Drive control mechanism of permanent magnetic and gear compound drive continuously variable transmission

A continuously variable transmission, transmission mechanism technology, applied in electromechanical transmission devices, electromechanical devices, electric components and other directions, can solve the problems of low power capacity, no slip transmission, reduced size and weight, etc., to improve efficiency and reliable locking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

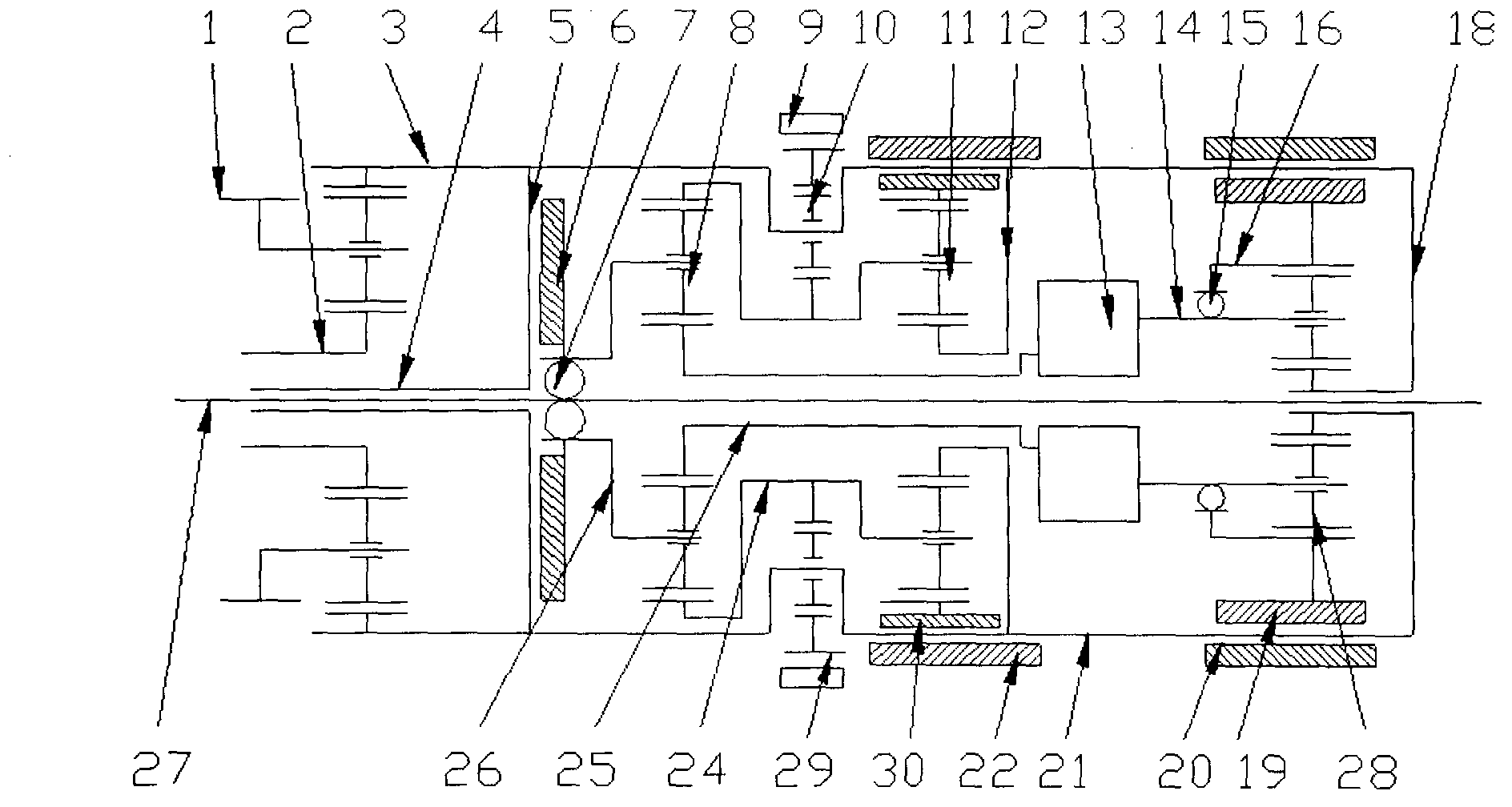

