Patents

Literature

51results about How to "Increase saliency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Image capture unit and method with an extended depth of field

ActiveUS20130038689A1Overcomes shortcomingMore capabilityImage enhancementTelevision system detailsBeam splitterImage resolution

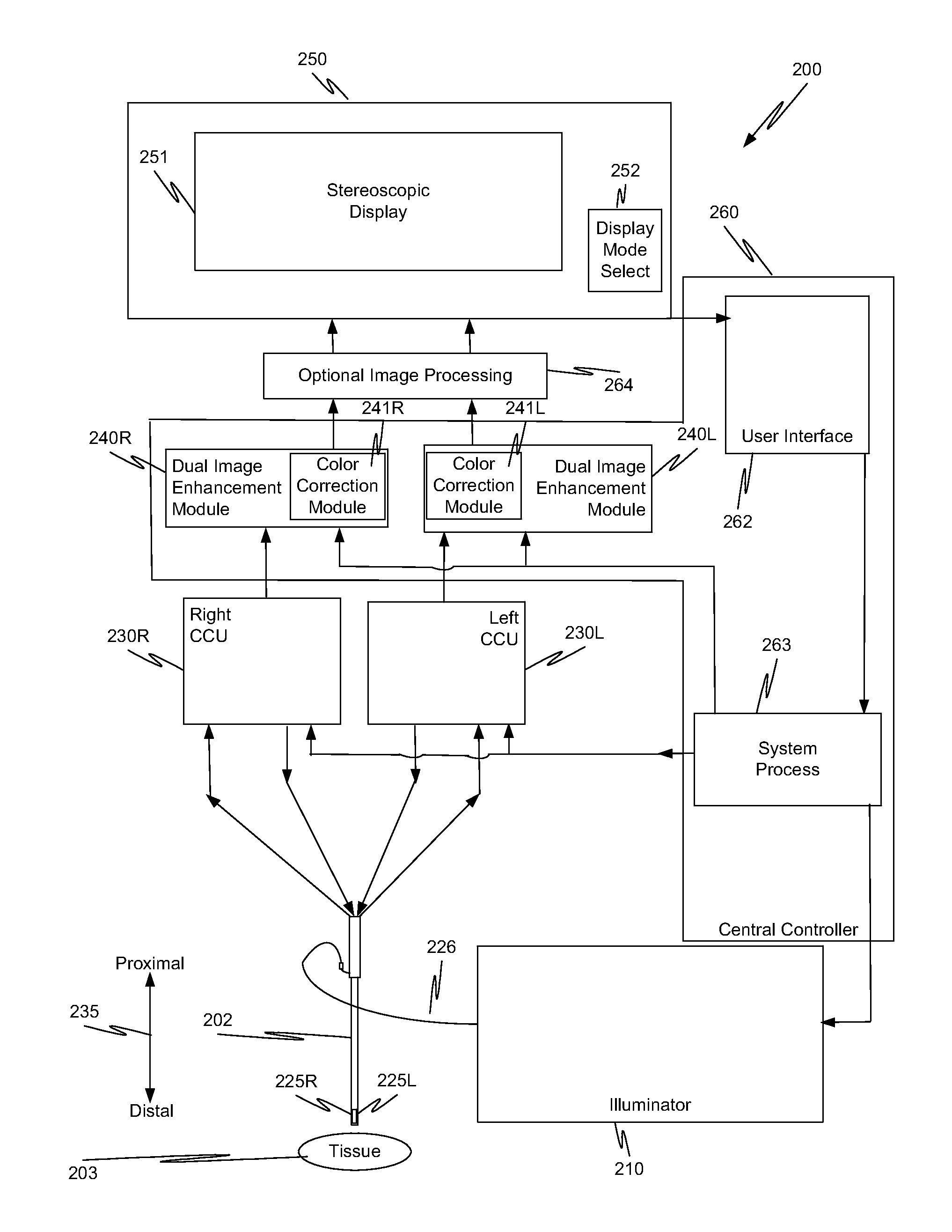

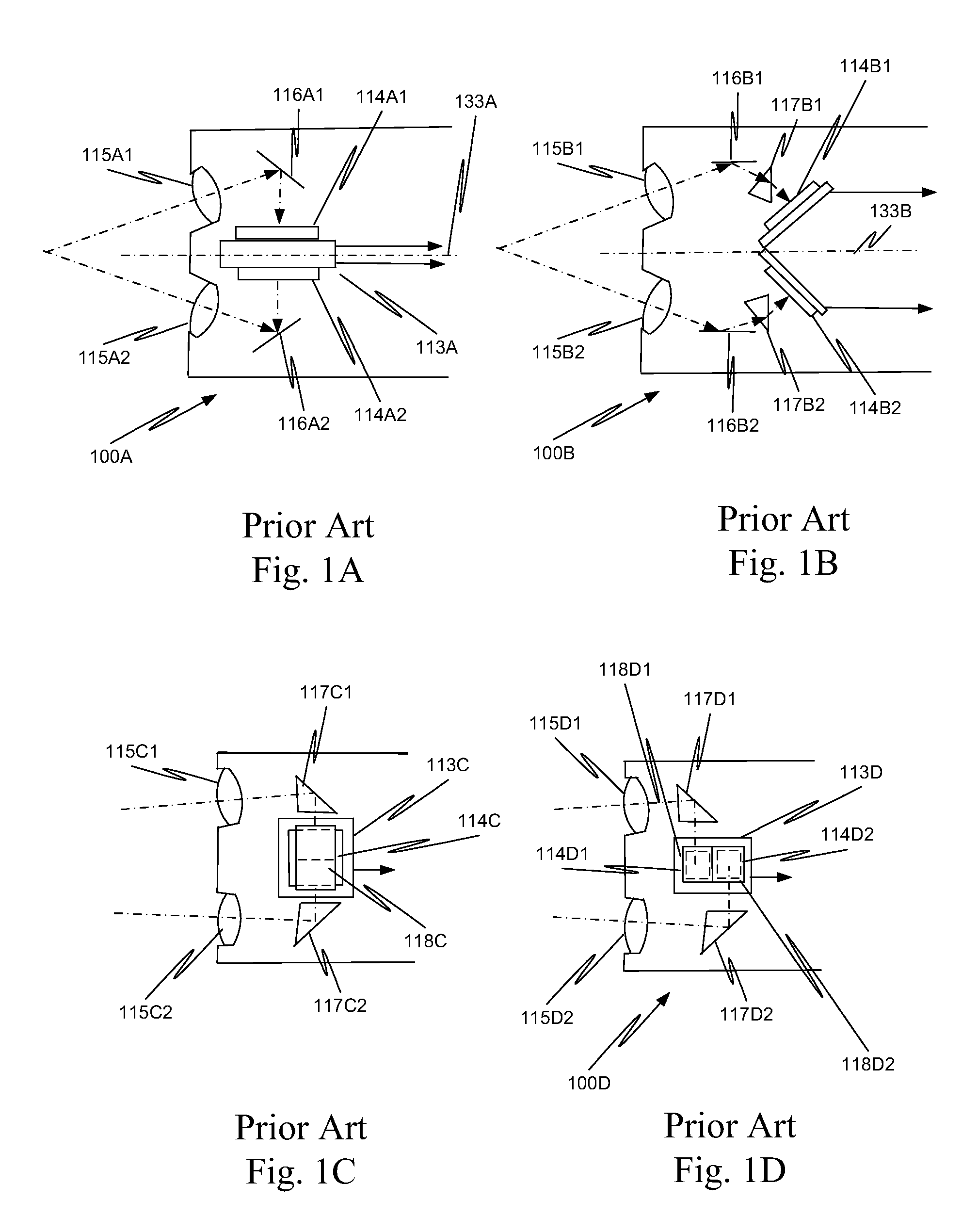

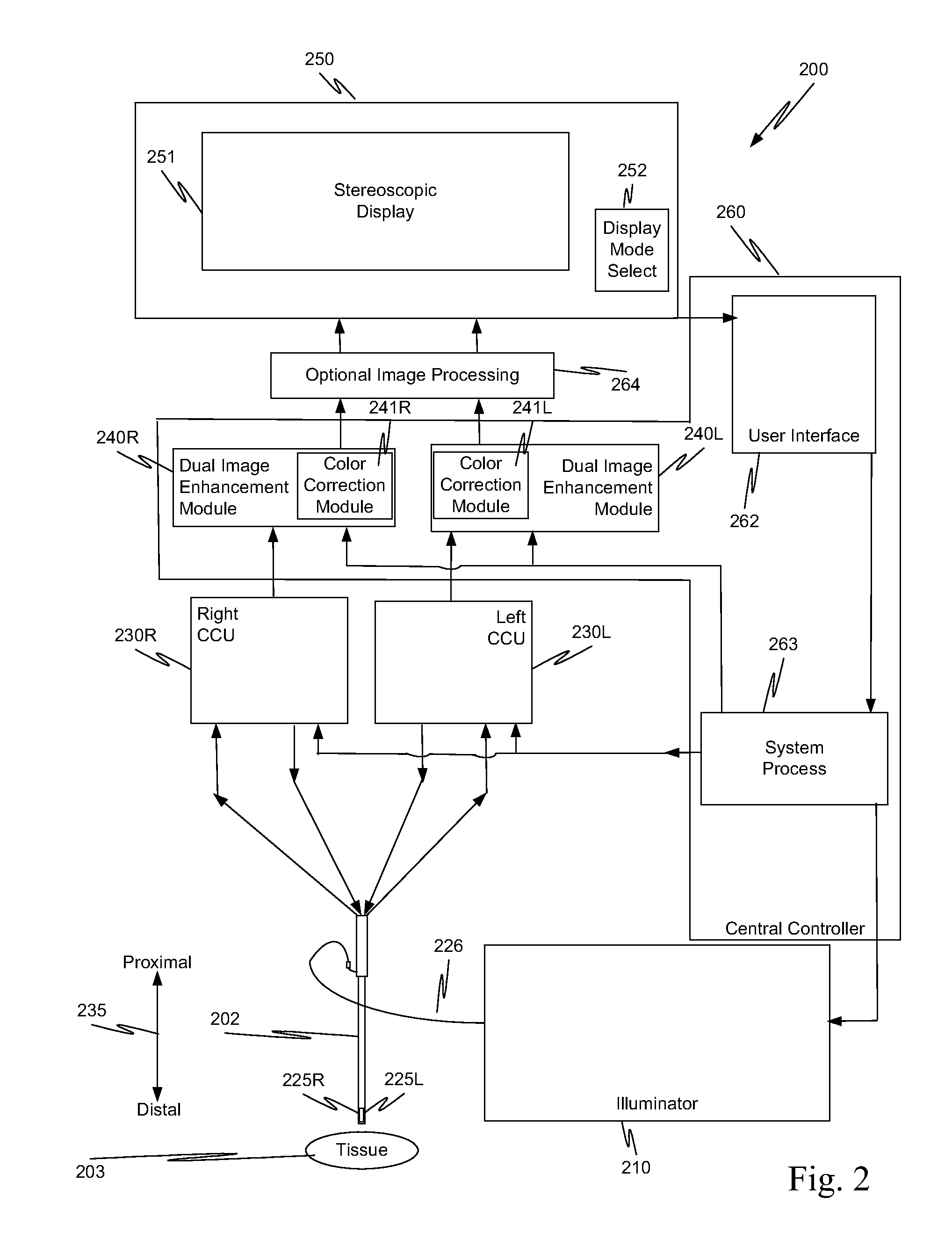

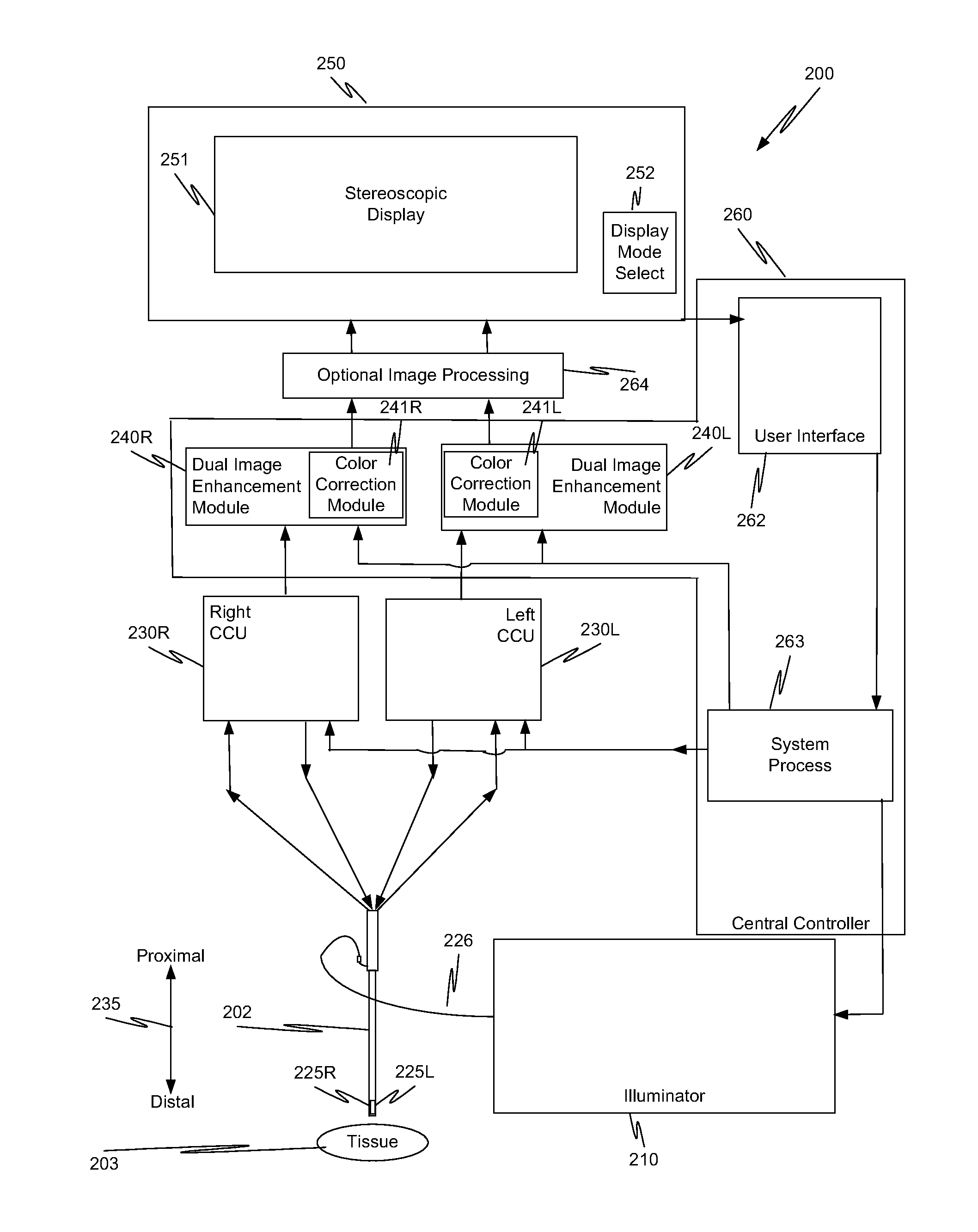

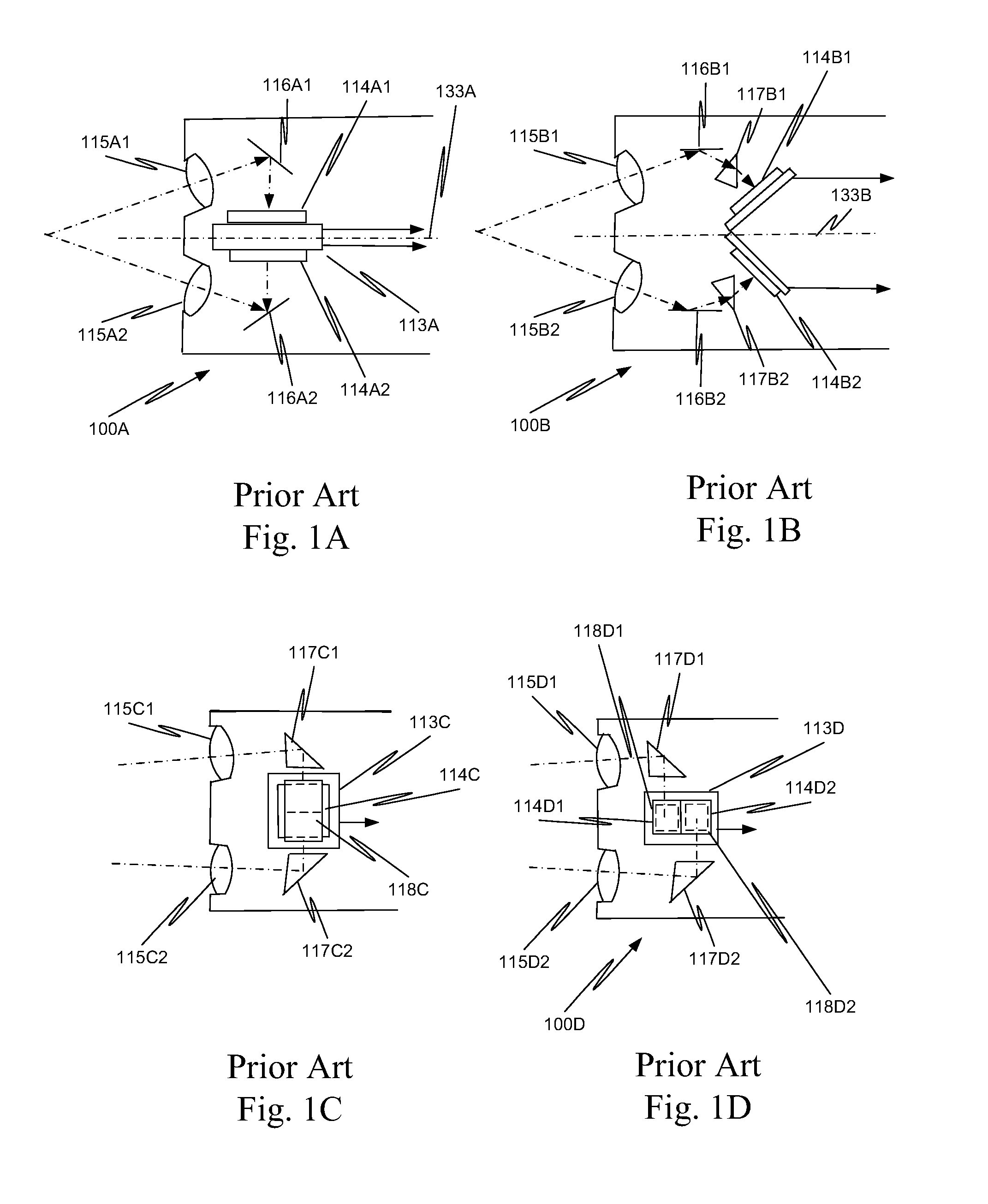

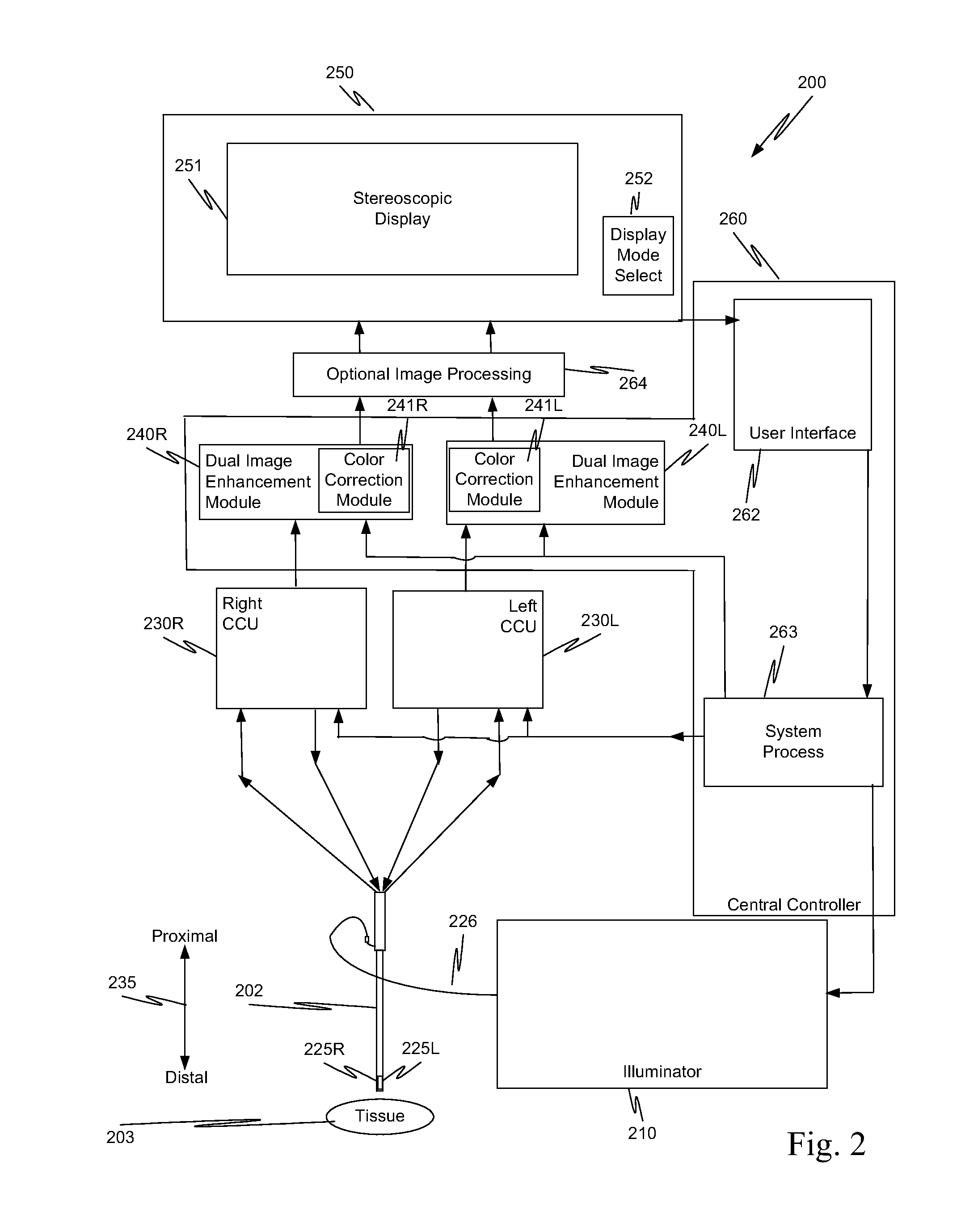

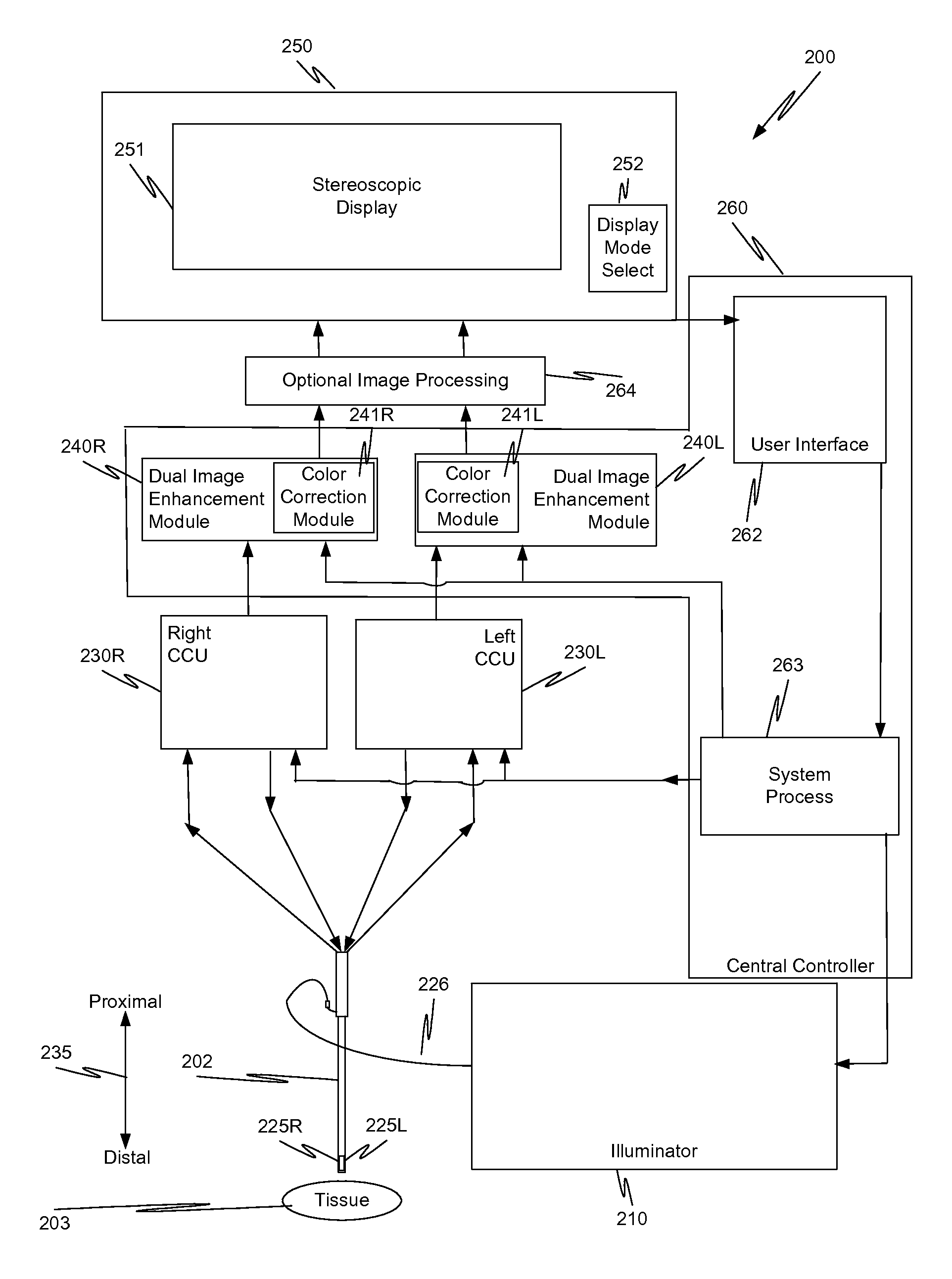

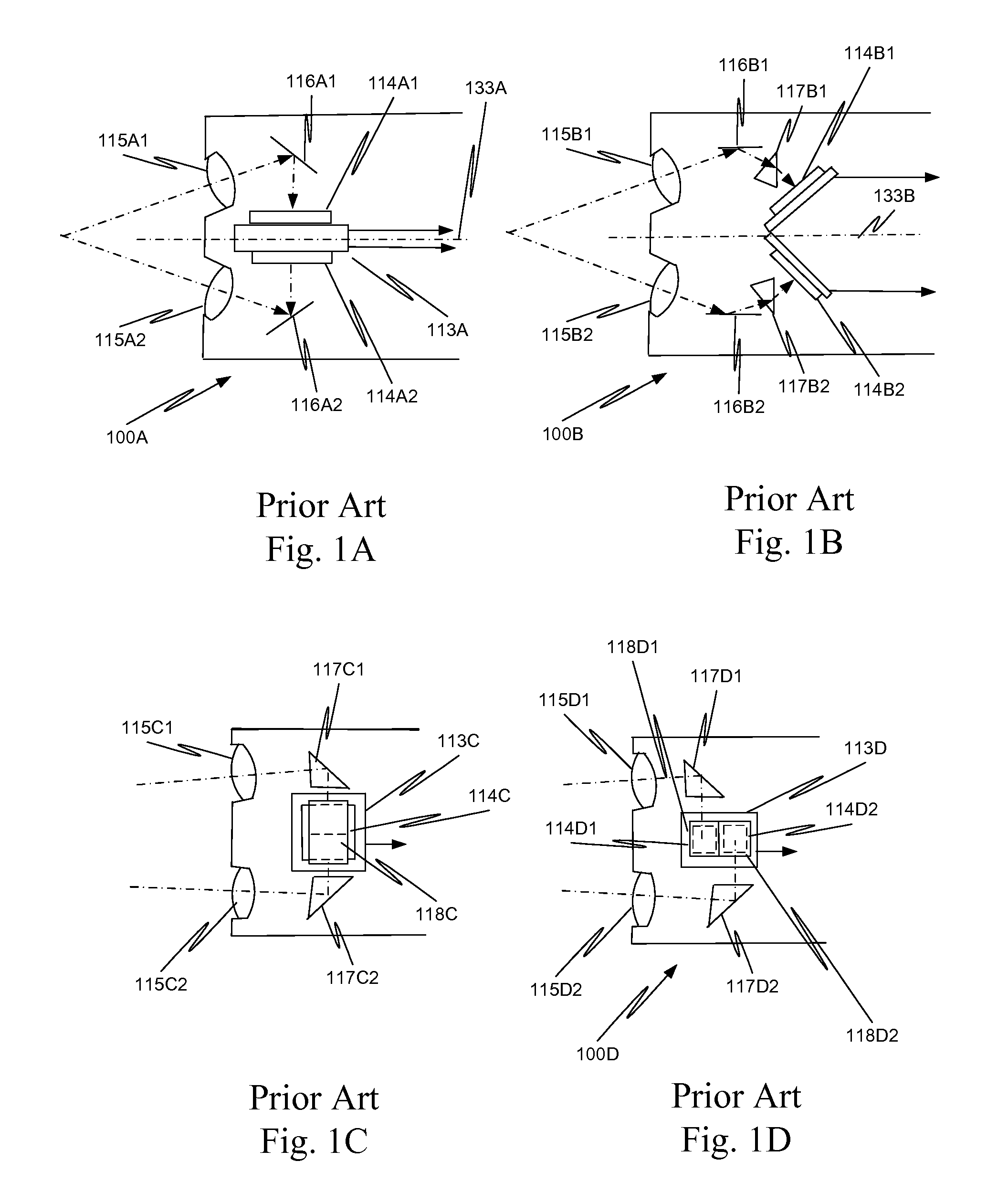

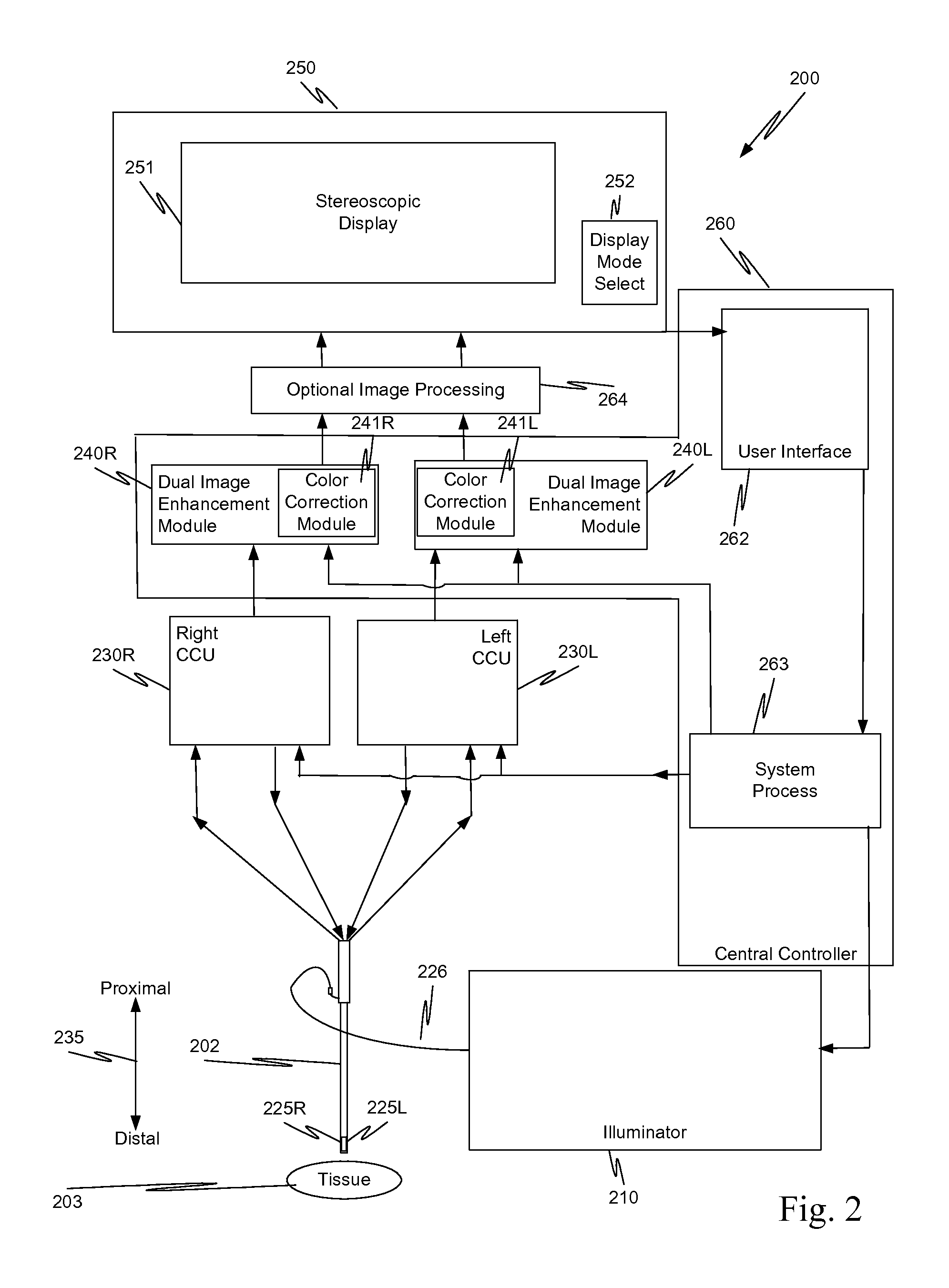

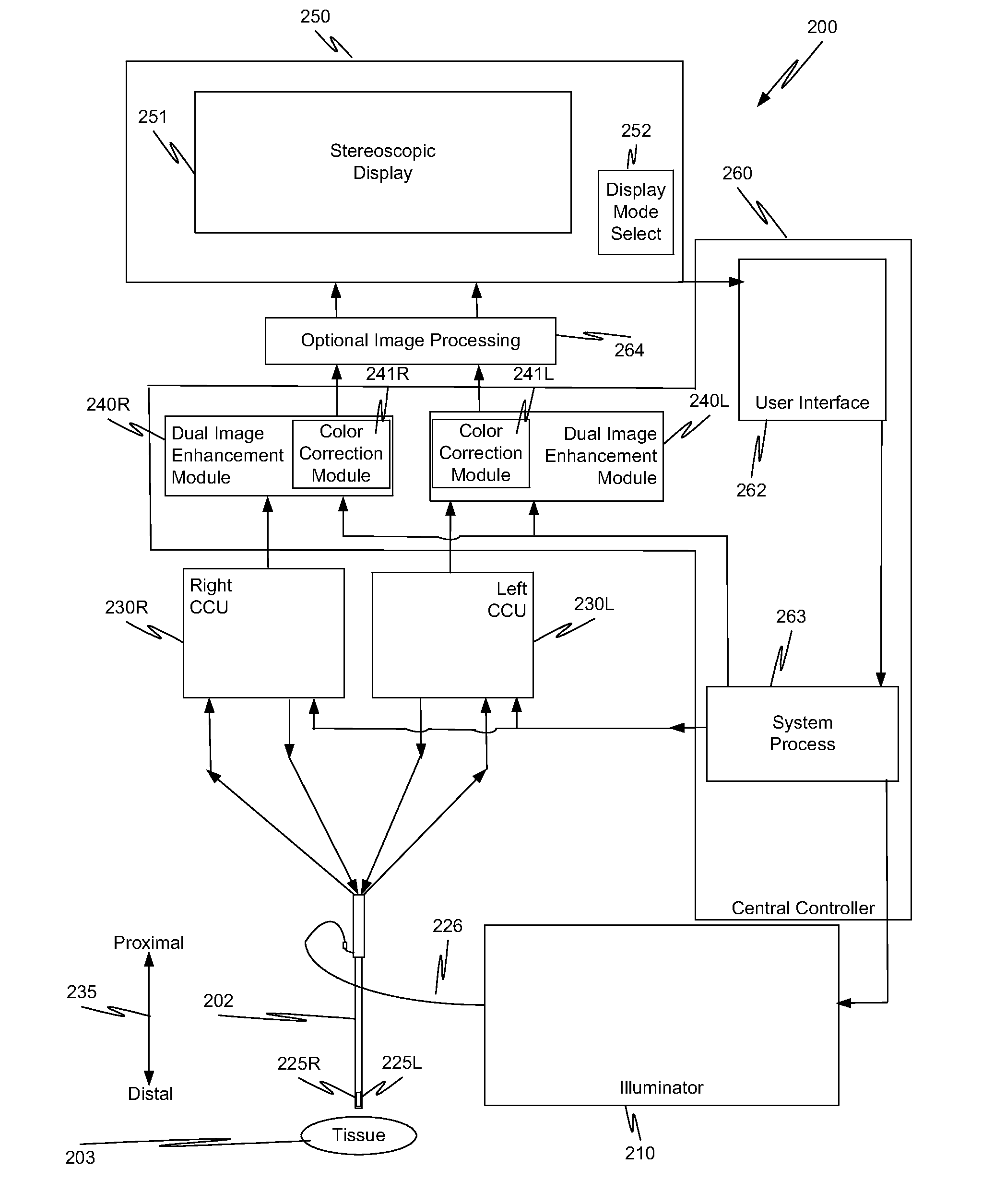

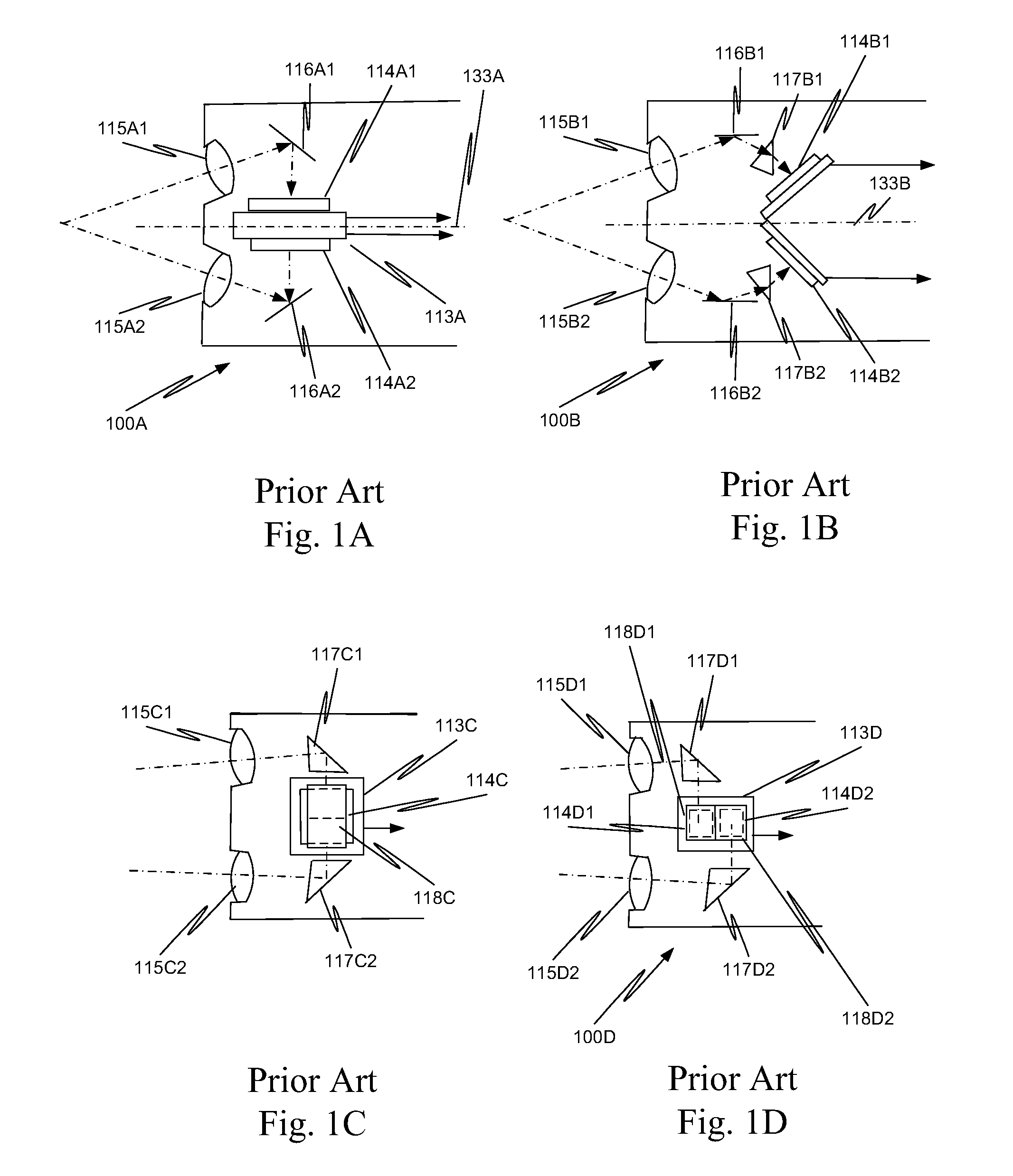

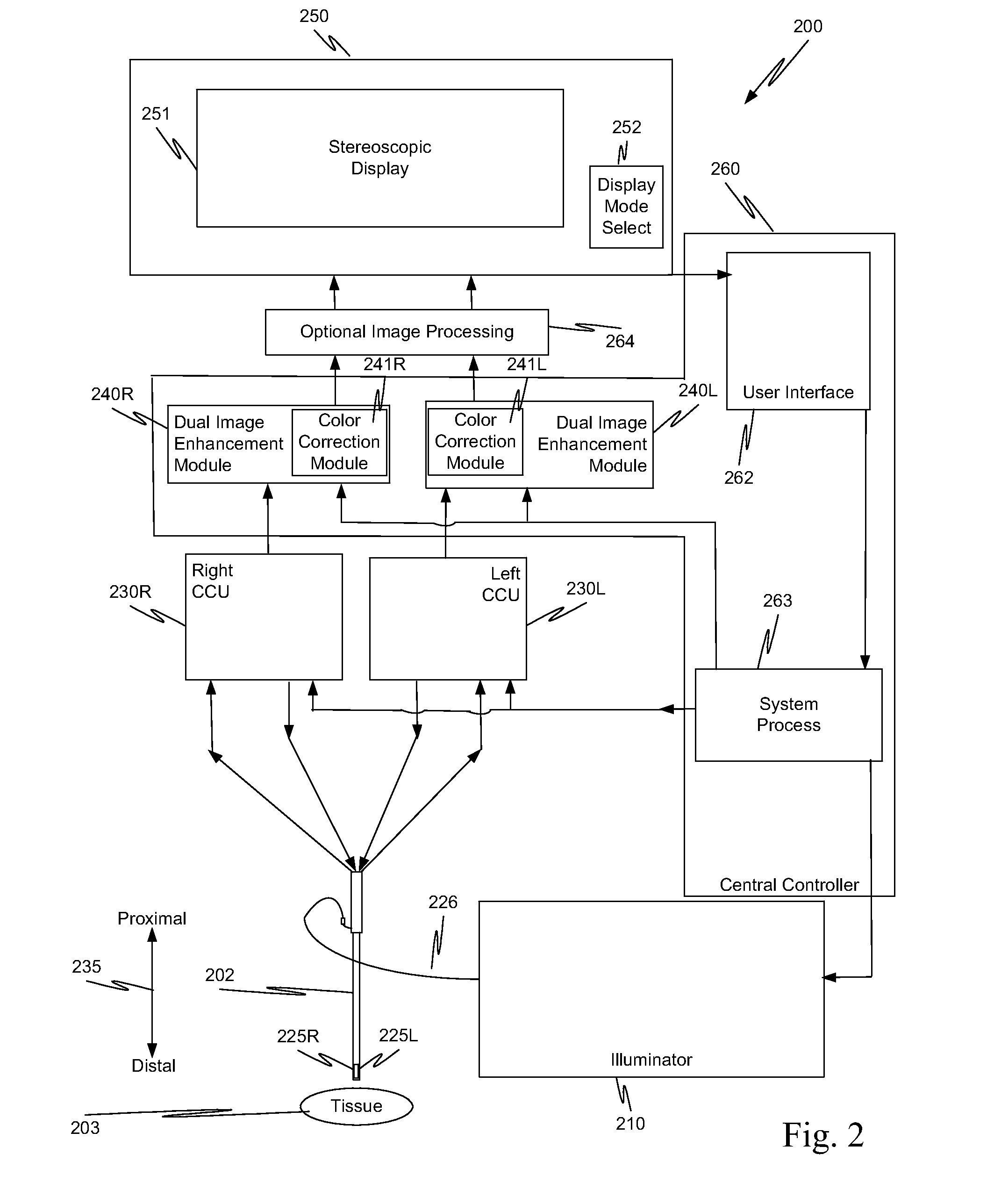

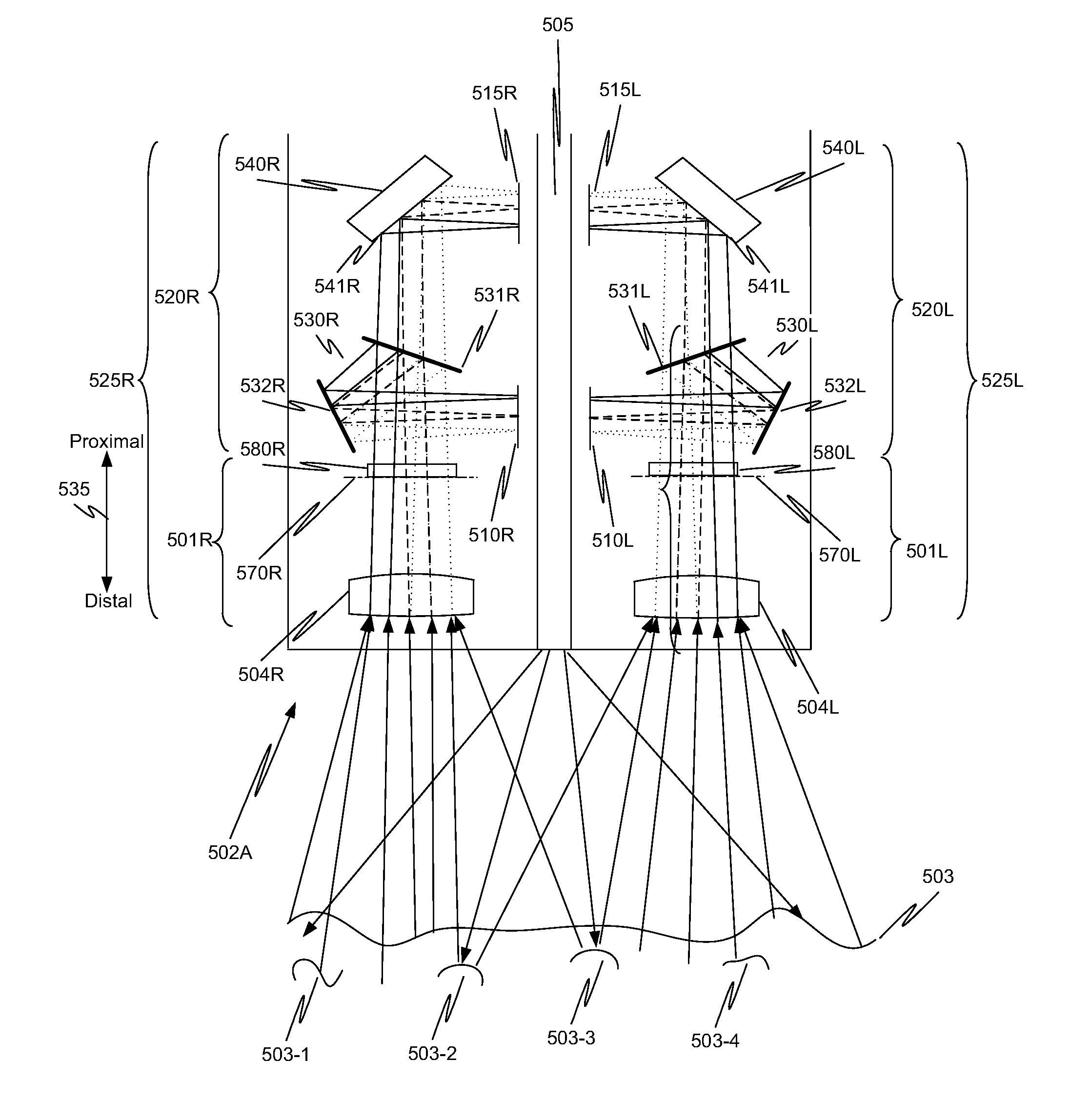

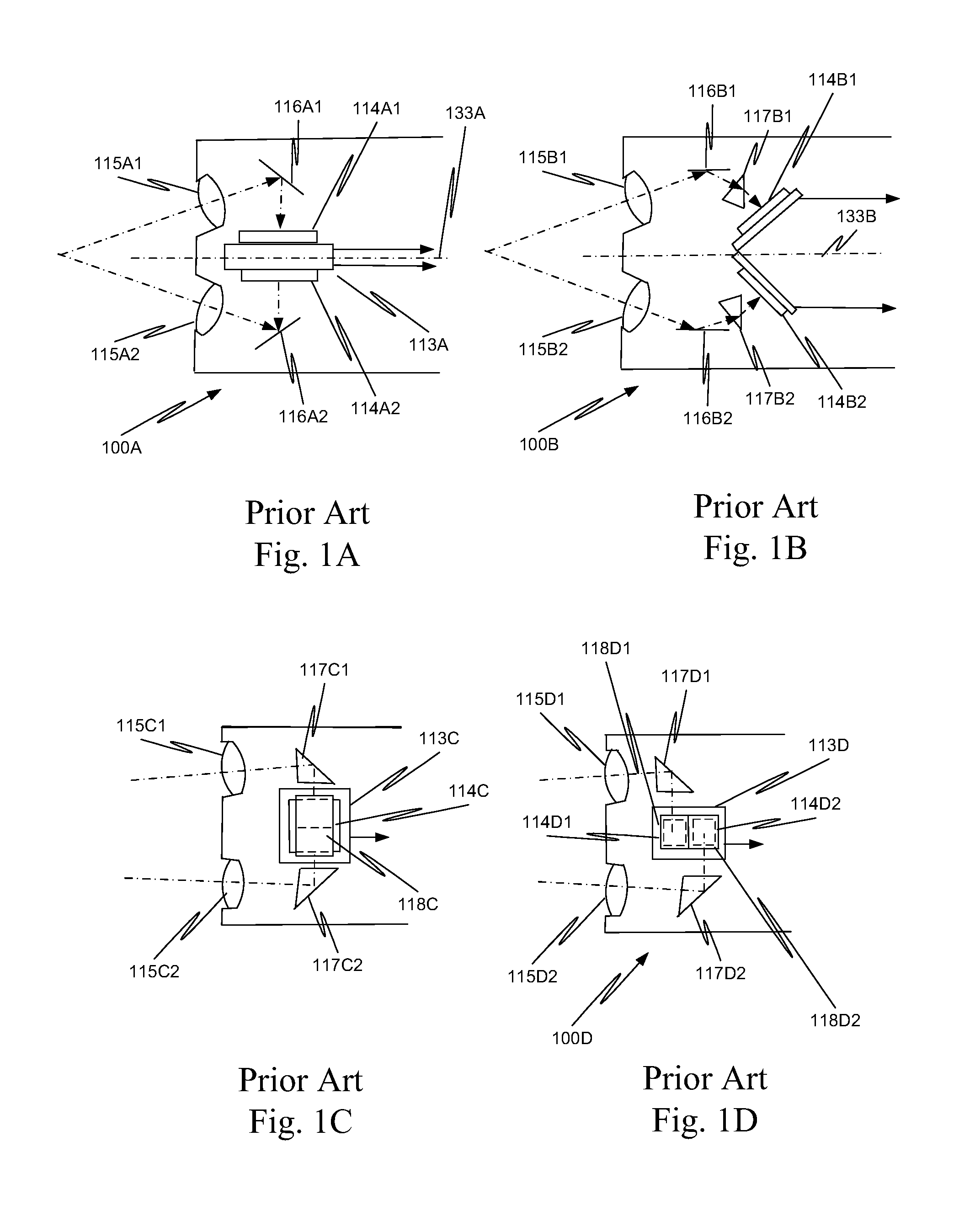

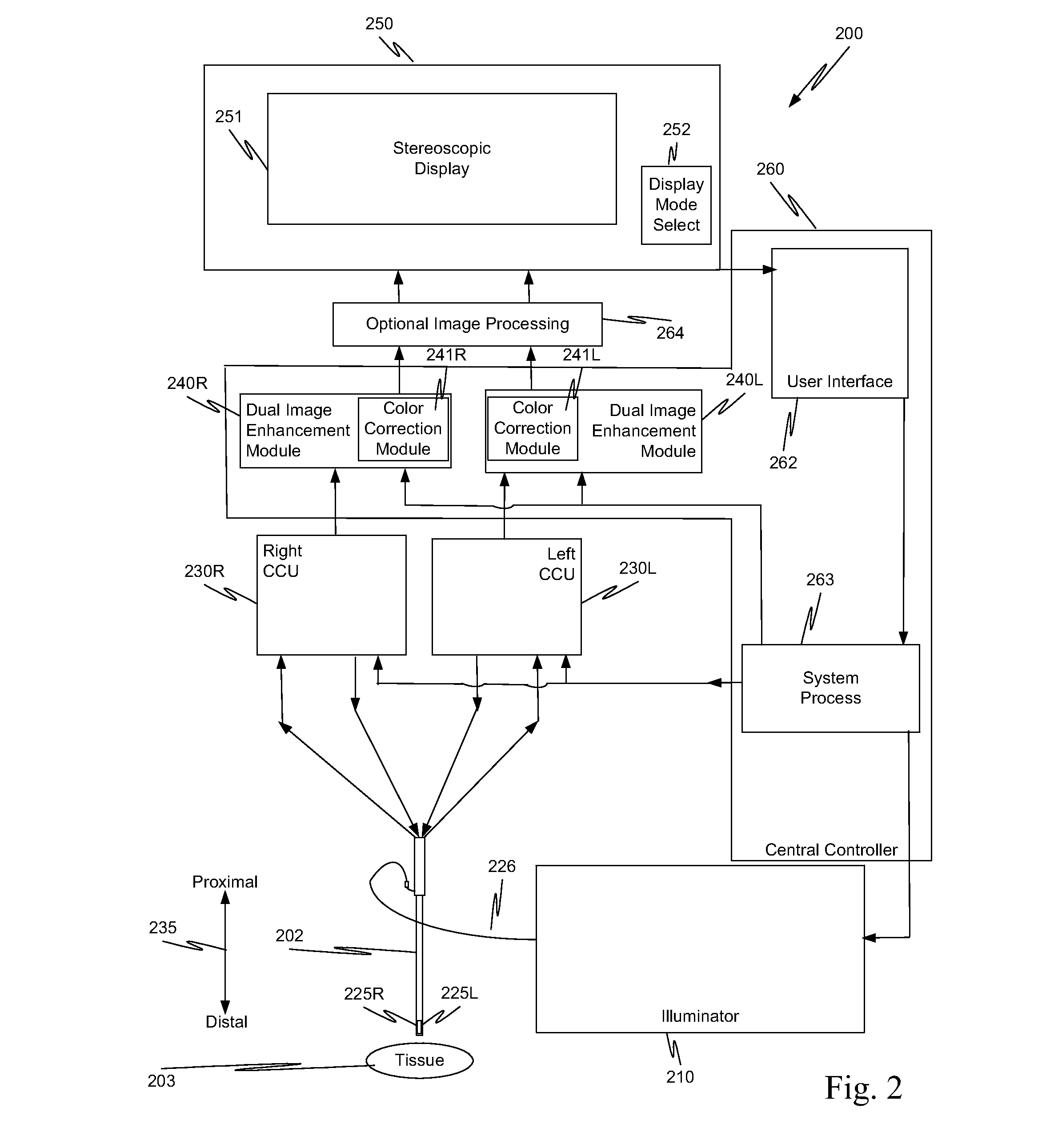

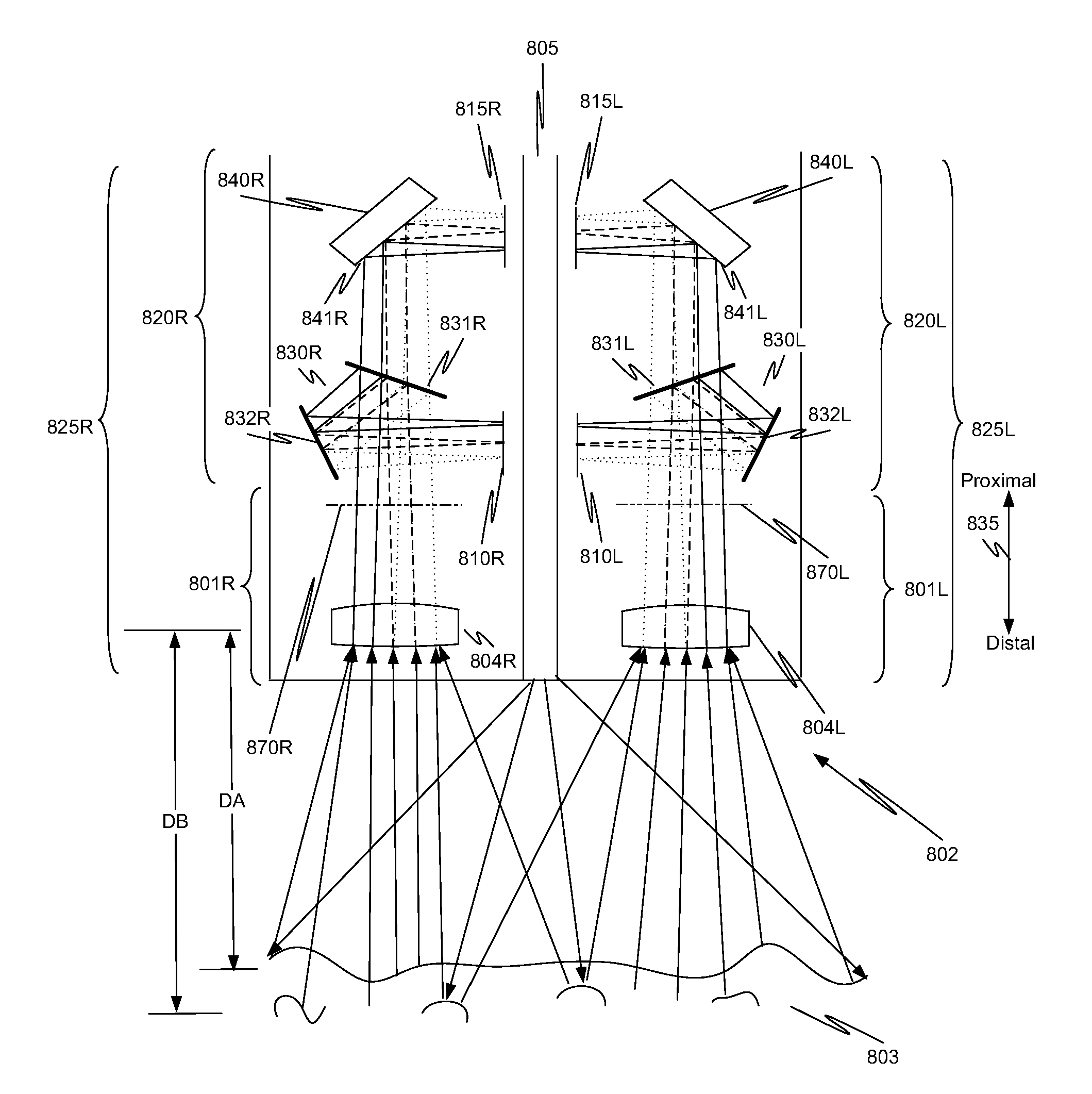

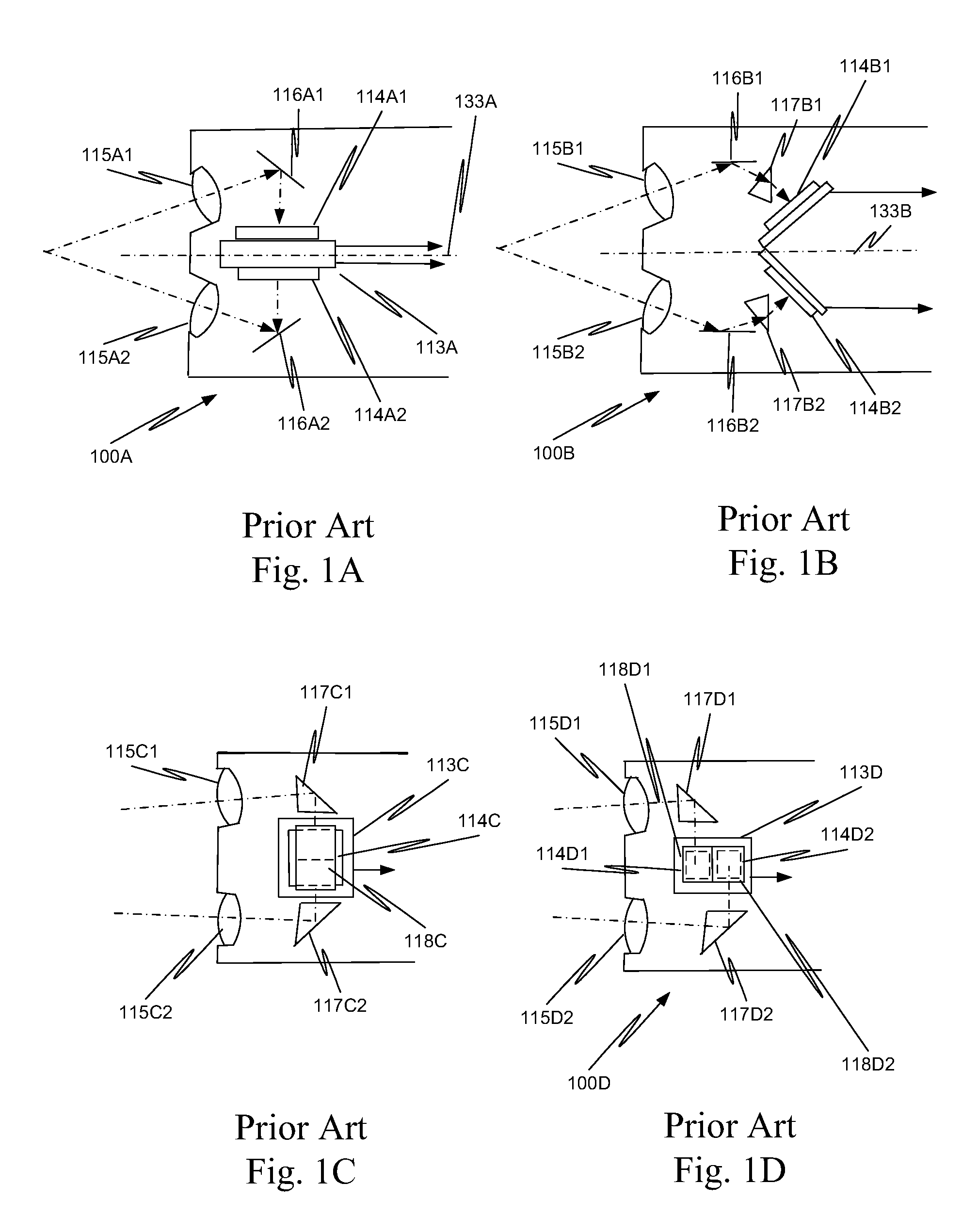

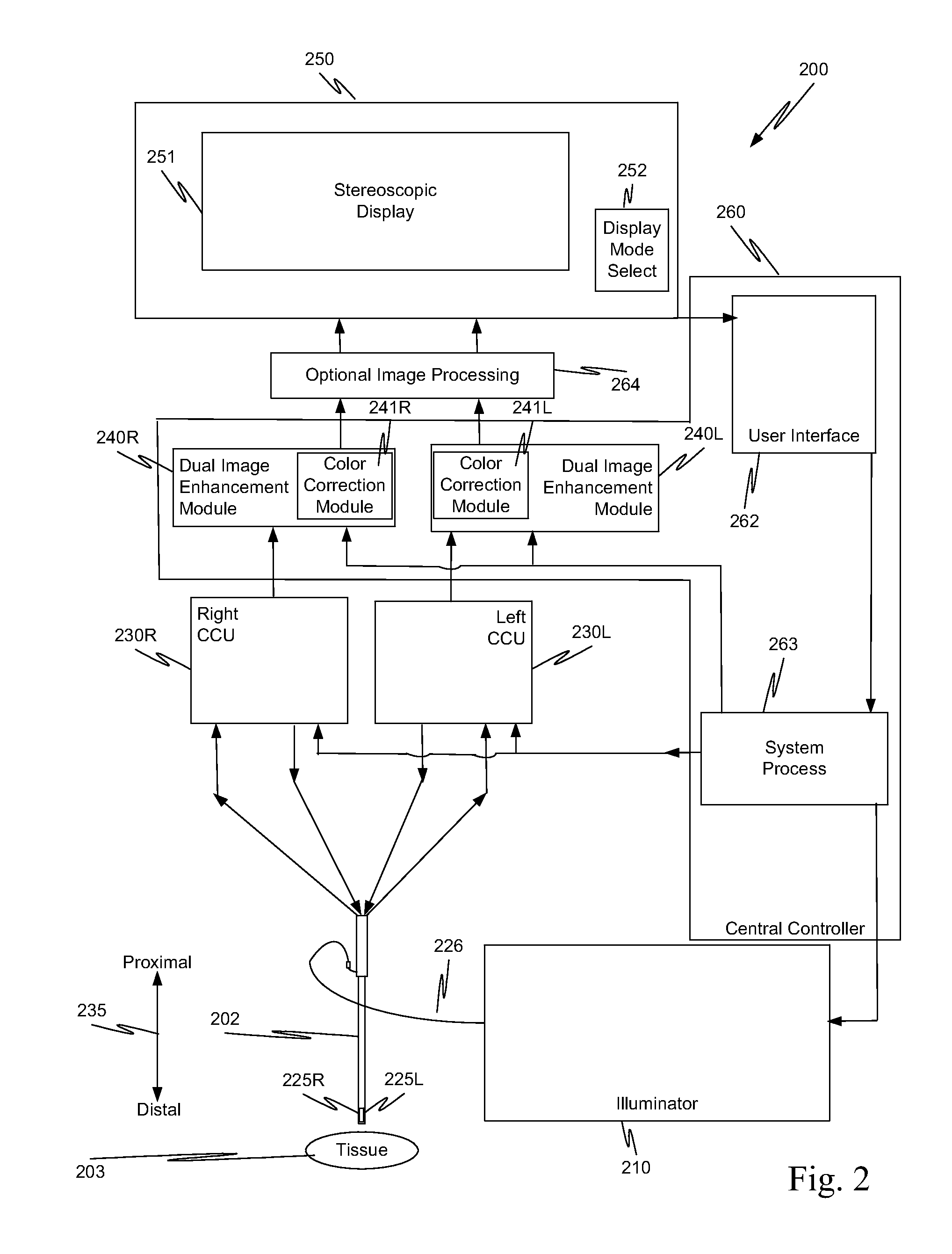

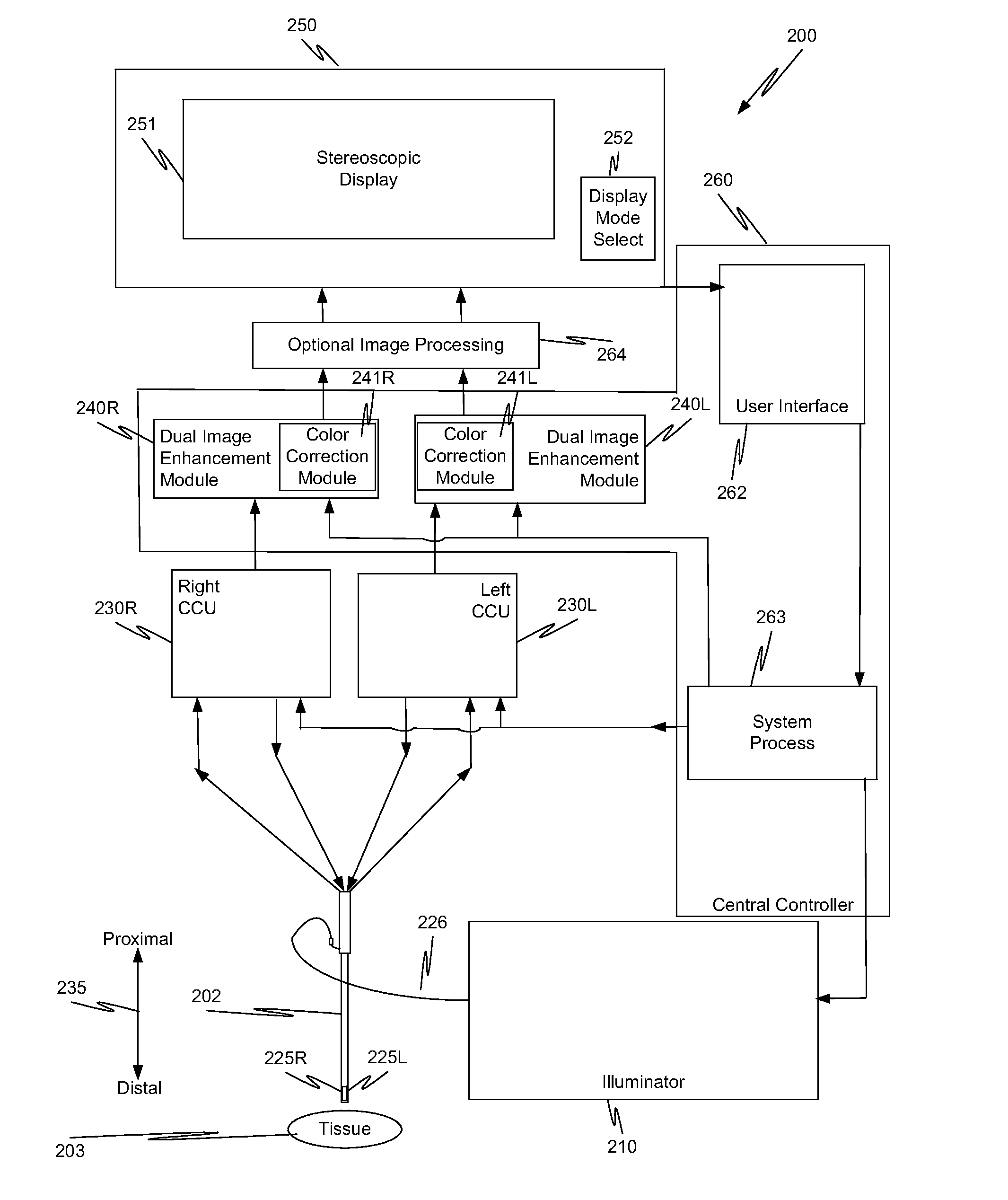

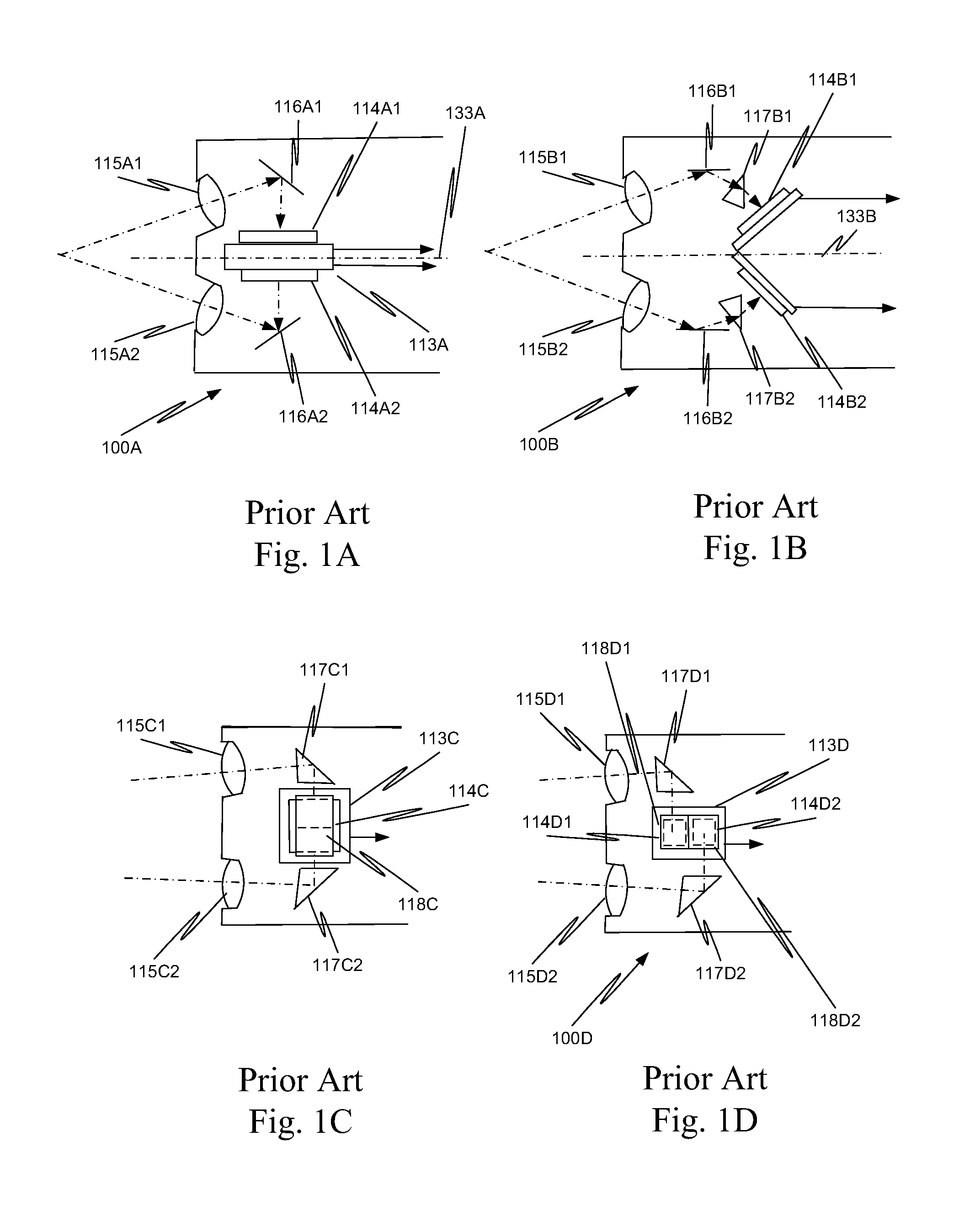

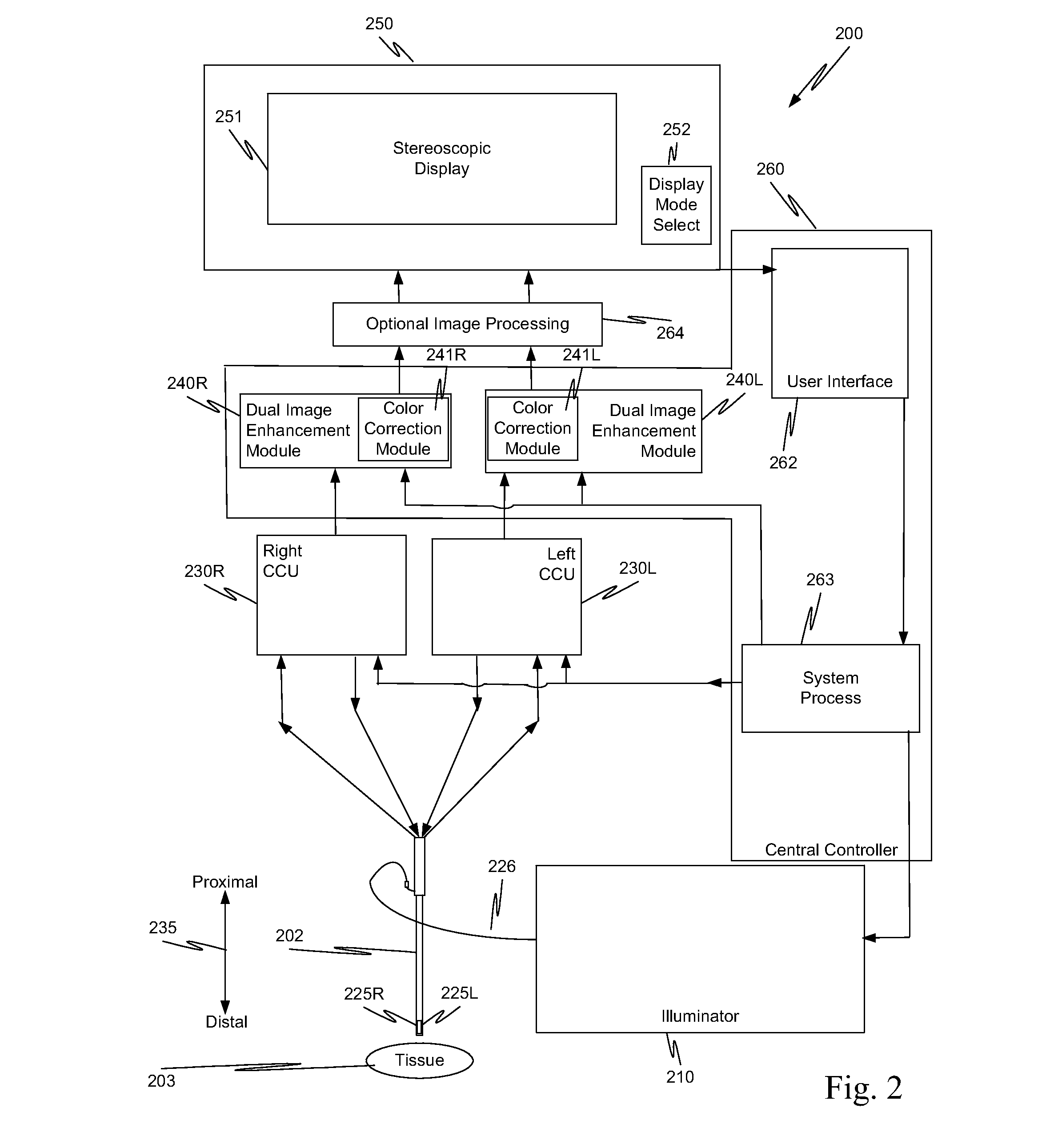

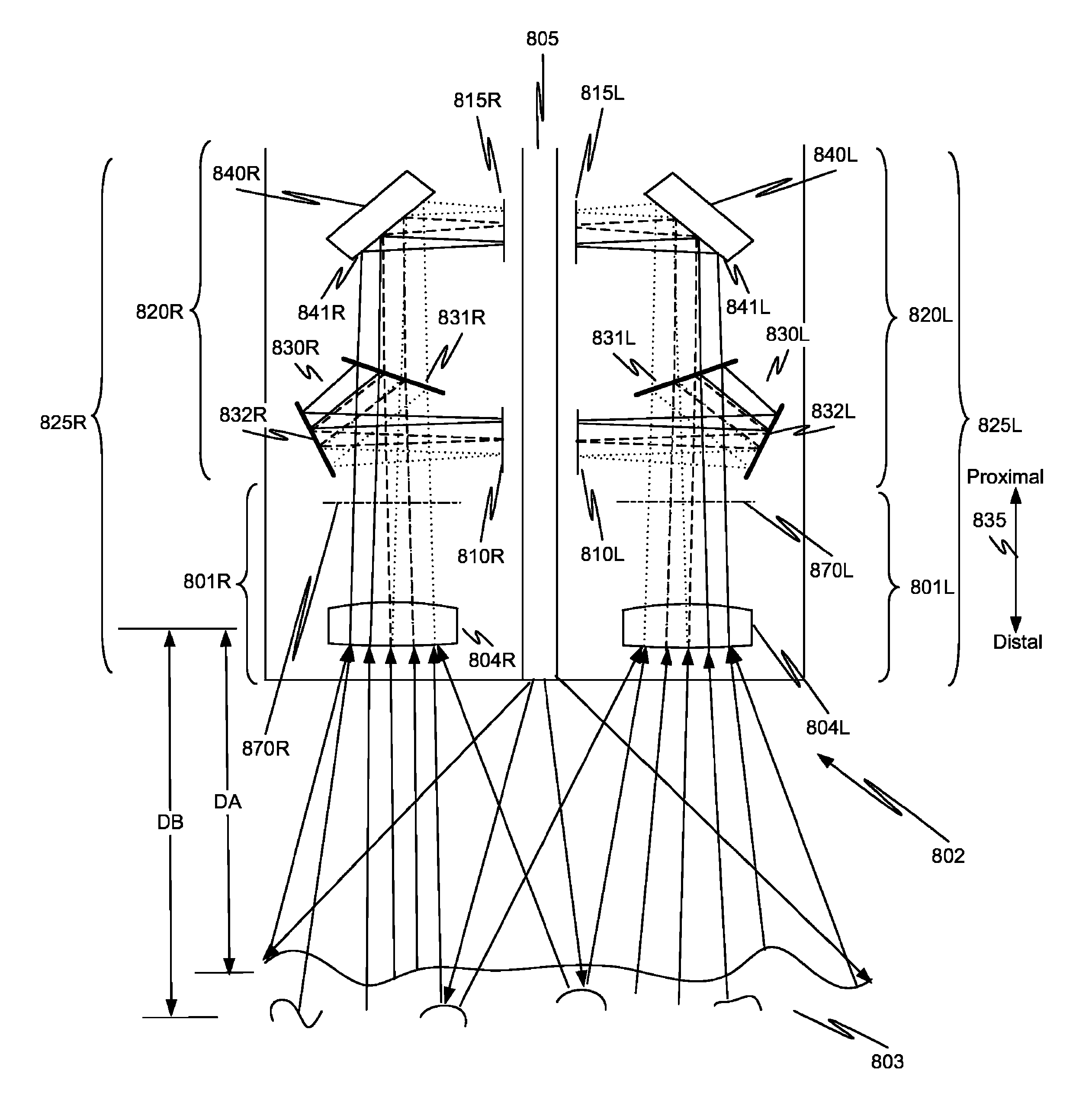

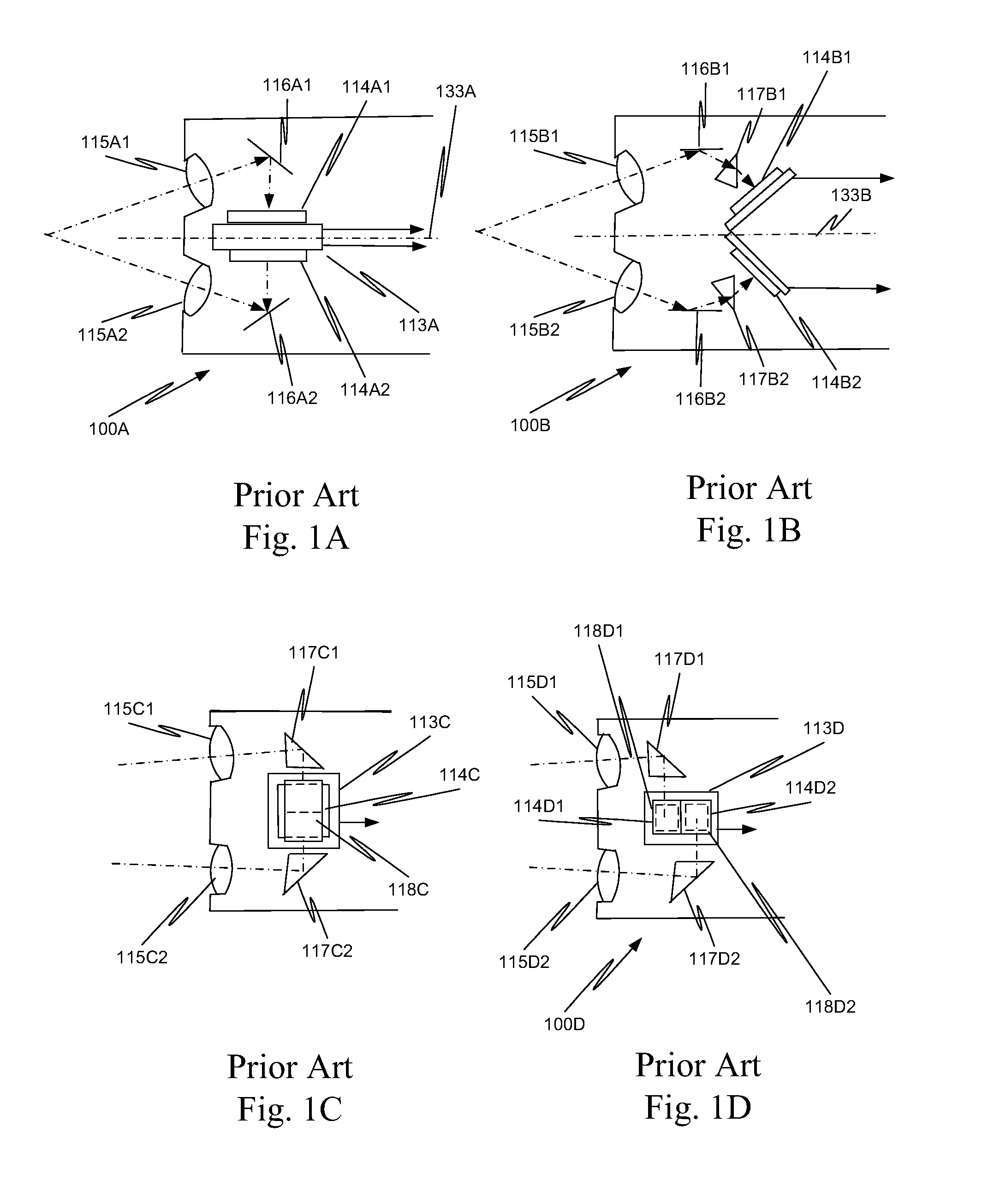

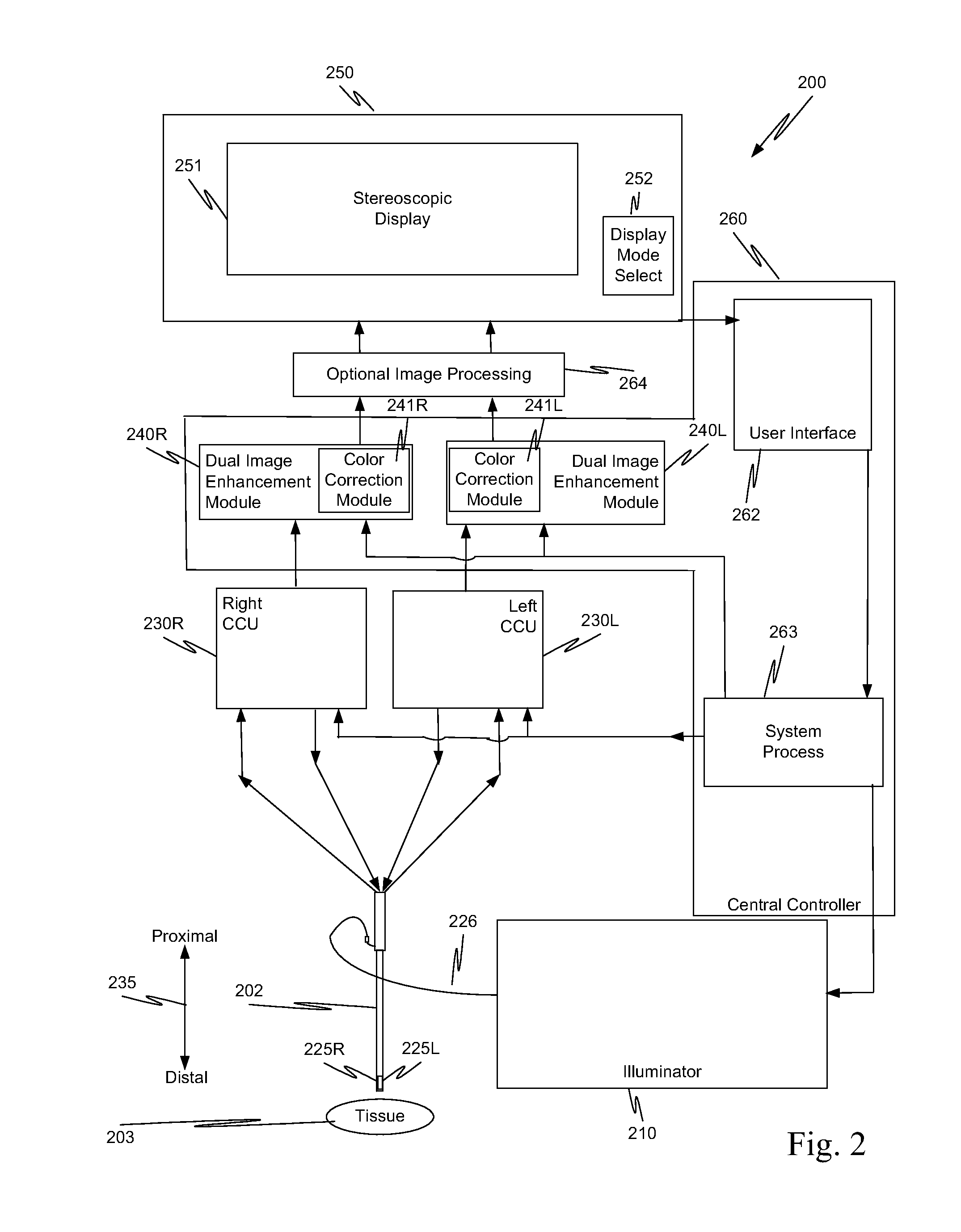

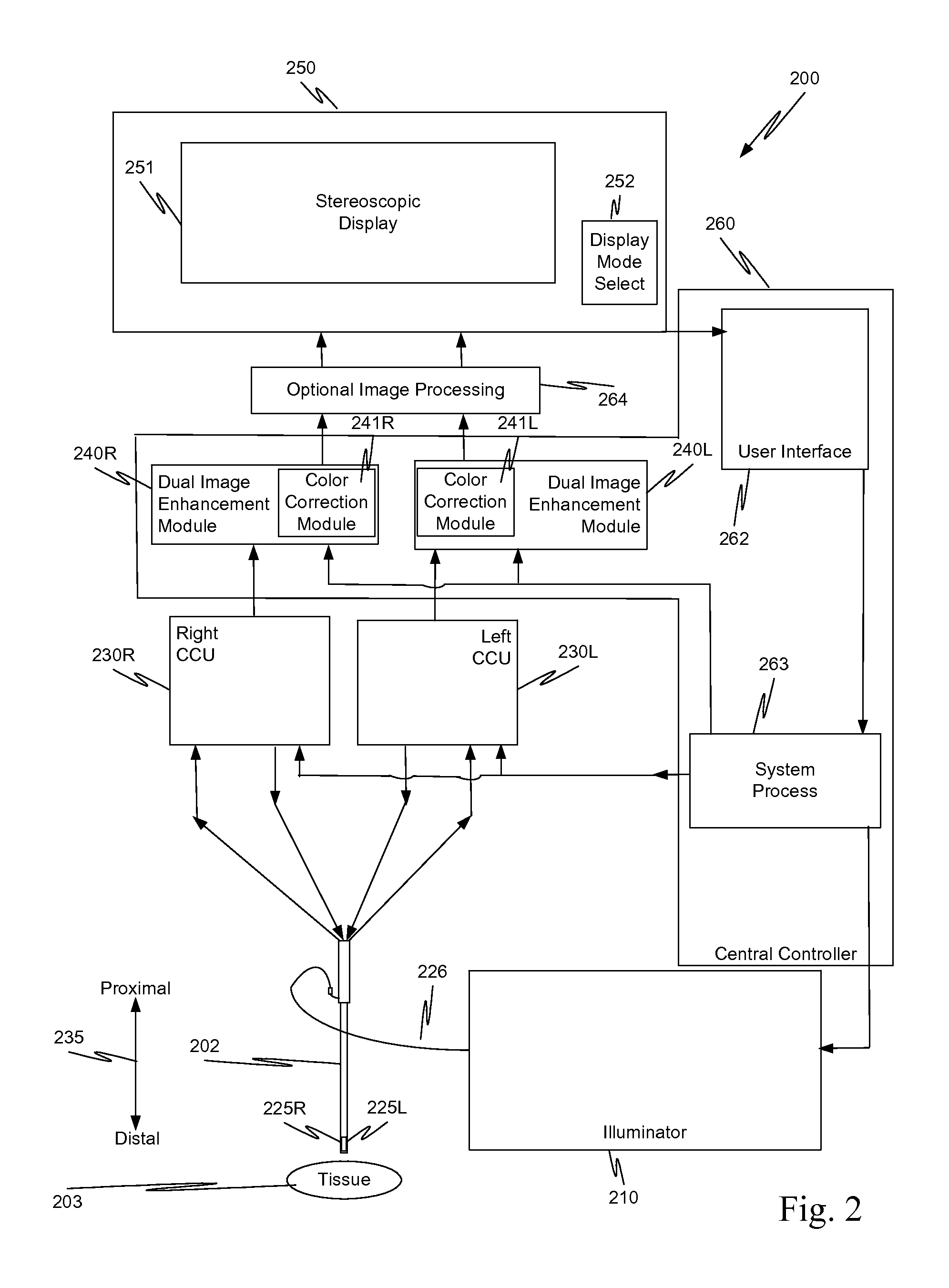

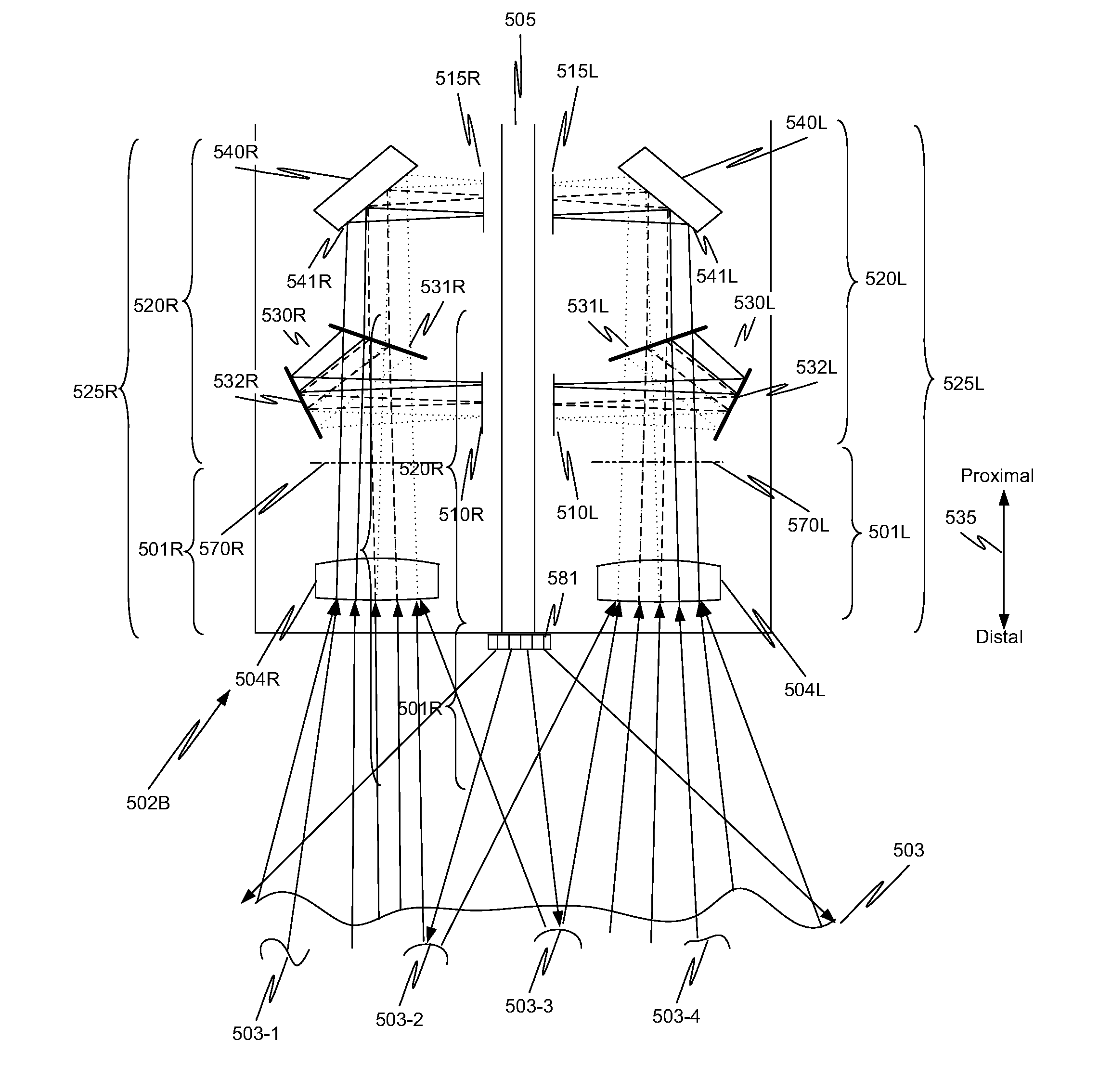

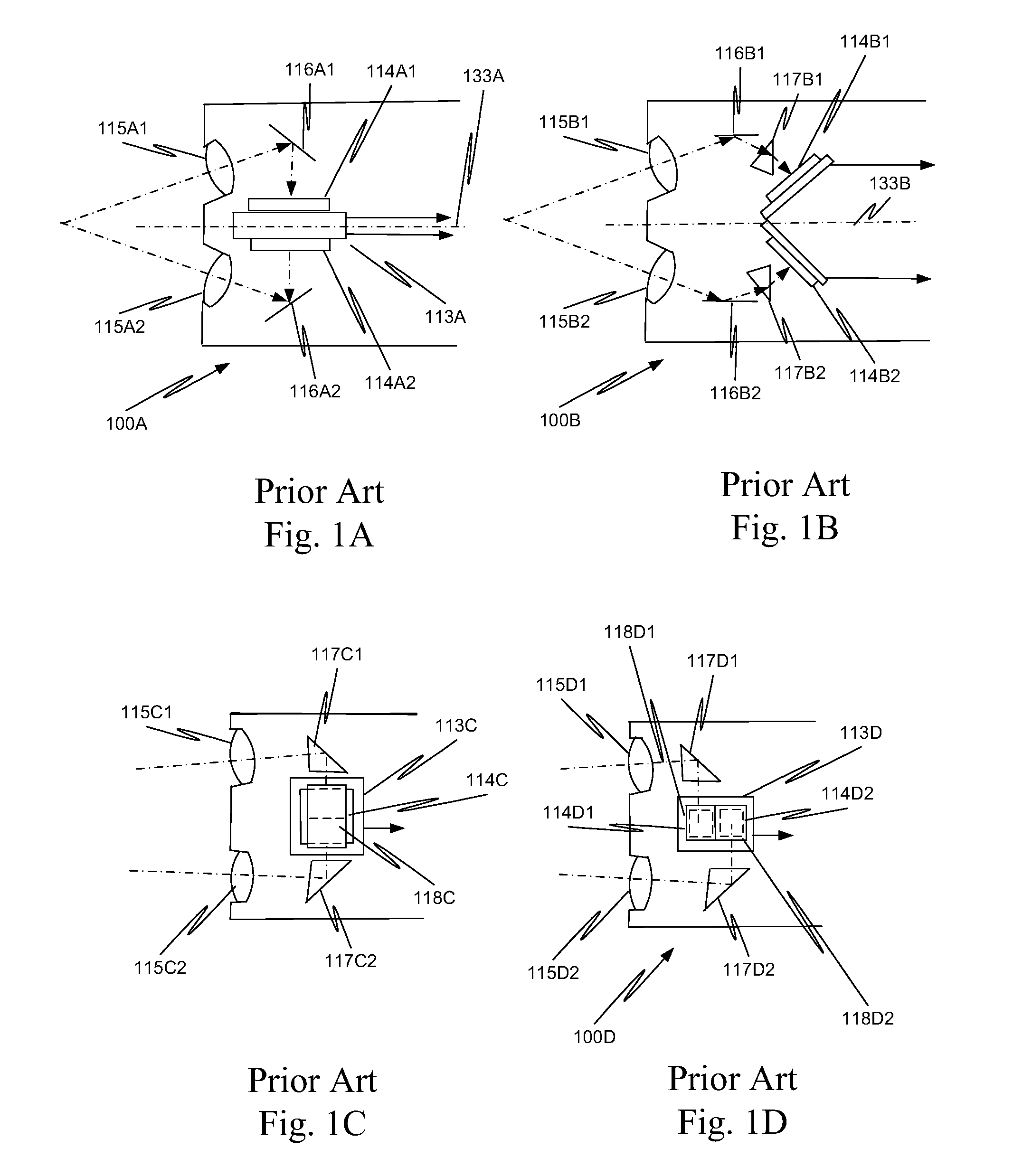

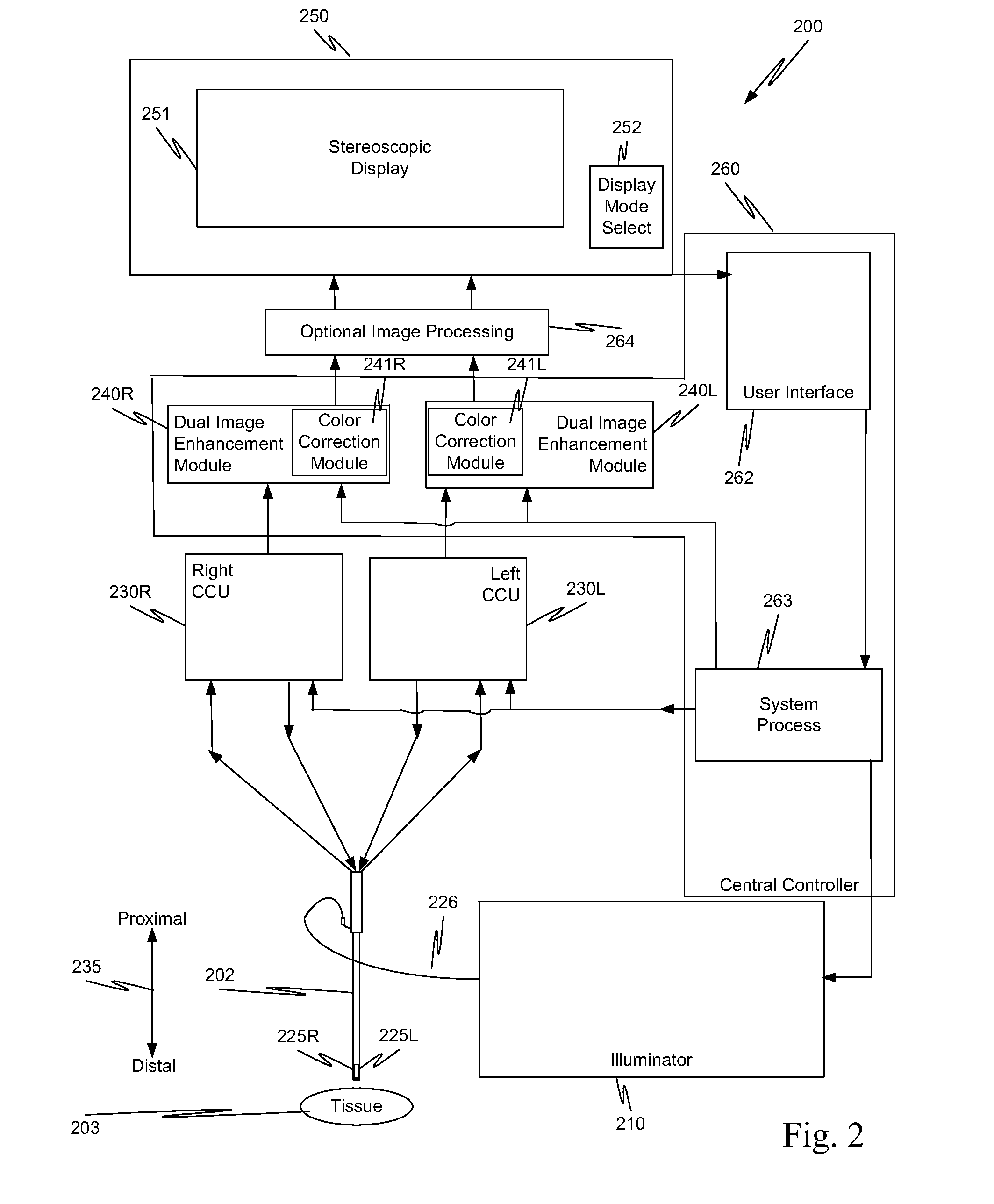

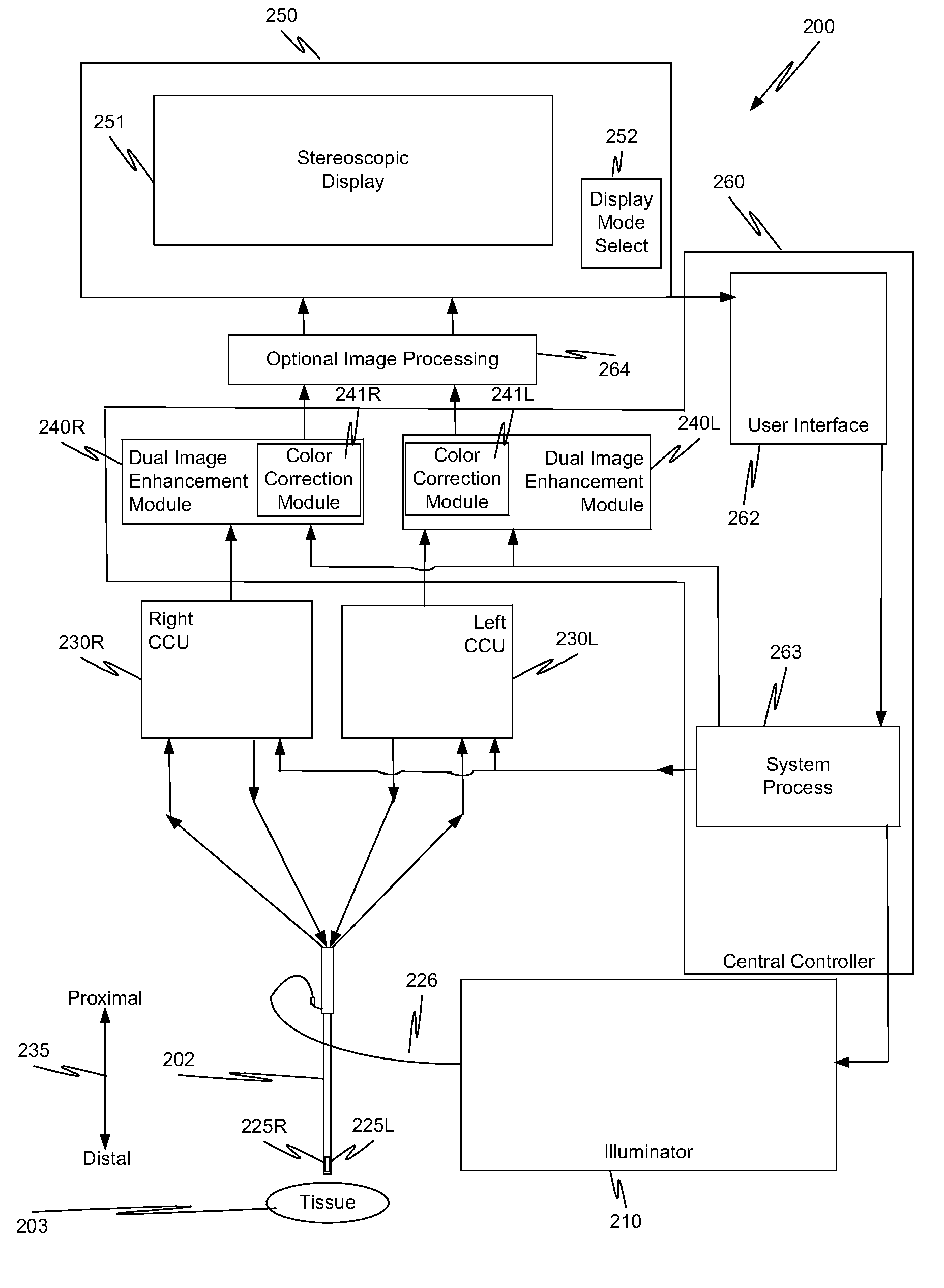

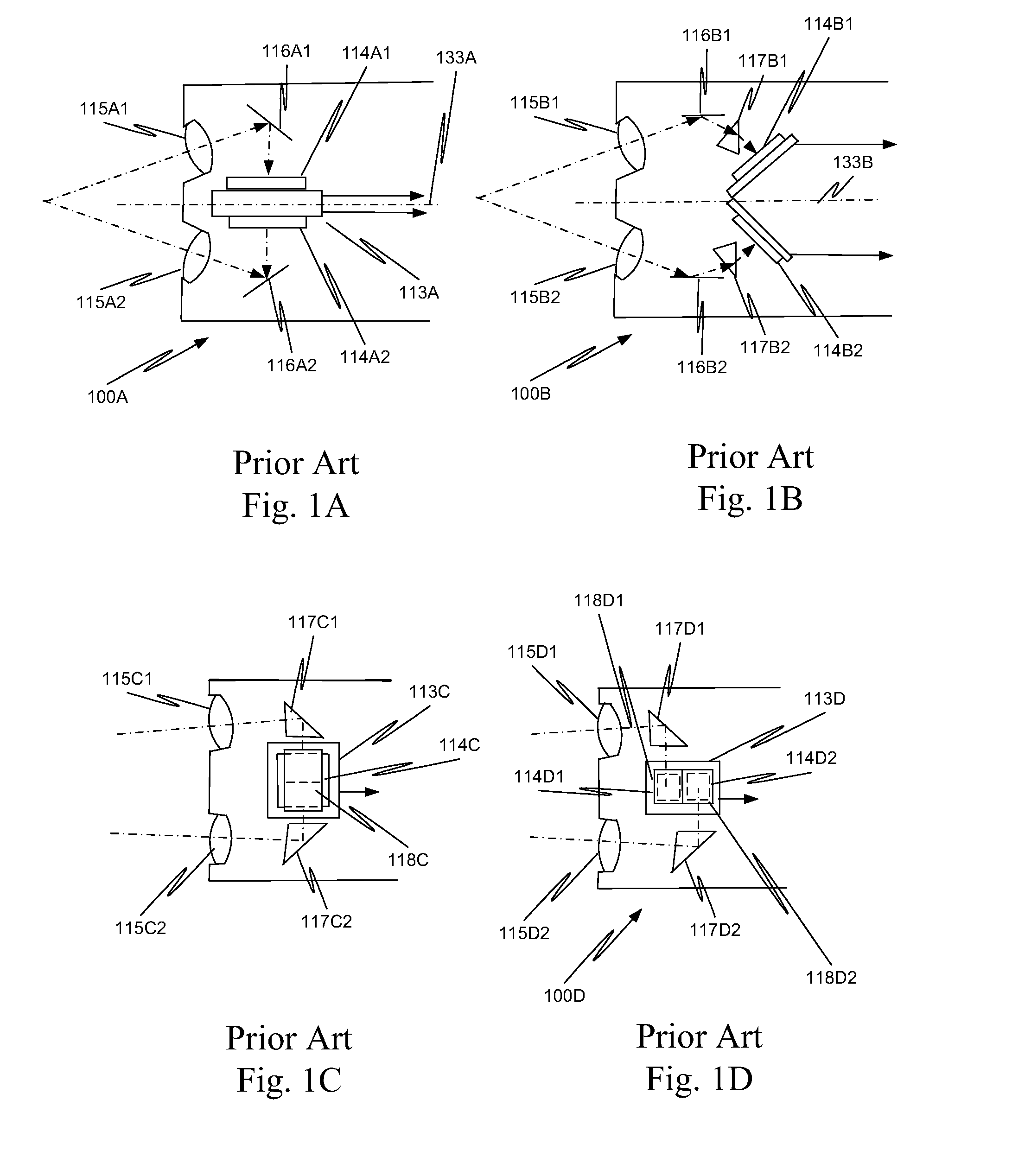

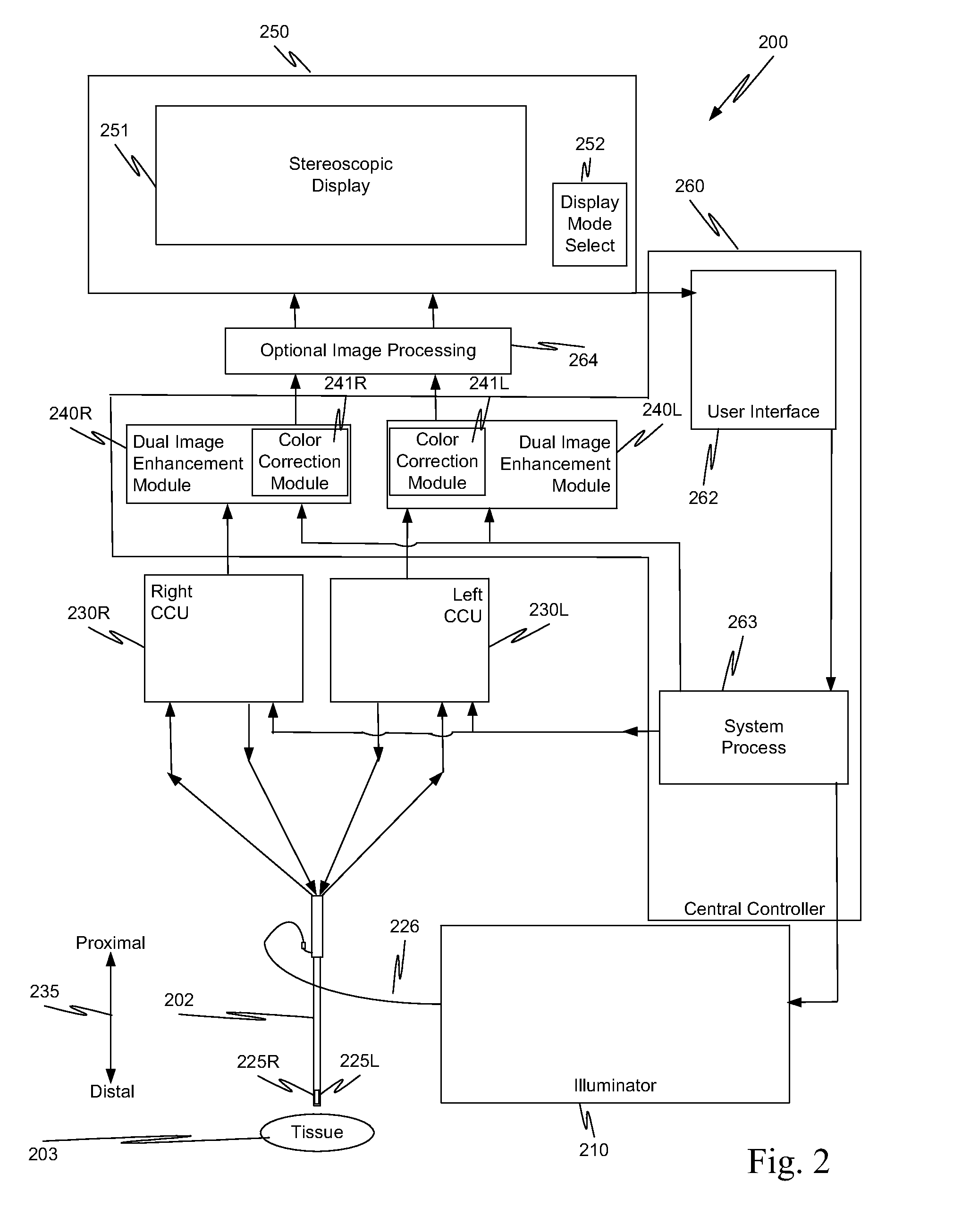

In a minimally invasive surgical system, an image capture unit includes a prism assembly and sensor assembly. The prism assembly includes a beam splitter, while the sensor assembly includes coplanar image capture sensors. Each of the coplanar image capture sensors has a common front end optical structure, e.g., the optical structure distal to the image capture unit is the same for each of the sensors. A