Engine and motor power coupling mechanism and automobile

A technology of power coupling and engine, applied in the direction of motor vehicles, hybrid vehicles, power units, etc., can solve the problems of poor power performance, large space occupation, complex structure, etc., and achieve the effects of good power performance, compact structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

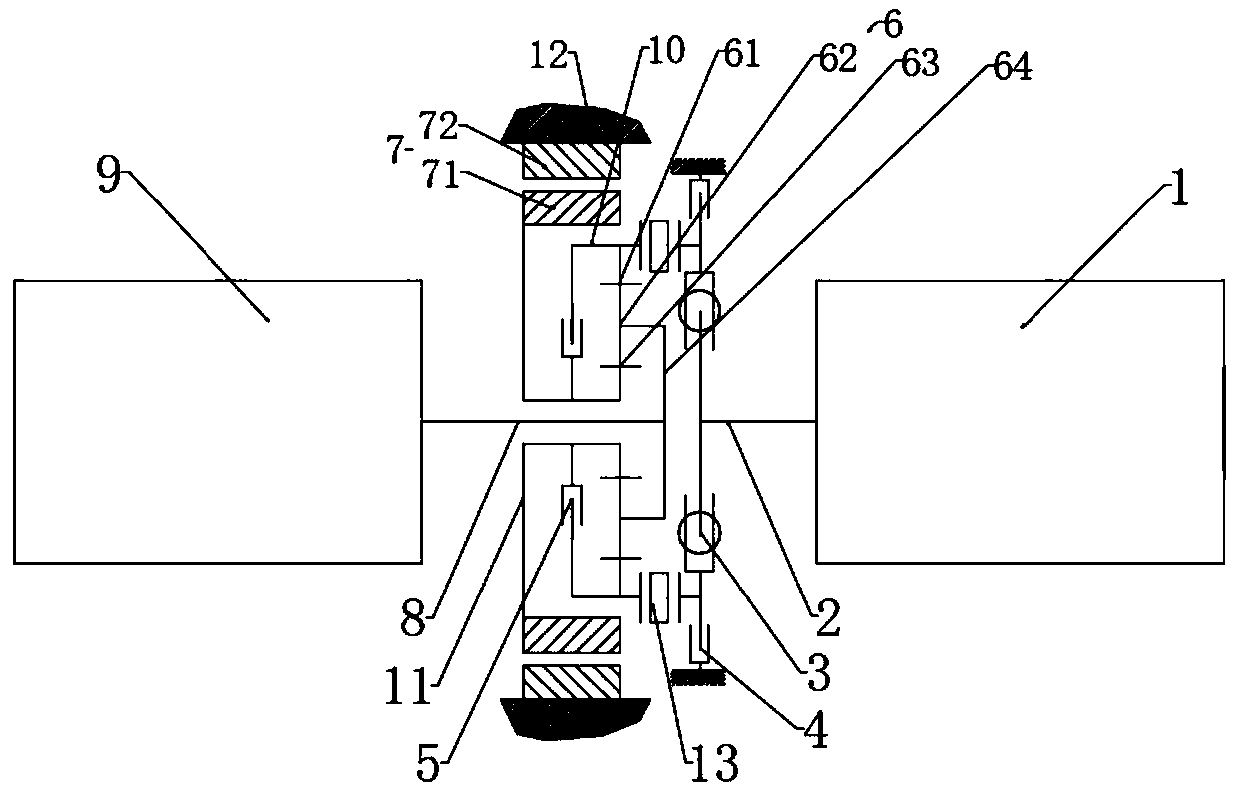

[0030] Such as figure 1 As shown, Embodiment 1 of the present invention provides a power coupling mechanism for an engine and a motor, including an engine 1, a motor 7, a one-way clutch 13, a brake 4, a lock-up clutch 5, a planetary gear mechanism 6 and an automatic transmission 9, and the planetary The gear mechanism 6 is a single planetary gear mechanism, including a ring gear 61, a planetary gear 62, a sun gear 63 and a planetary carrier 64. The planetary gear 62 is supported on the planetary carrier 64 through a bearing, and one end of the planetary gear 62 is connected to the planetary carrier 64. The ring gear 61 is meshed, the other end of the planetary gear 62 is meshed with the sun gear 63 , and the planet carrier 64 is connected with the input shaft 8 .

[0031] The engine 1 is connected to the ring gear connecting shaft 10 through the output shaft 2 and the one-way clutch 13, the ring gear connecting shaft 10 is connected to the ring gear 61, the driving end of the ...

