Patents

Literature

48results about How to "Raise the saliency ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

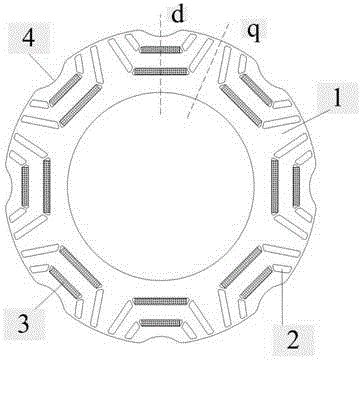

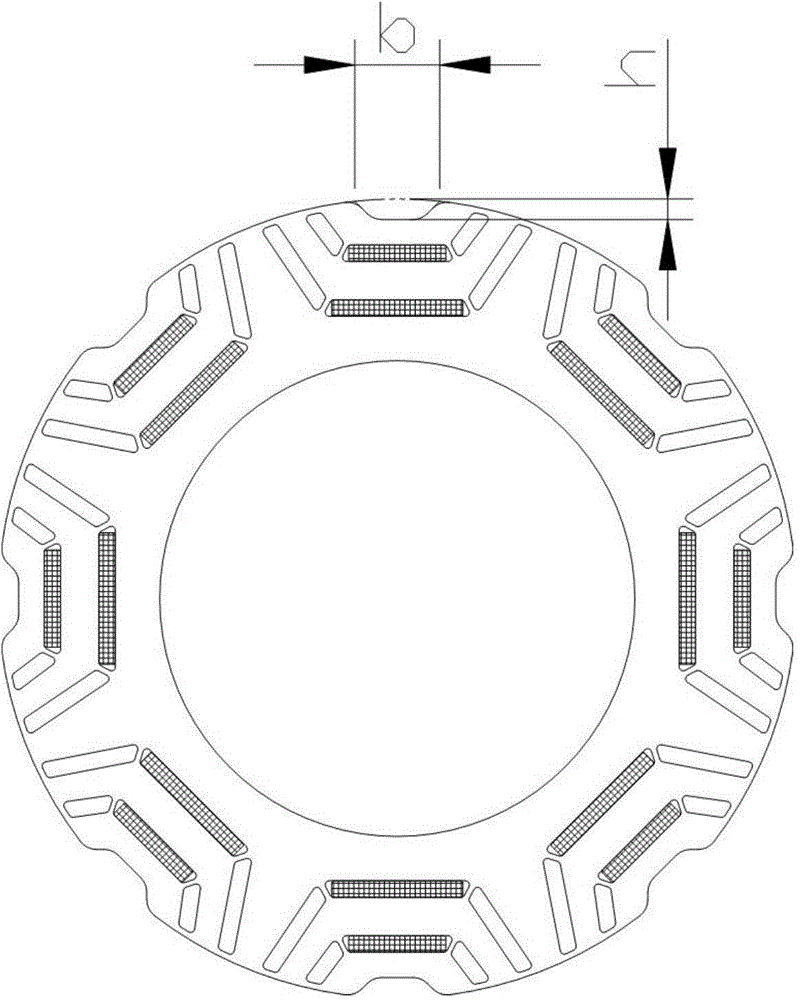

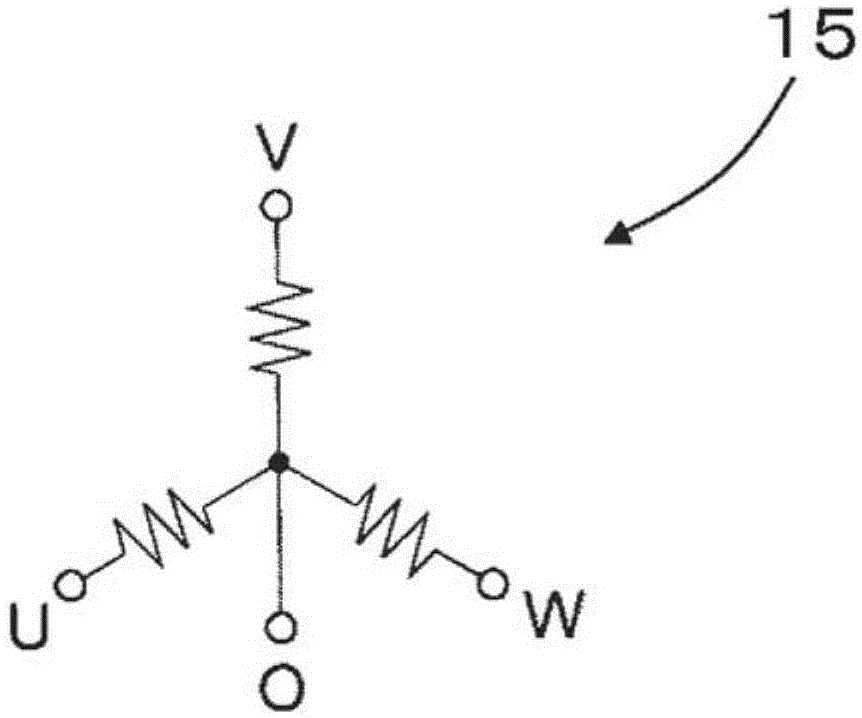

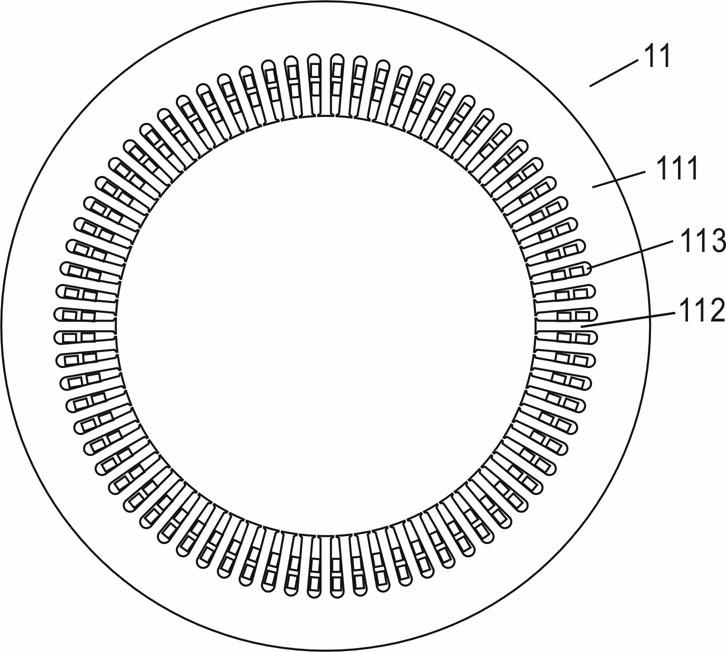

Self-starting synchronous reluctance motor and rotor thereof

ActiveCN103208894ARaise the saliency ratioImprove efficiencySynchronous machinesAsynchronous induction motorsSynchronous reluctance motorInductance