controller enhances images acquired by the coplanar image capture sensors. The enhanced images may include (a) visible images with enhanced feature definition, in which a particular feature in the scene is emphasized to the operator of minimally invasive surgical system; (b) images having increased image apparent resolution; (c) images having increased dynamic range; (d) images displayed in a way based on a pixel color component vector having three or more color components; and (e) images having extended depth of field.

Owner:INTUITIVE SURGICAL OPERATIONS INC

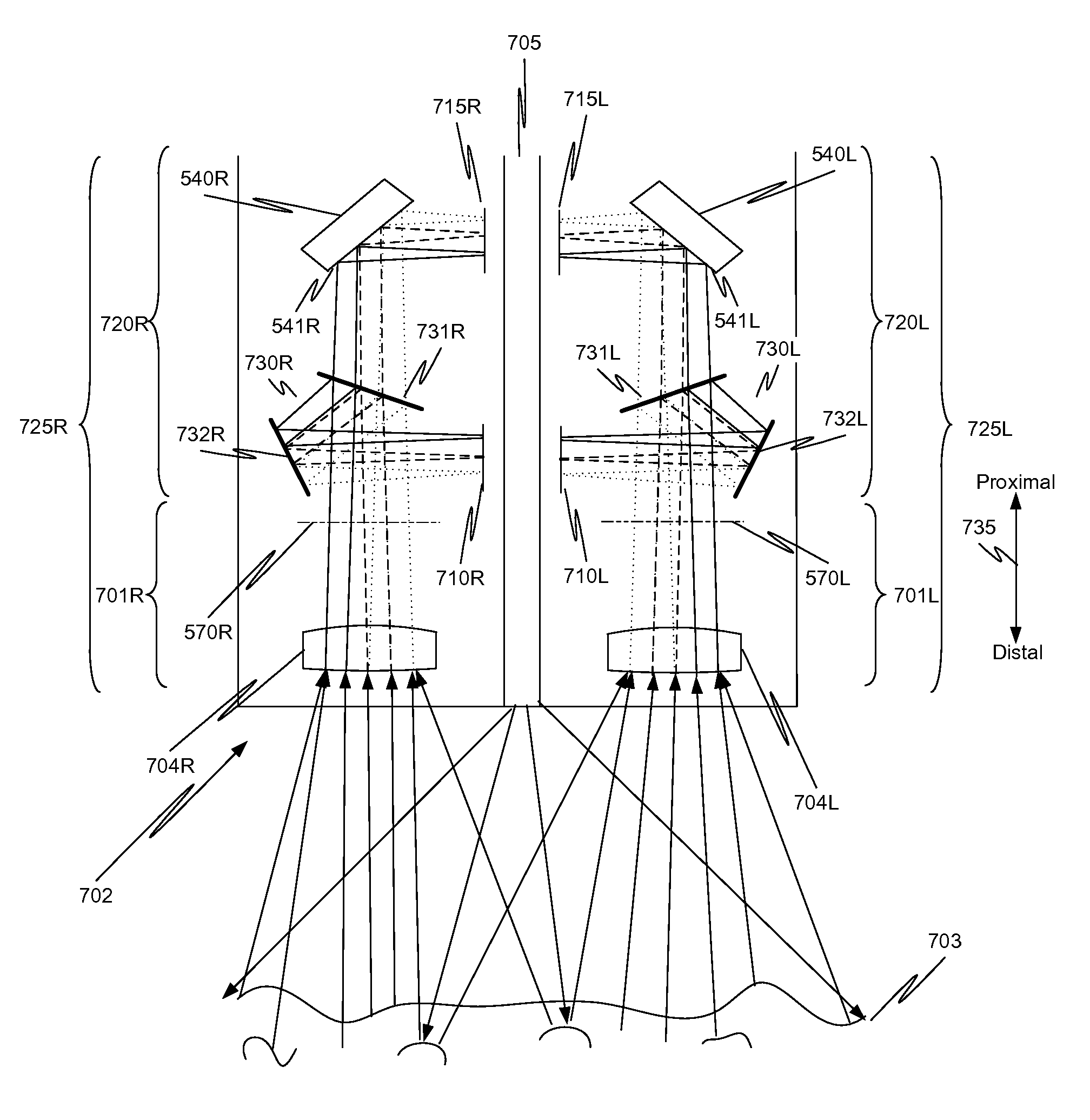

Image capture unit in a surgical instrument

ActiveUS20130041226A1Overcomes shortcomingMore capabilitySurgeryEndoscopesImage resolutionDepth of field

In a minimally invasive surgical system, an image capture unit includes a prism assembly and sensor assembly. The prism assembly includes a beam splitter, while the sensor assembly includes coplanar image capture sensors. Each of the coplanar image capture sensors has a common front end optical structure, e.g., the optical structure distal to the image capture unit is the same for each of the sensors. A controller enhances images acquired by the coplanar image capture sensors. The enhanced images may include (a) visible images with enhanced feature definition, in which a particular feature in the scene is emphasized to the operator of minimally invasive surgical system; (b) images having increased image apparent resolution; (c) images having increased dynamic range; (d) images displayed in a way based on a pixel color component vector having three or more color components; and (e) images having extended depth of field.

Owner:INTUITIVE SURGICAL OPERATIONS INC

Image capture unit and an imaging pipeline with enhanced color performance in a surgical instrument and method

ActiveUS20130041221A1Overcomes shortcomingMore capabilityTelevision system detailsColor signal processing circuitsBeam splitterImage resolution

