Patents

Literature

62results about How to "Large reluctance torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

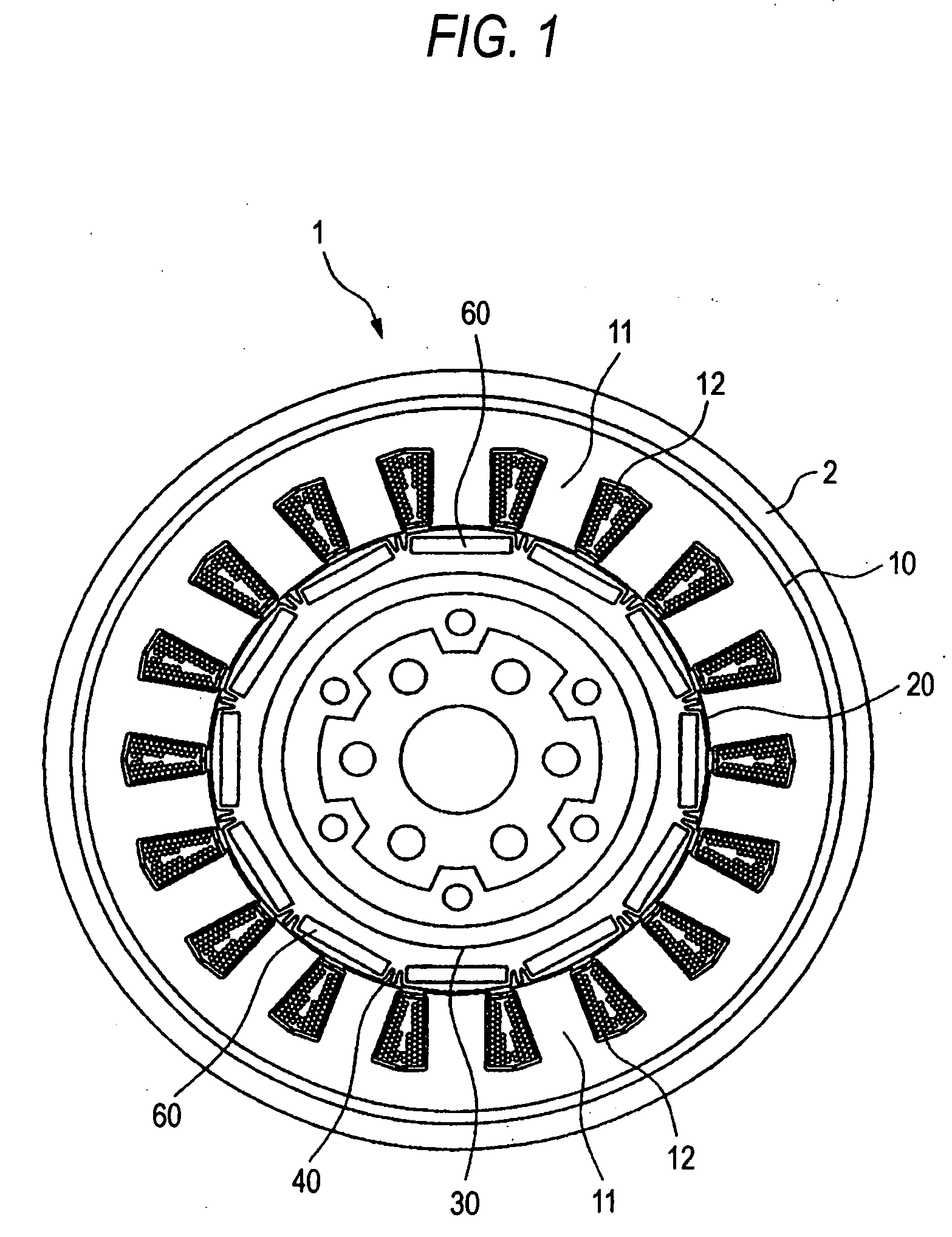

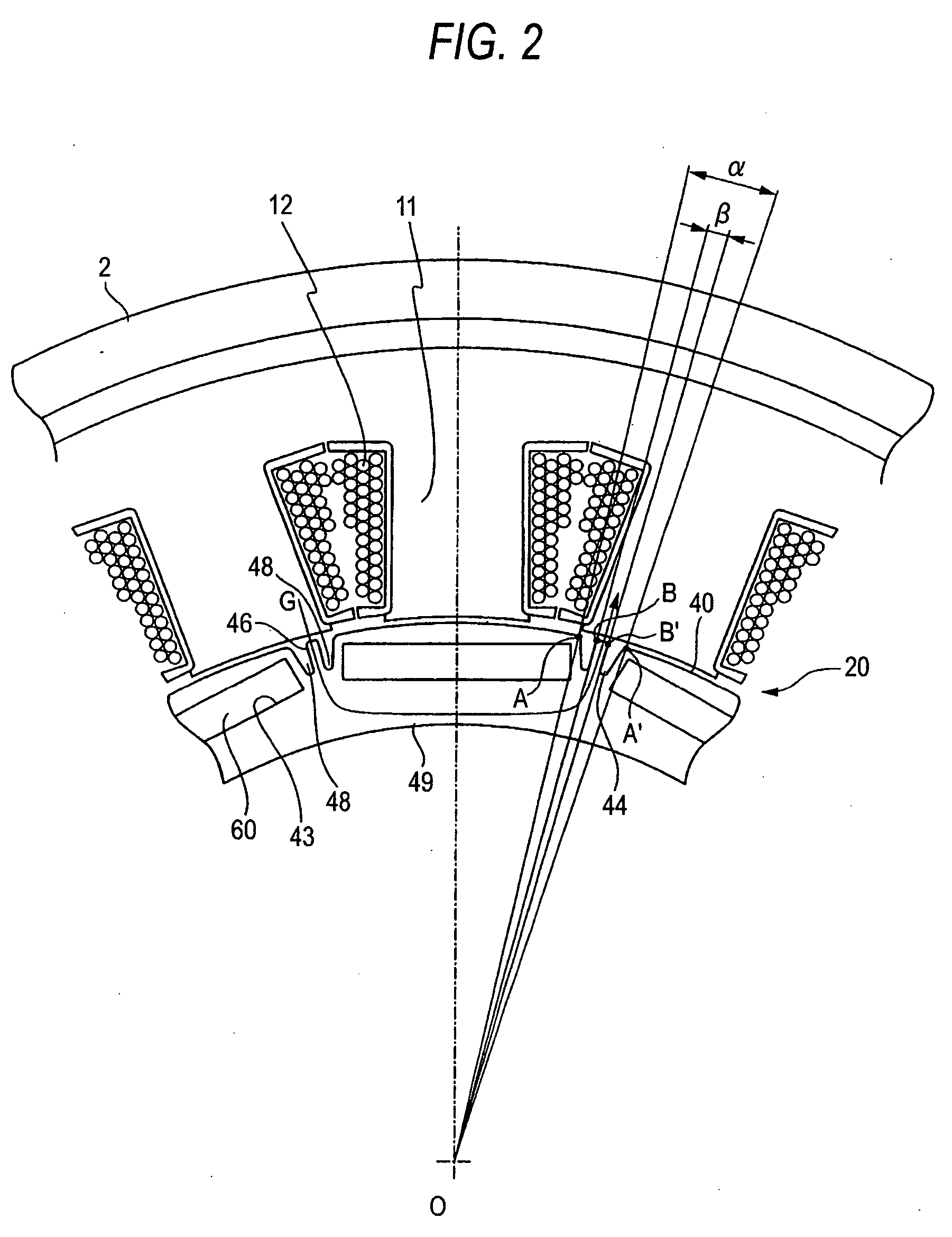

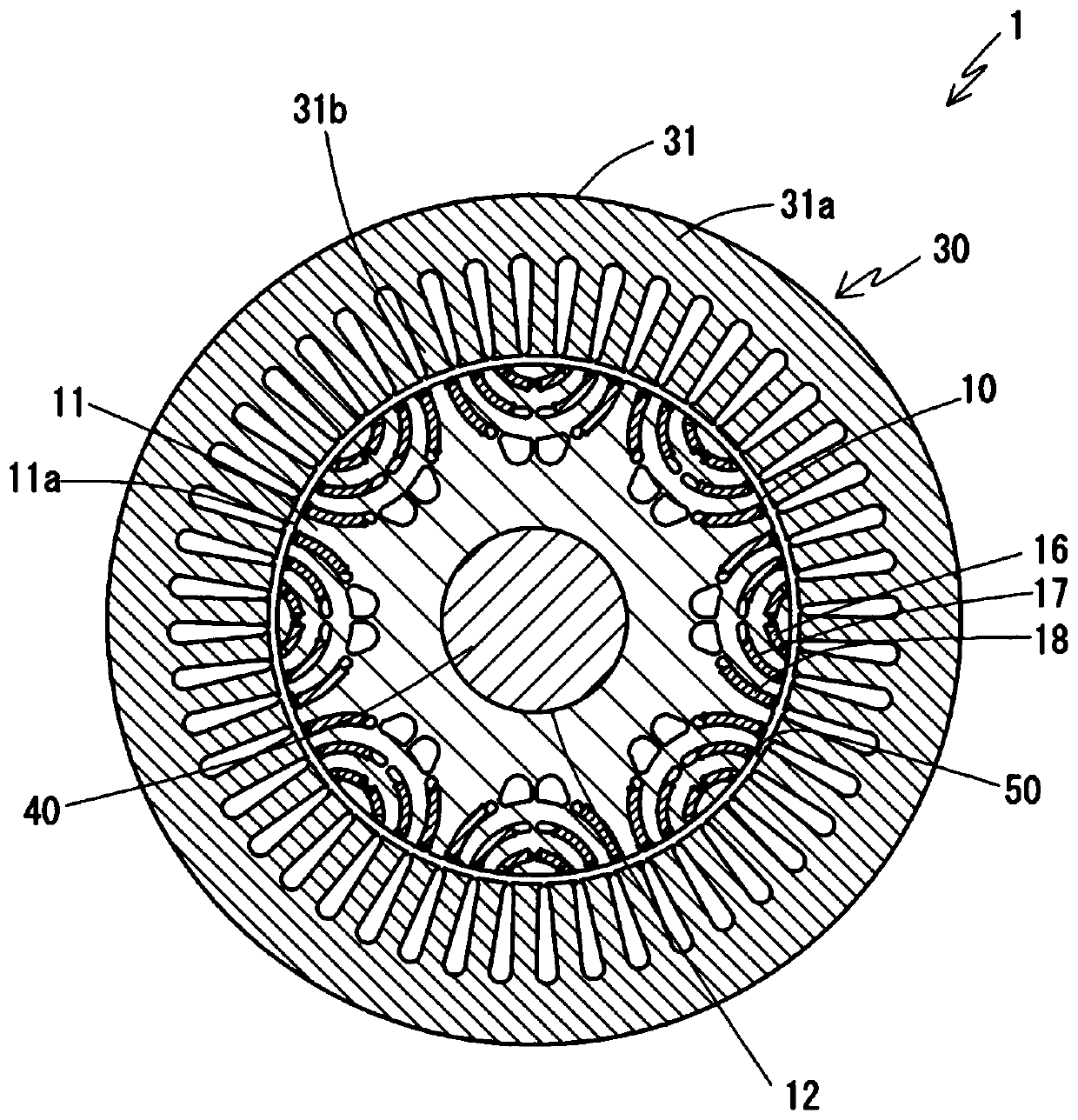

Permanent magnet rotor and brushless motor

InactiveUS6940199B2Large reluctance torqueImprove accuracyMagnetic circuit rotating partsManufacturing stator/rotor bodiesBrushless motorsPermanent magnet rotor

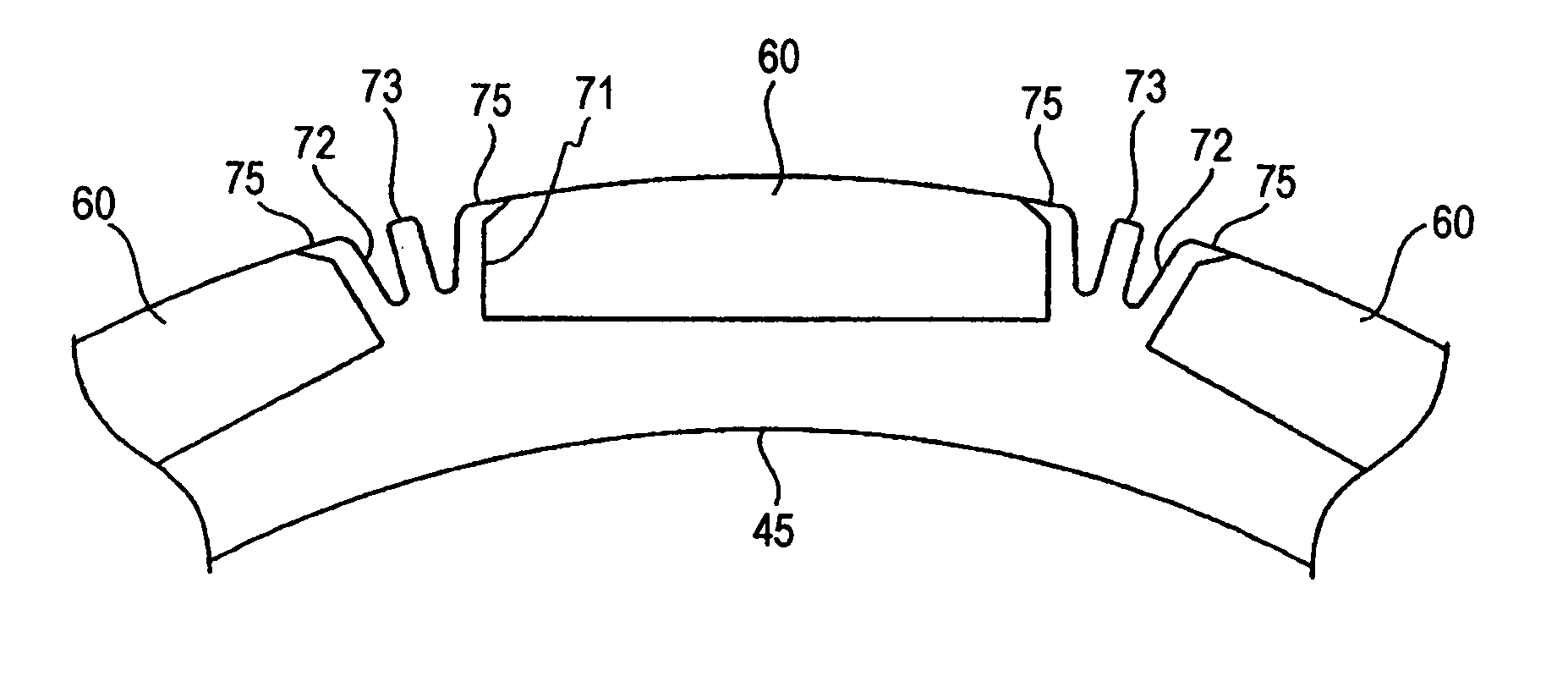

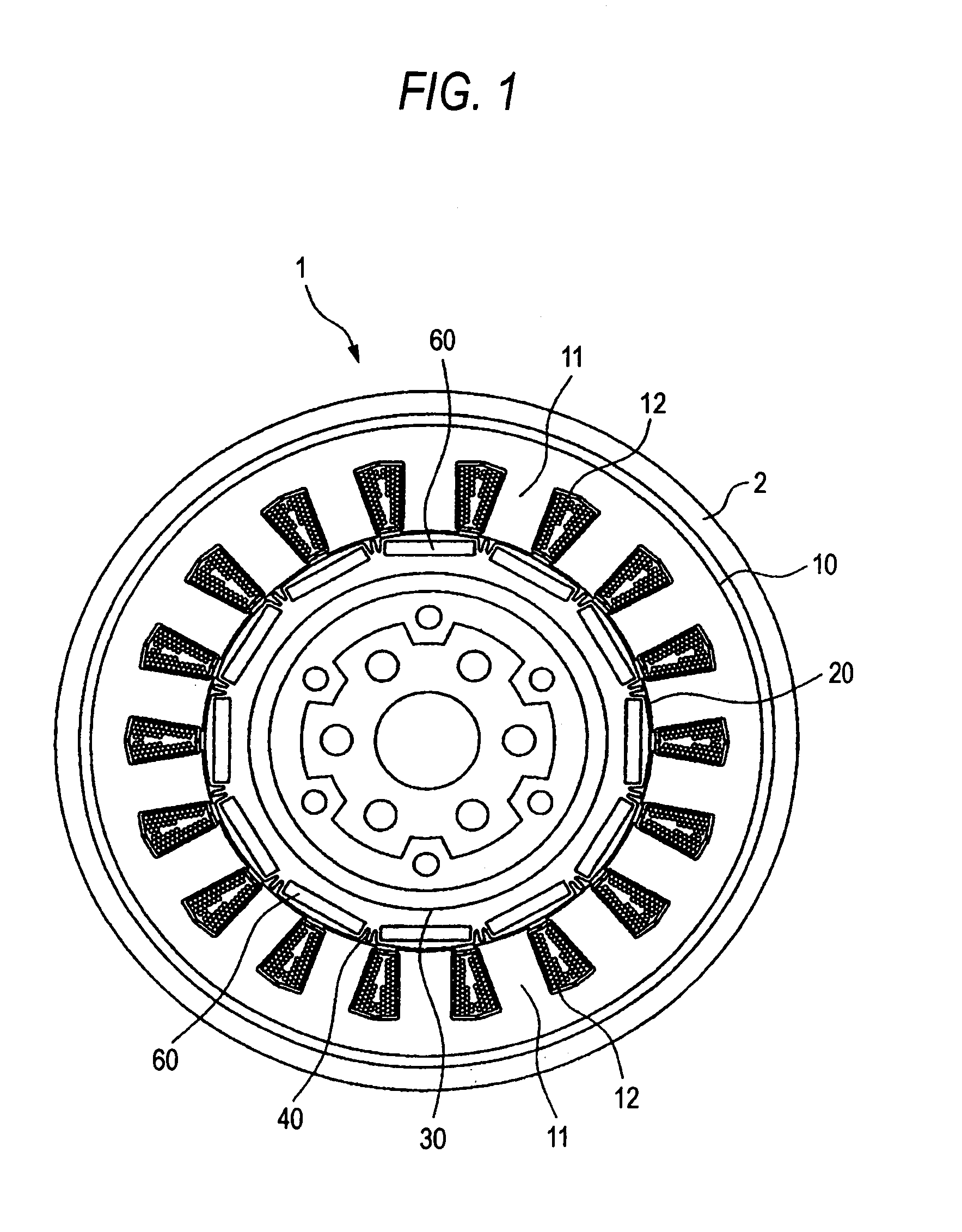

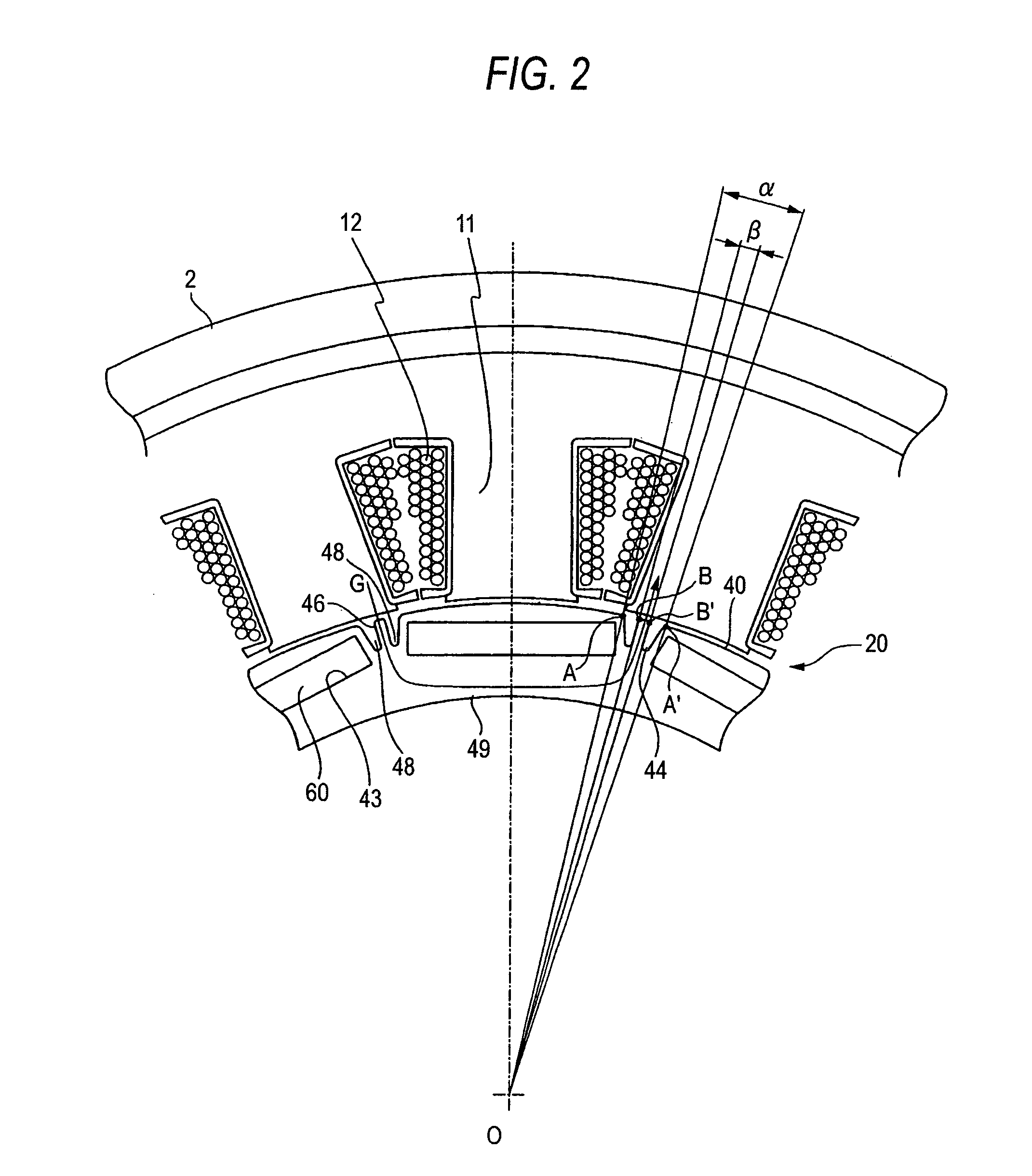

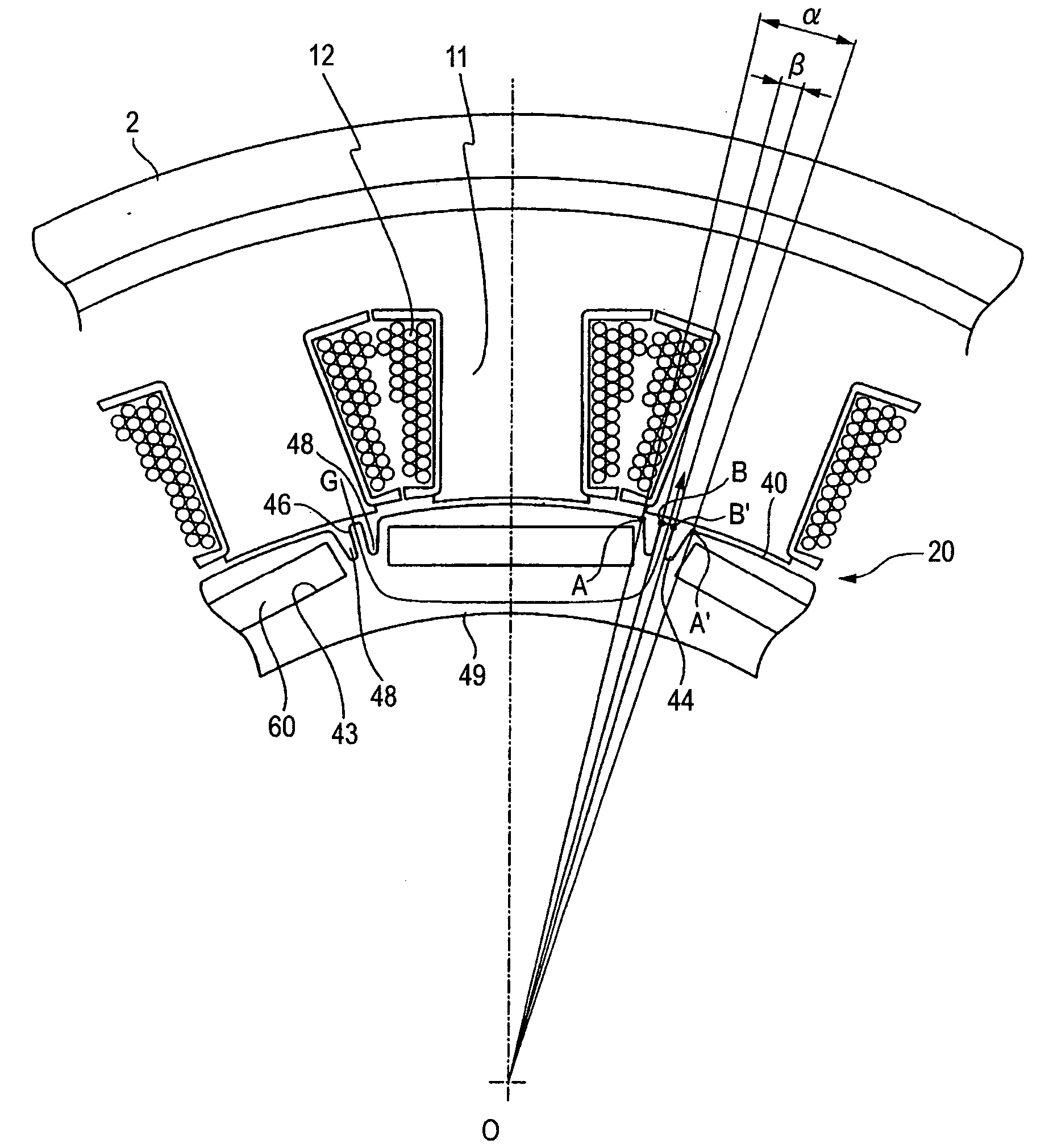

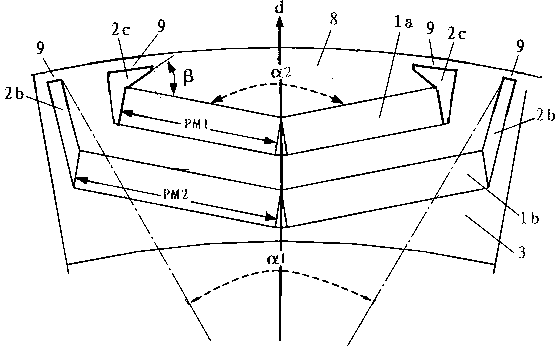

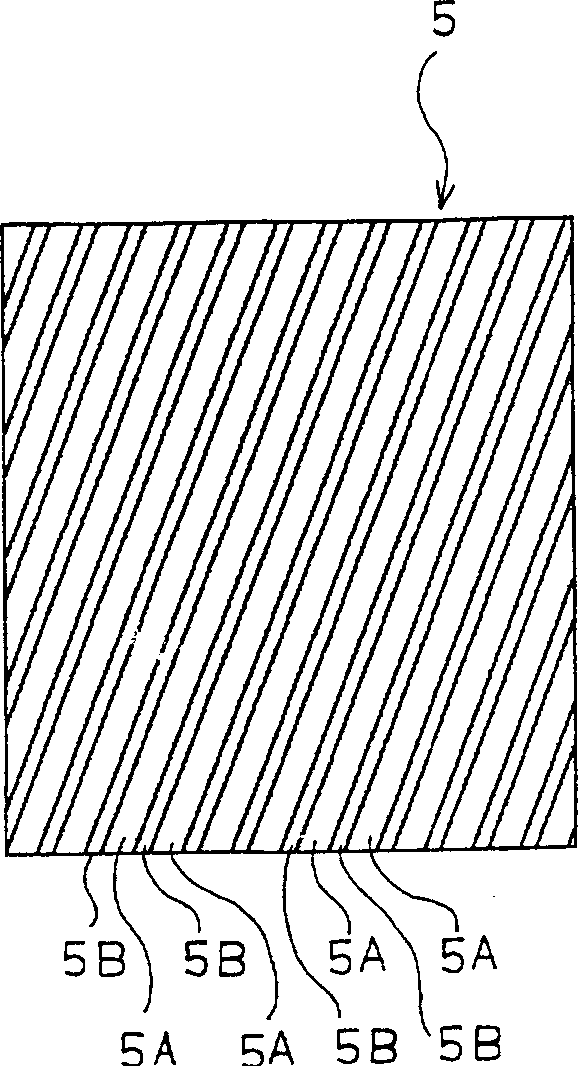

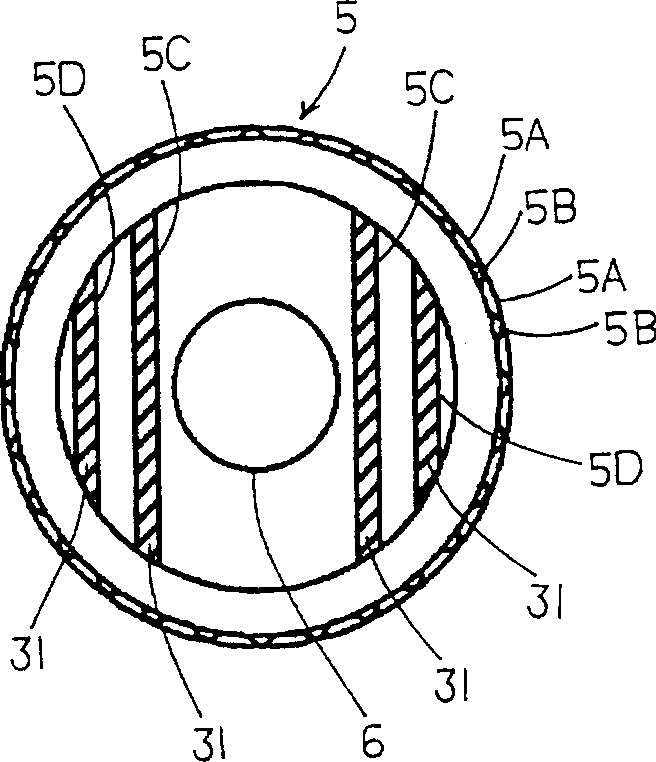

In a rotor 20 including a plurality of permanent magnet pieces 60 fixed in a plurality of magnet insertion slots 43 provided on the outer periphery of a rotor yoke 40, respectively, and the rotor yoke 40 having concaves 44 each provided between the permanent magnet pieces 60 adjacent to each other and protrusions 46 each provided in each the concaves 44 to protrude outwardly in the radial direction of the rotor yoke 40, between the sandwiching angle α formed by two sides connecting both outer ends A and A′ of each the concaves 44 to the center axis O of the rotor yoke 40 and the sandwiching angle β formed by two sides connecting both outer ends B and B′ of each the protrusions 46 to the center axis O of the rotor yoke 40, the following relationship is satisfied:0.3<β / α<0.5.