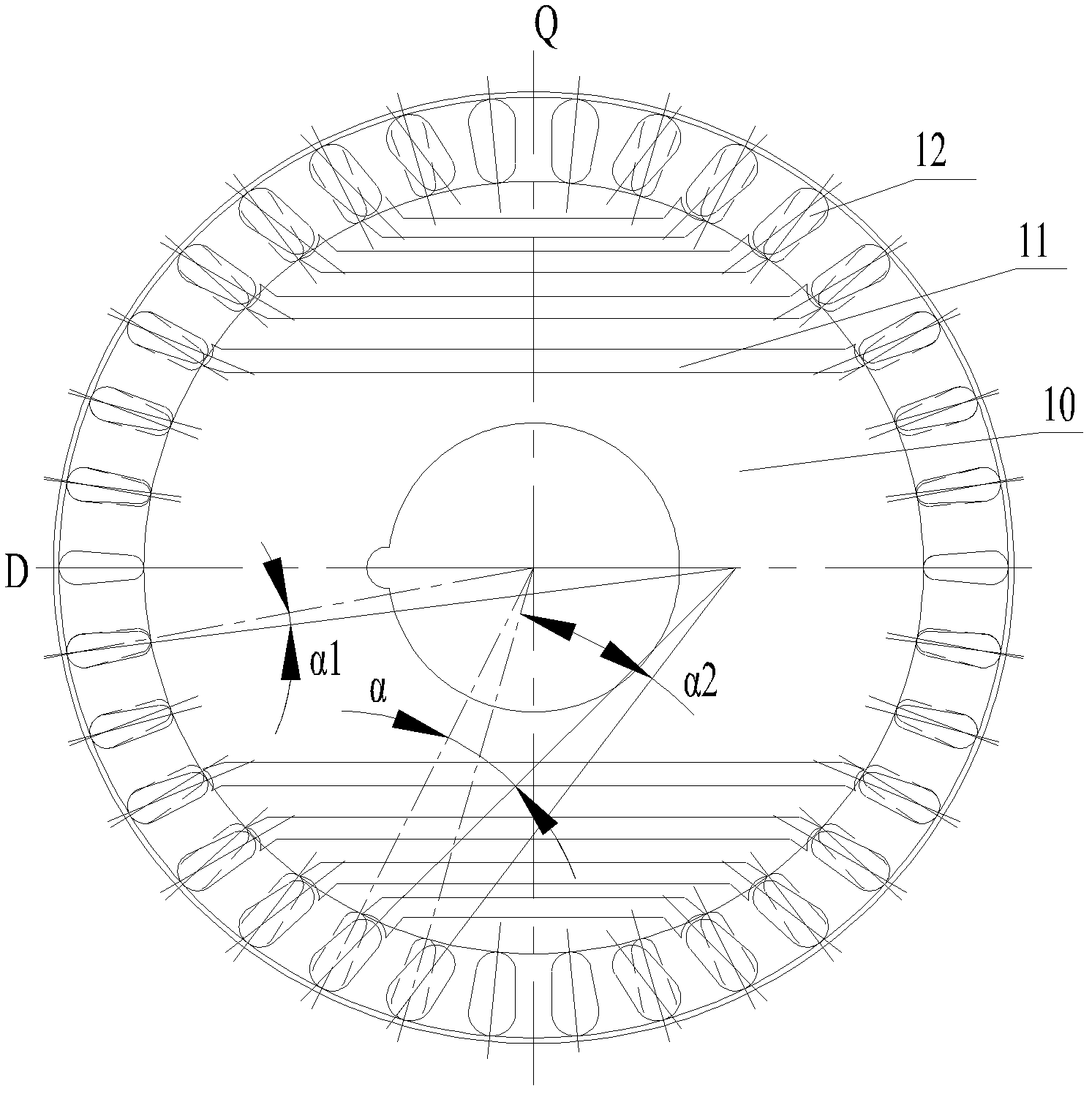

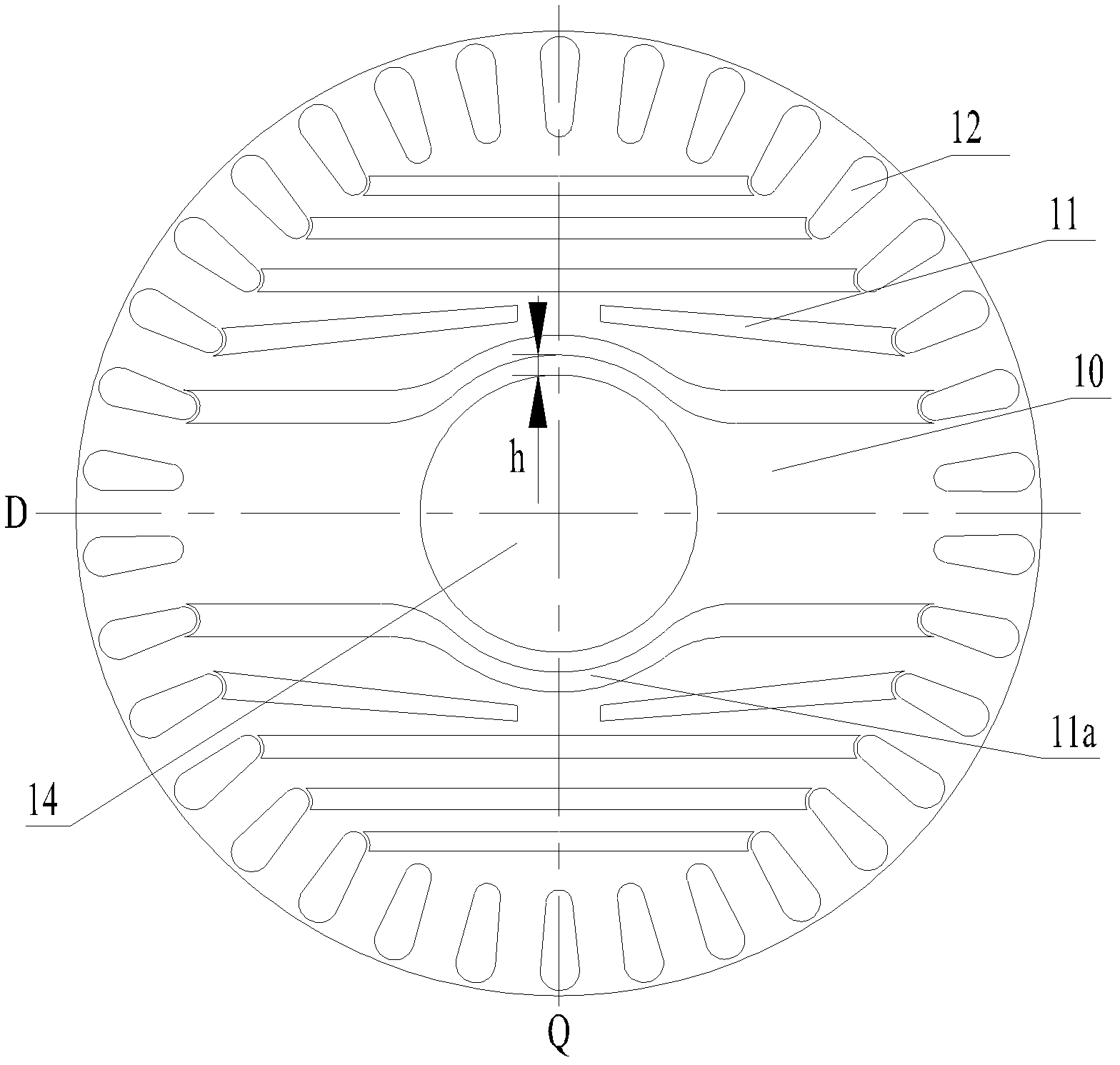

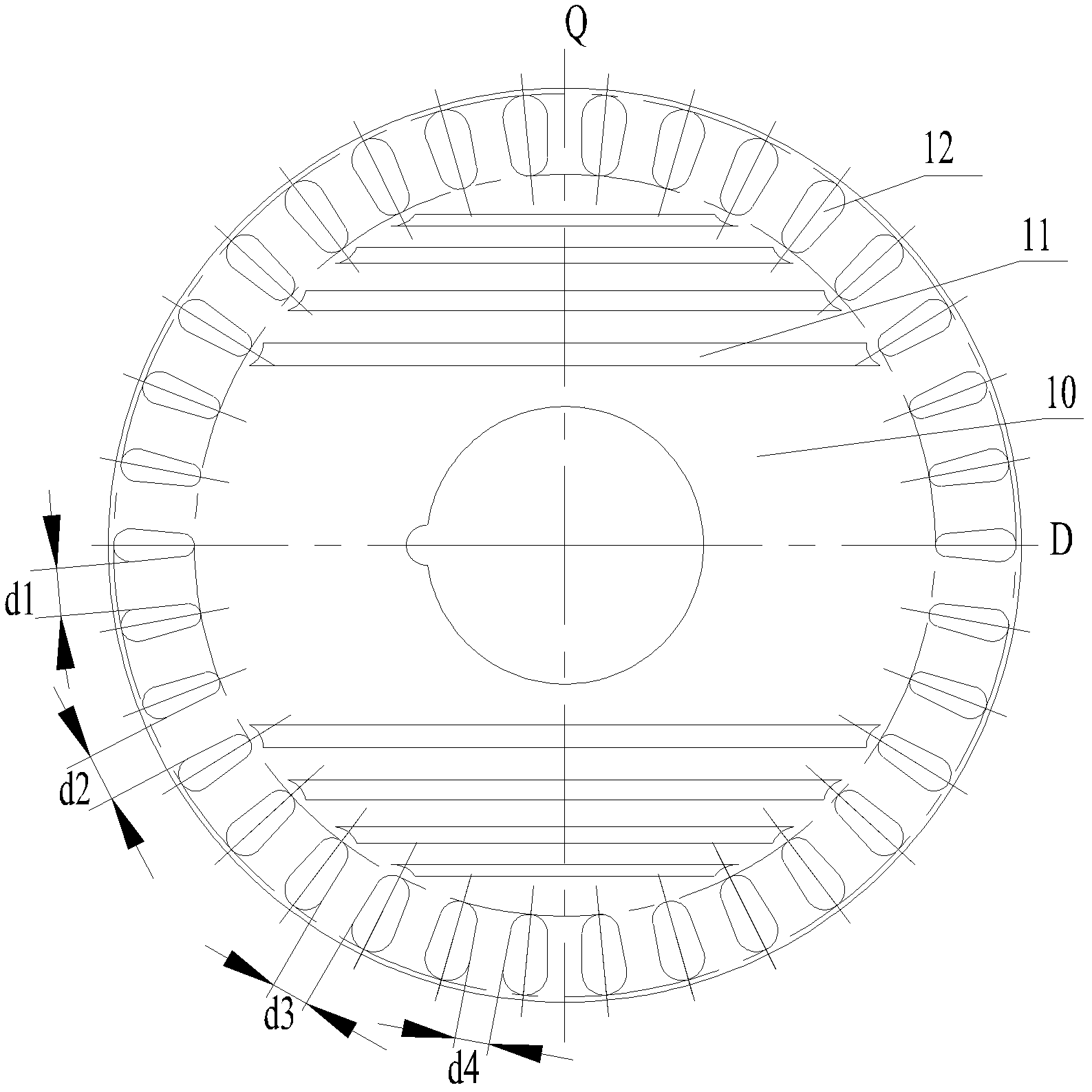

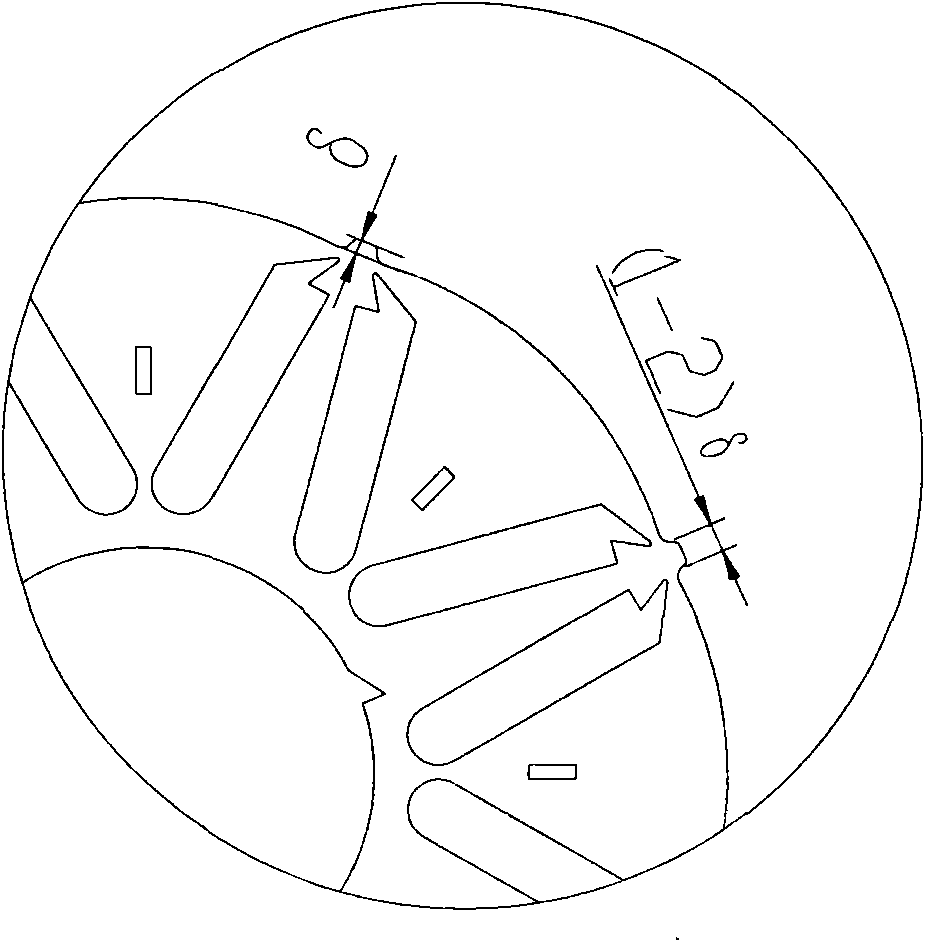

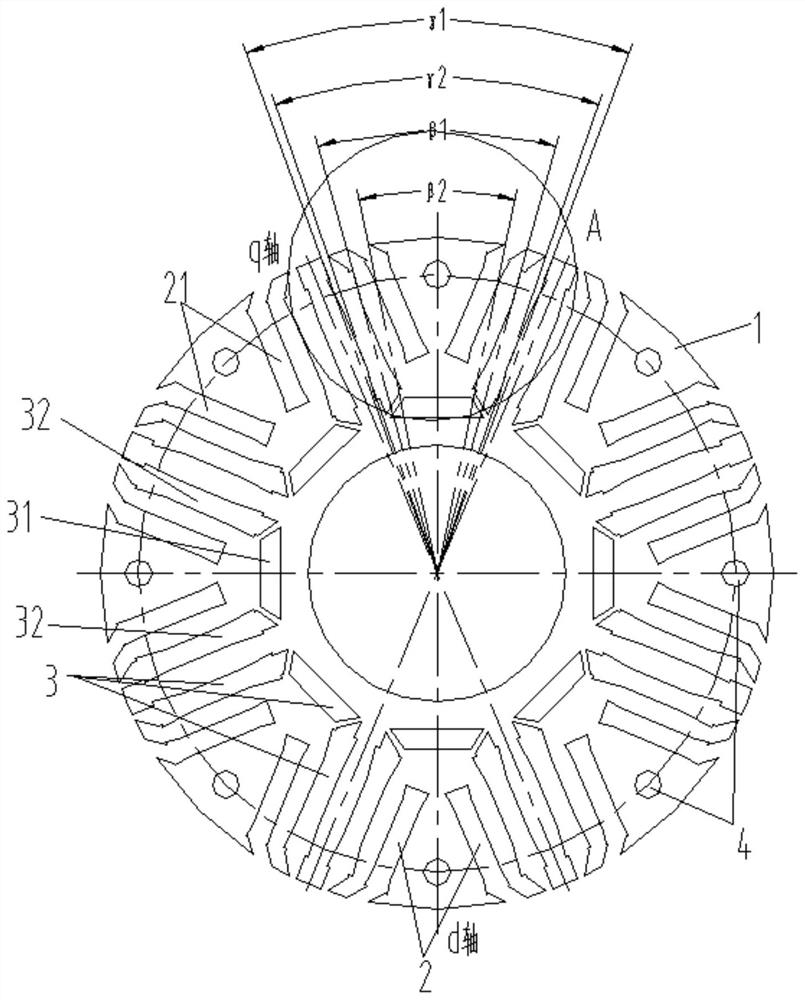

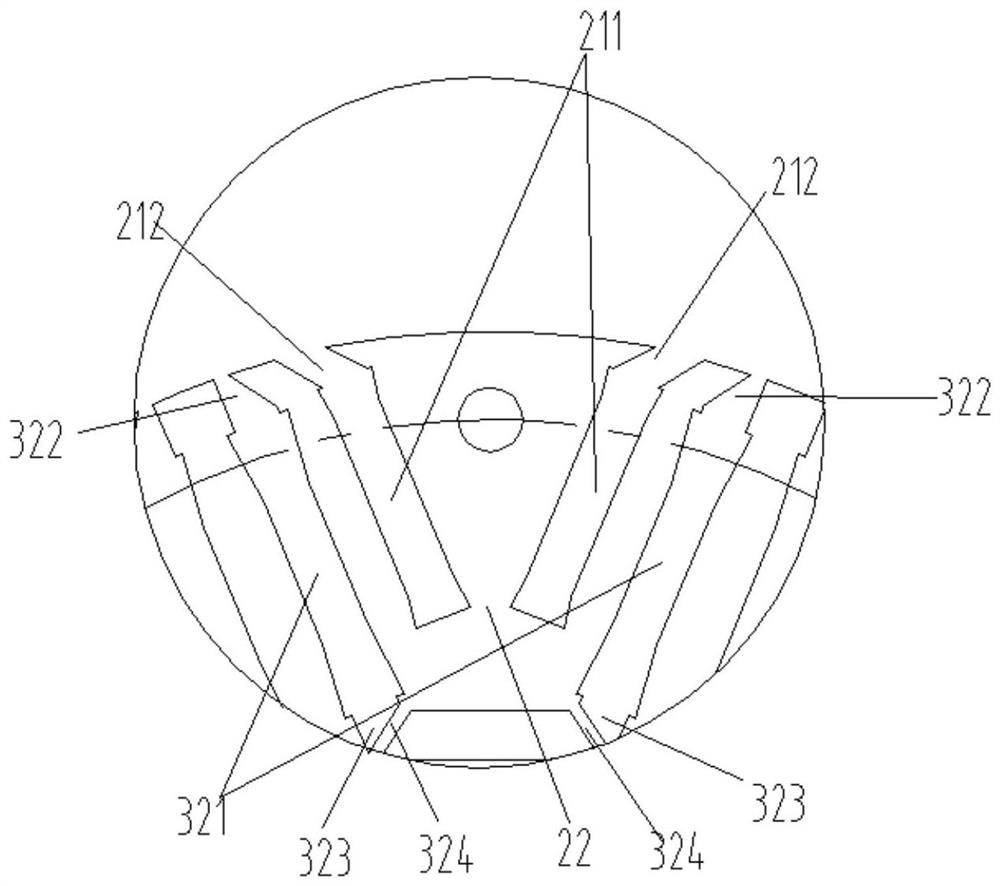

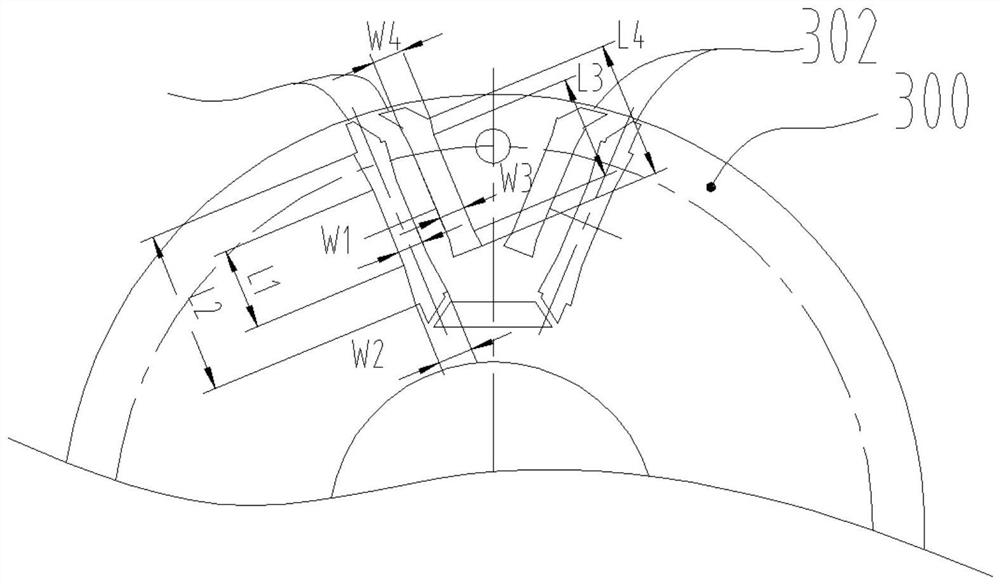

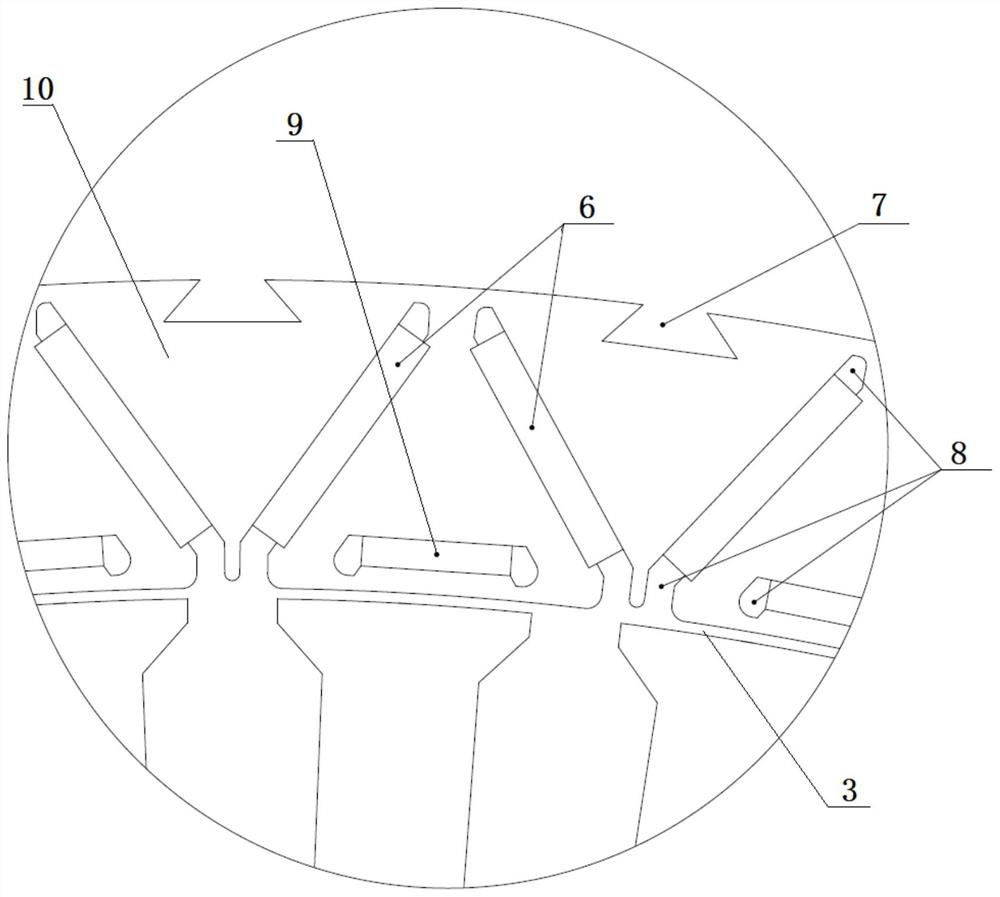

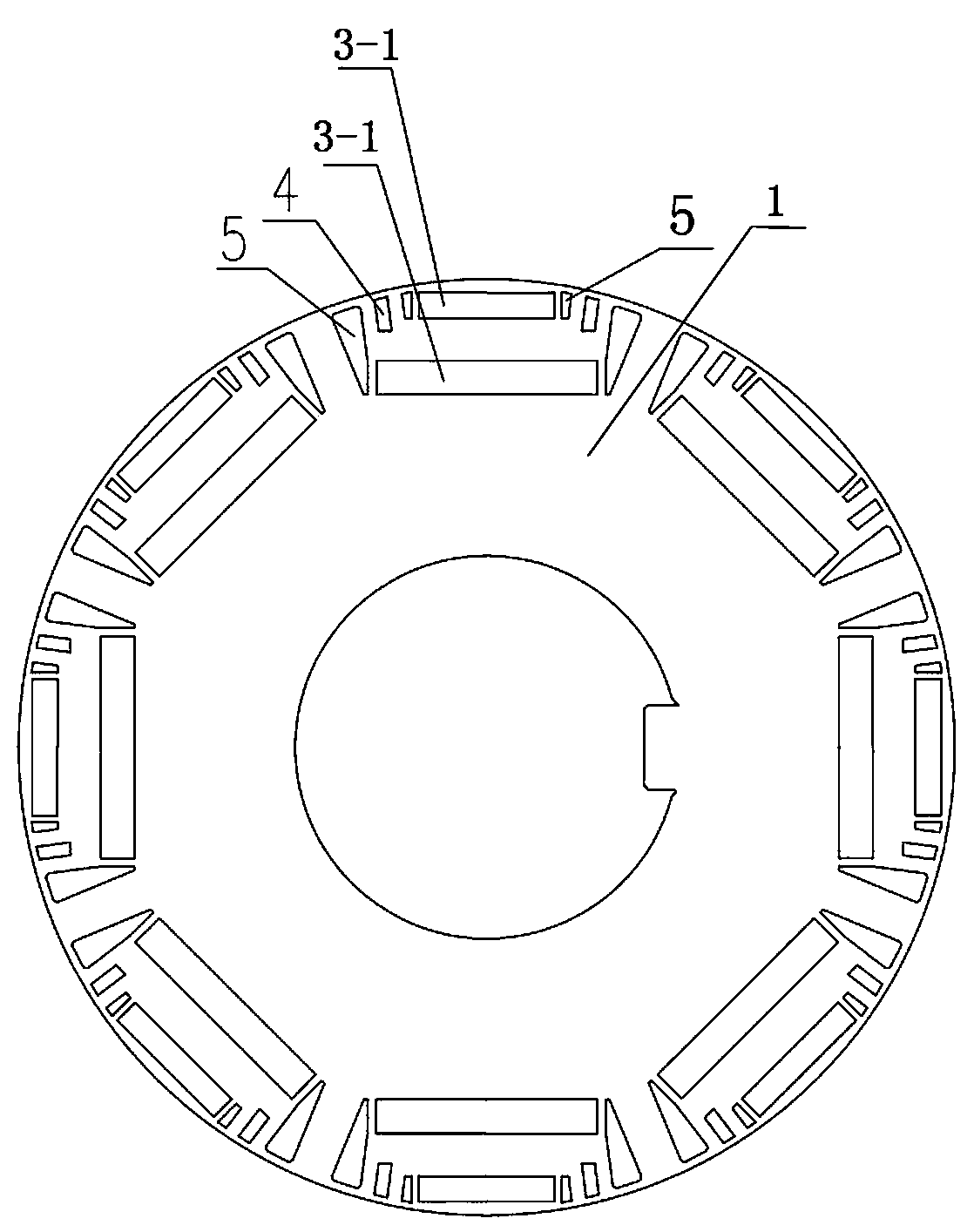

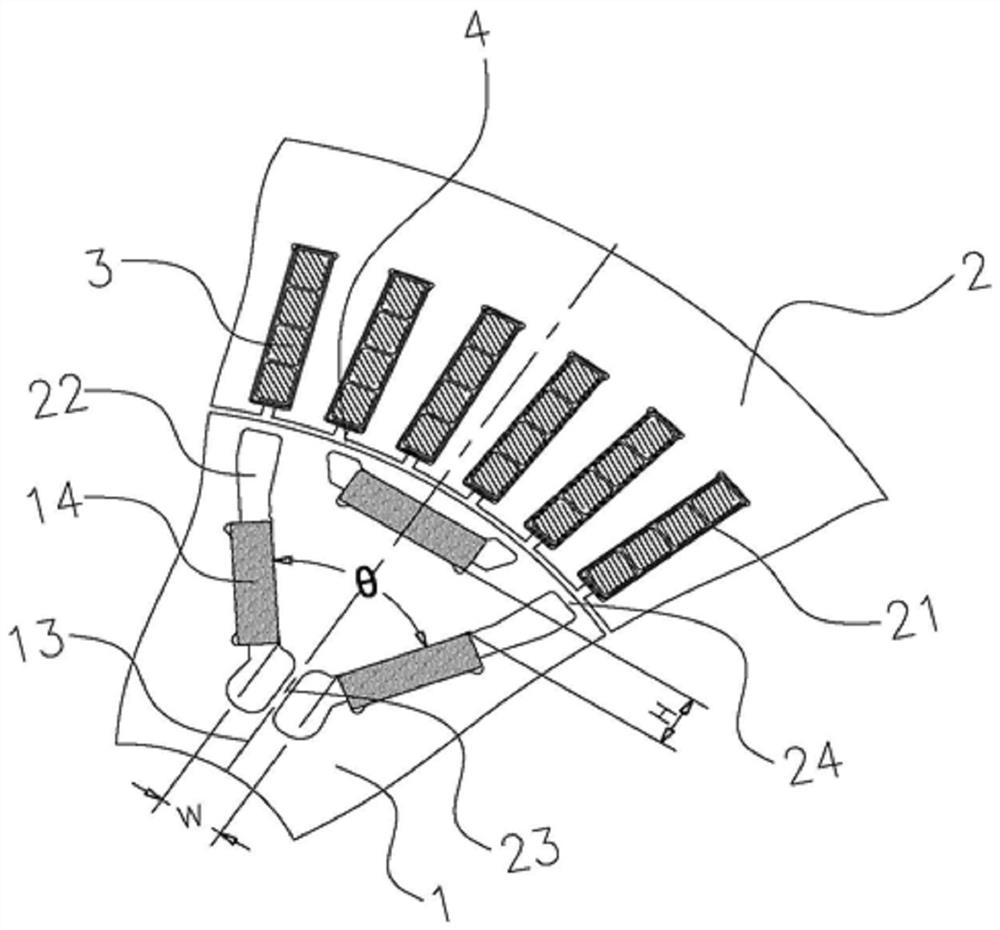

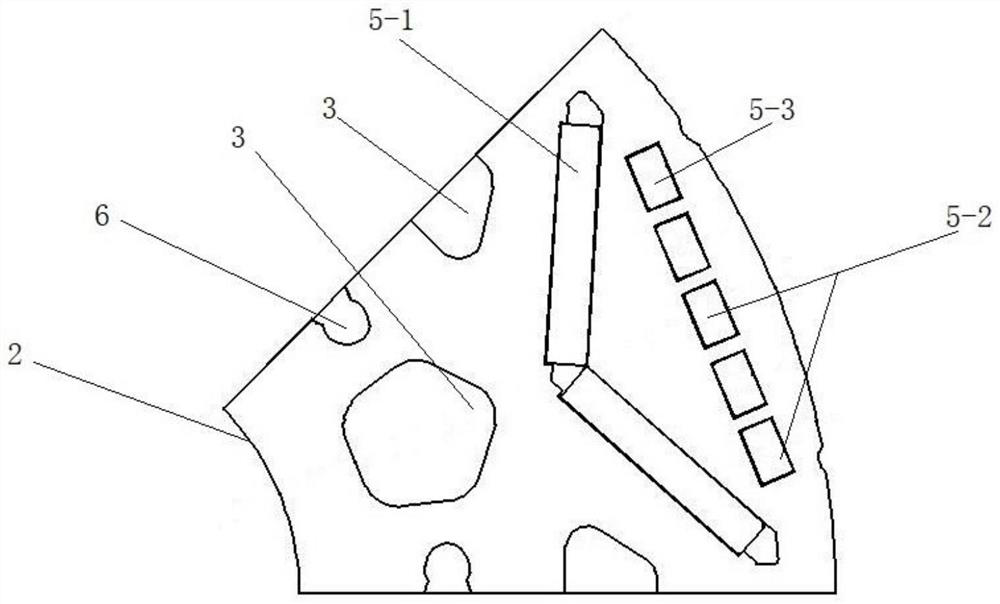

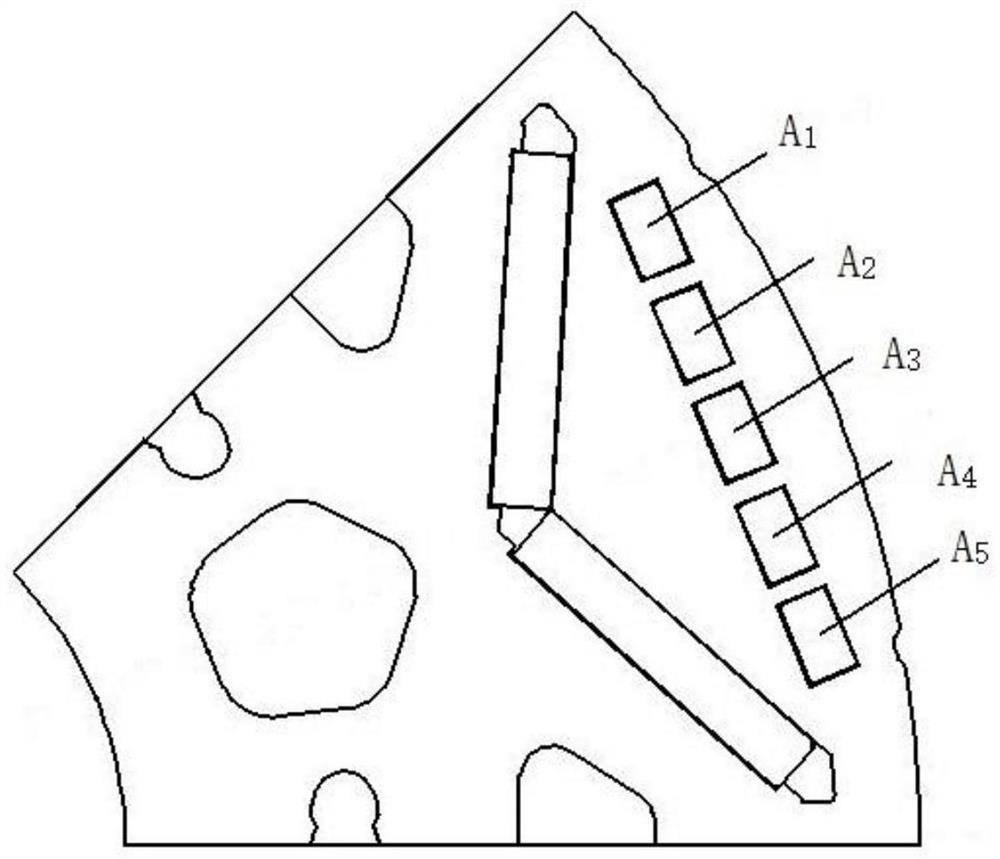

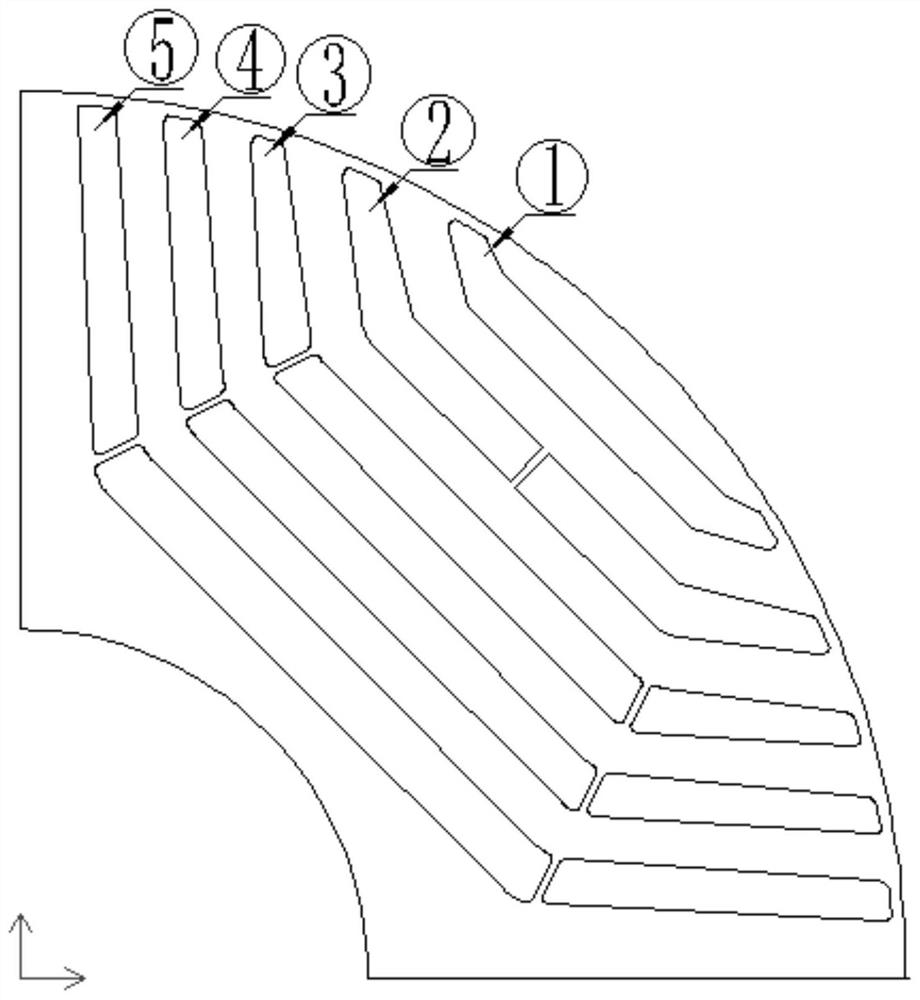

The invention provides a self-starting synchronous reluctance motor and a rotor thereof. The rotor of the self-starting synchronous reluctance motor comprises an iron core and squirrel-cage grooves, wherein magnetic flux separation grooves are arranged on the iron core, and the squirrel-cage slots are distributed along the periphery of the iron core. In the cross section of the rotor, the center line of the cross sections of the squirrel-cage slots deviates from the center circle of the iron core. The self-starting synchronous reluctance motor comprises a stator and the rotor of the self-starting synchronous reluctance motor. According to the self-starting synchronous reluctance motor and the rotor, the center line of the cross sections of the squirrel-cage grooves is led to deviate from the center circle of the iron core by adjusting the angle of the squirrel-cage grooves arranged on the rotor, magnetic permeability in the direction of the D axis is improved, magnetic permeability in the direction of the Q axis is reduced, inductance Ld in the direction of the D axis is increased and inductance Lq in the direction of the Q axis is reduced, namely salient pole ratio (Ld / Lq) of the motor is improved, and further motor efficiency is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Permanent magnet synchronous motor

InactiveCN102420475AReduce cogging torqueEasy to manufacture and assembleMagnetic circuit rotating partsSynchronous machine detailsPermanent magnet synchronous motorMagnetic poles

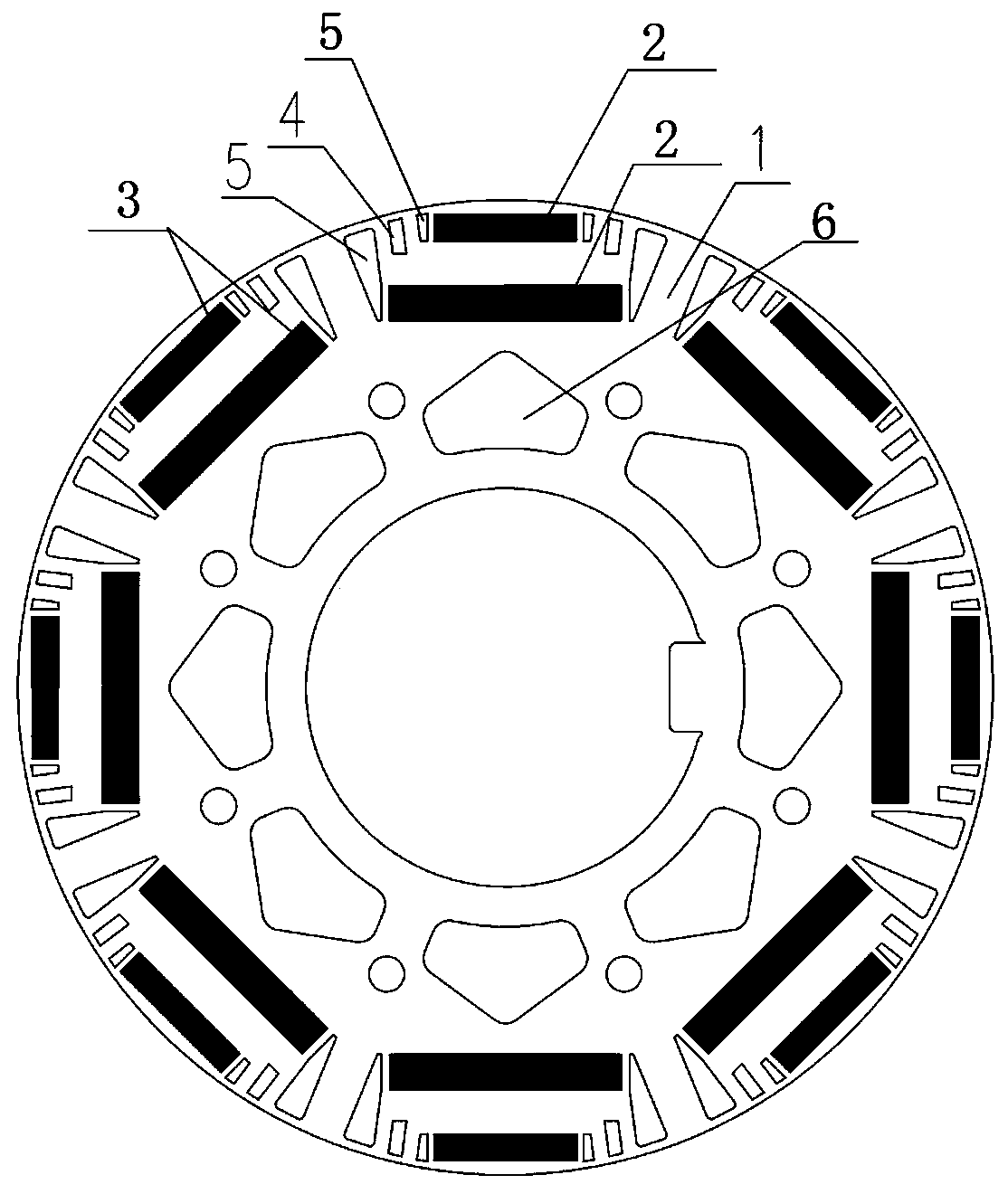

A purpose of the present invention is providing a permanent magnet synchronous motor rotor structure which has high air gap flux density and is easy to generate back electromotive force with a sine wave. In a permanent magnet synchronous motor, a circumferential surface of the rotor is uniformly provided with a plurality of magnetic steel grooves which are independently enclosed and do not contact mutually. Every two magnetic steel grooves are arranged to form a V shape, an opening of the V shape faces excircle of the rotor, and a tip of the V shape faces a rotor center. Each magnetic steel groove is provided with magnetic steel. In each group of V-shaped magnetic steel grooves, two magnetic steel facing the excircle of the rotor core have a same magnetic pole, and magnetic poles of magnetic steel facing the excircle of the rotor core in two adjacent groups of V-shaped magnetic steel grooves are opposite with the magnetic pole of the two magnetic steel. The excircle of the rotor goes down toward the center with depth delta and smooth transition at a crossing position of axes, which means that air gap width at the crossing position is less than air gap width at a straight axis position by delta. Through improving the rotor, the permanent magnet synchronous motor rotor has high mechanical strength and a large salient pole ratio, and weakened magnetism speed expansion is facilitated.

Owner:TIANJIN SANTROLL ELECTRIC SCI & TECH

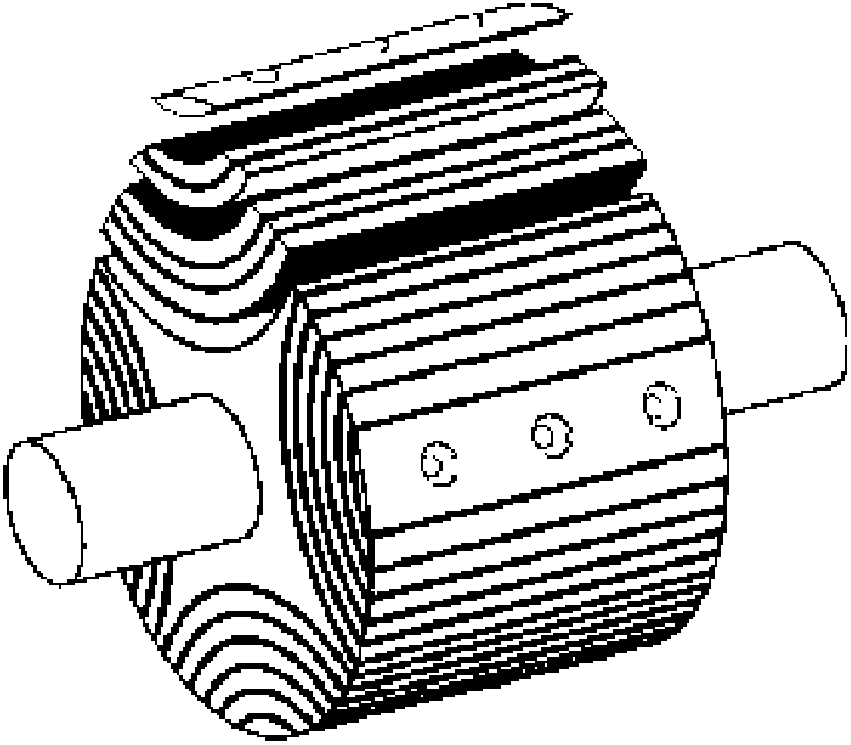

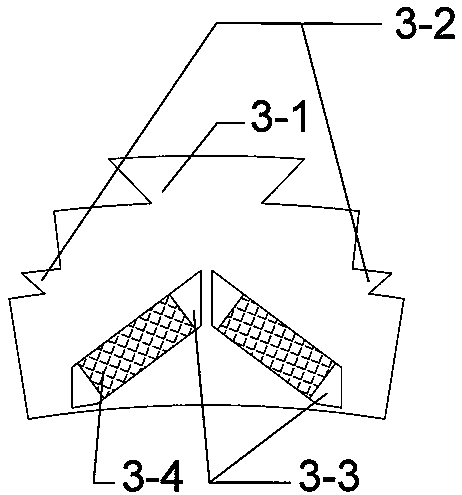

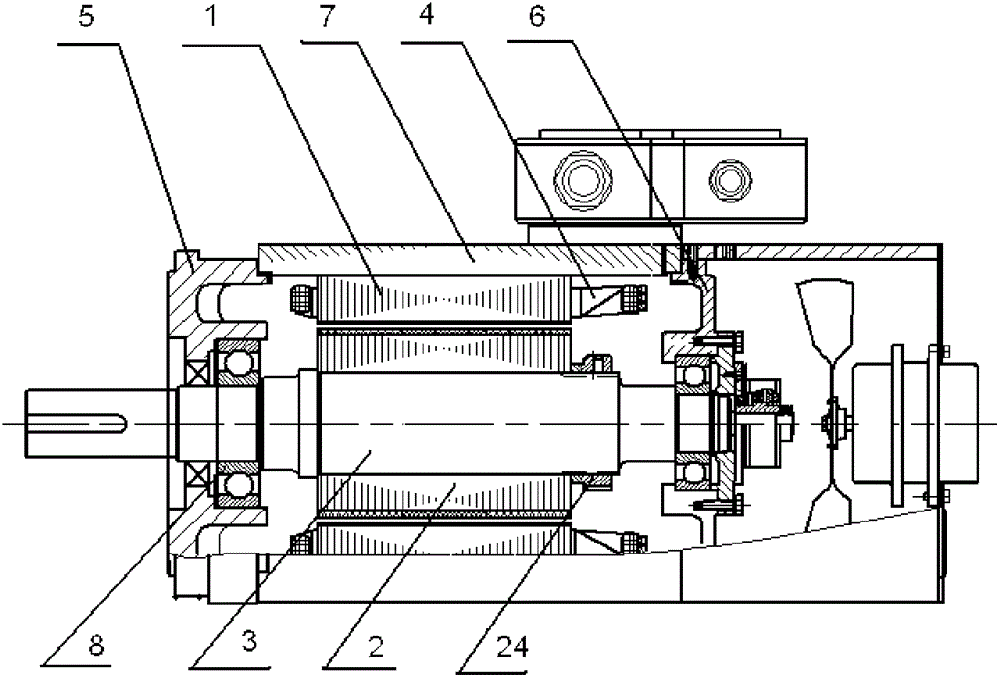

Transverse laminated synchronous reluctance motor with auxiliary permanent magnets

ActiveCN103095078AImprove power factorBroaden the range of constant power speed regulationMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsSynchronous reluctance motorConstant power