In a minimally invasive surgical system, an image capture unit includes a prism assembly and sensor assembly. The prism assembly includes a beam splitter, while the sensor assembly includes coplanar image capture sensors. Each of the coplanar image capture sensors has a common front end optical structure, e.g., the optical structure distal to the image capture unit is the same for each of the sensors. A controller enhances images acquired by the coplanar image capture sensors. The enhanced images may include (a) visible images with enhanced feature definition, in which a particular feature in the scene is emphasized to the operator of minimally invasive surgical system; (b) images having increased image apparent resolution; (c) images having increased dynamic range; (d) images displayed in a way based on a pixel color component vector having three or more color components; and (e) images having extended depth of field.

Owner:INTUITIVE SURGICAL OPERATIONS INC

Feature differentiation image capture unit and method in a surgical instrument

ActiveUS20130041215A1Eliminate needEliminates the need for calibration of lens artifactsSurgeryEndoscopesSurgical instrumentImage resolution

In a minimally invasive surgical system, an image capture unit includes a prism assembly and sensor assembly. The prism assembly includes a beam splitter, while the sensor assembly includes coplanar image capture sensors. Each of the coplanar image capture sensors has a common front end optical structure, e.g., the optical structure distal to the image capture unit is the same for each of the sensors. A controller enhances images acquired by the coplanar image capture sensors. The enhanced images may include (a) visible images with enhanced feature definition, in which a particular feature in the scene is emphasized to the operator of minimally invasive surgical system; (b) images having increased image apparent resolution; (c) images having increased dynamic range; (d) images displayed in a way based on a pixel color component vector having three or more color components; and (e) images having extended depth of field.