Owner:HONDA MOTOR CO LTD

Permanent magnet rotor and brushless motor

InactiveUS20050110356A1Easy to passDifficult to passMagnetic circuit rotating partsManufacturing stator/rotor bodiesPermanent magnet rotorBrushless motors

In a rotor 20 including a plurality of permanent magnet pieces 60 fixed in a plurality of magnet insertion slots 43 provided on the outer periphery of a rotor yoke 40, respectively, and the rotor yoke 40 having concaves 44 each provided between the permanent magnet pieces 60 adjacent to each other and protrusions 46 each provided in each the concaves 44 to protrude outwardly in the radial direction of the rotor yoke 40, between the sandwiching angle α formed by two sides connecting both outer ends A and A′ of each the concaves 44 to the center axis O of the rotor yoke 40 and the sandwiching angle β formed by two sides connecting both outer ends B and B′ of each the protrusions 46 to the center axis O of the rotor yoke 40, the following relationship is satisfied: 0.3<β / α<0.5

Owner:HONDA MOTOR CO LTD

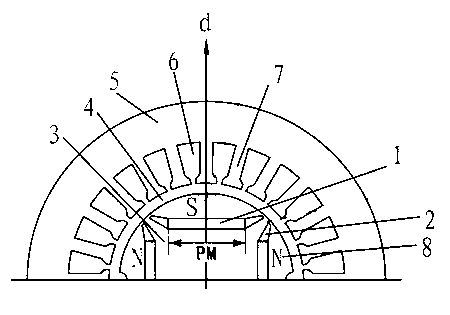

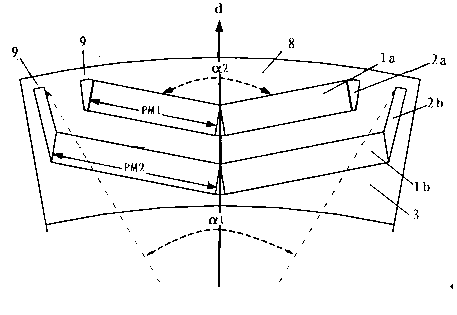

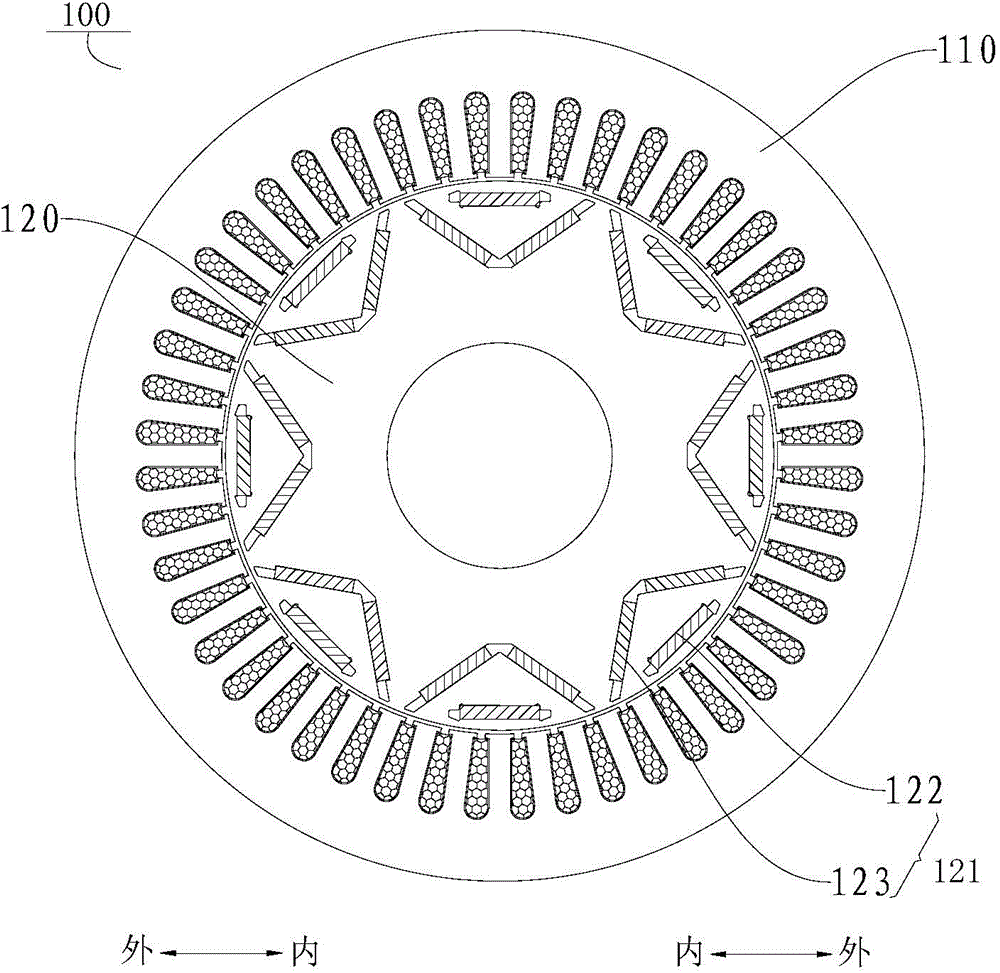

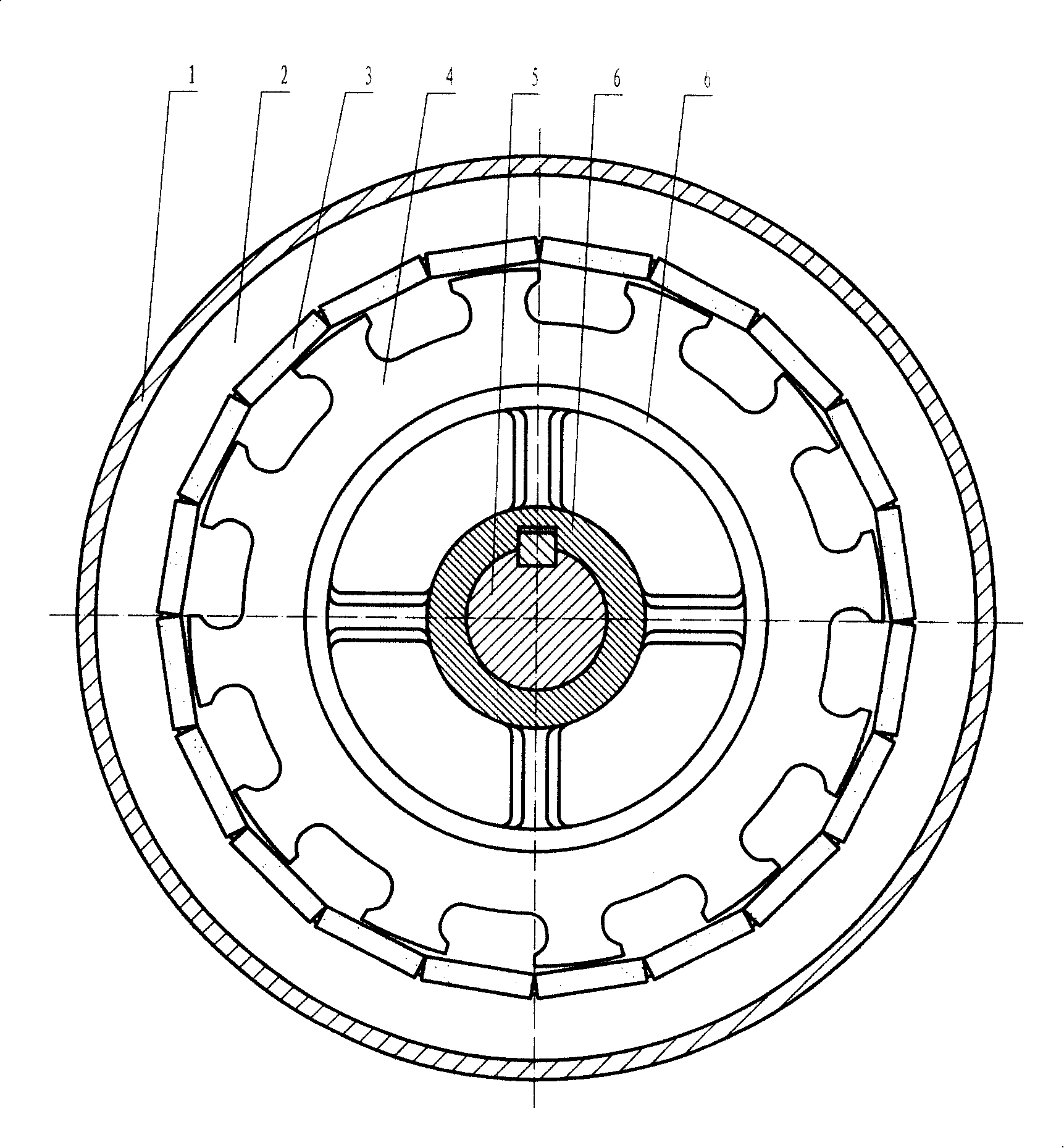

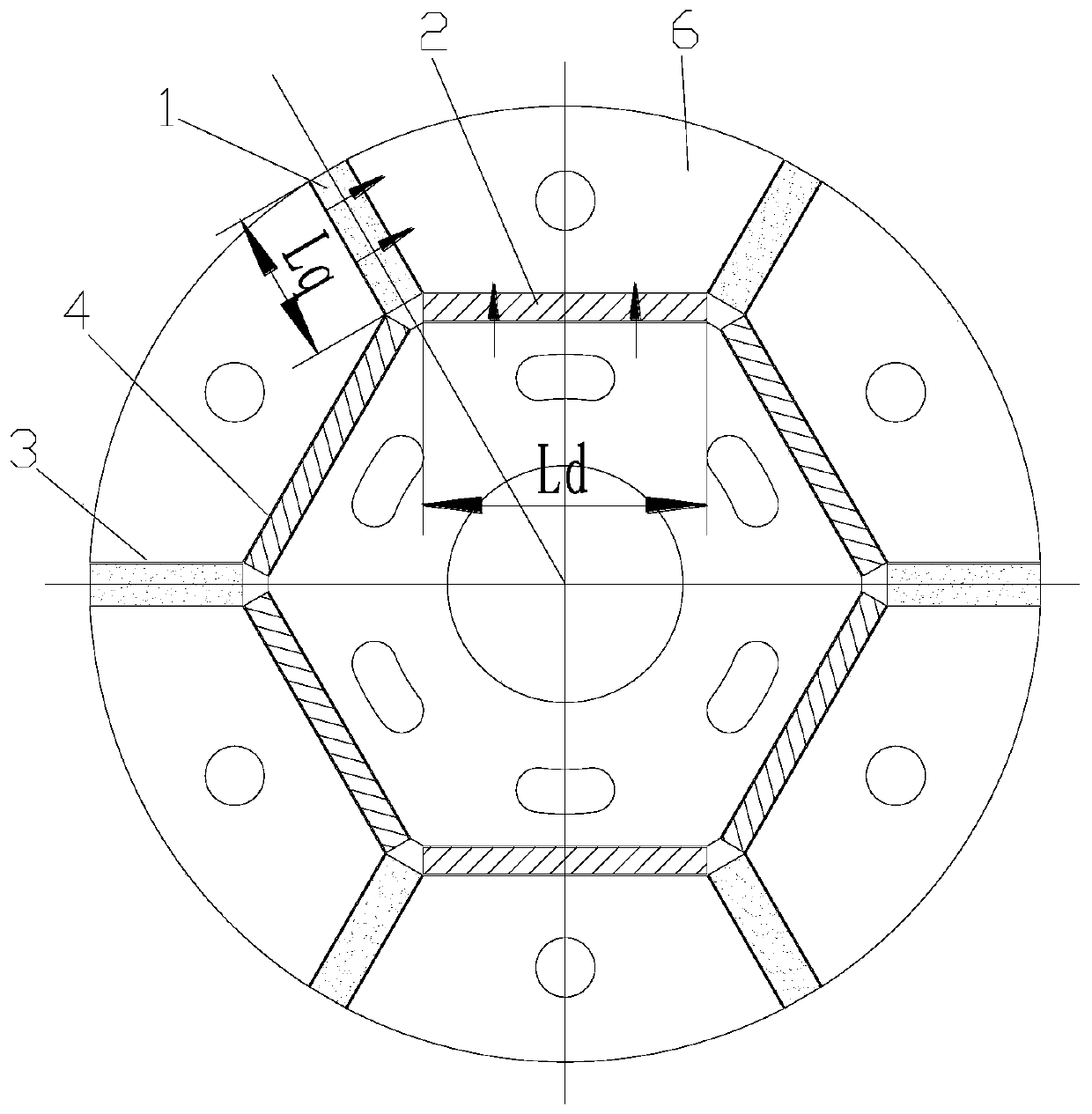

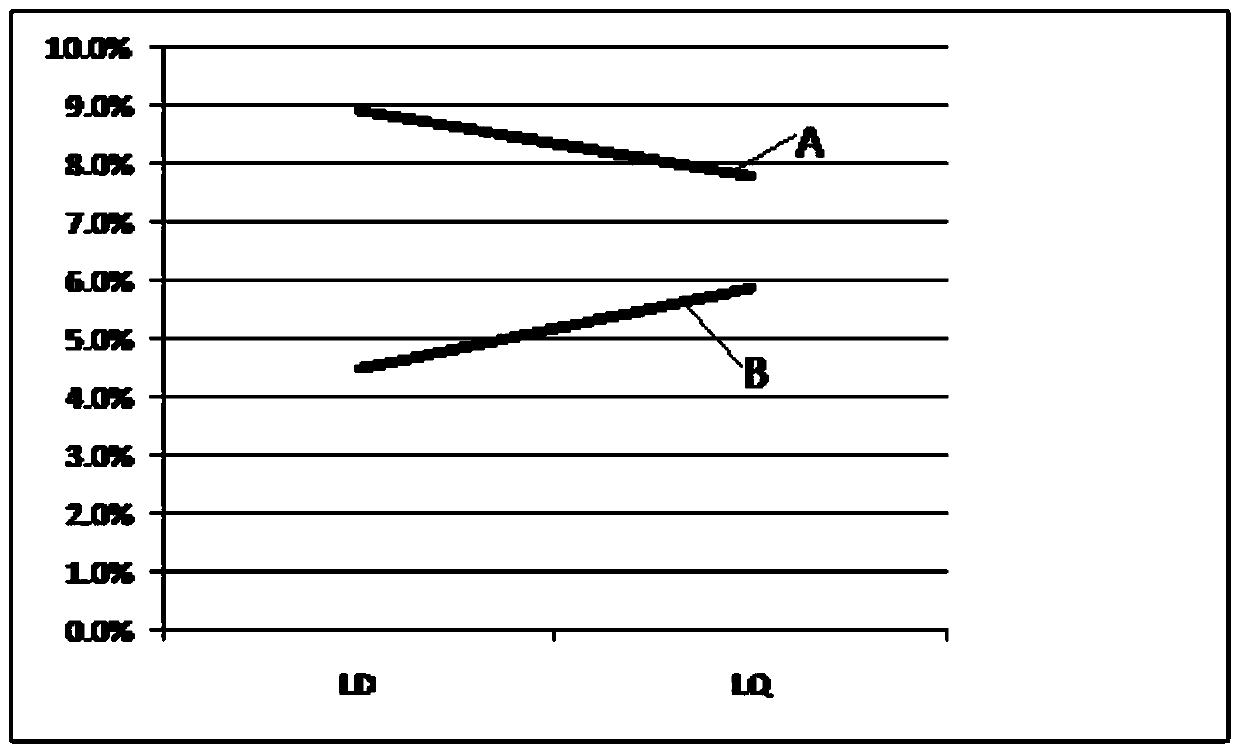

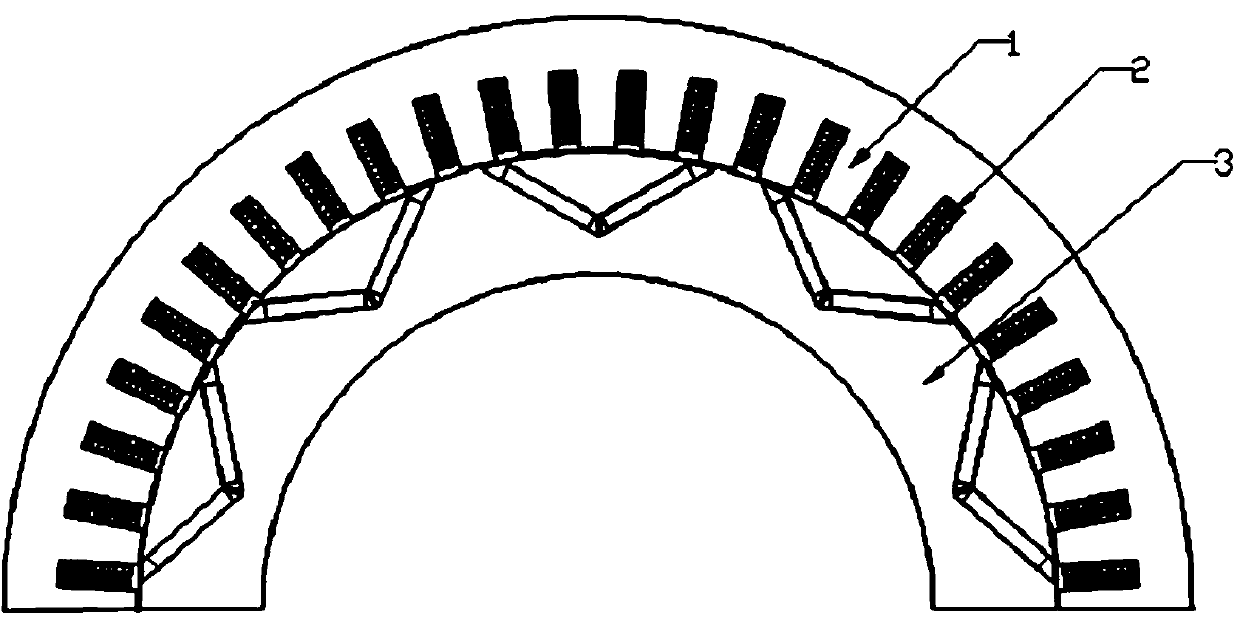

Double-layer V-shaped built-in permanent magnet motor rotor for electric automobile

InactiveCN103280904AImproved air gap magnetic field waveformImprove resultant torque rippleSynchronous machine detailsMagnetic circuit rotating partsConstant powerMagnet

The invention relates to a double-layer V-shaped built-in permanent magnet motor rotor for an electric automobile. Multiple groups of permanent magnet slots which are radially arranged in an inner layer and an outer layer are uniformly arranged on the iron core of the rotor at intervals along the circumferential direction; one or more V-shaped magnetized stripy magnetic steel is embedded in each permanent magnet slot. By virtue of the optimization of structures such as the angle of polar arc of inner-layer V-shaped magnetic steel, the included angle of outer-layer V-shaped magnetic steel, the width proportion of the inner-layer magnetic steel to the outer-layer V-shaped magnetic steel and the included angle of the outer-layer forcipated permanent magnet slot and the outer-layer magnetic steel, the air-gap flux density waveform is more approximate to the sinusoidal distribution, the harmonic component is reduced, the air-gap field waveform of the motor is improved, the fundamental wave frequency of spline torque fluctuation is improved, the spline fundamental wave and the ultraharmonics torque amplitude value are reduced, the torque fluctuation caused by splines is reduced, and the synthesis torque fluctuation of the motor is greatly reduced; and meanwhile, the reluctance torque is obviously increased, the salient pole rate and flux weakening speed expanding capability of the motor are improved, a constant-power speed range wider than that of a surface-mounted permanent magnet motor can be obtained, and the driving requirement of electric and hybrid automobiles can be met.

Owner:苏州和鑫电气股份有限公司

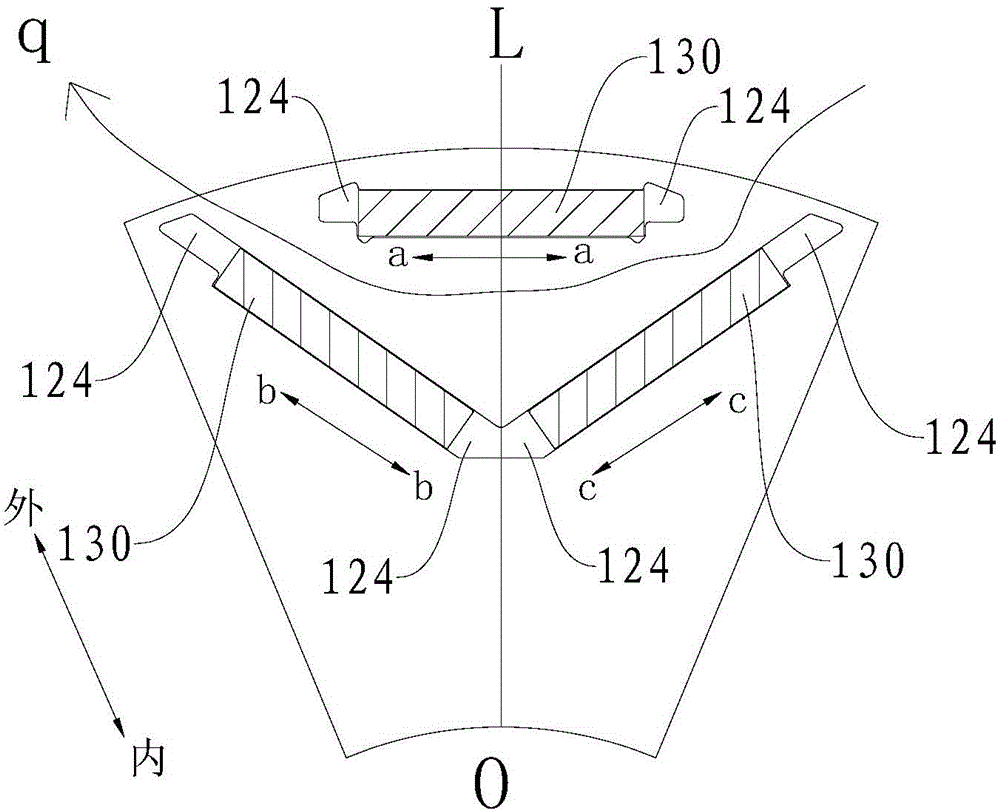

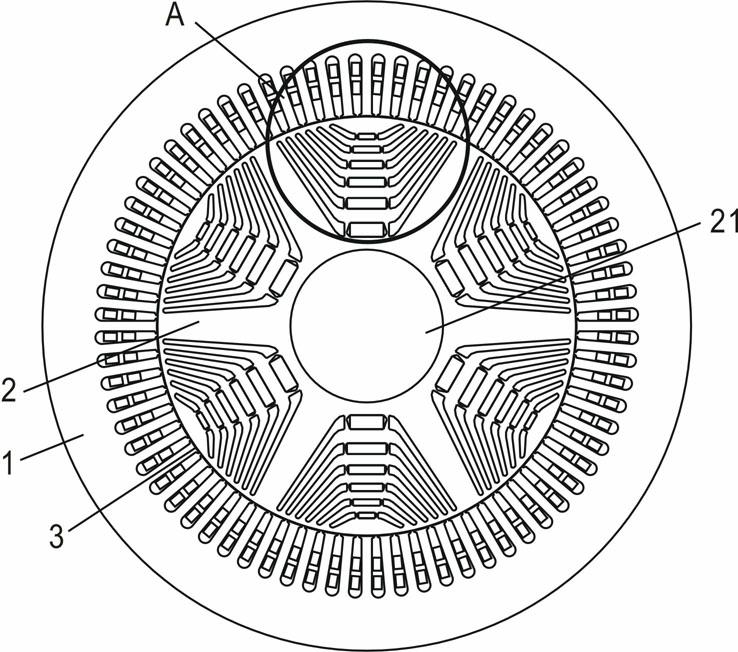

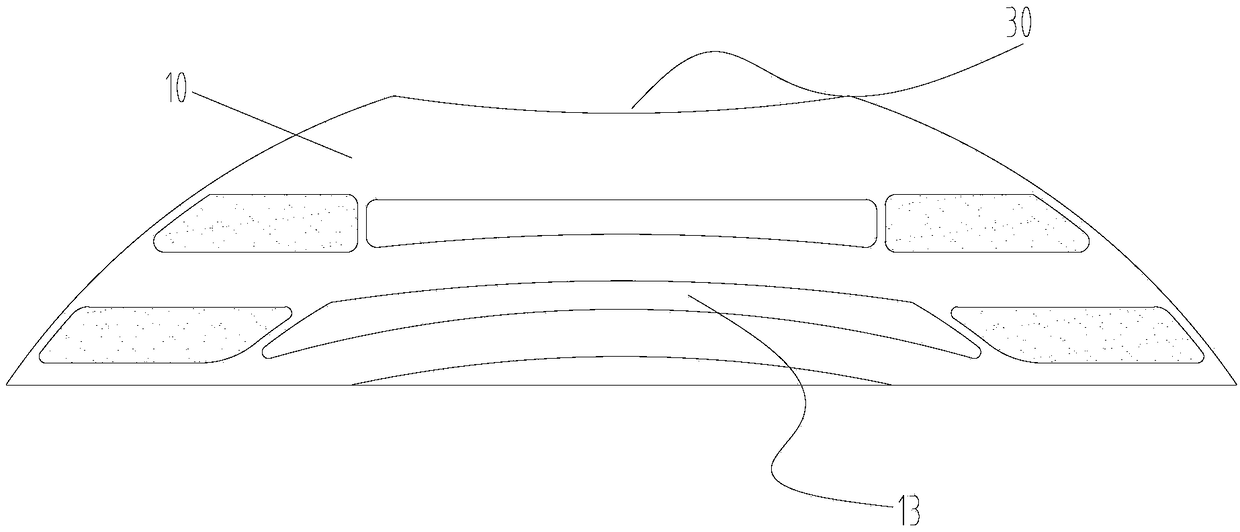

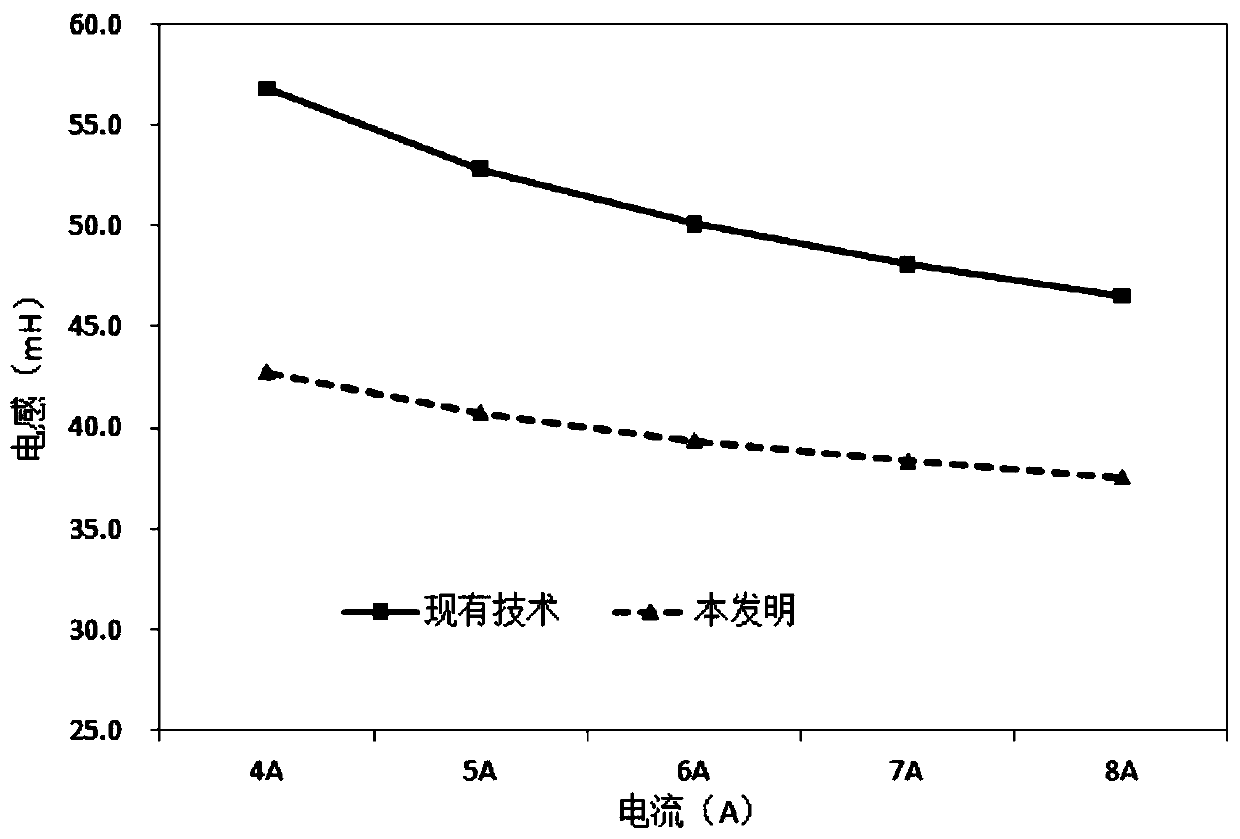

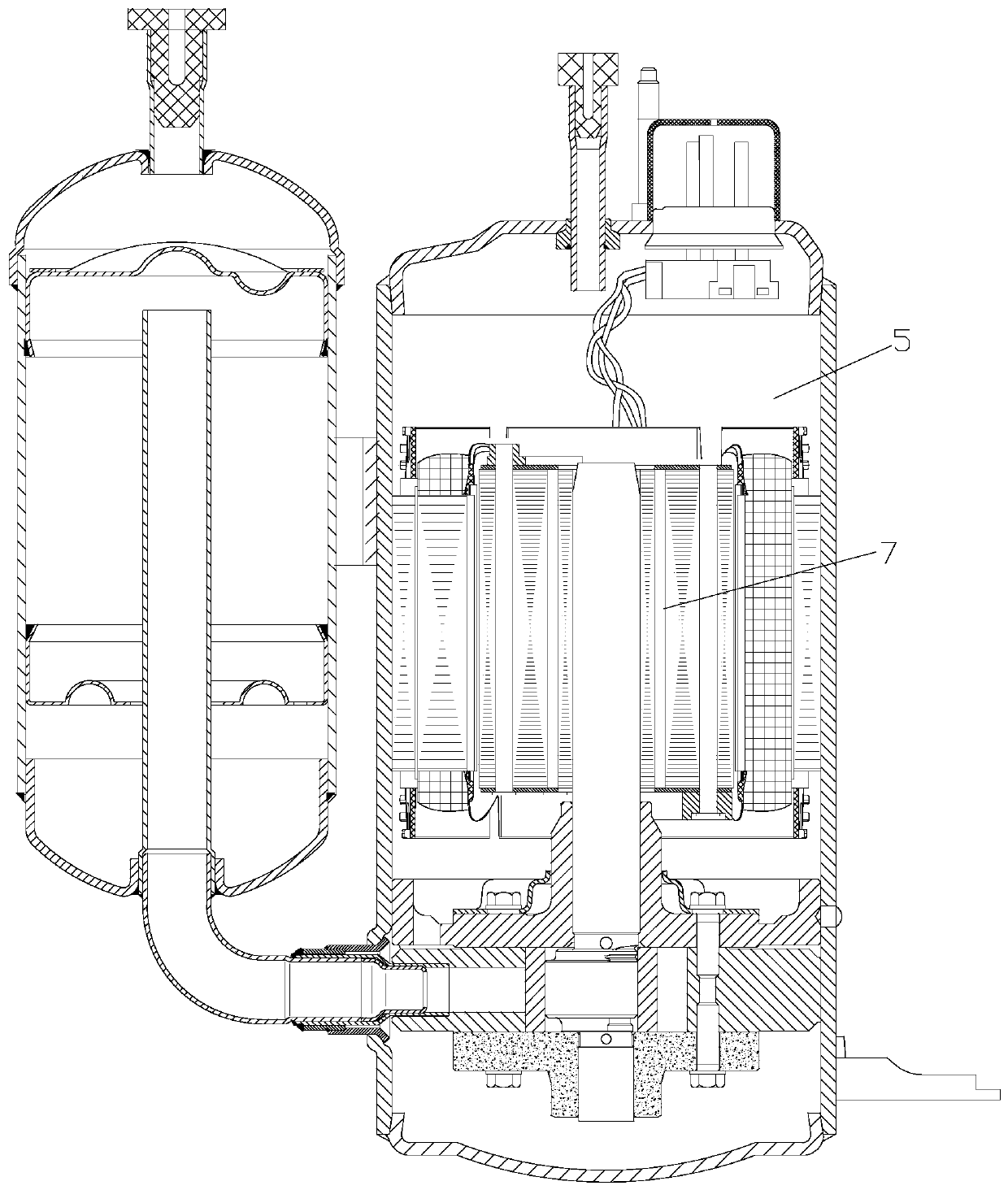

Permanent-magnet synchronous motor and compressor with same

InactiveCN104600939AIncrease the q-axis inductanceLarge reluctance torqueMagnetic circuit rotating partsPiston pumpsSynchronous motorPermanent magnet synchronous motor

The invention discloses a permanent-magnet synchronous motor and a compressor with the same. The permanent-magnet synchronous motor comprises a stator and a rotor arranged inside the stator, the rotor is provided with a plurality of groups of magnet grooves distributed circumferentially, each group of magnet grooves comprises an outer groove and an inner groove, and on the cross section of the rotor, the outer grooves extend along the circumferential direction of the rotor, and the V-shaped inner grooves are positioned on the radial inner sides of the outer grooves. The permanent-magnet synchronous motor has the advantages that the rotor is provided with the outer grooves extending along the circumferential direction of the rotor, and the V-shaped inner grooves positioned on the radial inner sides of the outer grooves, so that q-axis inductance of the motor can be enhanced effectively, a difference value between the q-axis inductance and d-axis inductance is further increased, and reluctance torque of the permanent-magnet synchronous motor can be increased.

