Double-shaft jaw clutch

A technology of jaw clutches and bearings, which is applied in clutches, magnetic drive clutches, non-mechanical drive clutches, etc., can solve the problems of being difficult to adapt to the narrow installation space and the large volume of double-shaft clutches, and achieve a simple and smart overall structure and quick assembly , design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

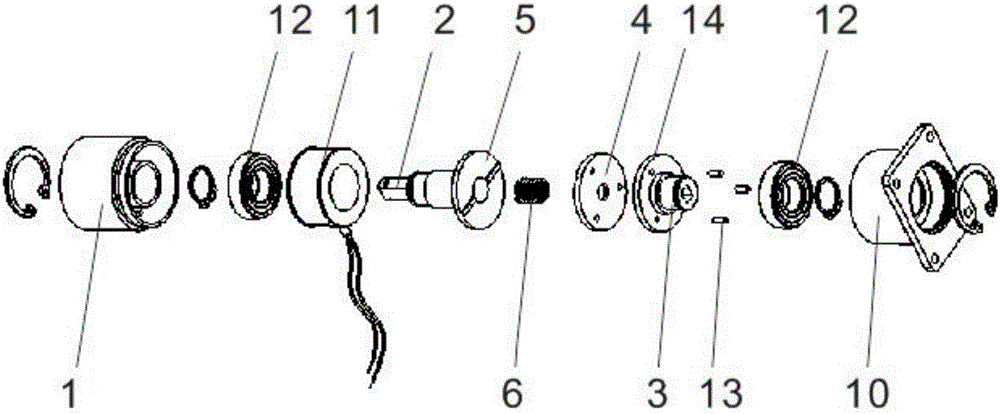

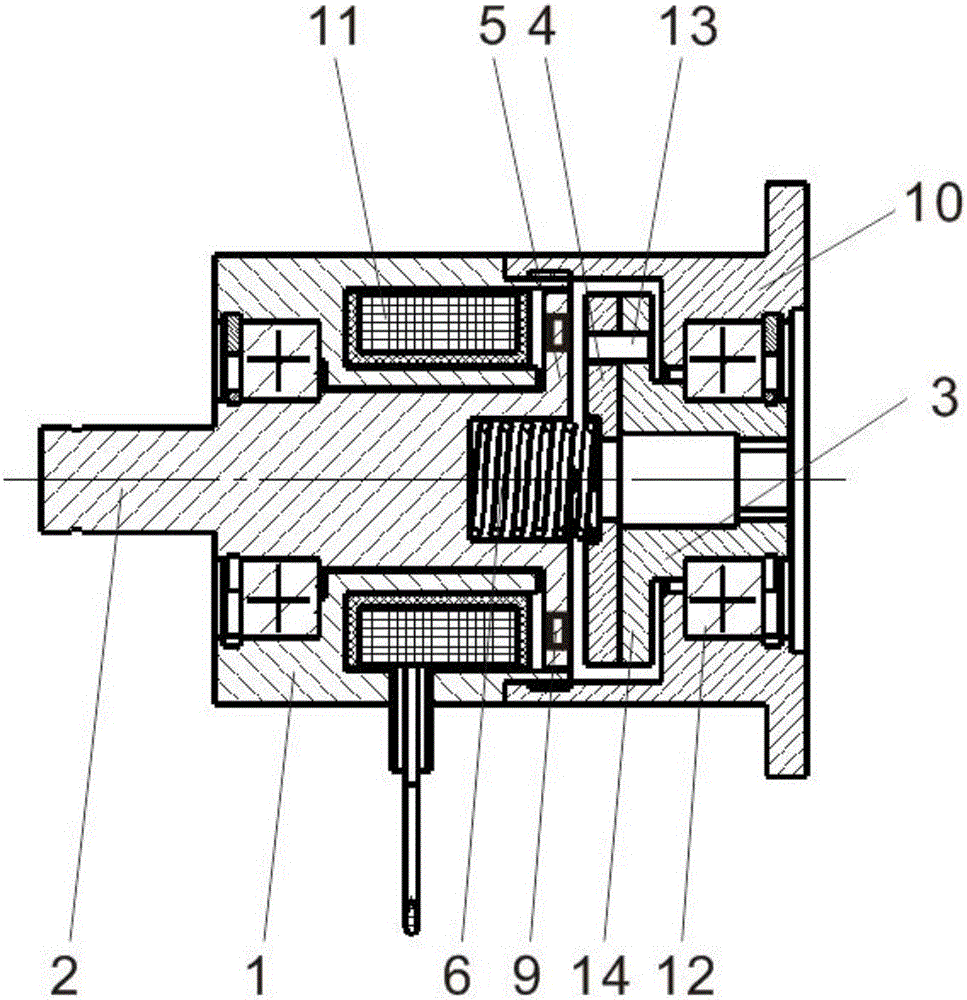

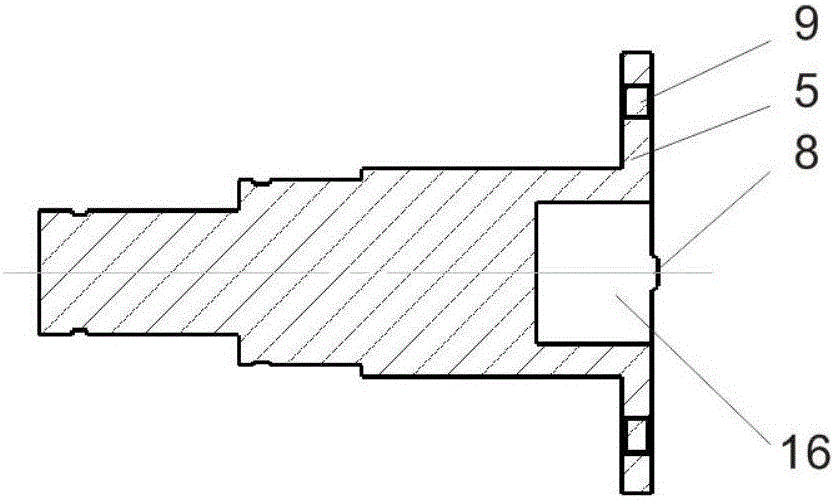

[0020] Such as Figure 1 to Figure 9 As shown, the double-shaft jaw clutch includes a casing 1 with an exciting coil 11 inside, a mounting seat 10 connected to the casing 1, and an input shaft 3 with an input turntable 14 placed on the inner end of the mounting seat 10, placed in the casing The inner end surface of the body 1 has the output shaft 2 of the output turntable 5, the end of the input turntable 14 close to the output turntable 5 is connected with the armature 4, the center of the casing 1 is provided with a spring seat 15, and the casing 1 is located on the spring A plurality of grooves 7 are evenly distributed around the periphery of the seat 15, and the center of the end face of the output dial 5 near the armature 4 is provided with a spring hole 16 opposite to the spring seat 15. The rac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com