Rubber permanent magnet accessorial excitation bond-type synchronous reluctance machine

A technology of synchronous reluctance motor and auxiliary excitation, which is applied in the field of synchronous reluctance permanent magnet motor and axial lamination synchronous reluctance motor, which can solve the problems of motor performance degradation, low motor power factor and efficiency, and large excitation power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

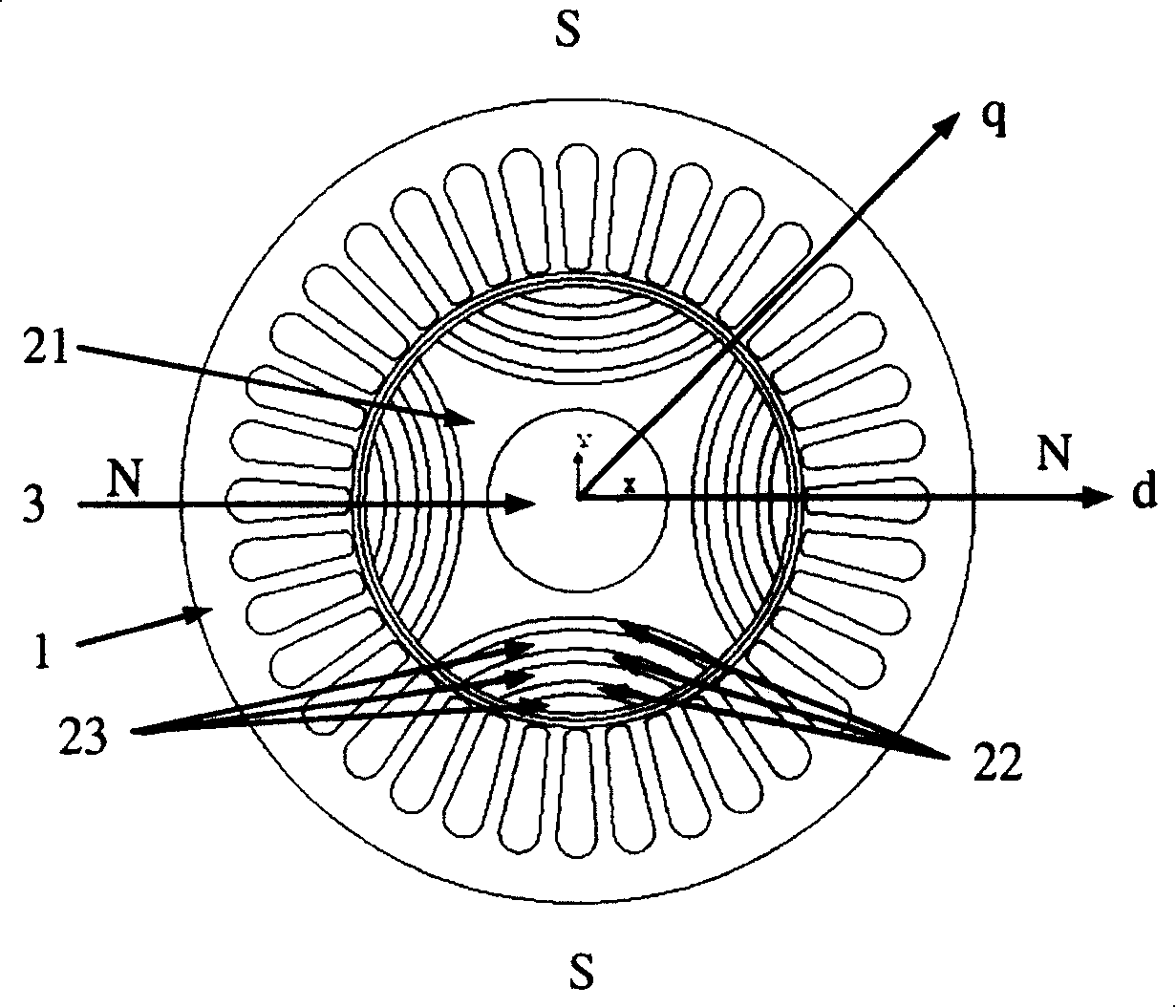

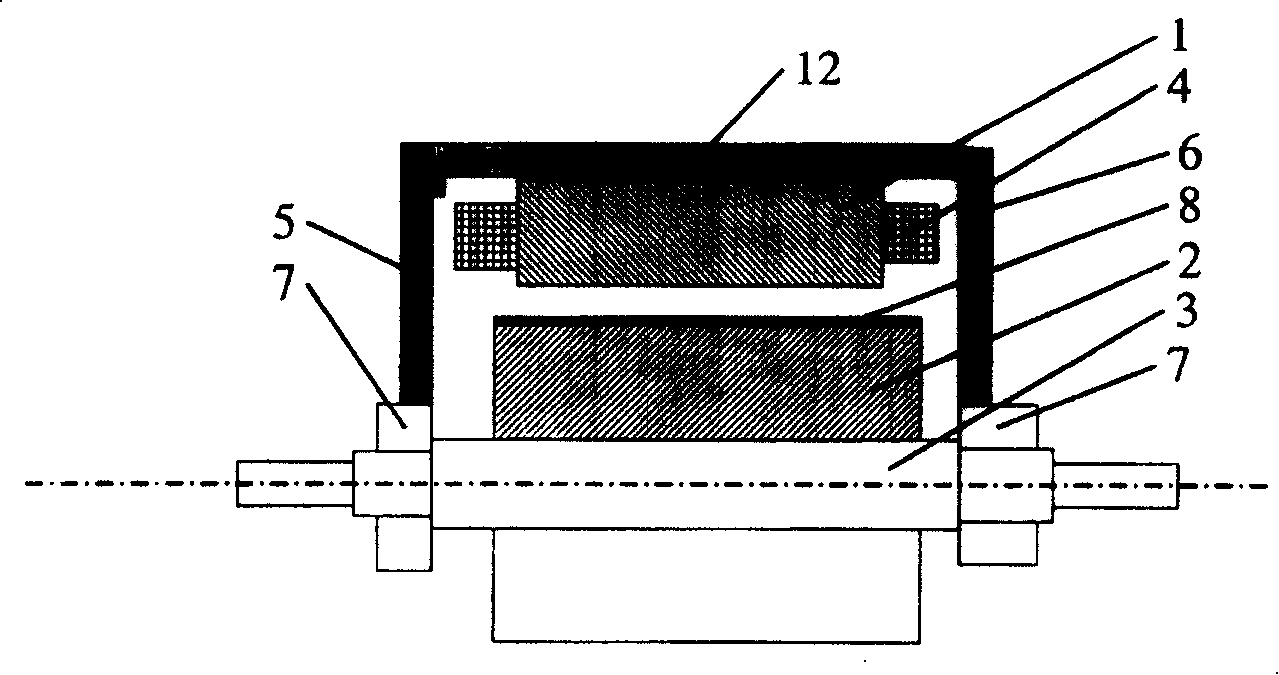

[0026] First of all, it is made of silicon steel sheets figure 1 As shown in the rotor bracket 21, glue is applied on each arc slot in turn, and the rubber permanent magnet sheet 22 cut into a rectangle is glued to the bracket 21. The polarities of the two adjacent poles are opposite, and then the rubber permanent magnet sheet Apply glue on 22, bond the axial silicon steel sheet 23 layer by layer to the corresponding thickness of each layer, then continue to bond the next layer of rubber permanent magnet sheet 22 and the corresponding axial silicon steel sheet 23, after bonding enough layers, Grind the outer circle of the rotor to a suitable size, and then tightly fit the processed stainless steel rotor sleeve 8 on the rotor 2. The machining process of the stator is similar to that of the universal asynchronous motor, but requires the same number of pole pairs as the rotor 2.

[0027] Since the thickness of the rubber permanent magnet sheet 22 can be made very thin (about 0....

Embodiment 2

[0029] The main difference from Scheme 1 is that the rotor bracket 21 is directly formed from magnetically permeable steel, and the rest of the steps are the same as Scheme 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com