Owner:GUANGDONG MEIZHI COMPRESSOR +1

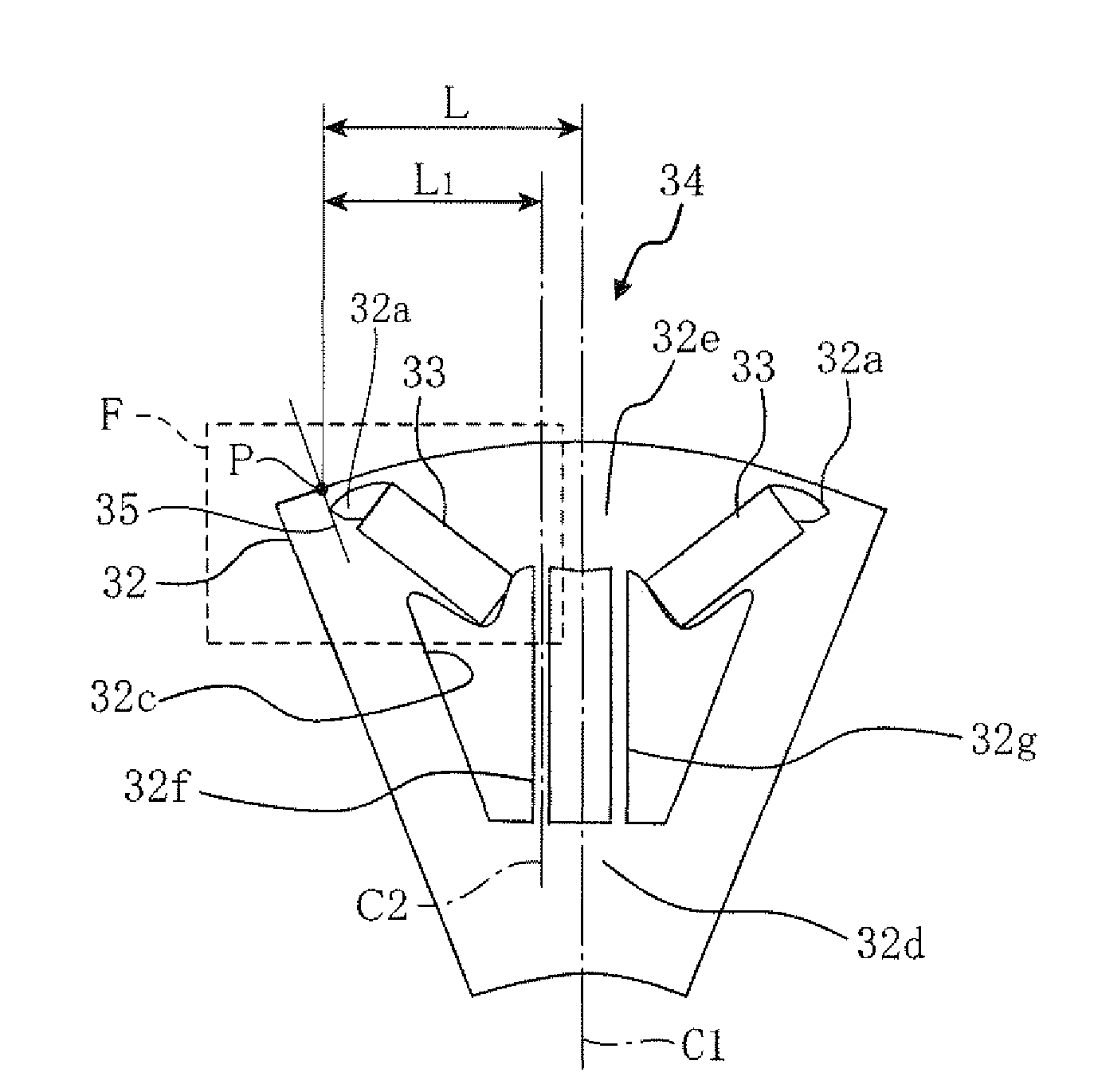

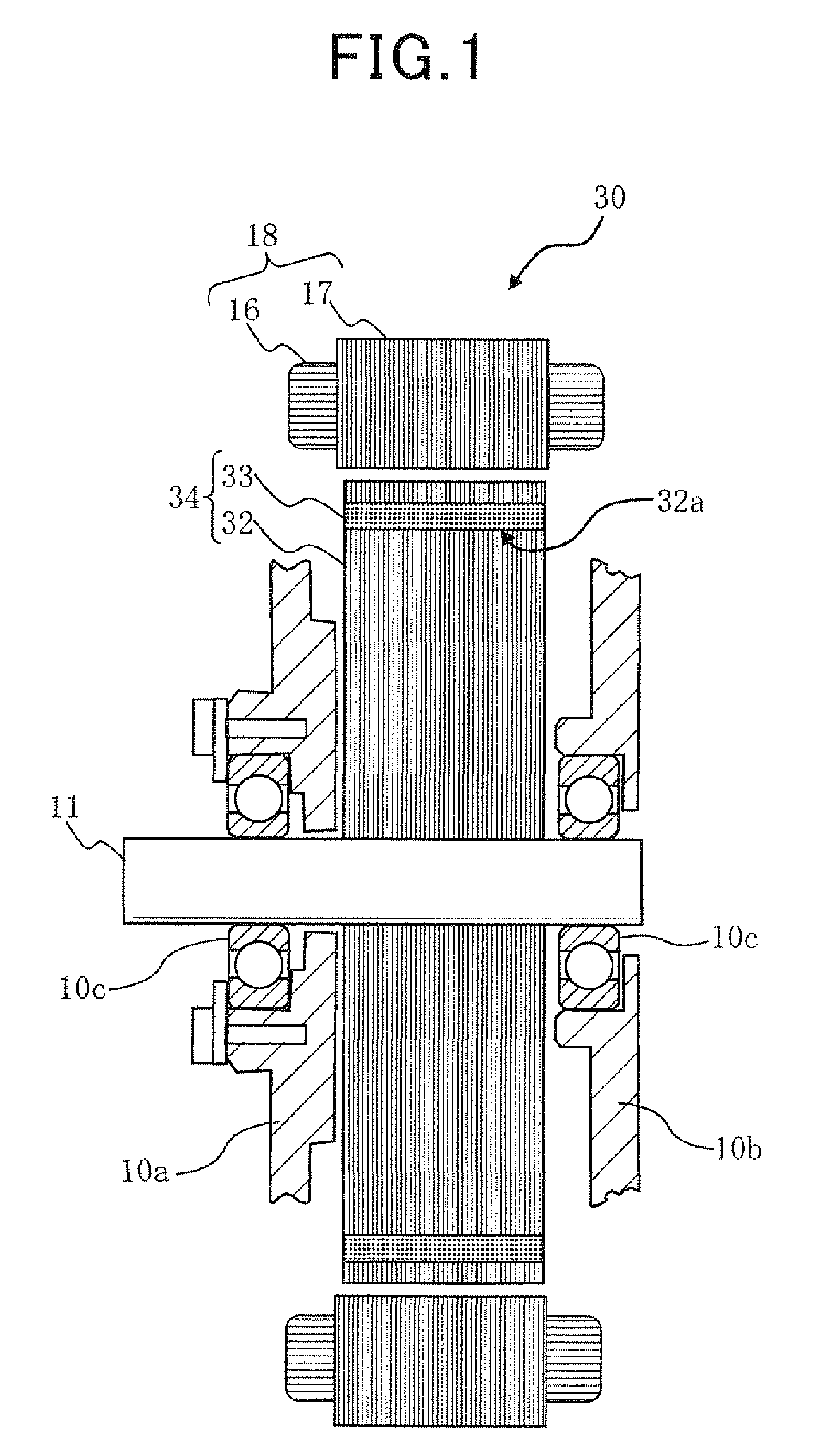

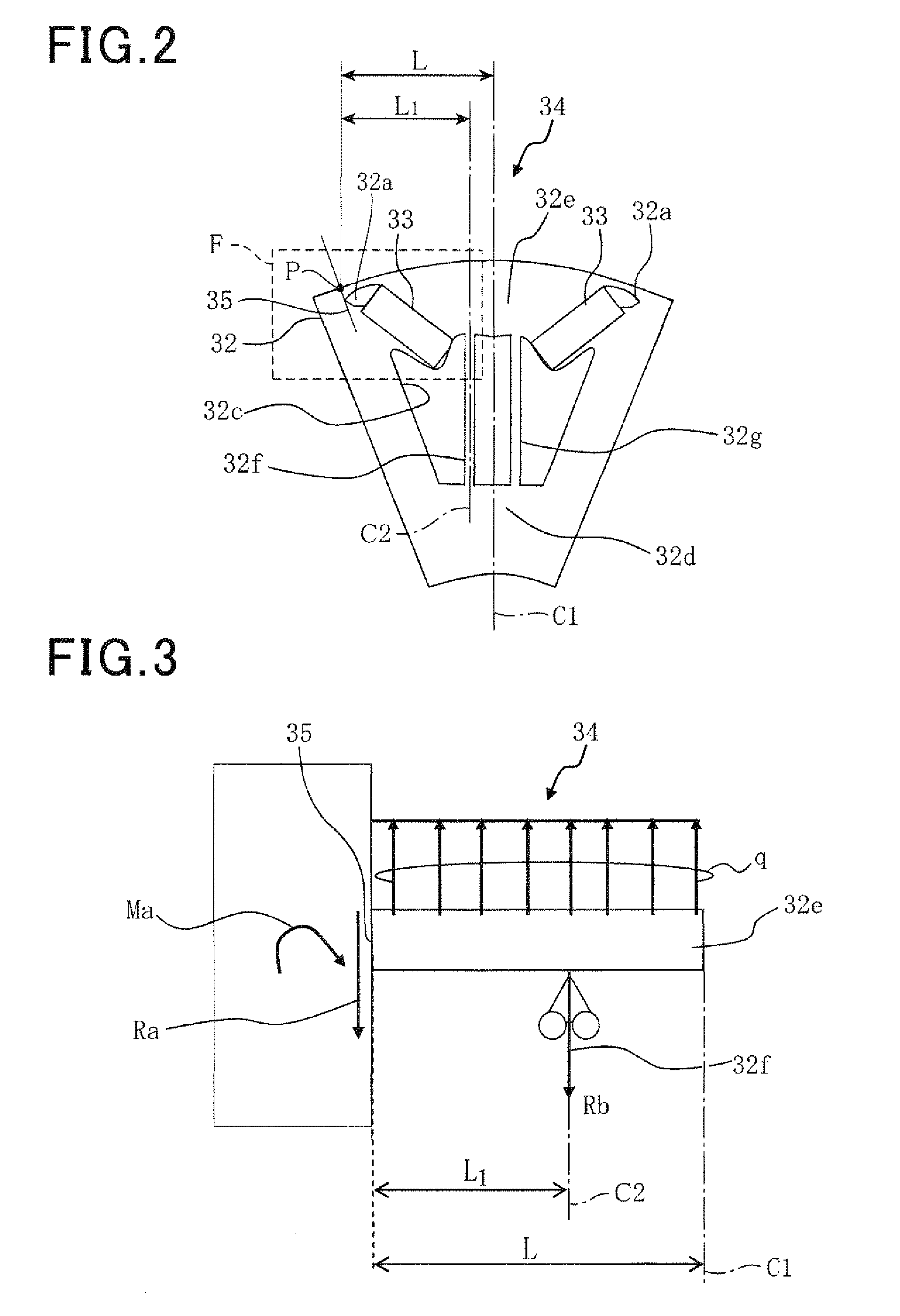

Rotor for electric rotating machine

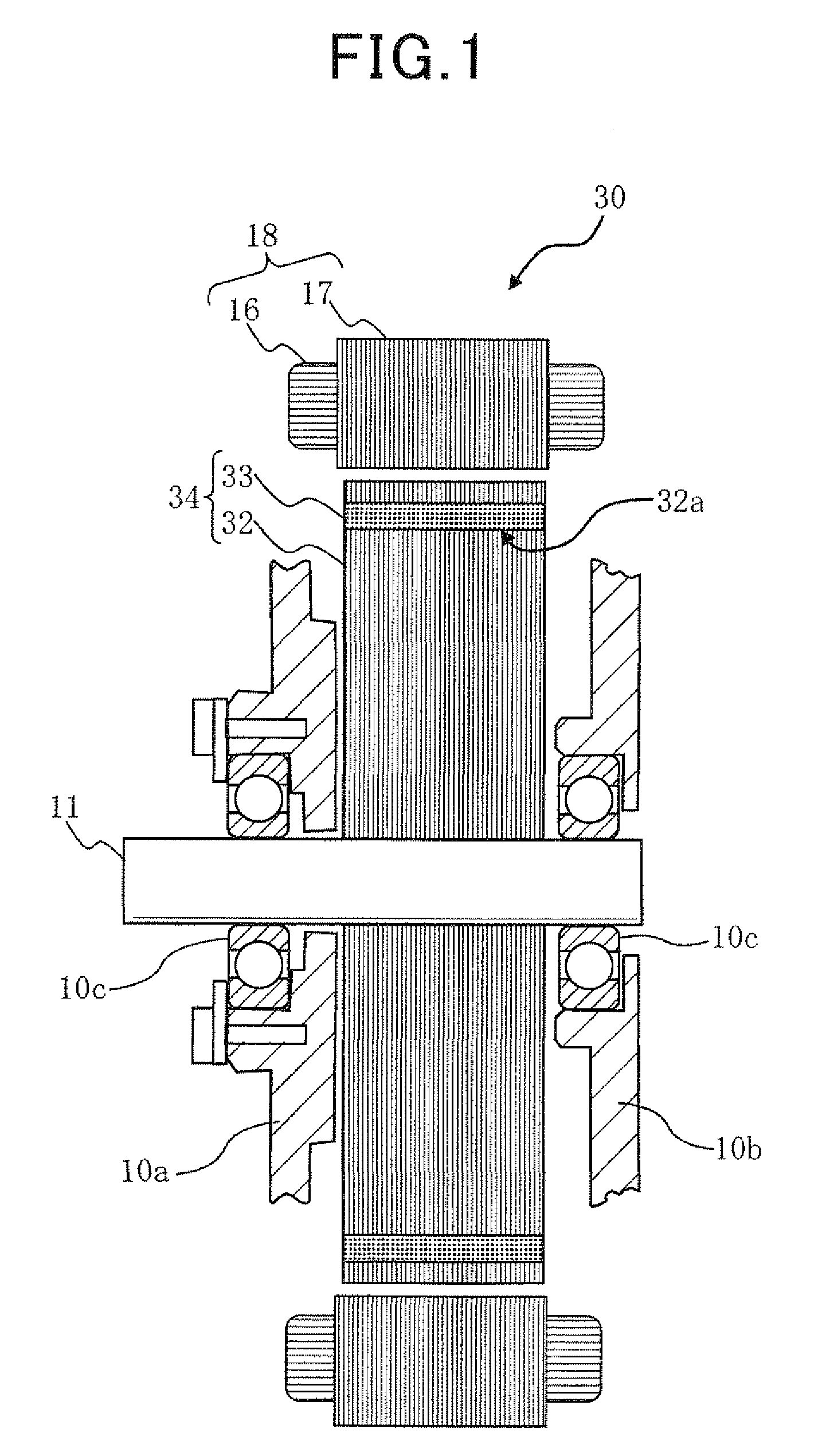

ActiveUS20110278977A1Reduce magnetic flux leakageMagnetic reluctanceMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsEngineeringMagnetic poles

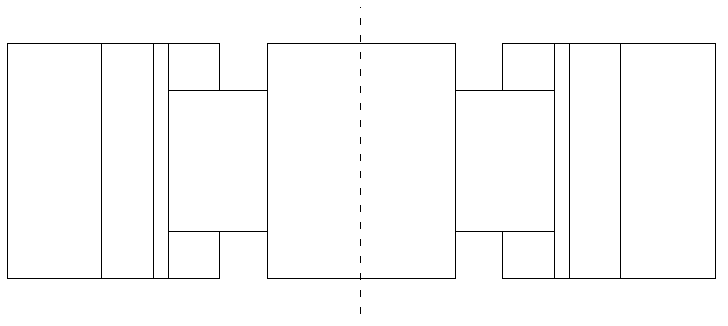

A rotor includes a hollow cylindrical rotor core and permanent magnets embedded in the rotor core to form a plurality of magnetic poles on the radially outer periphery of the rotor core. The rotor core has a plurality of openings each of which extends in the axial direction of the rotor core so as to penetrate it. When viewed along the axial direction, each of the openings is symmetrically positioned with respect to the centerline of a corresponding one of the magnetic poles. For each of the openings, there are provided n reinforcing portions, where n is an integer not less than 2. The n reinforcing portions extend to connect a pair of radially-inner and radially-outer peripheral portions of the rotor core, thereby partitioning the opening into (n+1) parts. The n reinforcing portions are symmetrically arranged with respect to the centerline of the corresponding magnetic pole.

Owner:DENSO CORP

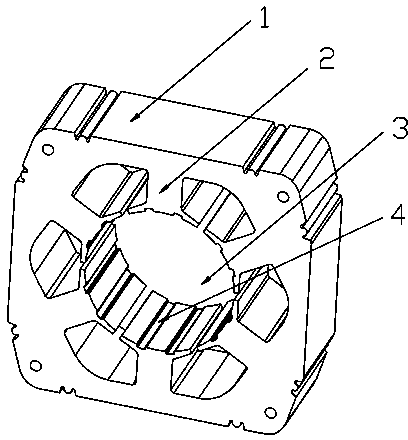

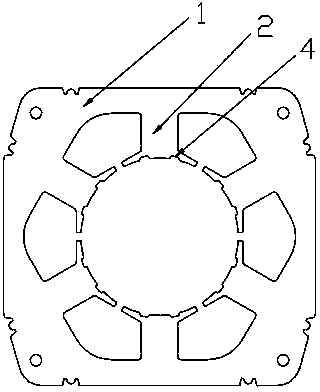

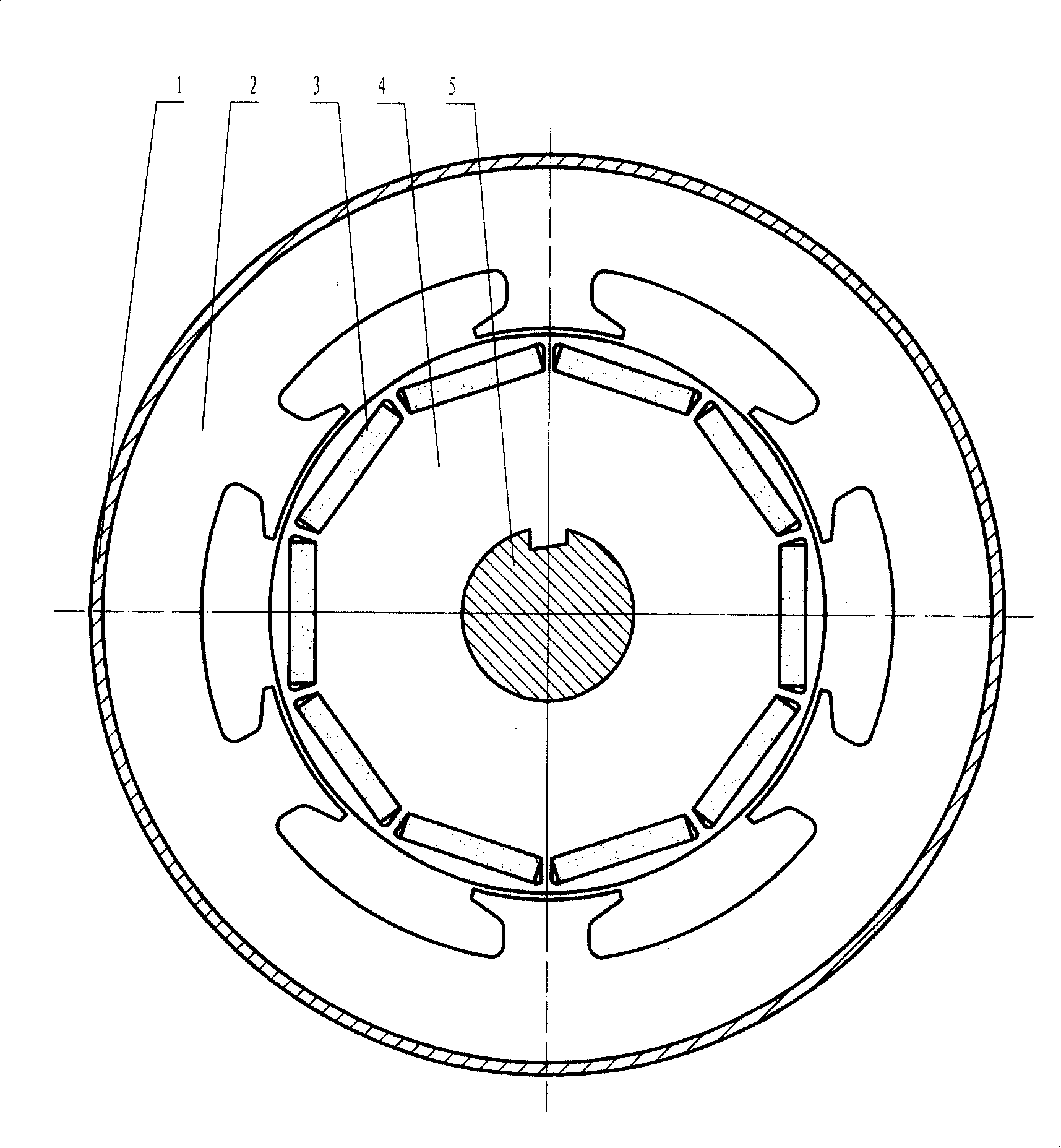

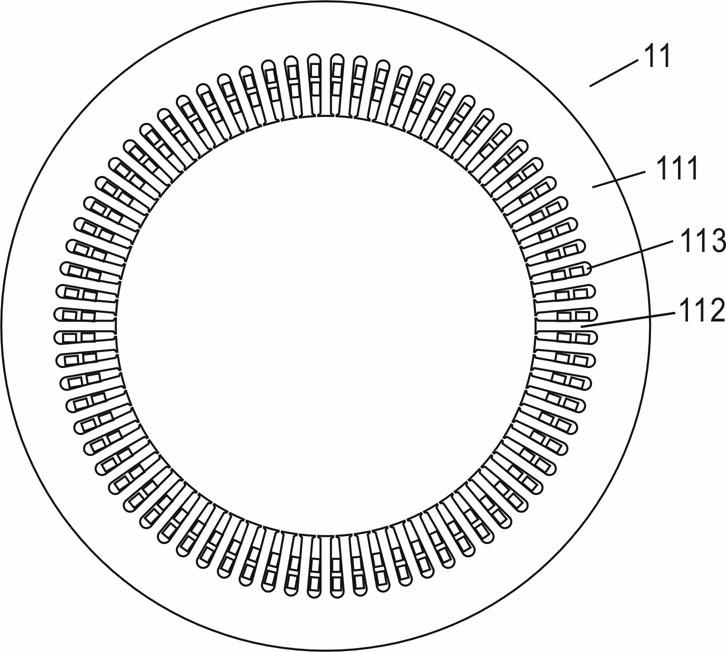

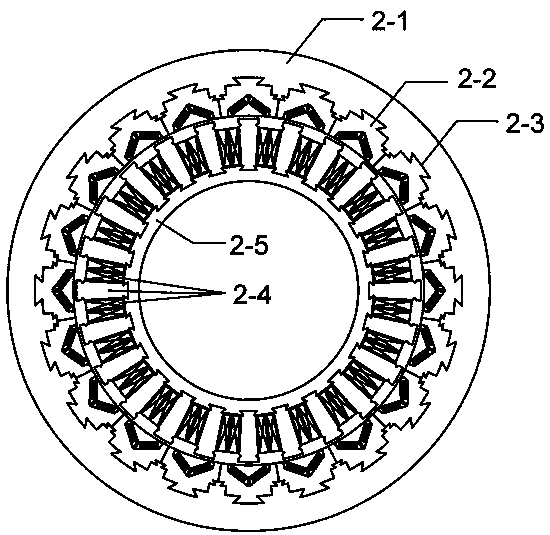

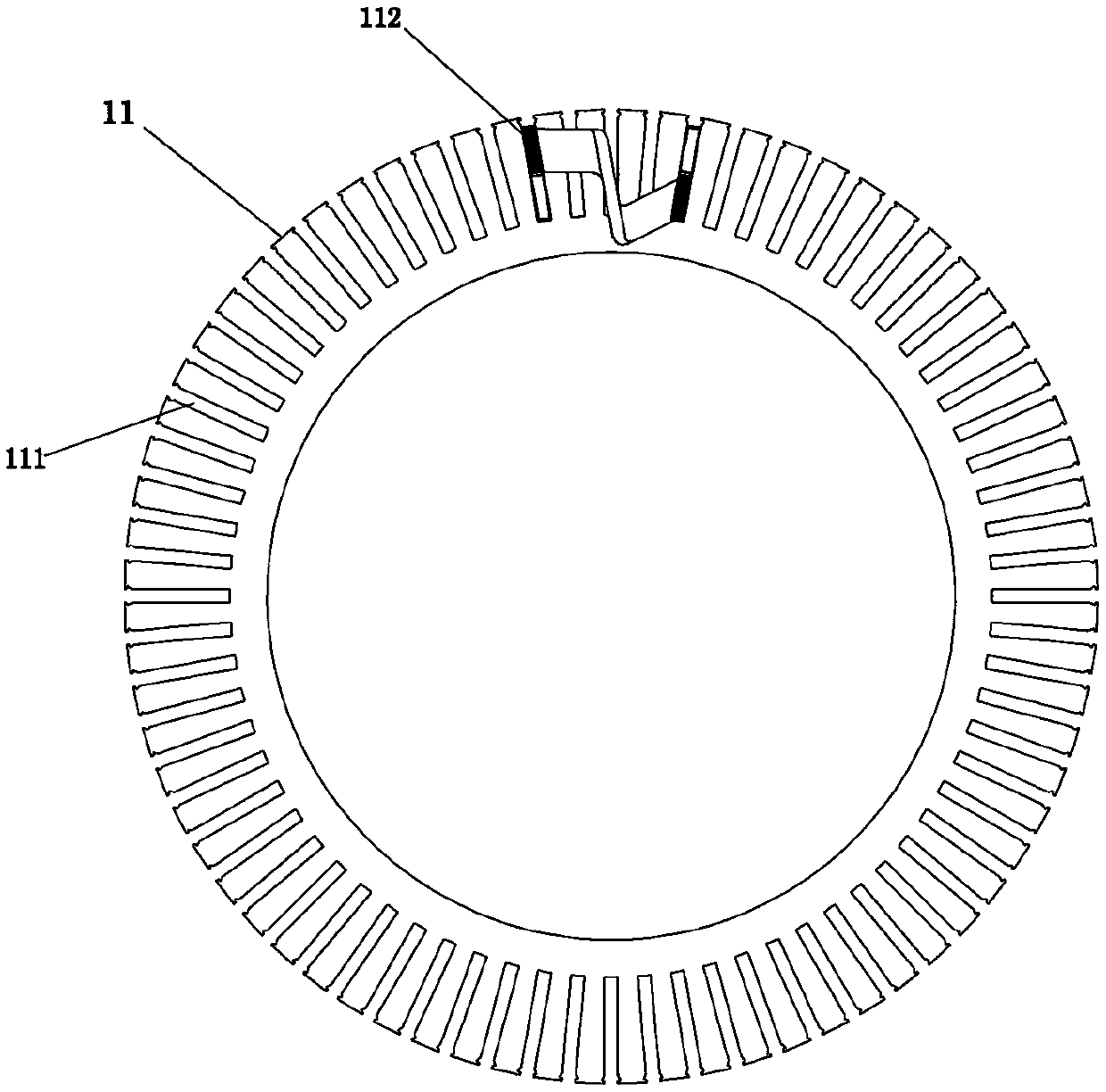

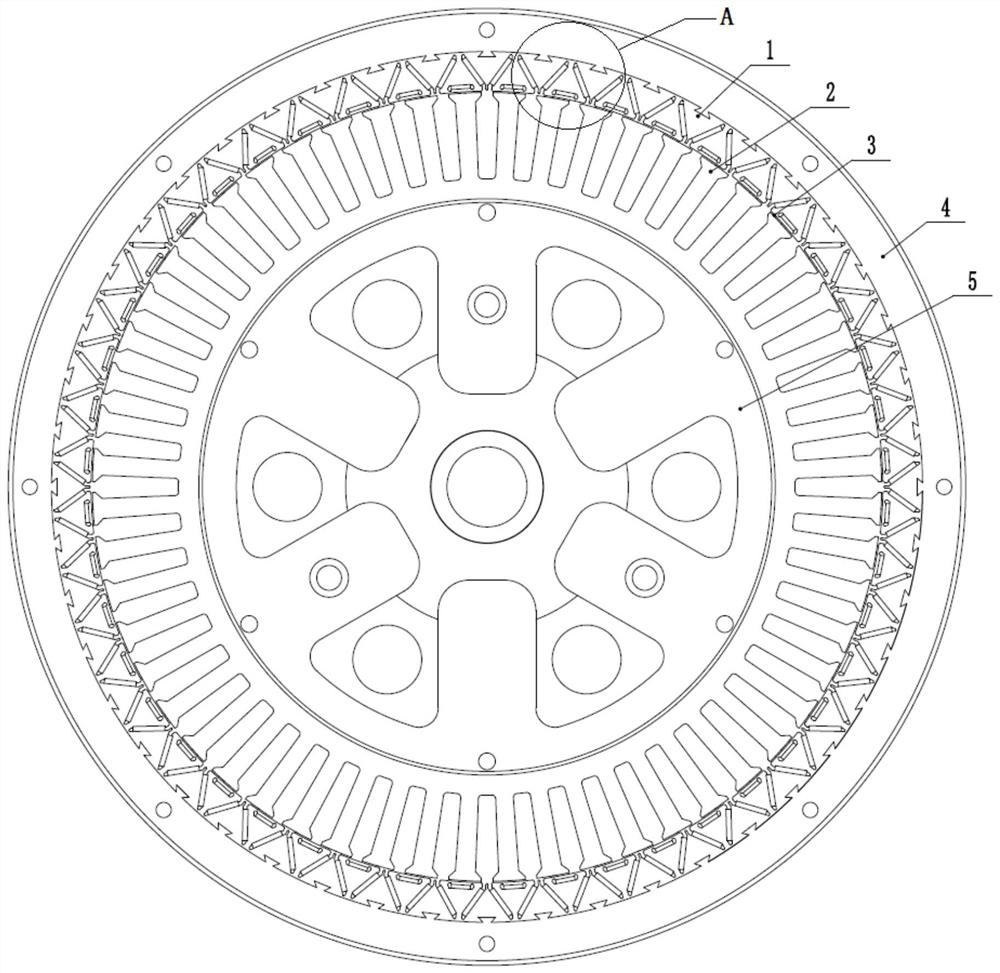

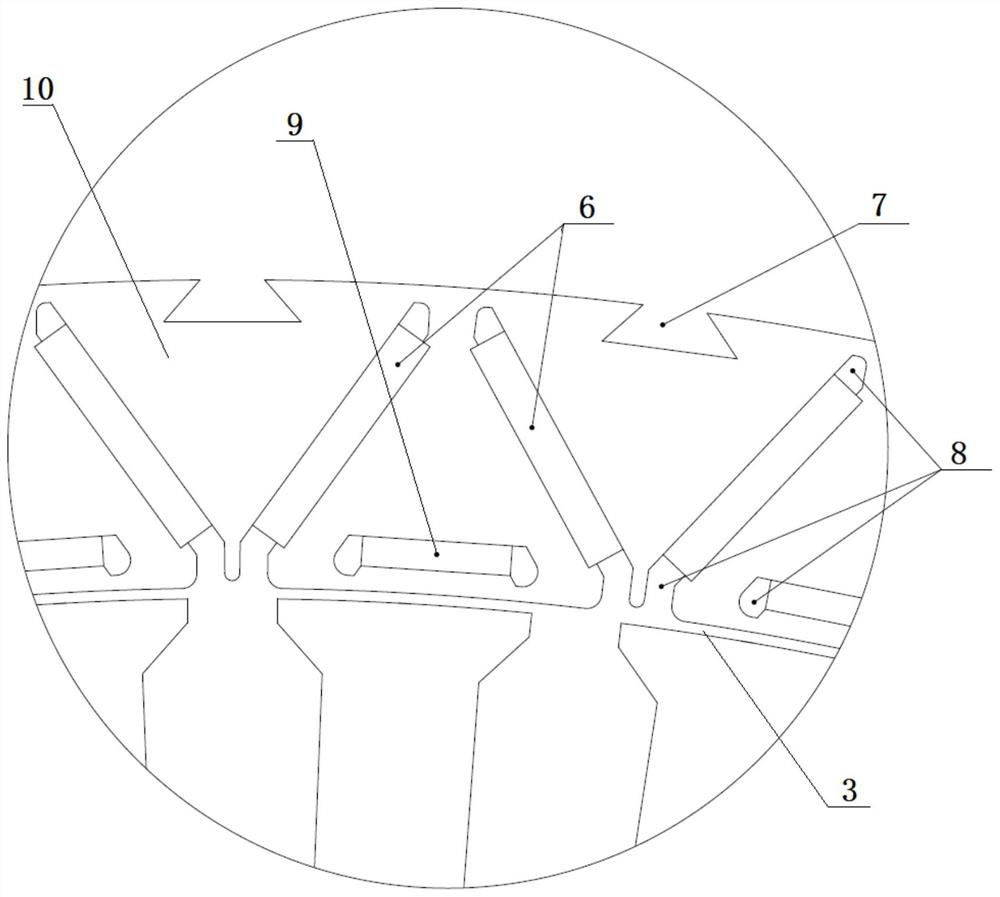

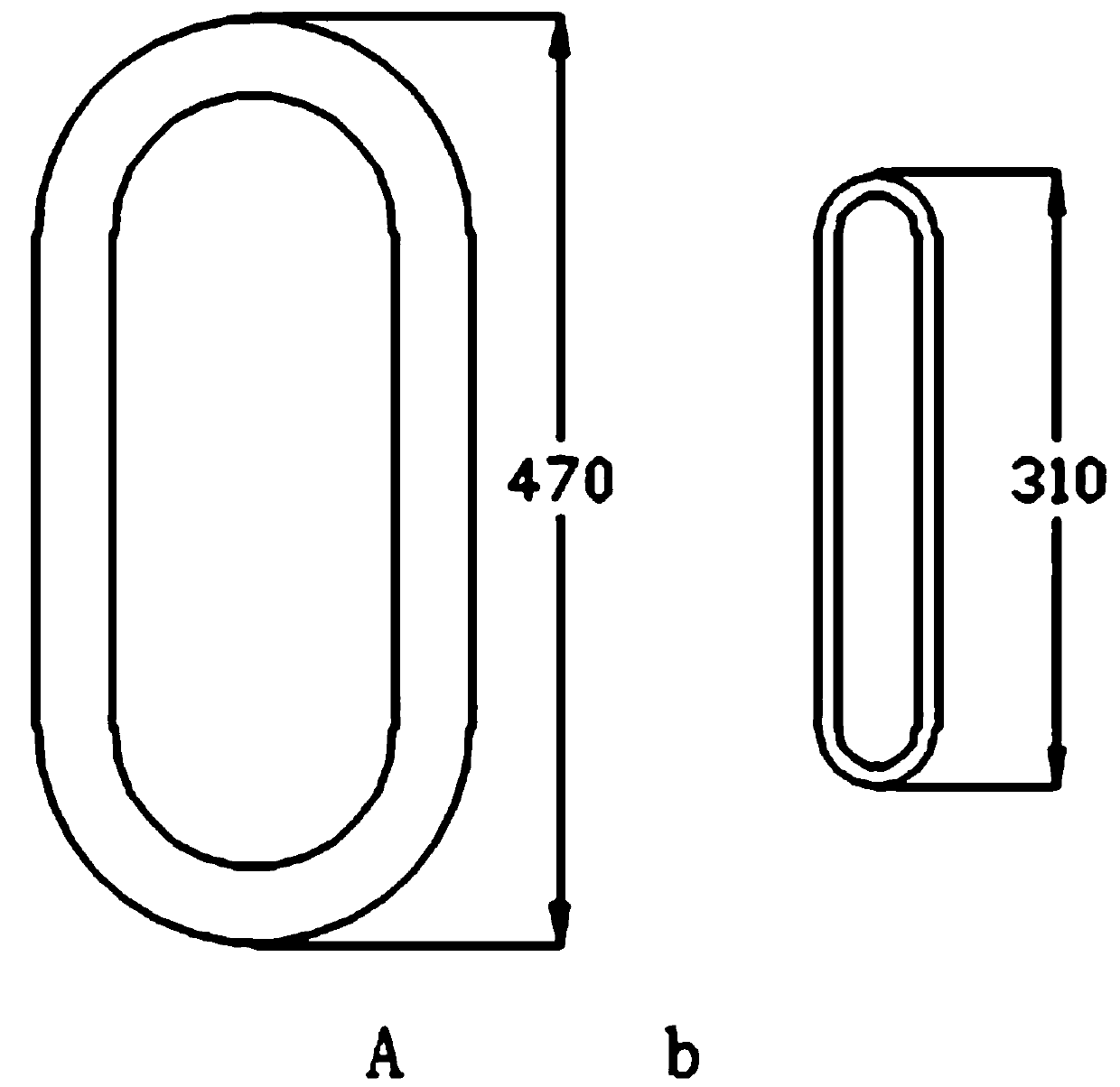

Stator used in brushless direct current motor and used for reducing fundamental wave cogging torque

InactiveCN103956838AImprove reliabilityEasy to controlMagnetic circuit stationary partsConductor CoilSilicon

The invention relates to the technical field of motors, in particular to a stator used in a brushless direct current motor and used for reducing fundamental wave cogging torque. The stator is provided with a stator iron core formed by overlaying a plurality of pieces of stamped silicon steel. A winding is arranged on the iron core, a center hole is formed in the stator iron core, and a plurality of crown structures are arranged around the center hole. The stator is characterized in that at least one axial groove is formed in the arc end face of each crown. According to the stator used in the brushless direct current motor and used for reducing the fundamental wave cogging torque, the fundamental wave cogging torque is effectively reduced, the motor power is improved, the motor is convenient to start, and low in vibration and noise, and the stator is mainly applicable to the improvement of the brushless direct current motor.