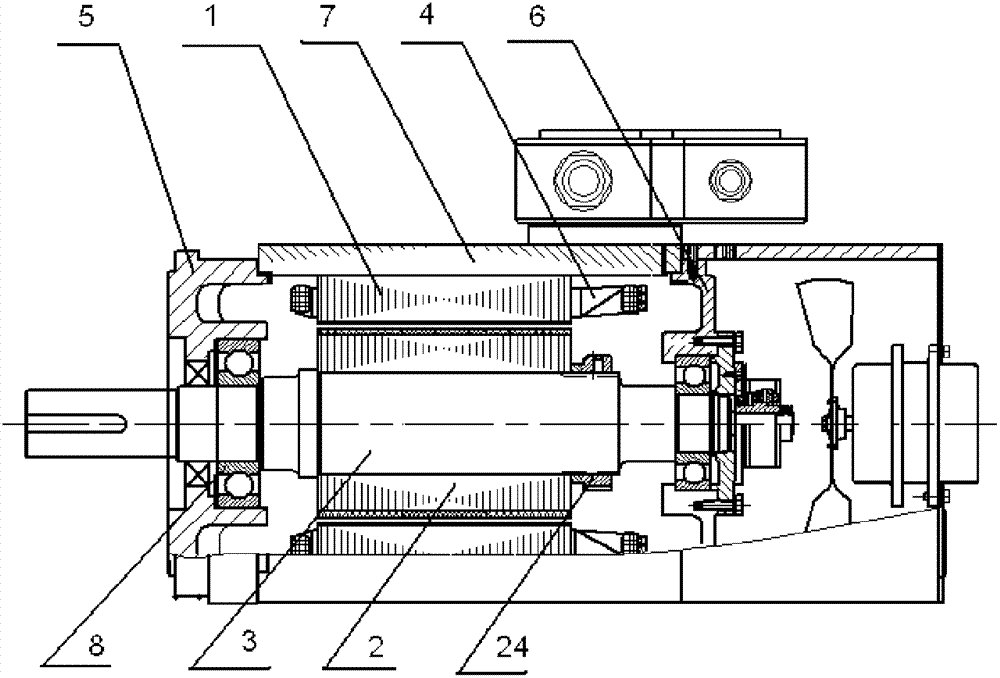

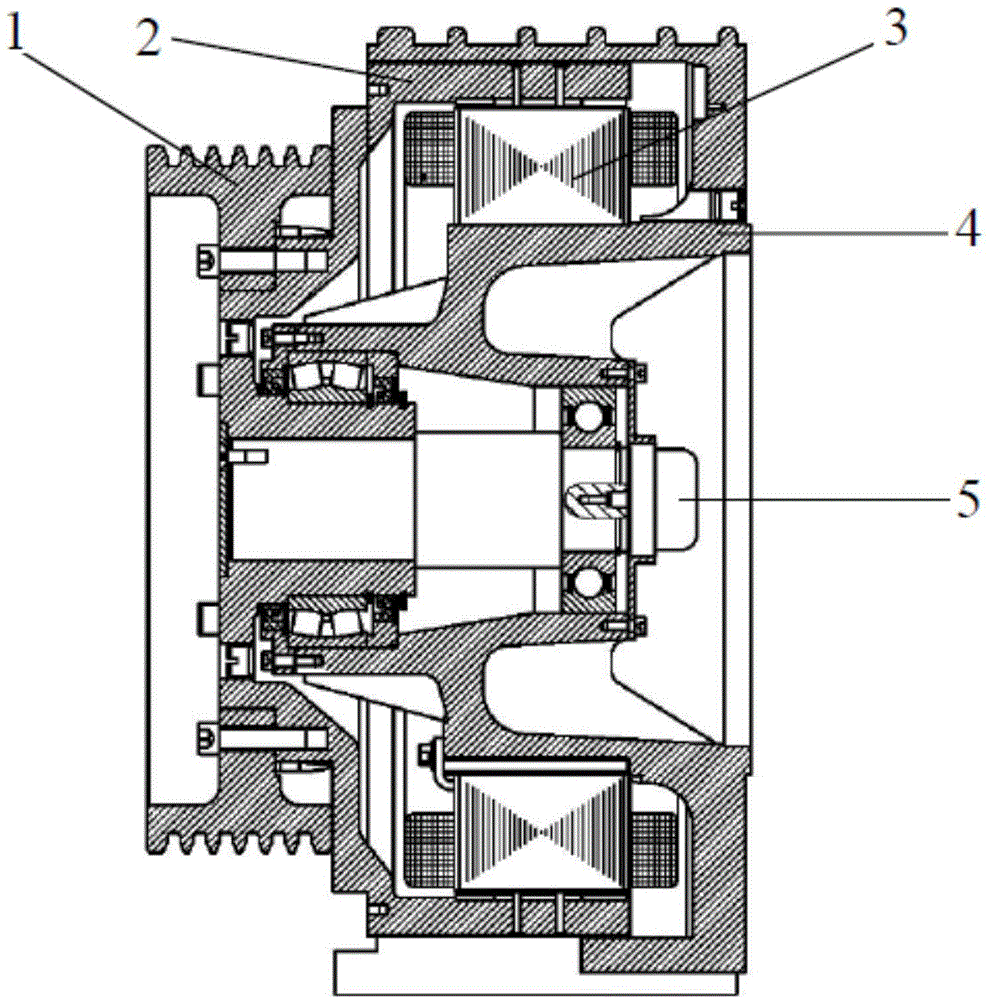

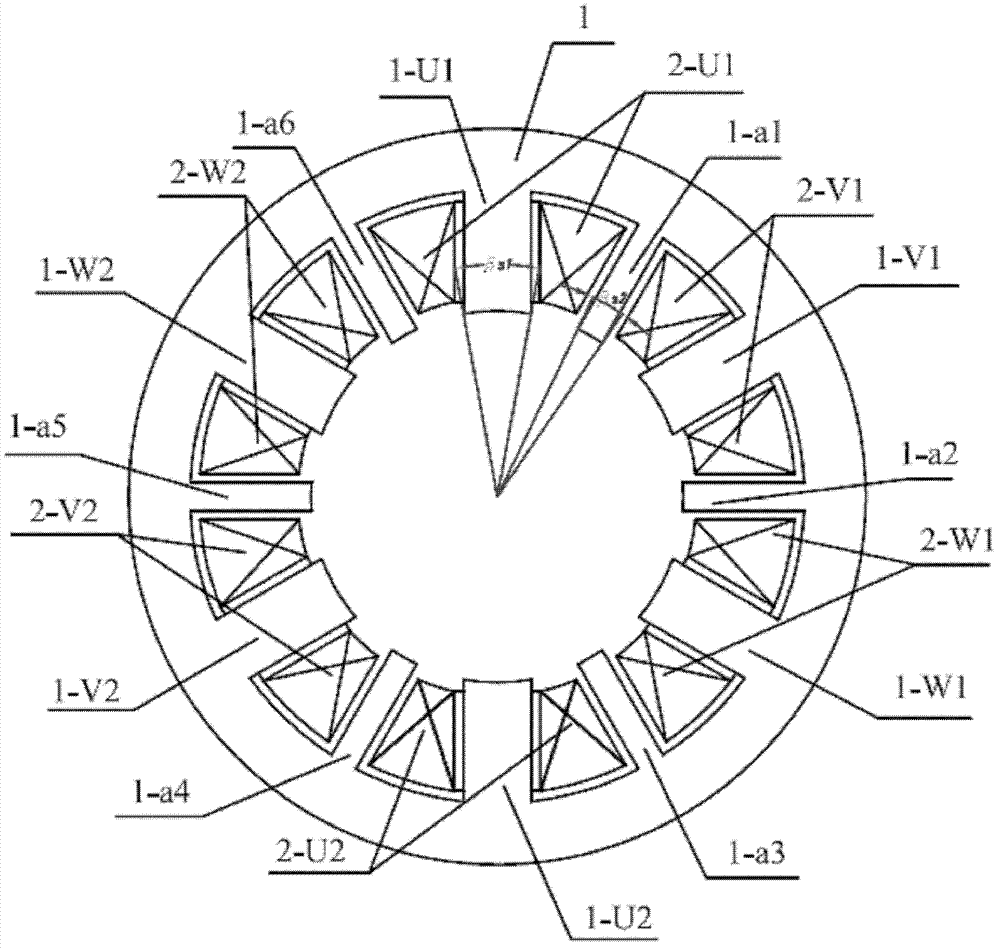

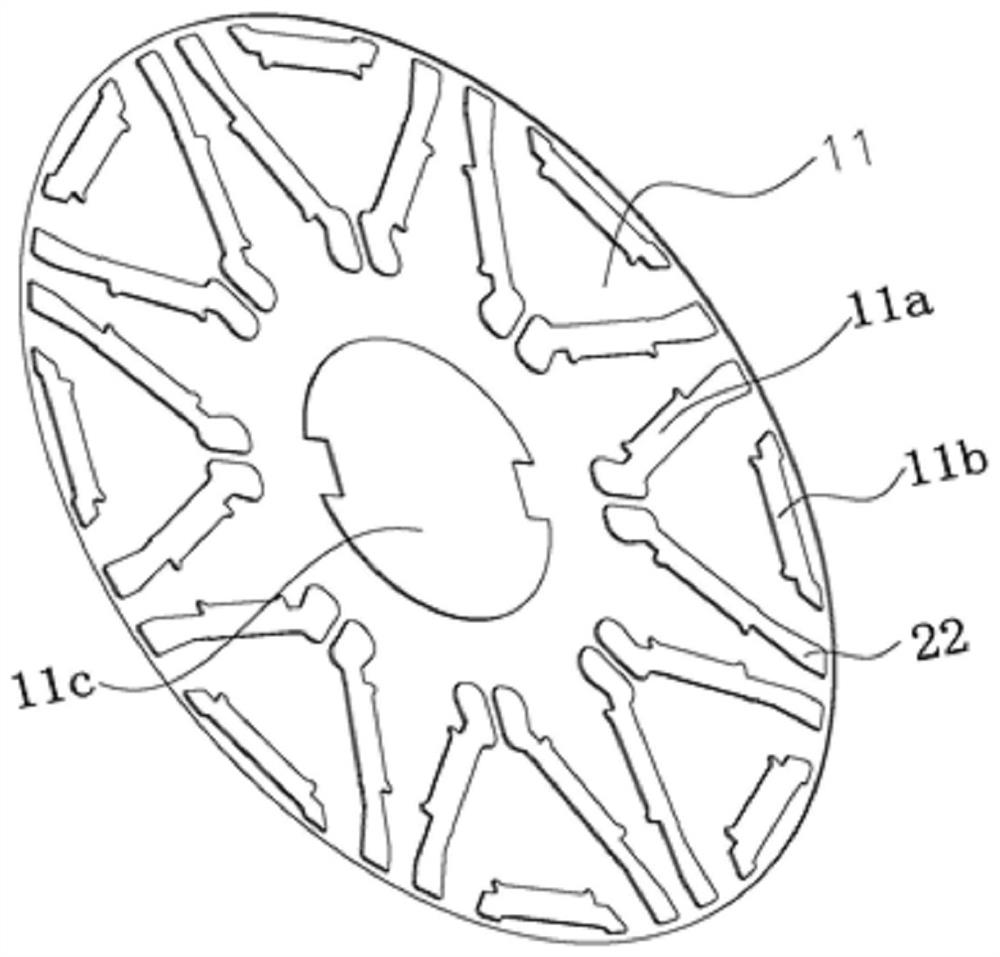

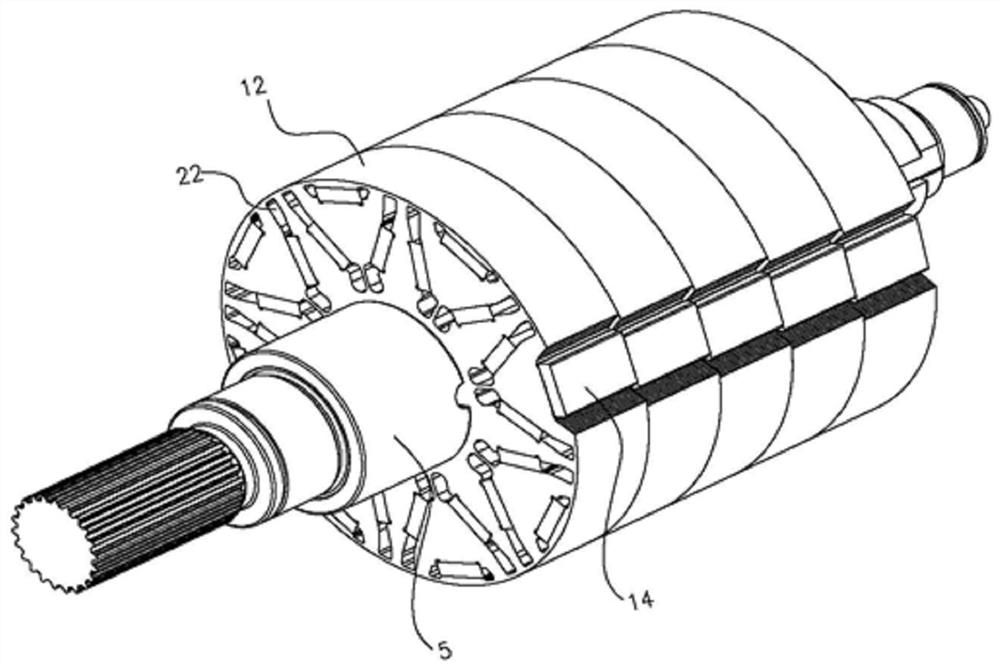

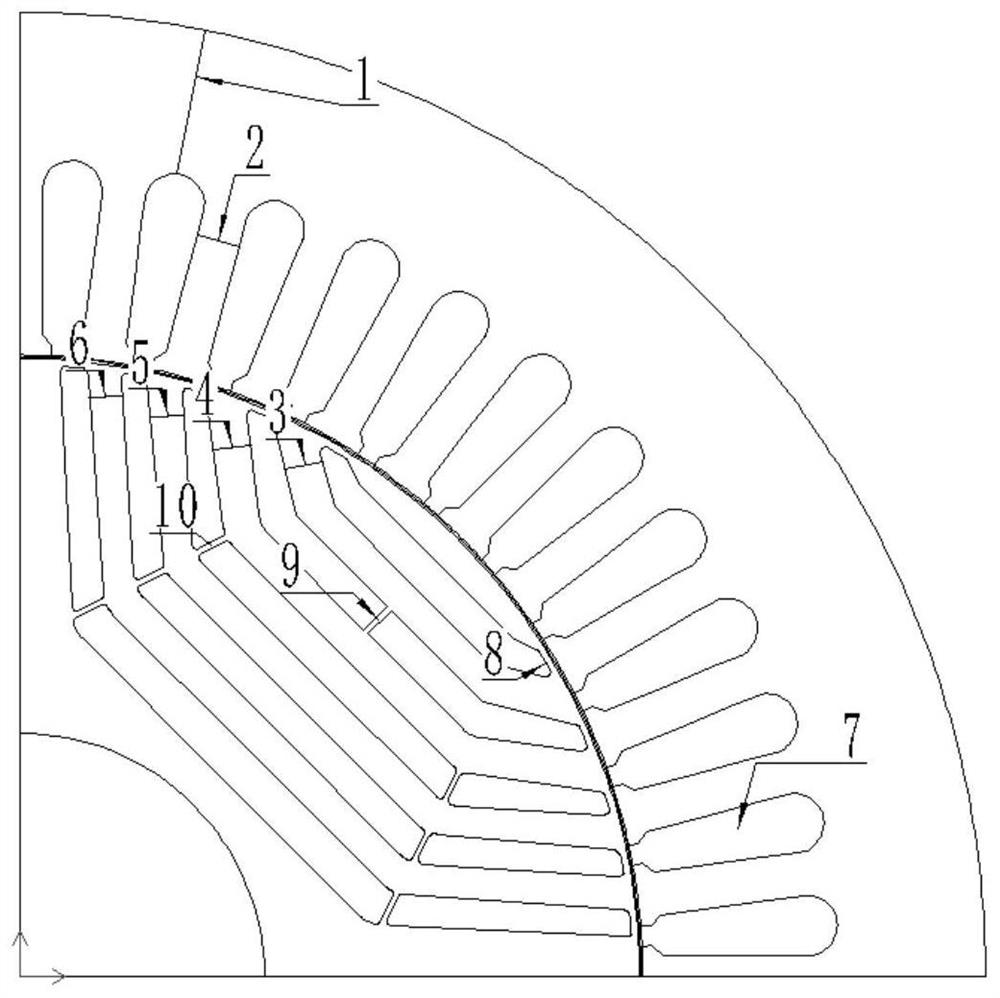

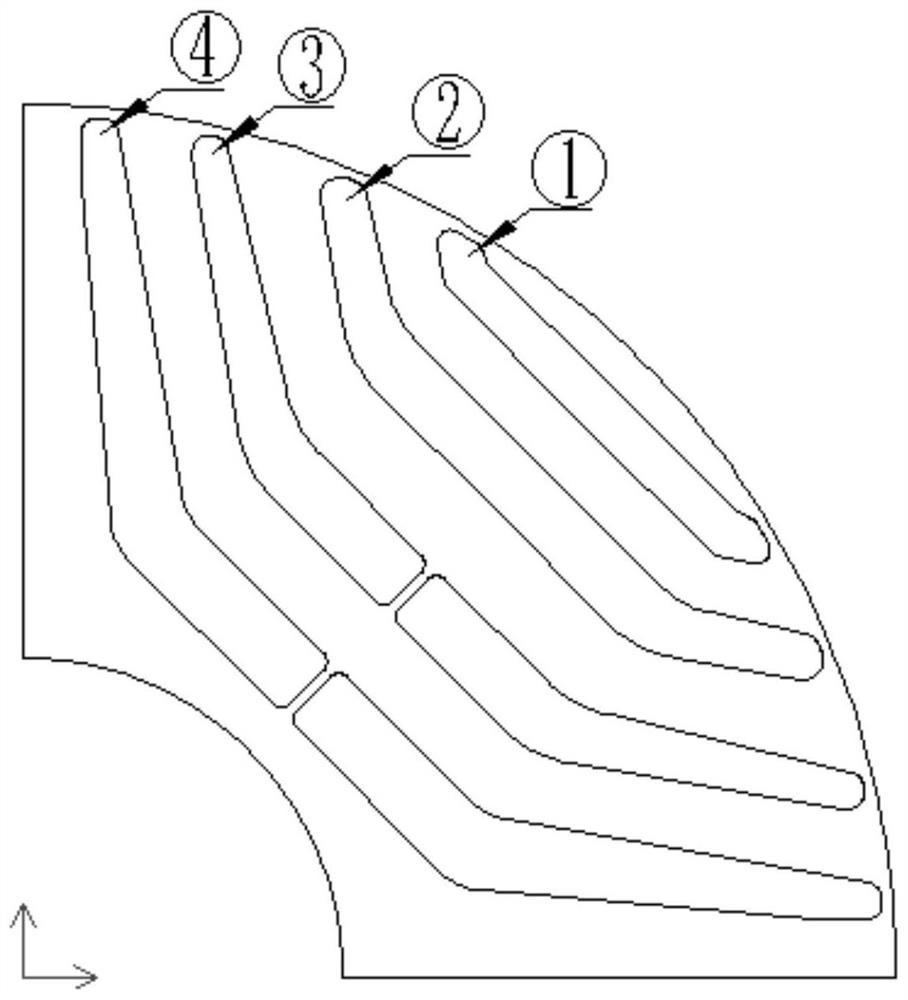

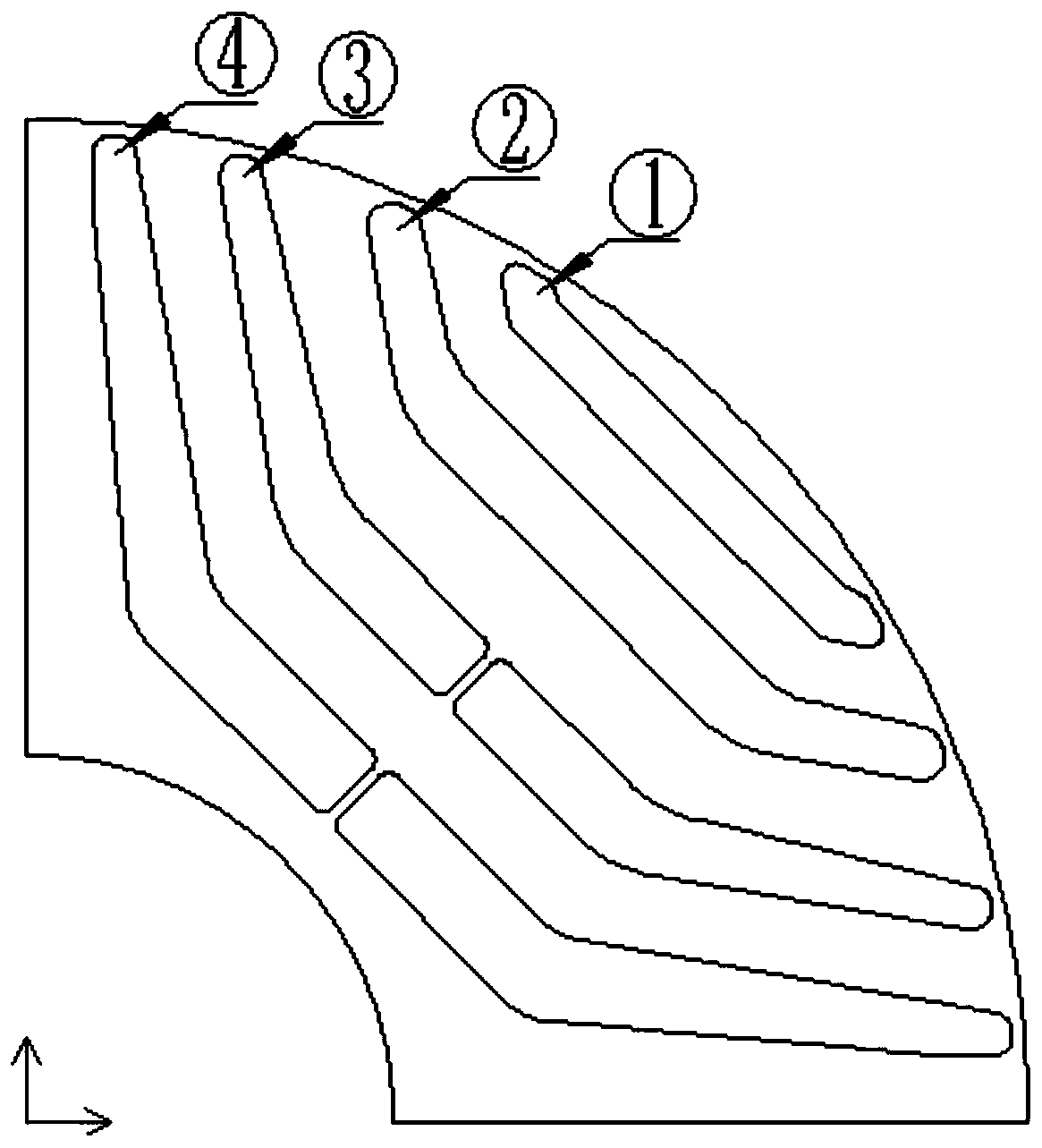

The invention discloses a transverse laminated synchronous reluctance motor with auxiliary permanent magnets. The transverse laminated synchronous reluctance motor with the auxiliary permanent magnets comprises a stator core, stator windings, a rotor core assembly, a rotating shaft, a bearing used for supporting the rotating shaft, a front end cover, a rear end cover and a machine shell. The rotor core assembly comprises the rotor core and a plurality of block-shaped permanent magnets, wherein the rotor core and the plurality of block-shaped permanent magnets are sleeved on the rotating shaft. The rotor core is formed by transversely laminating a plurality of single-shaped complete steel sheets along the rotating shaft. The rotor core is provided with a plurality of layers of arc grooves suitable for insertion of the blocked-shaped permanent magnets. The block-shaped permanent magnets are arranged in the arc grooves. The polarities of the permanent magnets in the layers of arch grooves of the same polar are the same and form a magnetic pole group. The polarities of magnetic pole sets of two adjacent poles are opposite. According to the synchronous reluctance motor, the auxiliary block-shaped permanent magnets are arranged in the arc grooves of the rotor core, and therefore power factors of the motor are improved, and constant power speed adjustable ranges of the motor are widened; and due to the fact that the rotor core is formed by transversely laminating the plurality of single-shaped complete silicon steel sheets, the motor can have good mechanical strength.

