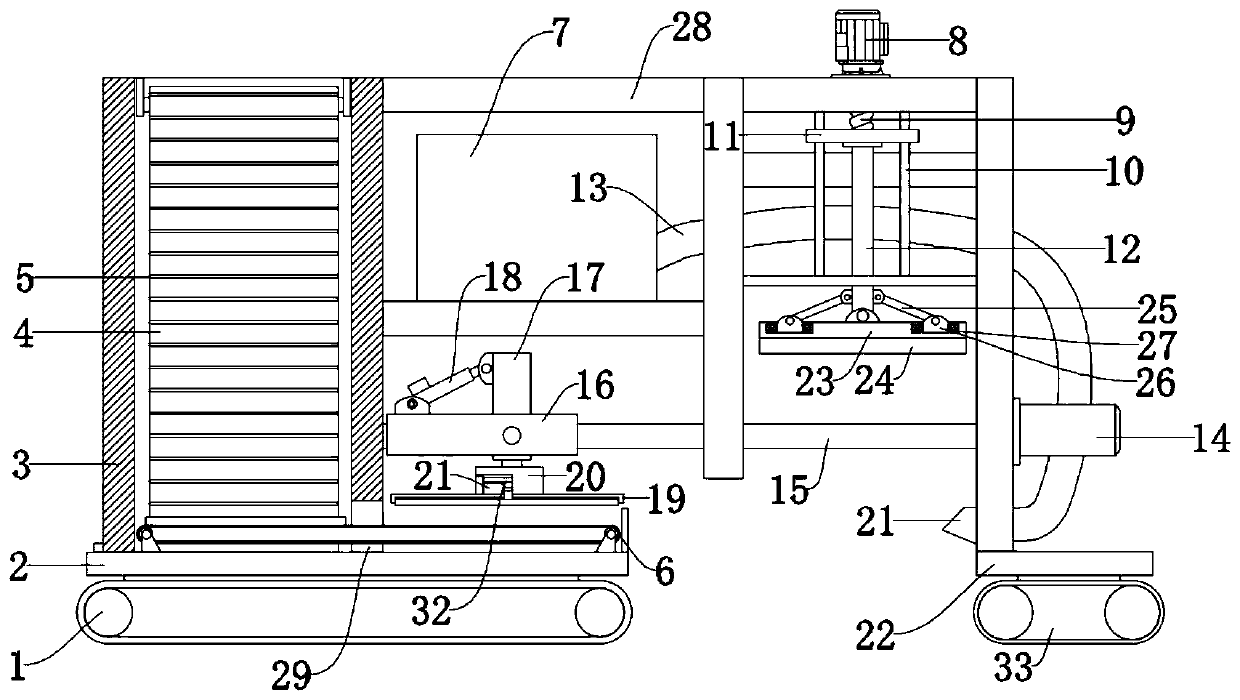

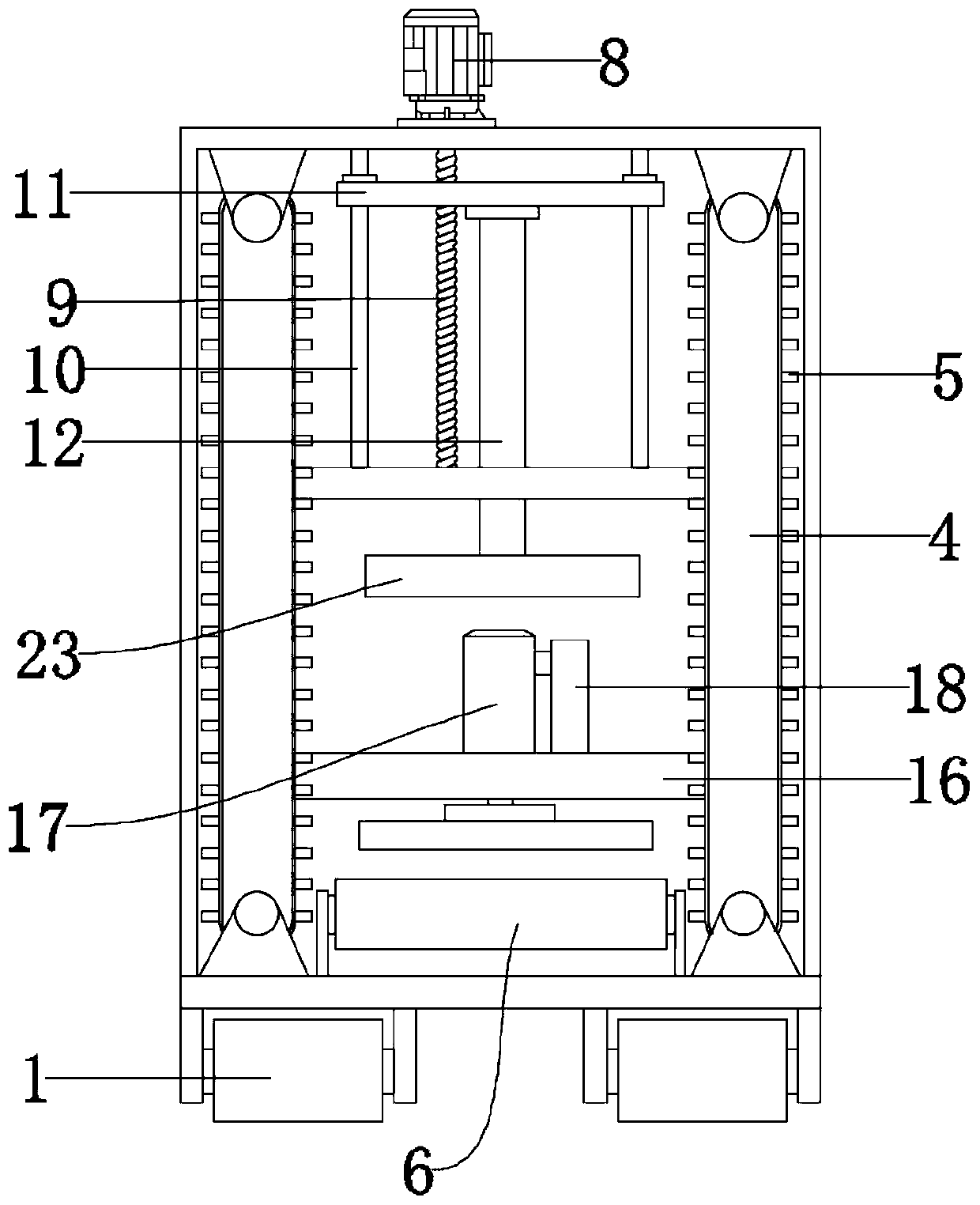

[0027] See Figure 1-3 , A construction floor tile laying device, including a bottom plate 2. The bottom of the bottom plate 2 is rotatably installed with a drive wheel 1 equipped with a power mechanism, and the bottom plate 2 is further driven to move by the drive wheel 1, and the bottom plate 2 is fixedly installed for storage of the floor tiles 31 The device, one side of the storage device is fixedly connected with a bracket 28, the device is built with a frame structure through the bracket 28, and the discharging device, the vibration device and the transfer device are fixedly installed on the frame structure; and the device is in use , The floor tiles 31 are output from the storage device, and the floor tiles 31 are transported through the transfer device. During the transportation of the floor tiles 31, the vibration device achieves vibration and hydraulic leveling against the ground, and the discharge device described later is flattened. Spray the mud on the bonding surf...