Owner:HUANGSHI DONGBEI ELECTRICAL APPLIANCE

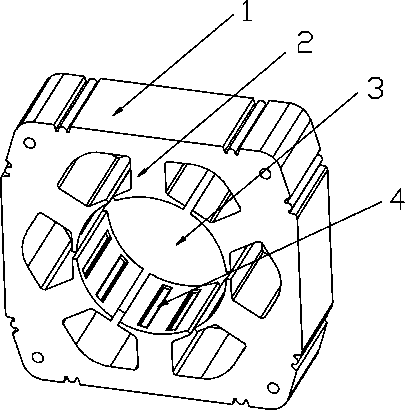

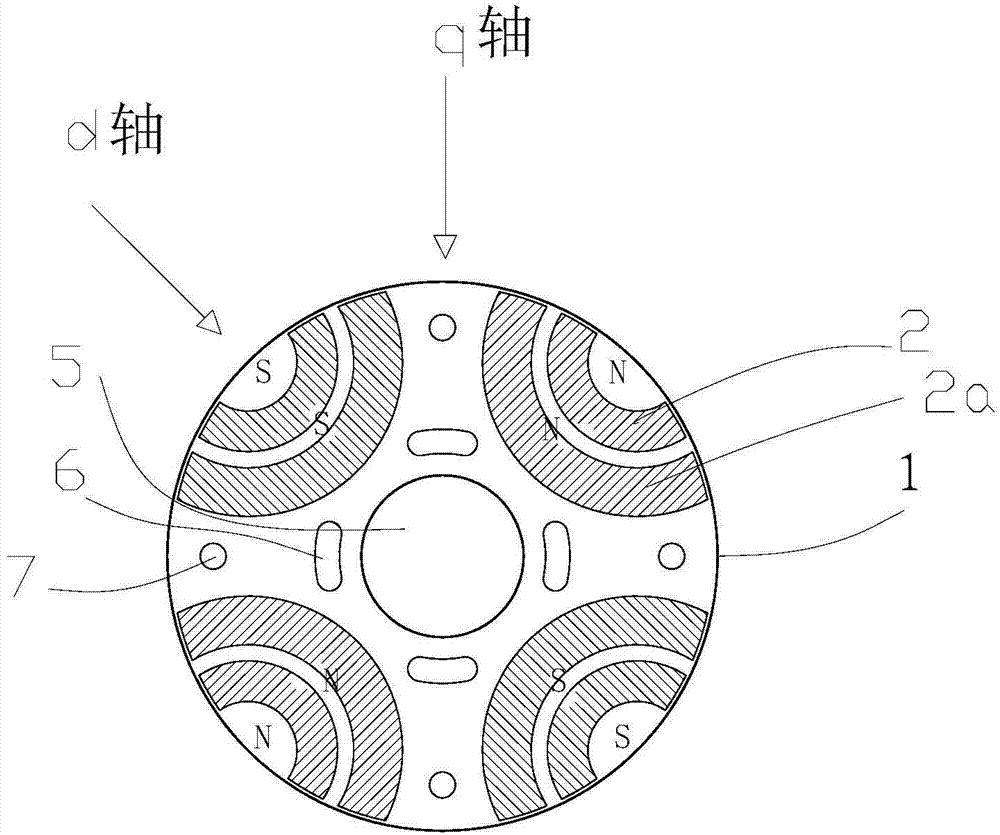

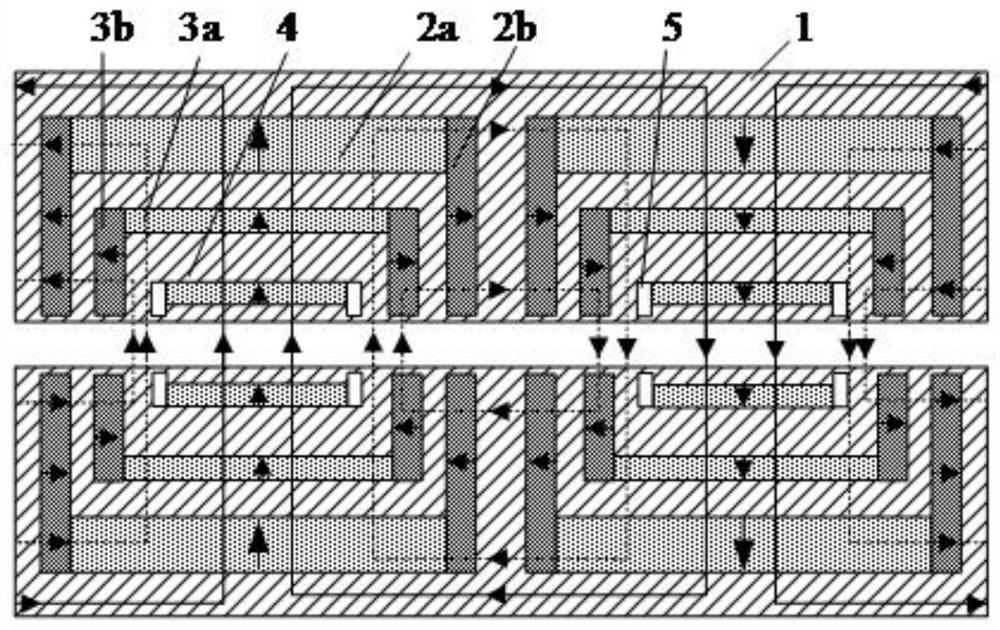

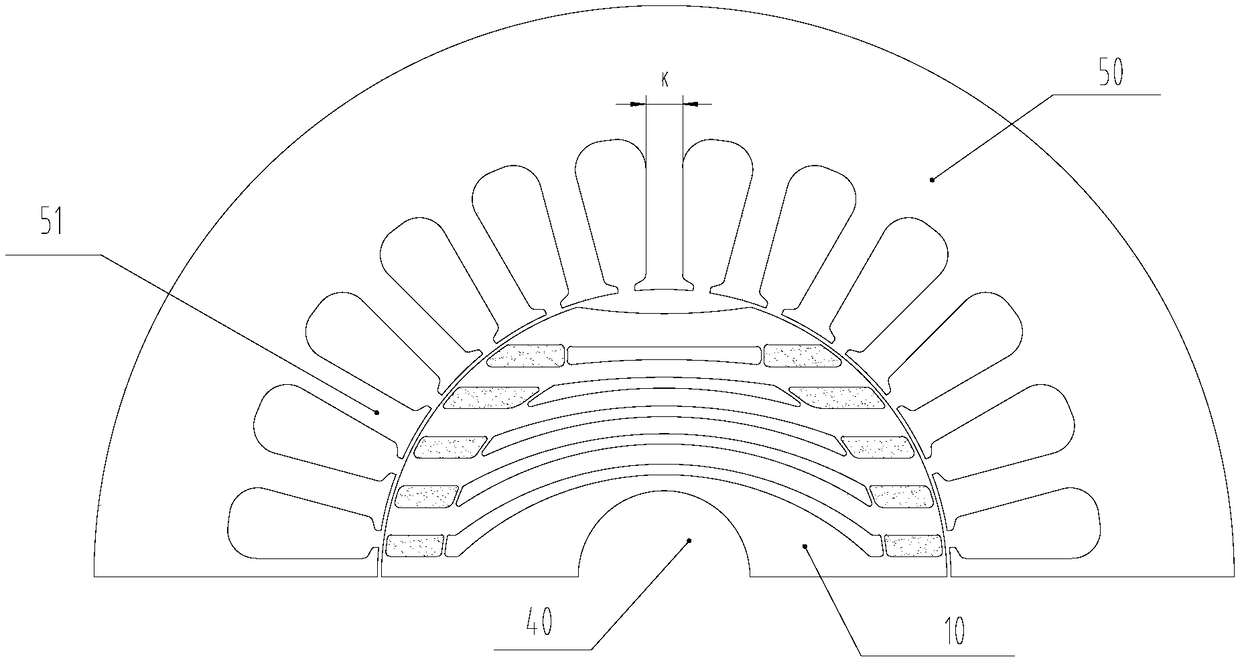

Rotor structure, asynchronous starting synchronous reluctance motor and compressor

InactiveCN108011459ALarge reluctance torqueIncrease output torqueMagnetic circuit rotating partsSynchronous motorsSynchronous reluctance motorElectric machine

The invention provides a rotor structure, an asynchronous starting synchronous reluctance motor and a compressor. The rotor structure comprises a rotor body; multiple accommodating grooves are formedin the rotor body; the multiple accommodating grooves are formed in the circumferential direction of the rotor body at intervals; the accommodating grooves extend in the q-axis direction; a first magnetic flux channel is formed between adjacent two accommodating grooves; the magnetic flux direction of the first magnetic flux channel is parallel to the q-axis direction; and the magnetic flux direction of the first magnetic flux channel is perpendicular to the d-axis direction. By enabling the accommodating grooves to be arranged in the q-axis direction, the q-axis magnetic flux can be in barrier-free circulation, so that the magnetic flux difference between the d-axis and the q-axis can be improved effectively, thereby enabling the motor with the rotor structure to generate higher reluctance torque, improving the output torque and efficiency of the motor, and further improving motor performance.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

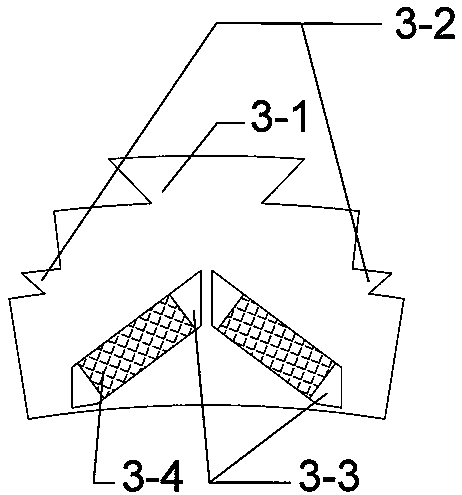

Rotor and permanent magnet motor

PendingCN108711977AReduce mechanical stressReduce Flux LeakageMagnetic circuit rotating partsMagnetic polesPermanent magnet motor

The invention provides a rotor and a permanent magnet motor. The rotor comprises a rotor core, the rotor core comprises a plurality of magnetic poles distributed on the circumferential direction, andeach magnetic pole comprises a first magnetic steel slot; the first magnetic steel slot adopts a center line as a symmetric axis, and the center line is distributed along the radial direction of the rotor core; the first magnetic steel slot comprises an outer wall surface, an inner wall surface and two side wall surfaces, wherein the outer wall surface and the inner wall surfaces are respectivelyplanes and are respectively vertical to the center line; the two side wall surfaces are respectively located at two ends of the first magnetic steel slot and are respectively connected with the outerwall surface and the inner wall surface; each side wall surface is provided with a peak-shaped projection that protrudes toward the outer circumferential surface of the rotor core, and the end part ofthe first magnetic steel slot is located on the inner side of the peak-shaped projection. According to the rotor provided by the invention, the peak-shaped projections are added on the two ends of the first magnetic steel slot to reduce the mechanical stress on the two ends of the first magnetic steel slot during the high-speed running of the rotor while reducing the magnetic flux leakage of therotor core.

Owner:SUZHOU INOSA UNITED POWER SYST CO LTD

Single protrusion permanent magnetic motor scheme

InactiveCN101237167AIncrease the number of effective teethReduced torque ripple at low speedsMagnetic circuit rotating partsManufacturing stator/rotor bodiesPermanent magnet rotorWinding machine

The invention relates to a single salient pole permanent magnet motor scheme, which is characterized in that: a stator keeps a salient pole structure which is often used in a general magnetic resistance motor; permanent magnets are orderly and fully embedded in a rotor core along the circumferential direction of an air gap; a novel motor is formed by similarly changing the stator of the general permanent magnet motor into the salient pole type magnetic resistance stator; by adopting the magnetic biasing theory of a major loop and a tooth socket magnetic biasing type magnetic resistance motor and referring to the permanent magnet rotor structure of the general permanent magnet motor, the single salient pole permanent magnet motor scheme has the characteristics of advanced technique and good manufacturability; moreover, because the invention can make a stator trunking and a notch bigger, thereby facilitating to the winding of a winding machine on the one hand and being capable of adopting the multi-span winding of the magnetic biasing motor on the other hand; as a result, the number of turns of each trunking are reduced times, and the consumption of copper wires is greatly reduced.

Owner:苏州扬名机电有限公司 +1

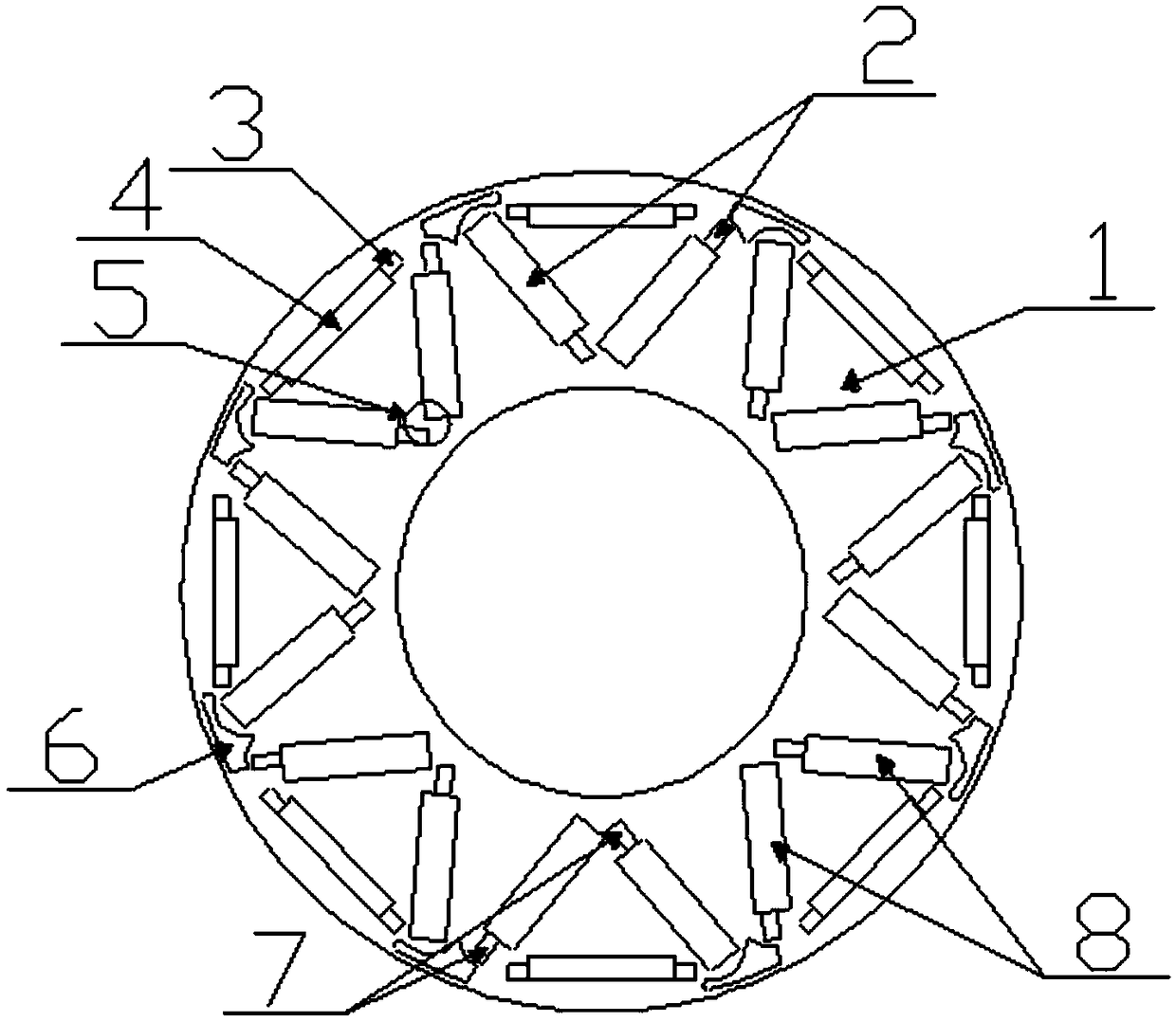

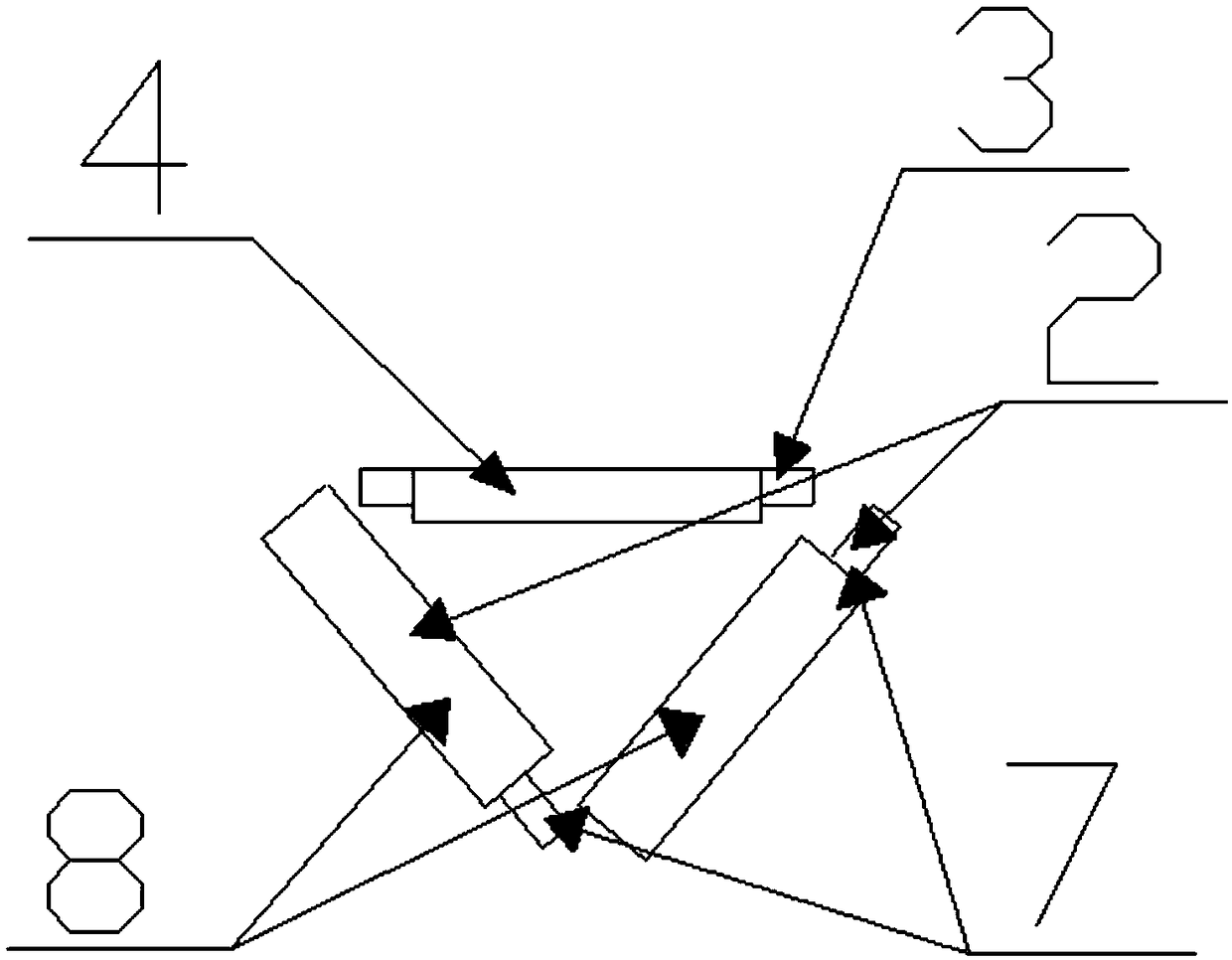

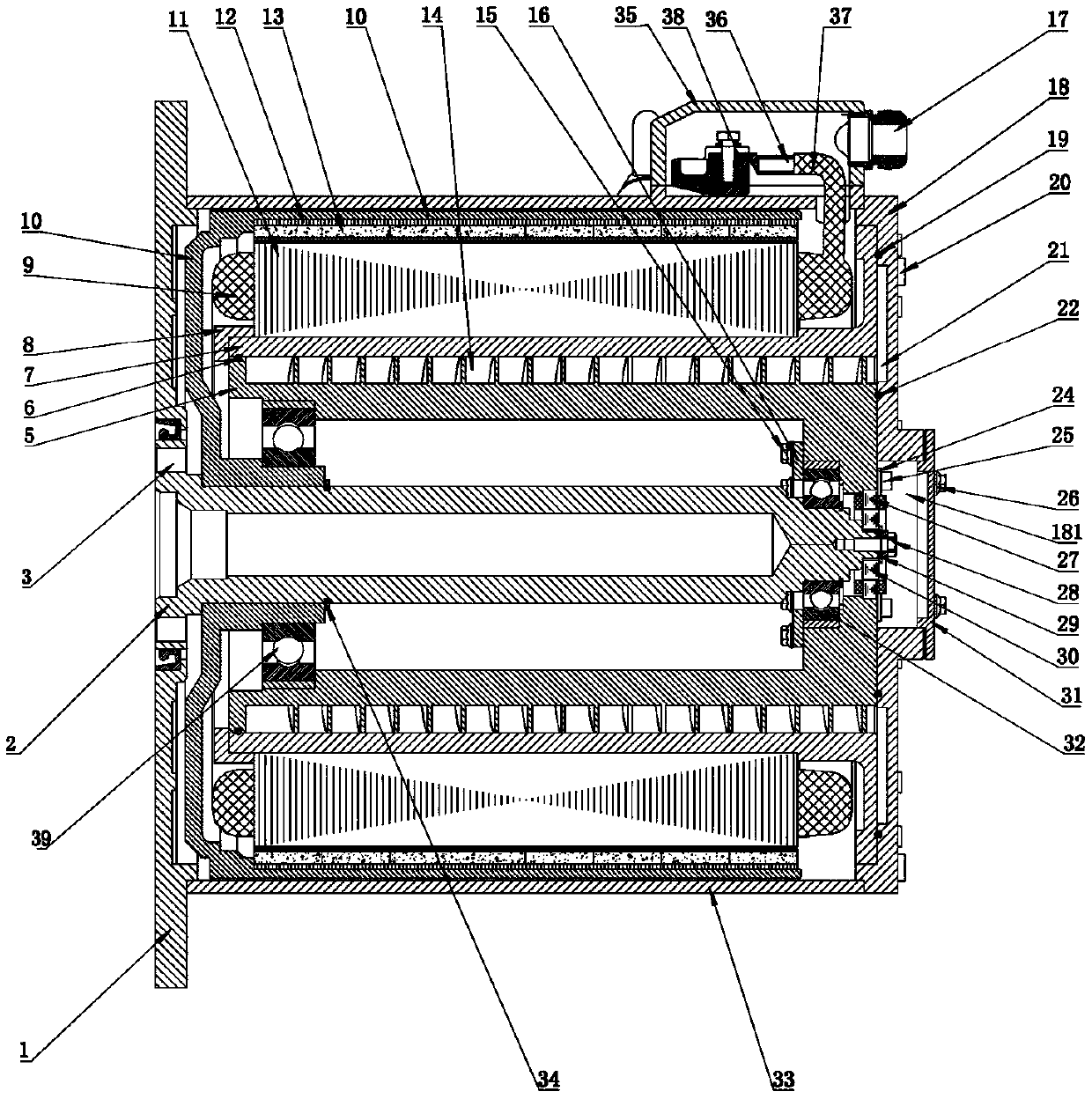

Switched reluctance motor with multidirectional magnetic field characteristic

InactiveCN102412681AIncrease profitImprove power densityDynamo-electric machinesLow speedReluctance motor

The invention provides a switched reluctance motor with a multidirectional magnetic field characteristic. The switched reluctance motor comprises a stator, an intermediate rotor, a left side rotor, a right side rotor, a shaft, and a cable. The intermediate rotor is installed between the left side rotor and the right side rotor. The stator is installed in space formed by the intermediate rotor, the left side rotor and the right side rotor. The shaft passes through an axle hole of the stator, a through hole of the left side rotor and a through hole of the right side rotor, and is connected witha stator iron core. A leading-out terminal of a stator winding is connected with one end of the cable. The other end of the cable is led to external of the motor. The switched reluctance motor has high power density. Utilization rate of the stator winding is high. Output reluctance torque is large, and since full length of the stator winding is fully utilized to energy conversion, on the premise of a same output rotating speed, a motor with structure of the present invention has the advantages of light quality and small volume, and satisfies a requirement of a low speed dragging occasion well.