Owner:SHANGHAI FUTIAN ELECTRIC TECH

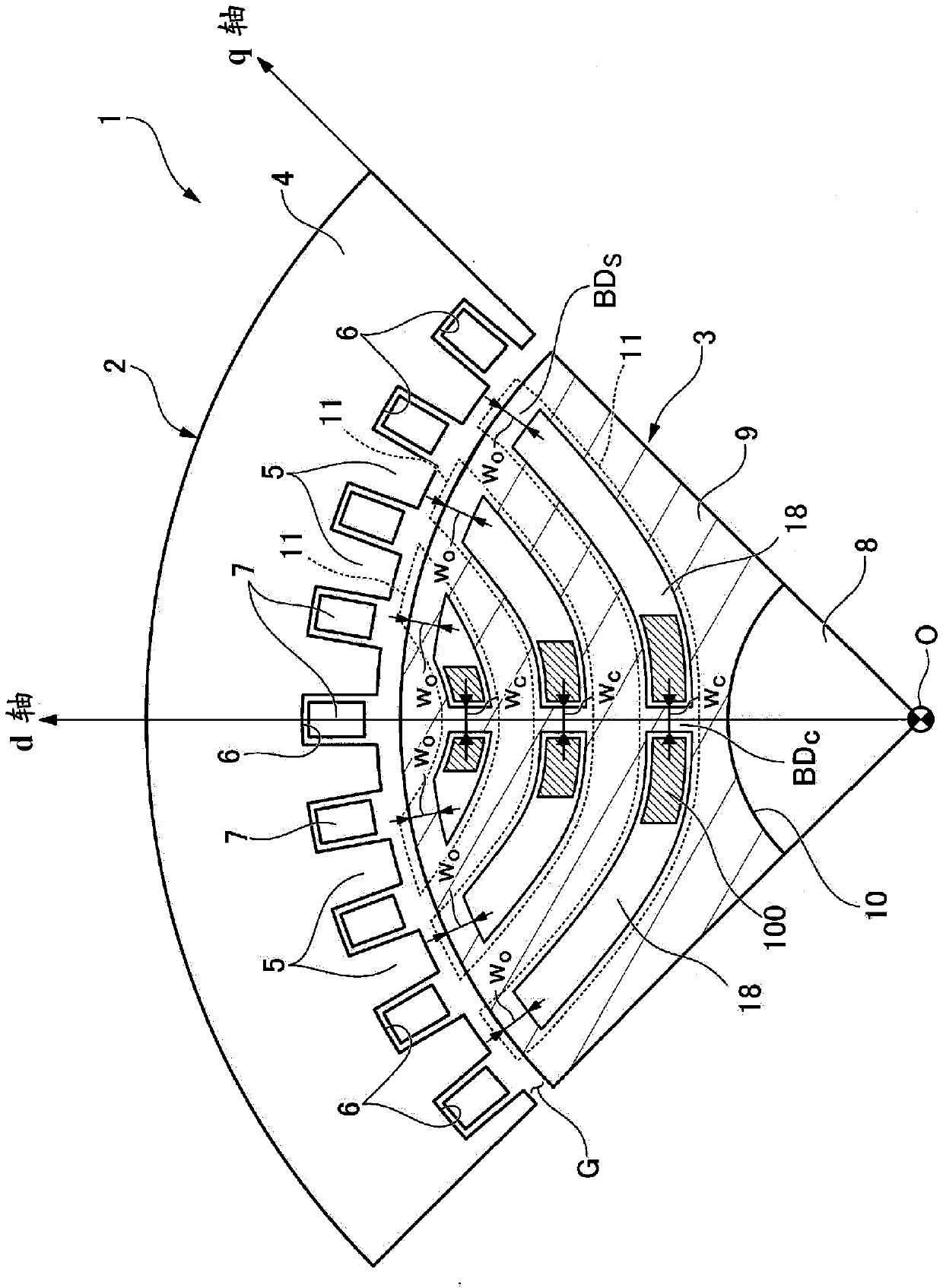

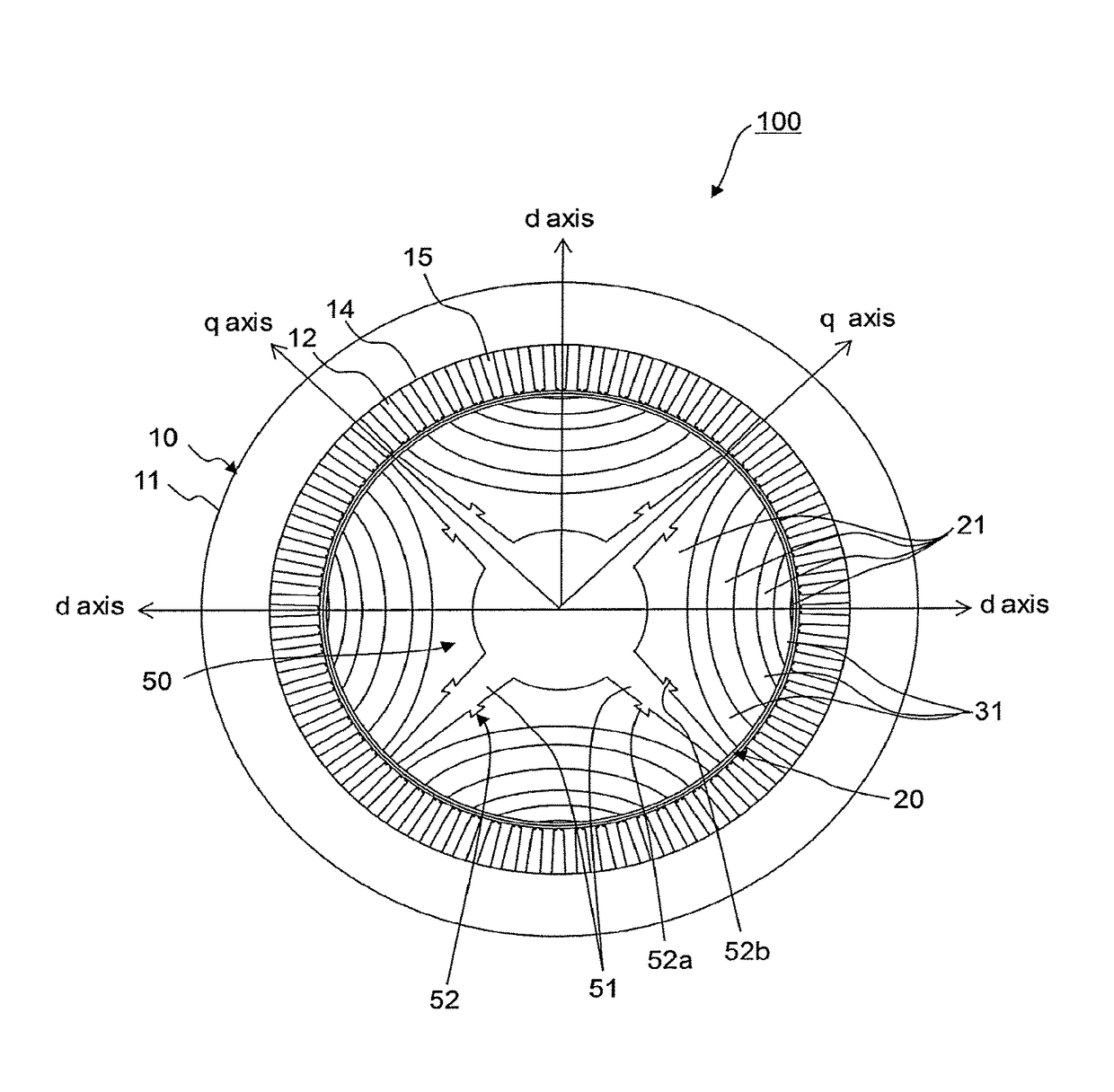

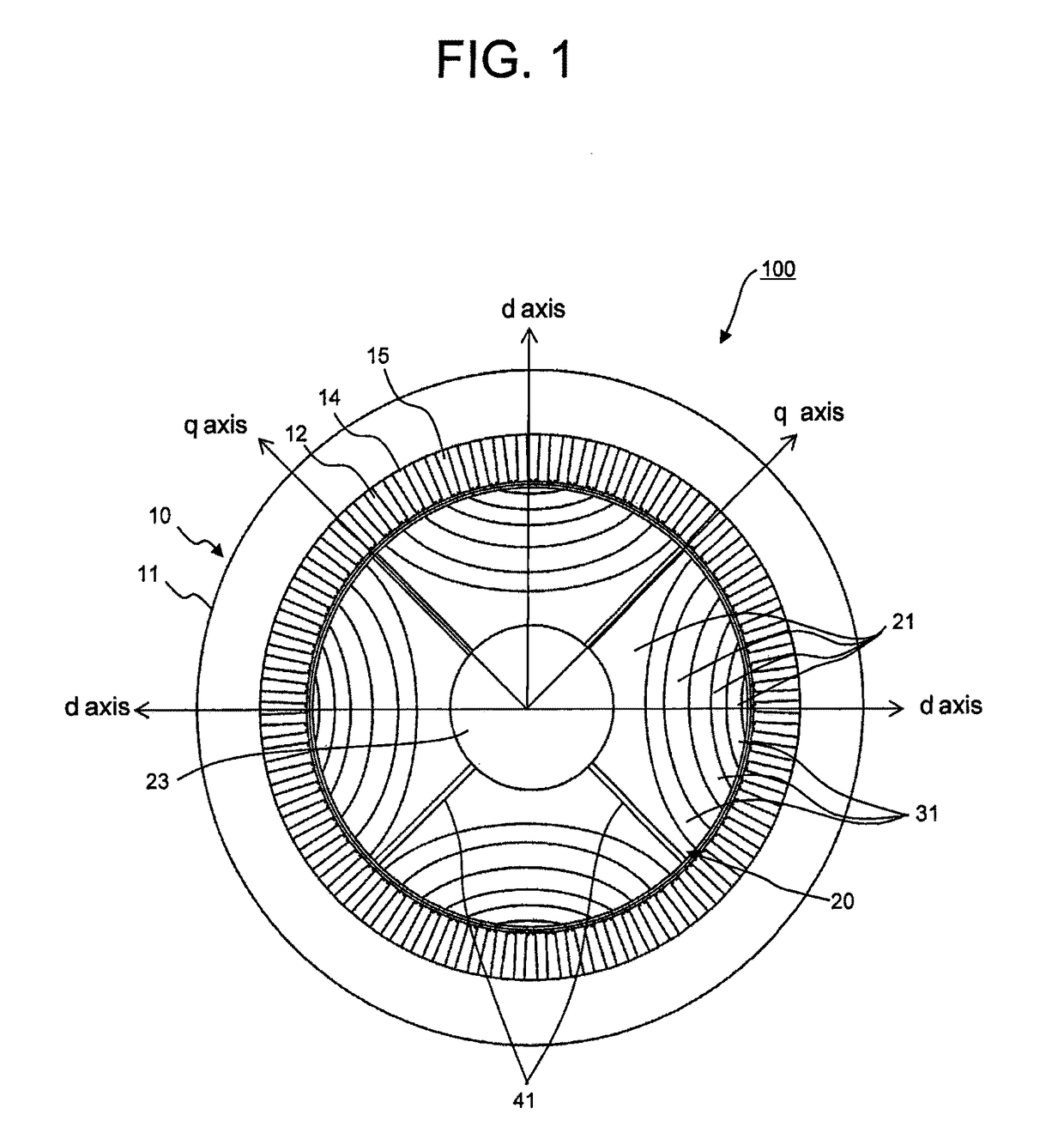

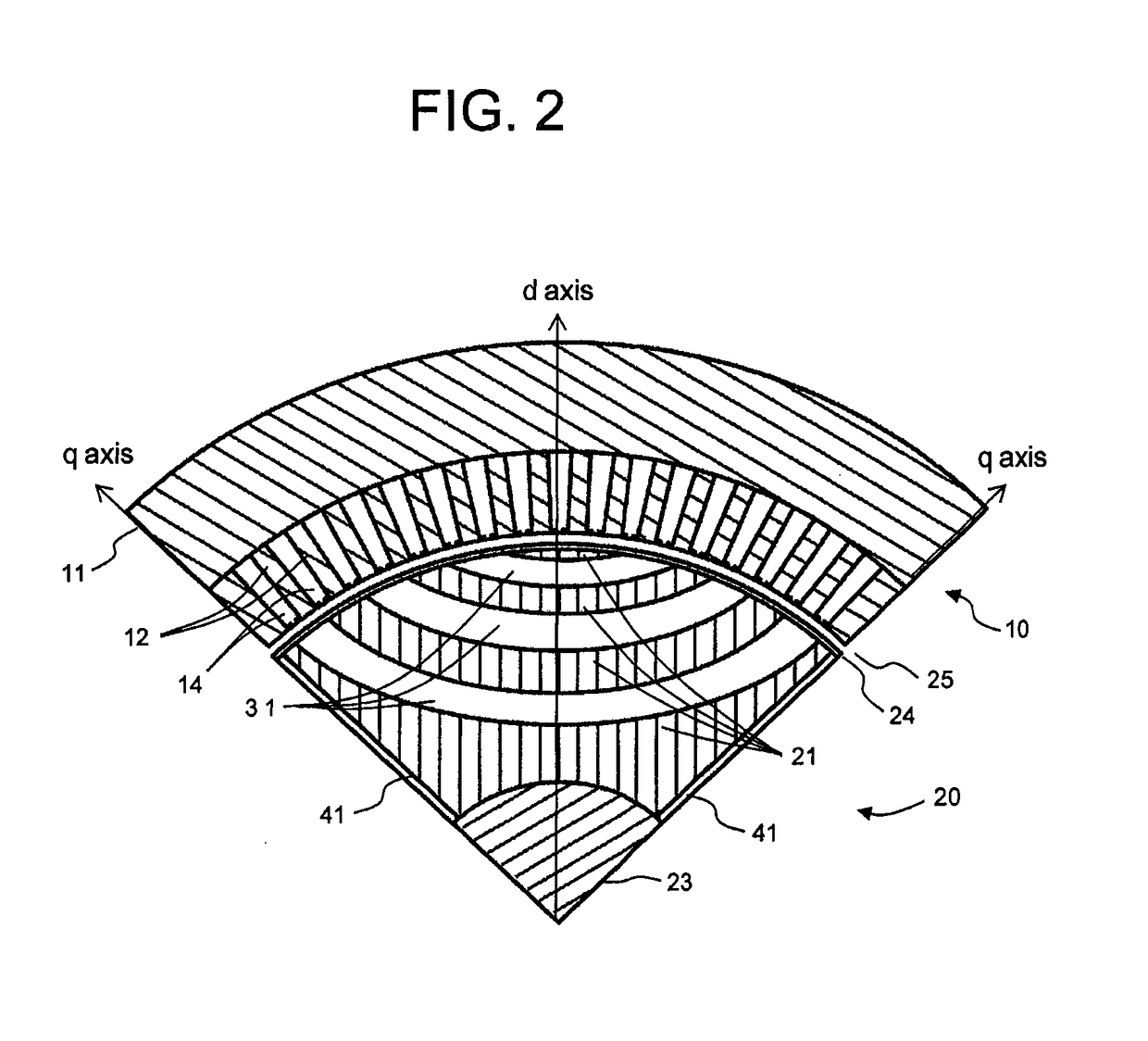

Synchronous reluctance motor and rotor for synchronous reluctance motor

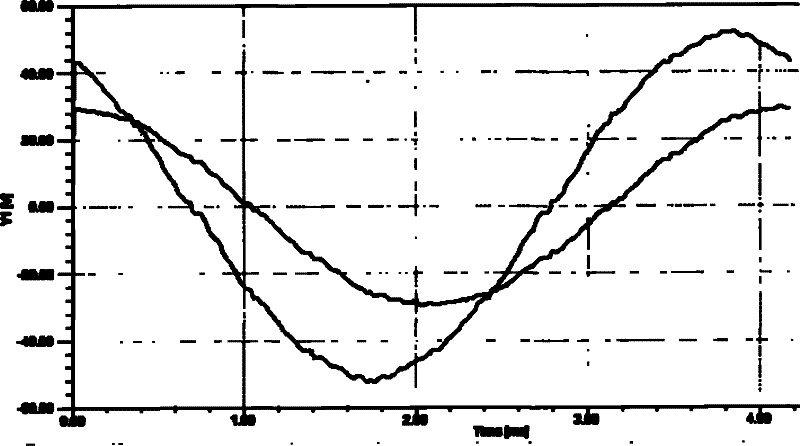

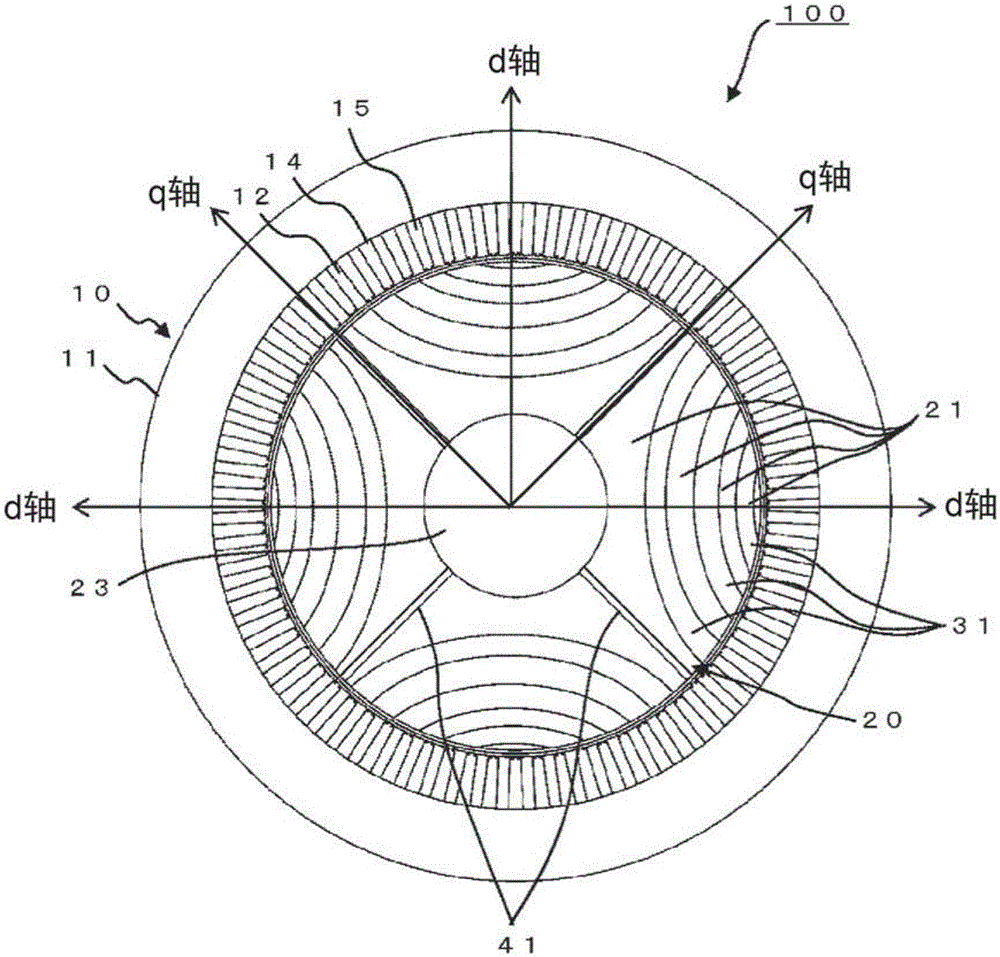

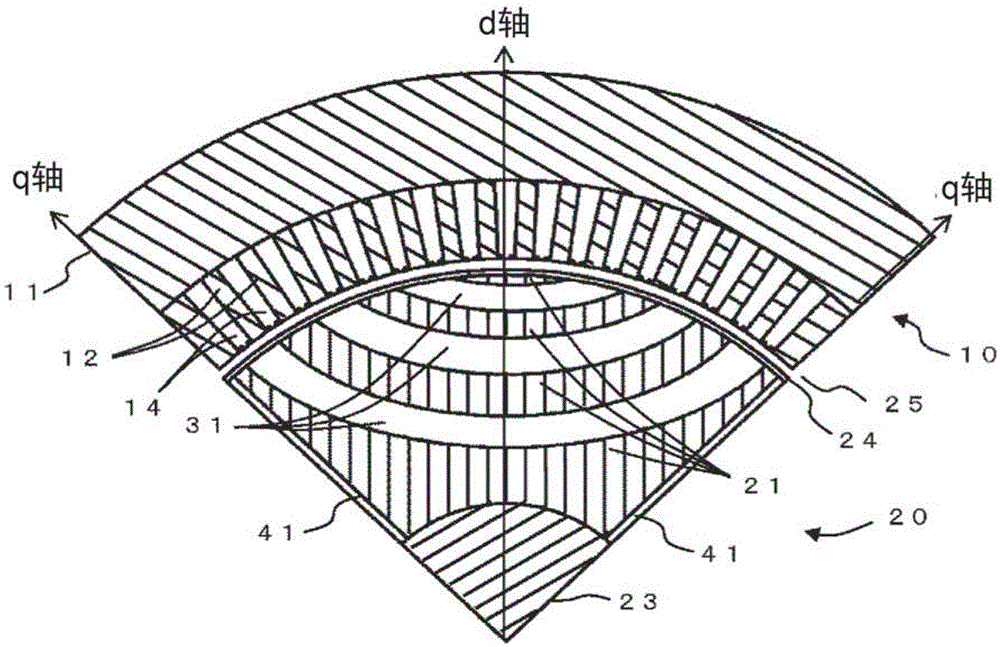

ActiveUS20160049835A1Raise the saliency ratioIncrease torqueMagnetic circuit rotating partsSynchronous motorsSynchronous reluctance motorPhysics

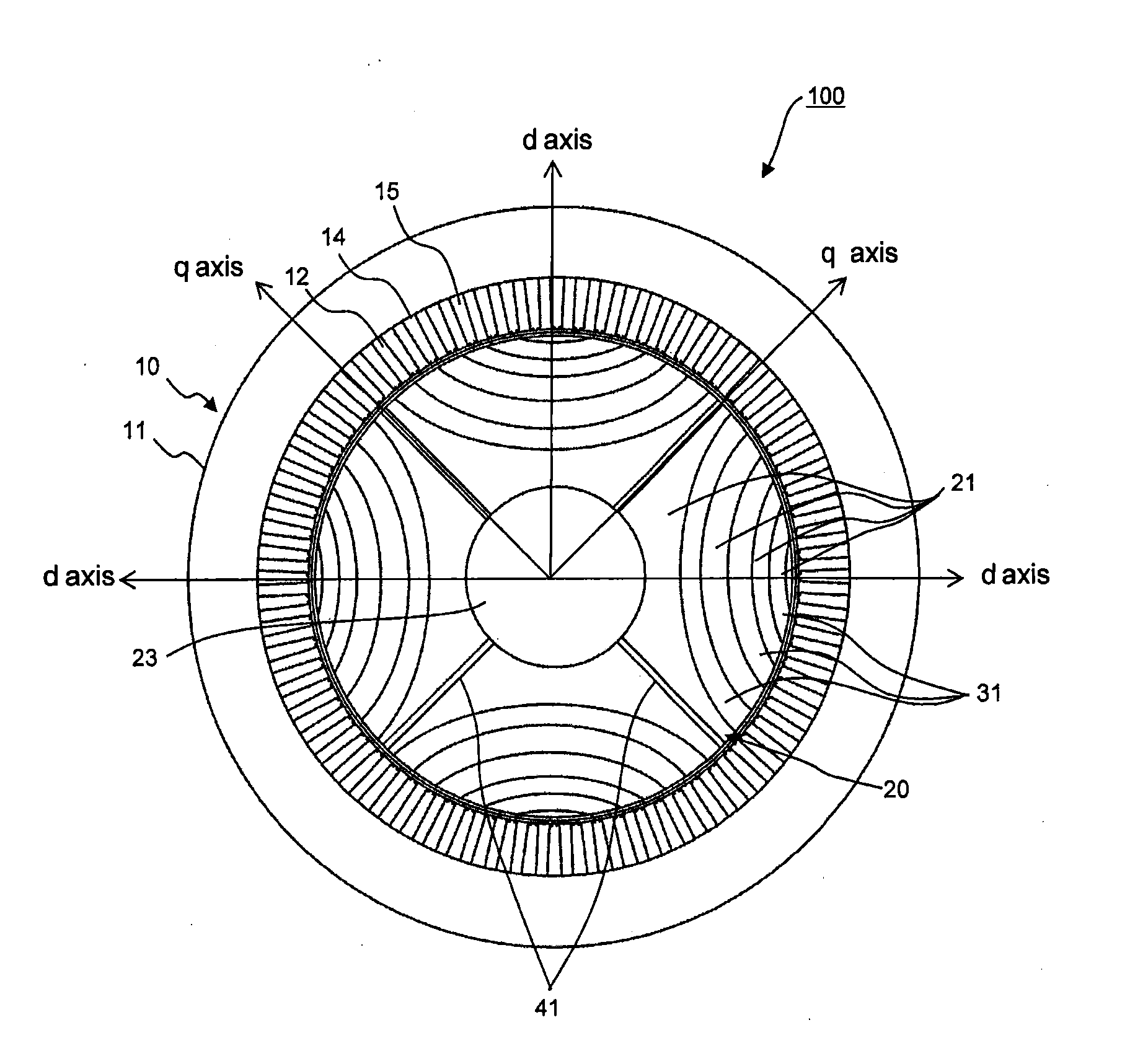

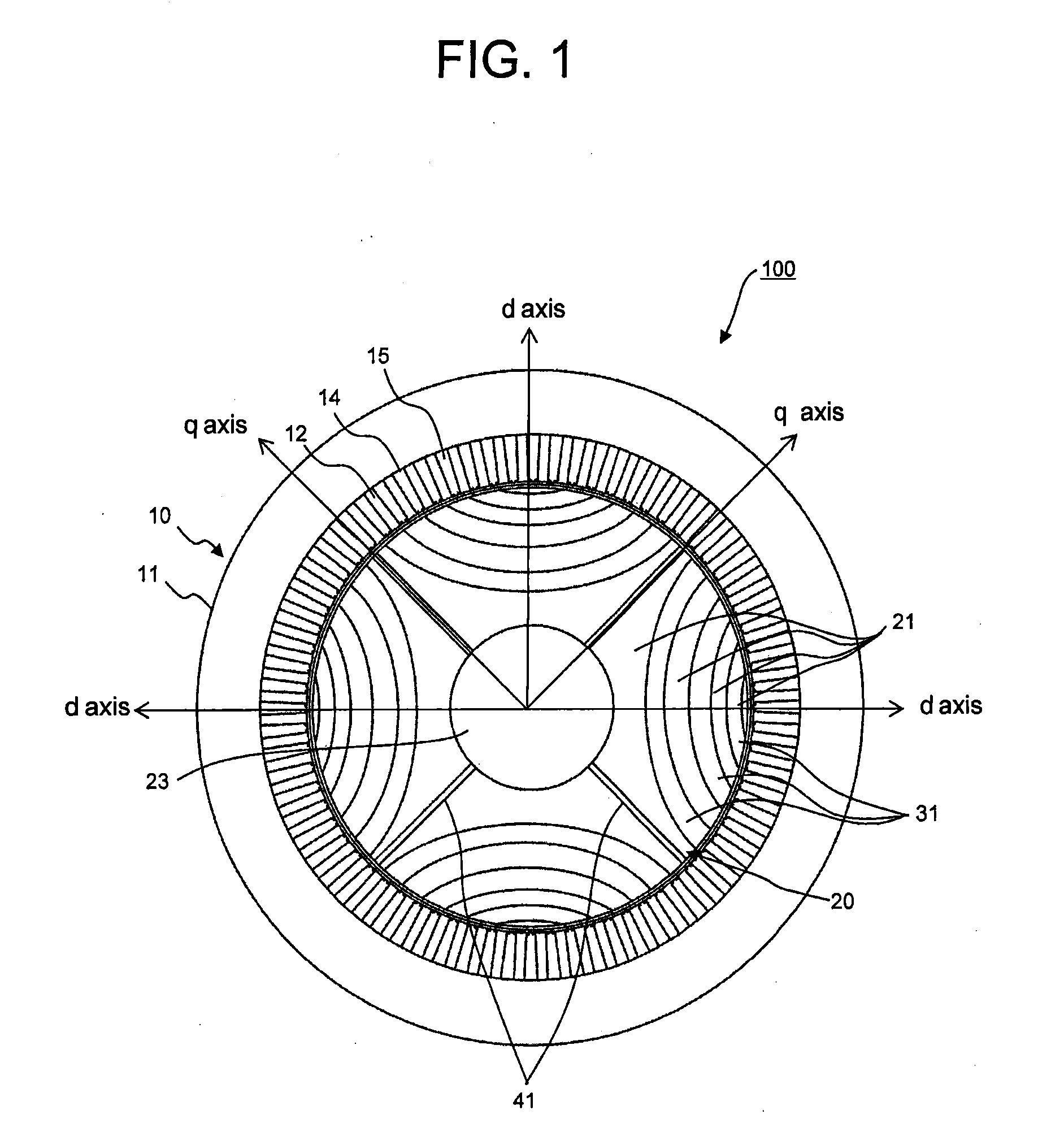

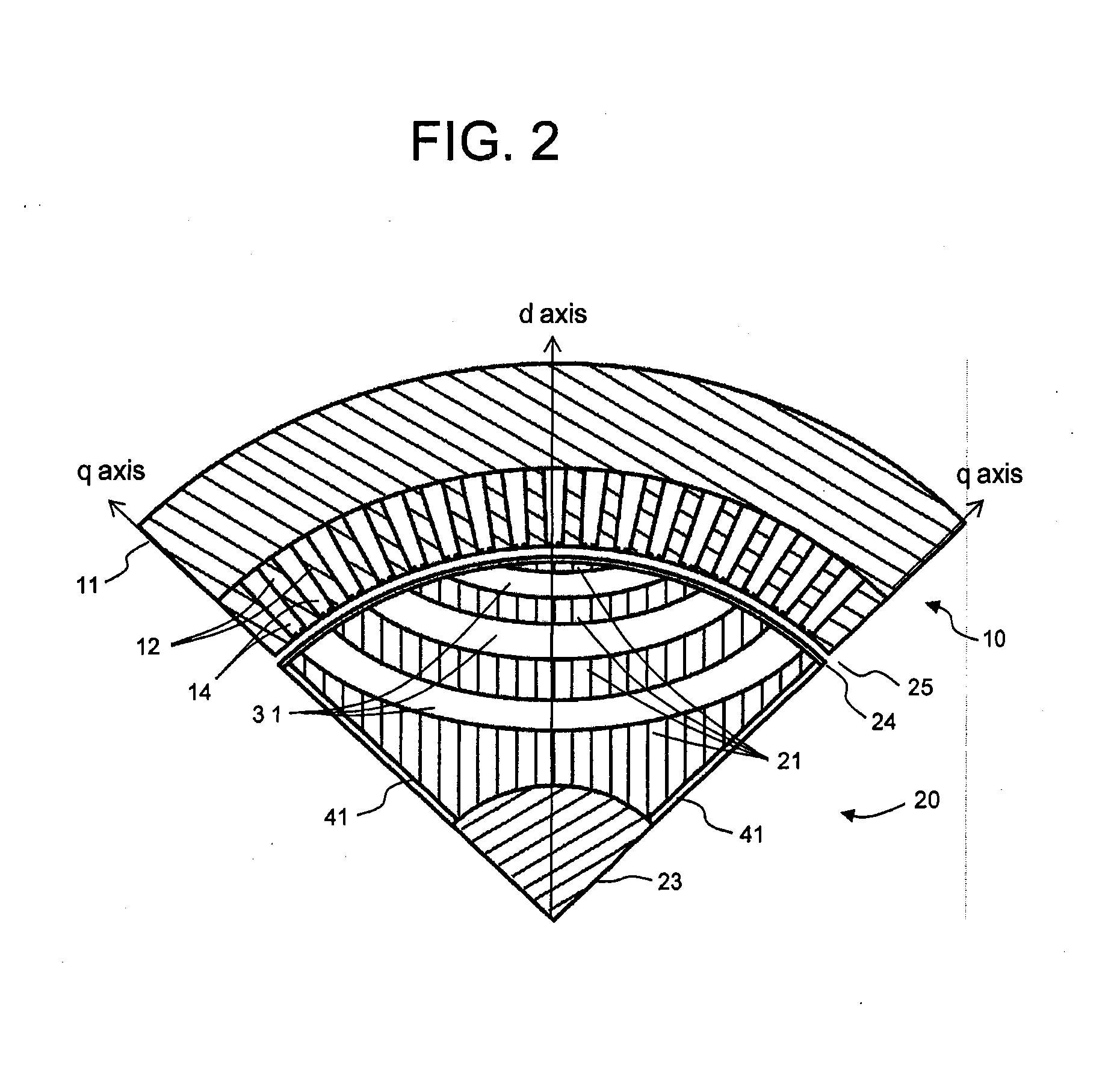

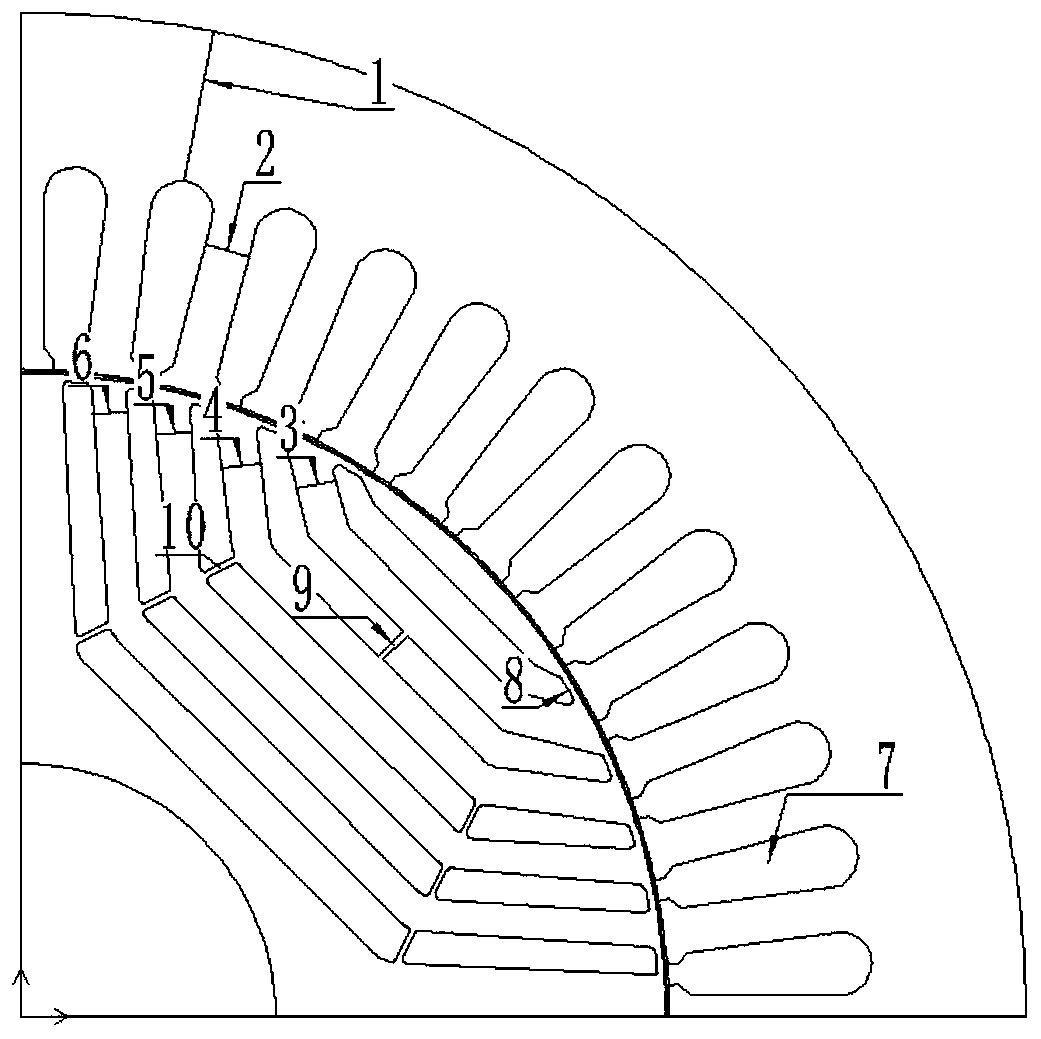

A synchronous reluctance motor includes: a rotor shaft; a rotor core fixed to the rotor shaft and on which a plurality of flux barriers are formed; a stator core on which a plurality of protruding stator teeth are formed; and multiphase armature windings of a plurality of poles wound around the plurality of stator teeth. The flux barriers include a plurality of first flux barriers formed to be spaced out in the circumferential direction from each other and extend in a radial direction, and a plurality of second flux barriers formed in each of circumferential angular regions sandwiched between the first flux barriers to form a curved surface convex toward the center of the rotation-axis and to spread and be spaced out in the circumferential direction from each other.

Owner:KK TOSHIBA

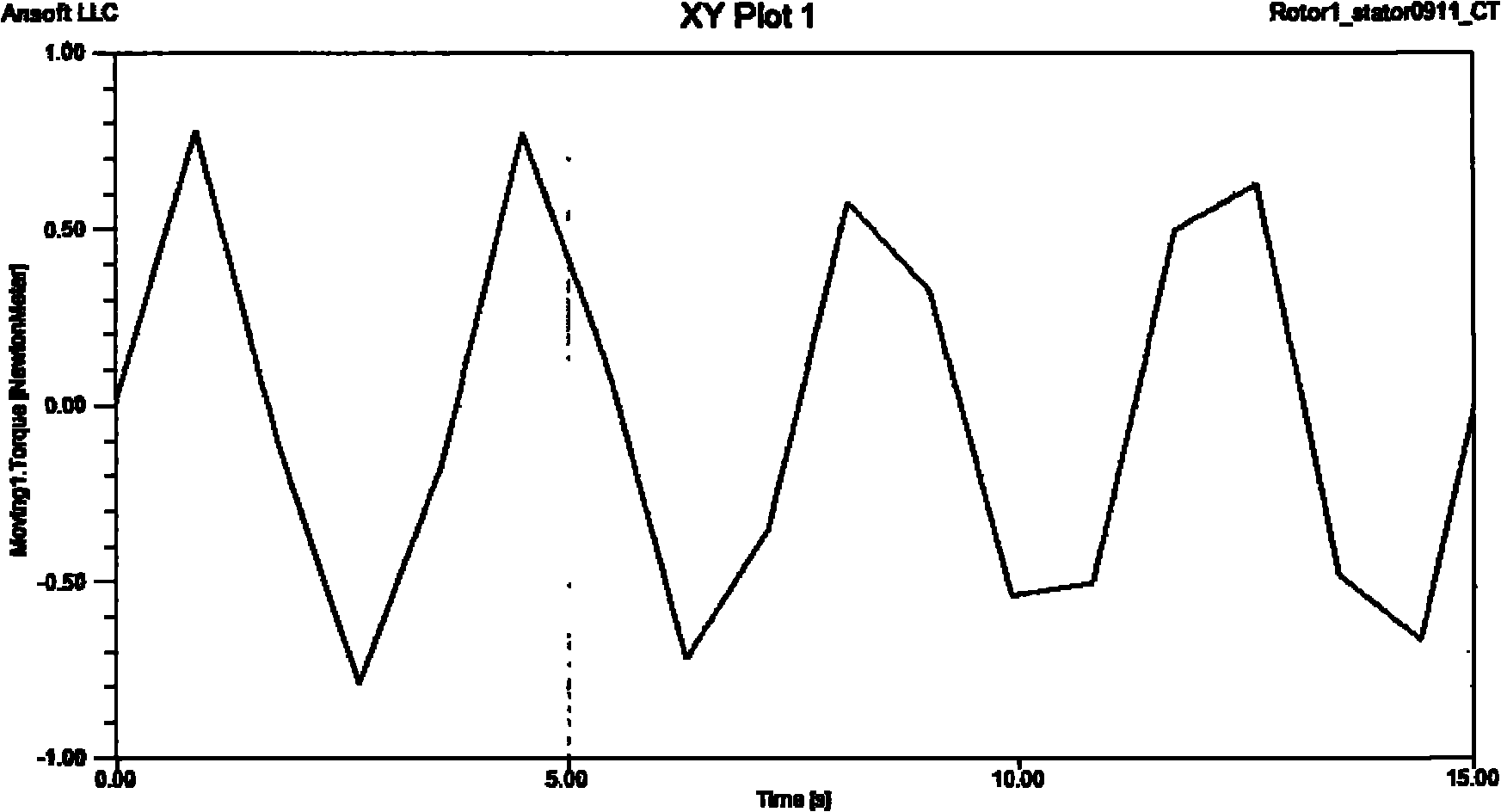

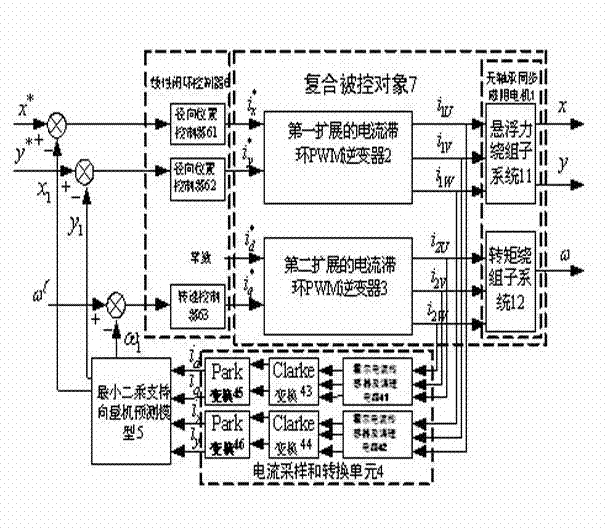

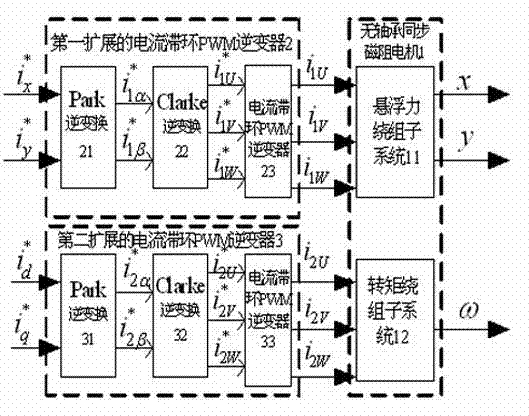

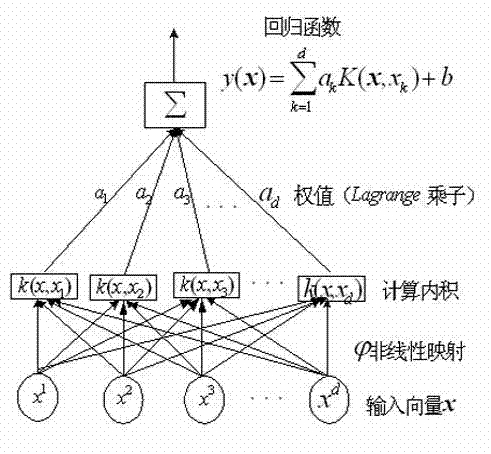

Sensorless controller of bearingless synchronous reluctance motor and method for controlling sensorless controller

ActiveCN102510253AImprove performanceSimple structureSingle motor speed/torque controlSynchronous reluctance motorElectric machine

The invention discloses a sensorless controller of a bearingless synchronous reluctance motor and a method for controlling the sensorless controller. The sensorless controller consists of a current sampling and conversion unit, a least square support vector machine prediction model, a linear closed-loop controller, and two expanded current hysteresis pulse width modulation (PWM) inverters which are connected in parallel, wherein the current sampling and conversion unit acquires an output current and generates an input current of the least square support vector machine prediction model; the least square support vector machine prediction model respectively compares prediction radial displacement and a rotary speed, which are output, with given reference values to obtain difference values which serve as input signals of the linear closed-loop controller; and control current components of a suspension force winding and a torque winding which are generated by the linear closed-loop controller are input into the two current hysteresis PWM inverters to respectively generate the input currents of a system. By the invention, the bearingless synchronous reluctance motor can be steadily suspended in a sensorless mode in a full-speed range, and high anti-interference performance and high robustness are realized.