Embodiment 2

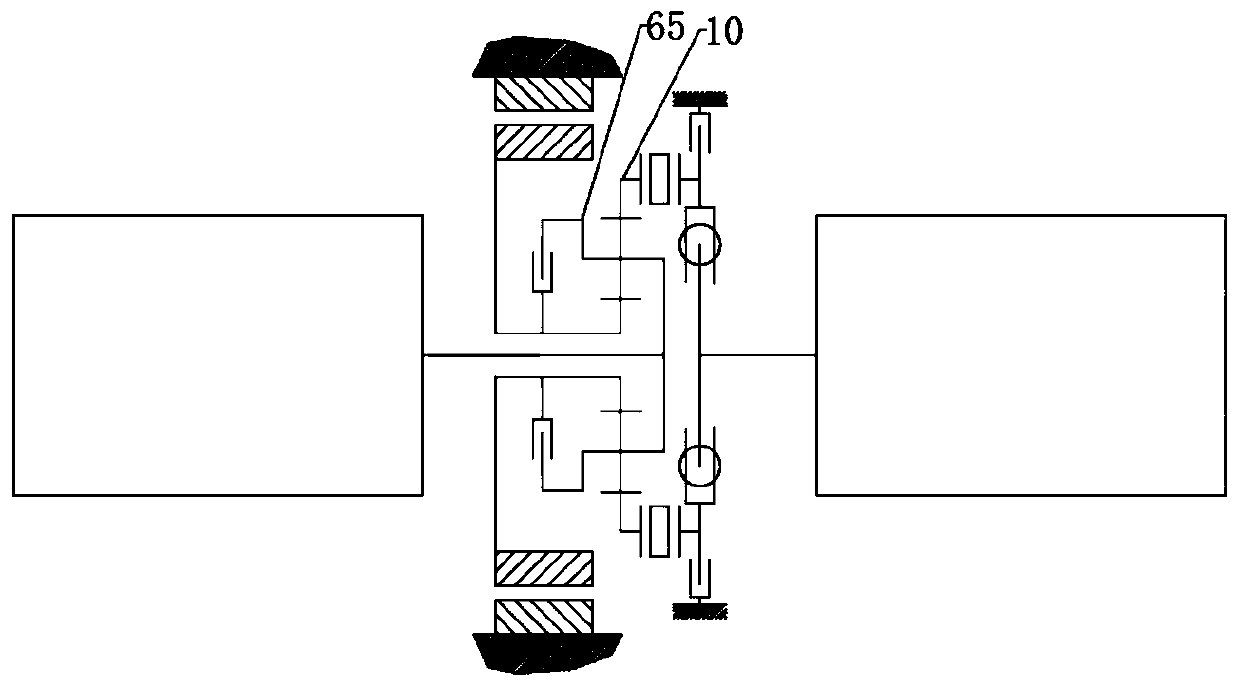

[0055] Such as figure 2 As shown, the difference between Embodiment 2 of the present invention and Embodiment 1 is that the planetary gear mechanism 6 includes a planetary gear connecting shaft 65, one end of the planetary gear connecting shaft 65 is connected to the planetary gear 62, and the planetary gear is connected to The other end of the shaft 65 is connected to the driven end of the lock-up clutch 5 . Specifically, the passive end of the lock-up clutch is integrally connected with the planetary carrier 64 and the input shaft through the planetary gear connecting shaft 65 and the planetary gear 62 . In practical applications, the motor power can be transmitted to the planetary gear mechanism through the planetary gear through the lock-up clutch 5 .

Embodiment 3

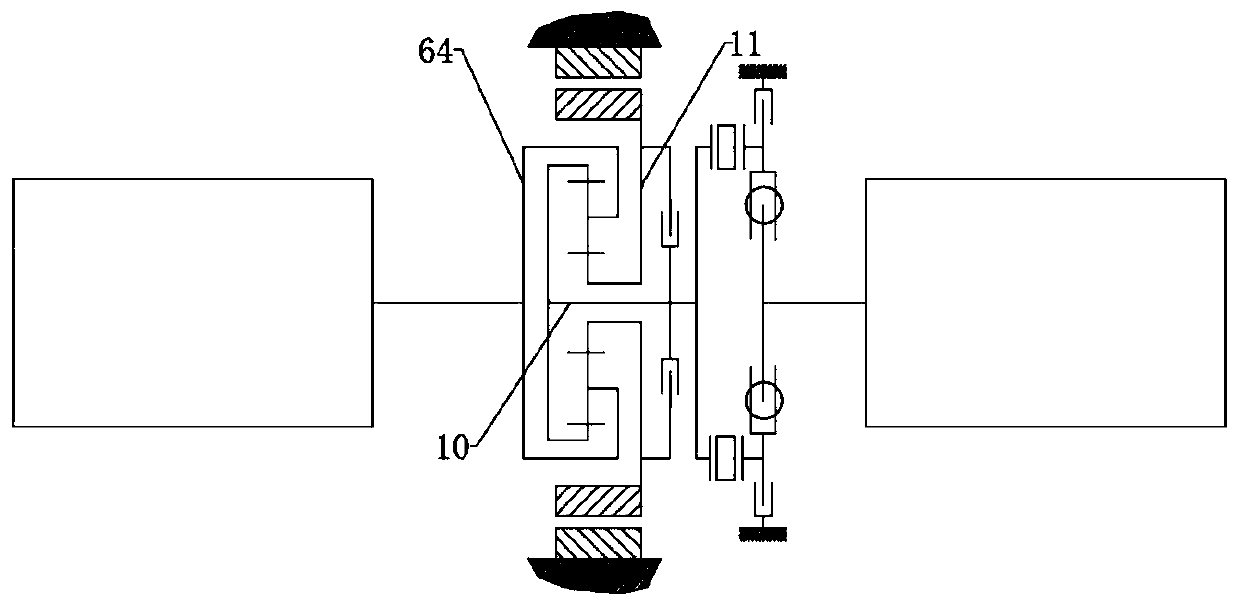

[0057] Such as image 3 As shown, the difference between Embodiment 3 of the present invention and Embodiment 1 is that one end of the ring gear connecting shaft 10 is connected to the ring gear 61, and the other end of the ring gear connecting shaft 10 is connected to the ring gear through the one-way clutch 13. The passive end of the brake 4 is connected as a whole, the gear connection shaft 10 is also connected to the driving end of the lock-up clutch 5, and the sun gear connection shaft 11 is connected to the passive end of the lock-up clutch 5 and the rotor respectively. 71 connections as one. Specifically, the lock-up clutch 5 and the motor 7 are arranged on the left side of the planetary gear mechanism 6 in Embodiment 1, and the lock-up clutch 5 and the motor 7 are arranged on the right side of the planetary gear mechanism 6 in Embodiment 3. The left and right sides are based on the directions in the accompanying drawings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com