Owner:HARBIN ENG UNIV

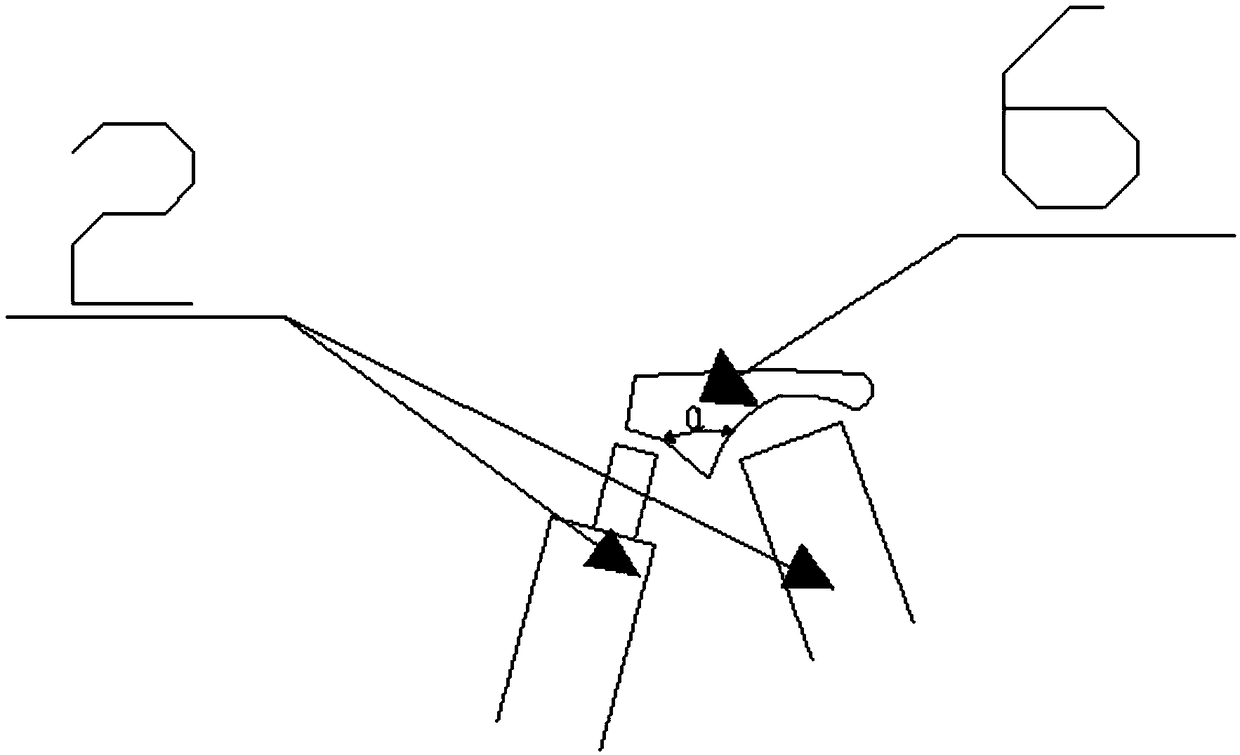

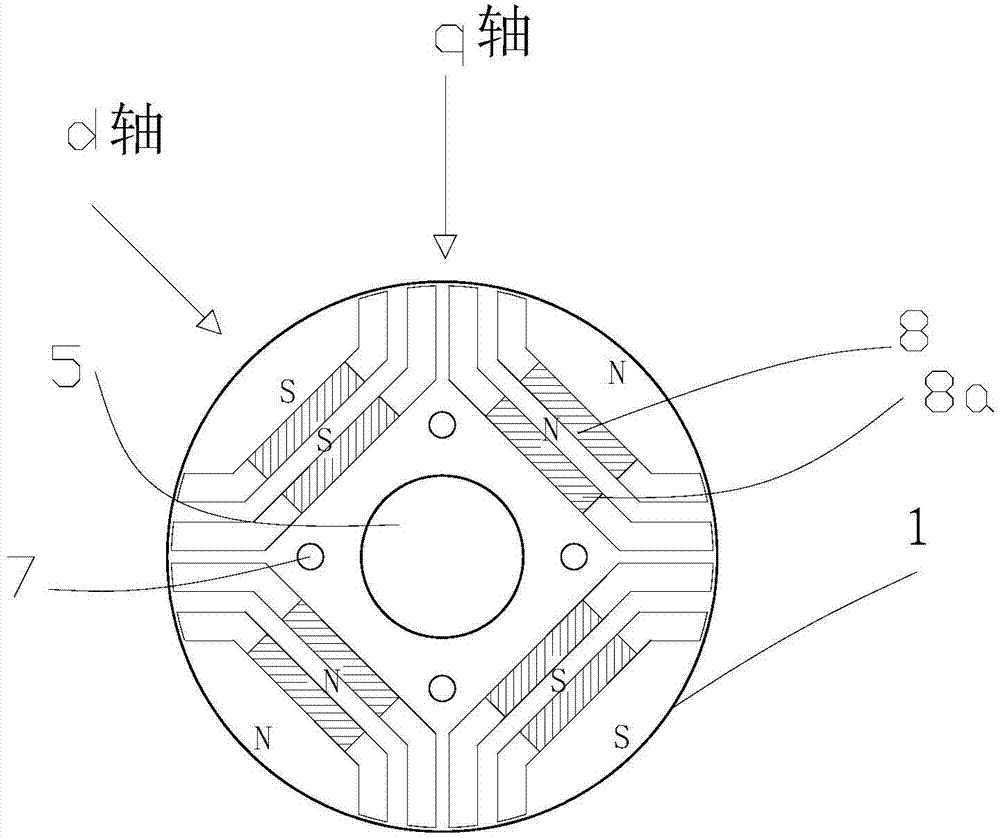

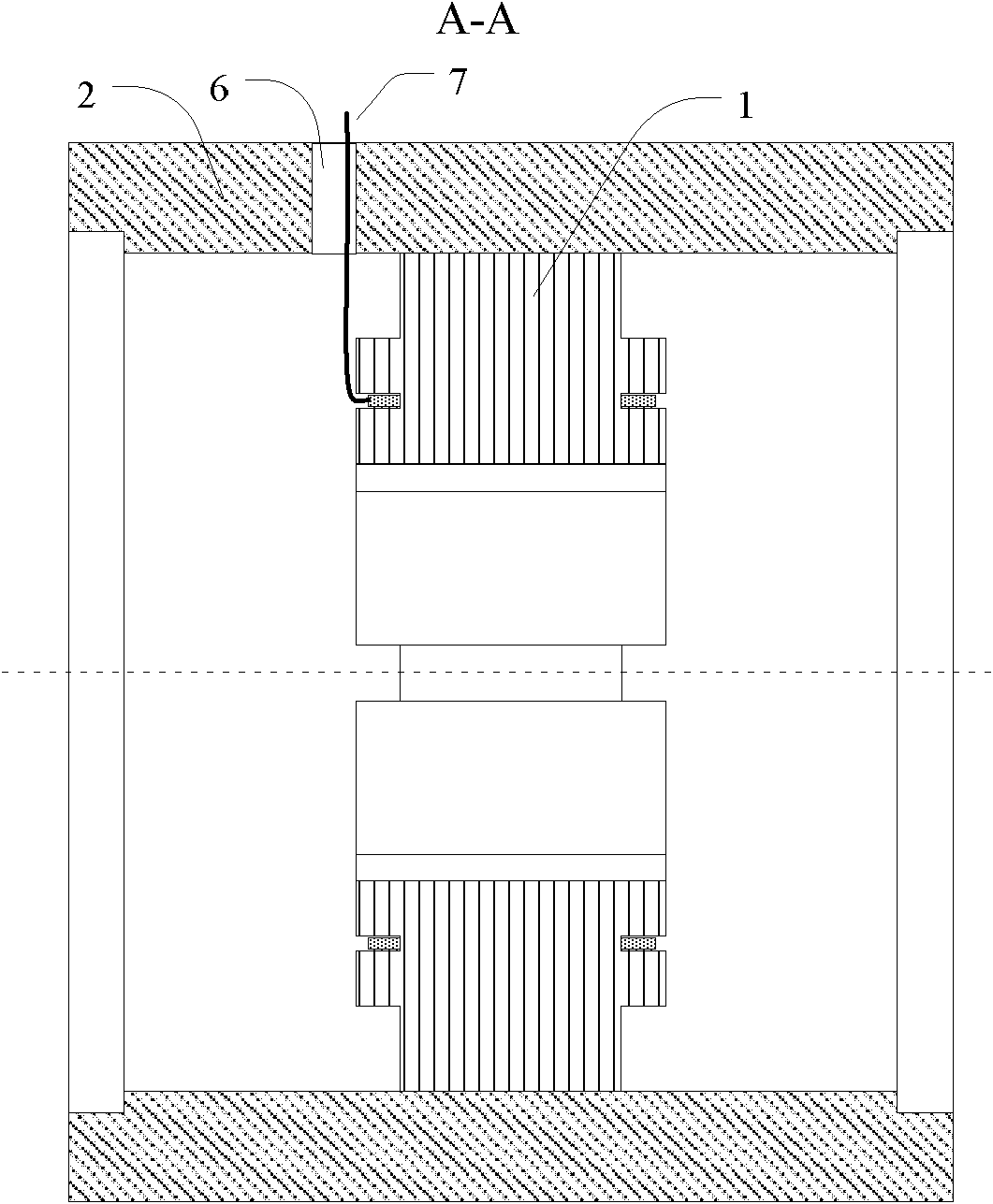

Built-in hybrid permanent magnet motor

ActiveCN108808910AIncrease profitImproved rotor flux pathMagnetic circuit rotating partsElectric machinePermanent magnet motor

The invention discloses a built-in hybrid permanent magnet motor. V-shaped grooves (2) are formed in the circumferential direction of a rotor (2); each side of the V-shaped groove is divided into an upper rectangular structure and a lower rectangular structure; the two rectangular structures are divided into a large rectangular structure (8) and a small rectangular structure (7); permanent magnetsmade of ferrite and neodymium iron boron are arranged in the grooves separately; Z-shaped reinforcing ribs (5) are arranged at the bottoms of the V-shaped grooves; a horizontal line-shaped groove (3)is formed between each V-shaped groove and the outer edge of the rotor; a neodymium-iron-boron permanent magnet (4) is placed in each horizontal line-shaped groove; a vertical magnetizing mode is adopted for all the permanent magnets; the V-shaped grooves and the horizontal line-shaped grooves form a group of groove structures; and a sickle-shaped magnetic isolation bridge (6) is arranged betweenthe two groups of groove structures. According to the built-in hybrid permanent magnet motor, the permanent magnet structures with different materials are arranged asymmetrically, so that the utilization rate, the output torque and efficiency of the permanent magnets of the motor are improved, and the torque pulsation is lowered.

Owner:JIANGSU UNIV

Rotor of electromotor

ActiveCN103501067AIncrease electromagnetic torqueImprove efficiencyMagnetic circuit rotating partsPhysicsElectromagnetic torque

The invention discloses a rotor of an electromotor. The rotor of the electromotor comprises a rotor core and multiple sets of permanent magnets, wherein the multiple sets of permanent magnets are buried in the rotor core. Each set of permanent magnets comprise multiple permanent magnet layers which are mutually arranged in the radial direction of the rotor core at intervals. The permanent magnet layer, closest to the surface of the outer circumference of the rotor core, of the multiple permanent magnet layers is a ferrite permanent magnet layer. The other permanent magnet layers of the multiple permanent magnet layers are rare earth neodymium ferrum boron permanent magnet layers. By the adoption of the rotor of the electromotor, the reluctance torque and the electromagnetic torque of the electromotor can be increased, efficiency of the electromotor is increased without increasing cost of the electromotor, and the problems of noise and vibration deterioration of the electromotor can not be caused. Besides, operating reliability of the electromotor can also be guaranteed, and the electromotor can also be stably operated under high frequency.

