Segmented magnetic control method of AC magnetic control memory motor

A technology of memory motor and control method, applied in AC motor control, motor control, motor generator control and other directions, can solve the problems of complex motor structure and high manufacturing process requirements, reduce armature copper consumption, and widen the range of power speed regulation. , Improve the effect of weak magnetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention will be further introduced below in combination with specific implementation methods and accompanying drawings.

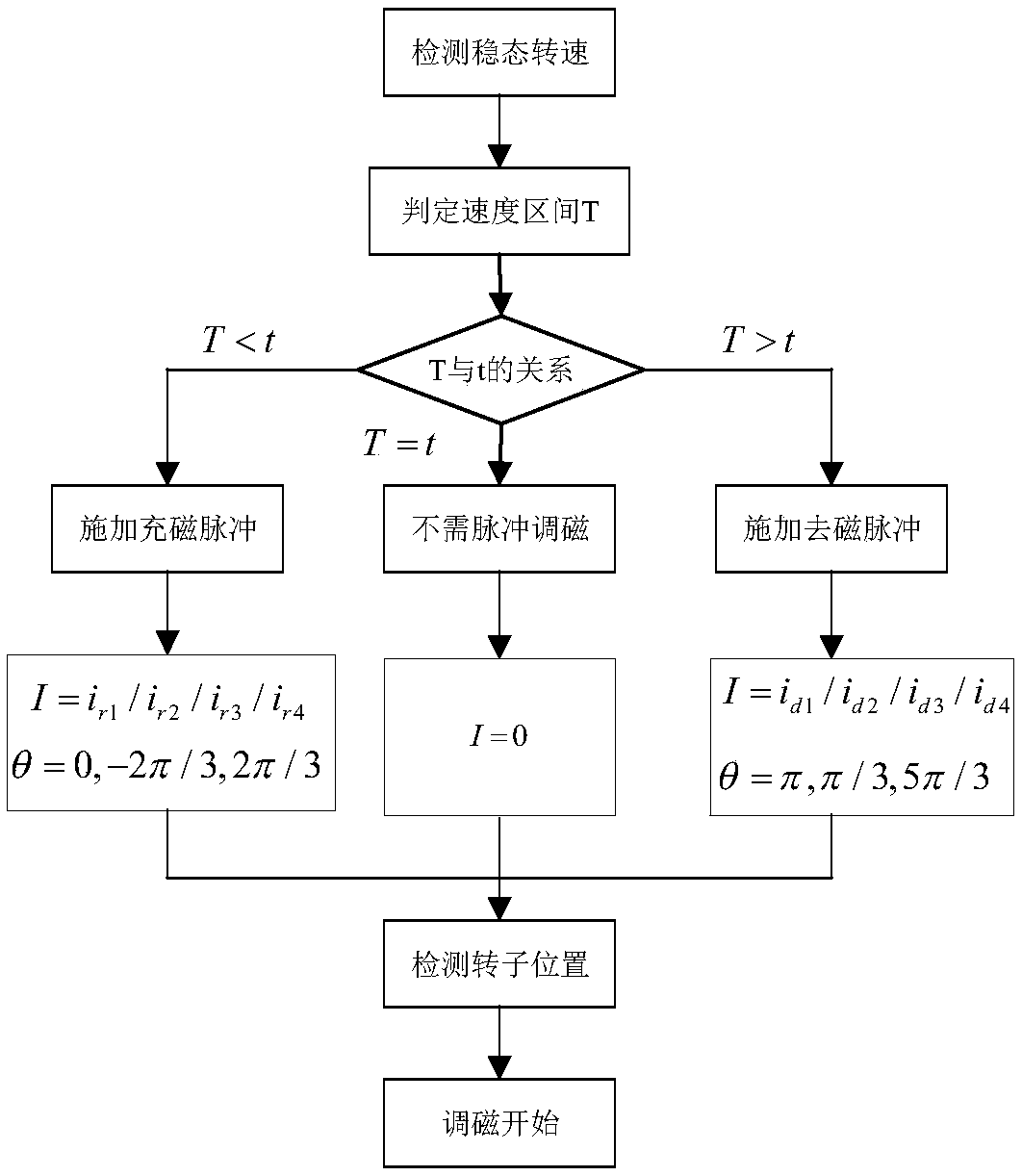

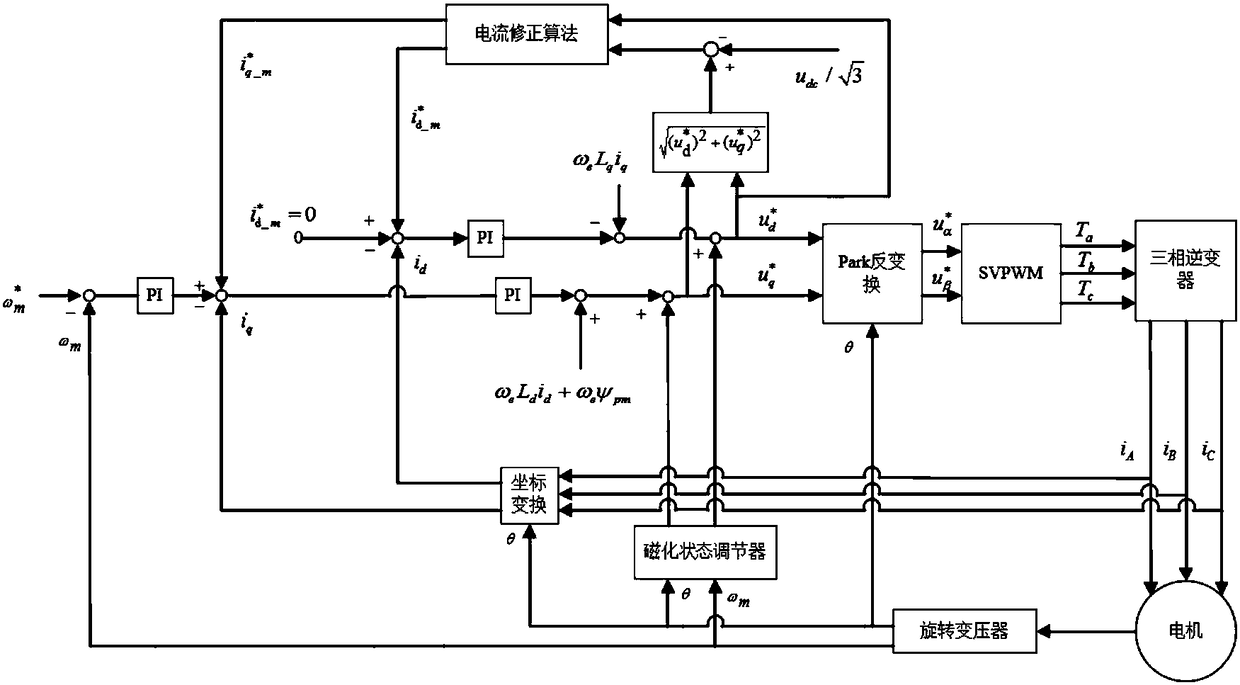

