Horizontal gearbox for micro-cultivators

A technology of gearbox and micro-tiller, applied in the field of gearbox, can solve the problems of high failure rate, poor safety performance of micro-tiller, large torque transmission of gears, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

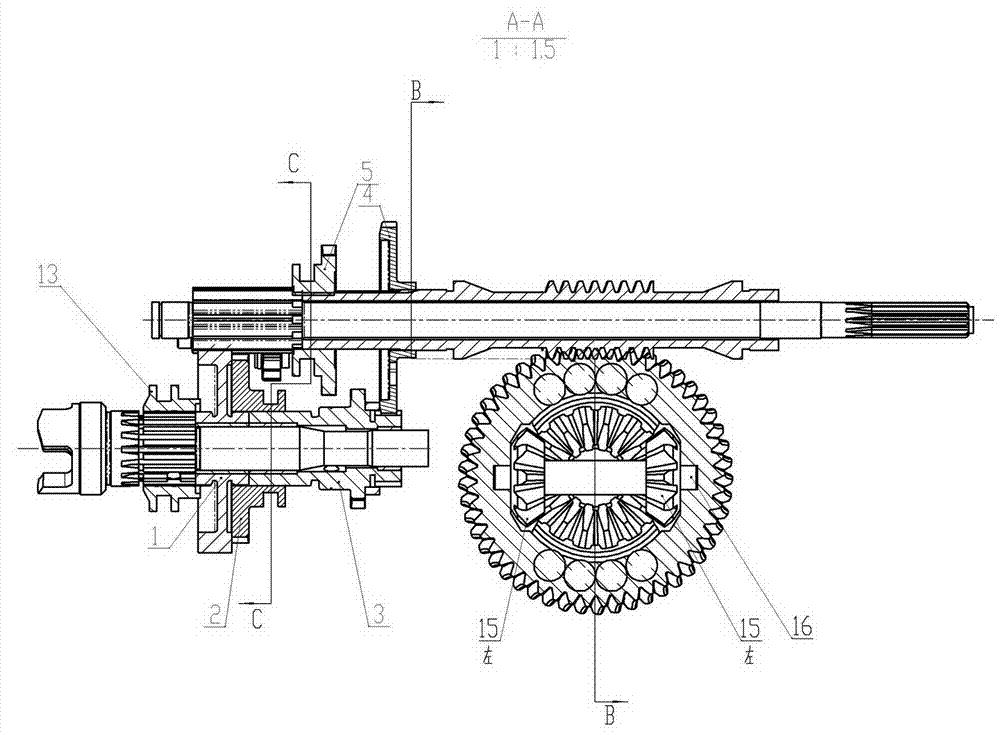

[0034] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

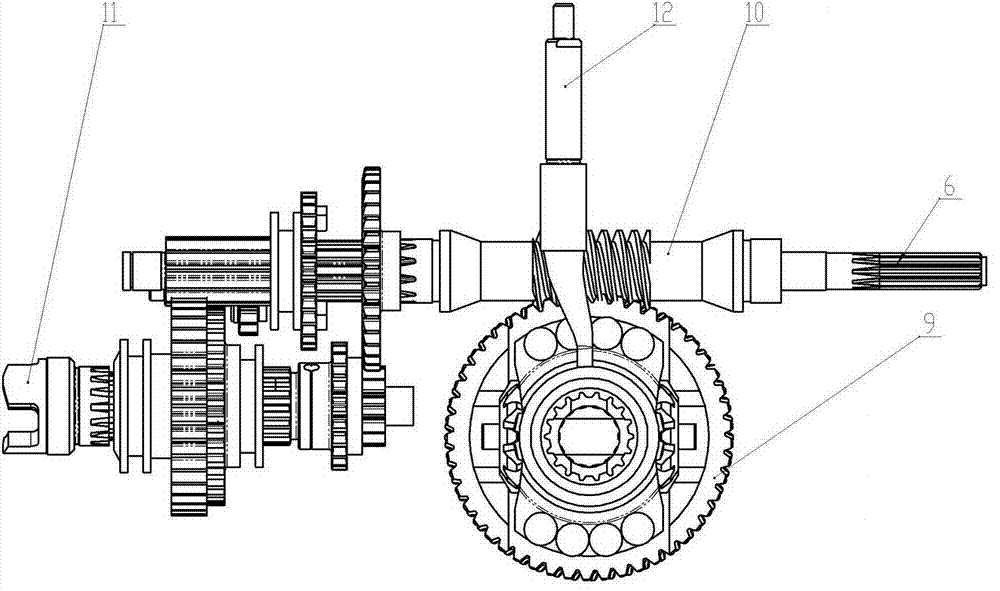

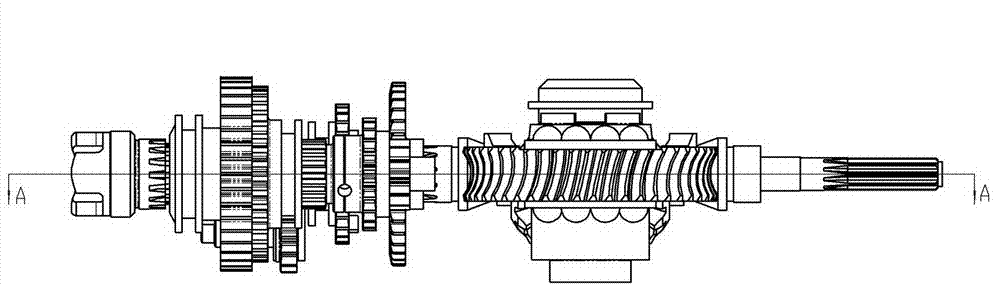

[0035] Such as Figure 1 to Figure 5As shown, the present invention proposes a new type of gearbox mechanism that is horizontal, the working power transmission box is separated from the travel steering device, and has a differential lock function. The horizontal gearbox is mainly composed of a gearbox housing, a gear shaft, a hollow worm, a power shaft of a rotary cultivator, a steering mechanism, a travel box, and a power output shaft; The right side of the gear structure at the left end of the gear shaft 6 is an external spline. A hollow worm 10 is sleeved on the outer circumference of the gear shaft between the external spline and the external spline at the right end of the gear shaft 6. The hollow worm 10 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com