Owner:GUANGDONG MEIZHI COMPRESSOR

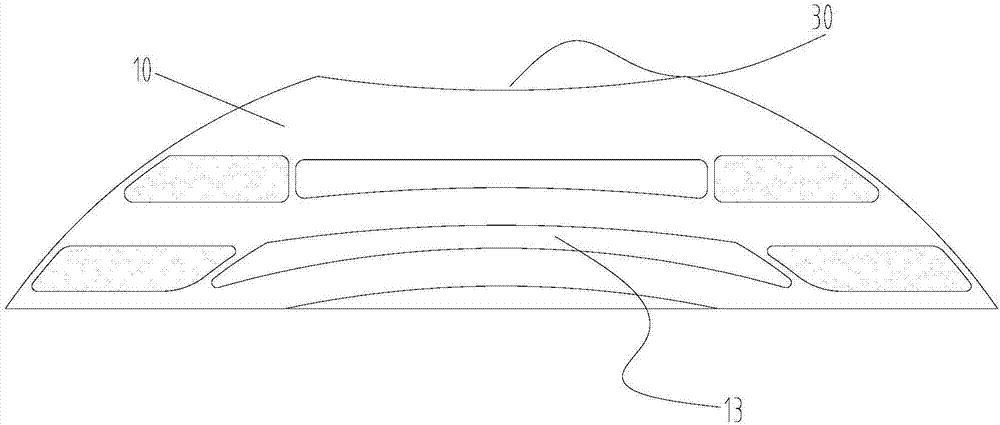

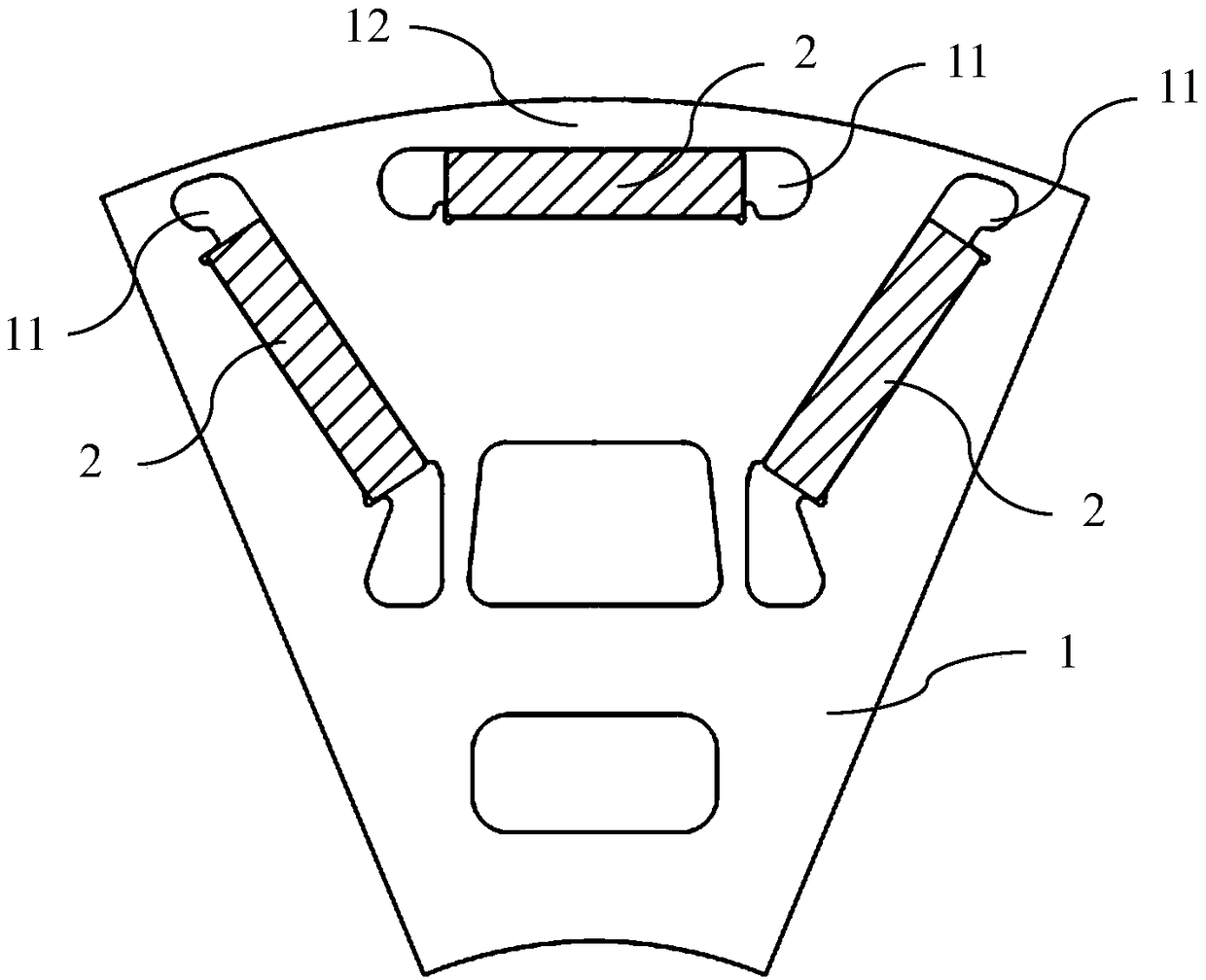

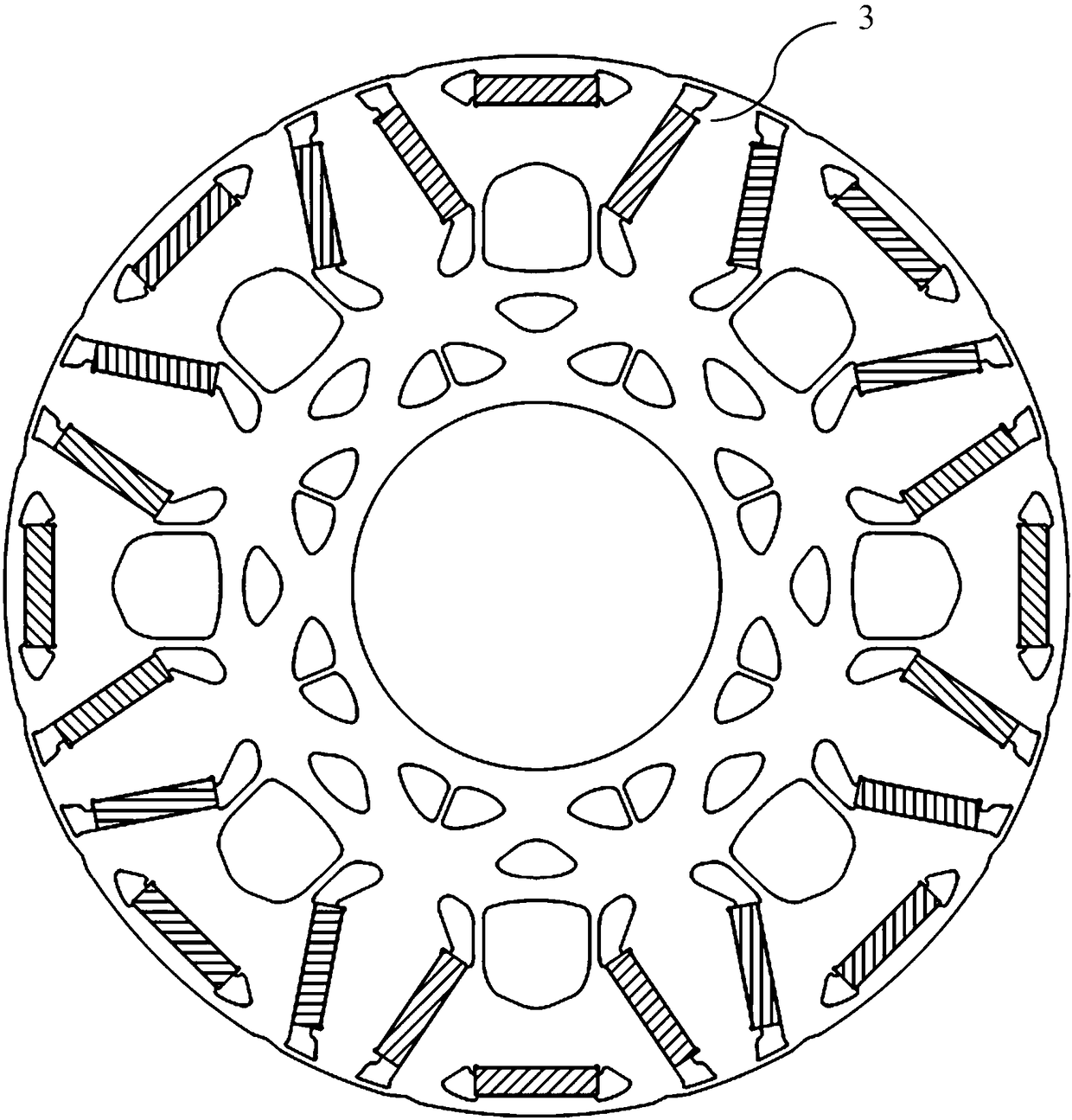

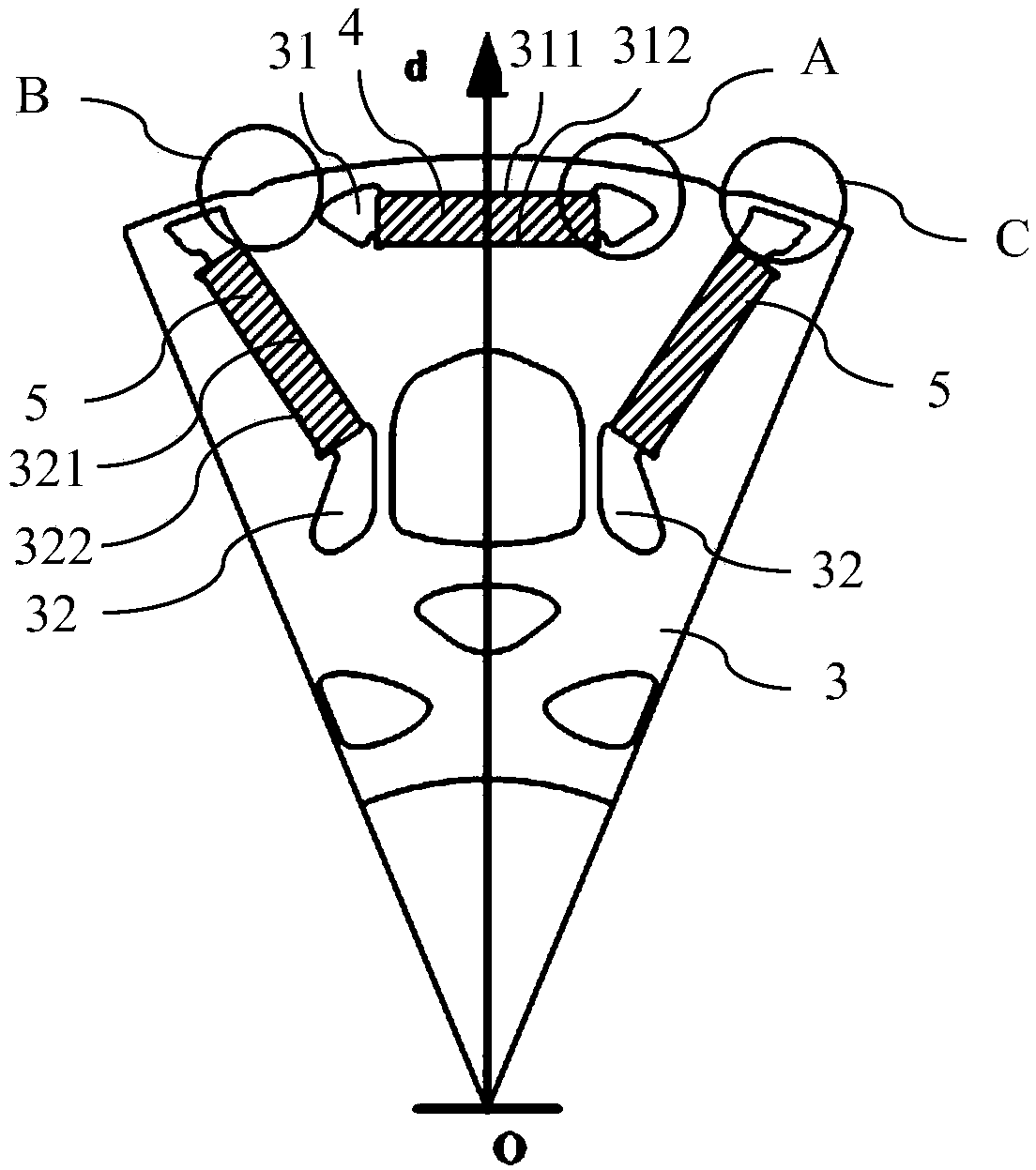

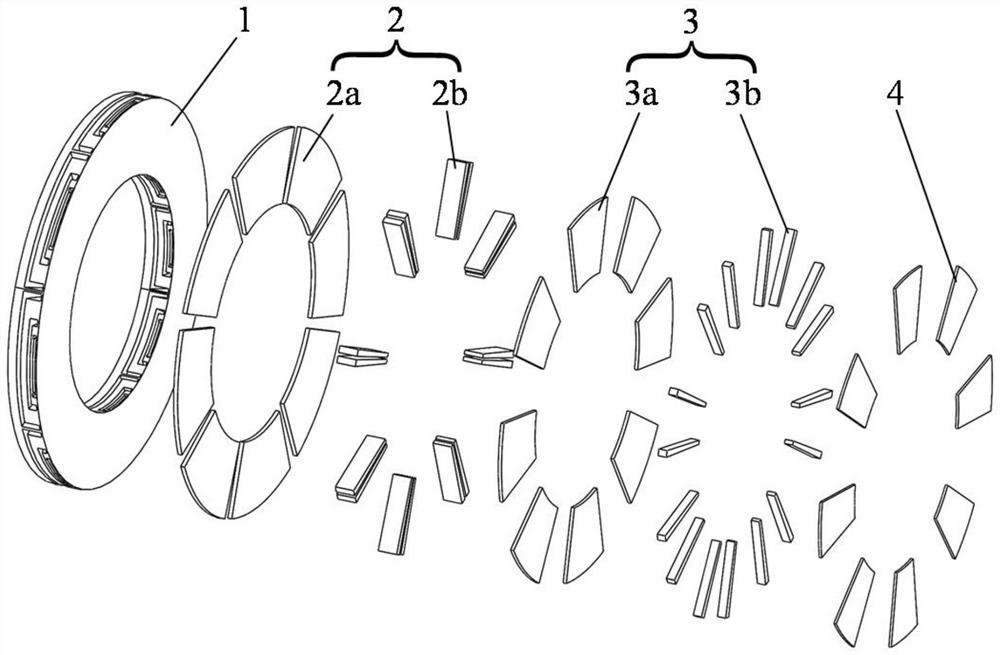

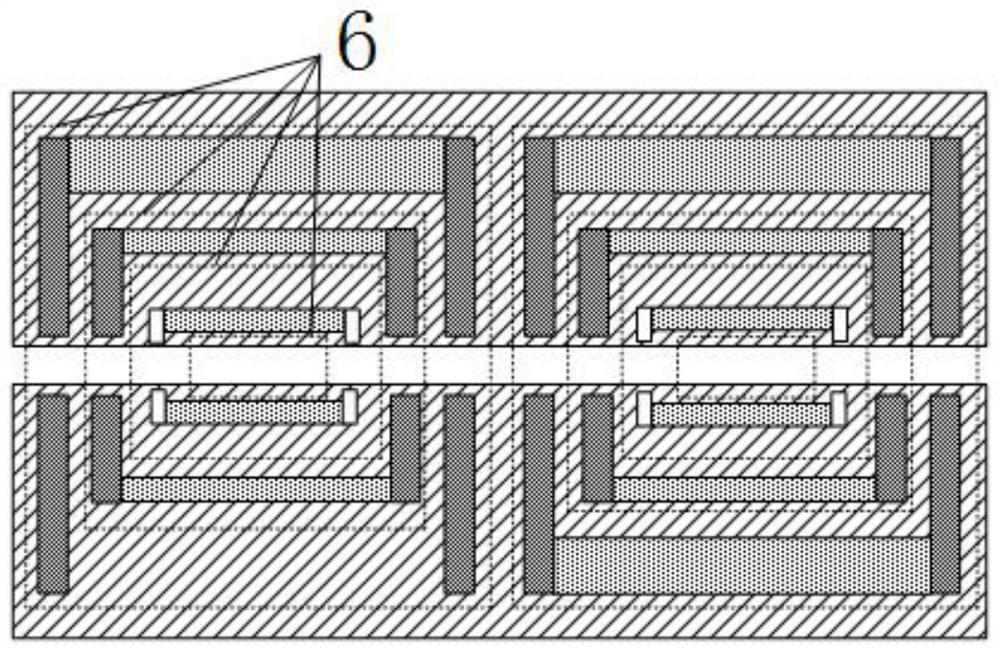

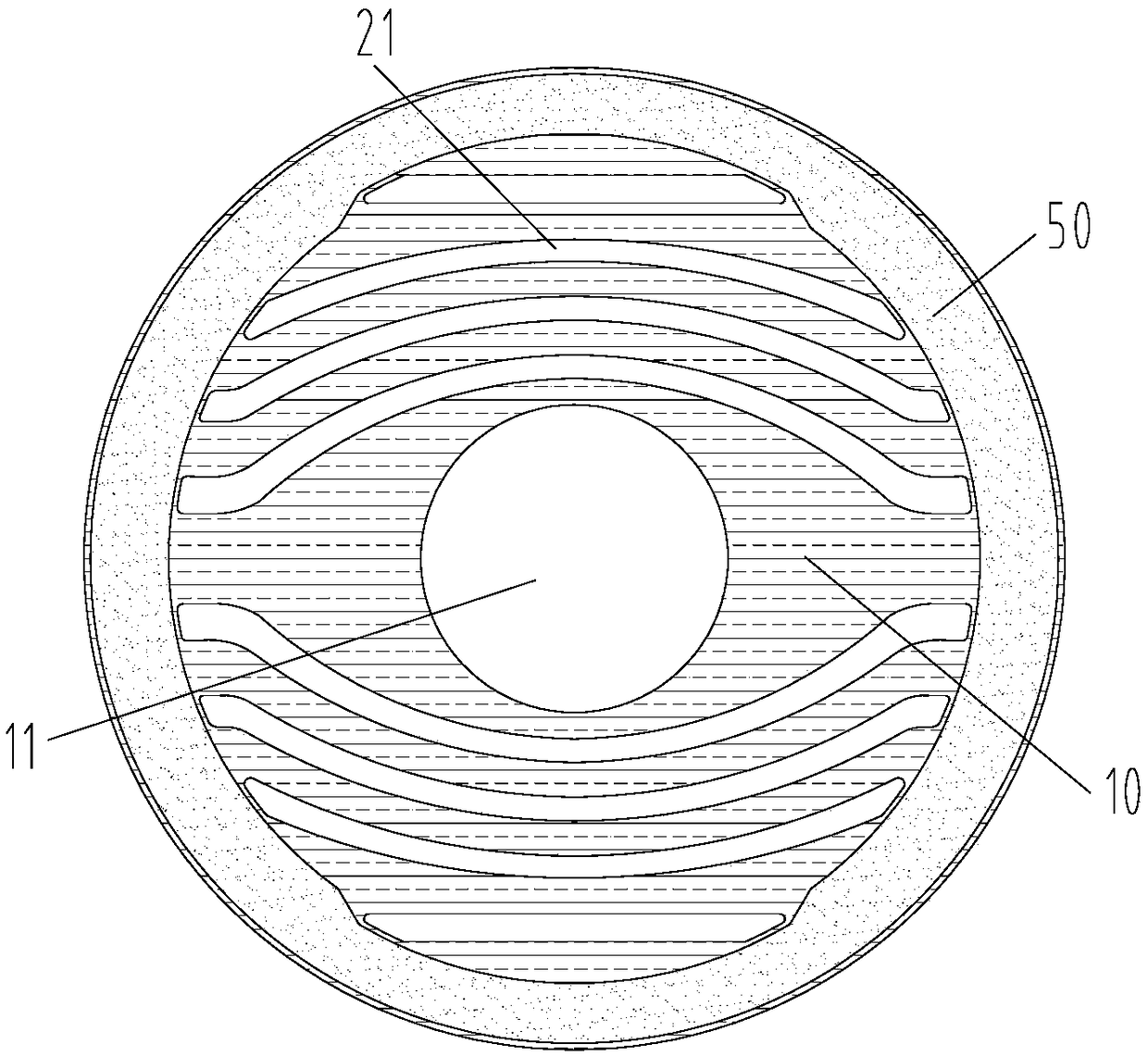

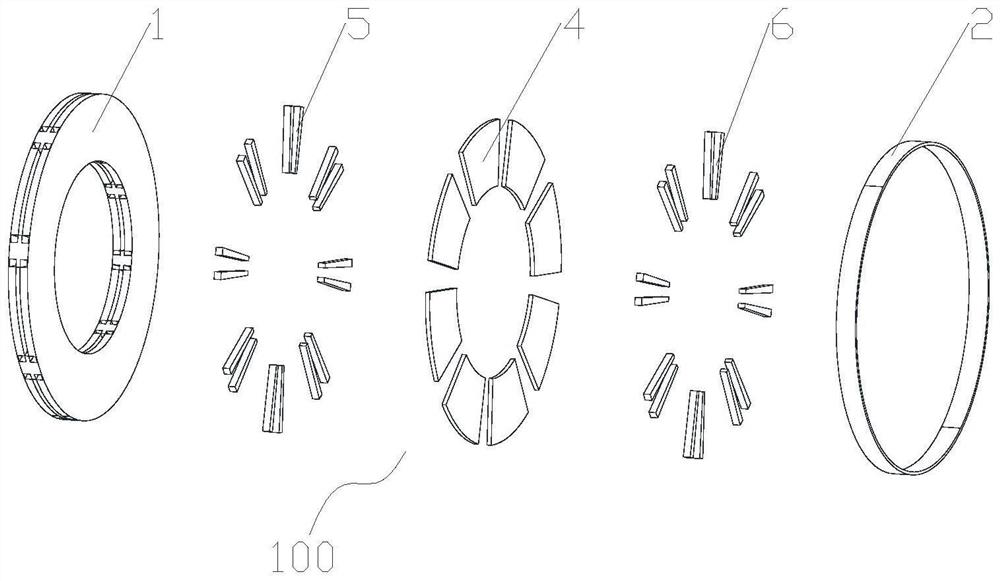

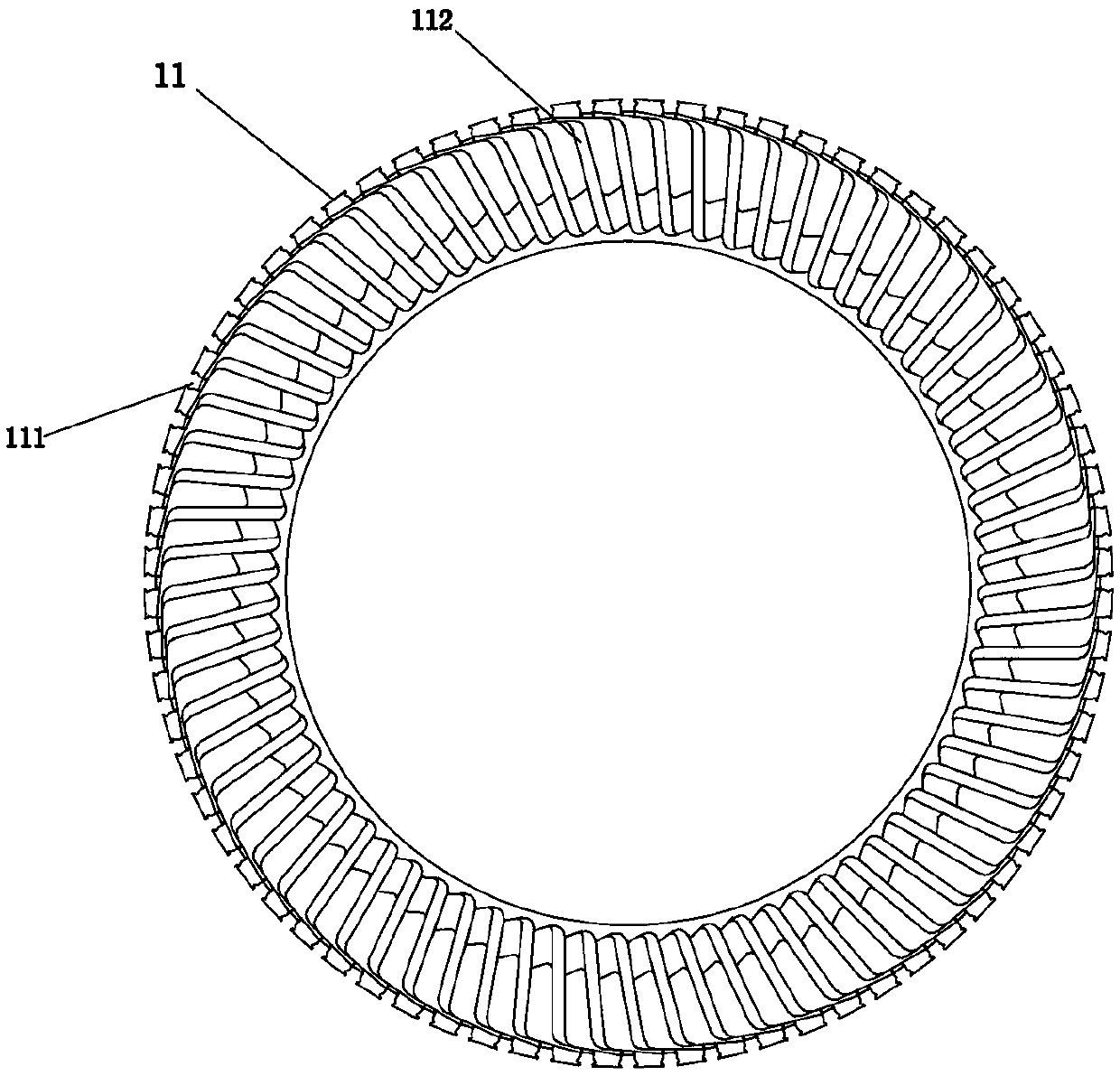

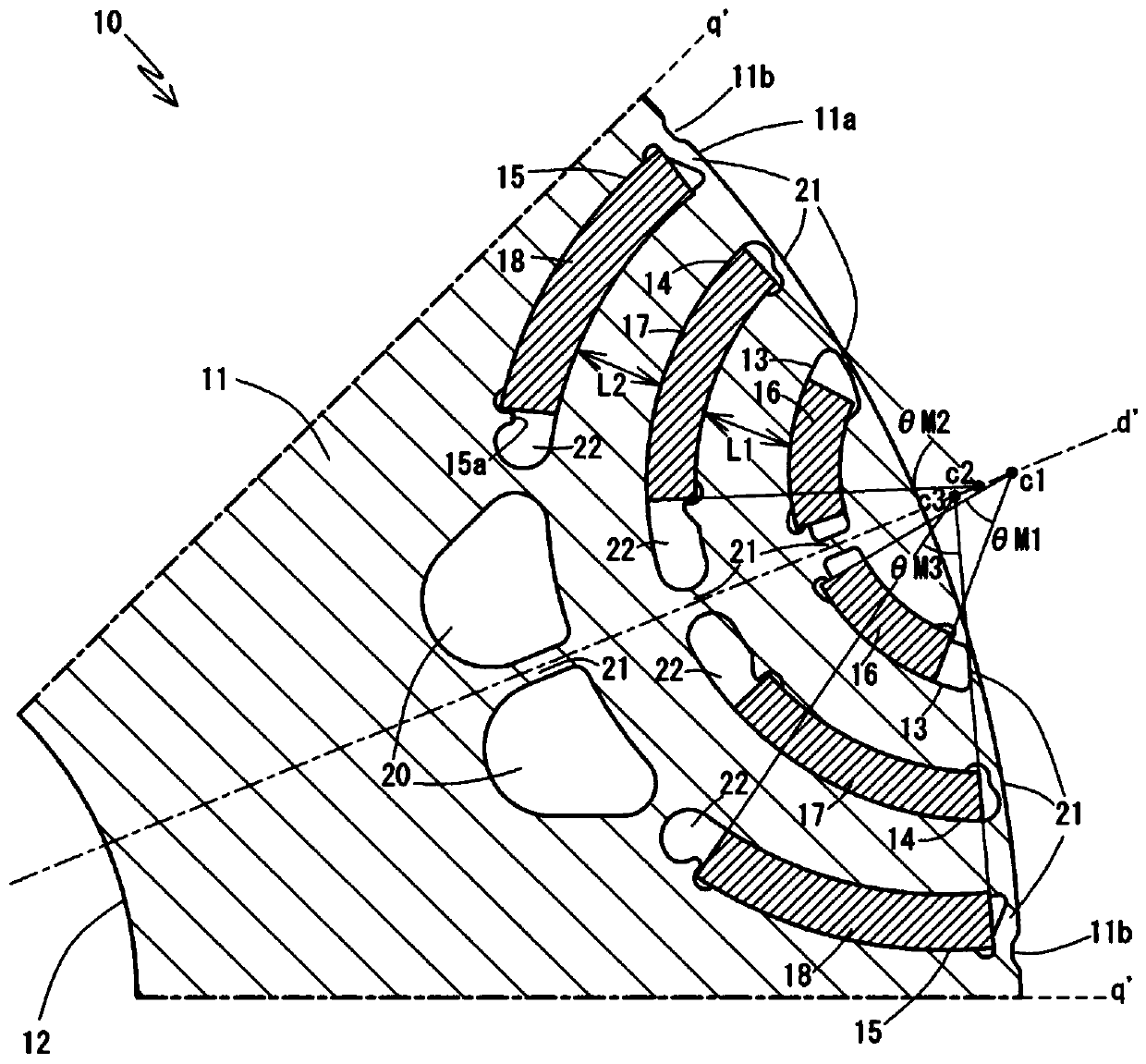

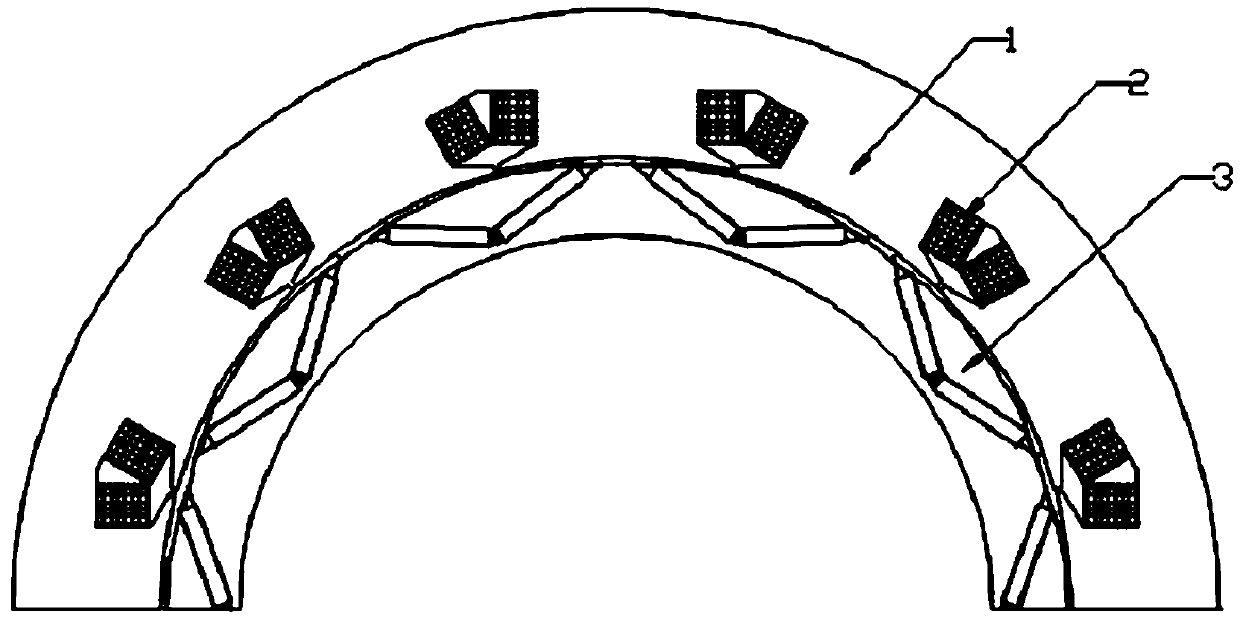

Built-in permanent magnet rotor structure of axial flux motor

PendingCN113381540AThe salient pole effect is obviousReduce dosageMagnetic circuit rotating partsPermanent magnet rotorElectric machine

The invention discloses a built-in permanent magnet rotor structure of an axial flux motor. The built-in permanent magnet rotor structure comprises two rotor discs; each rotor disc comprises a rotor core with an annular cross section; each rotor core is formed by circumferentially winding a thin silicon steel sheet, and three layers of permanent magnet groups are uniformly embedded in the circumferential direction of each rotor core; each permanent magnet group comprises a first layer of U-shaped magnetism gathering structure permanent magnet combination, a second layer of U-shaped magnetism gathering structure permanent magnet combination and a third layer of linear structure permanent magnet which are sequentially arranged from the outer side of the rotor core to the circle center of the rotor core; the two rotor discs are installed on a rotating shaft in a manner that permanent magnet faces are opposite to each other, and a stator disc is arranged between the two rotor discs. According to the built-in permanent magnet rotor structure of the axial flux motor of the invention, the magnetism gathering capability of the permanent magnet rotor discs is stronger, and highly sinusoidal air gap flux density can be realized; the U-shaped permanent magnetcombinations and the linear permanent magnet combinations adopted, so that the salient pole effect of the motor can be improved, the reluctance torque is fully utilized, and the torque or power density of the motor is improved; and the silicon steel sheet is slotted and wound to form the rotor core, so that the machining is convenient and the structural strength is high.

Owner:NANJING UNIV OF SCI & TECH

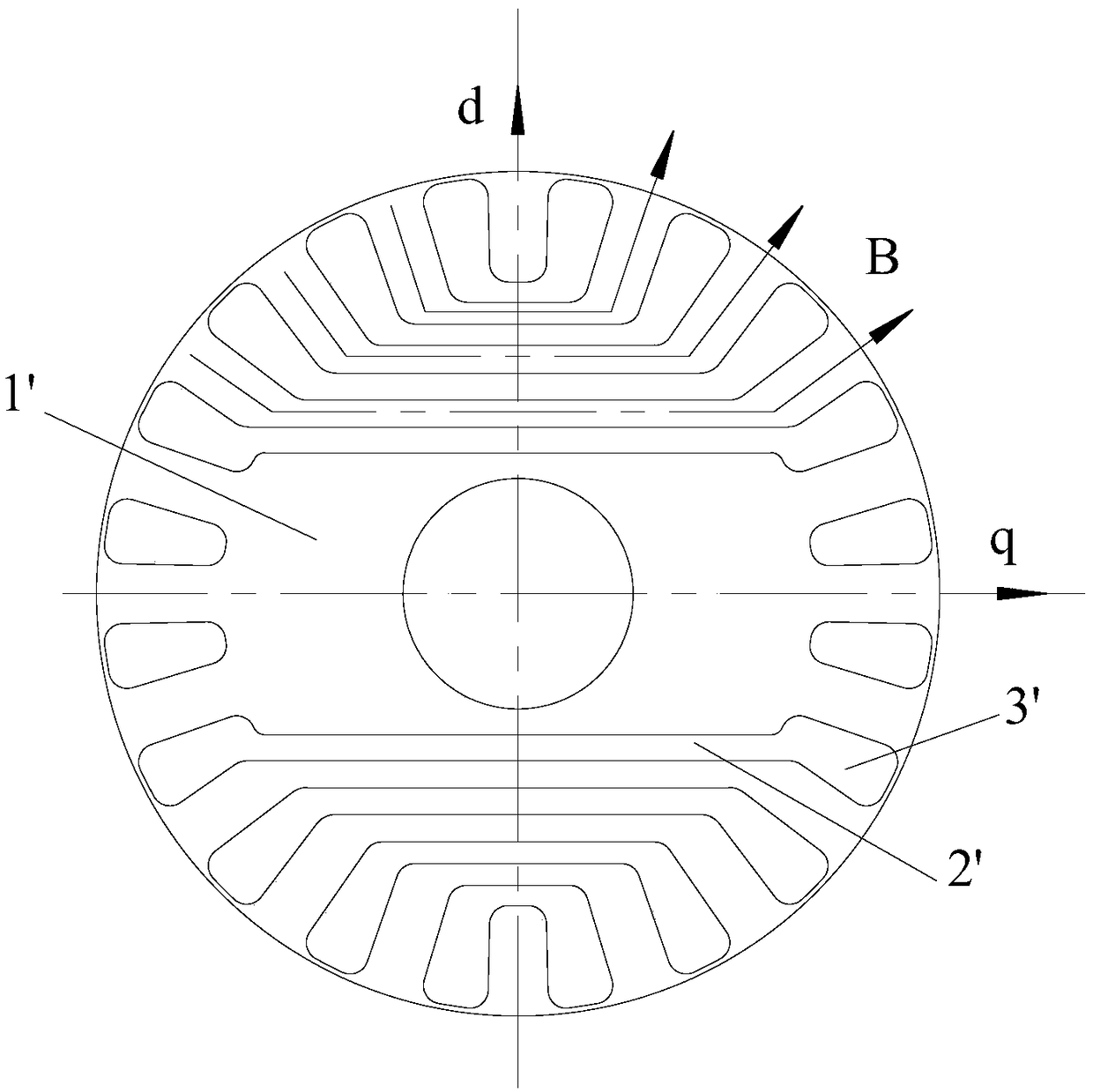

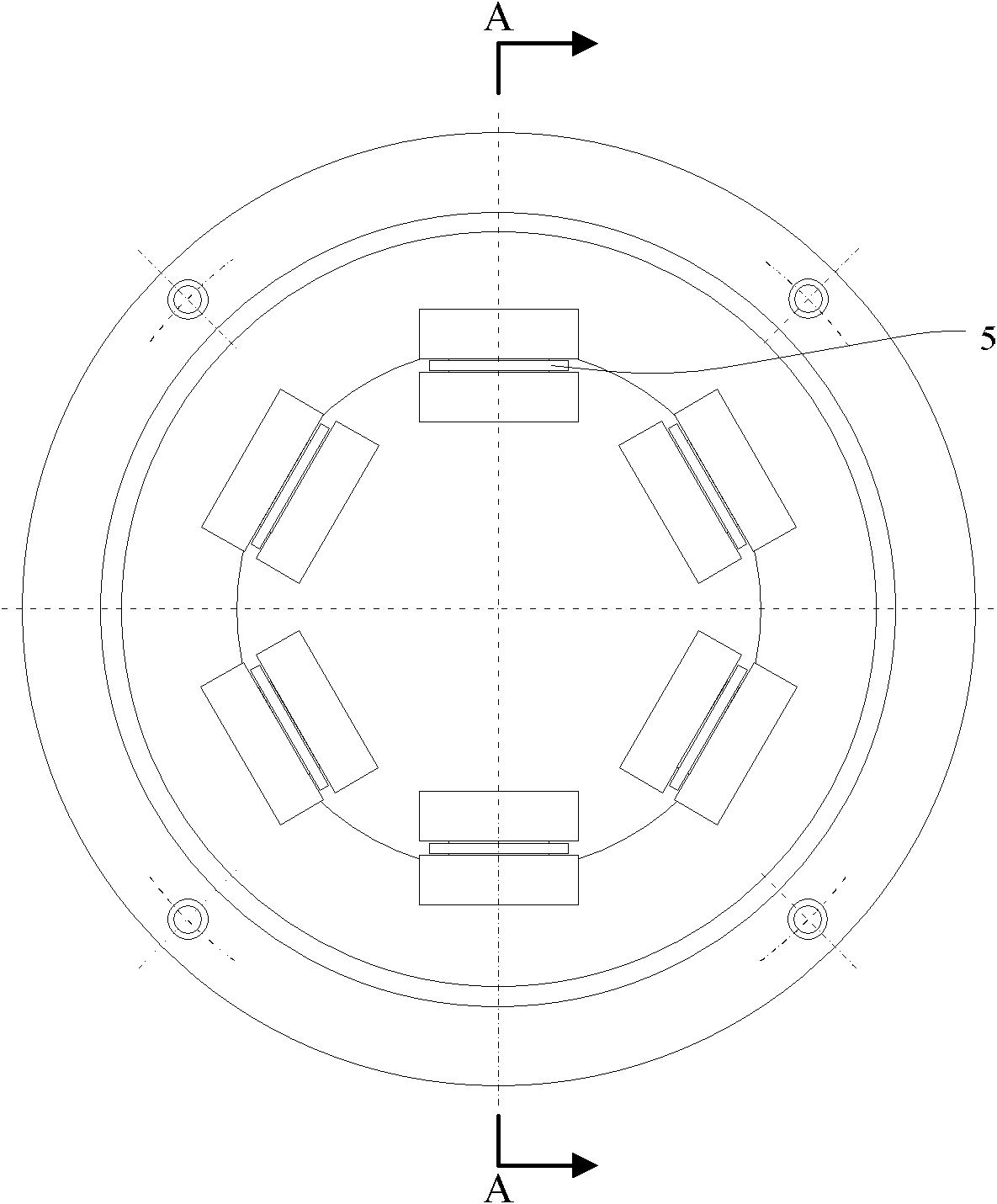

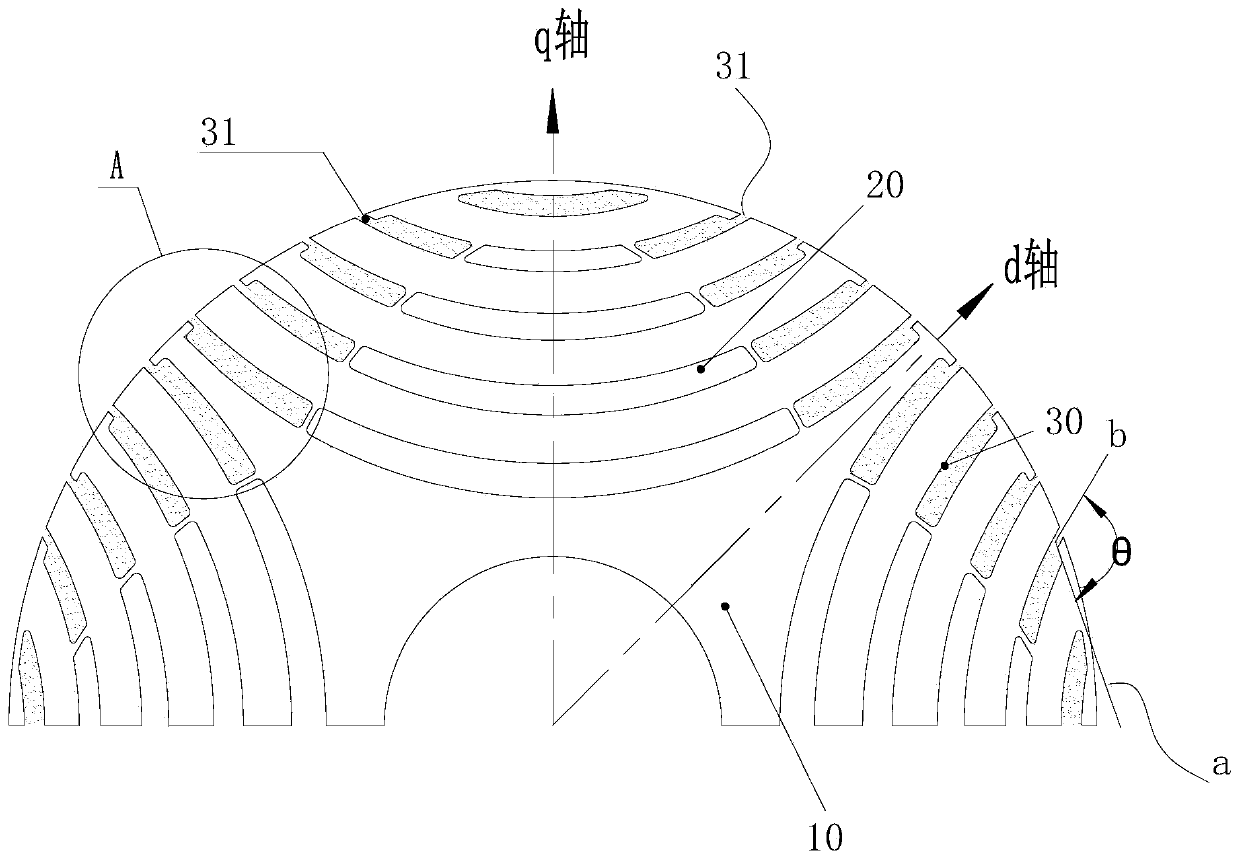

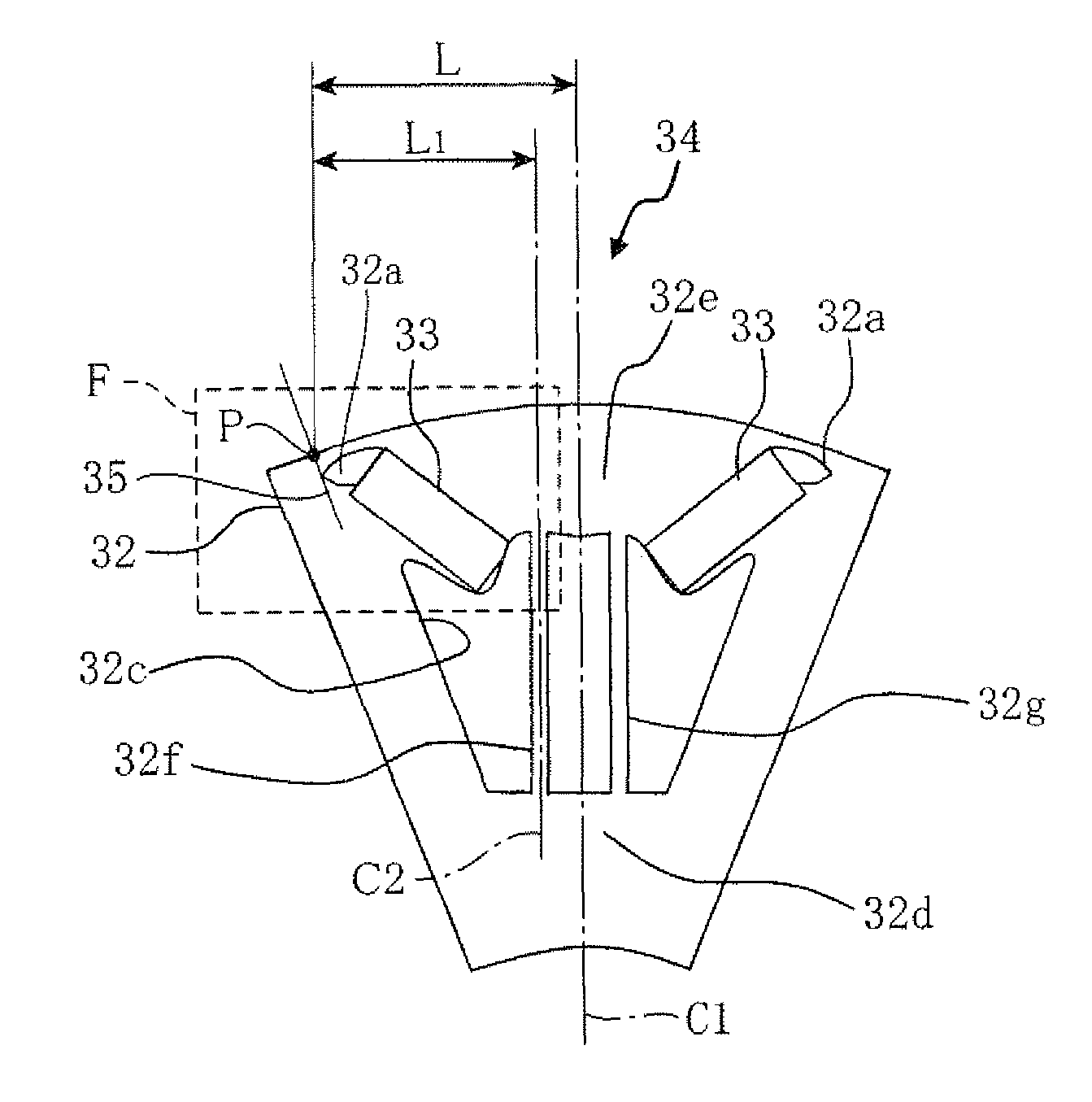

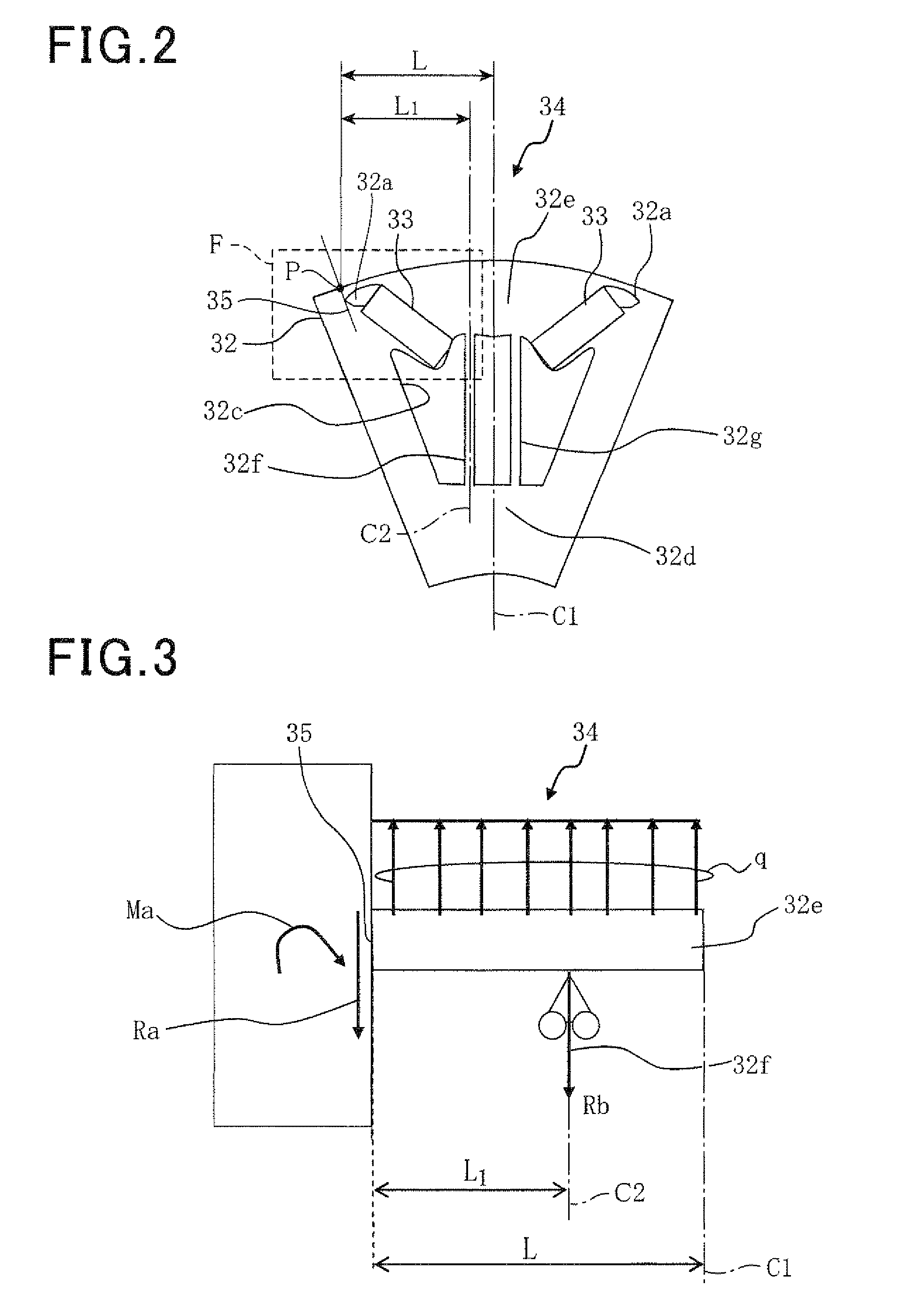

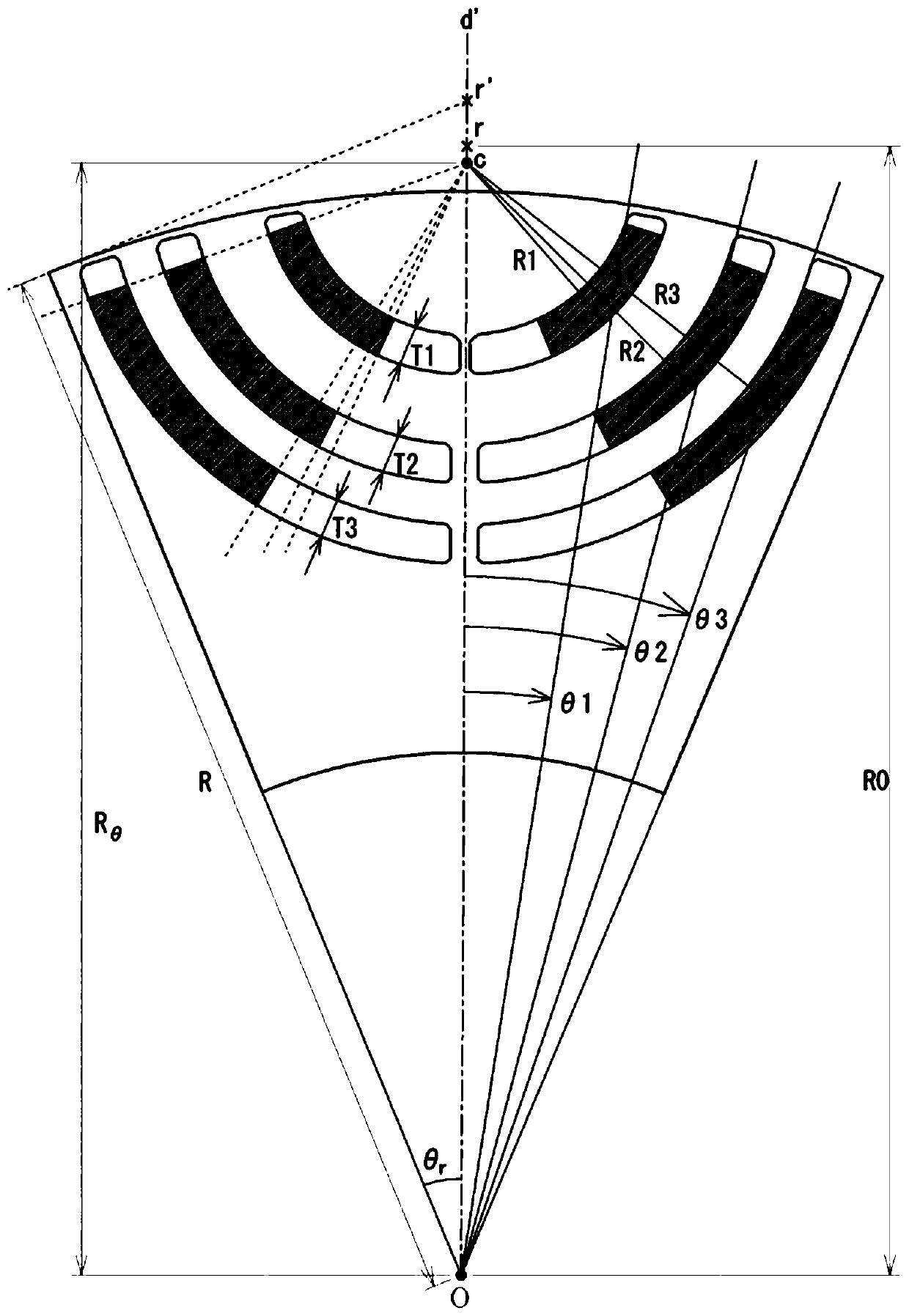

Asynchronous starting type synchronous reluctance motor rotor, motor and compressor

ActiveCN109347225AIncrease salient differenceImprove efficiencyMagnetic circuit rotating partsSynchronous motorsMagnetic barrierSynchronous reluctance motor

The invention provides an asynchronous starting type synchronous reluctance motor rotor, a motor and a compressor. The asynchronous starting type synchronous reluctance motor rotor comprises a rotor iron core; the rotor iron core comprises a plurality of supplementing grooves (214) and a plurality of first magnetic barrier parts (21); the supplementing grooves (214) are located between the end parts of the first magnetic barrier parts (21) and the outer edge of the rotor iron core (10); a distance between the center (a d axis) of each first magnetic barrier part (21) and a q axis is C1; a distance between the supplementing grooves (214) in the two ends of each first magnetic barrier part (21) and the q axis is C2; and a ratio C1 / C2 of C1 to C2 is 1-5. The problem of low working efficiencyof the asynchronous starting type synchronous reluctance motor rotor of the motor in the prior art is effectively solved; and meanwhile, a proper supplementing groove proportion is set, so that the starting performance of the motor is guaranteed.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Switched reluctance motor with radial and transverse magnetic field characteristics

InactiveCN102545498AIncrease profitImprove power densityMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic polesReluctance motor

The invention aims to provide a switched reluctance motor with radial and transverse magnetic field characteristics. The switched reluctance motor comprises a motor housing, a stator, a cable, a left side end cover body, a right side end cover body, a middle rotor, a left side rotor, a right side rotor and a shaft, wherein stator poles are arranged on a stator core and are uniformly distributed along the circumference of the stator core, four sides of the stator poles are provided with annular grooves, stator windings are arranged in the annular grooves, the motor housing is provided with line guiding holes, one end of the cable is connected with the stator windings and the other end is led to the outside of the motor by passing the line guiding holes, middle rotor poles are arranged on a middle rotor core and are uniformly distributed along the circumference, left and right side rotor cores are uniformly distributed on the rotor poles along the circumference, and the shaft passes through the middle rotor, the left and right side rotors and the left and right side end cover bodies and are connected with the middle rotor core and the left and right side rotor cores. According to the invention, the stator windings have the advantages of high utilization rate and high power density.