Owner:INTUITIVE SURGICAL OPERATIONS INC

Increased resolution and dynamic range image capture unit in a surgical instrument and method

ActiveUS8734328B2Eliminates the need for calibration of lens artifactsOvercomes shortcomingPrismsSurgeryBeam splitterImage resolution

In a minimally invasive surgical system, an image capture unit includes a prism assembly and sensor assembly. The prism assembly includes a beam splitter, while the sensor assembly includes coplanar image capture sensors. Each of the coplanar image capture sensors has a common front end optical structure, e.g., the optical structure distal to the image capture unit is the same for each of the sensors. A controller enhances images acquired by the coplanar image capture sensors. The enhanced images may include (a) visible images with enhanced feature definition, in which a particular feature in the scene is emphasized to the operator of minimally invasive surgical system; (b) images having increased image apparent resolution; (c) images having increased dynamic range; (d) images displayed in a way based on a pixel color component vector having three or more color components; and (e) images having extended depth of field.

Owner:INTUITIVE SURGICAL OPERATIONS INC

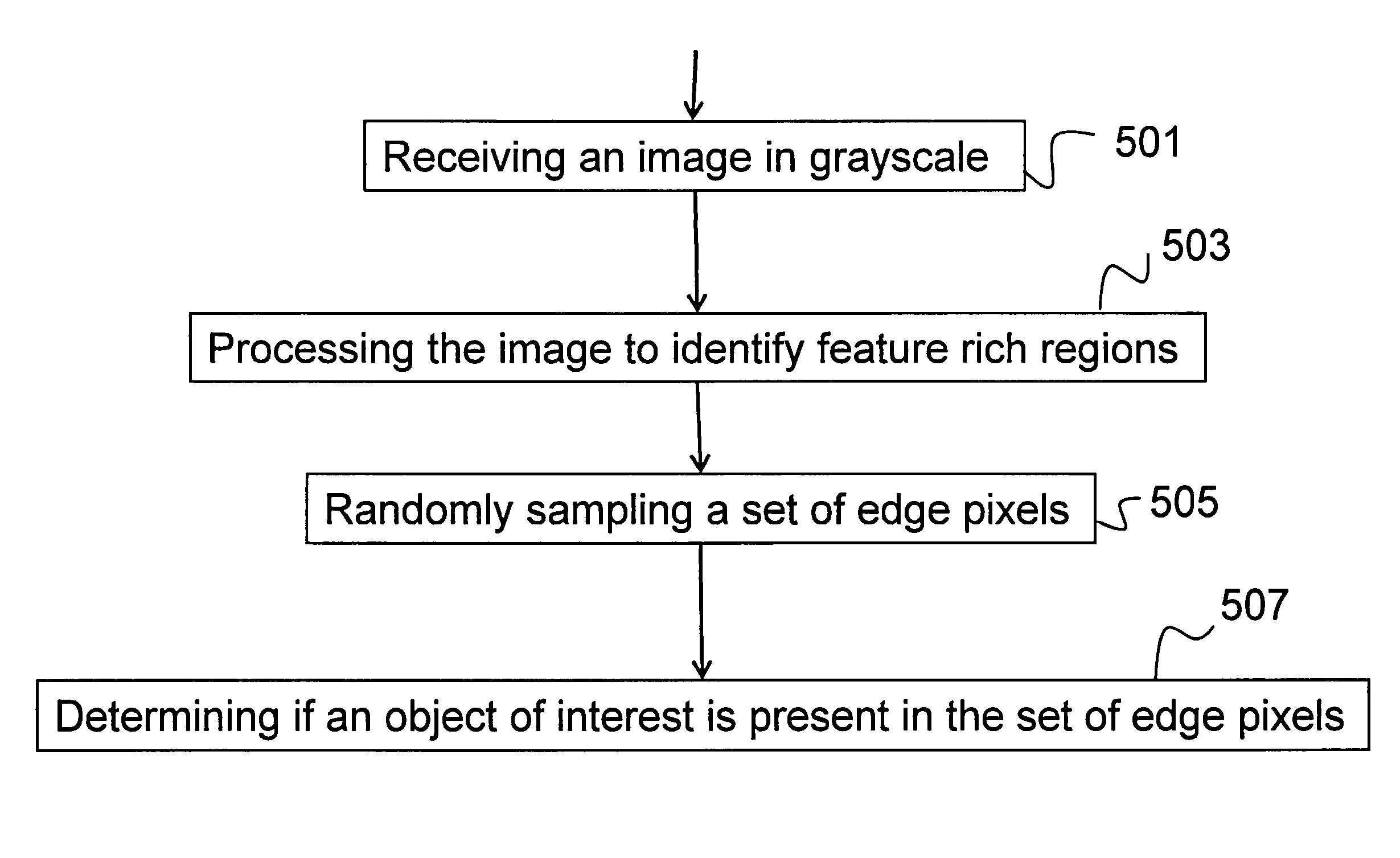

Shape-based object detection and localization system

InactiveUS8437556B1Increase saliencyImage enhancementImage analysisLocalization systemObject detector

Described is a system for identifying a concealed object of interest. The system is initialized by receiving an image in grayscale. The image is processed image to identify feature rich regions, which are identified as a binary mask describing edge pixels and non-edge pixels. A set of edge pixels are then randomly sampled. An object detector function is then used on the set of edge pixels to determine if an object of interest is present in the set of edge pixels.