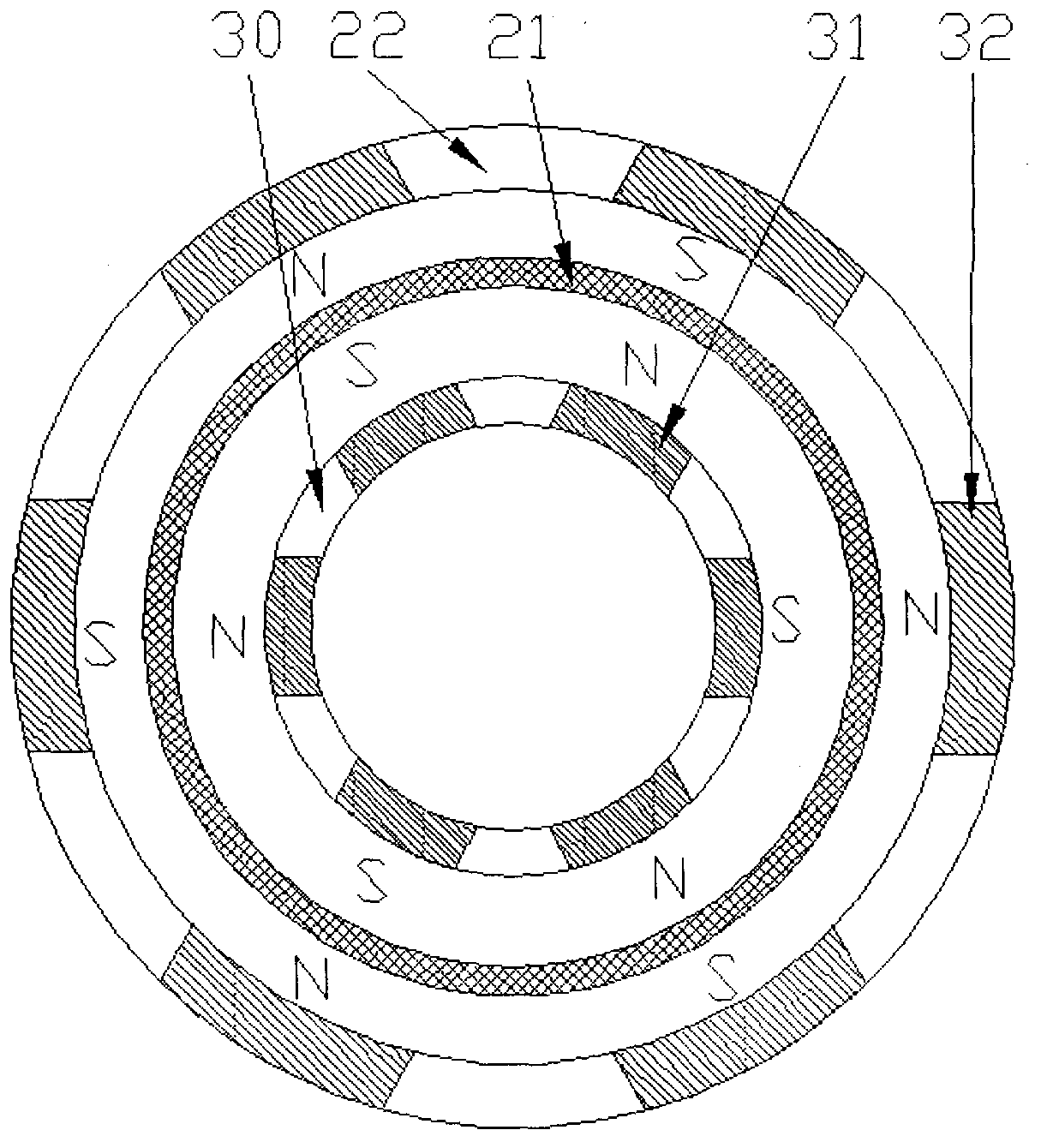

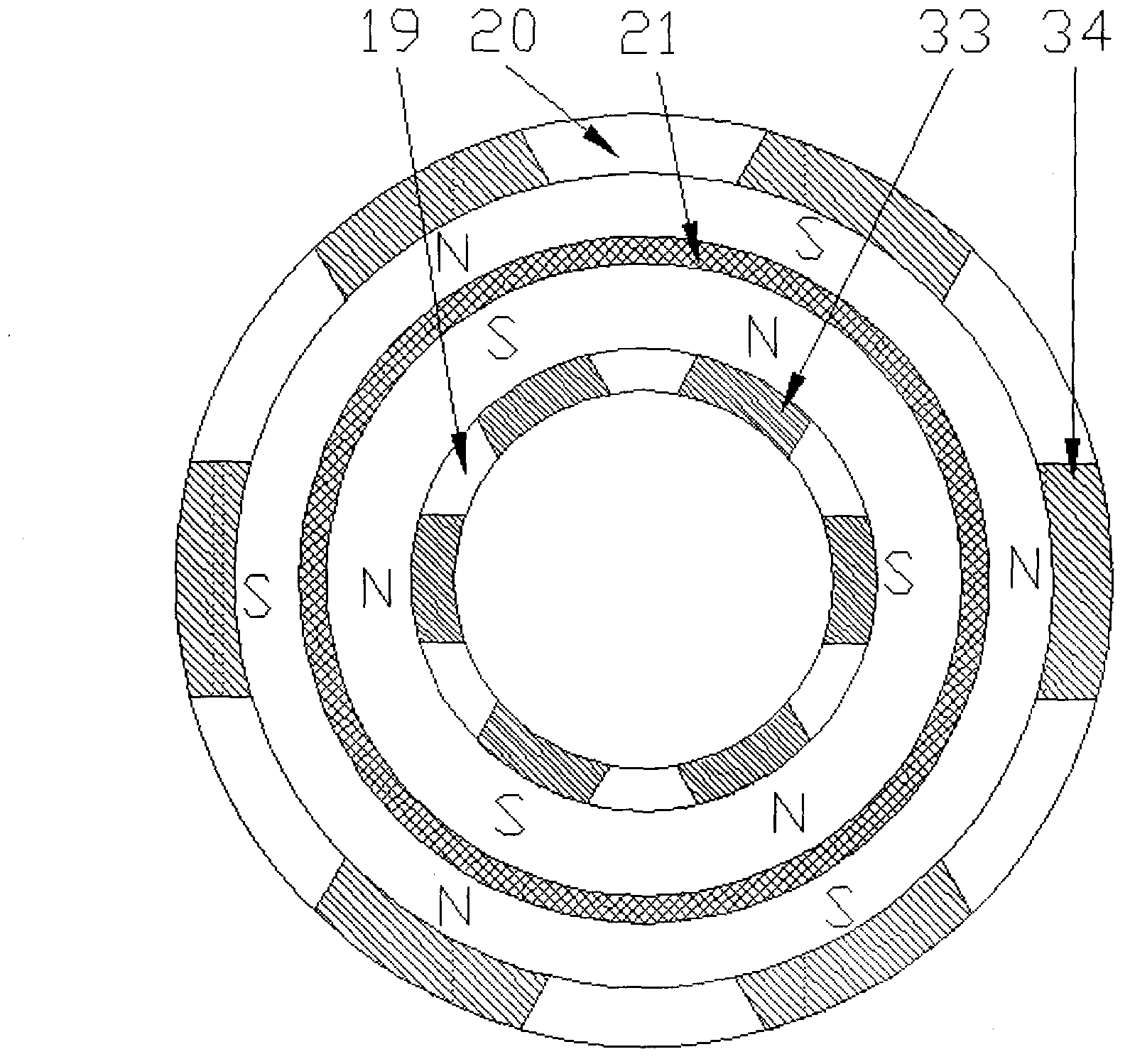

[0023] Referring to accompanying drawings 1 to 3, the structural characteristics of a control transmission mechanism of a permanent magnet and gear compound transmission continuously variable transmission are (as shown in accompanying drawings 1 to 3): the number of teeth of the internal ring gear of the distribution planetary row 8 is 109, and the sun The number of gear teeth is 81, the number of teeth of the planetary gear 27 is 14, the thin circular plate 18 is a bakelite board for electricians, and the thickness is 1mm. The gear ratios of the inner ring gear and the sun gear of the planet row 28 are both 1.5, and the arrangement positions of the permanent magnets on the moving part 30 of the permanent magnetic flexible locking mechanism and the fixed part 22 of the permanent magnetic flexible locking mechanism are shown in Figure 2. The arrangement positions of the permanent magnets on the movable part (19) of the flexible locking mechanism and the fixed part 20 of the perm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com