Owner:HARBIN ENG UNIV

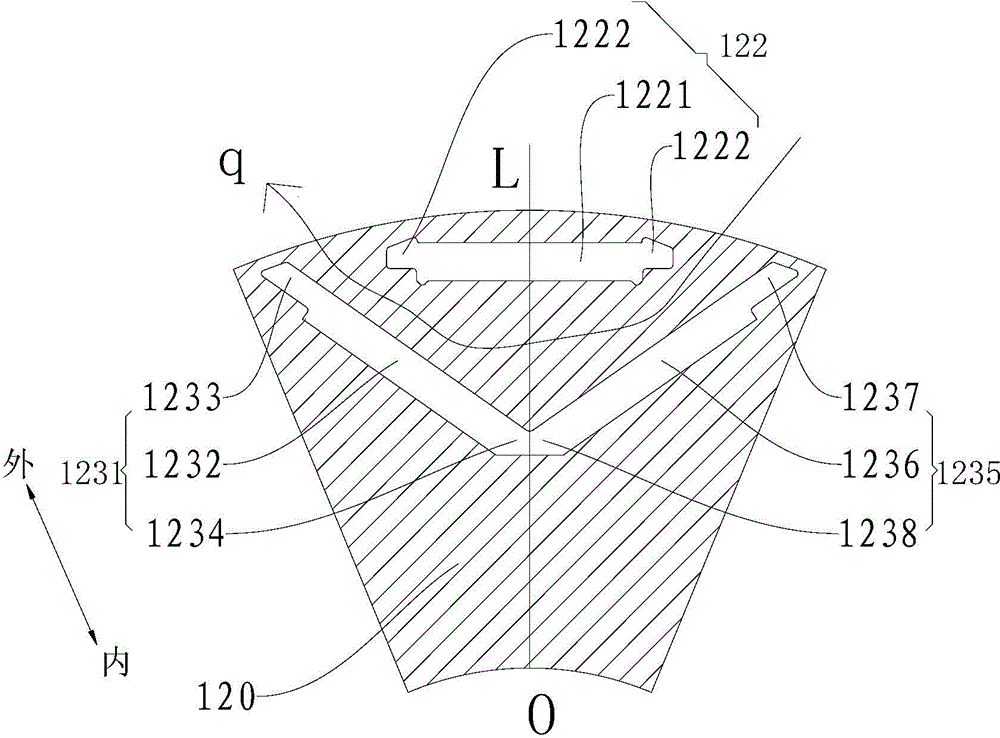

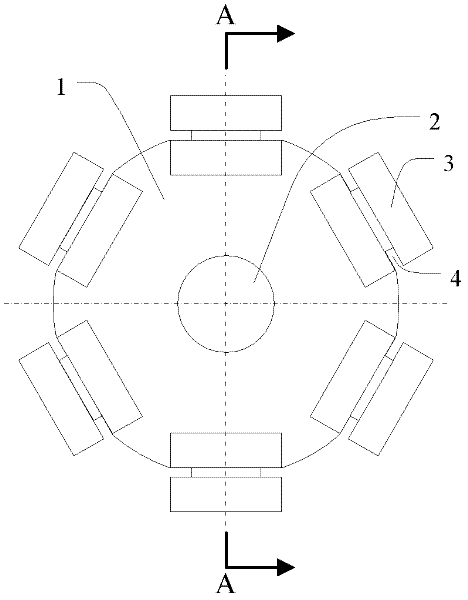

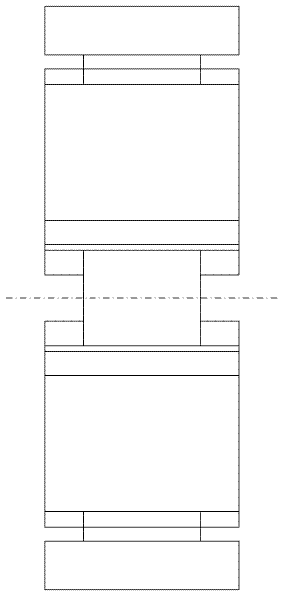

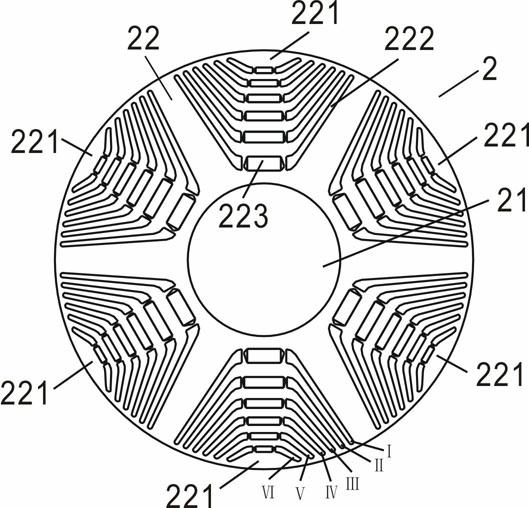

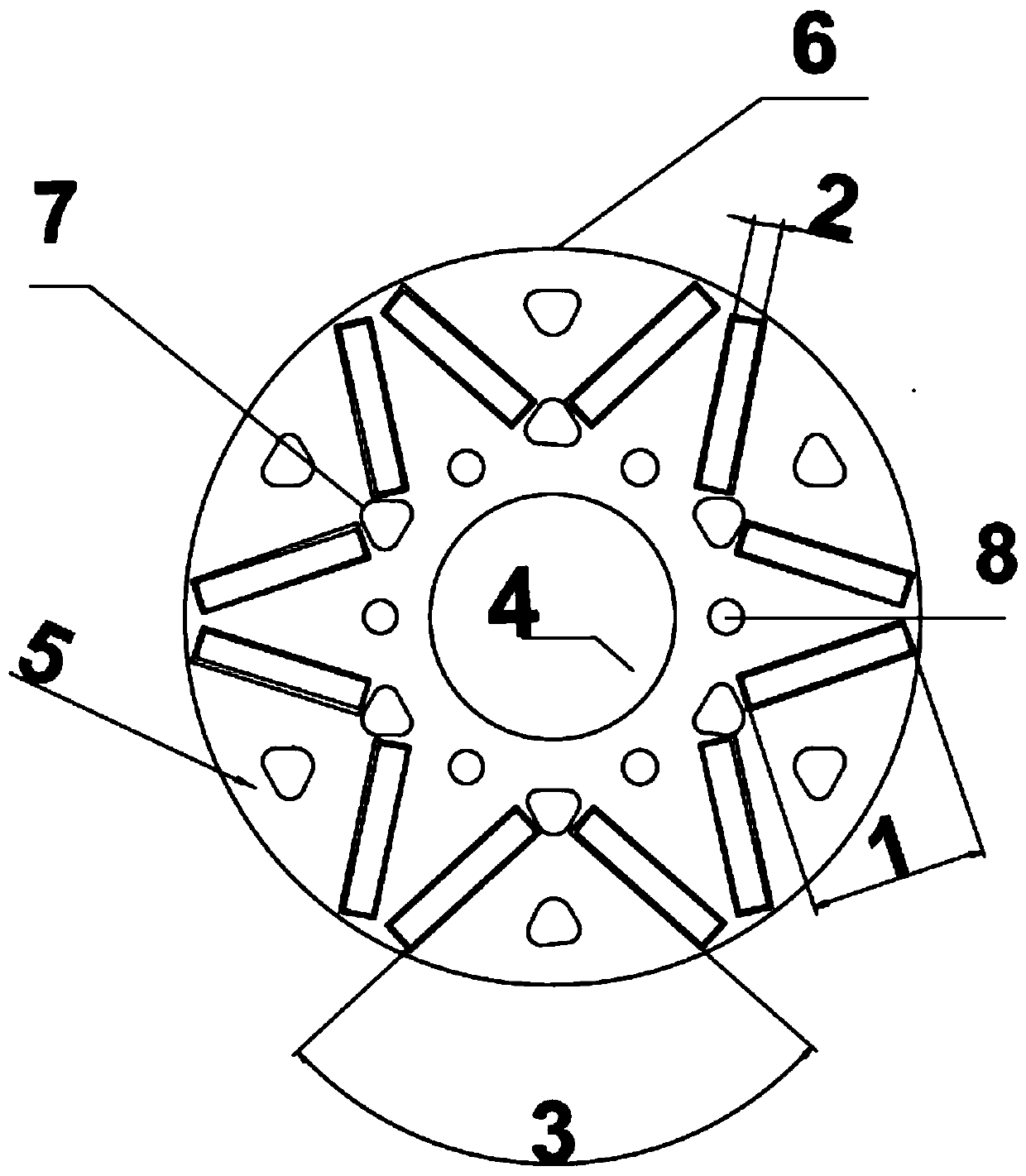

Built-in permanent magnet motor rotor and permanent magnet motor with rotor

InactiveCN102684342ARaise the saliency ratioLarge reluctance torqueMagnetic circuit rotating partsElectric machineryMagnetic poles

The invention provides a built-in permanent magnet motor rotor which comprises a rotation shaft (21) and a rotor core (22). Magnetic poles (221) are evenly arranged on the rotor core (22), each magnetic pole (221) is provided with at least two groups of magnetic resistance grooves (222), each group of magnetic resistance groove(222) penetrates through the rotor core (22) in the axial direction, each group of magnetic resistance groove(222) comprises a left hollow groove and a right hollow groove which are symmetrical, and a permanent magnet (223) is arranged in the symmetric center of the symmetrical hollow groove of at least one group of magnetic resistance grooves. The invention further provides a permanent magnet motor. Compared with the prior art, the built-in permanent magnet motor rotor improves salient pole ratio of the motor, greatly increases reluctance torque of the motor, reduces torque pulsation and lowers motor cost.

Owner:浙江西子富沃德电机有限公司

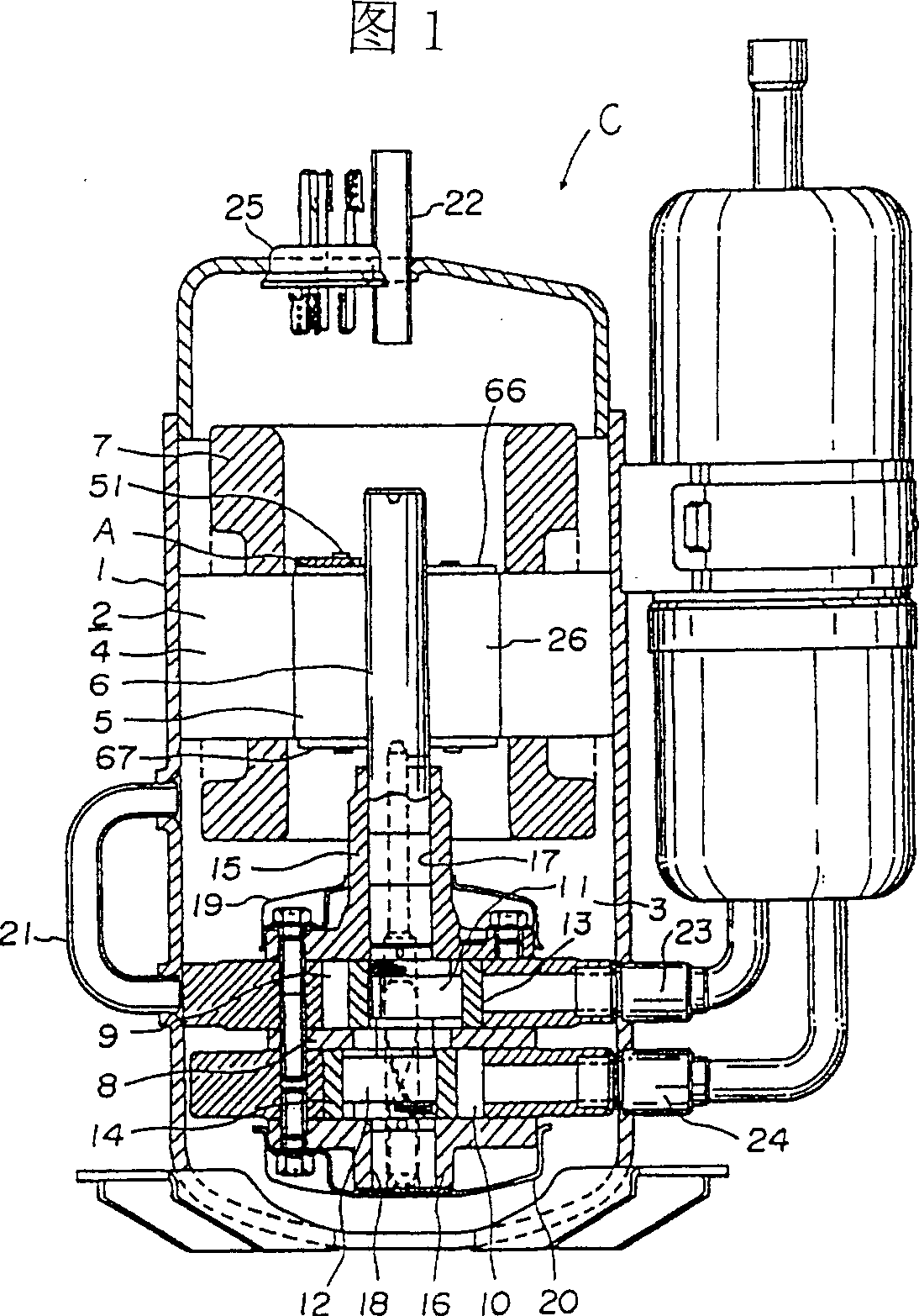

Induction synchro motor

InactiveCN1368784AImprove efficiencyHigh torqueMagnetic circuit rotating partsAsynchronous induction motorsElectrical conductorSynchronous motor

The induction synchronous motor 2 is composed of a stator 4 having a stator winding 7 and a rotor 5 rotating inside the stator 4 , and a cage-type secondary conductor 5B is provided around a rotor yoke 5A constituting the rotor 5 . A permanent magnet 31 having two poles is embedded in the rotor yoke portion 5A. In the specified range near the electrical angle of 0° and 180°, the magnetomotive force of one pole of the rotor is kept below 10% of the peak value. In this way, the magnetomotive force generated by the rotor having the permanent magnets constituted by two poles can be concentrated to realize a large reluctance torque and high efficiency.

Owner:SANYO ELECTRIC CO LTD

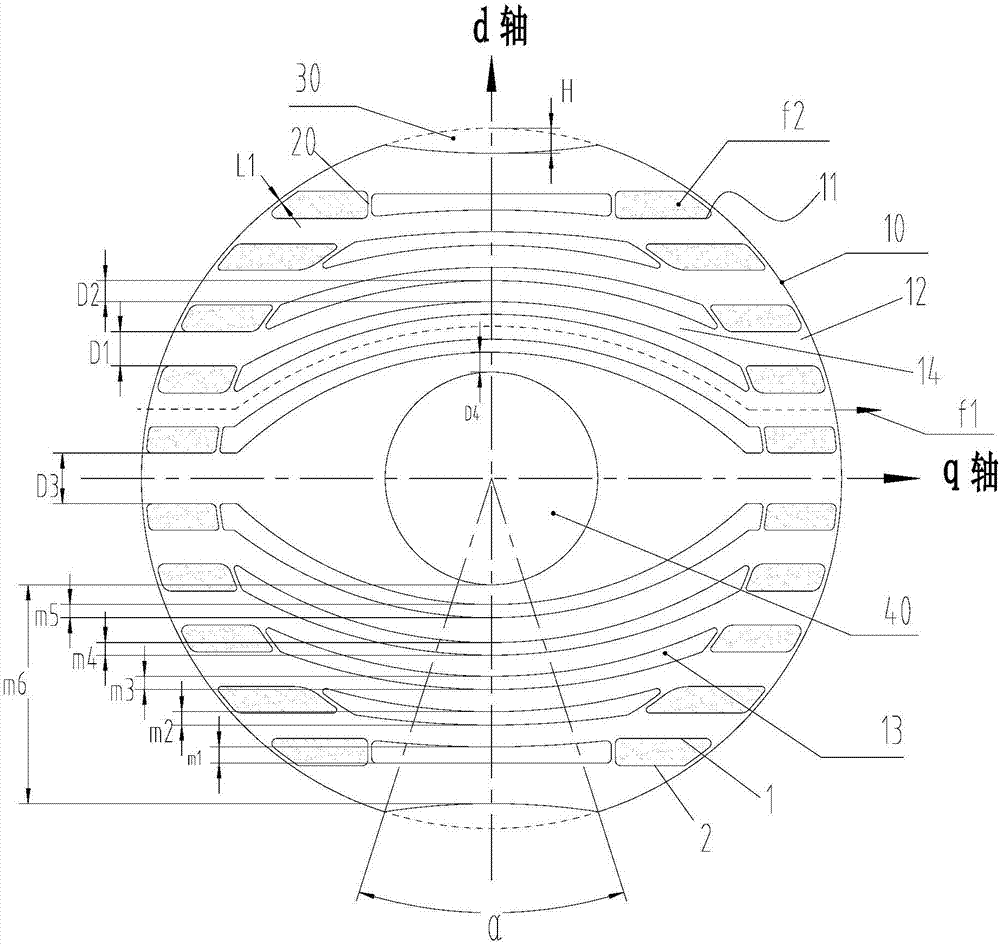

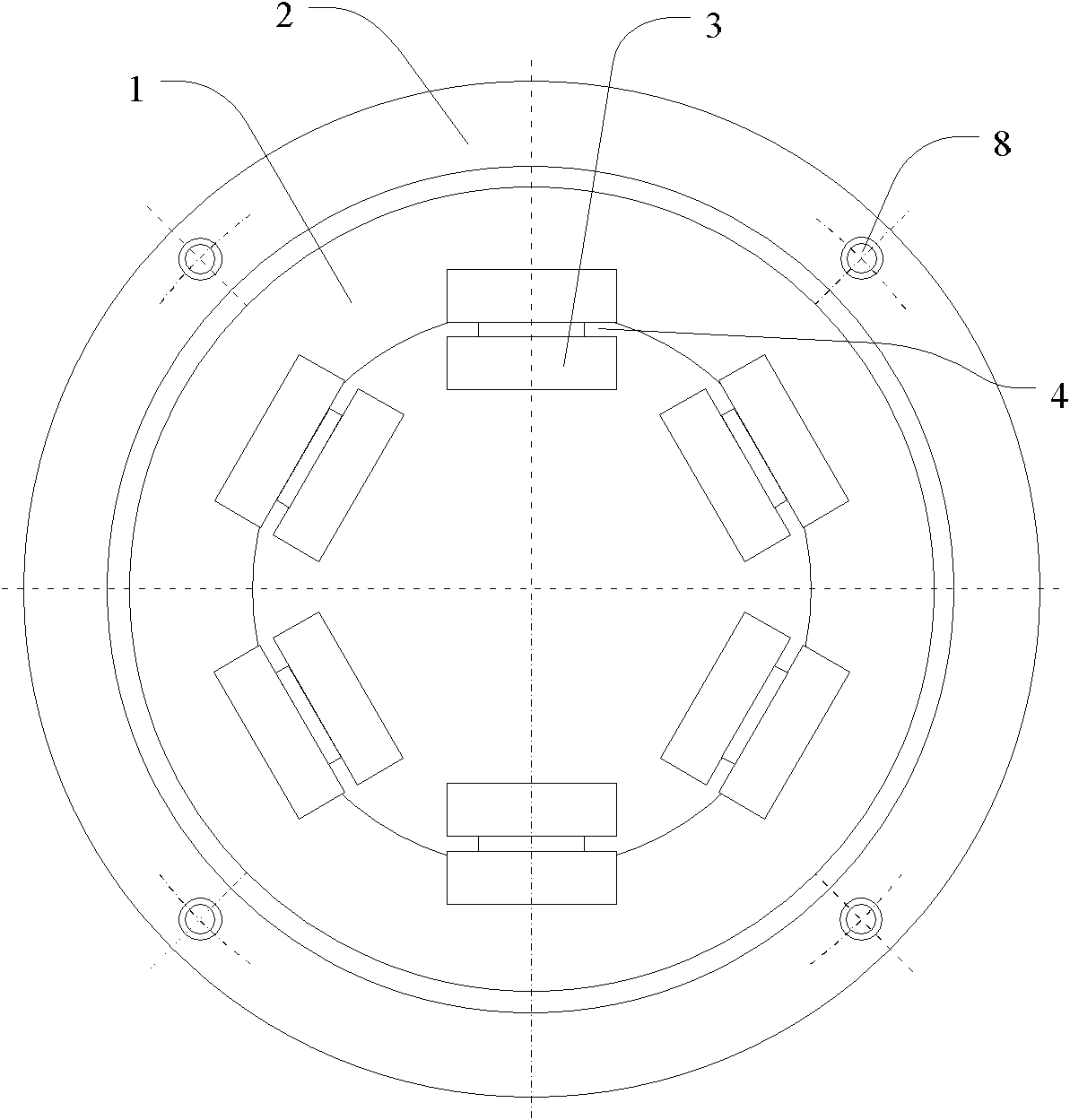

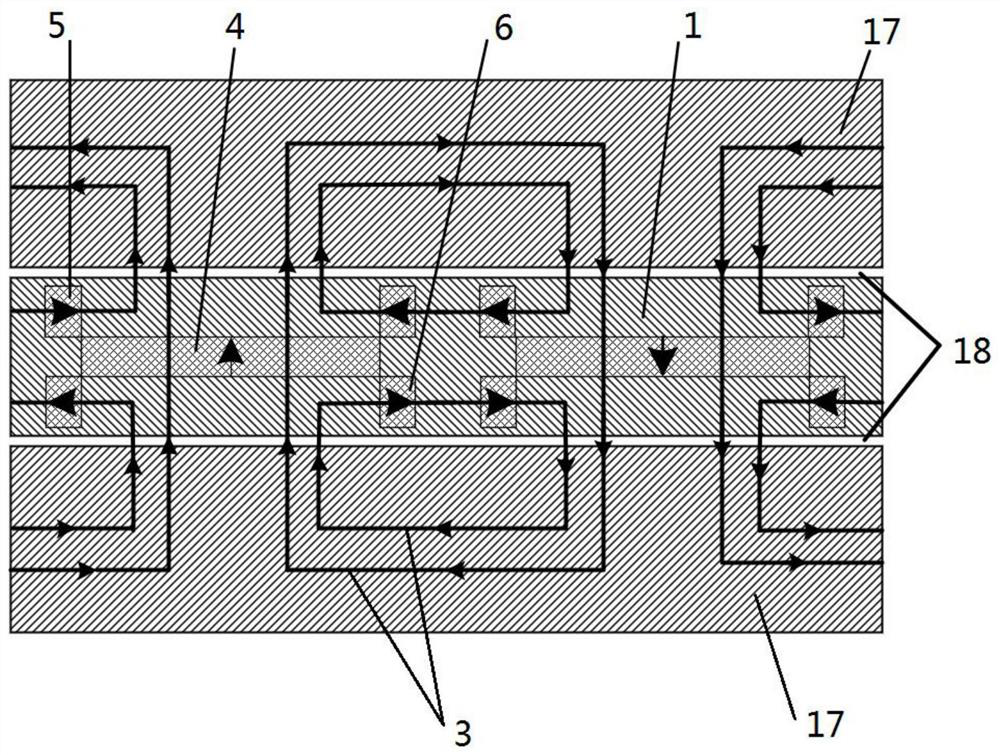

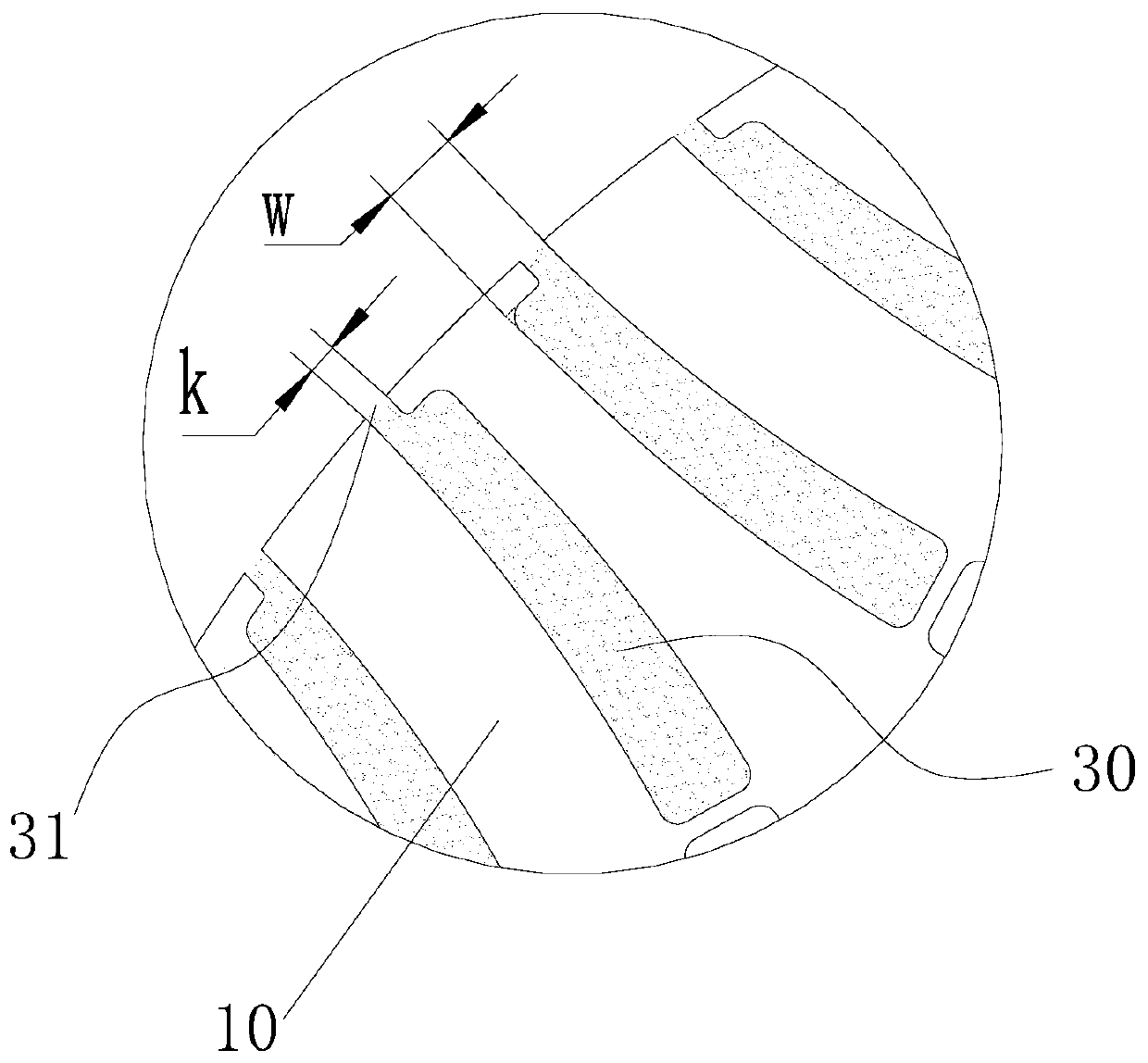

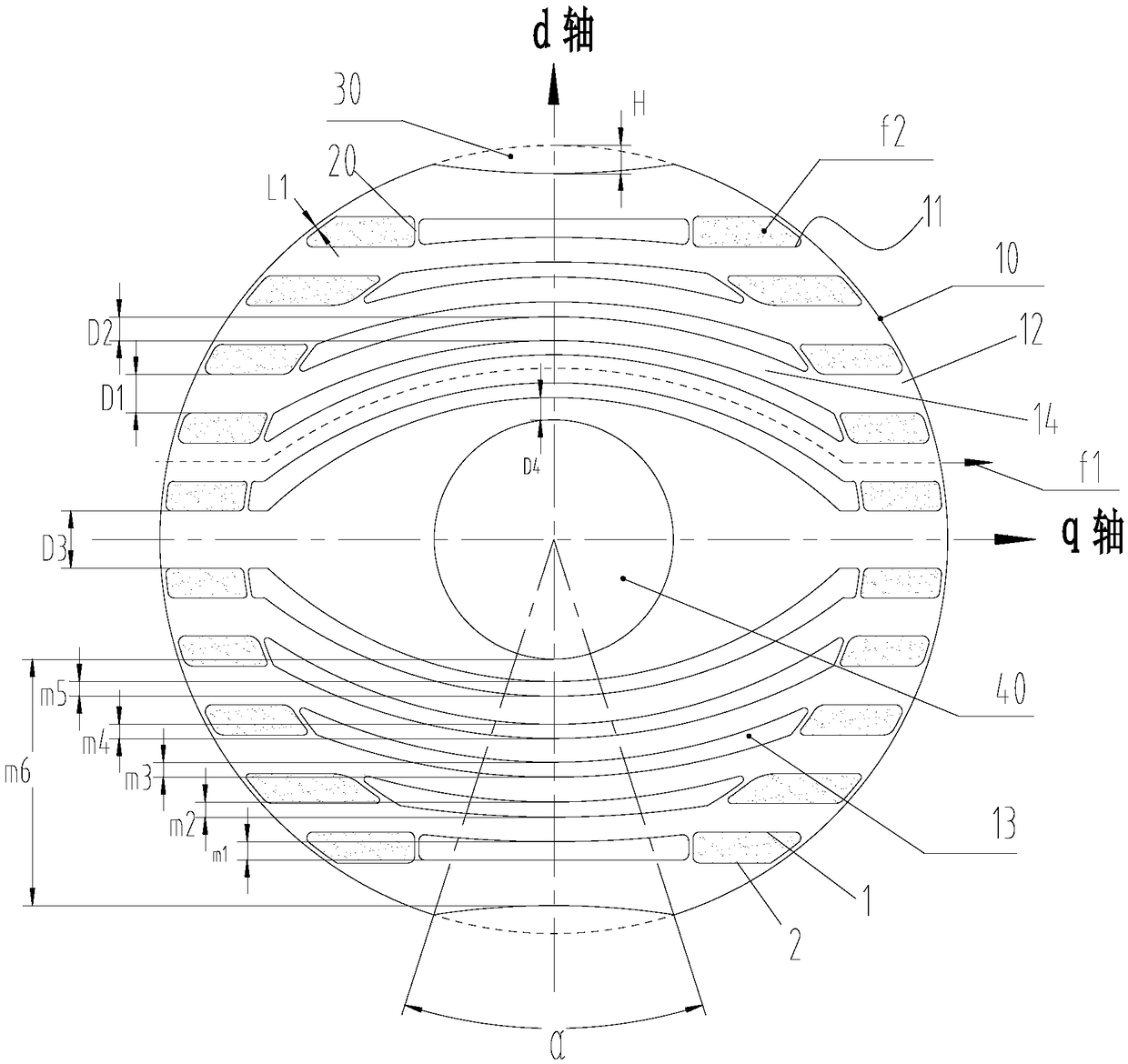

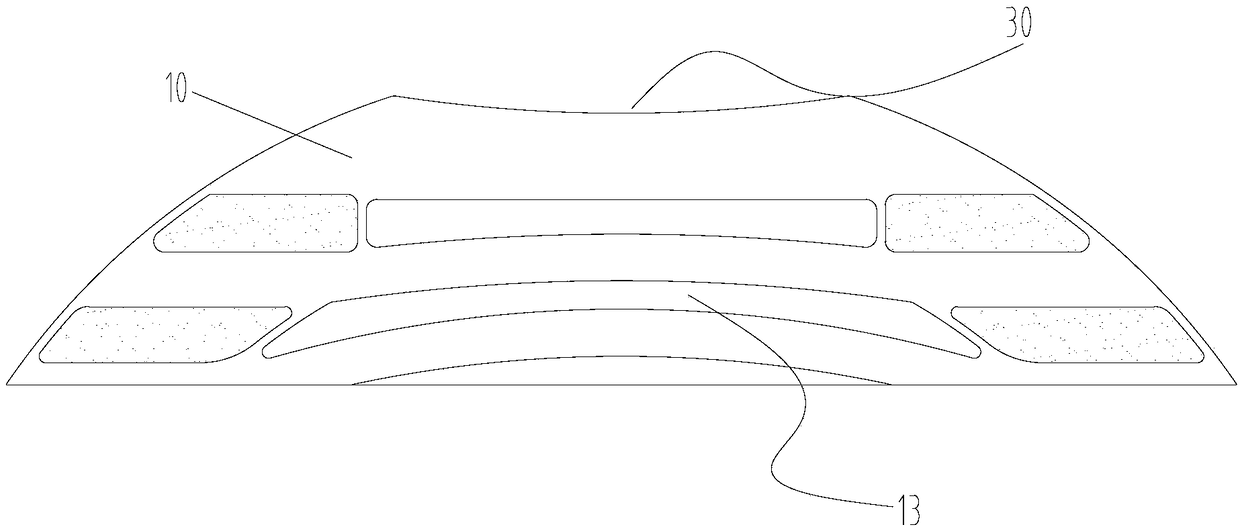

Rotor structure, asynchronous starting synchronization reluctance motor and compressor