Owner:江阴智产汇知识产权运营有限公司

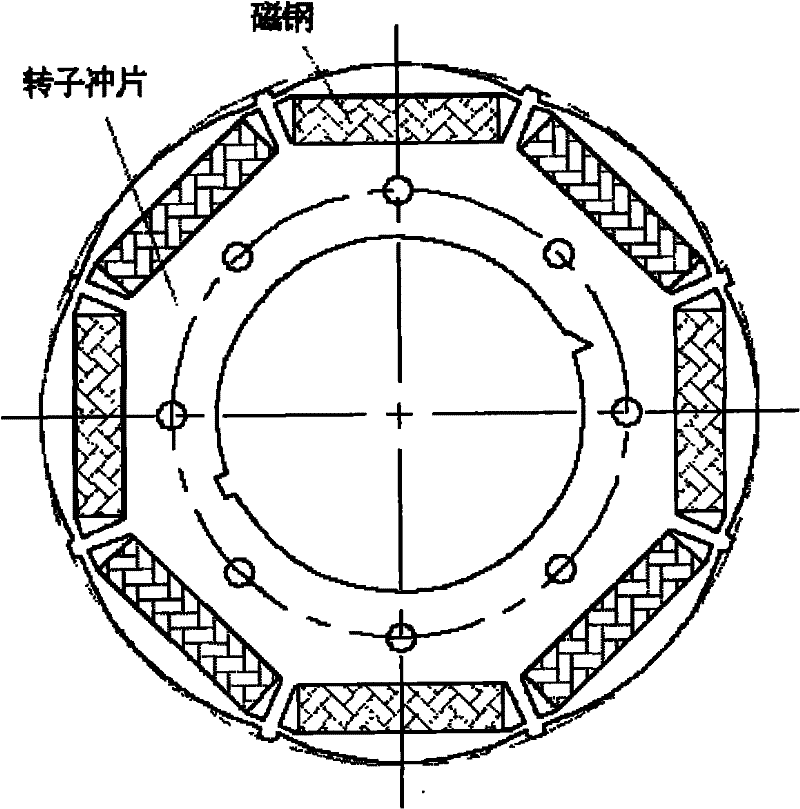

Synchronous reluctance motor rotor applied to hybrid power system

InactiveCN104810945AReduce usageLow costMagnetic circuit rotating partsSynchronous machine detailsSynchronous reluctance motorPunching

The invention discloses a synchronous reluctance motor rotor applied to a hybrid power system. The synchronous reluctance motor rotor applied to the hybrid power system comprises a rotor core and magnetic steel. The rotor core is formed by rotor punching sheets in an overlying mode. Each rotor punching sheet comprises a plurality of symmetrical magnetic poles, and the polarities of every two adjacent magnetic poles are opposite. Each magnetic pole comprises a plurality of layers of grids, wherein the magnetic steel is placed in the grids. Grooves are formed in the excircle of the rotor in the straight axes in the direction facing the circle center of the rotor.

Owner:TIANJIN SANTROLL ELECTRIC AUTOMOBILE TECH CO LTD

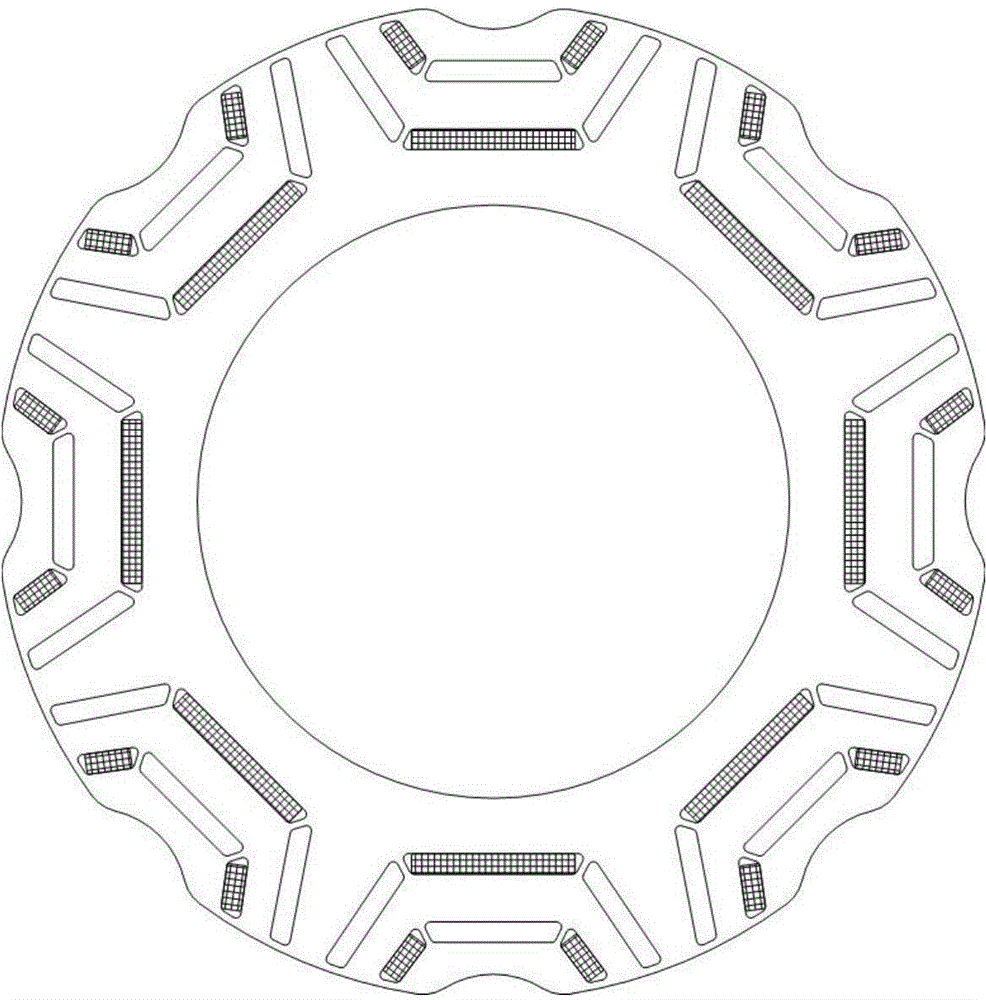

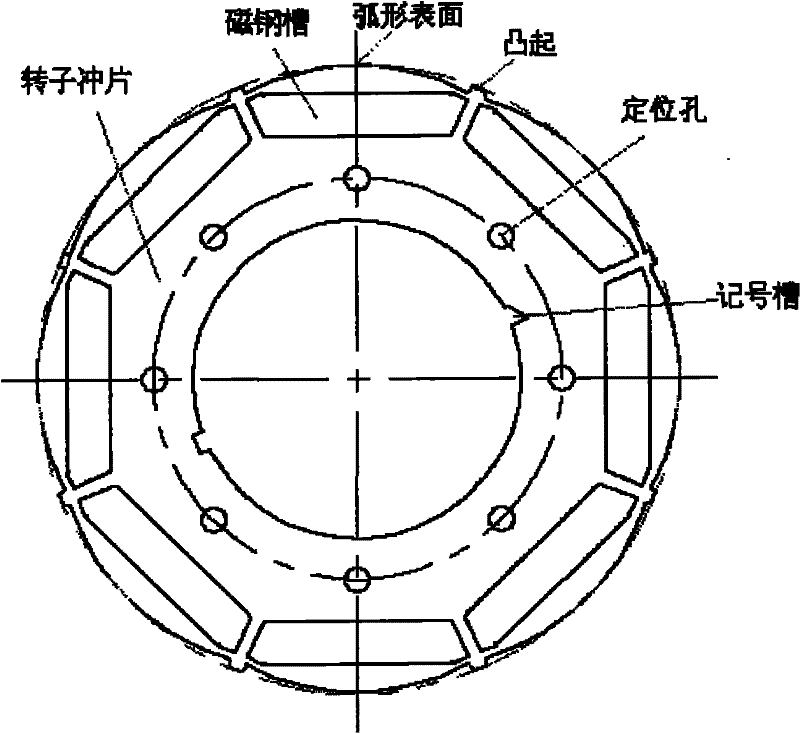

Novel rotor lamination structure

InactiveCN102214962AEasy to generate back EMFHigh mechanical strengthMagnetic circuit rotating partsEngineeringCounter-electromotive force

The invention relates to a novel rotor lamination structure which has the advantages of a surface type rotor magnetic path structure and a built-in type rotor magnetic path structure. The outer surface of the rotor lamination structure has eight uniformly distributed cambered surface structures; corresponding positions on the middle parts of magnetic steel slots are the highest points of cambered surfaces; and eight bulges are uniformly distributed at positions corresponding to gaps in the middle of every two adjacent magnetic steel slots. The novel rotor lamination structure can easily produce a back electromotive force with sine waveform, has high mechanical strength and a larger saliency ratio and is convenient for flux weakening speed expansion.

Owner:TIANJIN SANTROLL ELECTRIC AUTOMOBILE TECH CO LTD

Synchronous reluctance motor and rotor for synchronous reluctance motor

InactiveCN105103420ARaise the saliency ratioIncrease torqueMagnetic circuit rotating partsSynchronous motorsSynchronous reluctance motorConductor Coil

Owner:KK TOSHIBA

Rotor iron core piece, rotor iron core, rotor, permanent magnet synchronous motor and related products

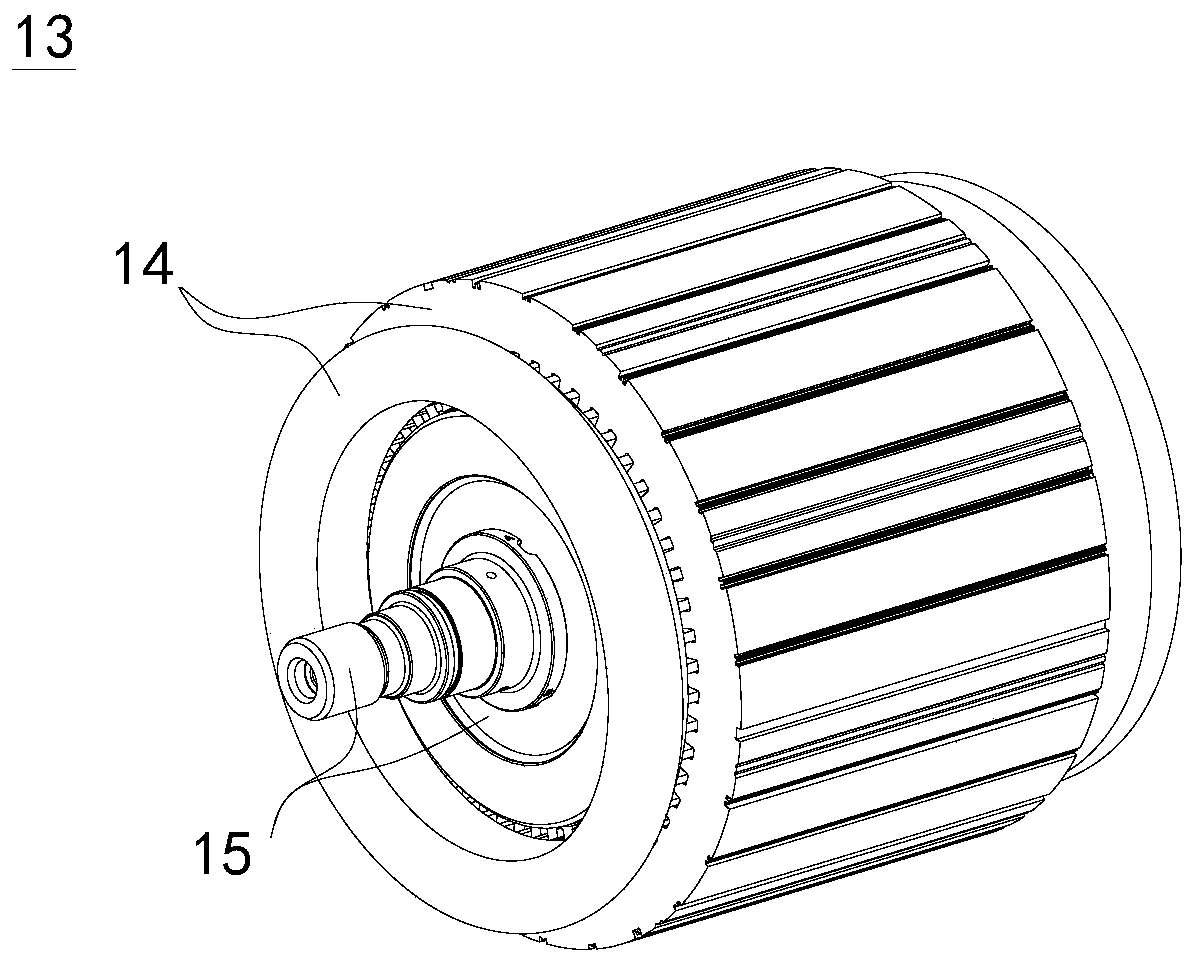

PendingCN110752685AReduce dosageRaise the saliency ratioMagnetic circuit rotating partsElectric machinesElectric vehiclePowertrain

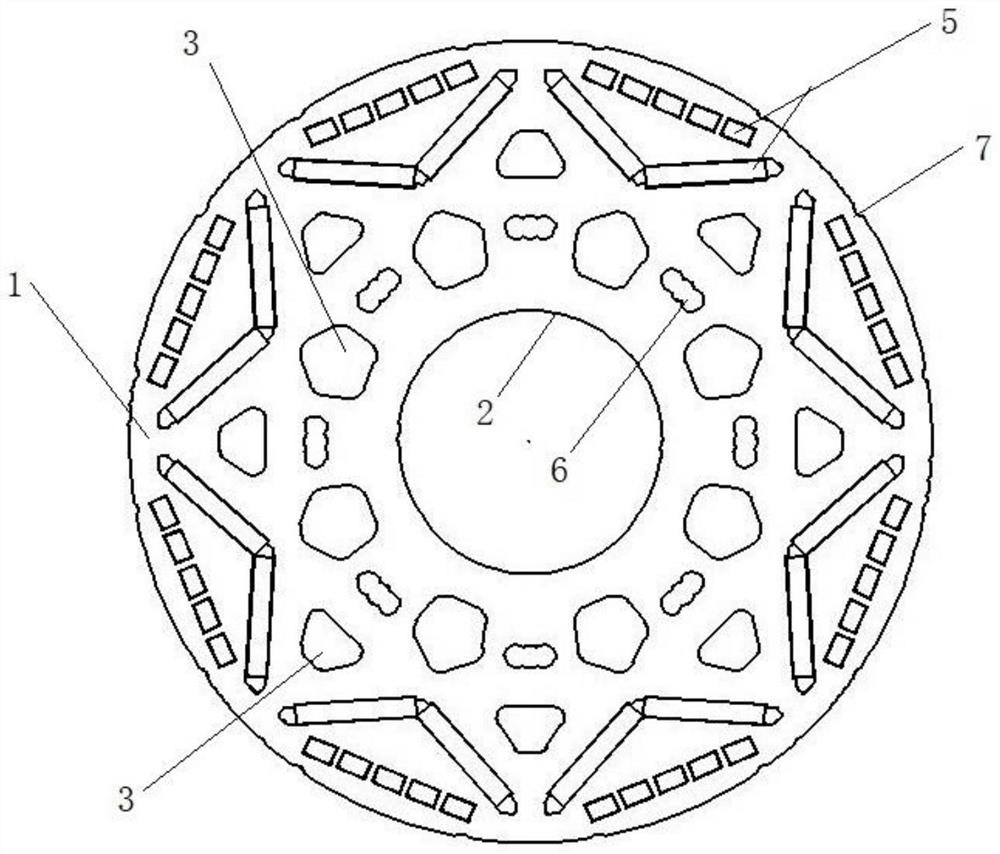

The application provides a rotor structure of a permanent magnet synchronous motor applied to an electric vehicle. The rotor structure uses a built-in double-layer V-shaped magnetic pole structure. Amagnetic pole included angle of an inner-layer V-shaped magnetic pole structure is larger than a magnetic pole included angle of an outer-layer V-shaped magnetic pole structure, and a difference valueof the two parts is within [0 degrees, 50 degrees]. Width of a permanent magnet slot of the inner-layer magnetic pole structure is 1.5-2 times of width of a permanent magnet slot of the outer-layer magnetic pole structure. The application also provides the permanent magnet synchronous motor including the rotor structure, a power assembly including the permanent magnet synchronous motor, and the electric vehicle including the power assembly. Through reasonable numerical matching on the magnetic pole included angle of the inner and outer magnetic pole structures and the width of the permanent magnet slots, the scheme of the application can increase a saliency ratio of the permanent magnet synchronous motor, reduce the amount of permanent magnet use, and reduce cost.

