Orientation silicon steel sheet rotor core and synchronous reluctance motor

A technology of synchronous reluctance motors and oriented silicon steel, which is applied in the direction of motors, electric components, electric vehicles, etc., can solve the problems of increasing the salient pole difference of synchronous reluctance motors, complex magnetic barrier shapes, and difficult manufacturing, and achieve reluctance Reduced size, convenient production and processing, avoiding the effect that is not easy to make

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

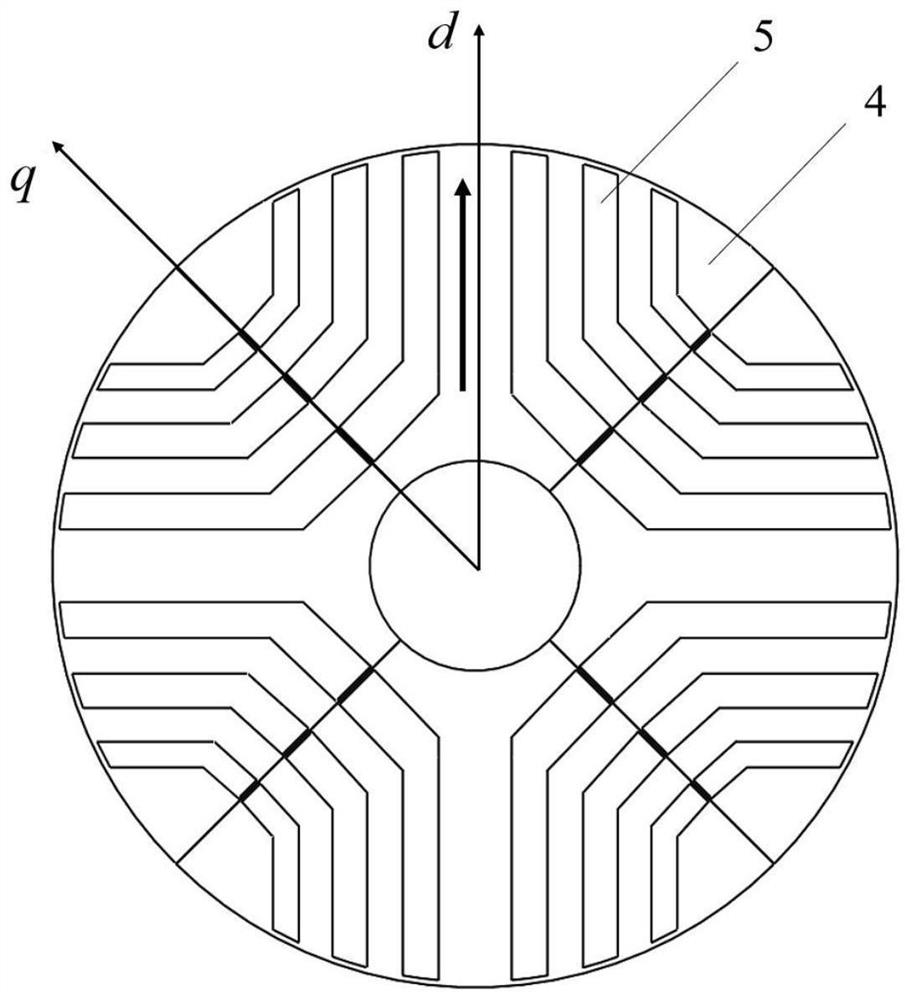

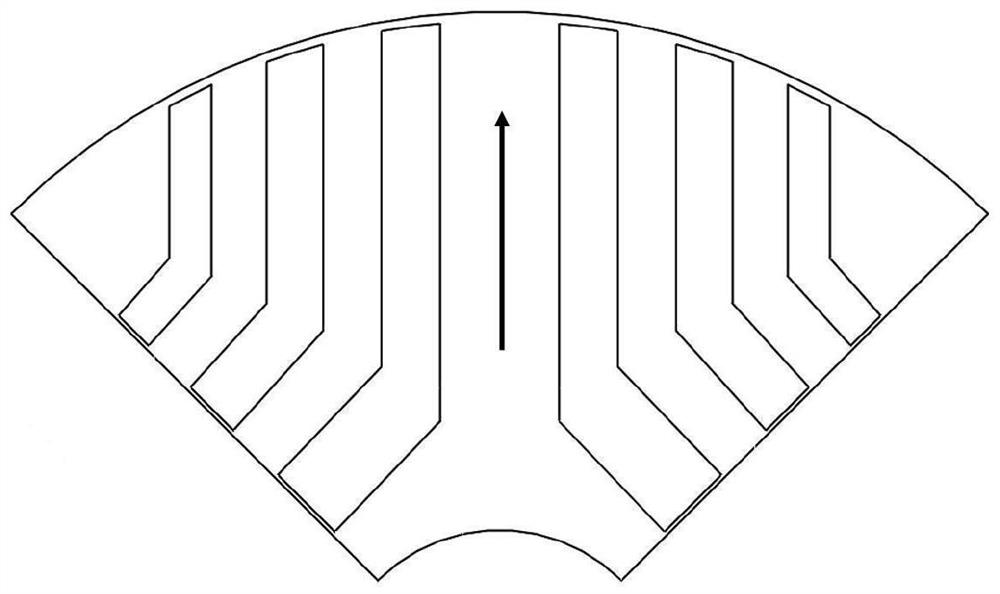

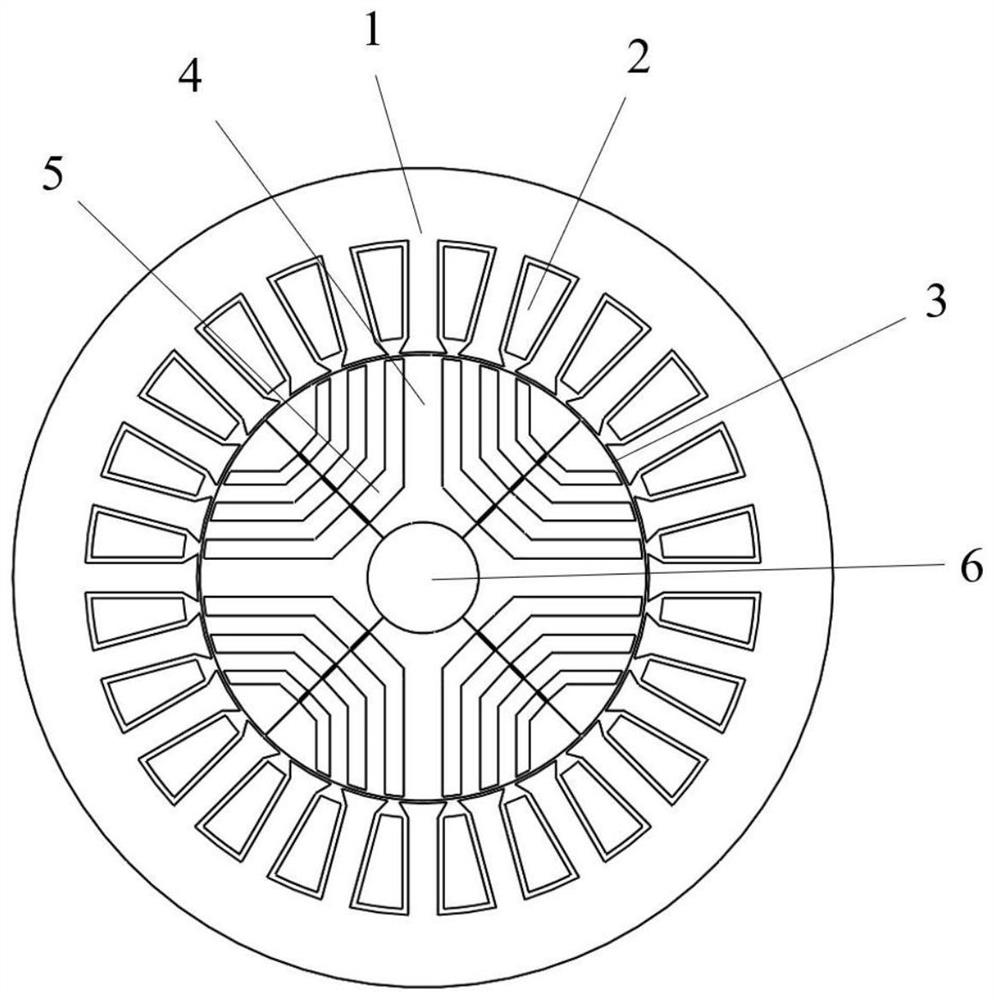

[0028] This embodiment provides an oriented silicon steel sheet rotor core (see Figure 1-2 ), characterized in that the rotor core is a hollow cylindrical structure assembled and bonded by four oriented silicon steel sheet components with the same structure and the same rolling direction, and the through hole at the center of the cylindrical structure is the motor shaft mounting hole; Each oriented silicon steel sheet assembly is formed by a plurality of identical oriented silicon steel sheets 4 aligned and laminated along the axial direction of the motor shaft, and two adjacent oriented silicon steel sheets 4 are fixed together by bonding. The rolling directions of the grain-oriented silicon steel sheets 4 are all the same.

[0029] The rolling direction of the oriented silicon steel sheet 4 is consistent with the d-axis direction of the rotor core, that is, the low reluctance direction at the location where it is installed. And two sets of magnetic barrier structures 5 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com