[0032] A segmented magnetic modulation control method for AC magnetically modulated memory motors based on rotor speed / position detection. The overall control block diagram of the motor operation is shown in image 3 As shown, the biggest difference between this method and the traditional permanent magnet synchronous motor control strategy is that it combines the magnetization state adjustment characteristics of the memory motor, and a pulse magnetic modulation module is added to the overall control system, which can perform permanent magnetization during the operation of the motor. Segmented real-time adjustment of the magnetization state of the magnet.

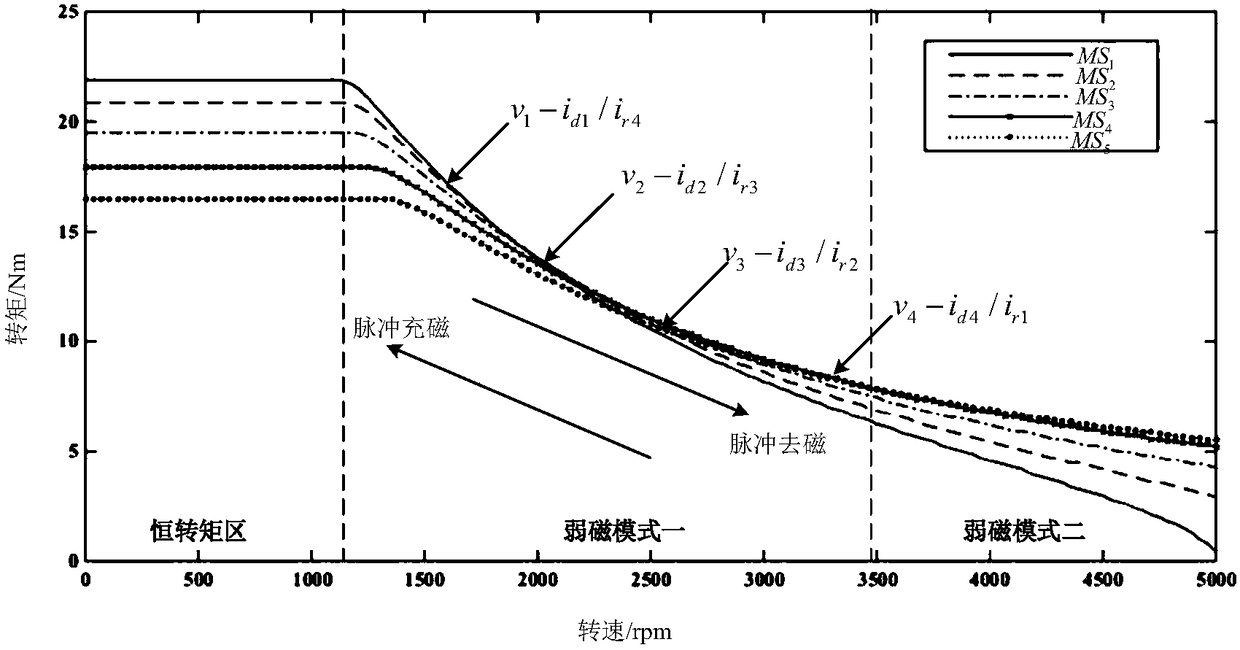

[0033] In this embodiment, the control strategy first selects five target magnetization states MS during the operation of the motor 1 , MS 2 , MS 3 , MS ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com