Owner:HUAWEI DIGITAL POWER TECH CO LTD

Series hybrid permanent magnet variable flux motor

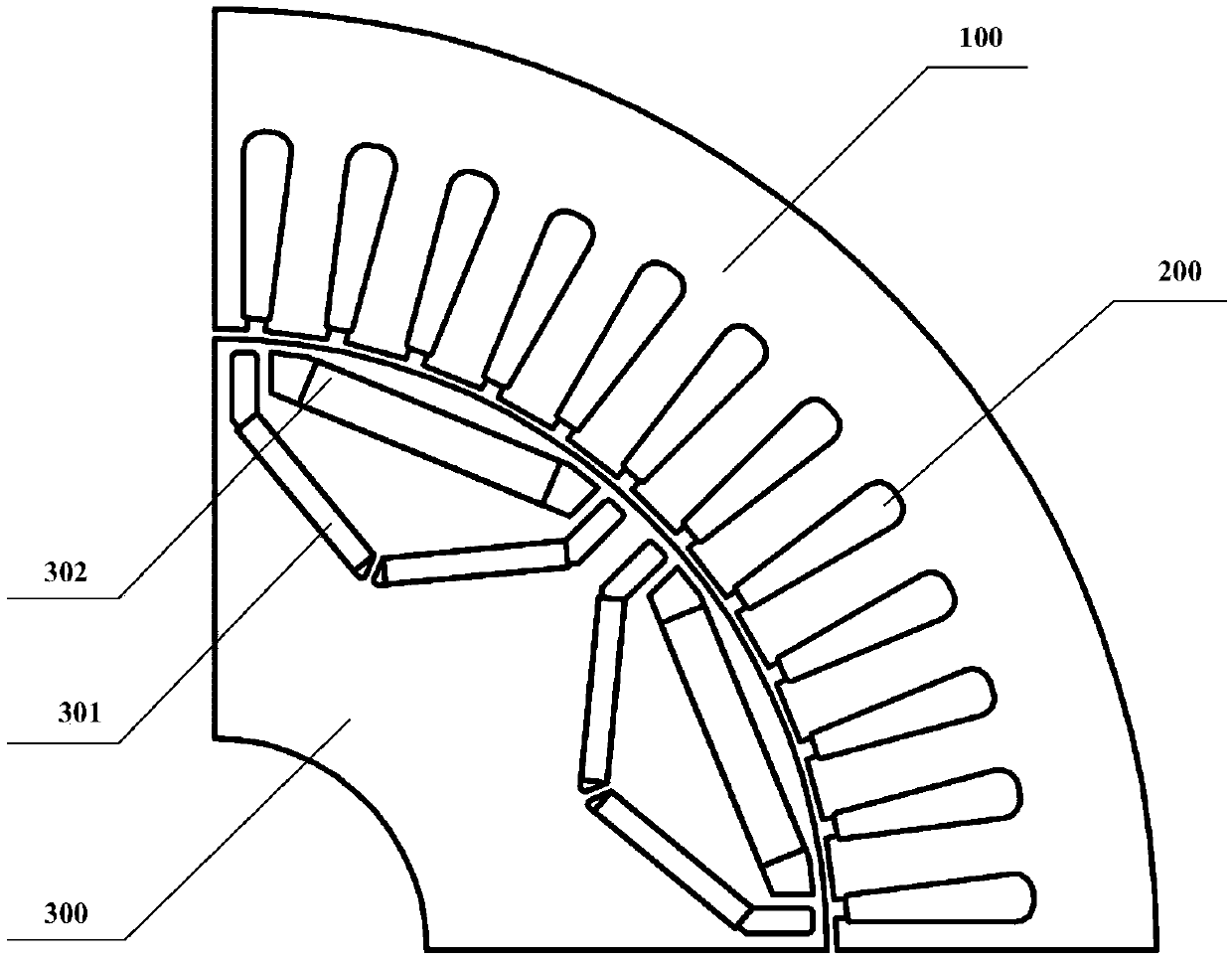

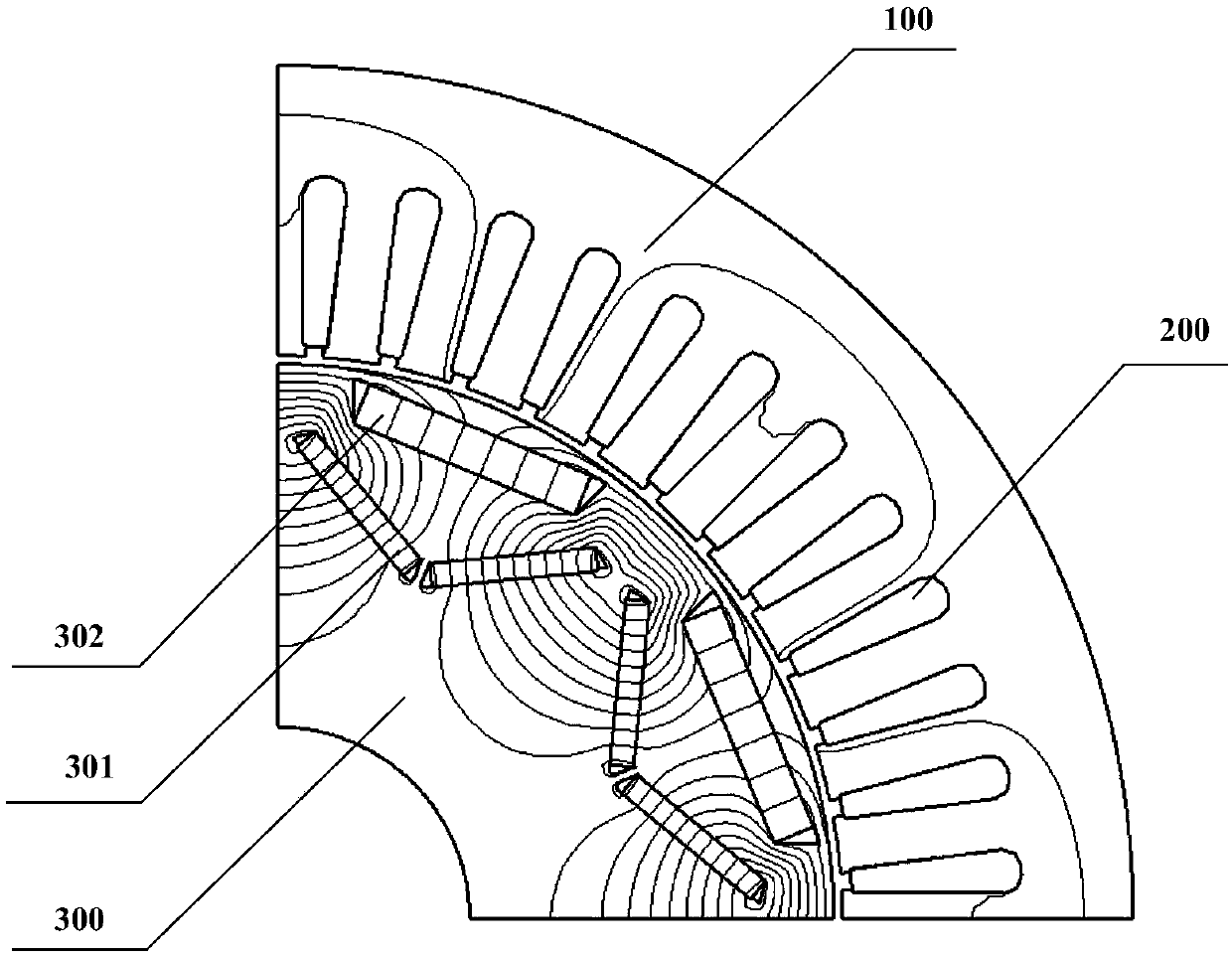

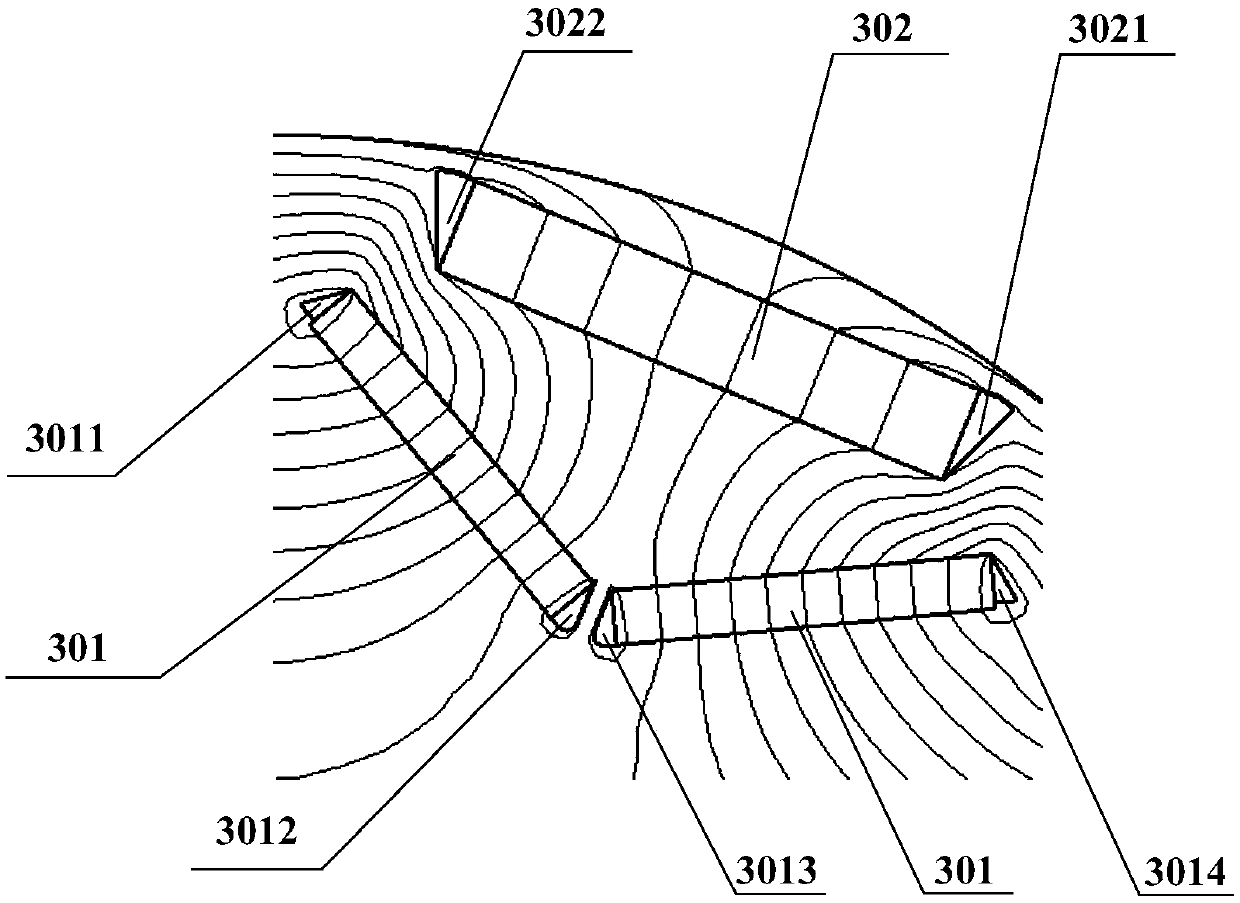

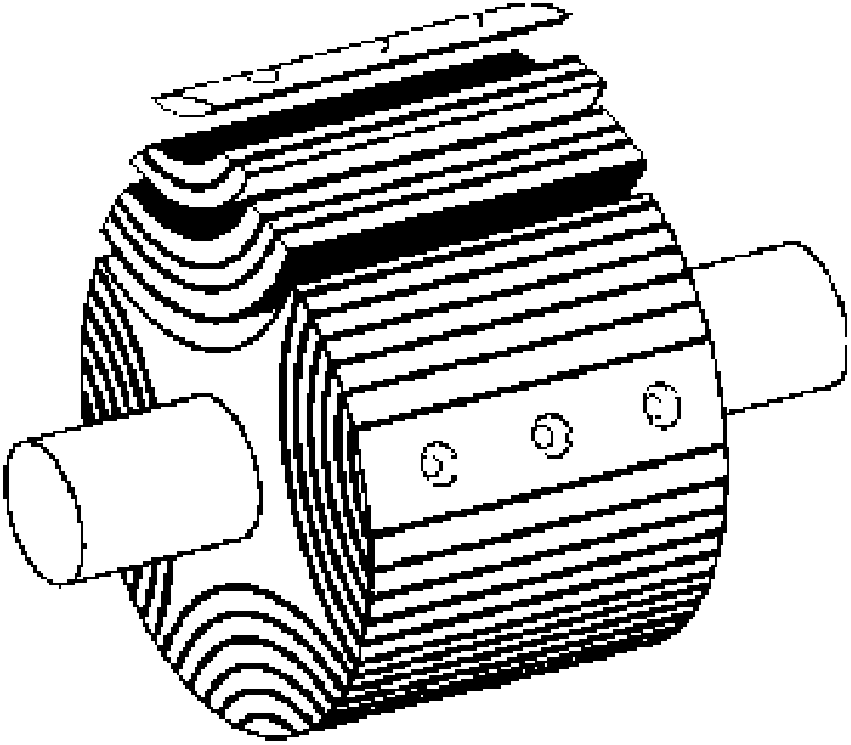

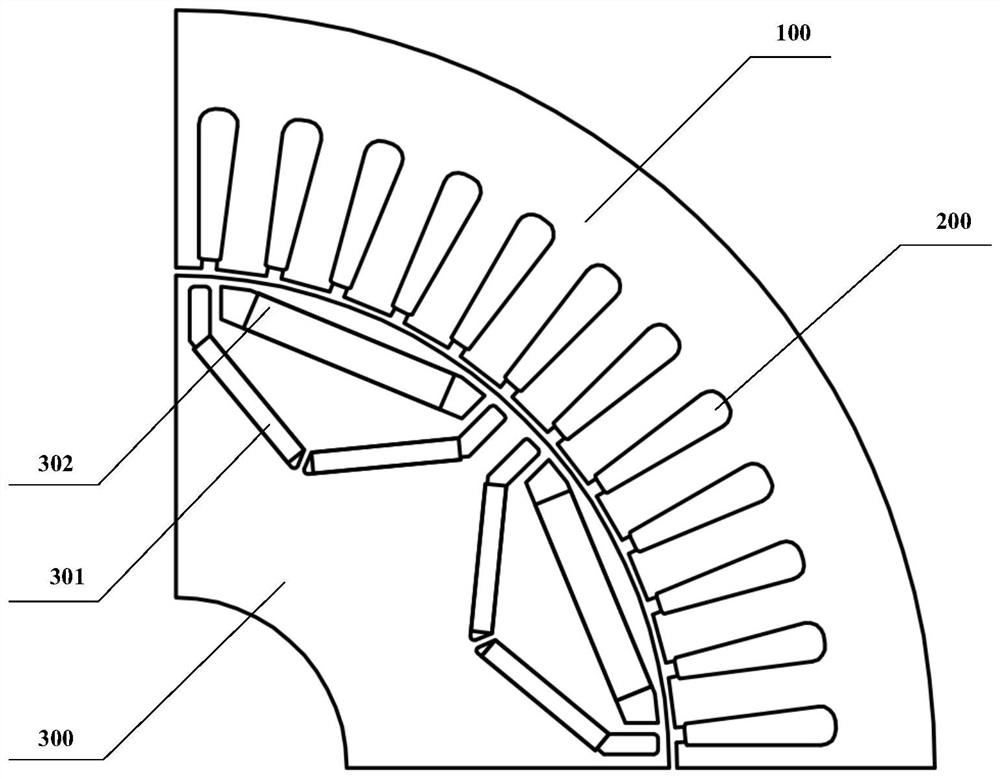

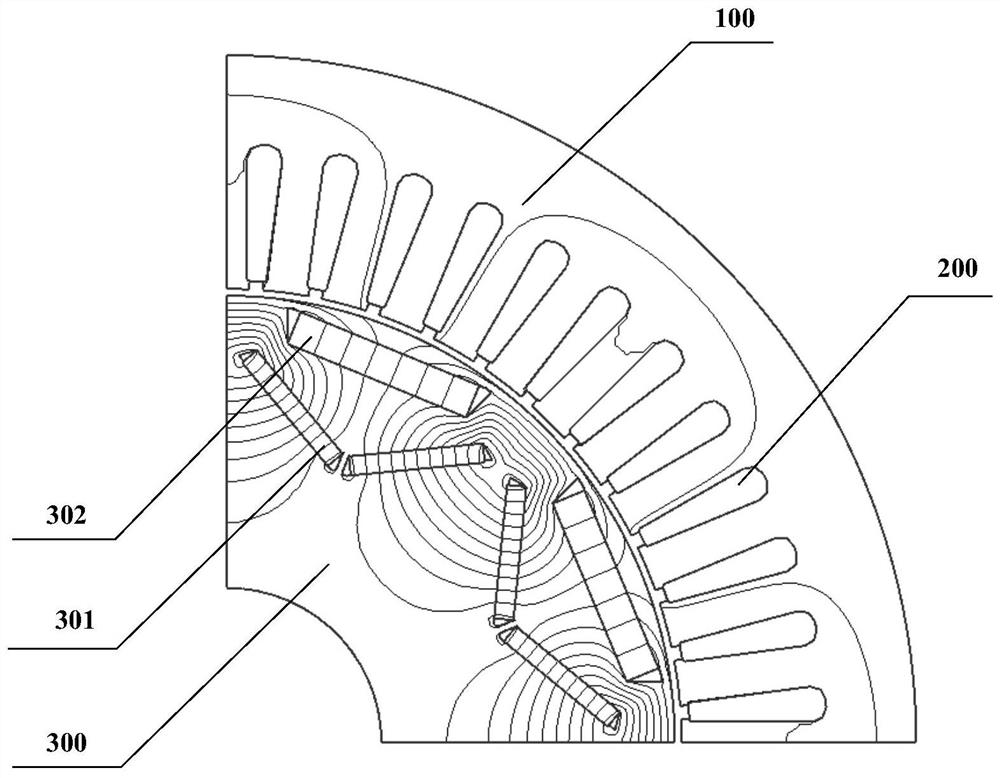

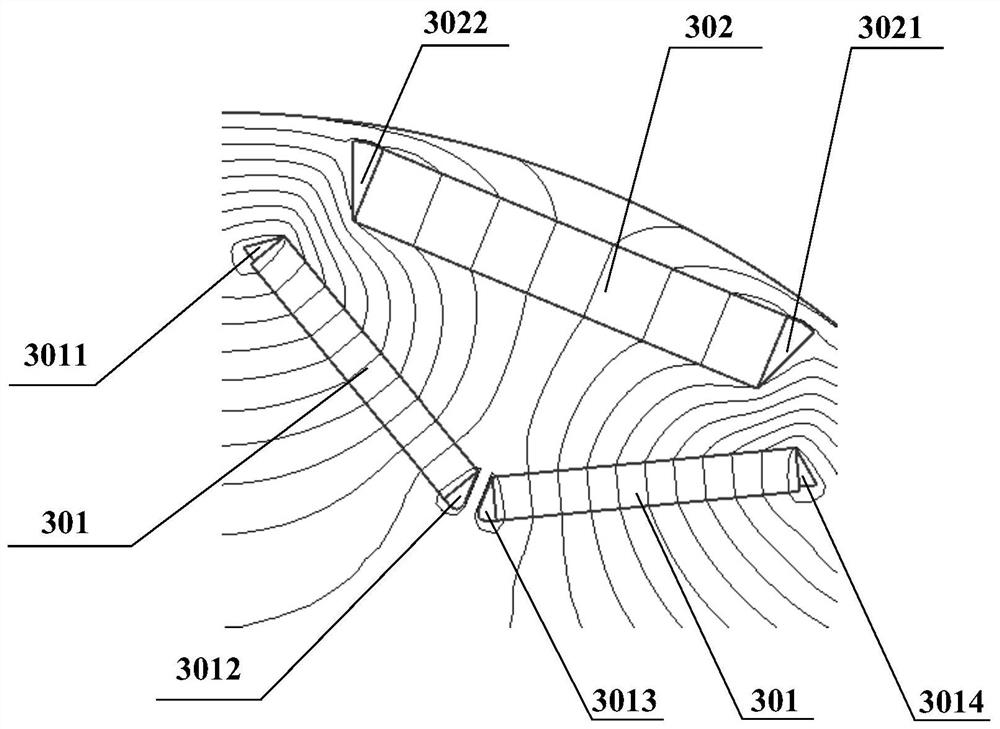

ActiveCN109660042AIncrease the degree of magnetizationIncreased torque output capabilityMagnetic circuit rotating partsPhysicsStator

The invention discloses a series hybrid permanent magnet variable flux motor. The series hybrid permanent magnet variable flux motor comprises a stator (100), an armature winding (200) wound on the stator (100), and a rotor core (300), wherein three permanent magnets which are not in direct contact and placed separately are arranged under each pole of the rotor core (300), the second permanent magnet (302) is placed on the outer sides in a linear shape, the two first permanent magnets (301) are placed on the inner side in a ''V'' shape, the second permanent magnet (302) is a high-coercivity permanent magnet or a low-coercivity permanent magnet, and the first permanent magnets (301) are high-coercivity permanent magnets or low-coercivity permanent magnets. According to the series hybrid permanent magnet variable flux motor, the low-coercivity permanent magnets and the high-coercivity permanent magnets adopt special placement positions and manners, such that the motor is of a magnetic circuit series structure, the high-coercivity permanent magnets are used for increasing magnetism of the low-coercivity permanent magnets, the working points and magnetization degrees of the low-coercivity permanent magnets are increased, the torque output capability is improved, and the magnetizing current of the motor is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

Built-in permanent magnet rotor structure of axial flux motor

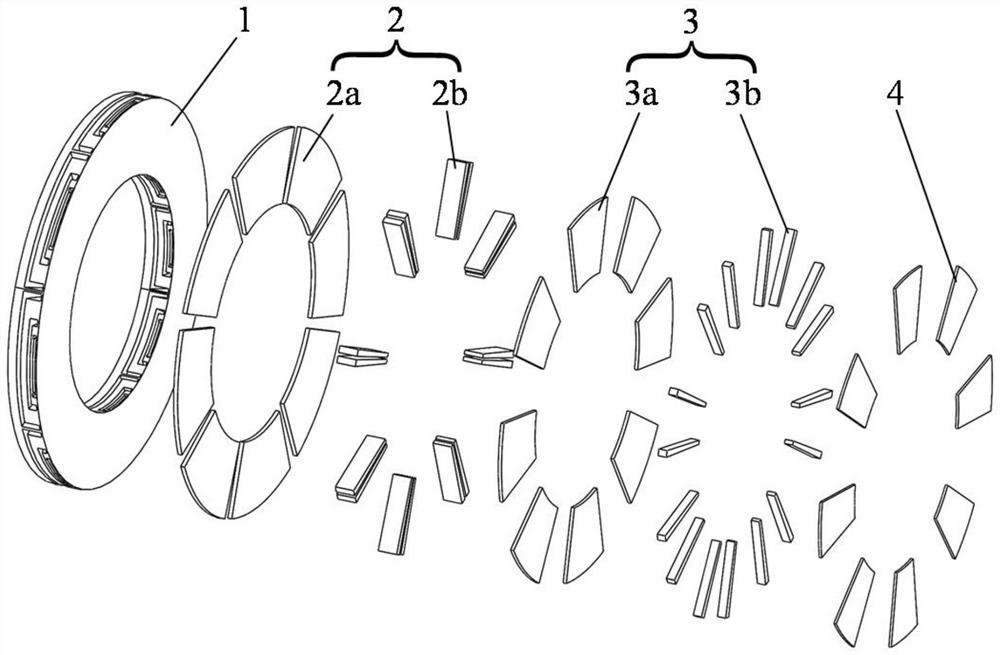

PendingCN113381540AThe salient pole effect is obviousReduce dosageMagnetic circuit rotating partsPermanent magnet rotorElectric machine

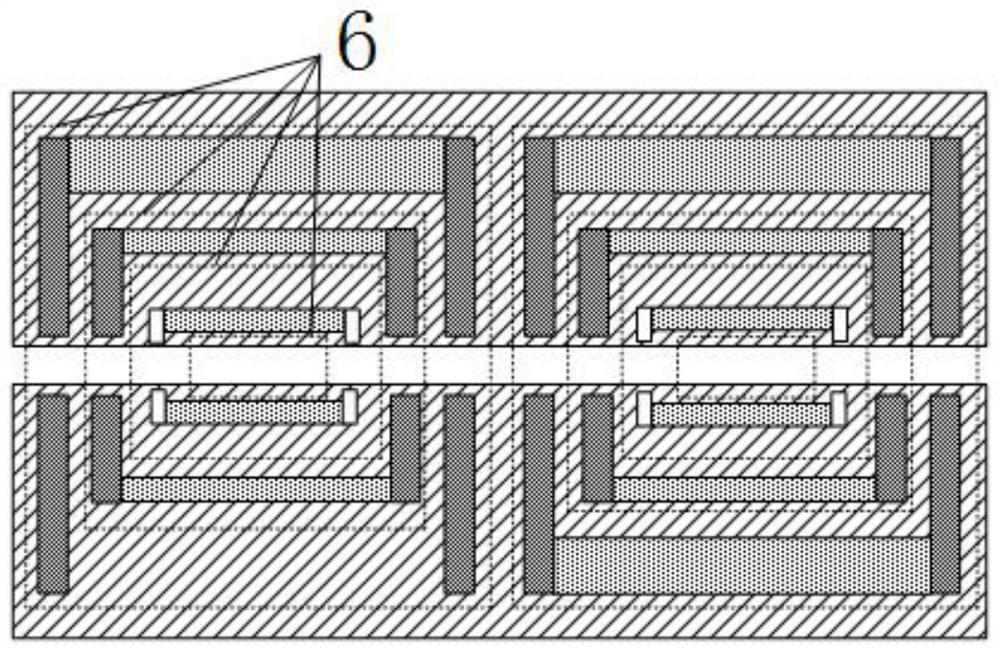

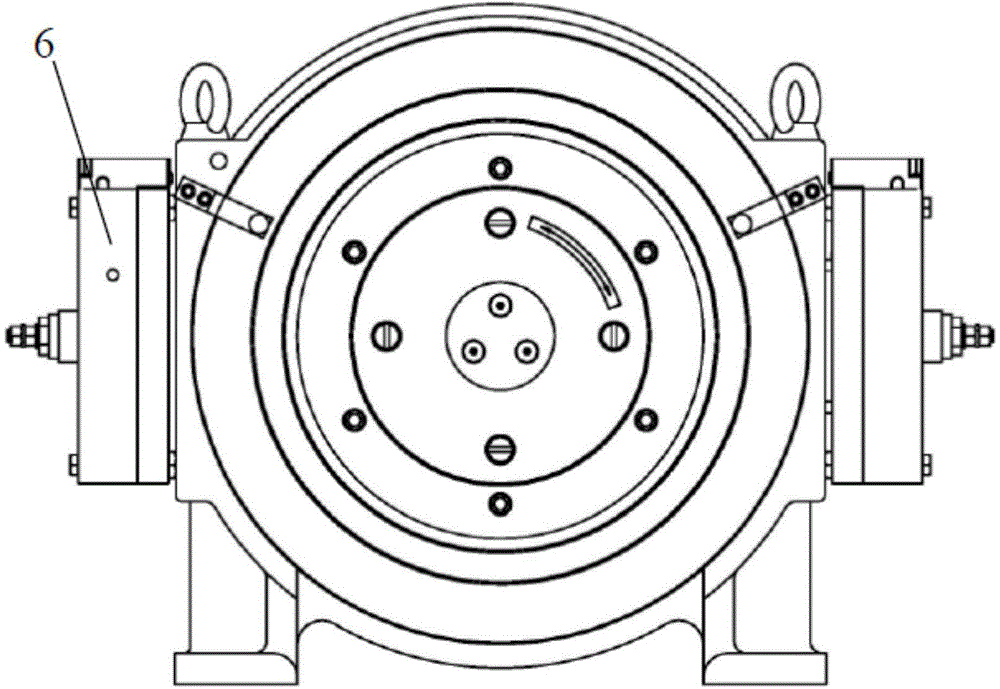

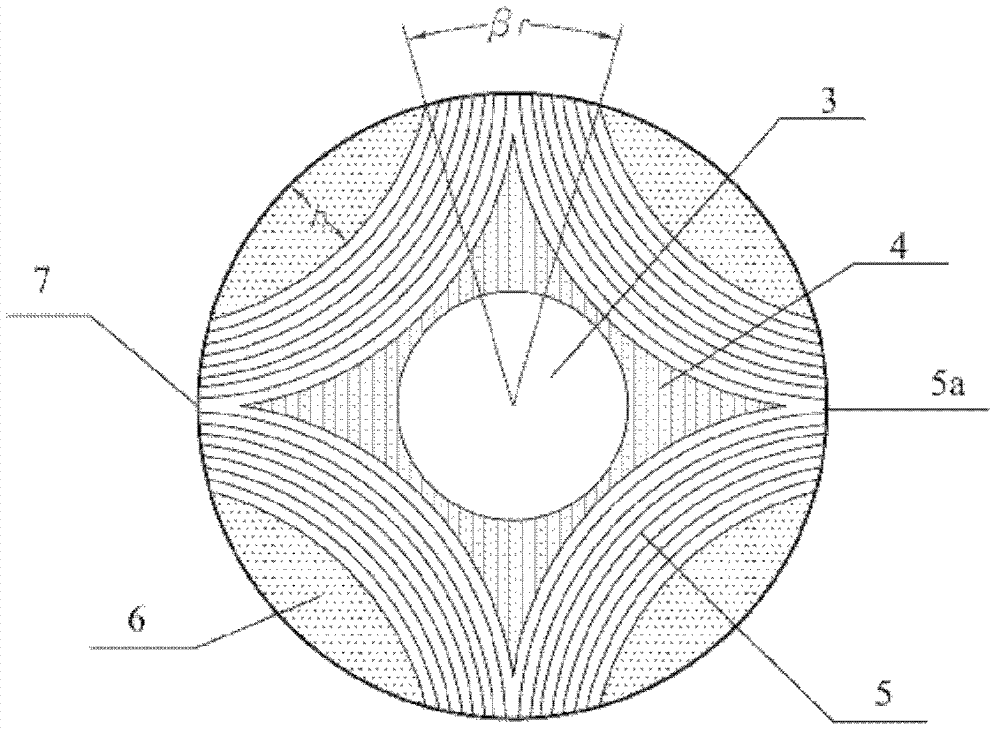

The invention discloses a built-in permanent magnet rotor structure of an axial flux motor. The built-in permanent magnet rotor structure comprises two rotor discs; each rotor disc comprises a rotor core with an annular cross section; each rotor core is formed by circumferentially winding a thin silicon steel sheet, and three layers of permanent magnet groups are uniformly embedded in the circumferential direction of each rotor core; each permanent magnet group comprises a first layer of U-shaped magnetism gathering structure permanent magnet combination, a second layer of U-shaped magnetism gathering structure permanent magnet combination and a third layer of linear structure permanent magnet which are sequentially arranged from the outer side of the rotor core to the circle center of the rotor core; the two rotor discs are installed on a rotating shaft in a manner that permanent magnet faces are opposite to each other, and a stator disc is arranged between the two rotor discs. According to the built-in permanent magnet rotor structure of the axial flux motor of the invention, the magnetism gathering capability of the permanent magnet rotor discs is stronger, and highly sinusoidal air gap flux density can be realized; the U-shaped permanent magnetcombinations and the linear permanent magnet combinations adopted, so that the salient pole effect of the motor can be improved, the reluctance torque is fully utilized, and the torque or power density of the motor is improved; and the silicon steel sheet is slotted and wound to form the rotor core, so that the machining is convenient and the structural strength is high.

Owner:NANJING UNIV OF SCI & TECH

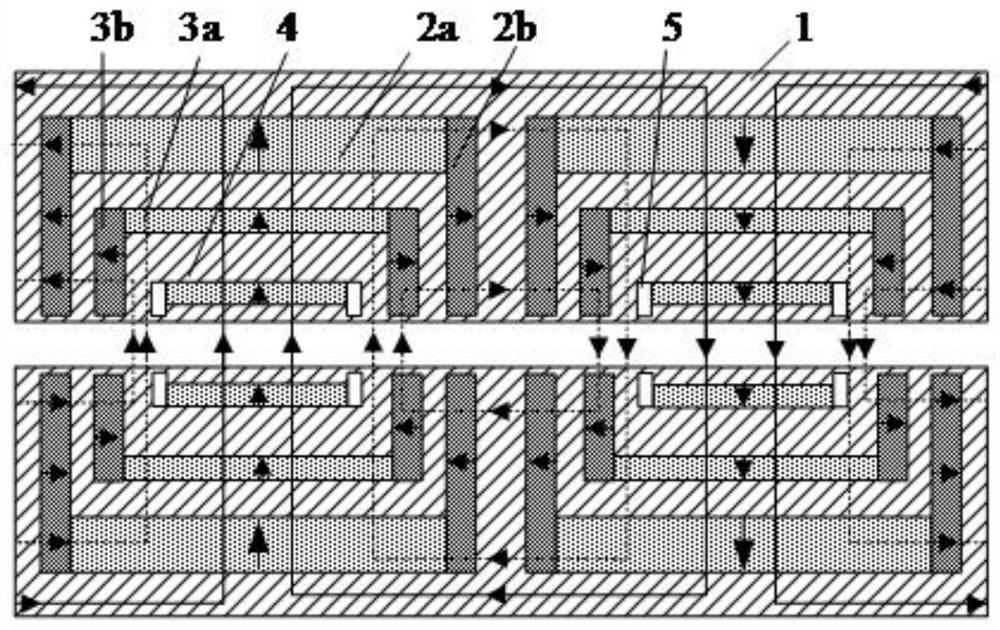

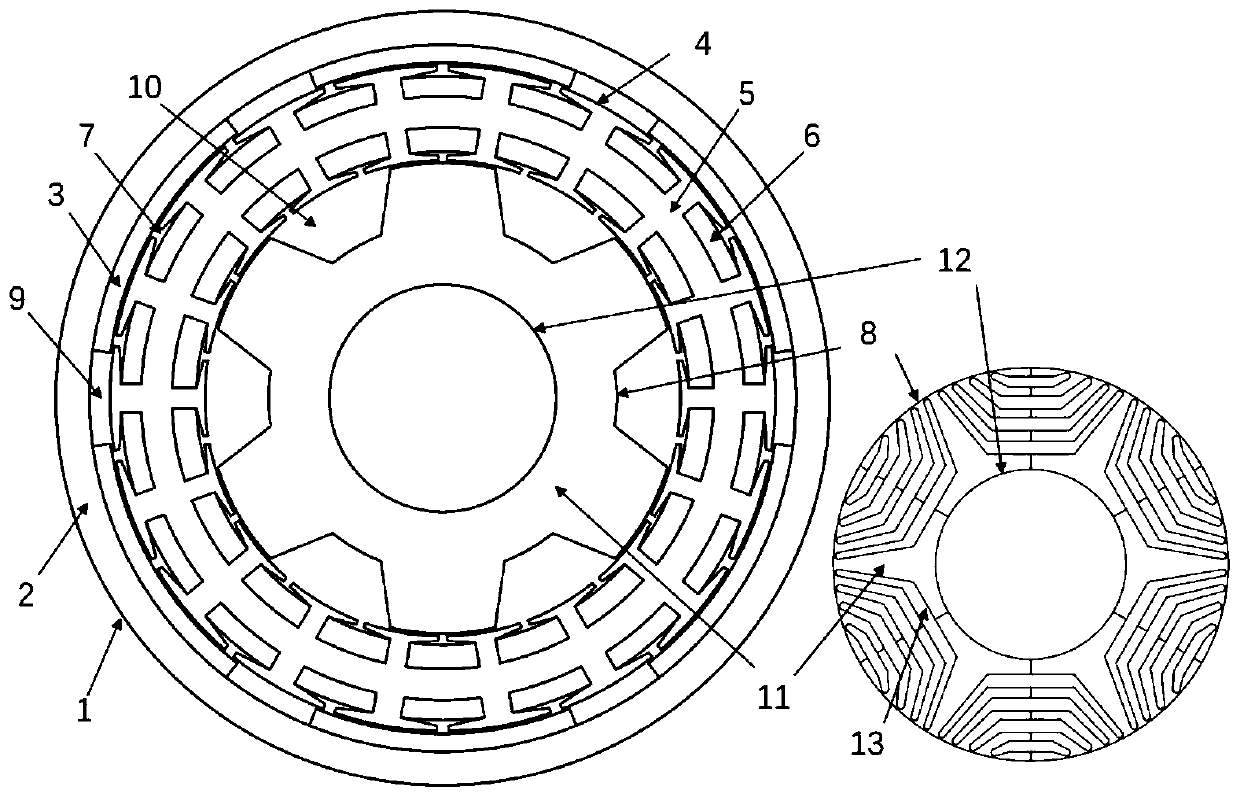

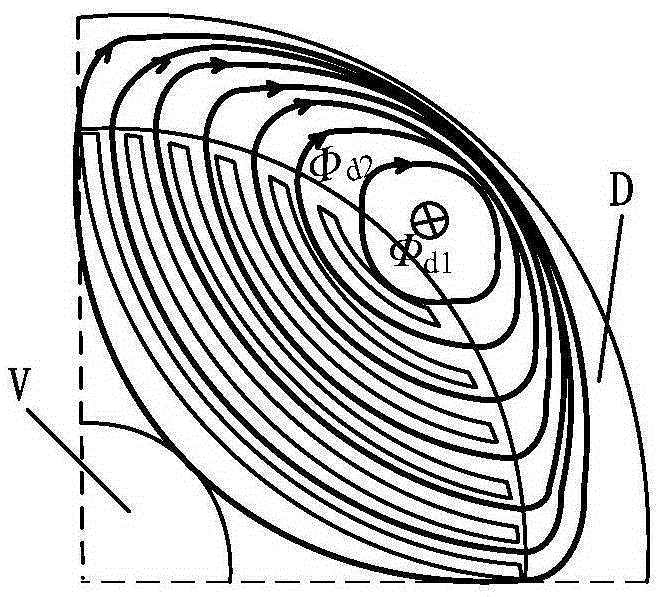

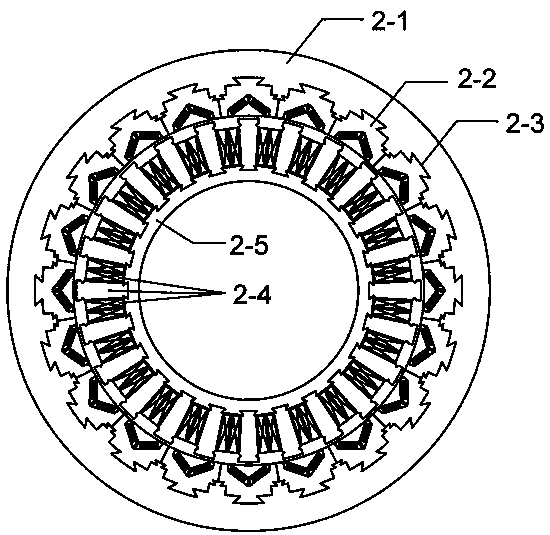

Birotor permanent magnet synchronous reluctance motor and configuration method

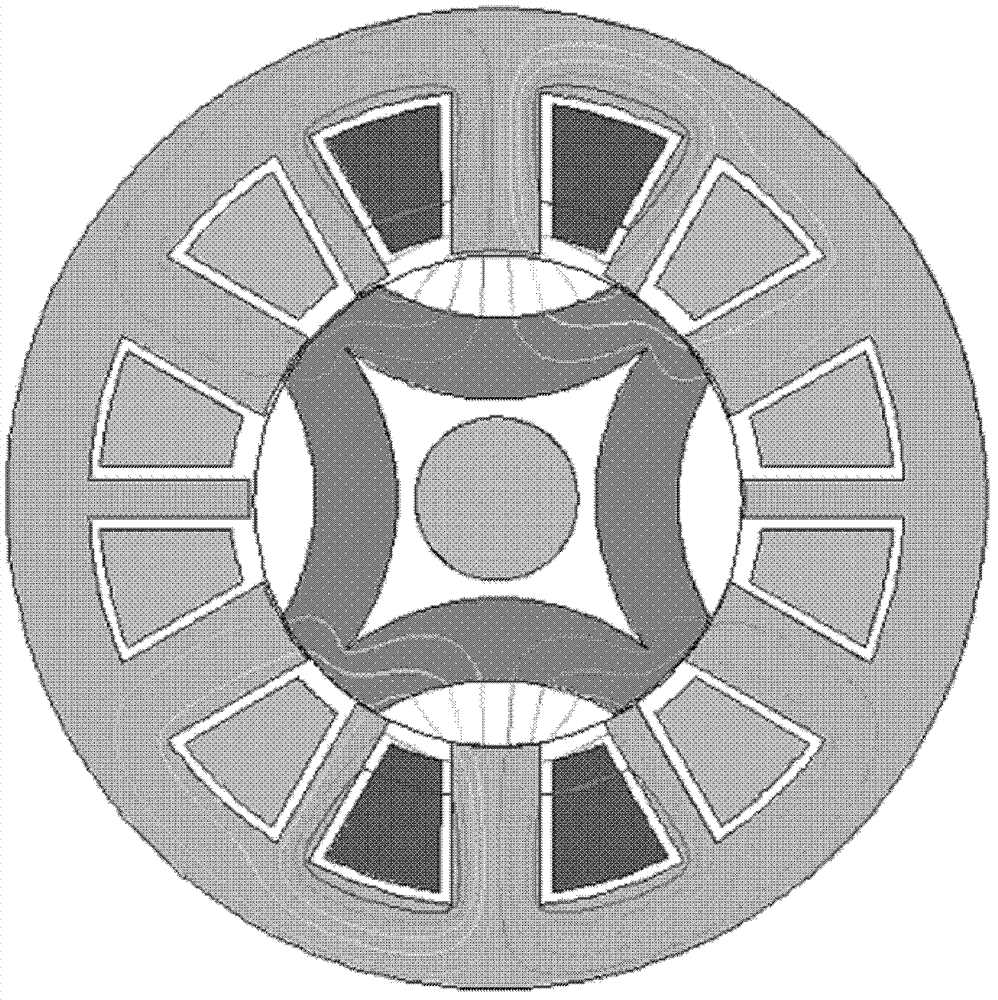

PendingCN110601481AIncreased torque densityHigh material utilizationMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet rotorSynchronous reluctance motor

