Branch torque transmission mechanism for speed reduction

A technology of split-torsion transmission and drive train, applied in transmission parts, mechanical equipment, belts/chains/gears, etc., can solve the problems of limiting the service life of the system and difficult to install, and achieve compact structure, light weight and easy processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

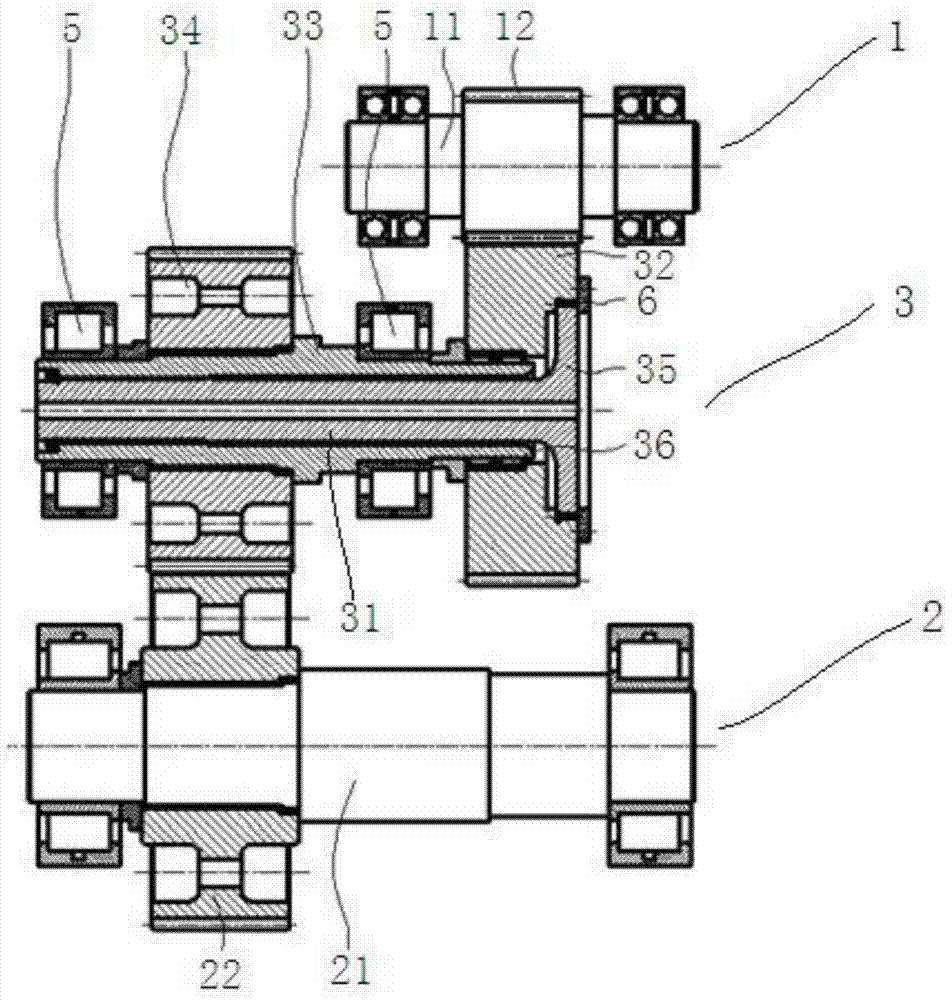

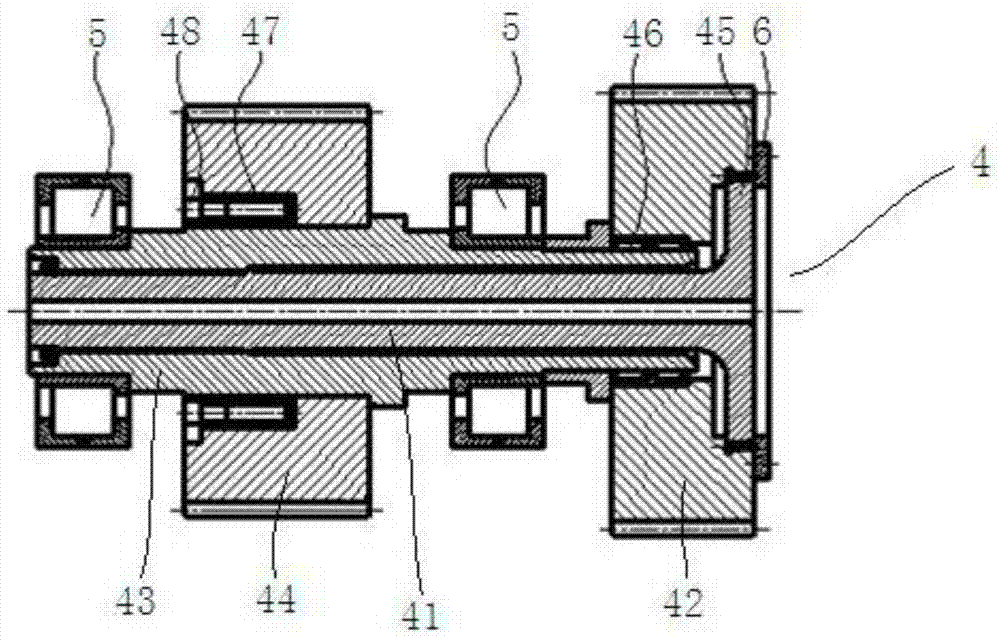

[0015] As shown in the figure, the split torque transmission mechanism for deceleration in this embodiment includes an input device 1, an output device 2, and a transmission system I3 and a transmission system II4 arranged between the input device 1 and the output device 2 for power transmission; The input device 1 is mainly composed of a power input shaft 11 and an input driving gear 12 arranged on the power input shaft 11; the output device 2 is mainly composed of a power output shaft 21 and an output driven gear 22 arranged on the power output shaft 21. The transmission system I3 includes a flexible shaft I31, an input driven gear I32, an intermediate shaft sleeve I33 and an output driving gear I34, the input driven gear I32 and the intermediate shaft sleeve I33 are arranged on the flexible shaft I31, and the output driving The gear I34 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com