Asynchronous starting type synchronous reluctance motor rotor, motor and compressor

一种同步磁阻电机、异步起动的技术,应用在异步感应电动机、用于单相电流的同步电动机、磁路等方向,能够解决同步磁阻电机转子工作效率低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

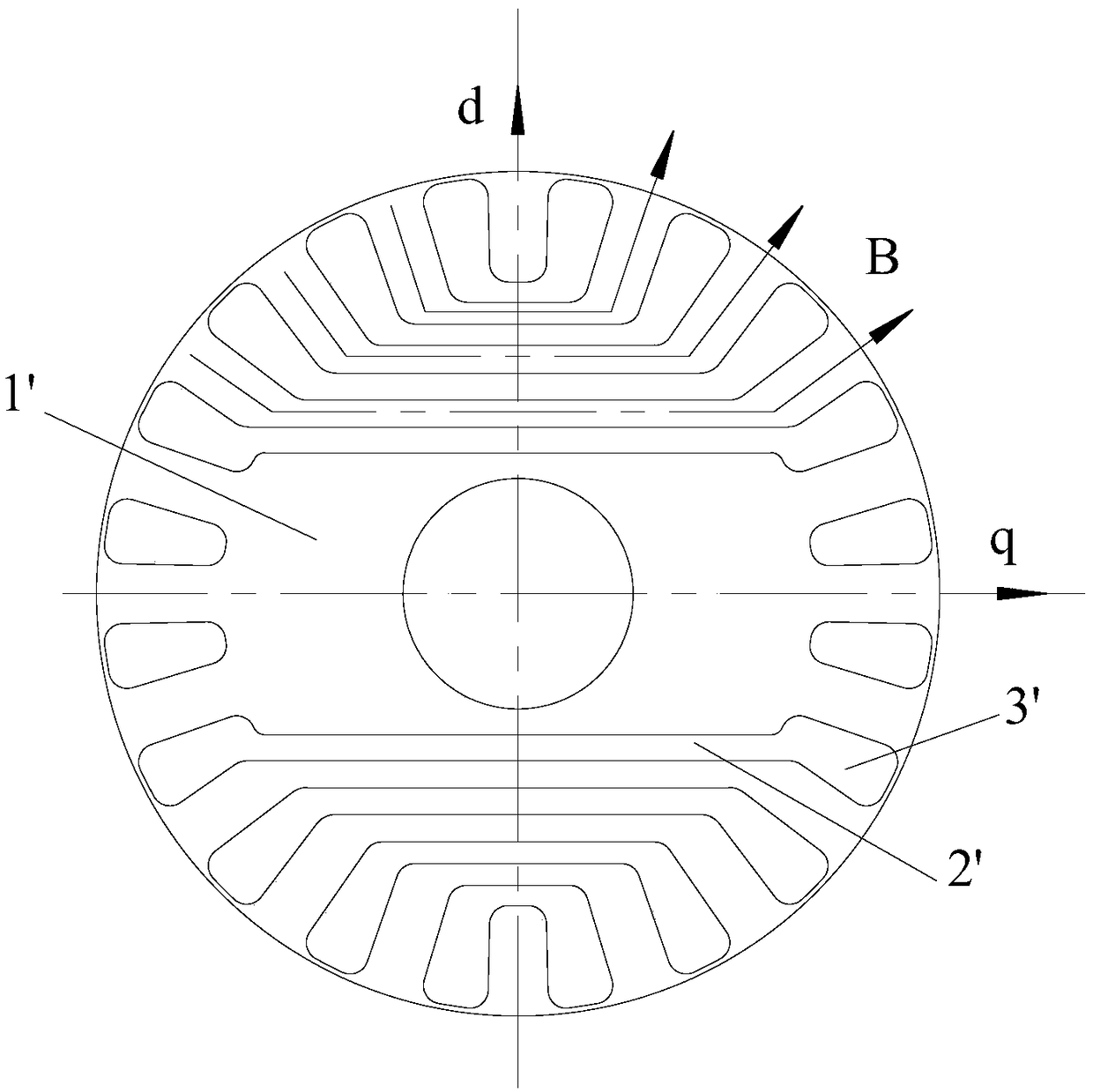

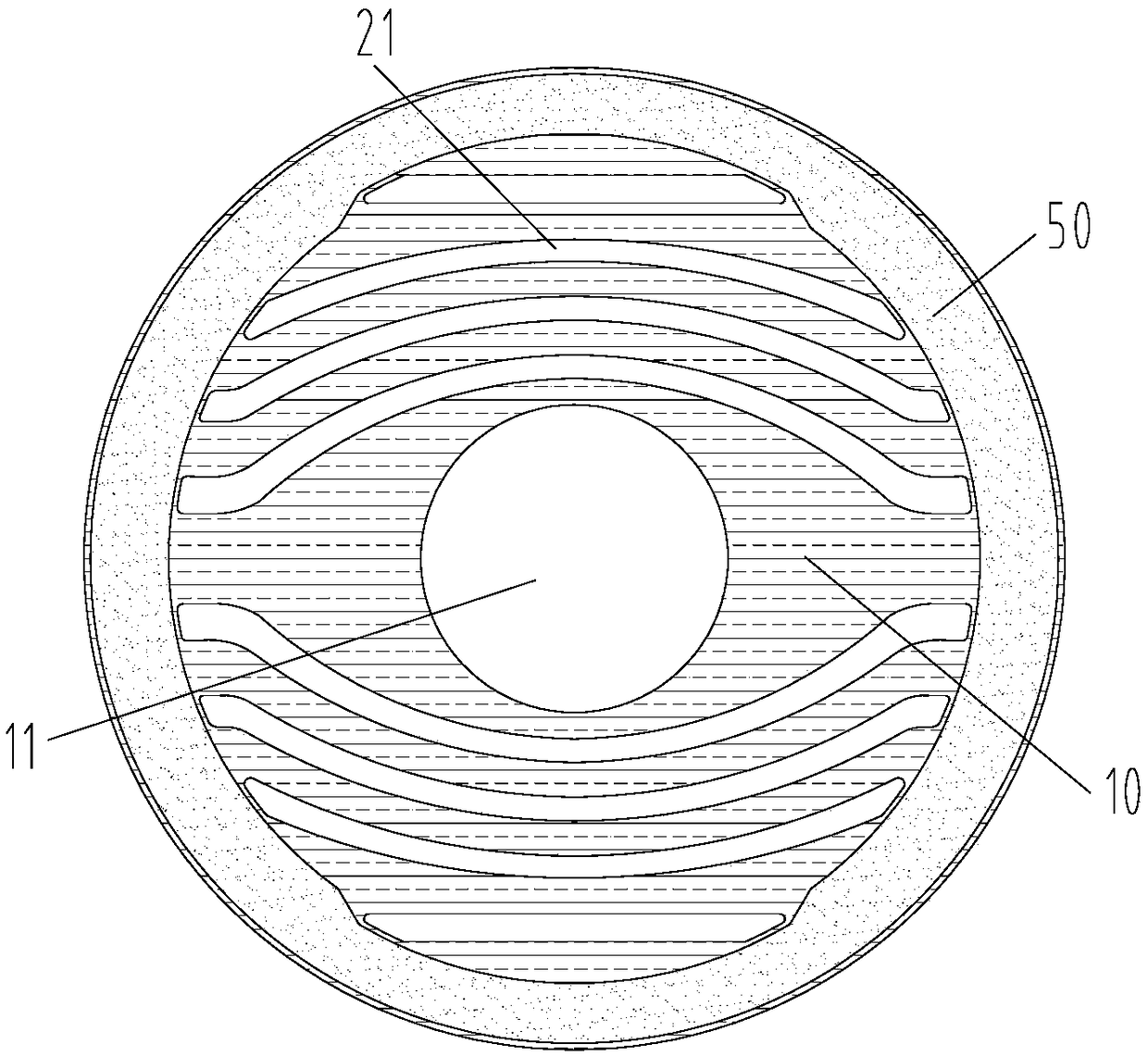

[0069] Such as Figure 2 to Figure 4 As shown, the asynchronous start synchronous reluctance motor rotor includes a rotor core 10, and the rotor core 10 includes a first magnetic barrier structure, including multiple sets of first magnetic barrier parts 21 and multiple supplementary slots 214, and each first magnetic barrier part 21 Arranged at intervals along the d-axis of the rotor core 10, a plurality of supplementary grooves 214 are respectively located between the end of the first magnetic barrier part 21 and the outer edge of the rotor core 10, and the first magnetic barrier part 21 passes through the d-axis The minimum distance from the point to the q-axis is C1, and the minimum distance from the supplementary slot 214 corresponding to the end of the first magnetic barrier portion 21 to the q-axis is C2, where C1 / C2=W, 1≤W≤5.

[0070] In the implementation of this city, applying the technical solution of the present invention, the rotor of the asynchronously started syn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com