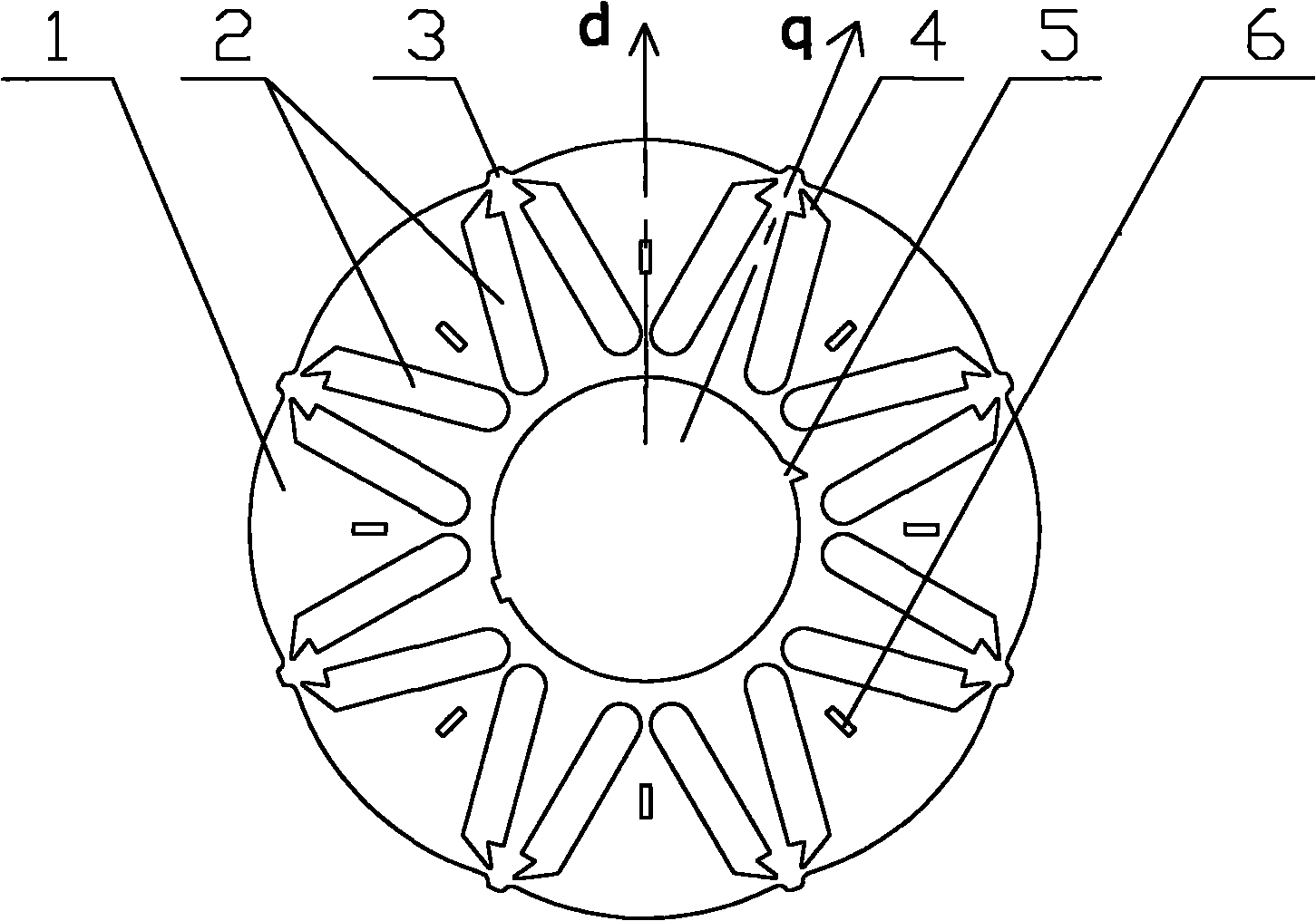

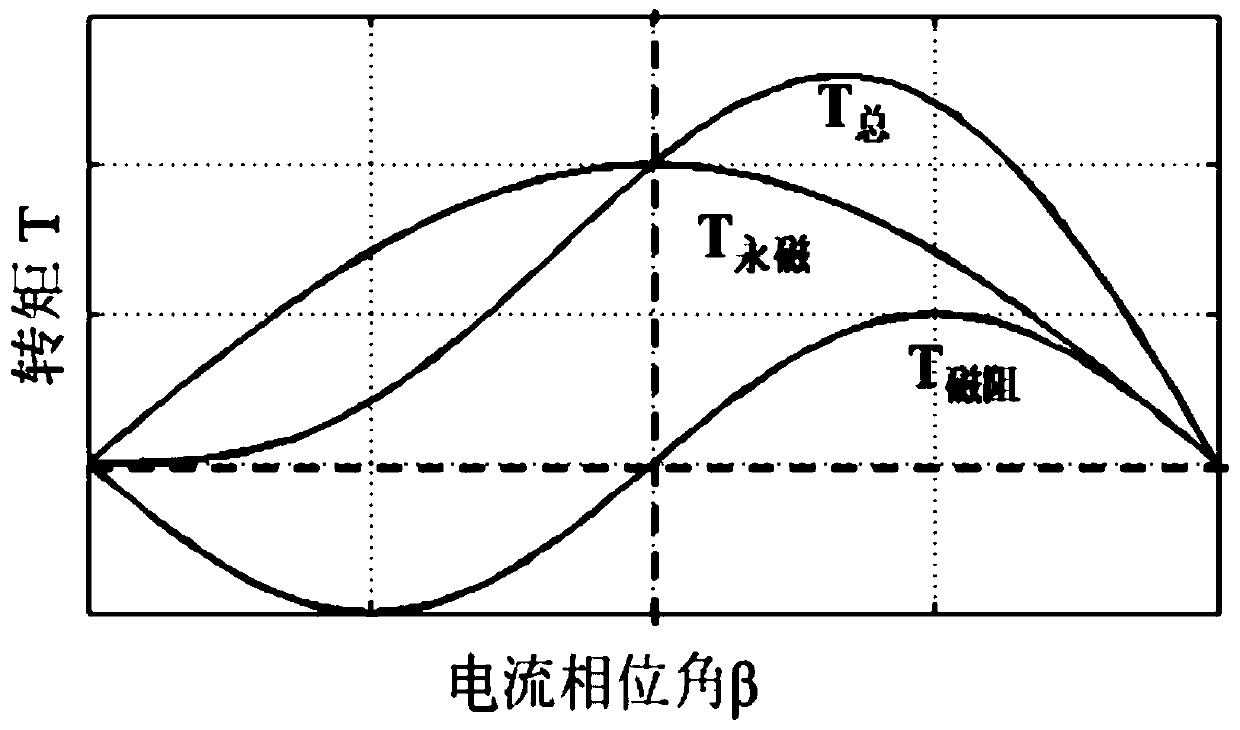

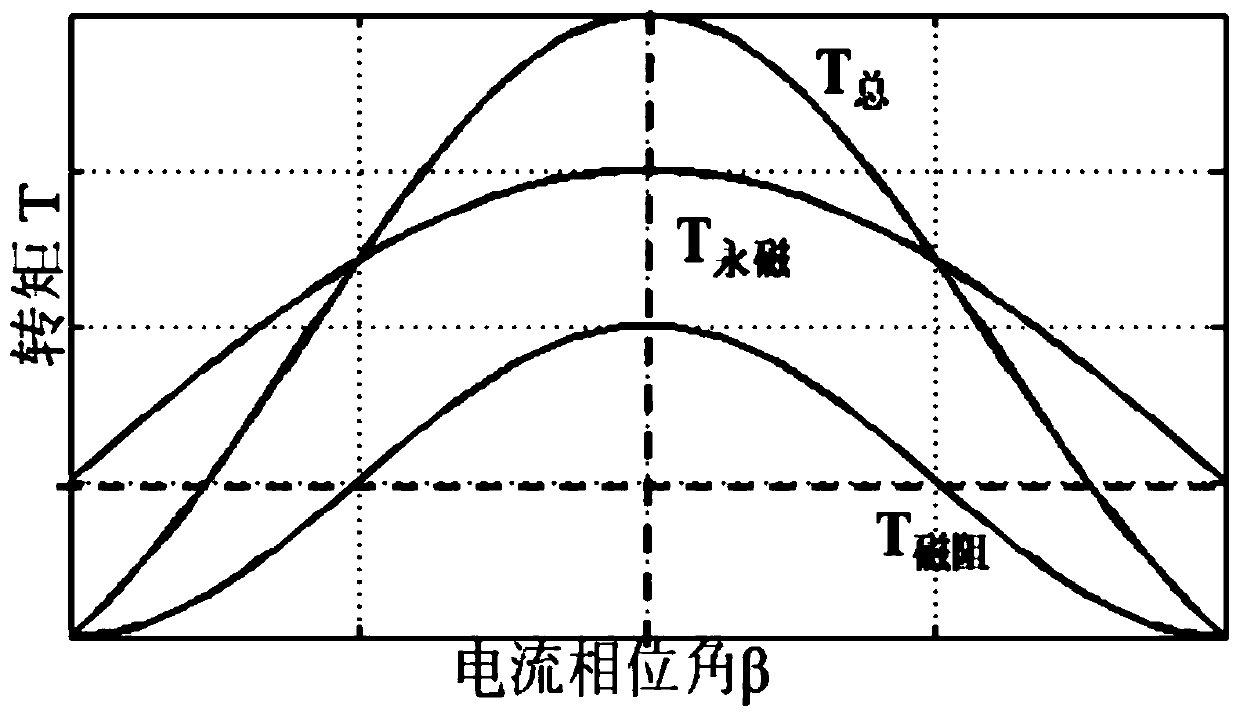

The invention discloses a birotor permanent magnet synchronous reluctance motor and a configuration method. A rotating shaft, a reluctance rotor, a stator and a permanent magnet rotor are sequentiallyarranged from inside to outside, wherein stator grooves are uniformly formed inside and outside the stator, the stator is arranged between the permanent magnet rotor and the reluctance rotor, a d axis is defined as a center line of ferrite of the permanent magnet rotor, a q axis is defined as a center line of a salient pole of the reluctance rotor, a mounting angle of the two rotors on the rotating shaft is defined as an included angle between the d axis and the q axis, a superposition mechanism of torque components is changed by adjusting the mounting angle between the permanent magnet rotorand the reluctance rotor, so the permanent magnet torque and the reluctance torque reach the maximum values at the same current phase angle. The motor is advantaged in that on the premise of not increasing mechanical manufacturing and cooling difficulty of the motor, the electromagnetic torque, the power density and the efficiency are comprehensively improved, the torque pulsation and other electromagnetic properties are inhibited, and the rotor is flexible in structural design, simple in machining process and high in mechanical strength.

Owner:SHANDONG UNIV

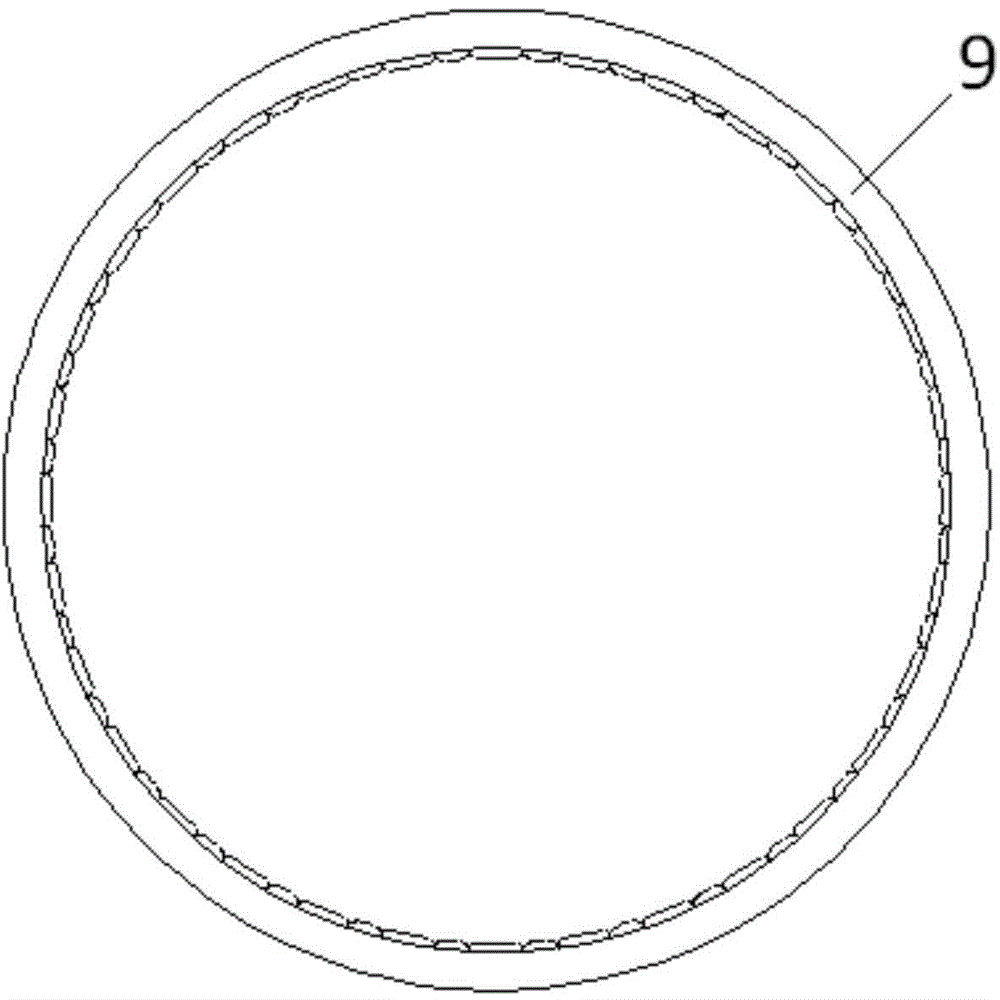

Mixing torque motor and traction machine adopting same

InactiveCN104578654AReduce torque rippleReduce noiseMagnetic circuit rotating partsBuilding liftsElectric machineTorque motor

Owner:浙江西子富沃德电机有限公司

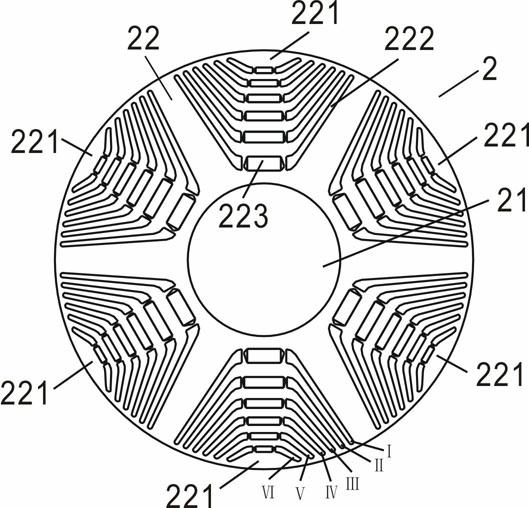

Built-in permanent magnet motor rotor and permanent magnet motor with rotor

InactiveCN102684342ARaise the saliency ratioLarge reluctance torqueMagnetic circuit rotating partsElectric machineryMagnetic poles

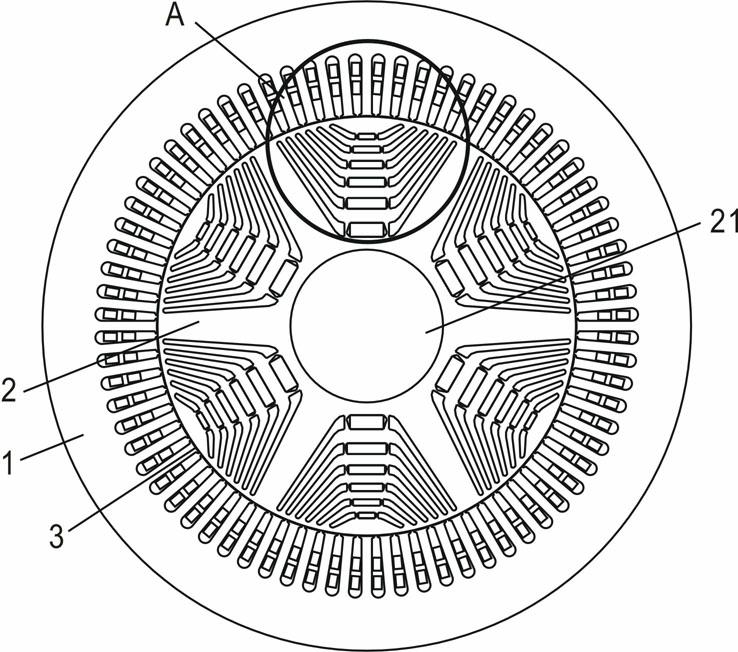

The invention provides a built-in permanent magnet motor rotor which comprises a rotation shaft (21) and a rotor core (22). Magnetic poles (221) are evenly arranged on the rotor core (22), each magnetic pole (221) is provided with at least two groups of magnetic resistance grooves (222), each group of magnetic resistance groove(222) penetrates through the rotor core (22) in the axial direction, each group of magnetic resistance groove(222) comprises a left hollow groove and a right hollow groove which are symmetrical, and a permanent magnet (223) is arranged in the symmetric center of the symmetrical hollow groove of at least one group of magnetic resistance grooves. The invention further provides a permanent magnet motor. Compared with the prior art, the built-in permanent magnet motor rotor improves salient pole ratio of the motor, greatly increases reluctance torque of the motor, reduces torque pulsation and lowers motor cost.

Owner:浙江西子富沃德电机有限公司

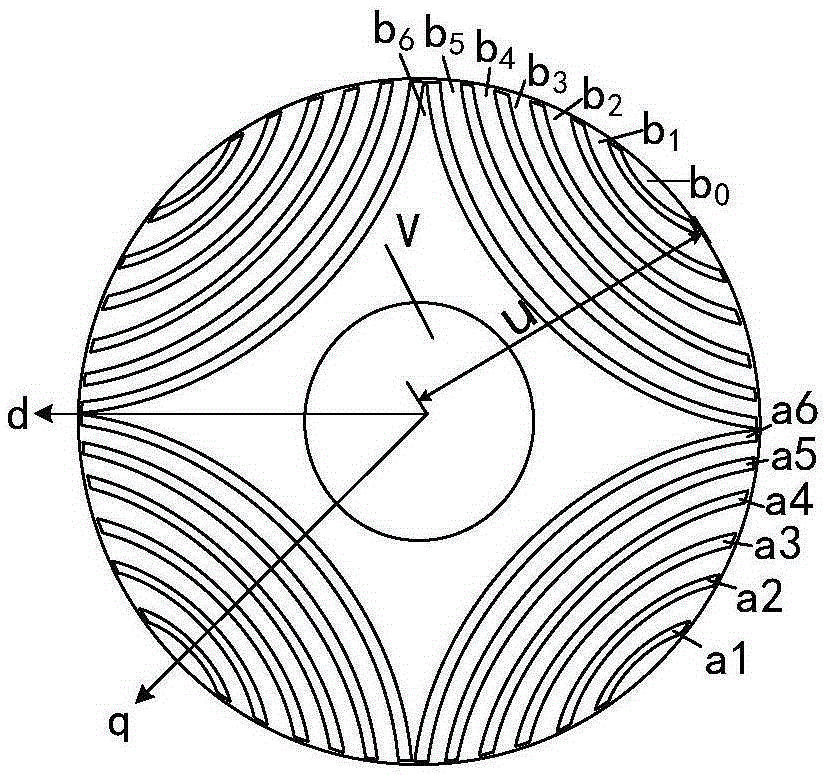

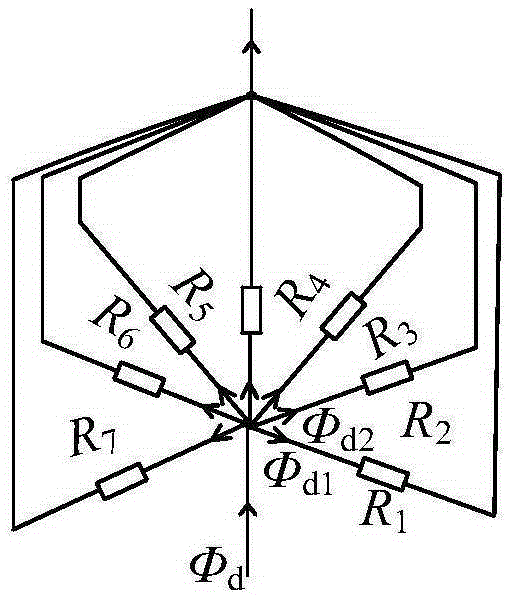

Method for improving saliency ratio of synchronous reluctance machine

ActiveCN105356804AReduce occupancyRaise the saliency ratioElectronic commutation motor controlVector control systemsSynchronous reluctance motorFinite element method

The invention relates to a method for improving the saliency ratio of a synchronous reluctance machine (SynRM). The method is based on the inherent stator and rotor structure parameters of SynRM, a saliency ratio calculation formula is obtained directly according to the equivalent d-axis and q-axis magnetic circuits of SynRM, the relational expression between the saliency ratio and a structure parameter to be optimized of the SynRM is obtained according to the saliency ratio calculation formula, and a higher saliency ratio is obtained by adjusting the value range of the structure parameter. Compared with a finite element method, by adopting the method of the invention, the computer memory resource occupied can be greatly reduced, the difficulty in mathematical operation is lowered, the saliency ratio of SynRM is improved significantly, and the inherent structure parameters of SynRM can be optimized.

Owner:HEBEI UNIV OF TECH

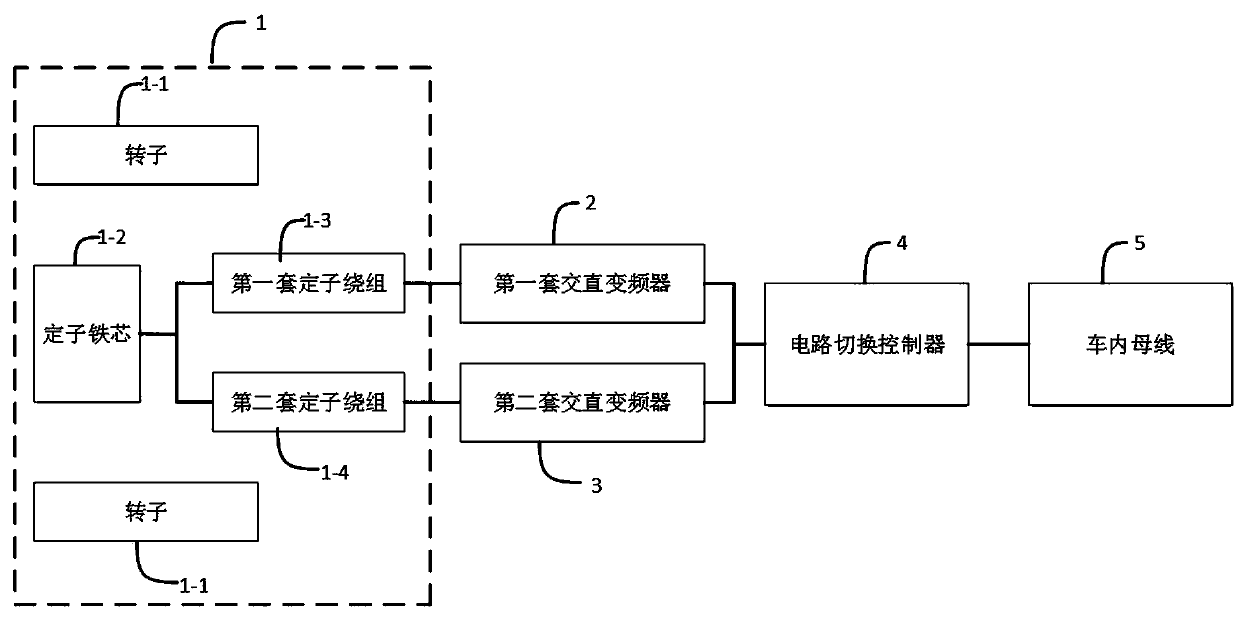

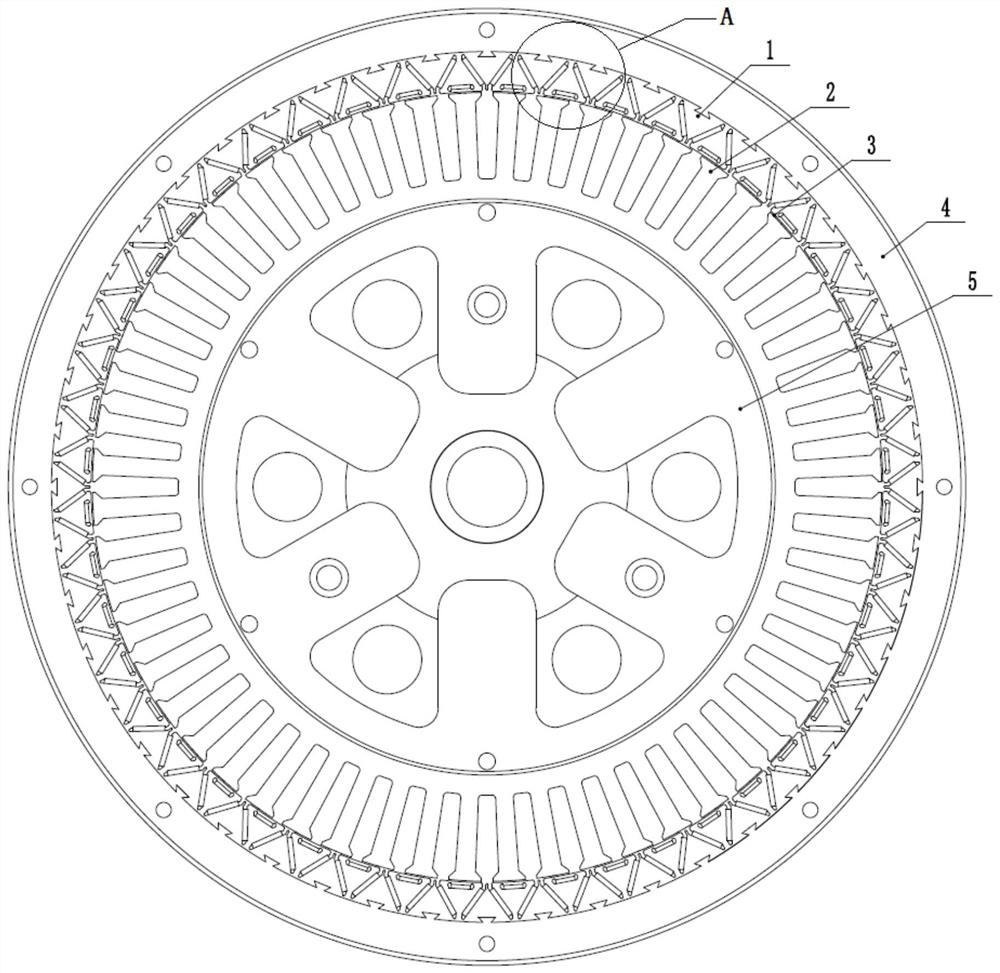

Variable branch modular permanent magnetic built-in outer rotor hub motor for electric vehicle

ActiveCN110365132AIncreased torque/power densityRaise the saliency ratioAssociation with control/drive circuitsMagnetic circuit rotating partsFrequency changerElectric machine

The invention discloses a variable branch modular permanent magnetic built-in outer rotor hub motor for an electric vehicle, and relates to the technical field of motors. A stator iron core is composed of Ns stator tooth modules and a stator yoke; each stator tooth module comprises a stator tooth and a winding coil wound on the stator tooth; a stator winding adopts a fractional slot concentrated winding structure to form m phases of windings; each phase is composed of k winding branches; the m phase of the windings with k winding branches are controlled by t m phases of DC-AC frequency converter; and a rotor consists of a rim and 2p rotor iron core modules. The hub motor has the advantages of high torque / power density, large reluctance torque, variable circuit control capability, capability of widening the speed regulation range, capability of realizing modular manufacturing and automatic production and the like.

Owner:武汉研道科技有限公司

Rotor punching sheet, rotor iron core, motor rotor, assembling method and motor

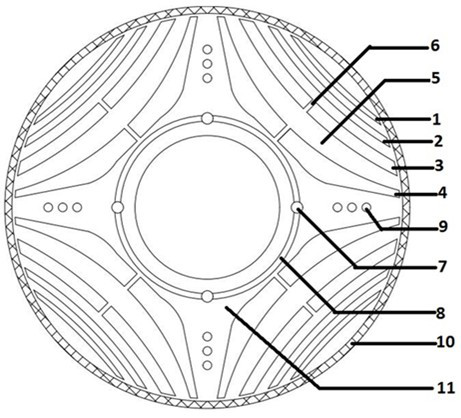

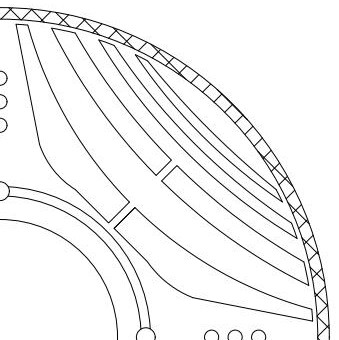

ActiveCN112821608ARaise the saliency ratioIncreased torque output capabilitySynchronous machine detailsMagnetic circuit rotating partsMagnetic barrierPunching

The invention provides a rotor punching sheet, a rotor core, a motor rotor, an assembling method and a motor, the rotor punching sheet comprises a punching sheet body, the punching sheet body is provided with a plurality of magnetic pole forming areas corresponding to the magnetic poles of the motor rotor, and the punching sheet body in each magnetic pole forming area is provided with a first magnetic barrier groove; the first magnetic barrier grooves are symmetrical about the d axis in the corresponding magnetic pole forming area and form a first field angle structure facing the peripheral side of the punching sheet body, the bottom of each first magnetic barrier groove is provided with a first magnetic isolation bridge located on the d axis, and each first magnetic barrier groove comprises two first laterally-extending magnetic barrier grooves symmetrical about the d axis. each first laterally-extending magnetic barrier groove comprises a first magnetic steel groove and a first air groove located on the radial outer side of the first magnetic steel groove, and the first air groove is communicated with the peripheral wall of the punching sheet body. According to the invention, because the outer circle of the rotor punching sheet is not provided with a magnetic isolation bridge, the magnetic leakage at the magnetic isolation bridge can be reduced, the salient pole ratio of the rotor is improved, and the torque output capability of the motor is enhanced.

Owner:GREE ELECTRIC APPLIANCES INC

A Transverse Laminated Synchronous Reluctance Motor with Auxiliary Permanent Magnets

ActiveCN103095078BImprove power factorBroaden the range of constant power speed regulationMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsConstant powerSynchronous reluctance motor

The invention discloses a transverse laminated synchronous reluctance motor with auxiliary permanent magnets. The transverse laminated synchronous reluctance motor with the auxiliary permanent magnets comprises a stator core, stator windings, a rotor core assembly, a rotating shaft, a bearing used for supporting the rotating shaft, a front end cover, a rear end cover and a machine shell. The rotor core assembly comprises the rotor core and a plurality of block-shaped permanent magnets, wherein the rotor core and the plurality of block-shaped permanent magnets are sleeved on the rotating shaft. The rotor core is formed by transversely laminating a plurality of single-shaped complete steel sheets along the rotating shaft. The rotor core is provided with a plurality of layers of arc grooves suitable for insertion of the blocked-shaped permanent magnets. The block-shaped permanent magnets are arranged in the arc grooves. The polarities of the permanent magnets in the layers of arch grooves of the same polar are the same and form a magnetic pole group. The polarities of magnetic pole sets of two adjacent poles are opposite. According to the synchronous reluctance motor, the auxiliary block-shaped permanent magnets are arranged in the arc grooves of the rotor core, and therefore power factors of the motor are improved, and constant power speed adjustable ranges of the motor are widened; and due to the fact that the rotor core is formed by transversely laminating the plurality of single-shaped complete silicon steel sheets, the motor can have good mechanical strength.