Owner:HRL LAB

Image capture unit and method with an extended depth of field

ActiveUS8784301B2Eliminates the need for calibration of lens artifactsOvercomes shortcomingImage enhancementTelevision system detailsBeam splitterImage resolution

In a minimally invasive surgical system, an image capture unit includes a prism assembly and sensor assembly. The prism assembly includes a beam splitter, while the sensor assembly includes coplanar image capture sensors. Each of the coplanar image capture sensors has a common front end optical structure, e.g., the optical structure distal to the image capture unit is the same for each of the sensors. A controller enhances images acquired by the coplanar image capture sensors. The enhanced images may include (a) visible images with enhanced feature definition, in which a particular feature in the scene is emphasized to the operator of minimally invasive surgical system; (b) images having increased image apparent resolution; (c) images having increased dynamic range; (d) images displayed in a way based on a pixel color component vector having three or more color components; and (e) images having extended depth of field.

Owner:INTUITIVE SURGICAL OPERATIONS INC

Increased resolution and dynamic range image capture unit in a surgical instrument and method

ActiveUS20130041216A1Eliminates the need for calibration of lens artifactsOvercomes shortcomingPrismsSurgeryBeam splitterImage resolution

In a minimally invasive surgical system, an image capture unit includes a prism assembly and sensor assembly. The prism assembly includes a beam splitter, while the sensor assembly includes coplanar image capture sensors. Each of the coplanar image capture sensors has a common front end optical structure, e.g., the optical structure distal to the image capture unit is the same for each of the sensors. A controller enhances images acquired by the coplanar image capture sensors. The enhanced images may include (a) visible images with enhanced feature definition, in which a particular feature in the scene is emphasized to the operator of minimally invasive surgical system; (b) images having increased image apparent resolution; (c) images having increased dynamic range; (d) images displayed in a way based on a pixel color component vector having three or more color components; and (e) images having extended depth of field.

Owner:INTUITIVE SURGICAL OPERATIONS INC

Image capture unit in a surgical instrument

ActiveUS8672838B2Eliminates the need for calibration of lens artifactsOvercomes shortcomingSurgeryEndoscopesImage resolutionDepth of field

Owner:INTUITIVE SURGICAL OPERATIONS INC

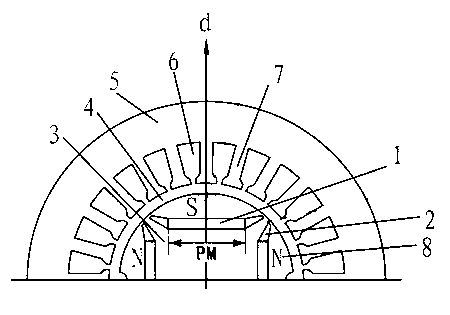

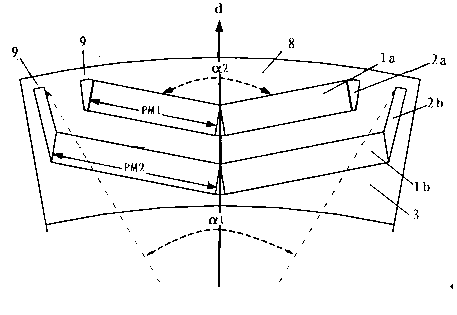

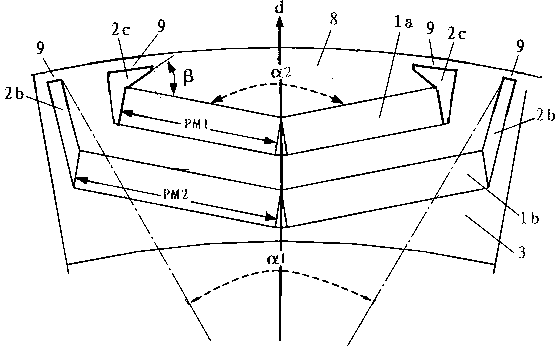

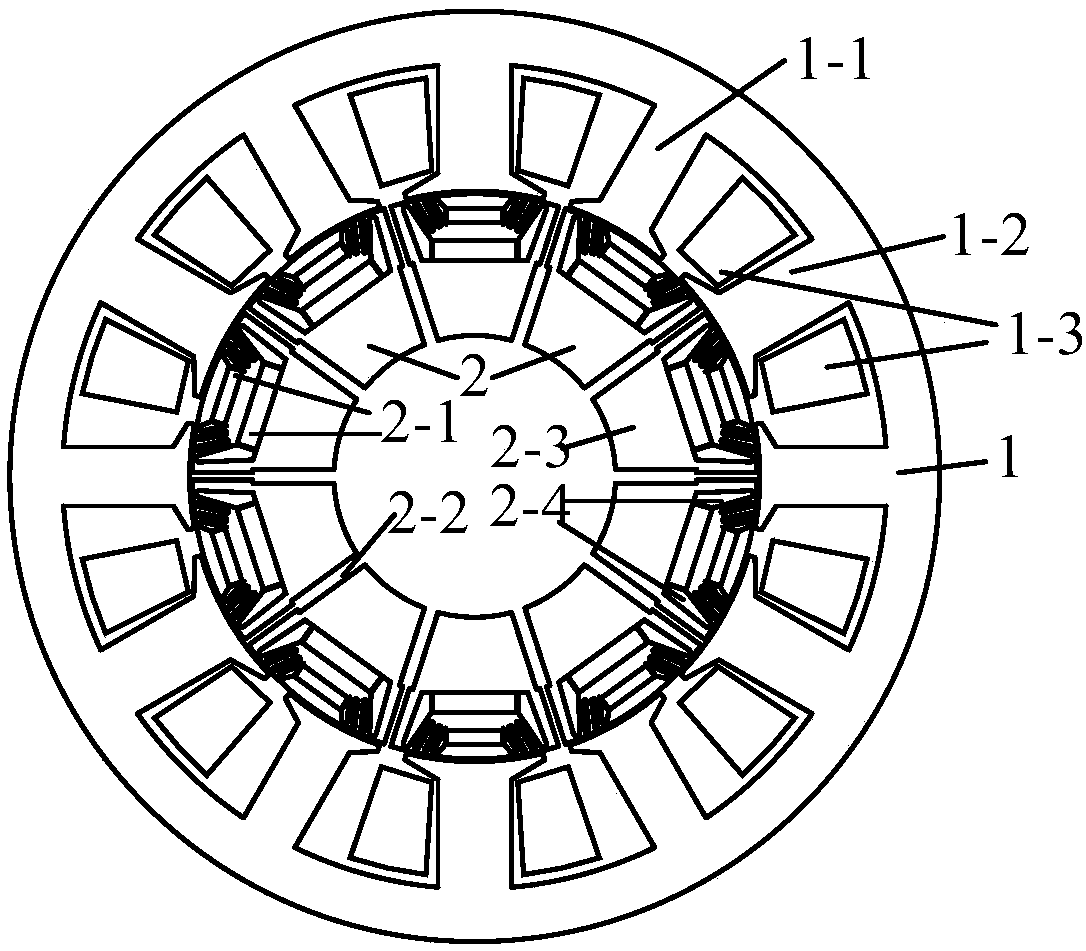

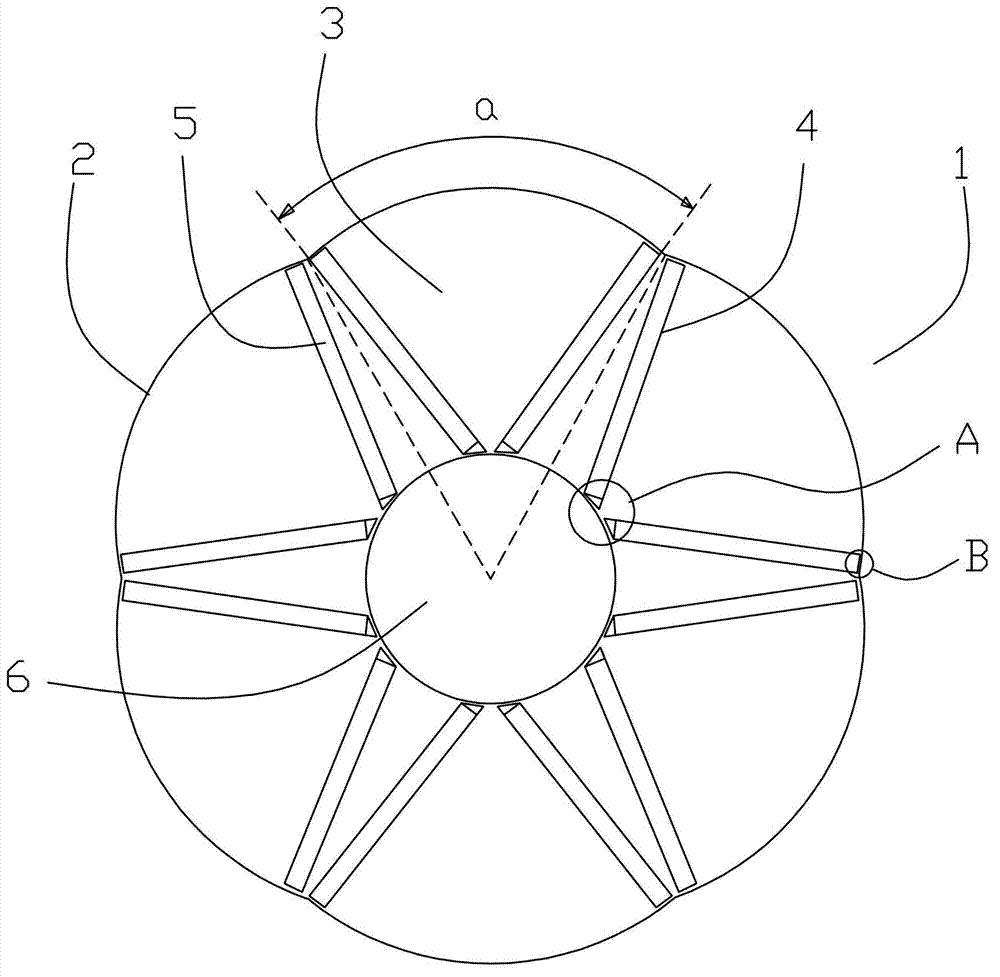

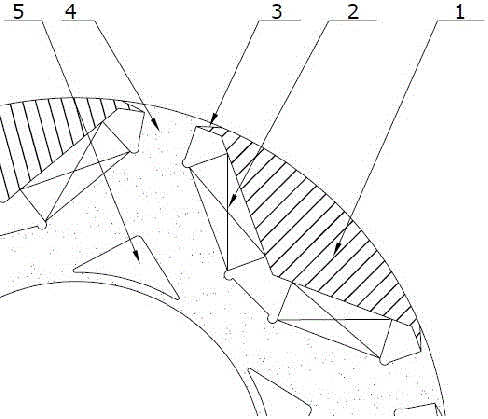

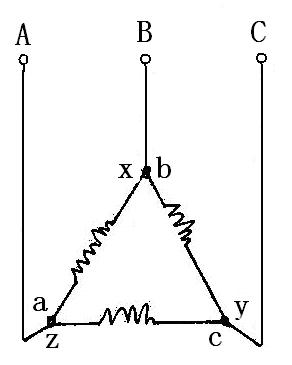

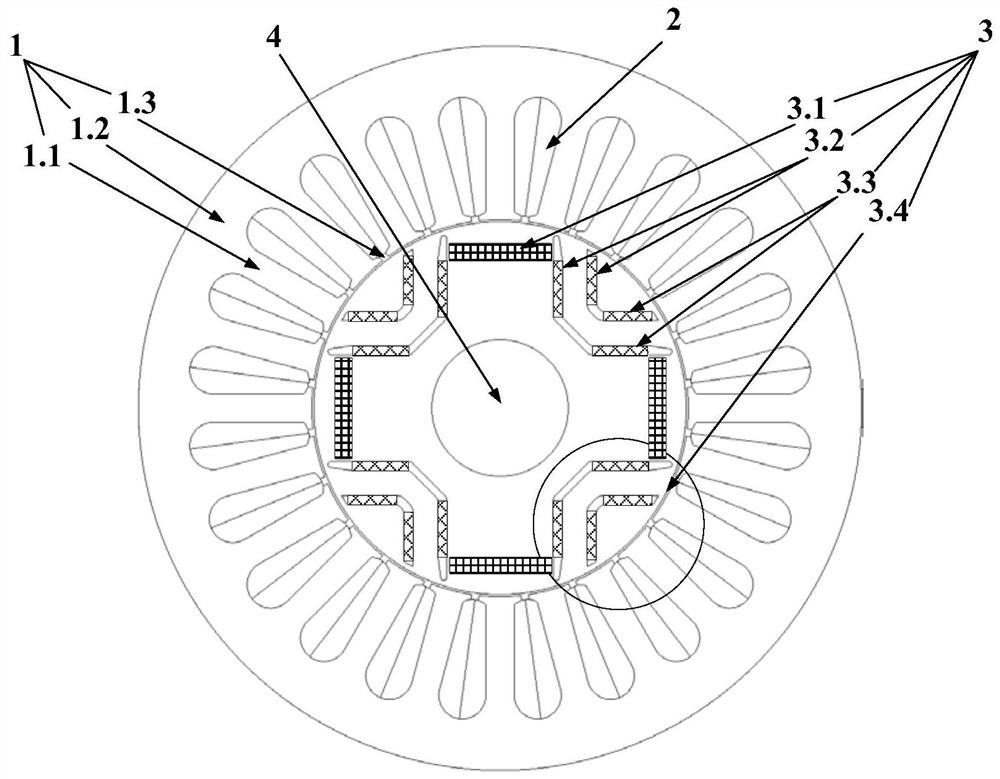

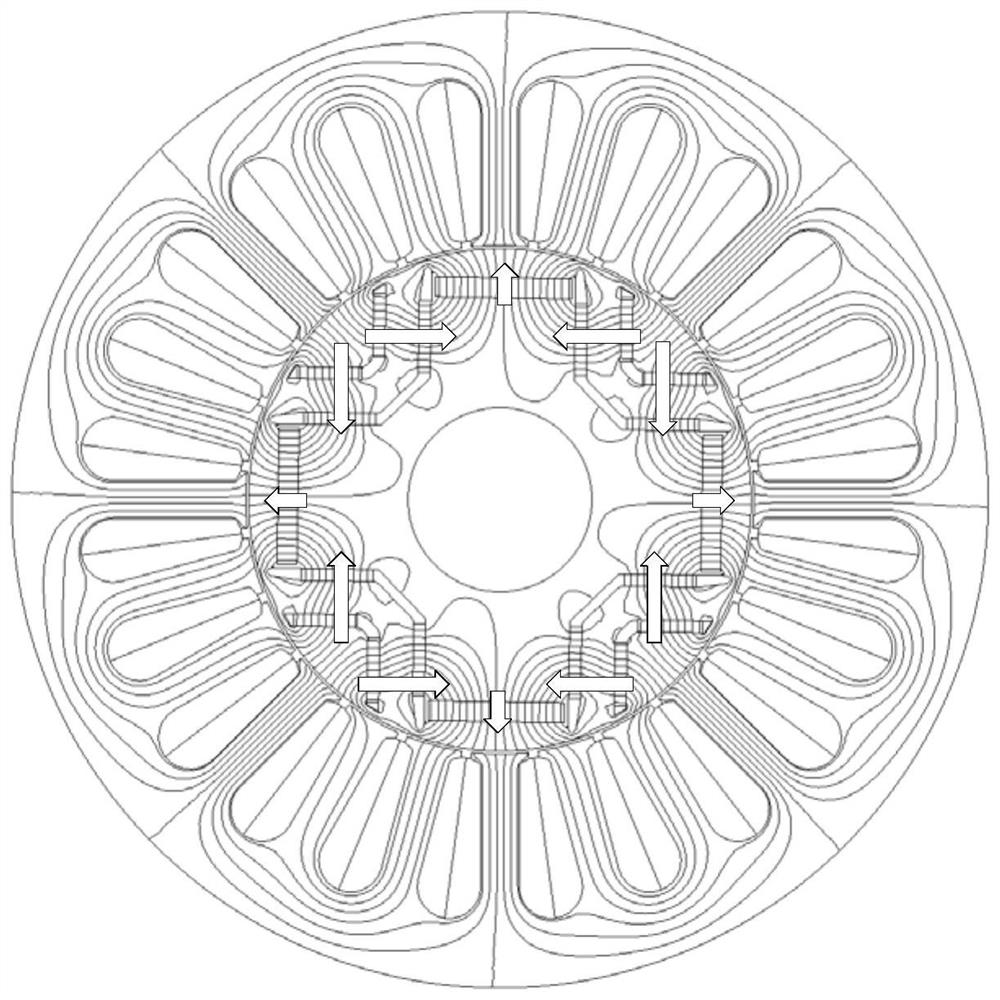

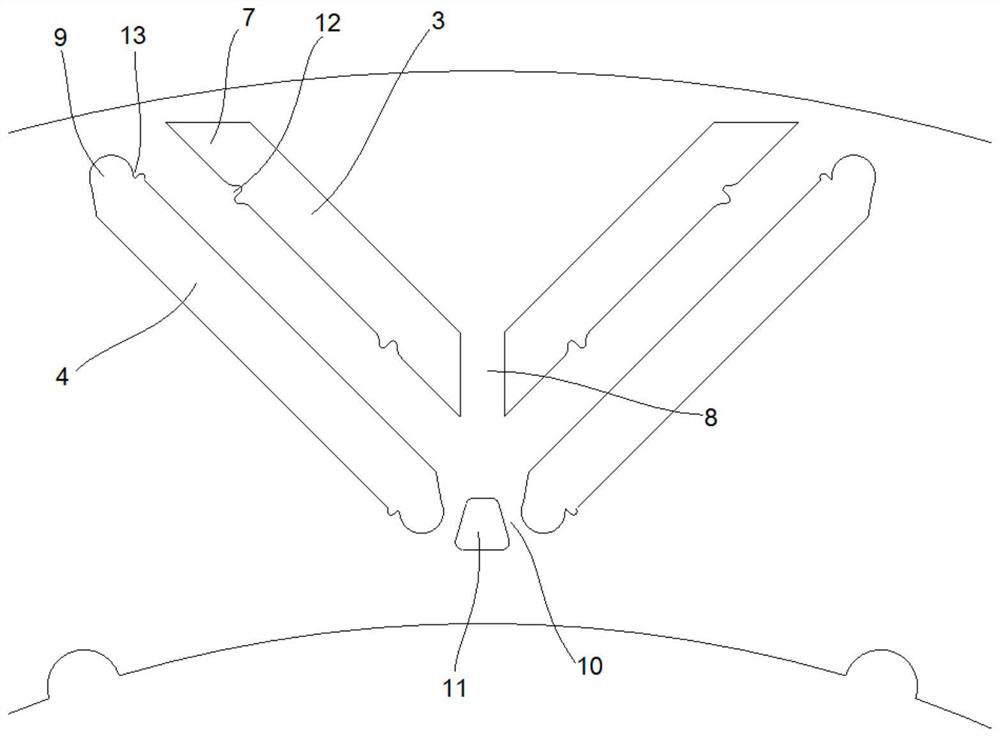

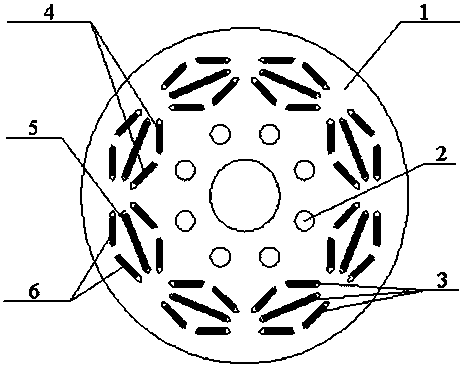

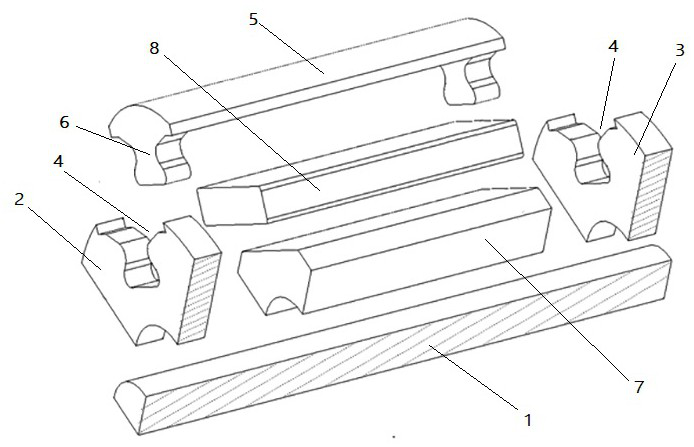

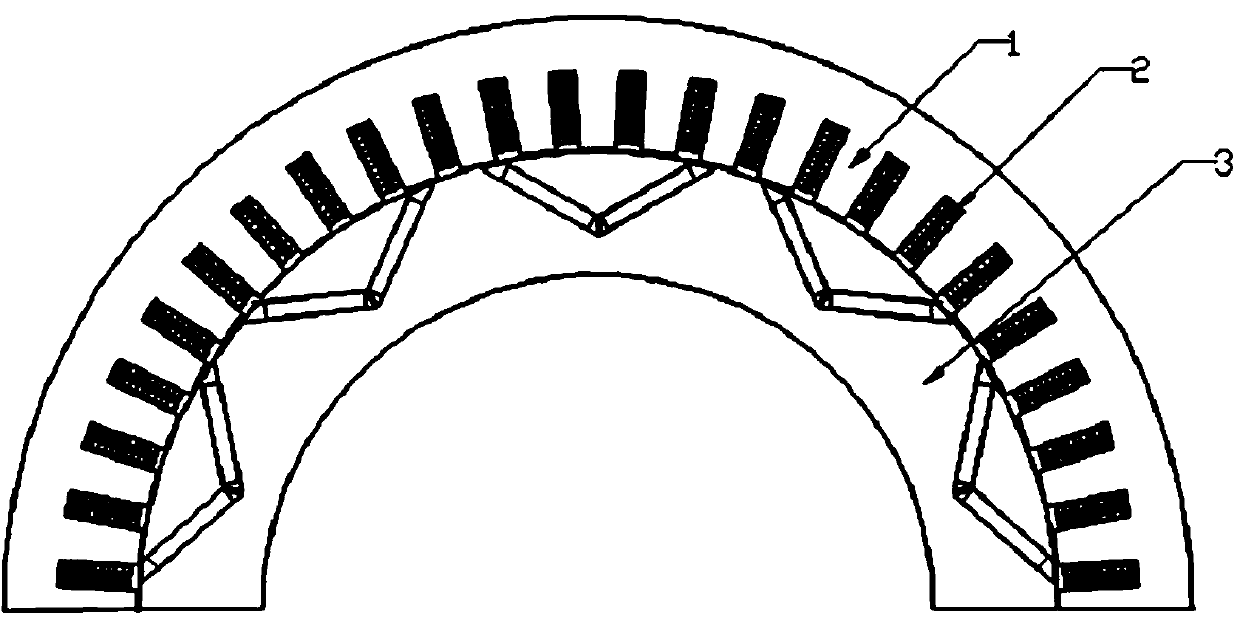

Double-layer V-shaped built-in permanent magnet motor rotor for electric automobile

InactiveCN103280904AImproved air gap magnetic field waveformImprove resultant torque rippleSynchronous machine detailsMagnetic circuit rotating partsConstant powerMagnet

The invention relates to a double-layer V-shaped built-in permanent magnet motor rotor for an electric automobile. Multiple groups of permanent magnet slots which are radially arranged in an inner layer and an outer layer are uniformly arranged on the iron core of the rotor at intervals along the circumferential direction; one or more V-shaped magnetized stripy magnetic steel is embedded in each permanent magnet slot. By virtue of the optimization of structures such as the angle of polar arc of inner-layer V-shaped magnetic steel, the included angle of outer-layer V-shaped magnetic steel, the width proportion of the inner-layer magnetic steel to the outer-layer V-shaped magnetic steel and the included angle of the outer-layer forcipated permanent magnet slot and the outer-layer magnetic steel, the air-gap flux density waveform is more approximate to the sinusoidal distribution, the harmonic component is reduced, the air-gap field waveform of the motor is improved, the fundamental wave frequency of spline torque fluctuation is improved, the spline fundamental wave and the ultraharmonics torque amplitude value are reduced, the torque fluctuation caused by splines is reduced, and the synthesis torque fluctuation of the motor is greatly reduced; and meanwhile, the reluctance torque is obviously increased, the salient pole rate and flux weakening speed expanding capability of the motor are improved, a constant-power speed range wider than that of a surface-mounted permanent magnet motor can be obtained, and the driving requirement of electric and hybrid automobiles can be met.

Owner:苏州和鑫电气股份有限公司

Image capture unit and an imaging pipeline with enhanced color performance in a surgical instrument and method

ActiveUS8684914B2Eliminates the need for calibration of lens artifactsOvercomes shortcomingTelevision system detailsSurgeryBeam splitterImage resolution

In a minimally invasive surgical system, an image capture unit includes a prism assembly and sensor assembly. The prism assembly includes a beam splitter, while the sensor assembly includes coplanar image capture sensors. Each of the coplanar image capture sensors has a common front end optical structure, e.g., the optical structure distal to the image capture unit is the same for each of the sensors. A controller enhances images acquired by the coplanar image capture sensors. The enhanced images may include (a) visible images with enhanced feature definition, in which a particular feature in the scene is emphasized to the operator of minimally invasive surgical system; (b) images having increased image apparent resolution; (c) images having increased dynamic range; (d) images displayed in a way based on a pixel color component vector having three or more color components; and (e) images having extended depth of field.