Embodiment 2

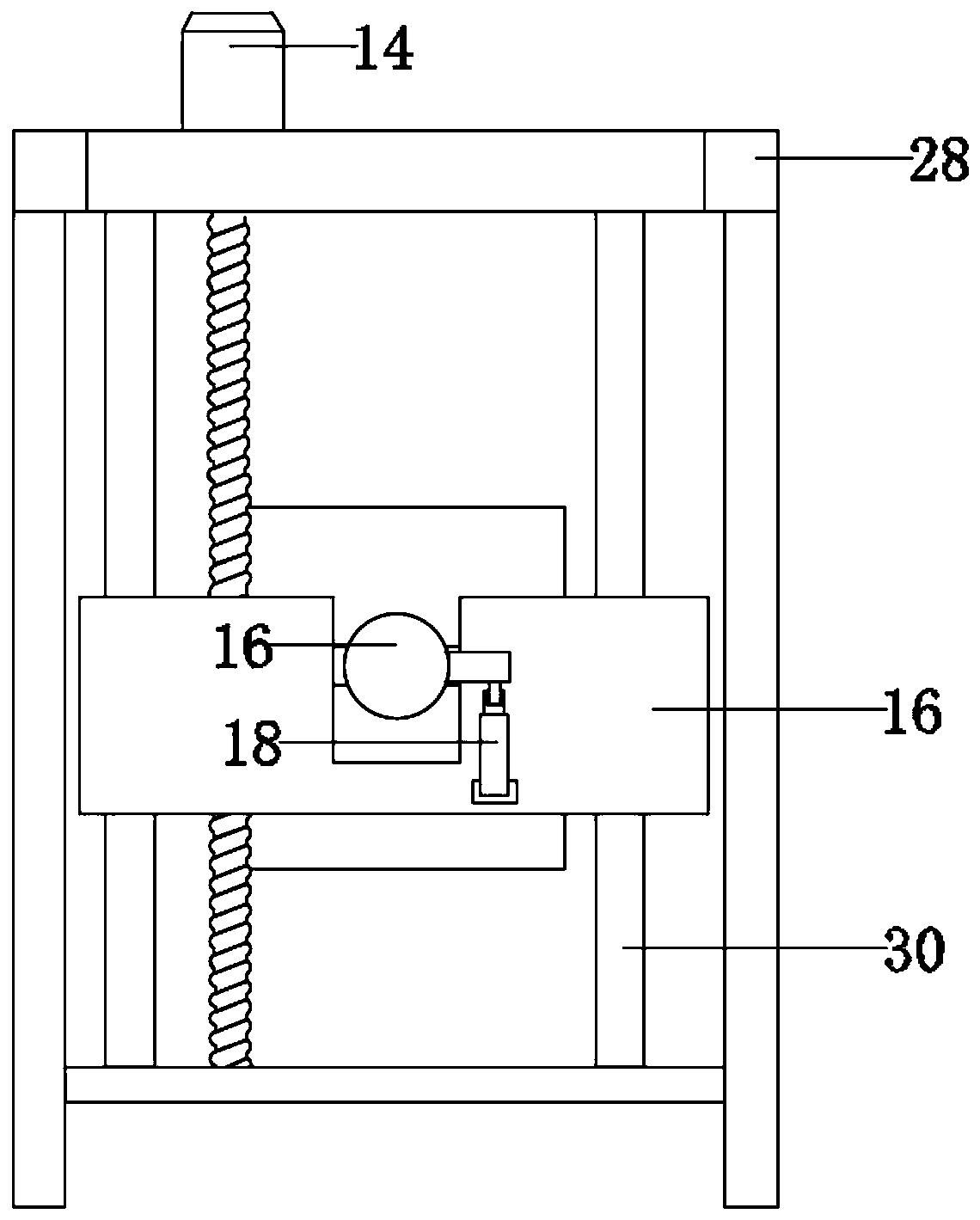

[0041] See Figure 4 The end of the conveying pipe 13 is inclined cloth, and the opening direction is inclined upward; when the clamping device clamps the floor tiles 31 and rotates a certain angle, the mud in the conveying pipe 13 is sprayed on the bonding surface of the floor tiles 31.

[0042] The working principle of this embodiment: the end of the conveying pipe 13 is inclined and the opening direction is inclined upward; when the clamping device clamps the floor tiles 31 and rotates a certain angle, the mud in the conveying pipe 13 is exactly sprayed onto the floor tiles 31 Surface.

[0043] It should be noted that the lifting motor and the transfer motor in this application are applications of the prior art. The transfer device and the vibration device are driven by the screw drive, which has the characteristics of small transmission torque, accurate transmission, and labor saving, and reduces the motor load; At the same time, the vibration plate 24 is an application of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com