Speed-increasing gearbox of wind driven generator

A technology of wind power generators and speed-increasing gears, which is applied to wind power generator components, wind power engines, engines, etc., which can solve the problems of increased manufacturing costs, large volume and weight of speed-increasing gear boxes, and difficult installation, and reduce installation costs. Effects of cost and difficulty, improvement of structural reliability, and ease of hoisting work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

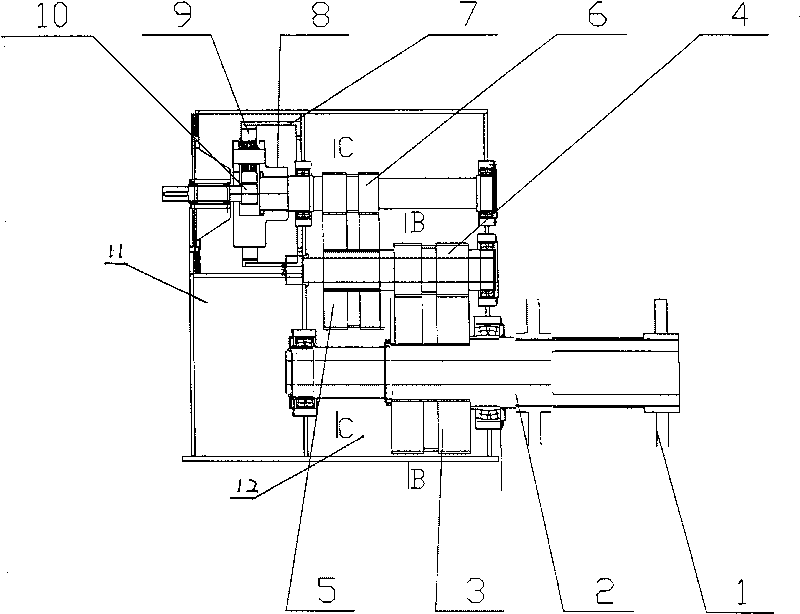

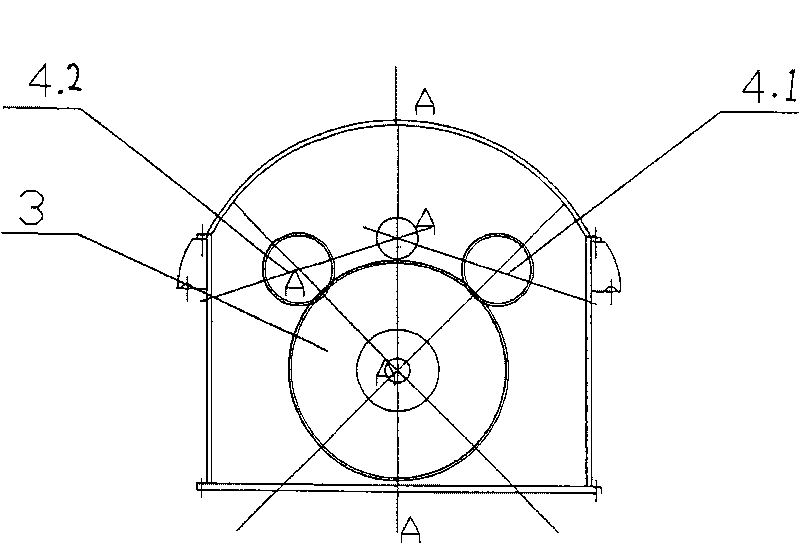

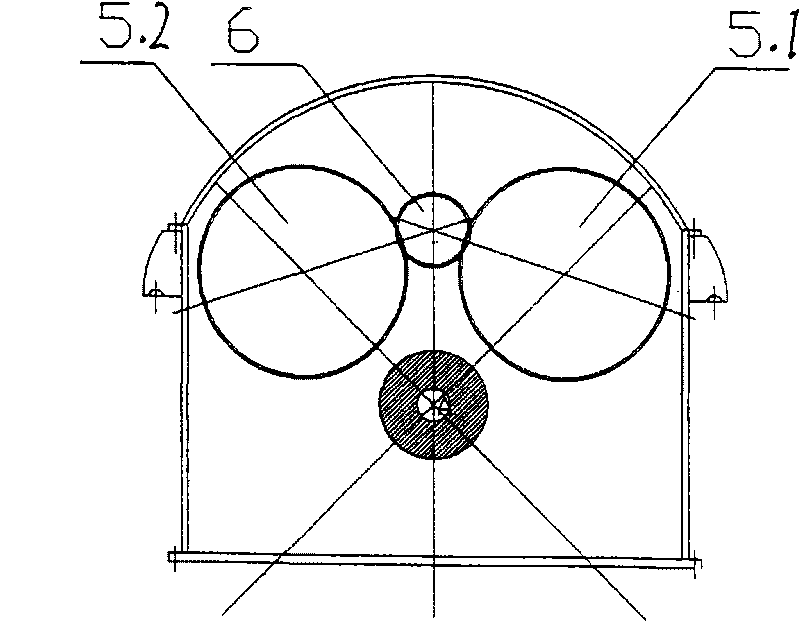

[0023] Embodiment 1: Referring to the accompanying drawings, taking the three-stage speed-up for wind power generation of 2 MW or below as an example, the wind power generator speed-up gearbox of the present invention is composed of two separated boxes 12 and 11 at the front and back, and the front box is 12 has a built-in two-stage double-arc cylindrical herringbone helical gear transmission, and the rear box 11 has a built-in one-stage planetary transmission. The outer side of the input spindle 2 (blade rotating shaft) is coaxially connected with the plate-type propeller hub bushing 1 (the big shaft of the blade and the input shaft of the speed-increasing gear are combined into one), and a large double arc is fixed on the inside of the box Cylindrical herringbone gear 3, gear 3 meshes with two small double-arc cylindrical herringbone gears 4.1 and 4.2 arranged on the intermediate shaft, and each intermediate shaft is coaxially equipped with a large double-arc cylindrical herr...

Embodiment 2

[0024] Embodiment 2: As in Embodiment 1, it is used in a 5-megawatt wind power generator speed-increasing gearbox, with a total of 4 stages of transmission, of which the first three stages are double-arc cylindrical herringbone helical gear transmissions, which are arranged in a gearbox. The first stage is a planetary gear transmission, which is set in another separate gearbox. The transmission ratio of the first three stages is about 3, and the speed is increased to 1500 rpm, and the transmission ratio is 115.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com