Owner:INTUITIVE SURGICAL OPERATIONS INC

Feature differentiation image capture unit and method in a surgical instrument

ActiveUS8764633B2Eliminates the need for calibration of lens artifactsOvercomes shortcomingSurgeryEndoscopesBeam splitterImage resolution

Owner:INTUITIVE SURGICAL OPERATIONS INC

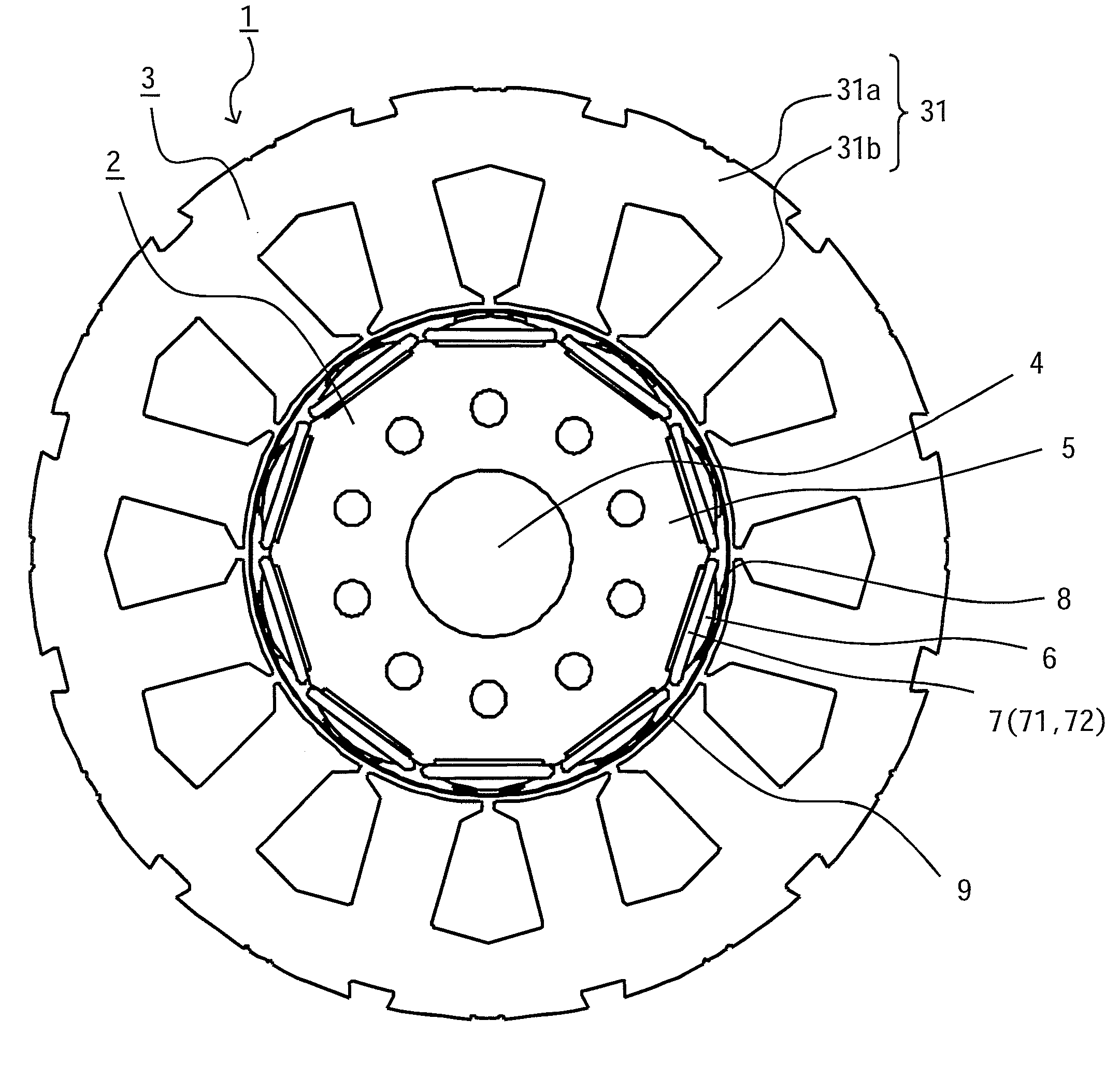

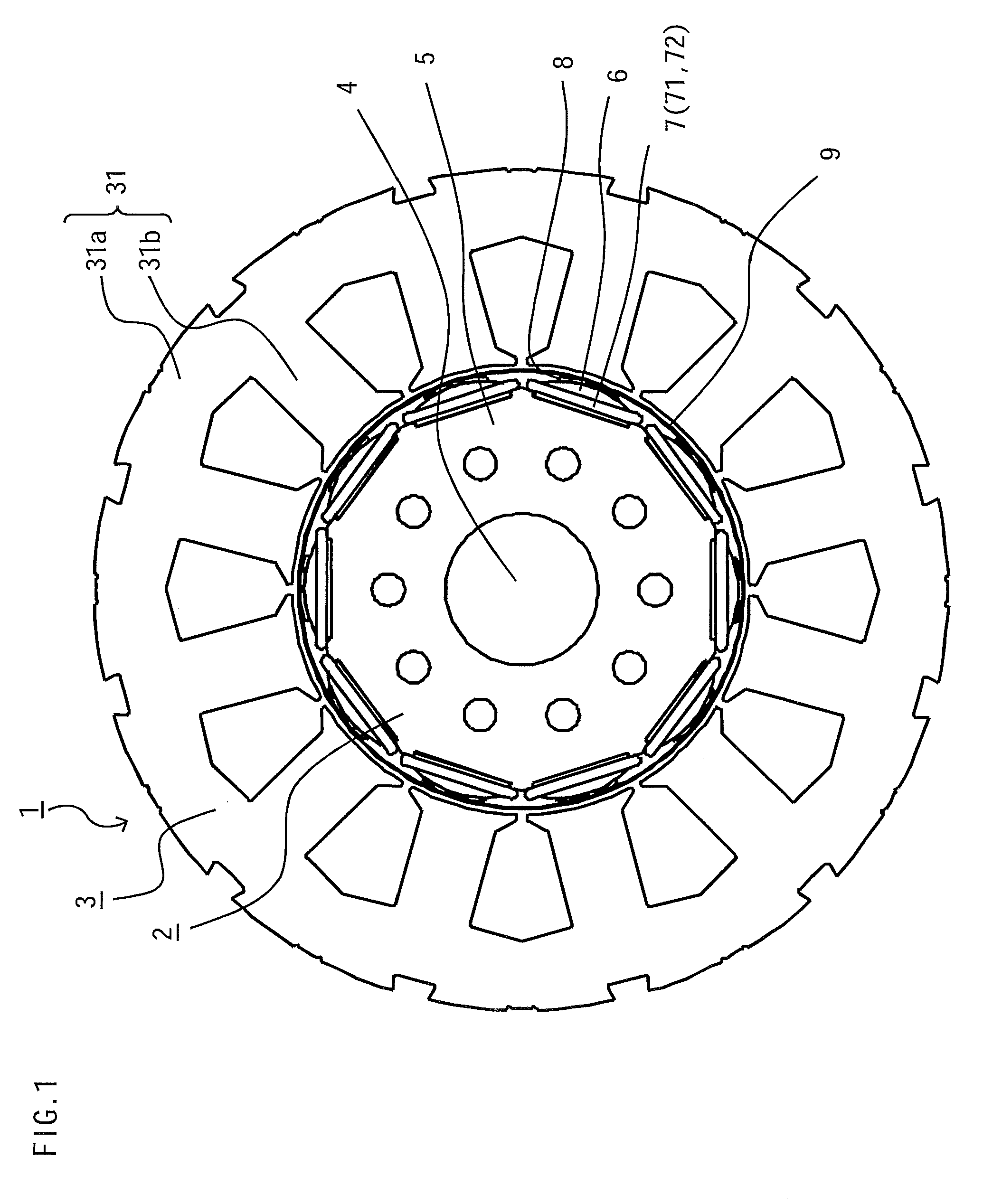

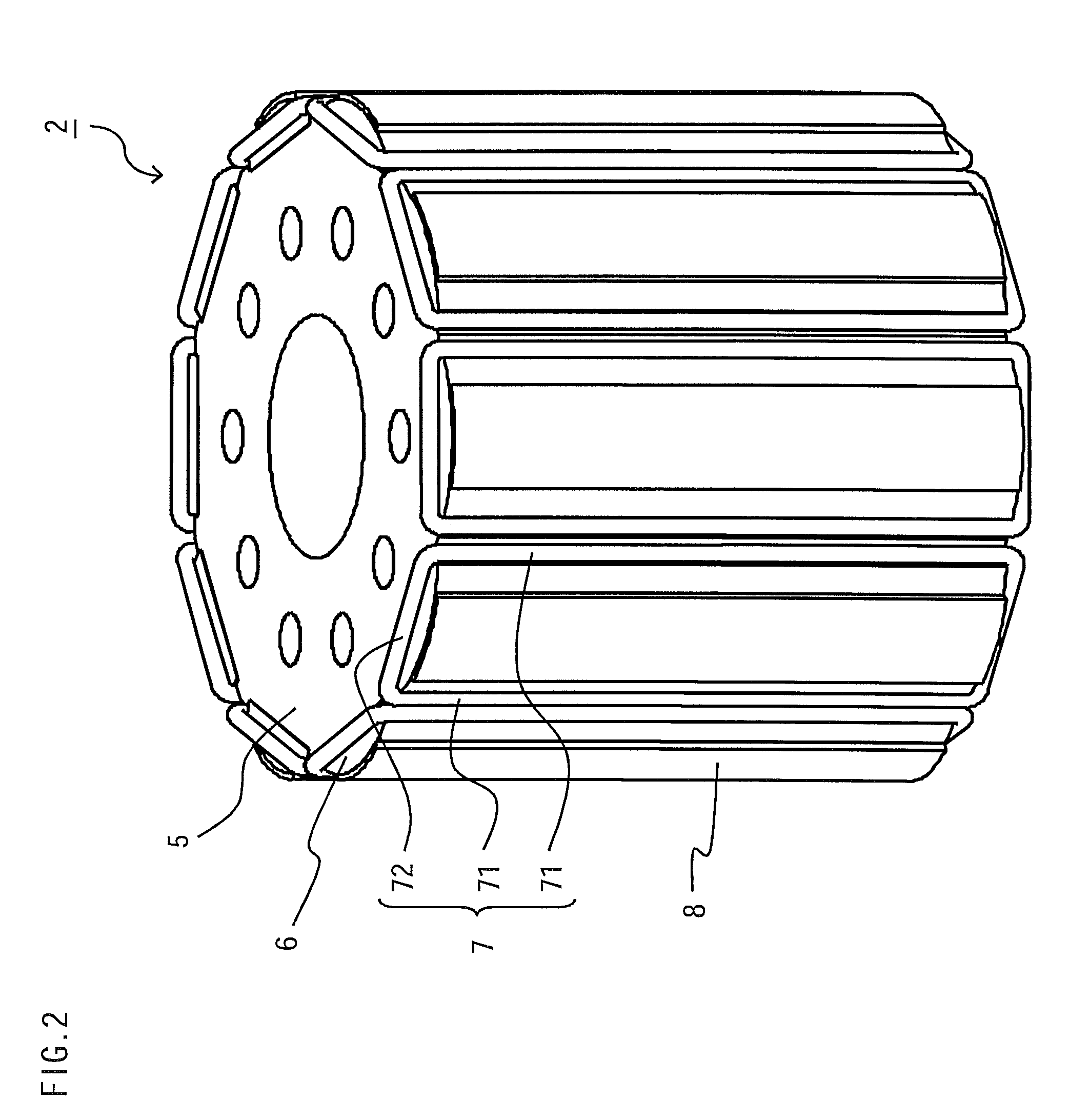

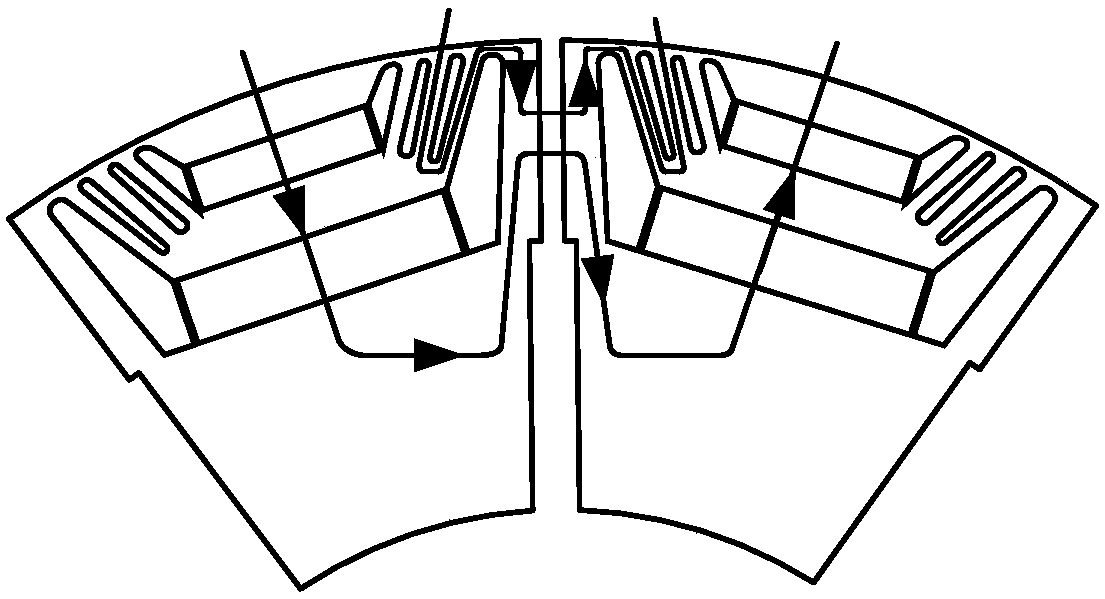

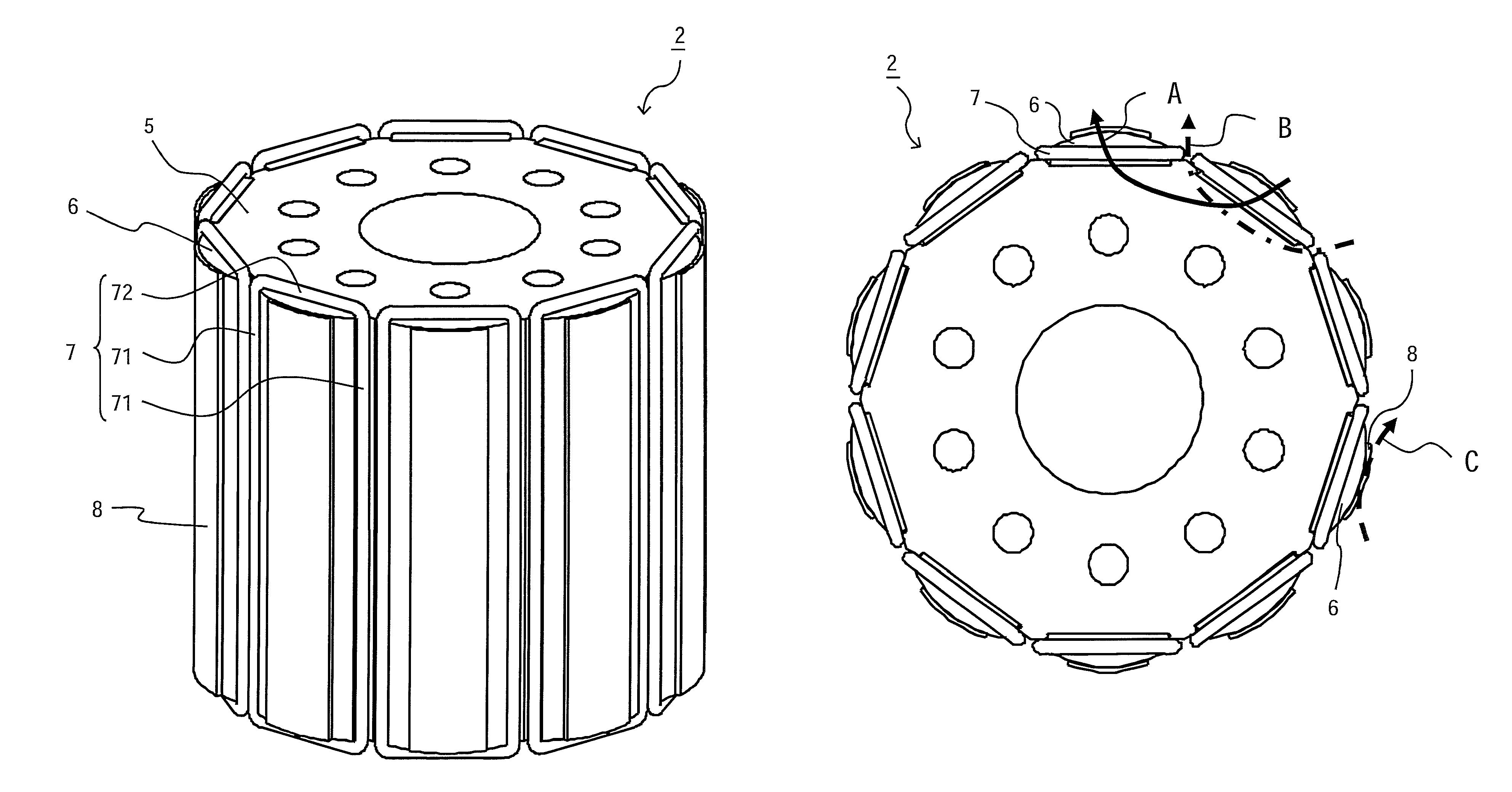

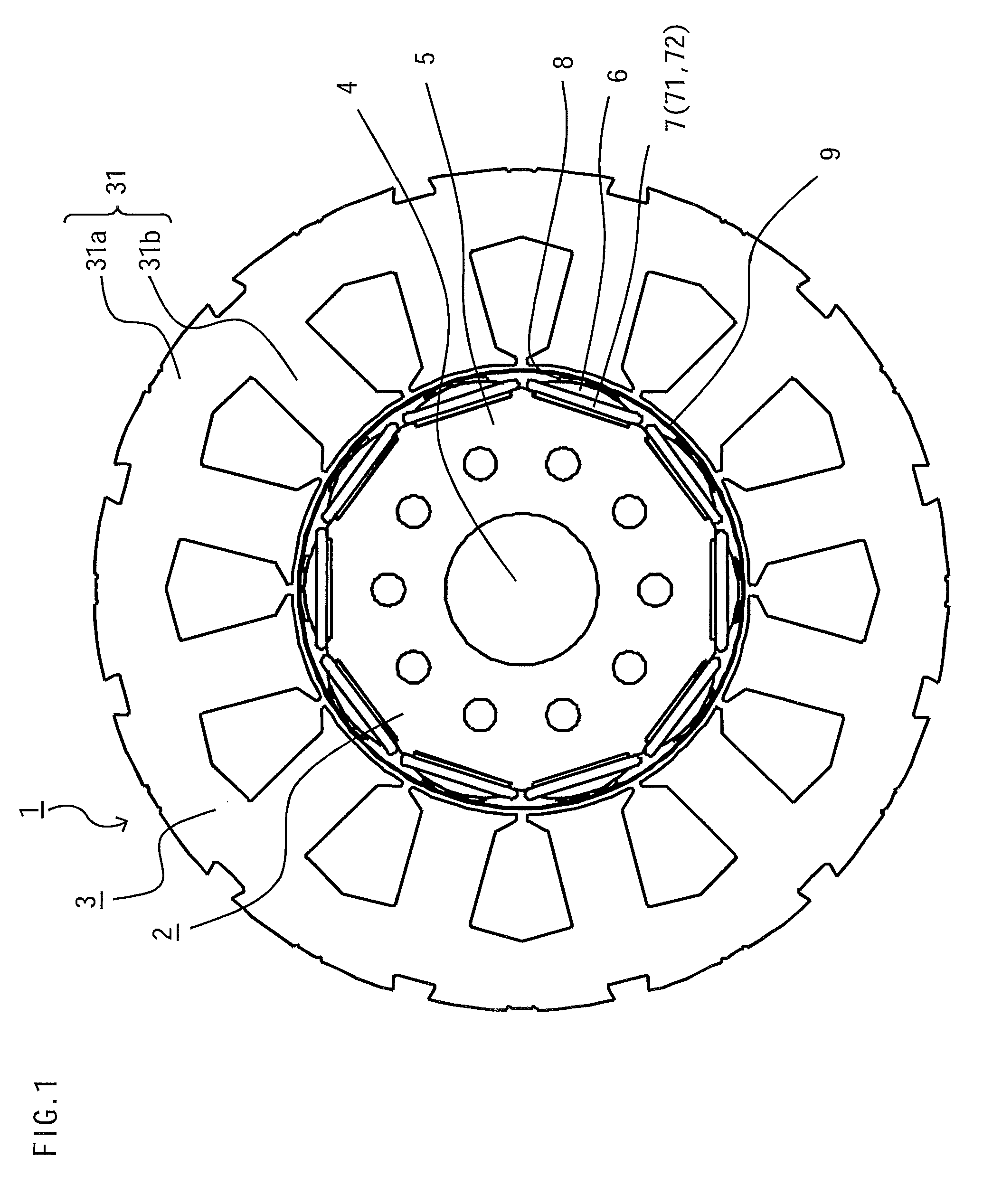

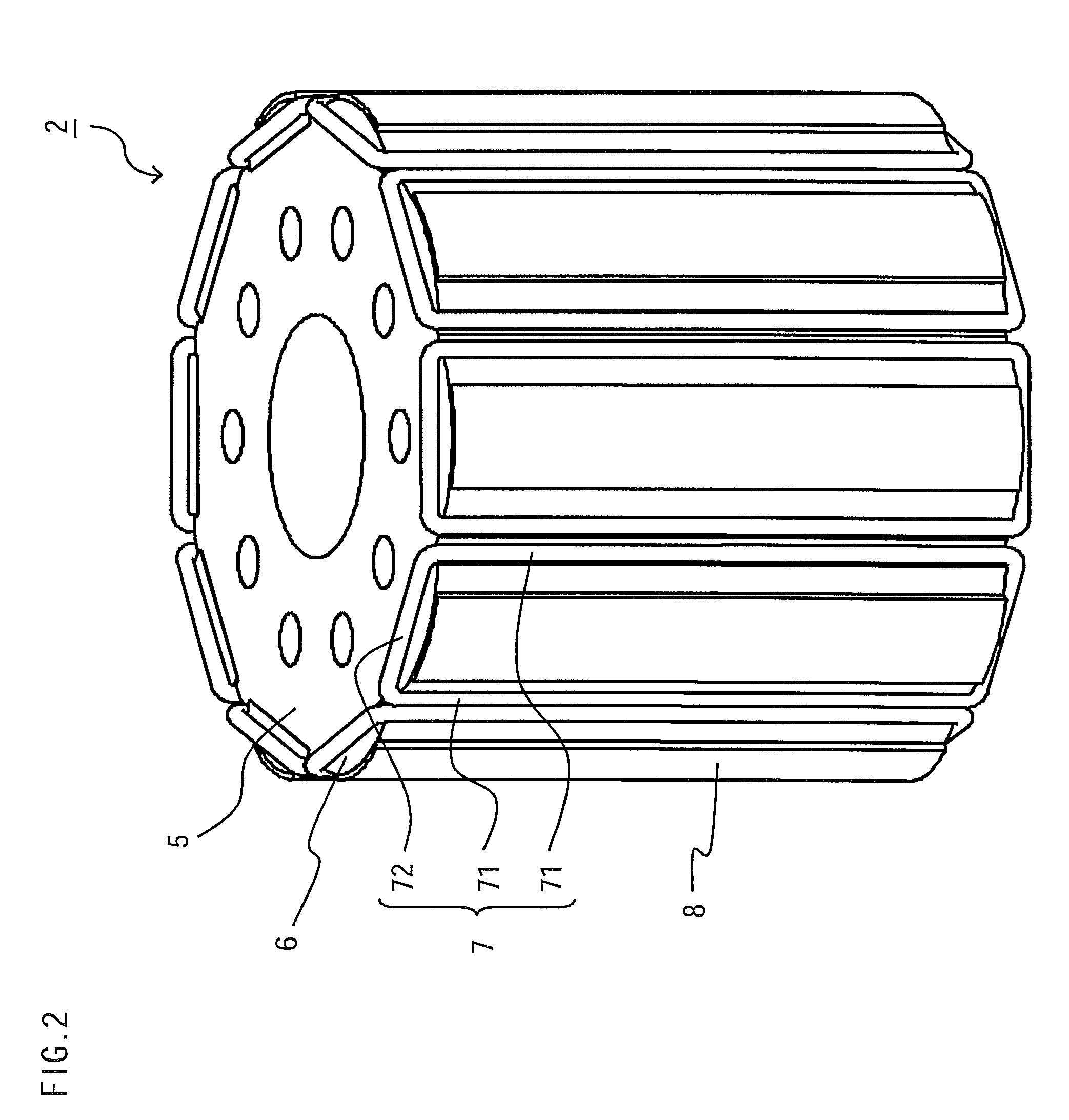

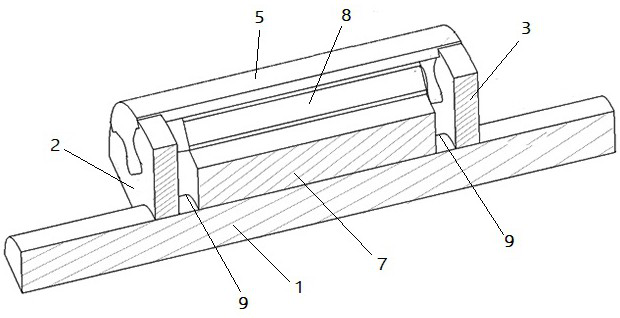

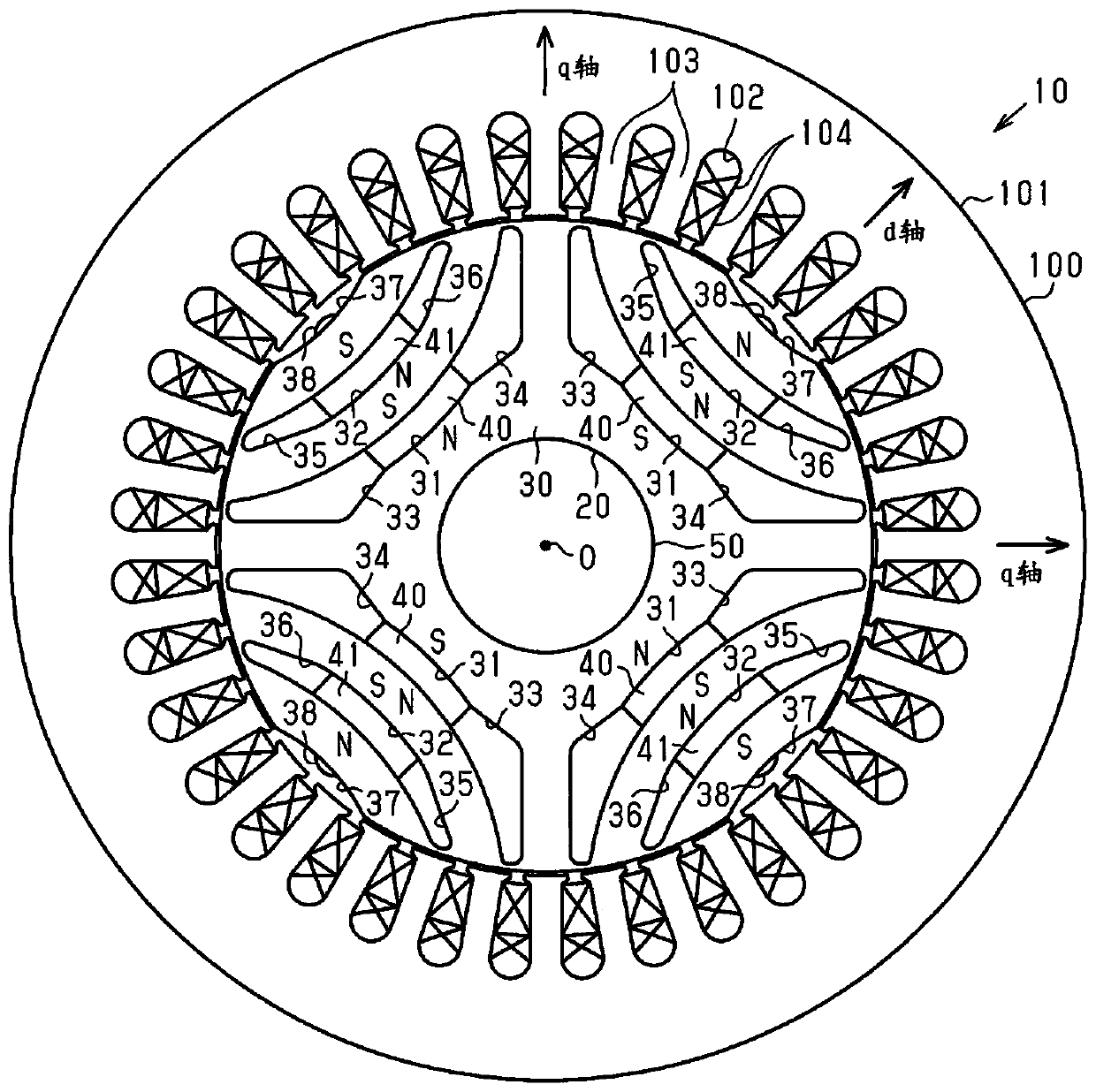

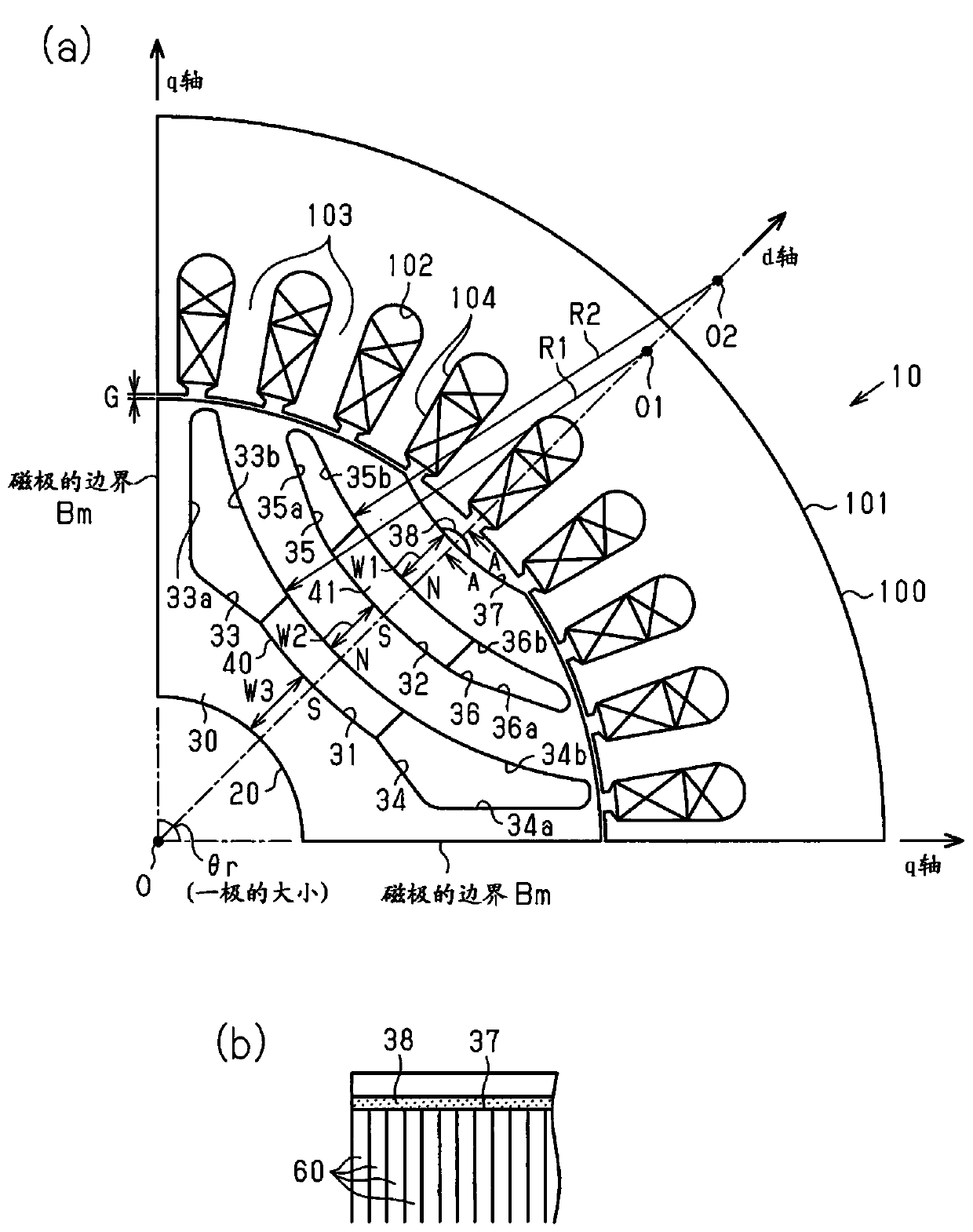

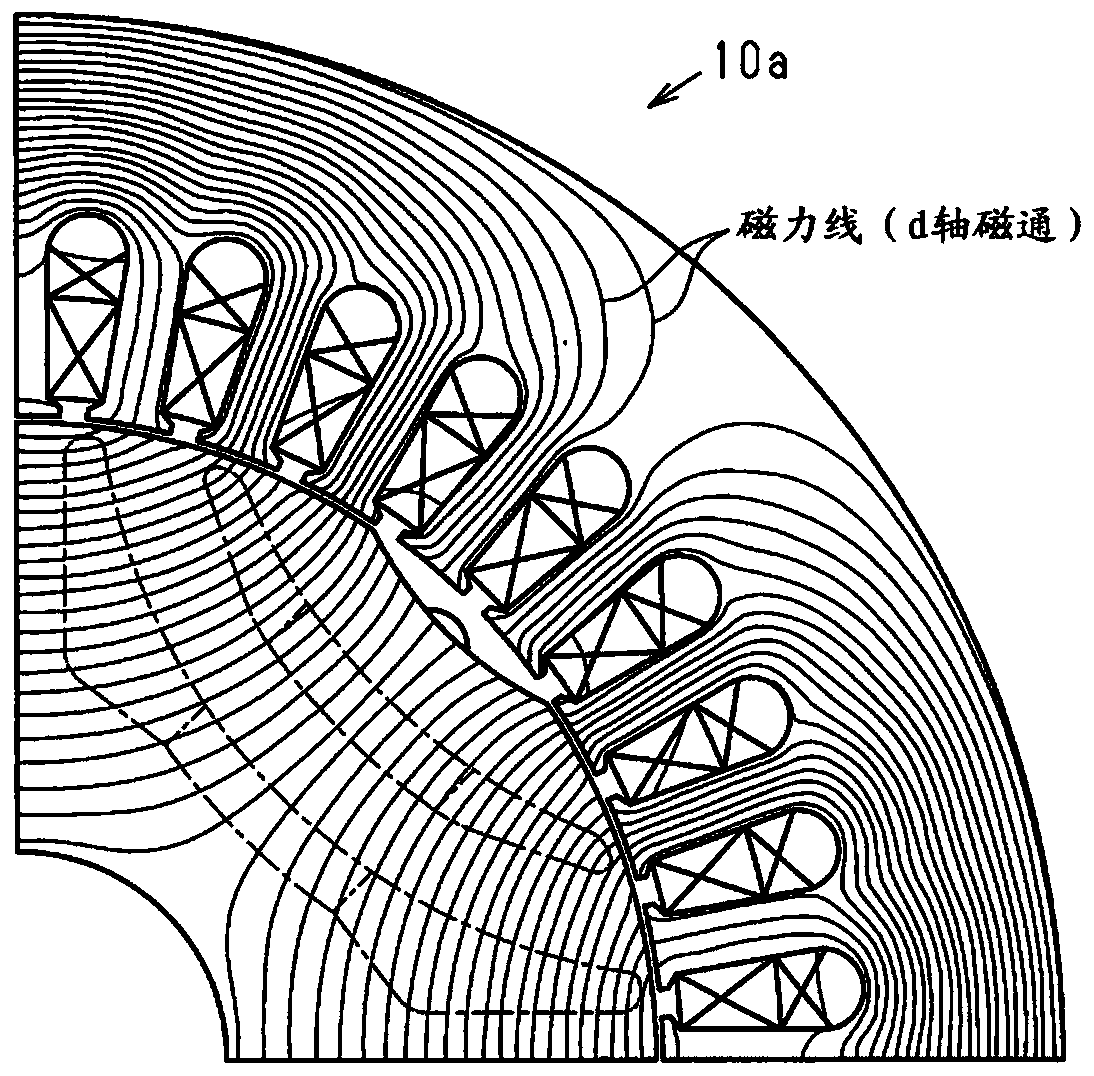

Rotor of permanent magnet rotary machine and manufacturing method of rotor

InactiveUS20100207475A1Increase saliencyEasy to detectMagnetic circuit rotating partsManufacturing stator/rotor bodiesElectrical conductorMagnetic poles

A rotor of a rotary machine includes a rotary shaft, a rotor core fixed to a circumferential surface of the rotary shaft, a plurality of permanent magnets arranged on a circumferential surface of the rotor core at specific intervals along a circumferential direction thereof, conducting circuits arranged to surround the permanent magnets, and magnetic material pieces arranged on outer surfaces of the individual permanent magnets. Each of the conducting circuits includes a pair of first conductor sections arranged between magnetic poles formed by the adjacent permanent magnets and a pair of second conductor sections electrically connecting the first conductor sections.

