Vacuum extruder with herringbone gear

A vacuum extruder, herringbone gear technology, applied in ceramic extrusion dies and other directions, can solve problems such as affecting service life and use effect, gear wear too fast, bearing axial movement, etc., and achieve increased gear coincidence. , the effect of improving the service life and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

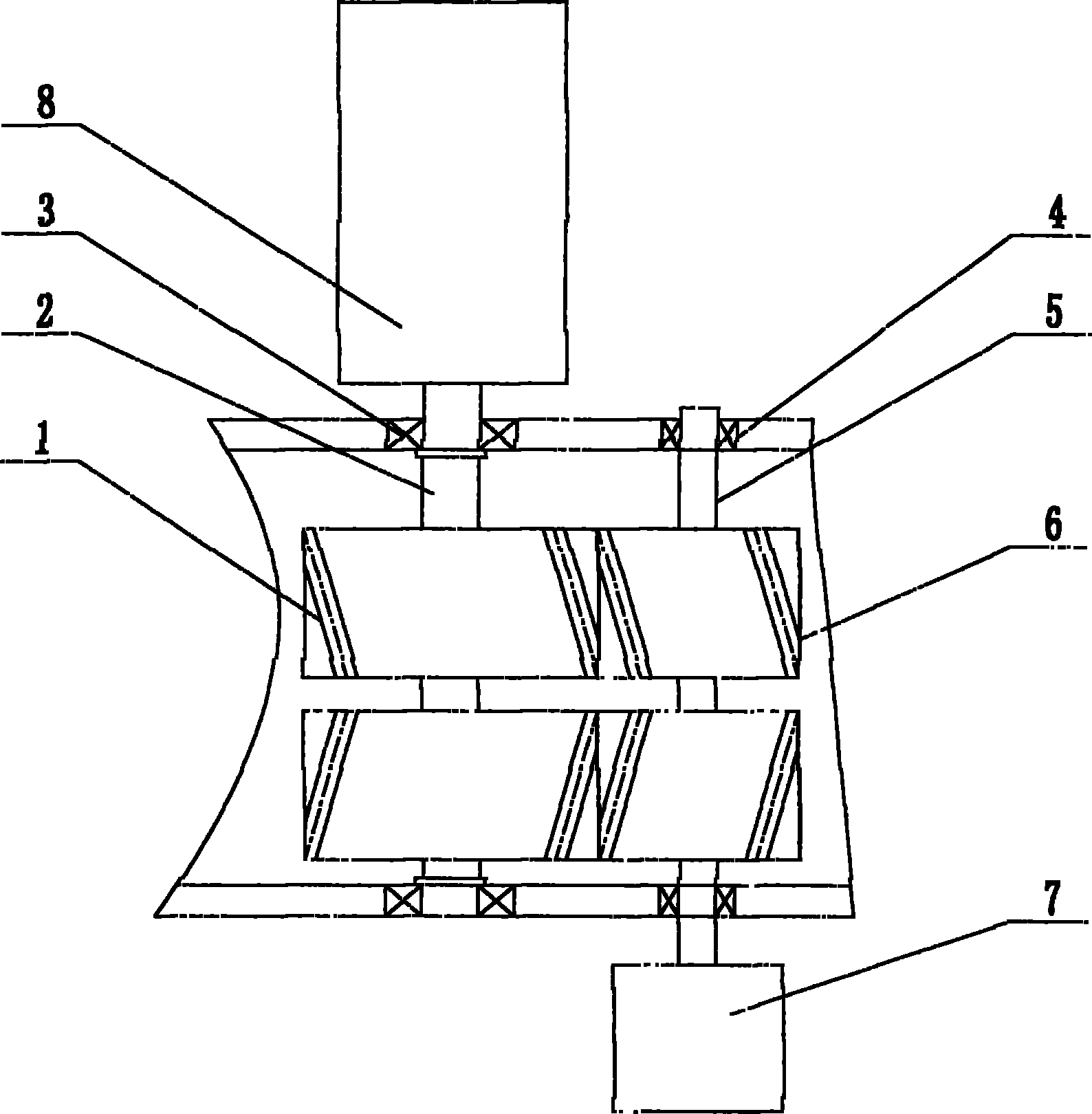

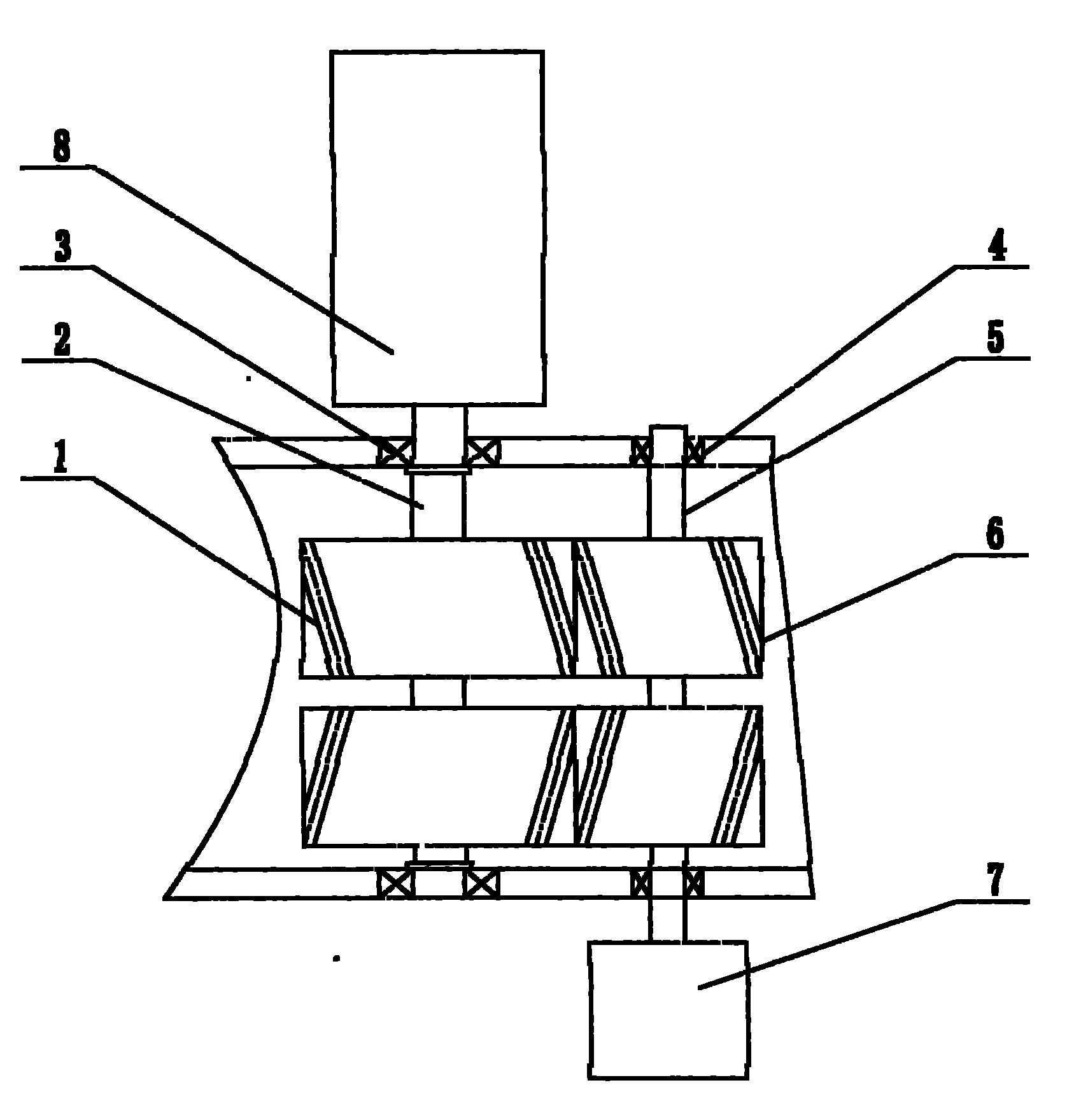

[0009] The transmission mechanism of the vacuum extruder actually used is basically multi-stage transmission, but in order to avoid redundancy and facilitate description, this embodiment only gives an example of one-stage transmission from the motor to the output shaft of the transmission mechanism. Multi-stage transmission and The reason is the same, those skilled in the art can generalize it. Such as figure 1 As shown, the motor 7 is connected to the input shaft 5 of the transmission mechanism 1, and the input shaft 5 is supported on the box body through the bearing 4. The input shaft 5 is processed with two pinions 6 with the same axial inclination angle and opposite directions. The two pinion gears 6 meshes with two large gears 1 on the output shaft 2 respectively. The output shaft 2 is supported on the box body through the bearing 3, the output shaft 2 is connected with the working mechanism 8, and the power is transmitted to the working mechanism. In this way, the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com