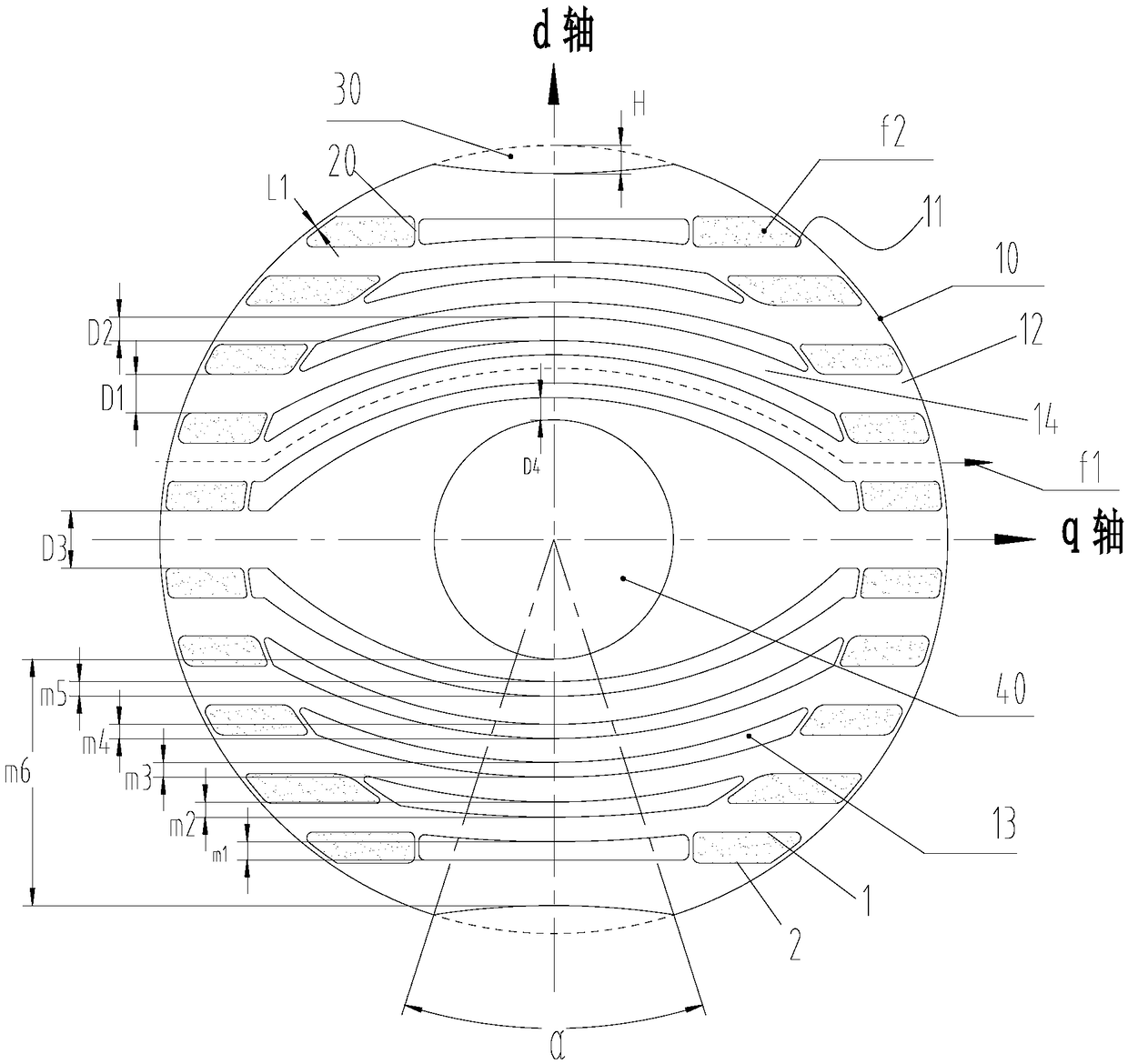

ActiveCN109309414AGuaranteed flux flowLarge reluctance torqueMagnetic circuit rotating partsSynchronous motorsMagnetic barrierSynchronous reluctance motor

The present invention provides a rotor structure, an asynchronous starting synchronization reluctance motor and a compressor. The rotor structure comprises a rotor body (10), the rotor body (10) is provided with holding grooves (11) and a magnetic barrier slit groove (13), one first magnetic flow channel (12), passing through a q axis, formed between each two adjacent holding grooves (11) is a main magnetic flow channel with a width D3, and the width D3 of the main magnetic flow channel is larger than these of the other two adjacent holding grooves (11). Therefore, the magnetic flow of the main magnetic flow channel is ensured to avoid supersaturation, effectively increase the difference of the magnetic flux between the d axis and the q axis, allow the motor having the rotor structure to generate a larger reluctance torque and increase the output torque and the efficiency of the motor so as to improve the performances of the motor.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

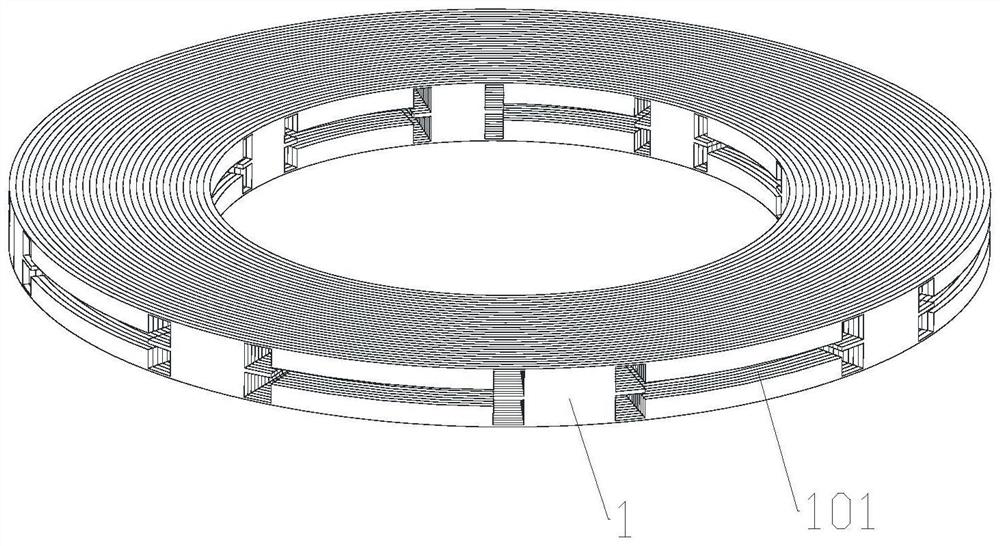

Built-in permanent magnet rotor disc and disc type motor

PendingCN114189074AImprove stabilityReduce dosageMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsPermanent magnet rotorMagnetic reluctance

The invention discloses a built-in permanent magnet rotor disc and a disc type motor comprising the built-in permanent magnet rotor disc, and relates to the field of permanent magnet motor rotors, the rotor disc comprises an annular rotor iron core, a non-magnetic conductive protective sleeve and a plurality of first permanent magnet groups, the plurality of first permanent magnet groups are uniformly arranged along the circumferential direction of the annular rotor iron core, a gap is formed between any two adjacent first permanent magnet groups, each first permanent magnet group is embedded in the annular rotor iron core, the annular rotor iron core is sleeved on a non-magnetic support of the motor, the non-magnetic protective sleeve is arranged on the outer side wall of the annular rotor iron core, and any two adjacent first permanent magnet groups are opposite in magnetizing direction. The first permanent magnet group, the annular rotor core and a stator disc of the motor can form a first closed magnetic circuit. The rotor disc permanent magnets are embedded, so that the stability of the rotor is good, the built-in structure enhances the magnetism gathering capability of the rotor, improves the salient pole effect of the rotor, improves the reluctance torque, and reduces the permanent magnet consumption of the rotor under the same power level.

Owner:NANJING UNIV OF SCI & TECH

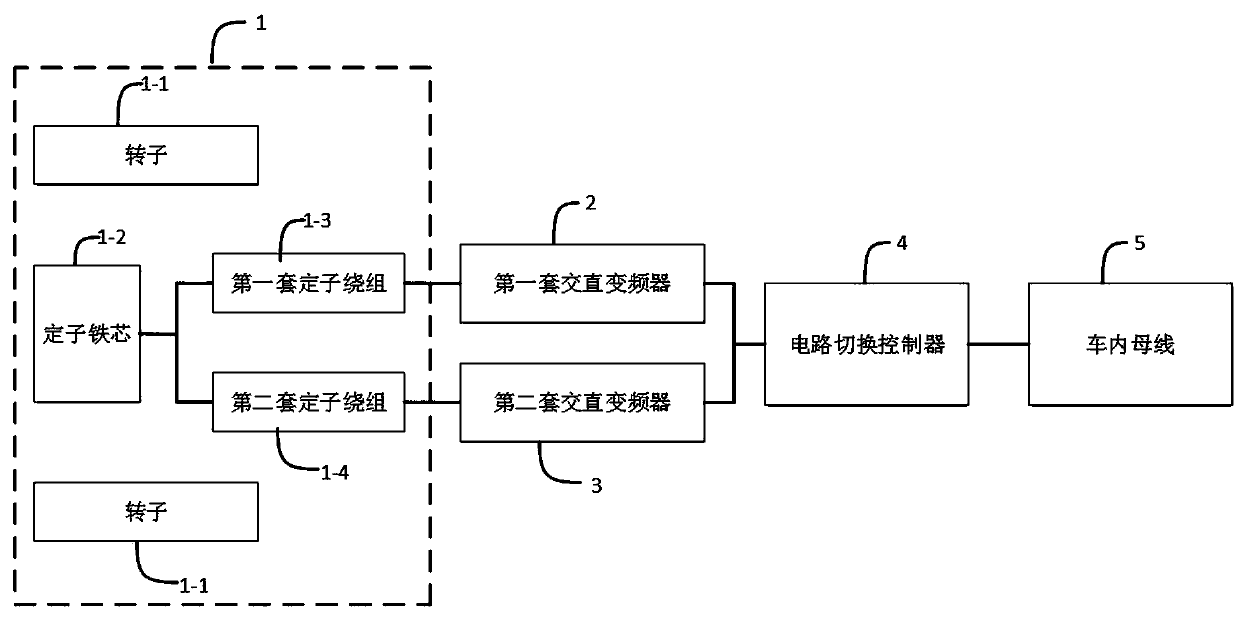

Variable branch modular permanent magnetic built-in outer rotor hub motor for electric vehicle

ActiveCN110365132AIncreased torque/power densityRaise the saliency ratioAssociation with control/drive circuitsMagnetic circuit rotating partsFrequency changerElectric machine

The invention discloses a variable branch modular permanent magnetic built-in outer rotor hub motor for an electric vehicle, and relates to the technical field of motors. A stator iron core is composed of Ns stator tooth modules and a stator yoke; each stator tooth module comprises a stator tooth and a winding coil wound on the stator tooth; a stator winding adopts a fractional slot concentrated winding structure to form m phases of windings; each phase is composed of k winding branches; the m phase of the windings with k winding branches are controlled by t m phases of DC-AC frequency converter; and a rotor consists of a rim and 2p rotor iron core modules. The hub motor has the advantages of high torque / power density, large reluctance torque, variable circuit control capability, capability of widening the speed regulation range, capability of realizing modular manufacturing and automatic production and the like.

Owner:武汉研道科技有限公司

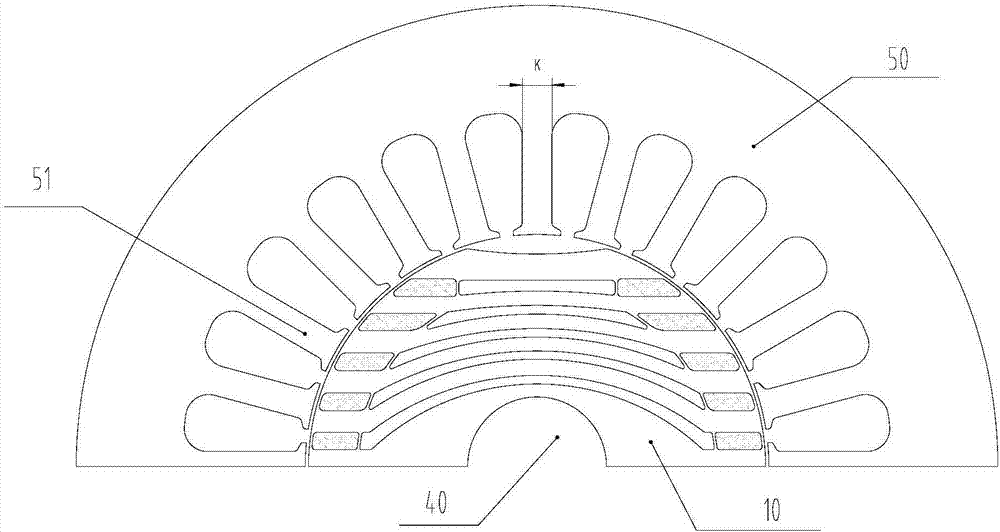

Synchronous reluctance motor rotor structure and motor with same

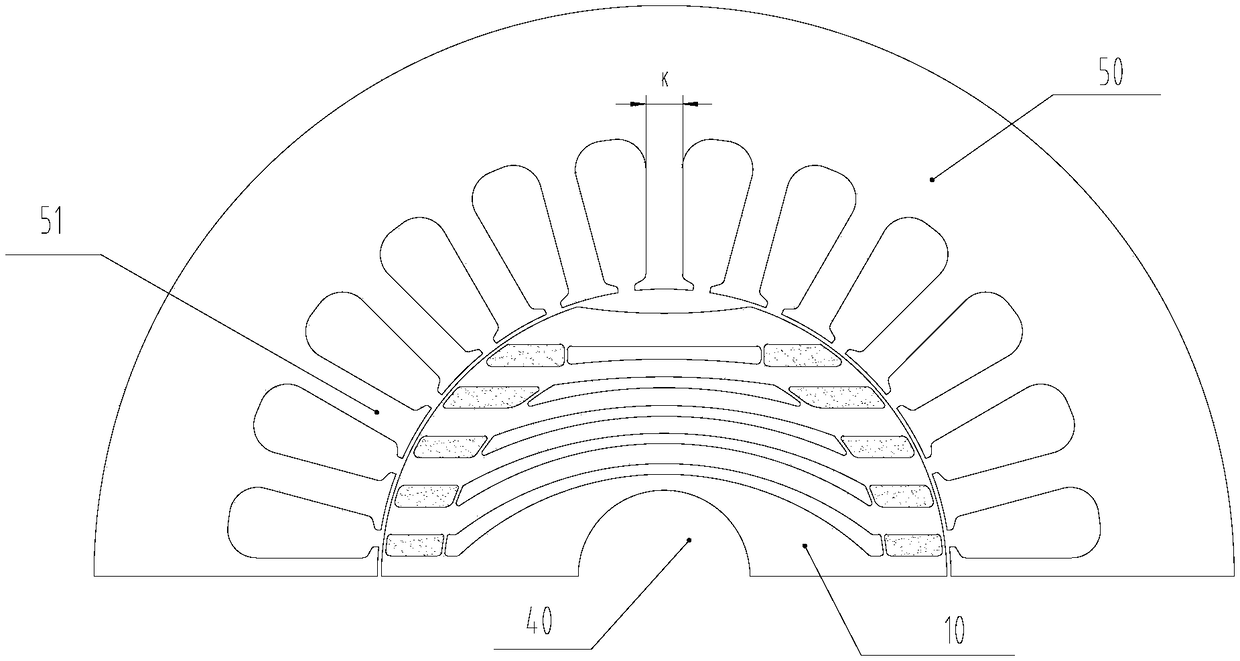

ActiveCN110112847ALarge reluctance torqueImprove output and efficiencyMagnetic circuit rotating partsSynchronous motorsEngineeringTorque ripple

The invention provides a synchronous reluctance motor rotor structure and a motor with the same. The synchronous reluctance motor rotor structure includes a rotor core which is provided with a plurality of slit slots. A filling slot is arranged at each of the two ends of each slit slot. Each filling slot has a first position near the d axis of the rotor core and a second position away from the d axis at the end near the edge of the rotor core. Each filling slot has a slot opening at the first position or at the second position. In the same pole of the rotor core, when one filling slot of two adjacent filling slots has a slot opening at the first position, the other filling slot has a slot opening at the second position. Thus, the q-axis flux can be further blocked without affecting the entry of the d-axis flux into the stator, the difference between the d-axis flux and the q-axis flux can be larger, greater reluctance torque can be generated, and the output and efficiency of the motorcan be increased. Moreover, the torque ripple of the motor is reduced, and the vibration noise of the motor is reduced.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

Flat copper wire formed stator coil high-reluctance torque outer rotor type permanent magnet drive motor

PendingCN109560627AIncrease profitImprove efficiencyMagnetic circuit rotating partsMagnetic circuit stationary partsCopper wireStator coil

The invention discloses a flat copper wire formed stator coil high-reluctance torque outer rotor type permanent magnet drive motor. The permanent magnet drive motor comprises a coupler shaft, whereinthe left and right sides of the coupler shaft are connected with a front end cover and a double-screw water channel ring respectively; a rear bearing is fixed onto the double-screw water channel ring;the double-screw water channel ring is matched with a water channel outer ring to form a double-screw water channel; the water channel outer ring is connected with an inner stator iron core; the coupler shaft is provided with an outer rotor magnet yoke fixed barrel; a self-buckle type outer rotor iron core is arranged on the inner surface of the outer rotor magnet yoke fixed barrel; and a plurality of magnetic steel is arranged on the self-buckle type outer rotor iron core in an inserted manner. By using the distribution of inverted V-shaped magnetic steel, the permanent magnet drive motor has the characteristic of high reluctance torque; a flat copper formed coil is used, a stator is an open slot, and the utilization rate of the slot is improved by 25% compared with that of a circular copper wire; a machine hand can be used for inserting winding; the efficiency of the motor can be improved by using more copper and few magnetic steel, the cost is reduced, the power density and torquedensity are improved, and the cost performance is higher; and the double-screw water channel has the advantages of low water resistance and high heat dissipation capacity.

Owner:宁德时代电机科技有限公司

Rotor structure, asynchronous starting synchronization reluctance motor and compressor

ActiveCN109309415AValid entryAvoid saturationMagnetic circuit rotating partsSynchronous motorsMagnetic barrierSynchronous reluctance motor

The present invention provides a rotor structure, an asynchronous starting synchronization reluctance motor and a compressor. The rotor structure comprises a rotor body (10), the rotor body (10) is provided with holding grooves (11) and a magnetic barrier slit groove (13), one first magnetic flow channel (12), passing through a q axis, formed between each two adjacent holding grooves (11) has a width D3, D3>K, wherein K is the width of the stator teeth of the stator core. The width of the first magnetic flow channel (12) passing through the q axis is larger than the width of the stator teeth to avoid the supersaturation of the magnetic channel, ensure that the magnetic flow effectively enters a stator, allow the motor having the having the rotor structure to generate a larger reluctance torque and increase the output torque and the efficiency of the motor so as to improve the performances of the motor.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Rotor with reinforcing portions for an electric rotating machine

ActiveUS8878410B2Large reluctance torqueHigh mechanical strengthMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsMagnetic polesEngineering

Owner:DENSO CORP

Permanent magnet rotor and rotary electric machine

ActiveCN110391700AReduce harmonic componentsReduce torque fluctuationMagnetic circuit rotating partsPermanent magnet rotorHarmonic

The present invention provides a permanent magnet rotor capable of reducing a harmonic component of a waveform of a magnetic flux density distribution formed in an air gap of a rotary electric machine, and a rotary electric machine having such a permanent magnet rotor.

Owner:DAIDO ELECTRONICS CO LTD +1

Rotor structure of permanent magnet synchronous motor

PendingCN110994843AImprove efficiencyIncrease fluxMagnetic circuit rotating partsPermanent magnet synchronous motorMagnetic reluctance

The invention provides a rotor structure of a permanent magnet synchronous motor. The end surface of a rotor is provided with a plurality of V-shaped magnetic steel grooves (1) which extend in the length direction of a rotor and are distributed in the circumferential direction, the V-shaped magnetic steel grooves (1) are distributed at equal intervals, and the V-shaped opening directions of the V-shaped magnetic steel grooves (1) face the outer diameter of the rotor; magnetic steel (2) is arranged in each V-shaped magnetic steel groove (1); and a magnetic isolation magnetic bridge (7) is arranged at the vertex angle position corresponding to each V-shaped magnetic steel groove (1), and a first air groove (8) is formed between every two adjacent V-shaped magnetic steel grooves (1). According to the invention, the sinusoidal property of the permanent magnet flux density waveform can be effectively improved, and the harmonic content in the flux density is reduced. In addition, the magnetic circuits of the V-shaped magnetic steel grooves can improve the reluctance effect, increases the reluctance torque, enhances the magnetic flux of the rotor, reduces the iron loss of a high-speed region, reduces the torque ripple, improves the efficiency of the permanent magnet synchronous motor to the maximum extent, saves materials and realizes low size and high efficiency.

Owner:SHANGHAI INST OF TECH

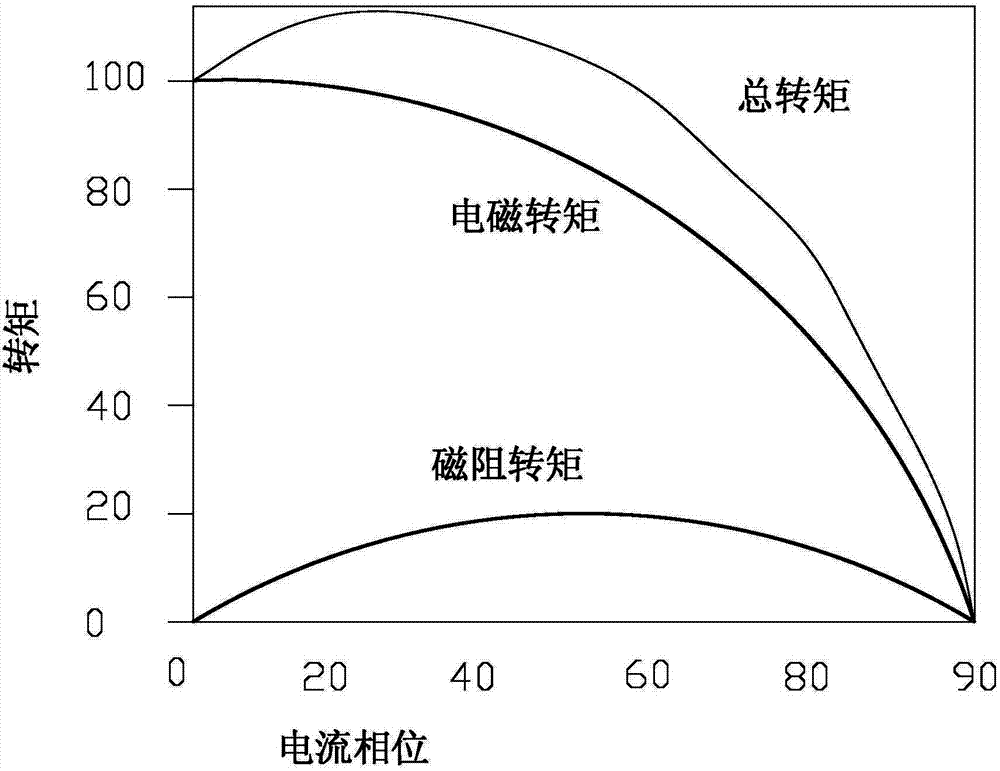

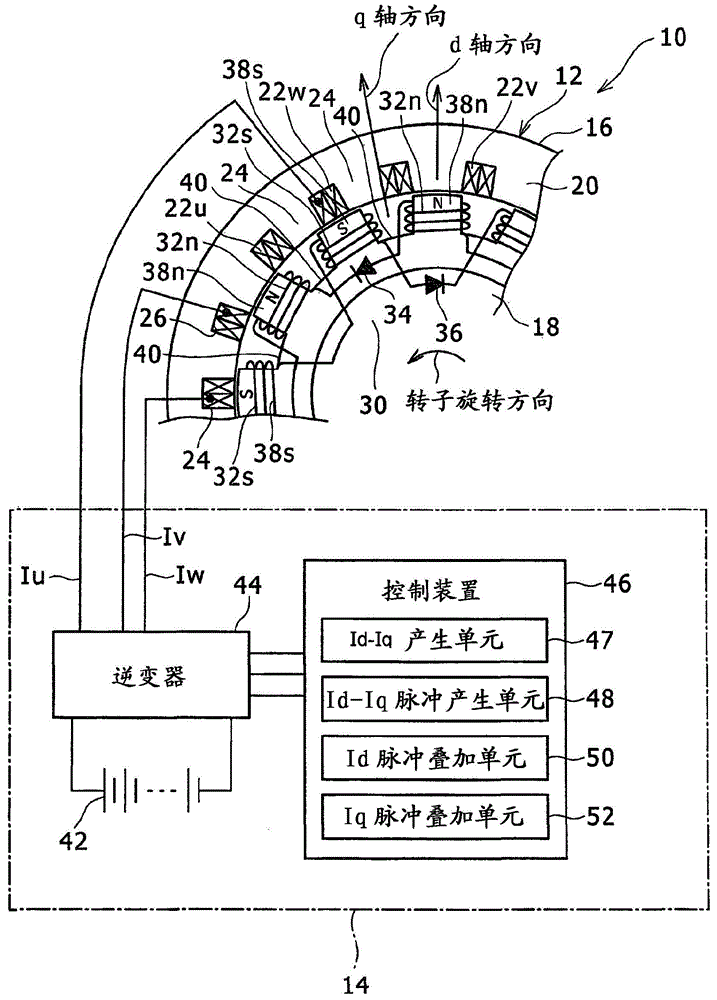

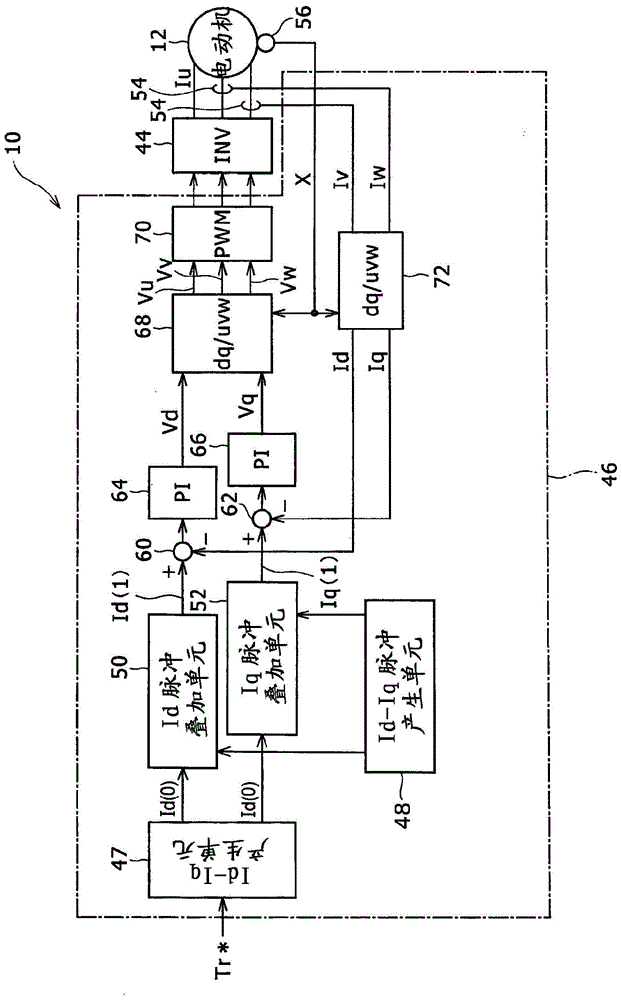

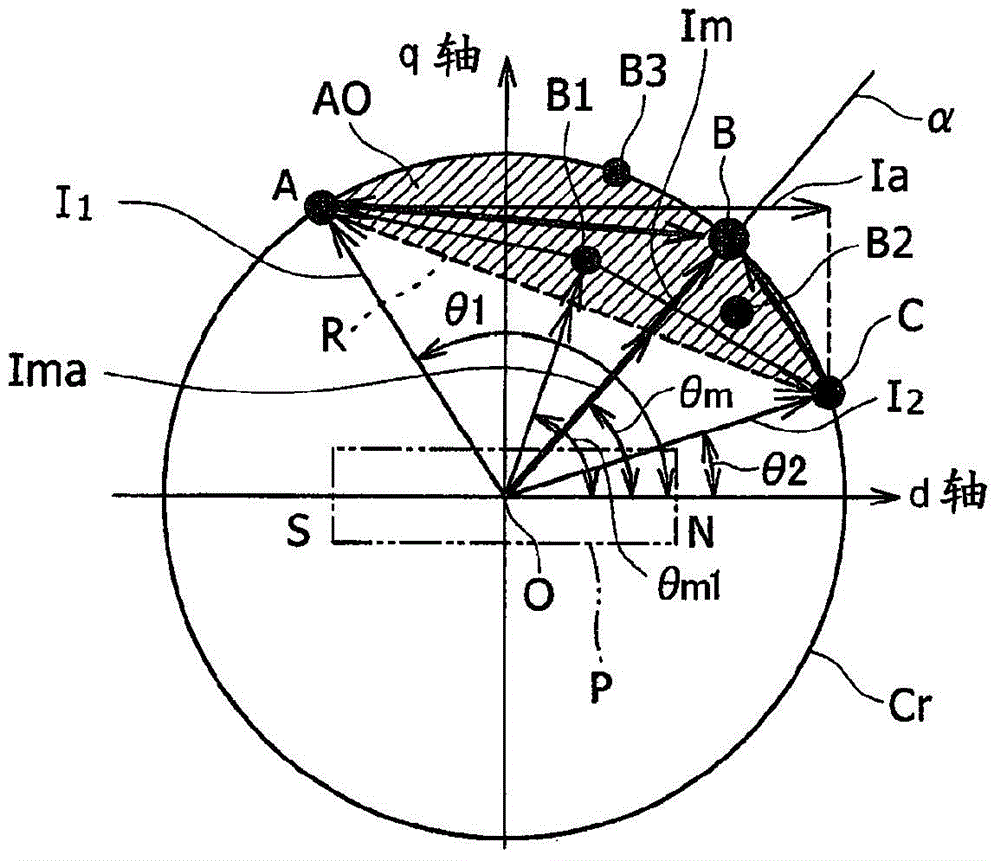

Rotary electric machine control system and rotary electric machine control method

InactiveCN104488186AIncrease torqueLarge reluctance torqueSynchronous generatorsElectronic commutation motor controlEngineeringCurrent pulse

A rotary electric machine control system includes a control device that controls a rotary electric machine. When there is a current phase at which a reluctance torque is maximum between a first current phase (theta 1) of a first current vector (I1) on which current pulses have not been superimposed yet and a second current phase (theta 2) of a second current vector (I2) obtained by increasing a d-axis current and reducing a q-axis current, the control device sets an intermediate current vector (Im) having an intermediate phase (theta m) between the first and second current phases (theta 1, theta 2). The intermediate current vector (Im) is set so as to be larger than an imaginary current vector (Ima) at the intermediate phase (theta m) in the case where a vector locus is varied in a straight line from the first current vector (I1) to the second current vector (I2). The current pulses are generated by changing the current vector in order of I1, Im and I2 and returning the current vector in order of Im and I1.

Owner:TOYOTA JIDOSHA KK

High-salient-pole-ratio permanent magnet motor for electric motorcycle

PendingCN112953152ARaise the saliency ratioIncrease torqueMagnetic circuit rotating partsSynchronous machine detailsElectric machineryPermanent magnet motor

The invention discloses a high-salient-pole-ratio permanent magnet motor for an electric motorcycle. The high-salient-pole-ratio permanent magnet motor comprises a stator and a rotor arranged on the outer side of the stator in a sleeving mode, wherein an air gap is formed between the stator and the rotor, and the stator is fixed to a connecting shaft through a fixing support, the rotor comprises a rotor iron core and a plurality of magnetic steel groove sets evenly arranged on the rotor iron core in the circumferential direction; each magnetic steel groove set is composed of two magnetic steel grooves distributed in a V shape and a linear magnetic steel groove, the large openings of the two magnetic steel grooves distributed in the V shape face the circle center, and the linear magnetic steel groove is formed in the large opening of the V shape; each magnetic steel groove is an axial through groove, a permanent magnet is embedded in each magnetic steel groove, and air gaps exist between the two non-axial end parts of each permanent magnet and the corresponding magnetic steel groove; and the ends, close to the stator, of the two magnetic steel grooves distributed in the V shape are communicated with the air gap, and the ends, away from the stator, of the two magnetic steel grooves are mutually independent. The high-salient-pole-ratio permanent magnet motor can solve the problems of magnetic density supersaturation, high iron loss, low motor efficiency and stress concentration of a V-shaped groove magnetic bridge part.

Owner:台铃科技(江苏)股份有限公司

Motor rotor, motor, compressor and air conditioner

InactiveCN110112850AImprove weak magnetic propertiesIncrease the maximum operating frequencyMagnetic circuit rotating partsBusiness efficiencyElectric machine

The application provides a motor rotor, a motor, a compressor and an air conditioner. The motor rotor comprises a plurality of magnetic poles which are distributed in the circumferential direction, wherein each magnetic pole comprises a first permanent magnet (1) and a second permanent magnet (2); the first permanent magnets (1) are positioned on the d shaft of thee motor; the second permanent magnets (2) are positioned on the q shaft of the motor; the first permanent magnets (1) are magnetized in the radial direction; the second permanent magnets (2) are magnetized in the tangential direction; and the coercive force temperature coefficients [alpha] d of the first permanent magnets (1) are greater than the coercive force temperature coefficients [alpha] q of the second permanent magnets (2). According to the motor rotor, the high-frequency operation capacity of the compressor can be improved, the low-frequency energy efficiency is not influenced, and the energy efficiency ratio of thewhole machine is improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Permanent magnet motor concentrated winding modulation method and adjustable winding

InactiveCN111478540ASmall sizeShorten the axial lengthSynchronous machine detailsMagnetic circuit stationary partsElectric machineMagnetic poles

The invention belongs to the field of motor design, and particularly relates to an armature winding design technology of a permanent magnet motor. Each phase of the windings provided by the inventionrealizes flexible armature magnetic field pole number change through the mutual offset effect of the coils wound on each tooth. According to the scheme, each coil is wound on a stator tooth, each phase winding is formed by connecting a plurality of coils wound on one tooth in series and in parallel according to a certain connection rule, and no matter how many rotor magnetic poles are, the windingcan always keep a single-tooth-winding centralized winding with the pitch of 1.

Owner:SHENYANG POLYTECHNIC UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com