Owner:MITSUBISHI ELECTRIC CORP

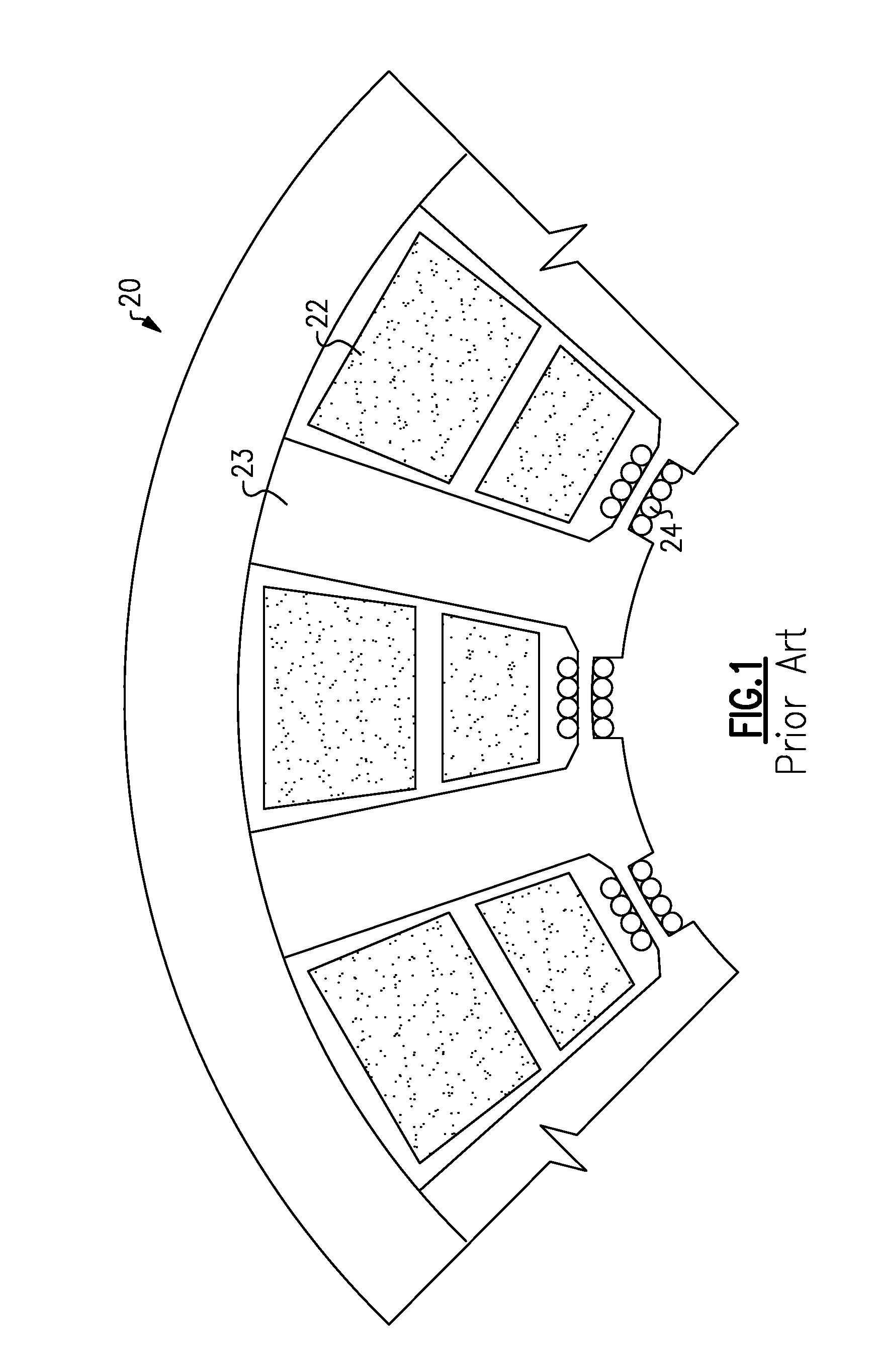

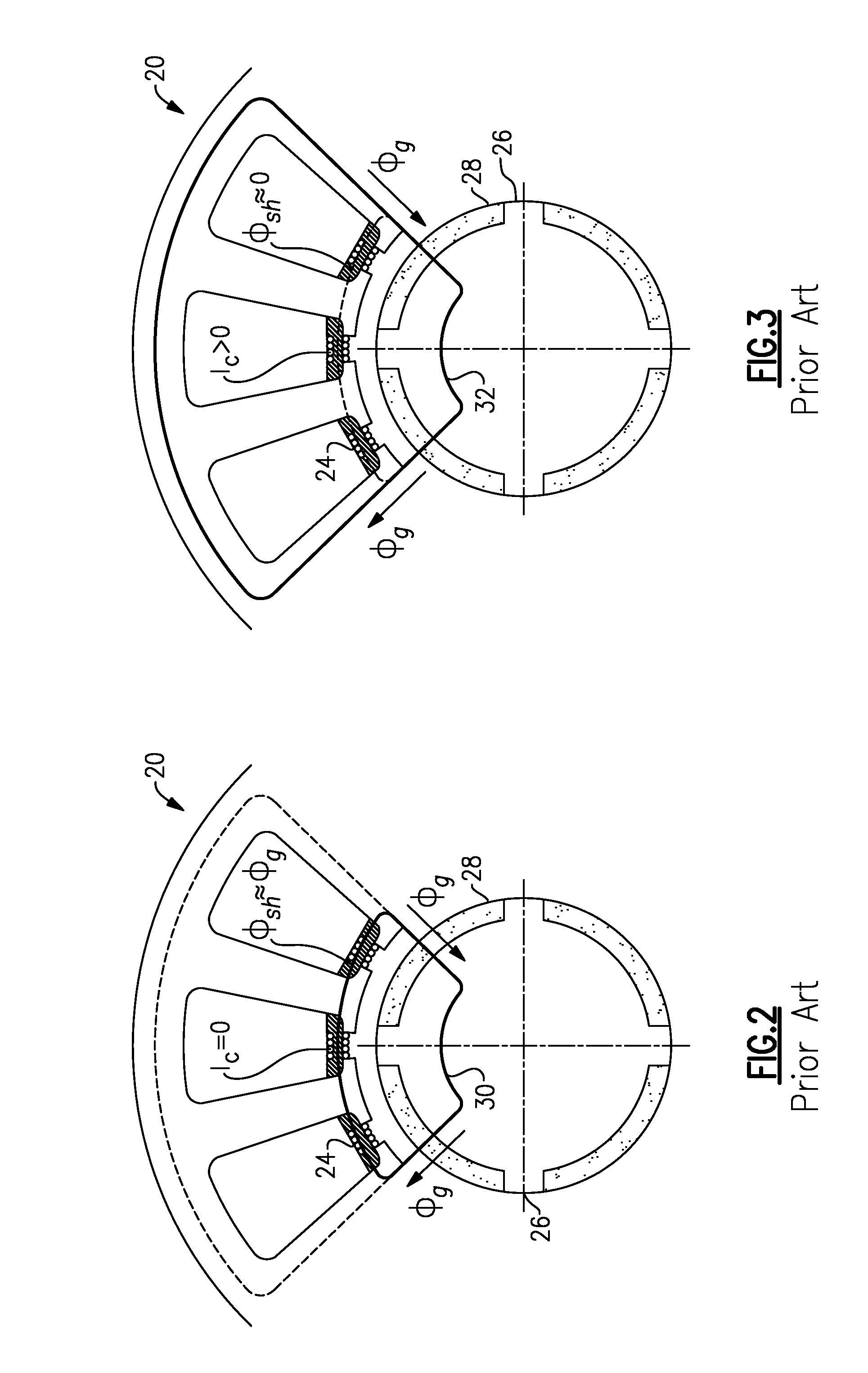

Direct flux regulated permanent magnet brushless motor utilizing sensorless control

InactiveUS7843155B2Increase saliencyEasy to identifyMotor/generator/converter stoppersWindingsBrushless motorsPermanent magnet rotor

A permanent magnet rotor for use in a flux regulated permanent magnet brushless machine is constructed such that the inductance along the direct and quadrature axes is markedly different to provide sensorless position feedback for the rotor.

Owner:HAMILTON SUNDSTRAND CORP

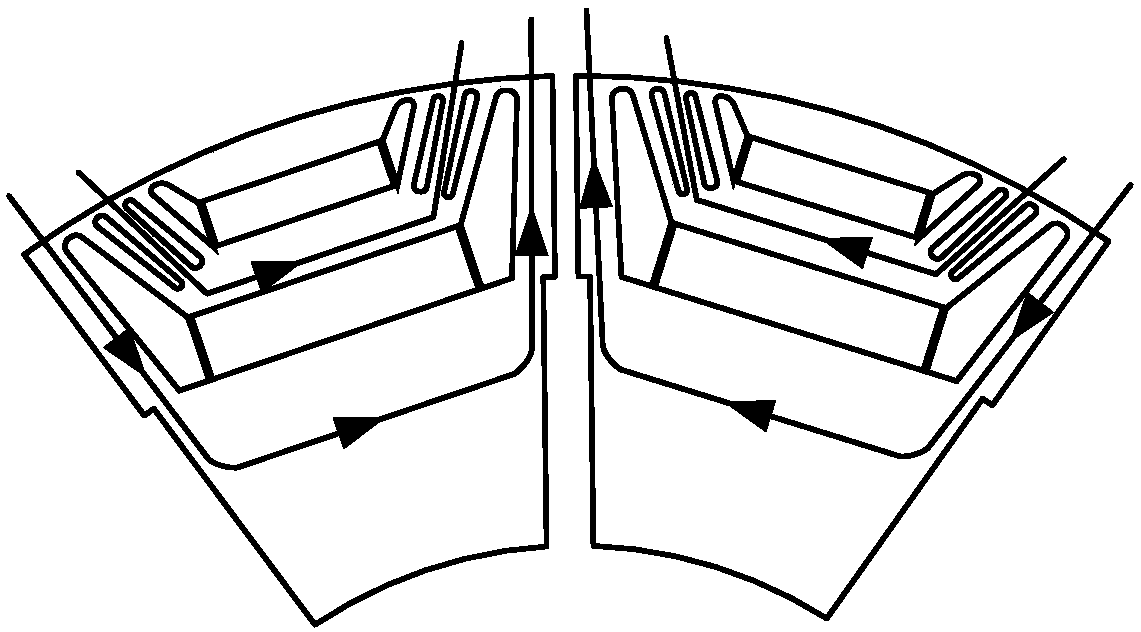

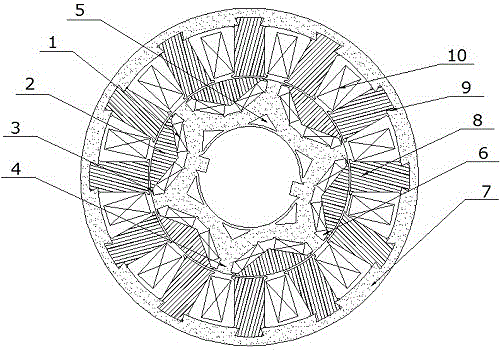

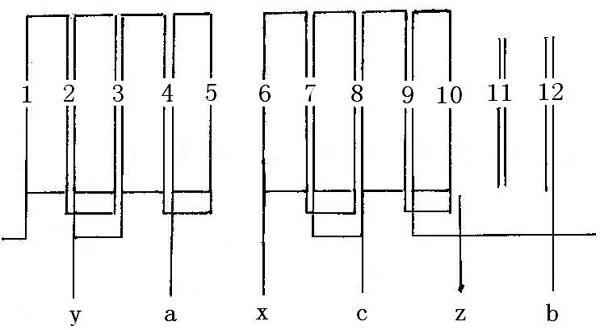

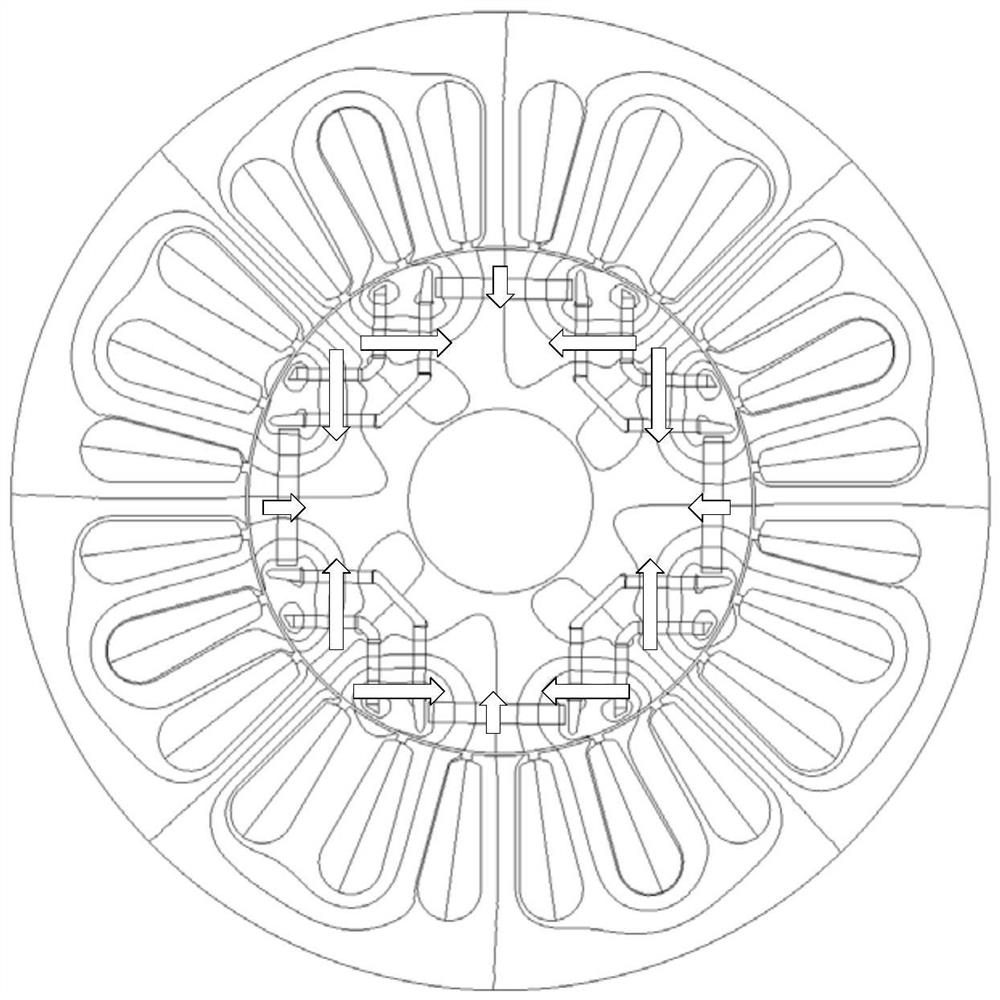

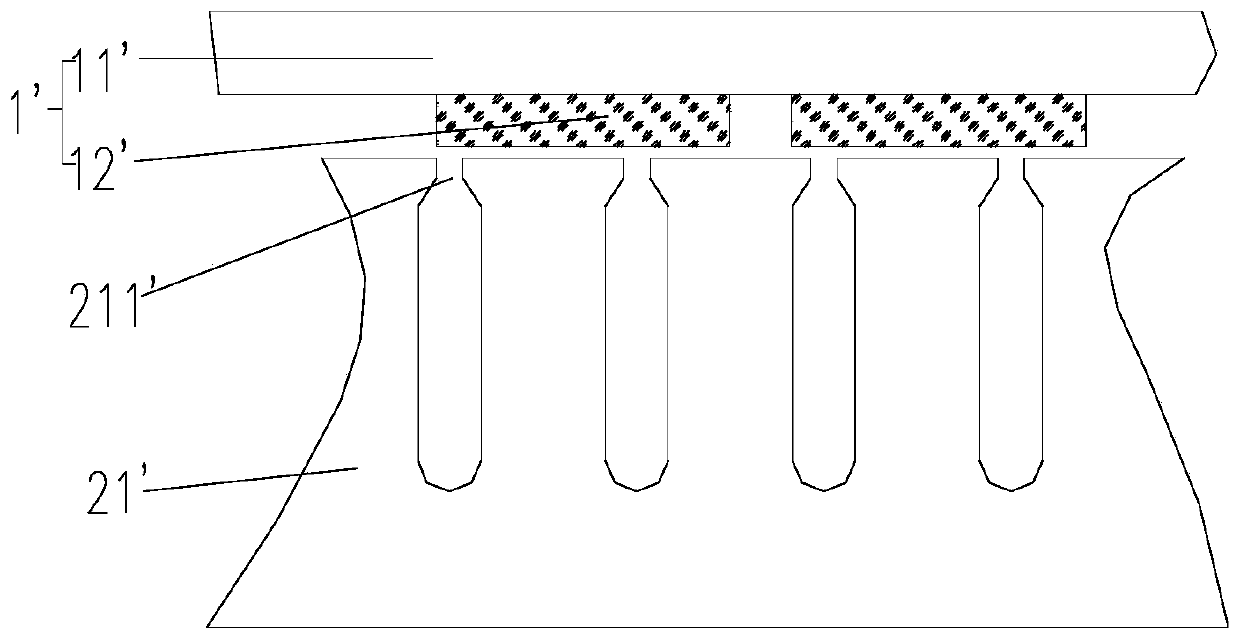

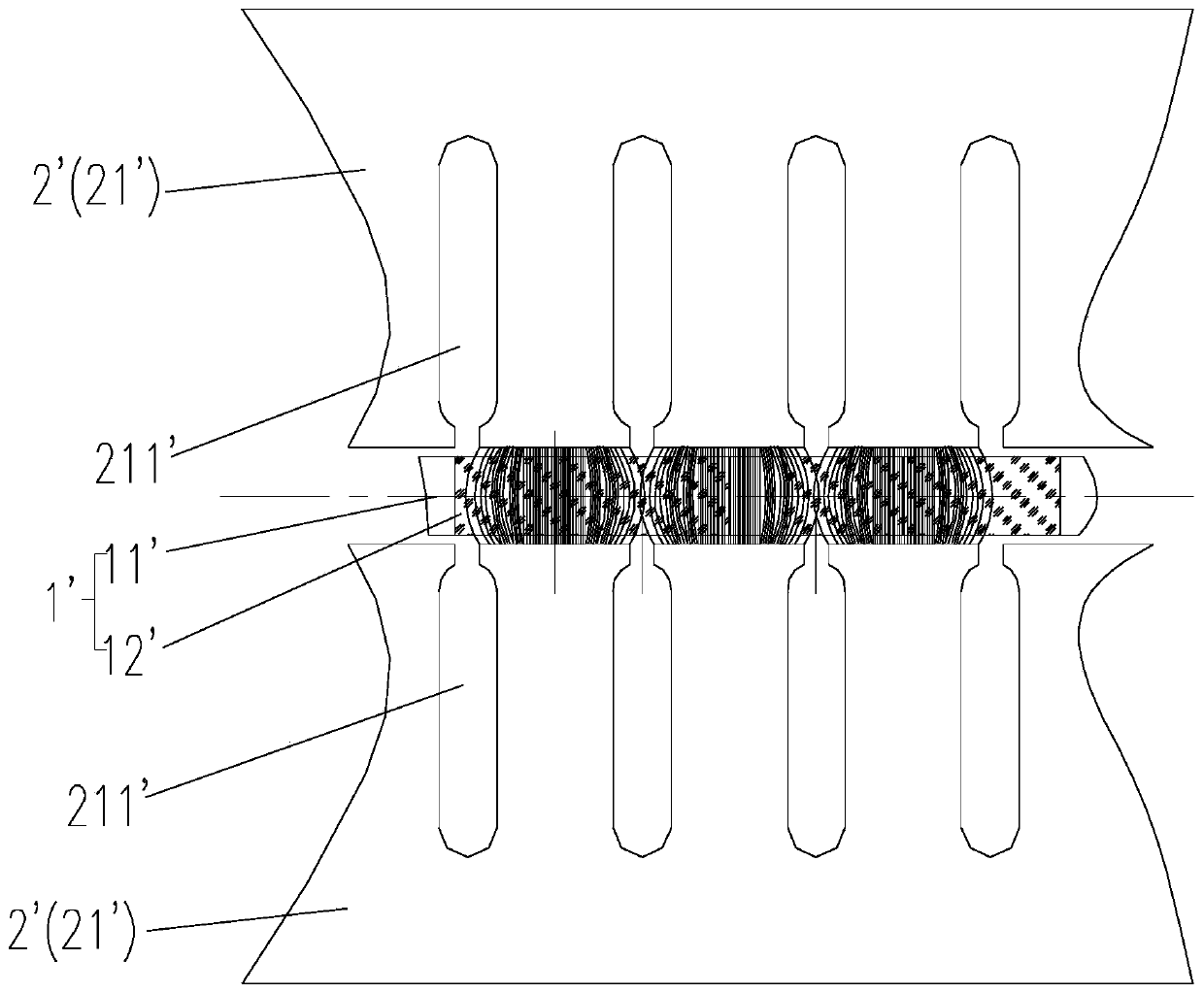

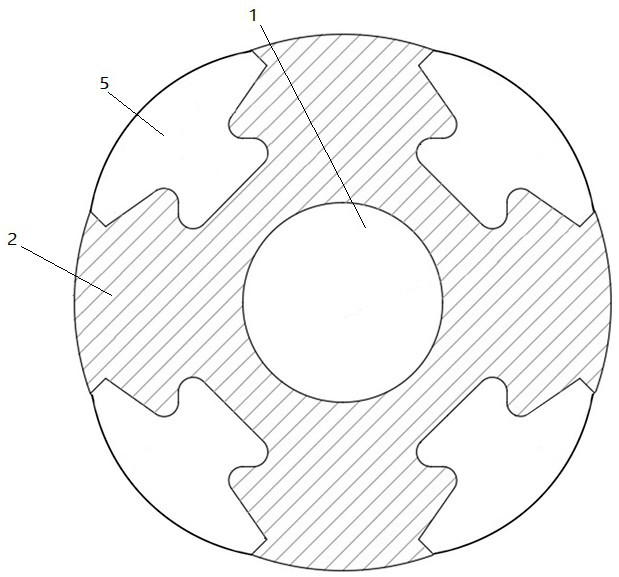

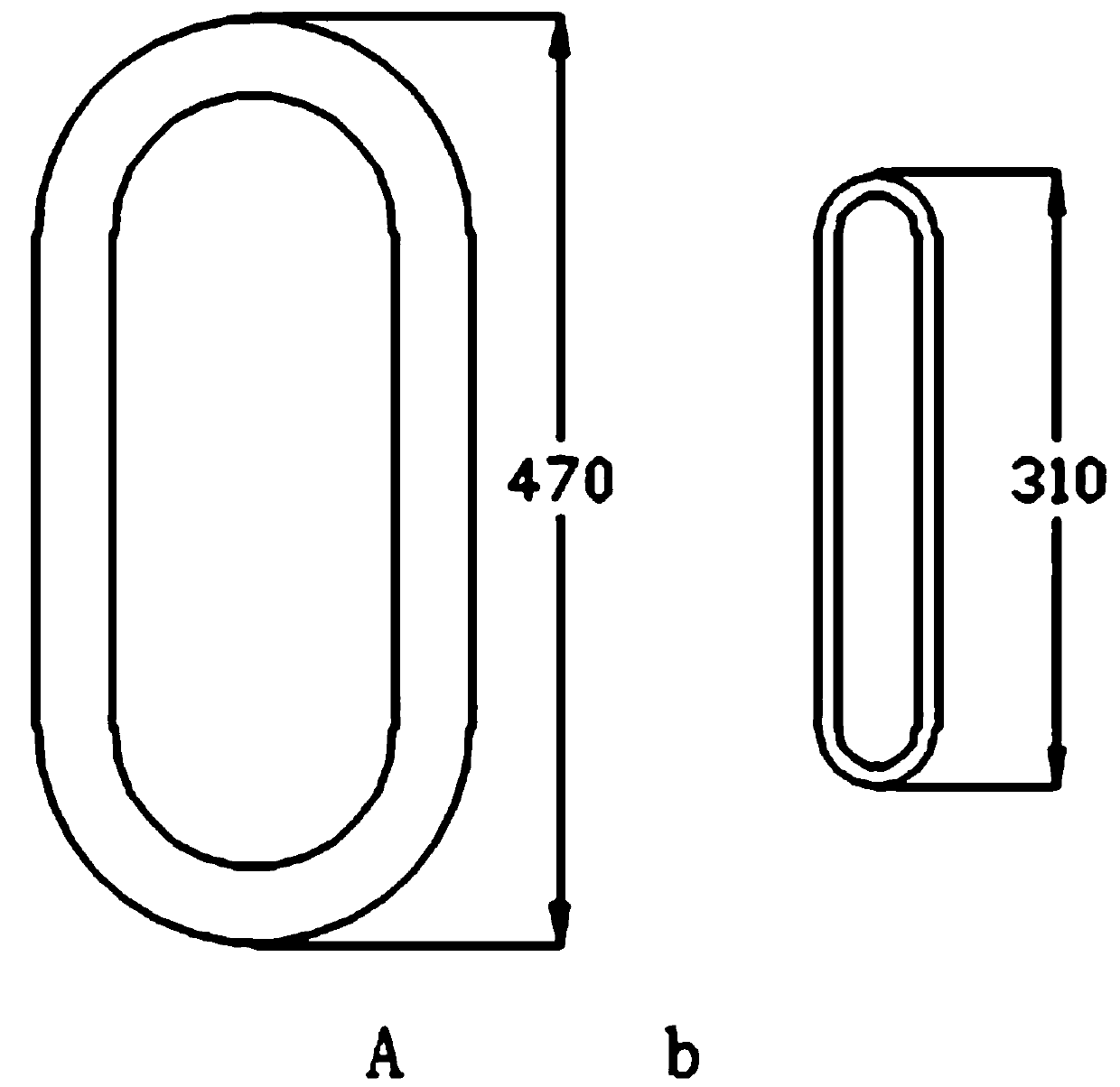

Fractional-slot concentrated winding permanent magnet synchronous motor and design method thereof for improving reluctance torque

InactiveCN108199509ALow failure rateReduce temperature riseMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet synchronous motorMetallic materials

The invention discloses fractional-slot concentrated winding permanent magnet synchronous motor and a design method thereof for improving reluctance torque. The fractional-slot concentrated winding permanent magnet synchronous motor comprises a stator and a rotor, wherein the stator is slotted along the peripheral direction to form fault-tolerant teeth and armature teeth arranged alternately; an armature winding is wound on the armature teeth, the fault-tolerant teeth and the armature teeth are different in widths, and the widths of the armature teeth are wider than those of the fault-tolerantteeth; the rotor consists of a permanent magnet, a rotor core and a magnetic obstacle, the permanent magnet is a double-layer permanent magnet, the rotor core is composed of a plurality of independent units, and during machining, the rotor is wrapped with a non-metal material to form a compact structure. The rotor core is segmented along the axis pole direction of the permanent magnet, and the width of the upper part of the magnetic obstacle during segmentation is narrower than that of the lower part. The permanent magnet synchronous motor has the advantages that the direct-axis inductance can be reduced through the special magnetic obstacle design, the influence on quadrature axis inductance can also be reduced as much as possible, and the subharmonic of the motor is free of obvious inhibition. Therefore, the reluctance torque of the motor can be improved effectively, and the iron loss and eddy-current loss of the motor are reduced.

Owner:JIANGSU UNIV

Rotor of permanent magnet rotary machine and manufacturing method of rotor

InactiveUS8217545B2Increase saliencyEasy to detectSynchronous generatorsWindingsElectrical conductorMagnetic poles

A rotor of a rotary machine includes a rotary shaft, a rotor core fixed to a circumferential surface of the rotary shaft, a plurality of permanent magnets arranged on a circumferential surface of the rotor core at specific intervals along a circumferential direction thereof, conducting circuits arranged to surround the permanent magnets, and magnetic material pieces arranged on outer surfaces of the individual permanent magnets. Each of the conducting circuits includes a pair of first conductor sections arranged between magnetic poles formed by the adjacent permanent magnets and a pair of second conductor sections electrically connecting the first conductor sections.