Owner:SHANGHAI FUTIAN ELECTRIC TECH

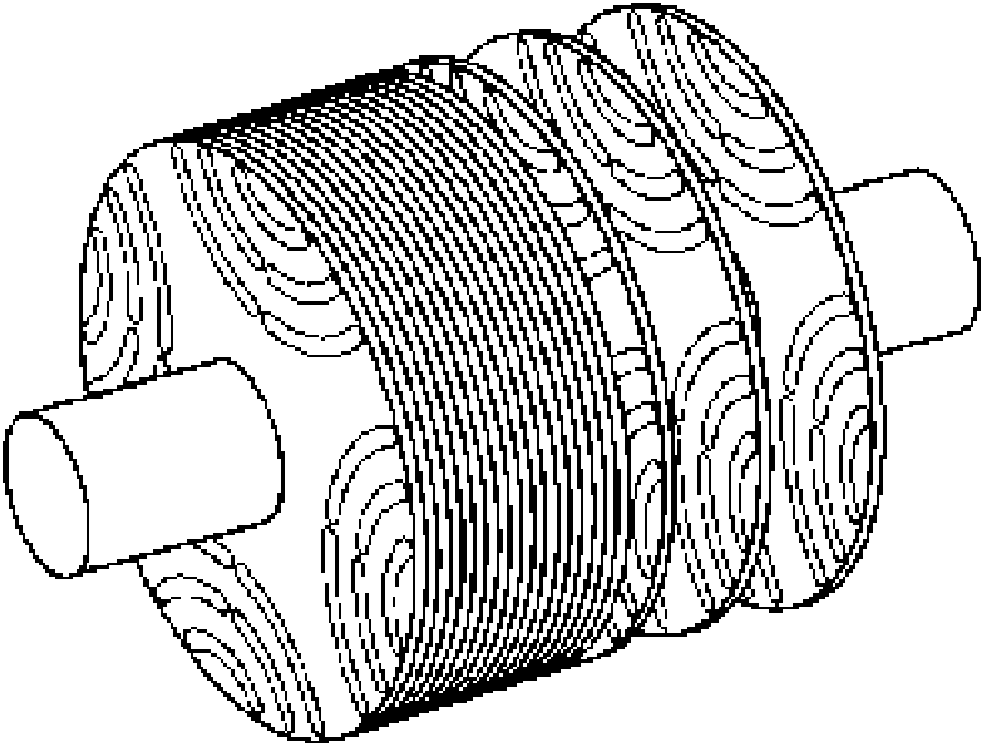

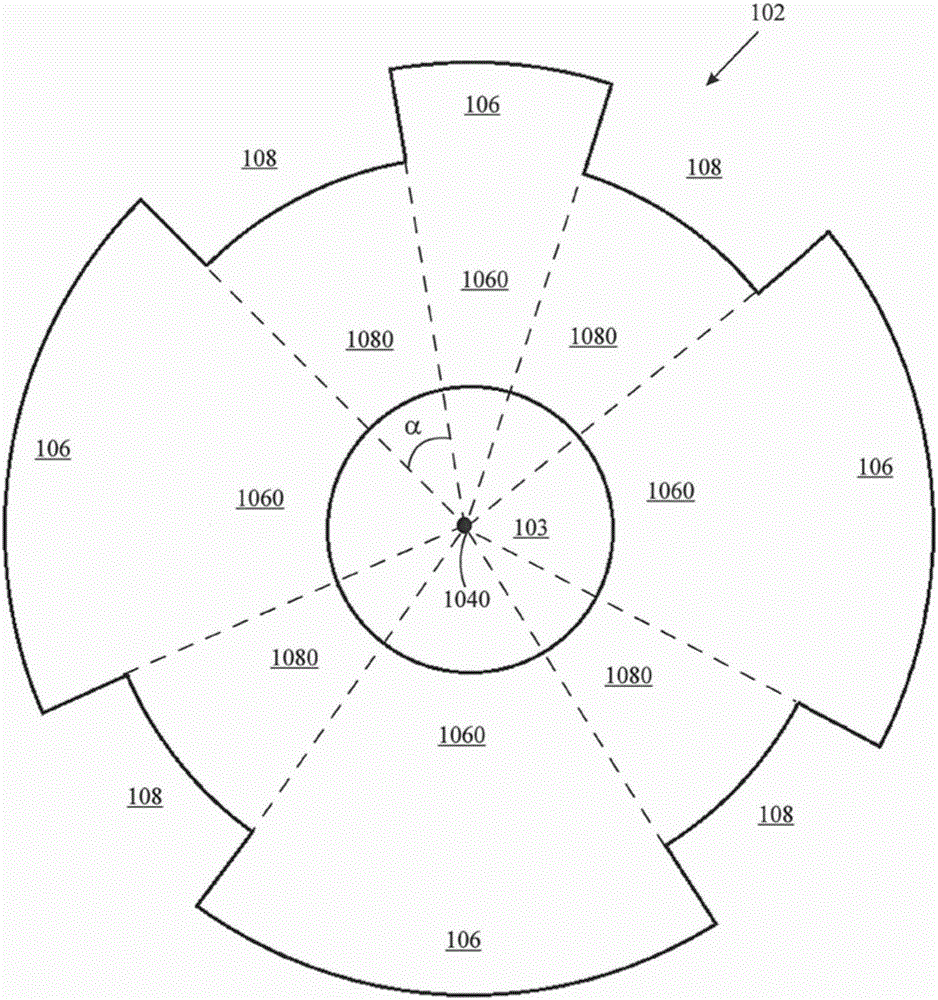

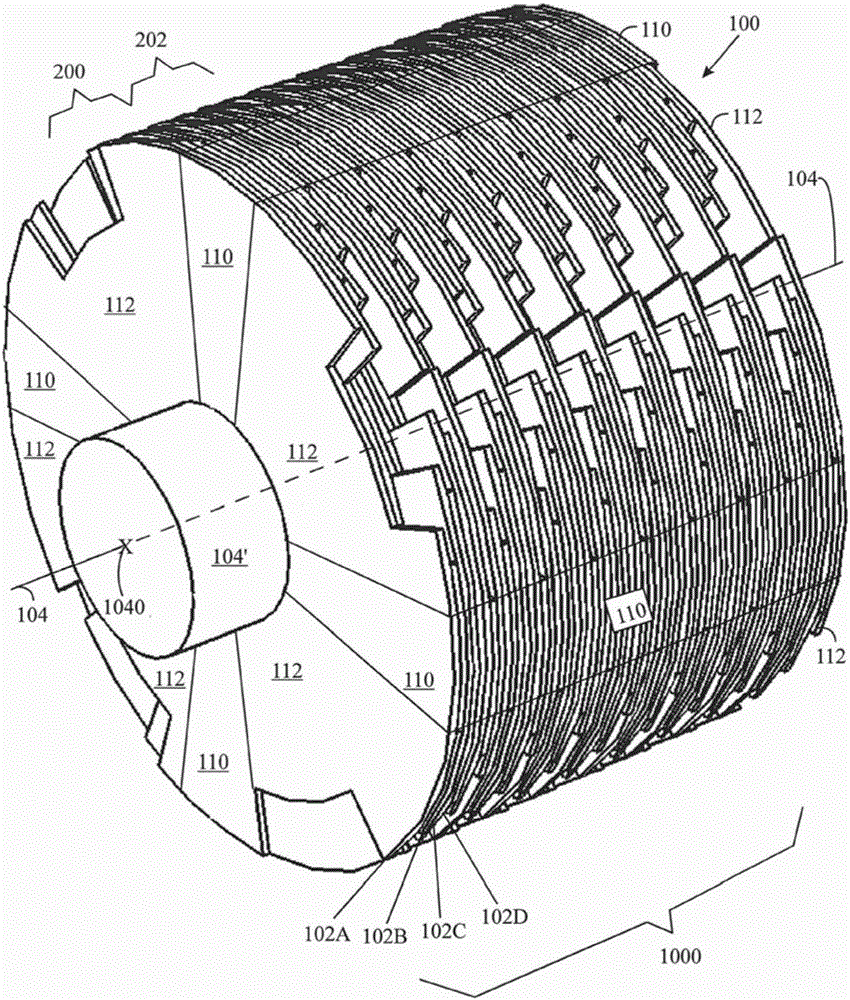

Rotor and method for manufacturing same

ActiveCN106612025ASimple Salient DesignSimple structureMagnetic circuit rotating partsManufacturing stator/rotor bodiesEngineeringMagnetic flux

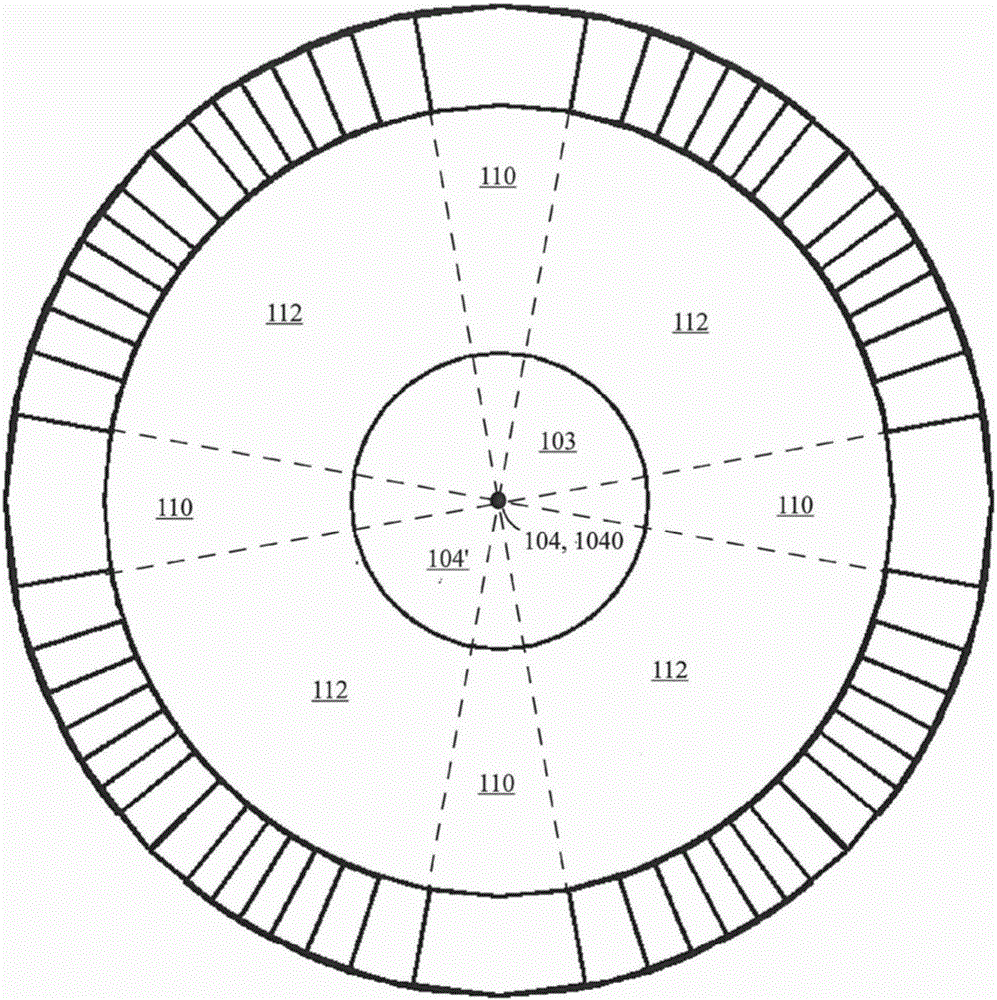

The invention relates to a rotor and a method for manufacturing the same. A rotor (100) of an electric motor (102) comprises a rotor shaft hole (103), first fan-shaped component parts (106), and second fan-shaped component parts (108). The first fan-shaped component parts and the second fan-shaped component parts are alternately distributed around a rotation axis (104) of the rotor (100). The distance from the outer contour of the second fan-shaped component parts (108) to the rotation axis (104) is shorter than that from the outer contour of the first fan-shaped component parts (106) to the rotation axis (104). When observed along the direction of the rotation axis (104), the second fan-shaped component parts (108) overlap the first fan-shaped component parts (106) of other rotor elements (102). The rotor (100) comprises magnetic flux guide pieces (150, 150', 152, 154, 154', 156, 158) which are configured to extend and pass through the rotor (100) between the rotor shaft hole (103) and the periphery of the protruding part of the rotor (100) when observed along the direction of the rotation axis (104).

Owner:ABB (SCHWEIZ) AG

A series hybrid permanent magnet variable flux motor

ActiveCN109660042BReduce the magnetizing currentWork lessMagnetic circuit rotating partsElectric machineCondensed matter physics

The invention discloses a serial hybrid permanent magnet variable flux motor, which comprises a stator (100), an armature winding (200) wound on the stator (100), and a rotor core (300). Each pole of (300) is provided with three permanent magnets that are not in direct contact and placed separately, wherein the second permanent magnet (302) is placed on the outside in a "one" shape, and the two first permanent magnets (301) are in a "V" shape. ” shape is placed on the inner side, the second permanent magnet (302) is a high coercive force permanent magnet or a low coercive force permanent magnet, and the first permanent magnet (301) is a high coercive force permanent magnet or a low coercive force permanent magnet force permanent magnet. In the motor of the present invention, the low coercive force permanent magnet and the high coercive force permanent magnet adopt special placement positions and methods, so that the motor is a magnetic circuit series structure, and the high coercive force permanent magnet acts on the low coercive force permanent magnet. The magnetization effect improves the working point and magnetization degree of the low-coercivity permanent magnet, improves the torque output capability, and reduces the magnetizing current of the motor.

Owner:HUAZHONG UNIV OF SCI & TECH

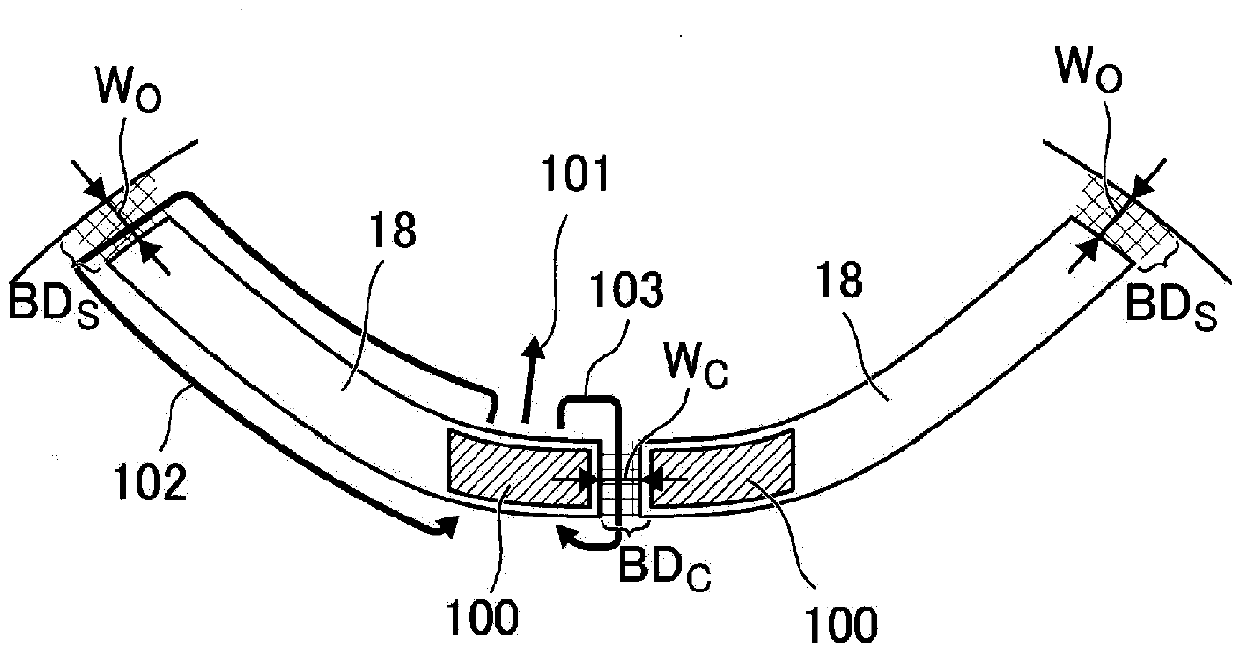

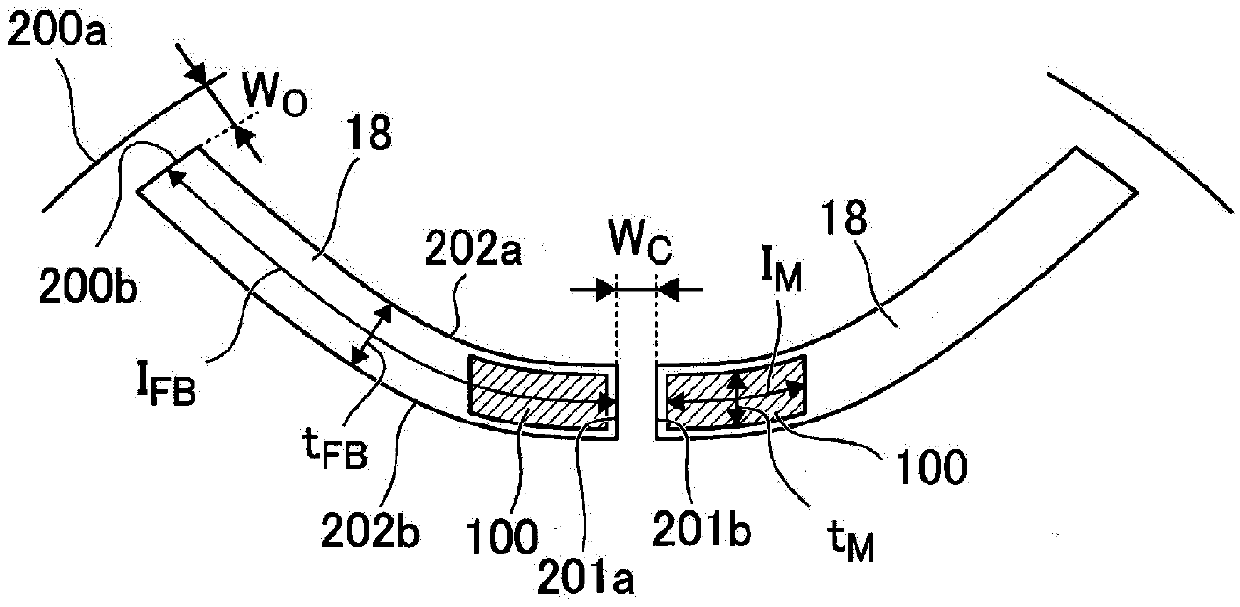

Rotor and reluctance motor

ActiveCN109565198ARaise the saliency ratioMagnetic circuit rotating partsSynchronous machinesMagnetizationMagnetic reluctance

A rotor of an embodiment has a shaft and a rotor core fixed to the shaft. Multiple flux barriers are formed on the rotor core. Multiple bridge parts are formed on each of the flux barriers, and one ormultiple barrier regions having a lower magnetic permeability than that of portions other than the flux barrier are formed between the multiple bridge parts. A permanent magnet is disposed in at least one of the barrier regions. The magnetization direction of the permanent magnet is aligned with a direction intersecting the longitudinal direction of the flux barrier. In addition, a value of ([mu]0*SMxBr) / ([mu]re*tFB*wB) is in a range of 1.2 to 3.0 inclusive.

Owner:KK TOSHIBA +1

High-salient-pole-ratio permanent magnet motor for electric motorcycle

PendingCN112953152ARaise the saliency ratioIncrease torqueMagnetic circuit rotating partsSynchronous machine detailsElectric machineryPermanent magnet motor

The invention discloses a high-salient-pole-ratio permanent magnet motor for an electric motorcycle. The high-salient-pole-ratio permanent magnet motor comprises a stator and a rotor arranged on the outer side of the stator in a sleeving mode, wherein an air gap is formed between the stator and the rotor, and the stator is fixed to a connecting shaft through a fixing support, the rotor comprises a rotor iron core and a plurality of magnetic steel groove sets evenly arranged on the rotor iron core in the circumferential direction; each magnetic steel groove set is composed of two magnetic steel grooves distributed in a V shape and a linear magnetic steel groove, the large openings of the two magnetic steel grooves distributed in the V shape face the circle center, and the linear magnetic steel groove is formed in the large opening of the V shape; each magnetic steel groove is an axial through groove, a permanent magnet is embedded in each magnetic steel groove, and air gaps exist between the two non-axial end parts of each permanent magnet and the corresponding magnetic steel groove; and the ends, close to the stator, of the two magnetic steel grooves distributed in the V shape are communicated with the air gap, and the ends, away from the stator, of the two magnetic steel grooves are mutually independent. The high-salient-pole-ratio permanent magnet motor can solve the problems of magnetic density supersaturation, high iron loss, low motor efficiency and stress concentration of a V-shaped groove magnetic bridge part.

Owner:台铃科技(江苏)股份有限公司

Novel synchronous reluctance motor rotor structure

InactiveCN113078750AHigh torqueRaise the saliency ratioMagnetic circuit rotating partsMagnetic barrierFiber

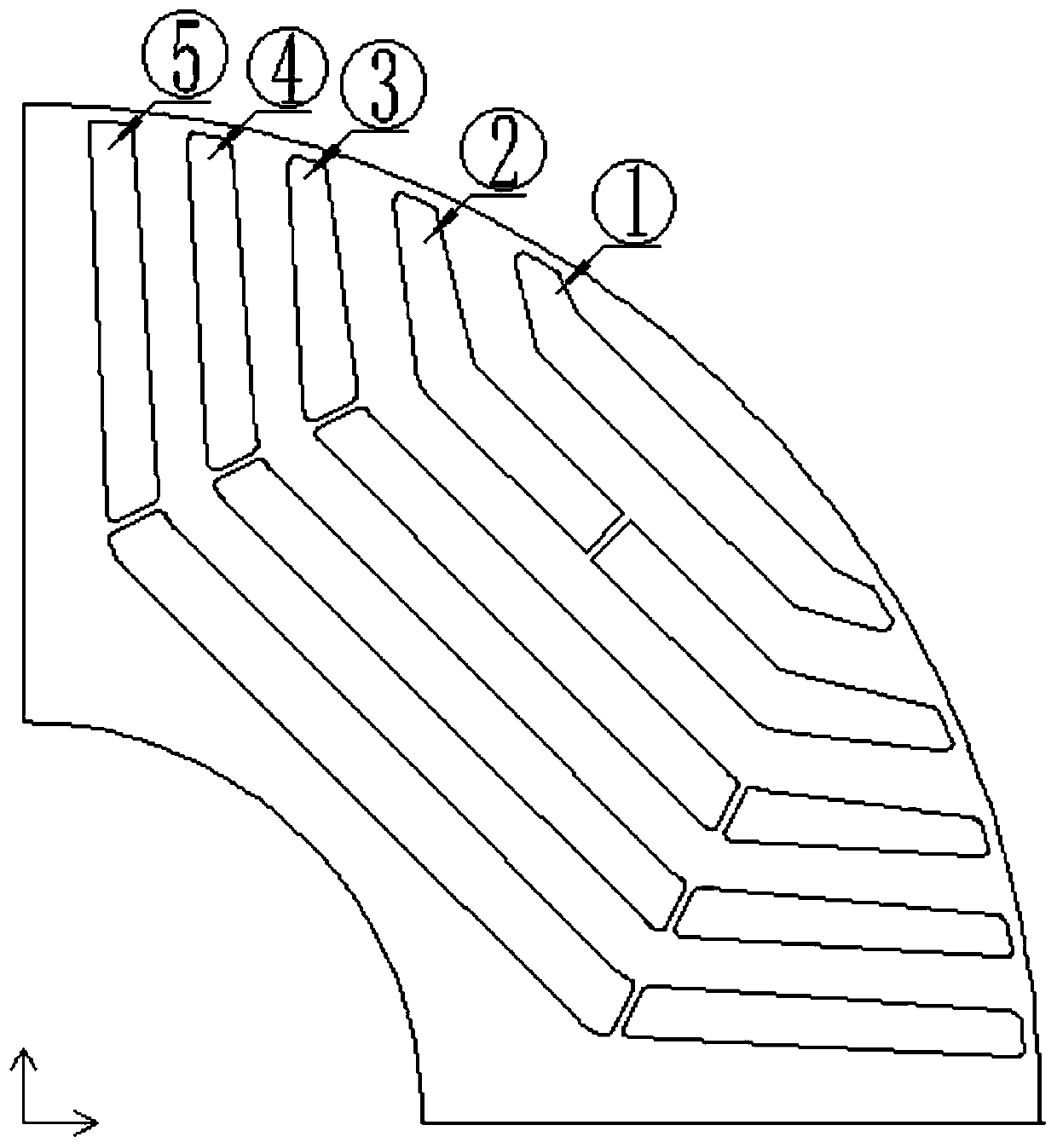

The invention discloses a synchronous reluctance motor rotor structure, which comprises an iron core and an iron core sheath, and is characterized in that the iron core is sequentially provided with a first layer of air magnetic barrier, a second layer of air magnetic barrier, a third layer of air magnetic barrier and a fourth layer of air magnetic barrier from outside to inside, and the first layer of air magnetic barrier, the second layer of air magnetic barrier, the third layer of air magnetic barrier and the fourth layer of air magnetic barrier have different thicknesses; magnetic conductive ribs are arranged between the adjacent air magnetic barriers and on the outer side of the first layer of air magnetic barrier; central ribs with the same thickness are arranged at the middle parts of the third-layer air magnetic barrier and the fourth-layer air magnetic barrier; the iron core is provided with a ventilation hole; and a layer of carbon fiber iron core sheath is wrapped outside the iron core. The synchronous reluctance motor rotor structure can well solve the problems that a motor rotor is serious in leakage inductance, low in mechanical strength, low in salient pole ratio, large in torque pulsation, low in torque and the like.

Owner:HARBIN UNIV OF SCI & TECH

Permanent magnet motor rotor with high saliency ratio and motor

InactiveCN107565714ARaise the saliency ratioEasy to processMagnetic circuit rotating partsSalient polesPermanent magnet motorNon magnetic

The present invention relates to a permanent magnet motor rotor with a high saliency ratio. The permanent magnet motor rotor with a high saliency ratio comprises a rotor sheet and permanent magnets; radial slot sets configured to put the permanent magnets and matching with the number of poles are uniformly arranged at a circumference direction of the rotor sheet, the radial slot sets are two or more than two layers of permanent magnet slots arranged on the rotor sheet along a radial direction, the permanent magnet slots are distributed in a line-shaped mode or a W-shaped mode along the circumference of the rotor sheet, the permanent magnets are arranged in the permanent magnet slots, and two ends of each permanent magnet slot are respectively provided with non-magnetic slots. The radial slot sets configured to put the permanent magnets and matching with the number of poles are uniformly arranged at the circumference direction of the rotor sheet, and a plurality of permanent magnets arearranged at each pole, so that a saliency ratio is greatly improved, and processing is very simple. The present invention further relates to a motor comprising the permanent magnet motor rotor with ahigh saliency ratio.

Owner:XEMC LIGHT ELECTRIC

Rotor slotless switched reluctance motor

InactiveCN102497077BReduce volumeReduce iron lossMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic polesReluctance motor

Owner:DALIAN UNIV OF TECH

Permanent magnet synchronous motor and rotor thereof

PendingCN114744795AReduce dosageImprove sinusoidalityMagnetic circuit rotating partsElectric machinesPermanent magnet synchronous motorMagnetic poles

The invention discloses a rotor of a permanent magnet synchronous motor. Each group of magnetic pole slots is divided into two inner magnetic pole slots positioned on the inner layer and one outer magnetic pole slot positioned on the outer layer along the radial direction of a rotor iron core sheet; two of the magnetic pole groups are first permanent magnets, the other one of the magnetic pole groups is a second permanent magnet, after the first permanent magnets are matched with the inner magnetic pole grooves, the two first permanent magnets are arranged in a V shape, and a magnetic pole straight shaft which is axially symmetric about the two first permanent magnets is arranged between the two first permanent magnets; at least one end of the inner magnetic pole groove extends to form a magnetic isolation groove located on the outer side of the first permanent magnet. After the second permanent magnets are matched with the outer magnetic pole grooves, the symmetry axes of the second permanent magnets coincide with the magnetic pole straight axes, and the distance between the second permanent magnets and the peripheral face of the rotor iron core piece is smaller than the distance between the first permanent magnets and the peripheral face of the rotor iron core piece. According to the invention, the counter electromotive force can be reduced, the no-load counter electromotive force waveform sinusoidal property is improved, the reluctance torque is improved, and the cogging torque is reduced.

Owner:成都华川电装有限责任公司

Multi-combination type permanent magnet motor rotor punching sheet and permanent magnet motor

ActiveCN113517770AIncrease diversityMeet needsMagnetic circuit rotating partsElectric machinesPunchingElectric machinery

The invention discloses a multi-combination permanent magnet motor rotor punching sheet, which comprises a rotor punching sheet body. The rotor punching sheet body is divided into a plurality of rotor poles which are distributed in a circumferential array, the rotor punching sheet body is provided with a shaft hole, lightening holes and inverted triangular magnetic steel grooves which are distributed in the circumferential direction, and each rotor pole is matched with one inverted triangular magnetic steel groove. Each inverted triangular magnetic steel groove comprises linear magnetic steel grooves and two bevel magnetic steel grooves; the linear magnetic steel grooves are formed by arranging an odd number of rectangular magnetic steel grooves with the length of a and the width of b at intervals, and the number of the linear magnetic steel groove is n; and the length of each bevel magnetic steel groove is n * a, and the width of each bevel magnetic steel groove is b. According to the invention, permanent magnets are inserted into the appropriate magnetic steel grooves and matched with different small round holes to form corresponding skewed pole angles, so that different performance requirements of a motor are met, the research, development and production periods of the punching sheet are shortened, and the material management and control, the purchase cost and the process complexity are also reduced; and meanwhile, asymmetry of magnetic poles can be realized, so that the effects of weakening harmonic waves and reducing torque fluctuation are achieved.

Owner:河南通宇新源动力有限公司

A Stator-Rotor Structure of a High Power Density Reluctance Motor

ActiveCN110932425BReduce leakage fluxReduce torque fluctuationMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic barrierElectric machine

The invention discloses a stator and rotor structure of a high-power-density reluctance motor. The structure comprises a stator and a rotor, the number of stator slots and the number of rotor magneticbridges meet the formula (1): Nr = Ns-4k (1), Ns is the number of stator slots corresponding to each pair of poles, Nr is the number of rotor magnetic bridges corresponding to each pair of poles, K is a positive integer, and the number of rotor magnetic bridges corresponding to each layer of rotor magnetic barriers is 2; the number of layers of the rotor magnetic barriers is Nr / 2, and then rounding is carried out; the opening angle alpha of the outermost layer magnetic bridge of the rotor meets the formula (2), wherein p is the number of pole pairs. According to the invention, the leakage flux of the motor can be reduced, the salient pole ratio of the motor is improved, the torque output capability of the motor is improved, and the torque ripple of the motor can be reduced.

Owner:HANGZHOU EASITECH

Stator and rotor structure of high-power-density reluctance motor

ActiveCN110932425ARaise the saliency ratioIncreased torque output capabilityMagnetic circuit rotating partsMagnetic circuit stationary partsEngineeringTorque ripple

The invention discloses a stator and rotor structure of a high-power-density reluctance motor. The structure comprises a stator and a rotor, the number of stator slots and the number of rotor magneticbridges meet the formula (1): Nr = Ns-4k (1), Ns is the number of stator slots corresponding to each pair of poles, Nr is the number of rotor magnetic bridges corresponding to each pair of poles, K is a positive integer, and the number of rotor magnetic bridges corresponding to each layer of rotor magnetic barriers is 2; the number of layers of the rotor magnetic barriers is Nr / 2, and then rounding is carried out; the opening angle alpha of the outermost layer magnetic bridge of the rotor meets the formula (2), wherein p is the number of pole pairs. According to the invention, the leakage flux of the motor can be reduced, the salient pole ratio of the motor is improved, the torque output capability of the motor is improved, and the torque ripple of the motor can be reduced.

Owner:HANGZHOU EASITECH

Synchronous reluctance motor and rotor for synchronous reluctance motor

ActiveUS9853508B2Raise the saliency ratioImprove power factorMagnetic circuit rotating partsSynchronous motorsSynchronous reluctance motorPhysics

A synchronous reluctance motor includes: a rotor shaft; a rotor core fixed to the rotor shaft and on which a plurality of flux barriers are formed; a stator core on which a plurality of protruding stator teeth are formed; and multiphase armature windings of a plurality of poles wound around the plurality of stator teeth. The flux barriers include a plurality of first flux barriers formed to be spaced out in the circumferential direction from each other and extend in a radial direction, and a plurality of second flux barriers formed in each of circumferential angular regions sandwiched between the first flux barriers to form a curved surface convex toward the center of the rotation-axis and to spread and be spaced out in the circumferential direction from each other.

Owner:KK TOSHIBA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com