Sensorless controller of bearingless synchronous reluctance motor and method for controlling sensorless controller

A synchronous reluctance motor and controller technology, applied in the direction of speed/torque control of a single motor, can solve the problems of weakening random interference and measurement noise, lack of parameter configuration, poor identification accuracy, etc., achieving excellent robustness, good Anti-interference performance, low loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

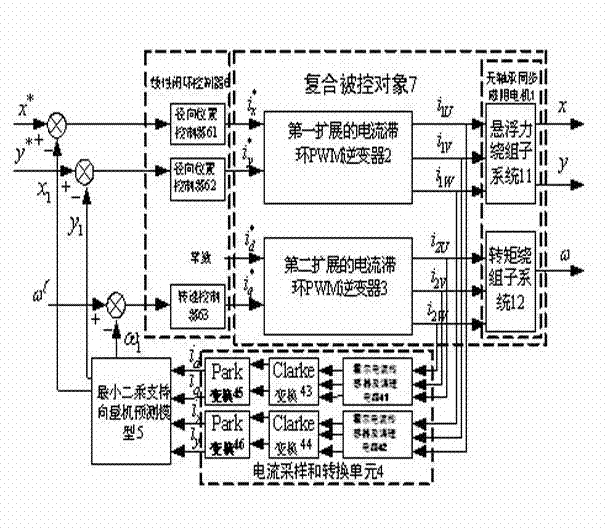

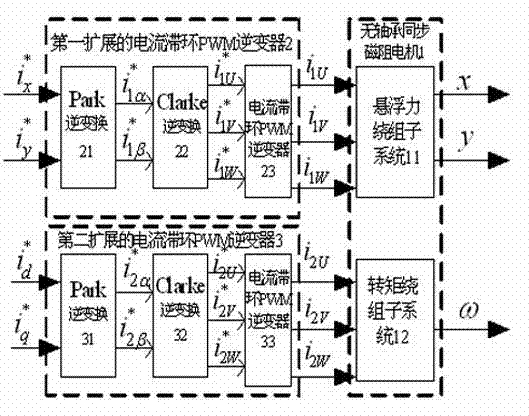

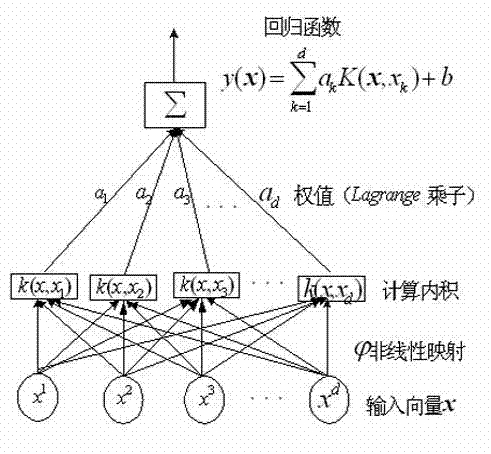

[0021] Such as figure 1 As shown, the sensorless controller of the bearingless synchronous reluctance motor of the present invention consists of a current sampling and conversion unit 4, a least squares support vector machine prediction model 5, a linear closed-loop controller 6 and parallel first and second extended current hysteresis The ring PWM inverters 2 and 3 are jointly formed, wherein the linear closed-loop controller 6 is composed of a rotational speed controller 63 and two radial position controllers 61 and 62, and the two radial position controllers 61 and 62 are respectively connected in series It is connected before the first extended current hysteresis PWM inverter 2 , and one speed controller 63 is connected in series before the second extended current hysteresis PWM inverter 3 . The first and second two extended current hysteresis PWM inverters 2, 3 and the bearingless synchronous reluctance motor 1 together form a composite controlled object 7; the bearingle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com