Owner:MITSUBISHI ELECTRIC CORP

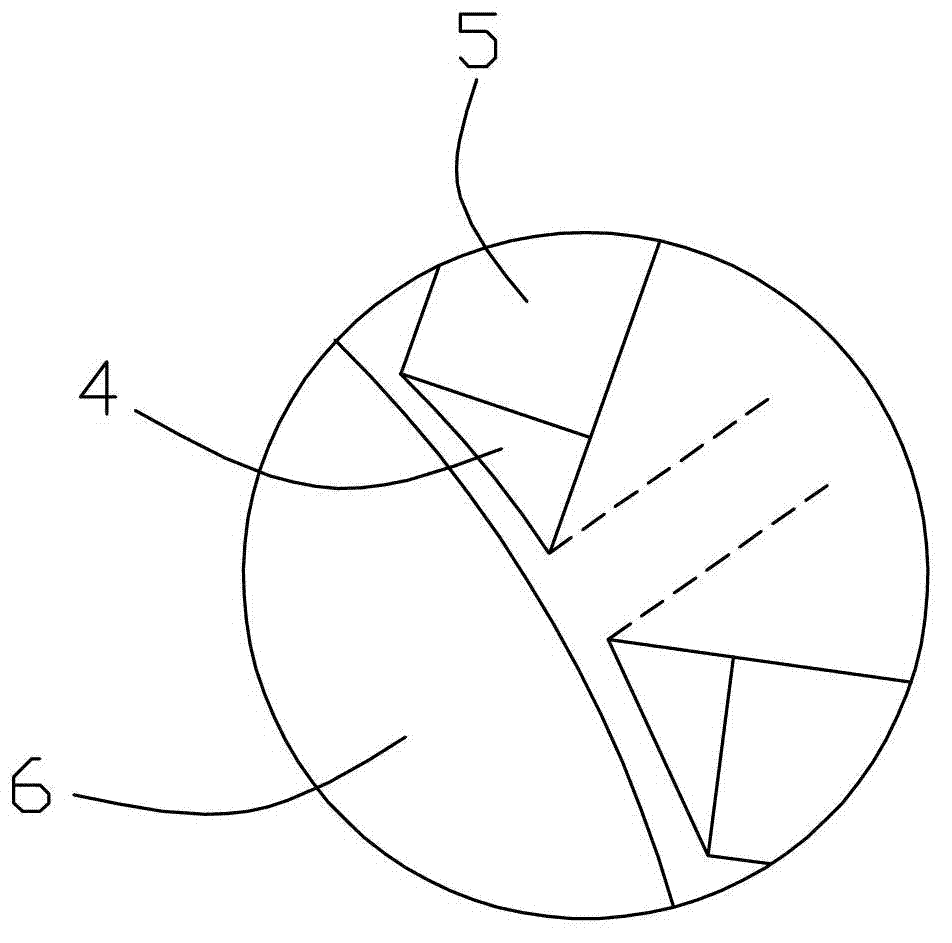

Embedded sine-profile permanent motor rotor

InactiveCN102857000AImprove reliabilityExtend your lifeMagnetic circuit rotating partsHarmonicInstability

The invention relates to an embedded sine-profile permanent motor rotor which solves the problem that permanent magnets in traditional motors in the prior art are generally attached to the outer sides of rotors and prone to shed in high-speed rotation of the rotors and the problem of vibration noise caused by instability in operation of the motors due to fluctuation in rotation of the rotors in normal shapes. A winding shaft on the surface of the rotor is provided with a plurality of arc protrusions in consecutive connection, the rotor is partitioned into a plurality of equal areas by the ligature of the rotor axis and the crosspoint of each two adjacent protrusions, two grooves in inverted splayed array are arranged in each area, and permanent magnets are inserted in the grooves. The embedded sine-profile permanent motor rotor has the advantages that the separation of the permanent magnets in high-speed rotation of the rotor is avoided, and reliability of the motor is improved while the service life of the motor is prolonged; salient pole rate is increased, larger salient pole torques can be generated, efficiency is improved, and the service life of the motor is prolonged; and the motor is more stable in operation, loss caused by harmonic waves is reduced, and vibration noise of the motor is improved to some extent.

Owner:HANGZHOU WAHAHA GROUP

Anti-flux leakage low-loss driving motor design

PendingCN106712335AHigh Saturation Flux DensityHigh torque low loss drive motorMagnetic circuit rotating partsMagnetic circuit stationary partsPhysicsDrive motor

The invention provides an anti-flux leakage low-loss driving motor, which comprises a stator and a rotor, wherein the stator comprises a stator iron core and stator windings; the rotor comprises a rotor iron core and rotor magnetic steels; the stator iron core comprises an annular stator iron core yoke ring base body formed by non-oriented silicon steel laminations and multiple stator iron core tooth inserts formed by oriented silicon steel laminations; the rotor iron core comprises an annular rotor iron core base body formed by non-oriented silicon steel laminations and multiple rotor iron core inserts formed by oriented silicon steel laminations. The oriented silicon steel lamination with higher permeability is used for replacing the non-oriented silicon steel lamination in the rotor polarization direction, and a stator pole shoe also uses the oriented silicon steel lamination. Thus, in a large current condition, the saturation flux density is high, the loss is reduced, the driving motor efficiency is improved, and a large-torque low-loss driving motor is thus realized.

Owner:上海英磁新能源科技有限公司

High-quality three-phase alternating current permanent magnet servo synchronous motor

InactiveCN102355108AReduce inertiaIncrease the axial wind pathMagnetic circuit rotating partsMagnetic circuit stationary partsSynchronous motorElectric machine

The invention relates to a high-quality three-phase alternating current permanent magnet servo synchronous motor, which comprises a stator and a rotor, wherein a stator core of the motor has 12 slots, the stator core is inclined for 7 / 32 pitches, the pole number is 10, and the phase number is 3; and a stator core three-phase winding is a fractional slot concentrated winding, the pitch of winding coils is 1, the number of turns of each coil is equal, and the difference of the three-phase winding is 120-degree electrical angles. The three-phase winding has 6 lead-out wires and provides two wiring methods. A rotor permanent magnet structure is in a built-in type, N and S poles of neodymium iron boron permanent magnets are alternately embedded into a ladder-shaped groove stacked into a rotor core by a rotor stamping piece, the rotor core is axially divided into two sections equally, and the central line of two sections of magnets with the same polarity is axially deflected for 4mm; and the excircle and the axle hole of a pole shoe of the rotor core are not concentric, ununiform air gaps are formed between the pole shoe of each pole and the inner circle of the stator core, and a plurality of measures are adopted to greatly improve the sine property of a phase voltage waveform of the motor and motor quality. The invention is suitable for the three-phase alternating current permanentmagnet servo synchronous motor.

Owner:江西省迪普安数字功率技术发展有限公司

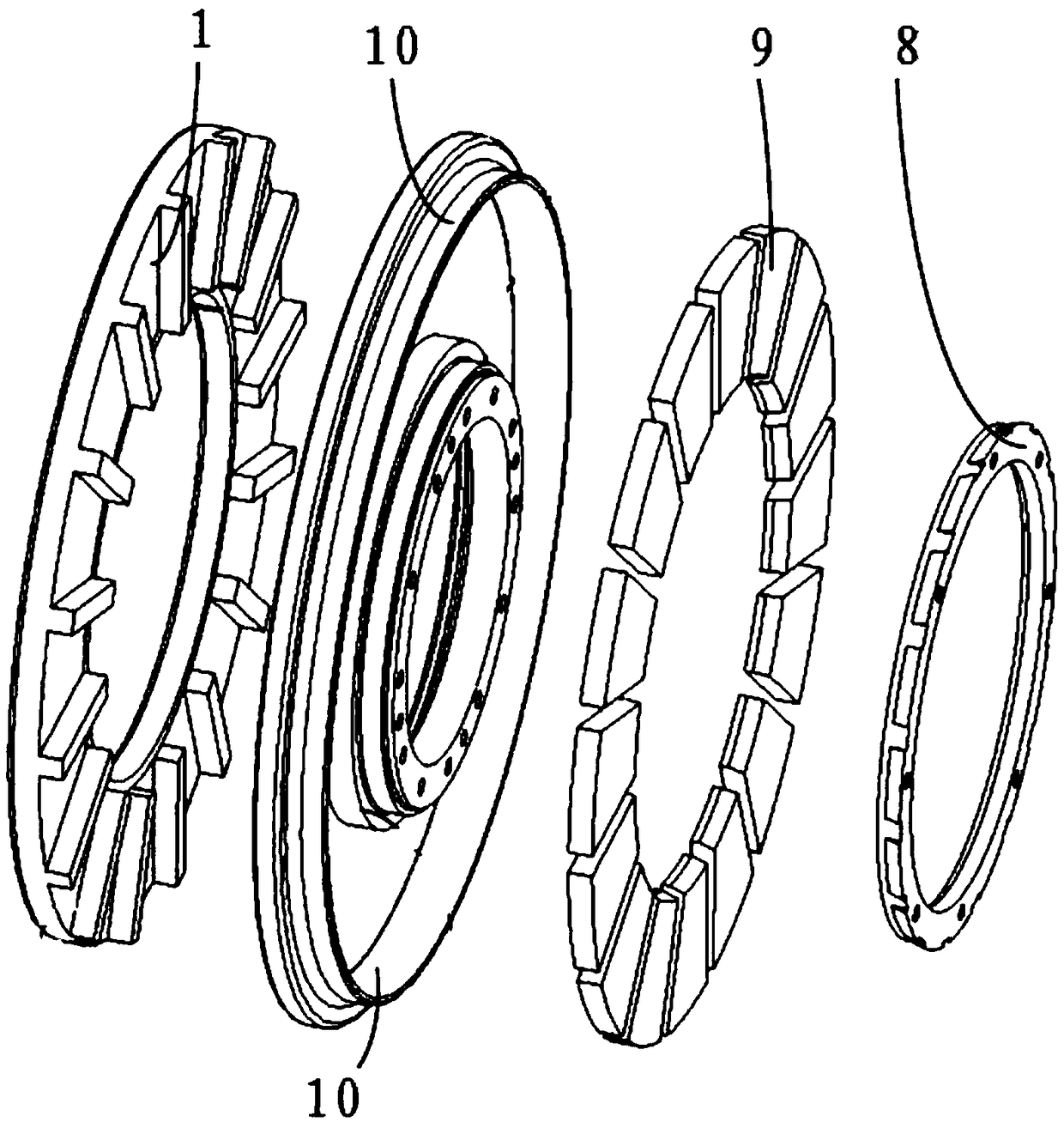

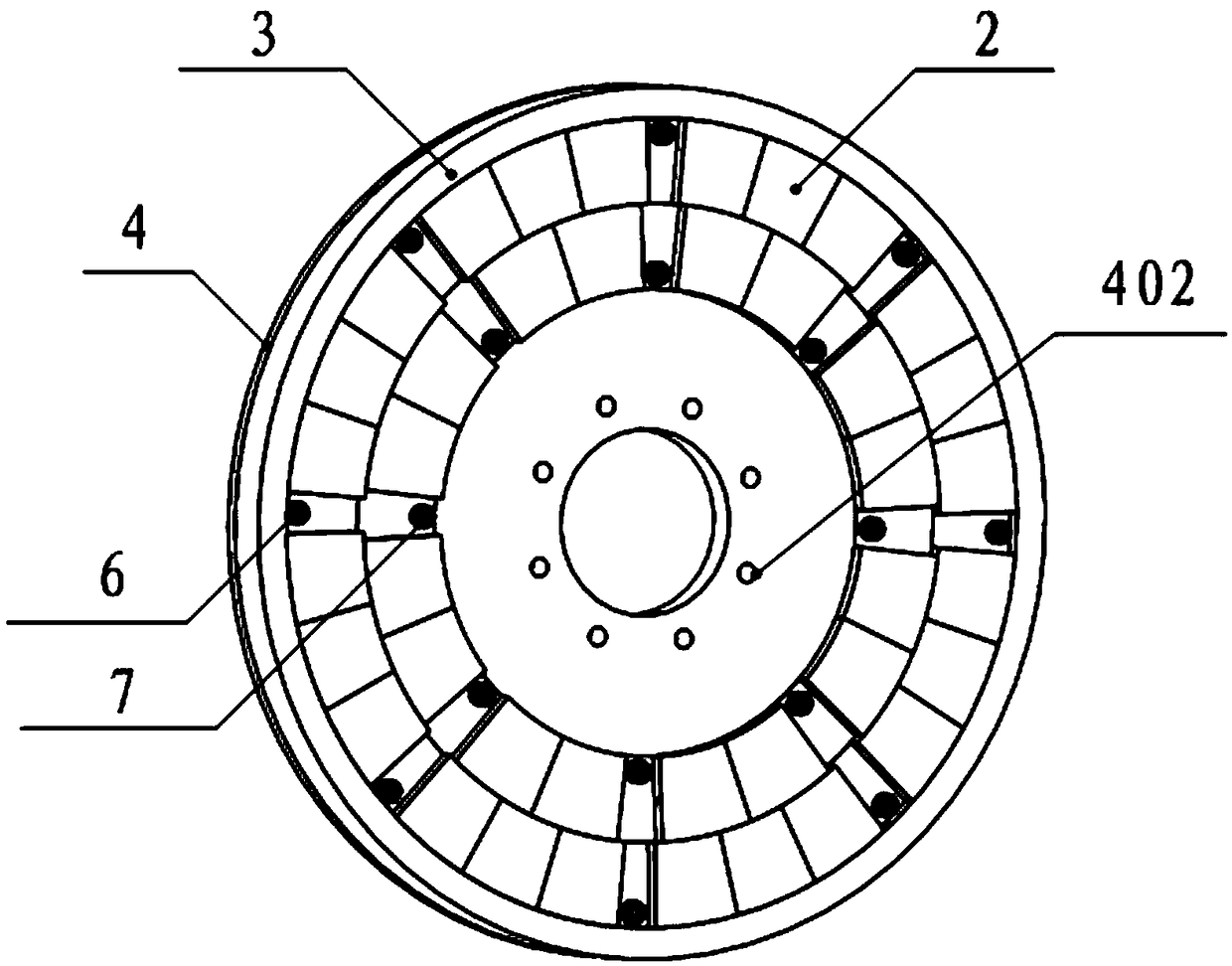

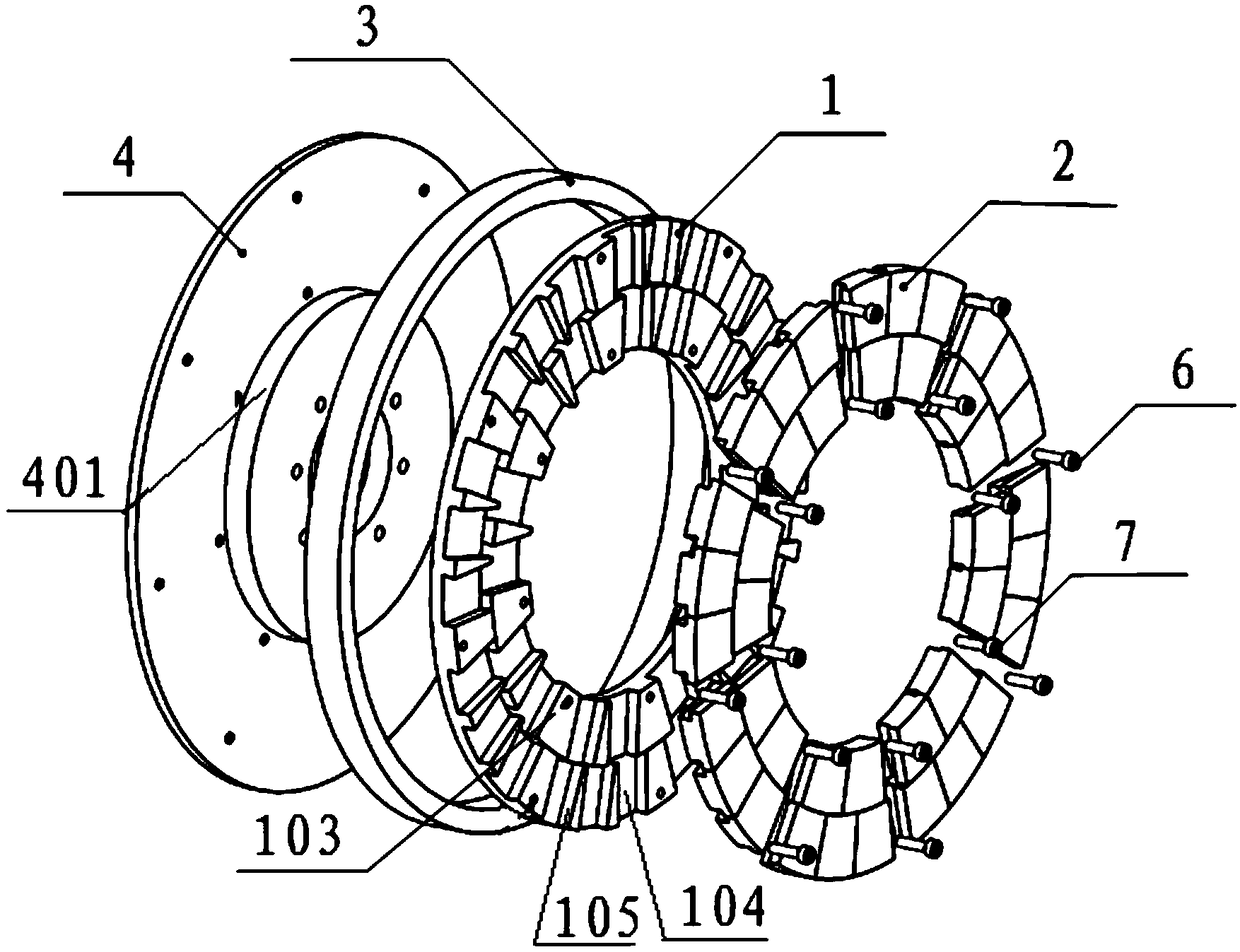

Disc rotor and disc motor

PendingCN108808921AIncrease productivitySuitable for mass productionMagnetic circuit rotating partsAxial displacementStator

The invention discloses a disc rotor and a disc motor. The disc rotor comprises a ring iron core which is provided with multiple sets of magnetic steel installing positions, wherein the magnetic steelinstalling positions are provided with buckle devices; magnetic steel which is installed in the magnetic steel installing positions and can be buckled in the magnetic steel installing positions by the buckle devices; a ring hoop which sleeves the outer circle of the ring iron core and is connected with the outer circumferential surface in an abutting way; and a rotor support which is provided with a ring boss which is inwardly sleeved in the inner circle of the ring iron core and connected with the inner circumferential surface in an abutting way, wherein the ring iron core is connected withthe rotor support through first screws. The ring iron core is fixed on the rotor support through the first screws and the rotor support axially limits the ring iron core so as to prevent axial displacement under the axial tension of the stator iron core. Besides, the buckle devices are arranged in the magnetic steel installing positions and the buckle devices can buckle the magnetic steel in the magnetic steel installing positions so as to prevent axial displacement of the magnetic steel.

Owner:SHANGHAI PANGOOD POWER TECH CO LTD

Feature differentiation image capture unit and method in a surgical instrument

ActiveUS20140228639A1Eliminates the need for calibration of lens artifactsOvercomes shortcomingSurgeryEndoscopesBeam splitterImage resolution

In a minimally invasive surgical system, an image capture unit includes a prism assembly and sensor assembly. The prism assembly includes a beam splitter, while the sensor assembly includes coplanar image capture sensors. Each of the coplanar image capture sensors has a common front end optical structure, e.g., the optical structure distal to the image capture unit is the same for each of the sensors. A controller enhances images acquired by the coplanar image capture sensors. The enhanced images may include (a) visible images with enhanced feature definition, in which a particular feature in the scene is emphasized to the operator of minimally invasive surgical system; (b) images having increased image apparent resolution; (c) images having increased dynamic range; (d) images displayed in a way based on a pixel color component vector having three or more color components; and (e) images having extended depth of field.

Owner:INTUITIVE SURGICAL OPERATIONS INC

Embedded-permanent magnet reluctance type hybrid magnetic pole type memory motor

ActiveCN112072811AImprove working point stabilityReduce dosageMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsPermanent magnet rotorElectric machine

The invention discloses an embedded-permanent magnet reluctance type mixed magnetic pole type memory motor which comprises a stator, an armature winding, a mixed permanent magnet rotor and a rotatingshaft, the armature winding is arranged on the stator, the stator, the mixed permanent magnet rotor and the rotating shaft are sequentially arranged from outside to inside, and a plurality of pairs ofmagnetic poles are arranged on a rotor core of the mixed permanent magnet rotor in the circumferential direction. an N pole is a first linear embedded radially-magnetized permanent magnet, a S pole is a permanent magnet auxiliary synchronous reluctance type, two pairs of tangentially-magnetized second and third permanent magnets are arranged at the S pole to form a double-layer V-shaped permanentmagnet auxiliary synchronous reluctance type structure, the first permanent magnet is placed by an air gap, and the bottom of the V-shaped permanent magnet structure is close to the rotating shaft. The coercive force of the first permanent magnet is smaller than that of the second and third permanent magnets. A large design space is obtained through mixed magnetic pole design so as to improve theoutput torque and reduce the torque pulsation, the series magnetic circuit structure can ensure the stability of the working points of the permanent magnets, and meanwhile, the use amount of the permanent magnets is reduced.

Owner:SOUTHEAST UNIV

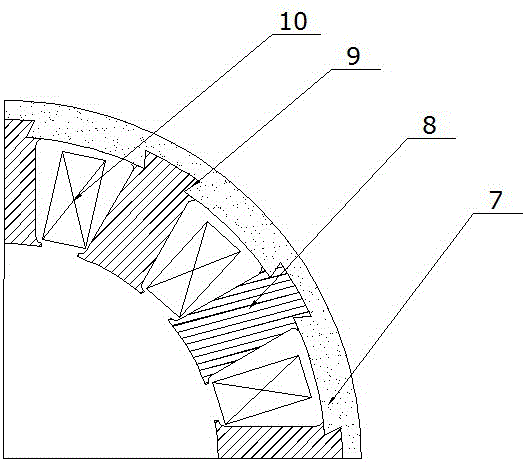

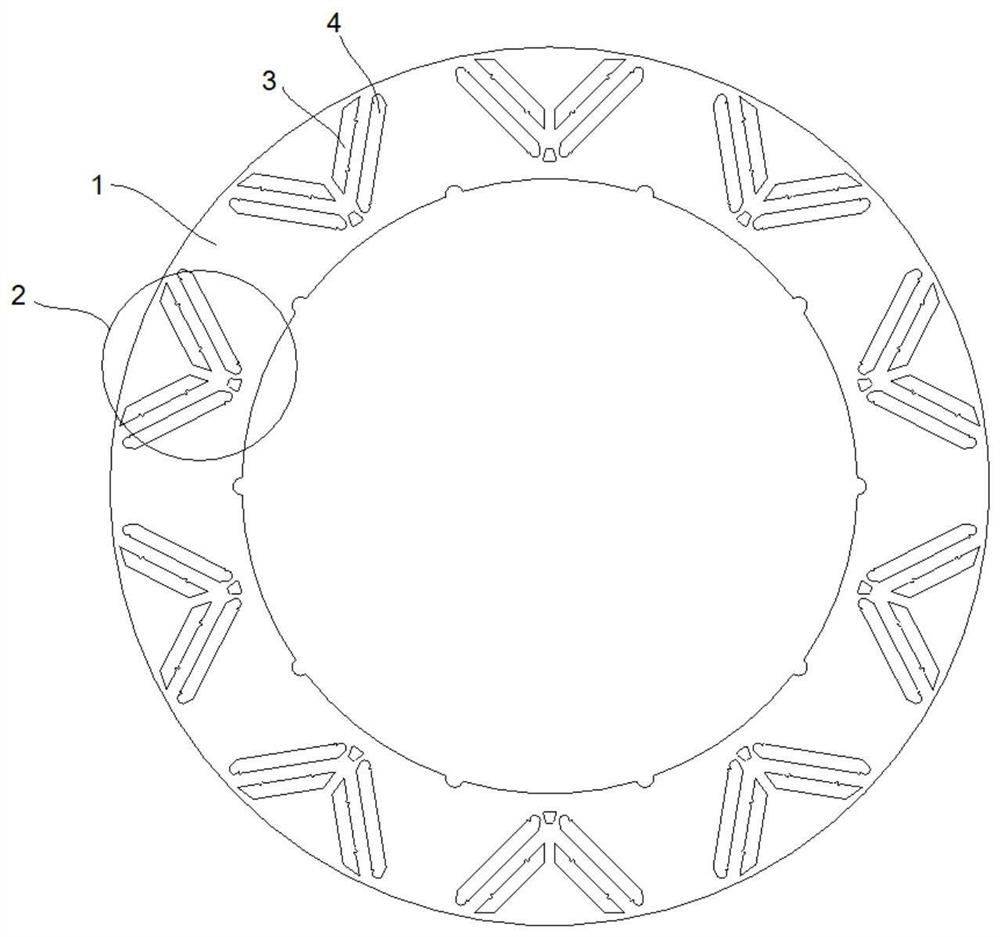

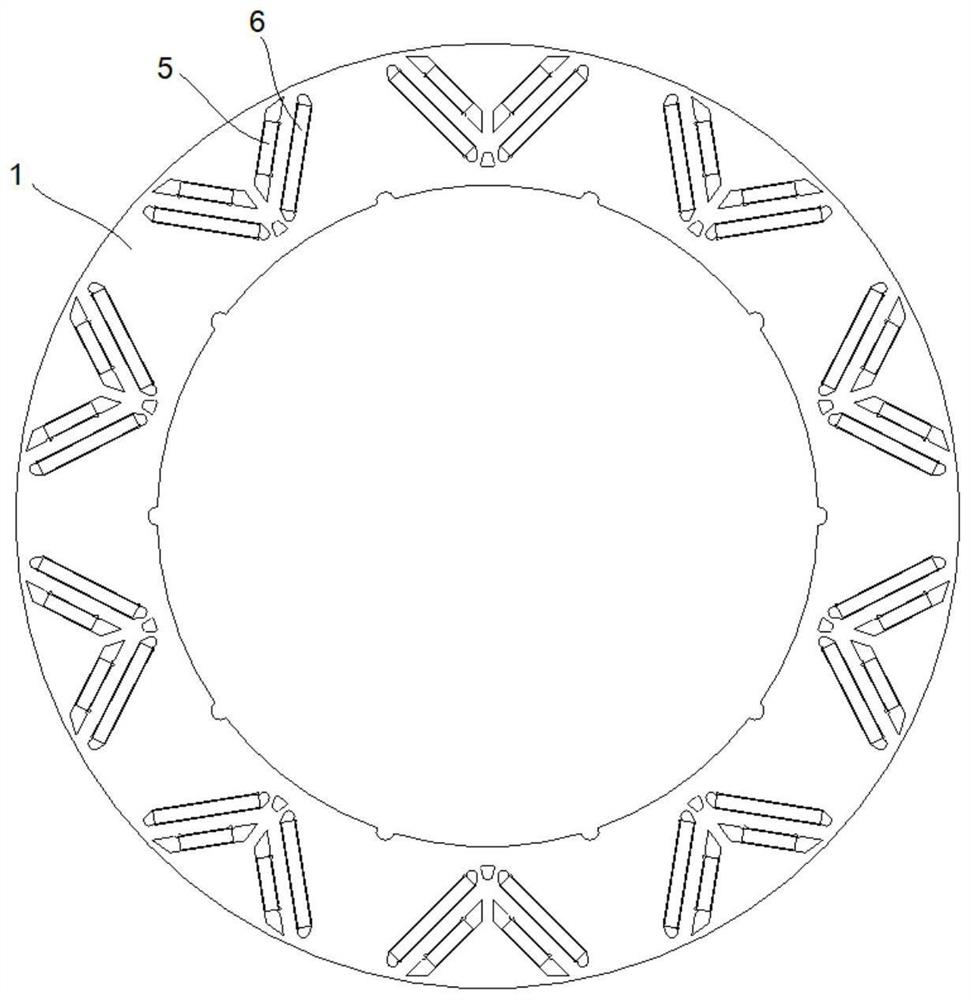

Multi-layer rotor magnetic steel structure of permanent magnet motor for high-power-density new energy automobile

PendingCN111786481AEasy to installGuaranteed mechanical strengthMagnetic circuit rotating partsNew energyElectric machinery

The invention discloses a multi-layer rotor magnetic steel structure of a permanent magnet motor for a high-power-density new energy automobile. The structure comprises a rotor core, a plurality of magnetic steel groove groups are arranged on the rotor core at interval along the circumferential direction, each magnetic steel groove group is composed of first layer V-shaped magnetic steel grooves and second layer V-shaped magnetic steel grooves, and a first layer of magnetic steel and a second layer of magnetic steel are respectively arranged in the first layer V-shaped magnetic steel groove and the second layer V-shaped magnetic steel groove; the first layer of V-shaped magnetic steel grooves are symmetrical about the radial direction of the rotor core, and the second layer of V-shaped magnetic steel grooves are symmetrically arranged at two sides of the first layer of V-shaped magnetic steel grooves; v-shaped openings of the first-layer V-shaped magnetic steel grooves face the outer ring of the rotor core, and the extending directions of the two side grooves of the first-layer V-shaped magnetic steel grooves and the extending directions of the two side grooves of the second-layerV-shaped magnetic steel grooves are correspondingly parallel. A rotor is high in structural strength, and the permanent magnet motor manufactured by the rotor is high in power density.

Owner:无锡欧瑞京机电有限公司

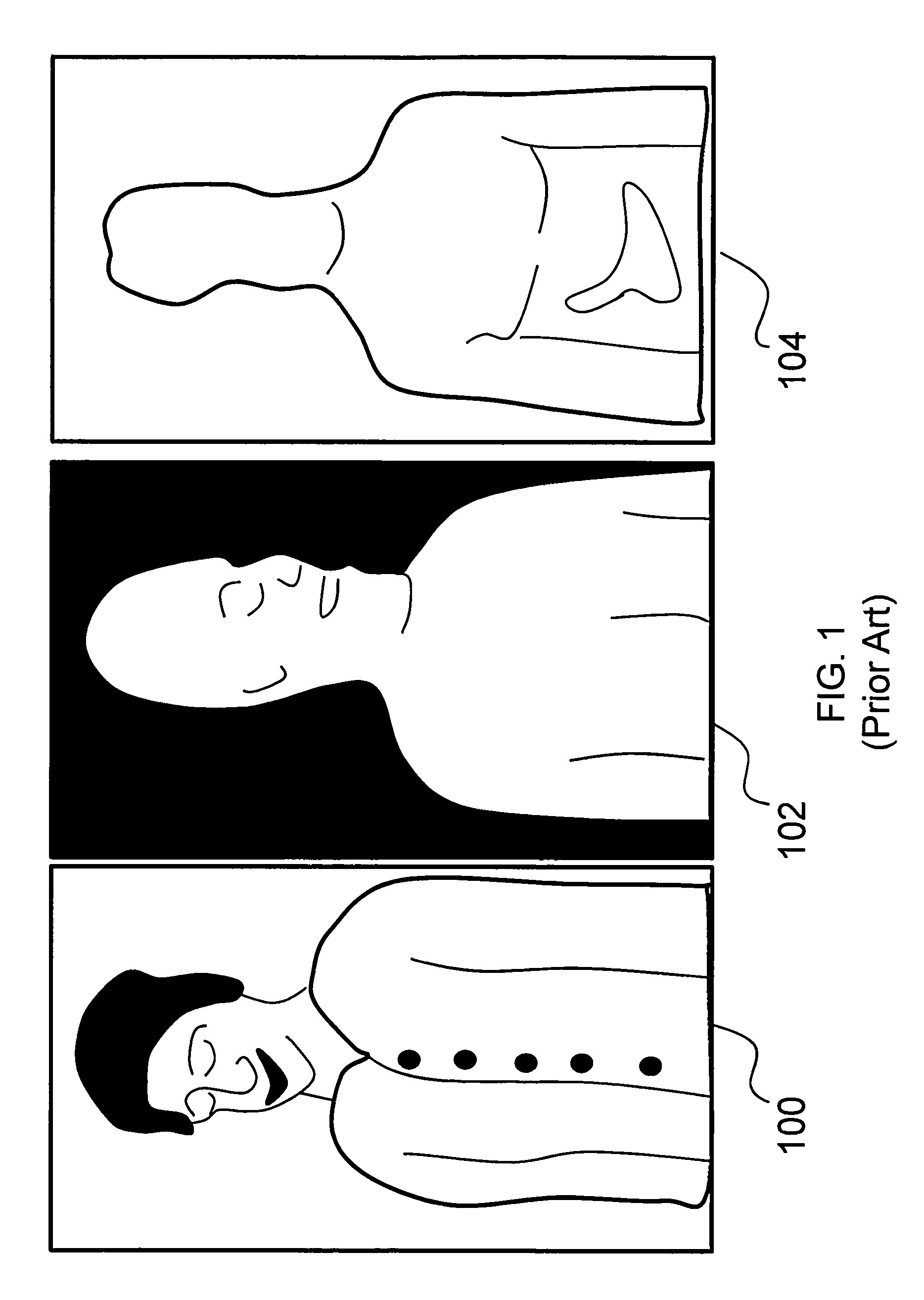

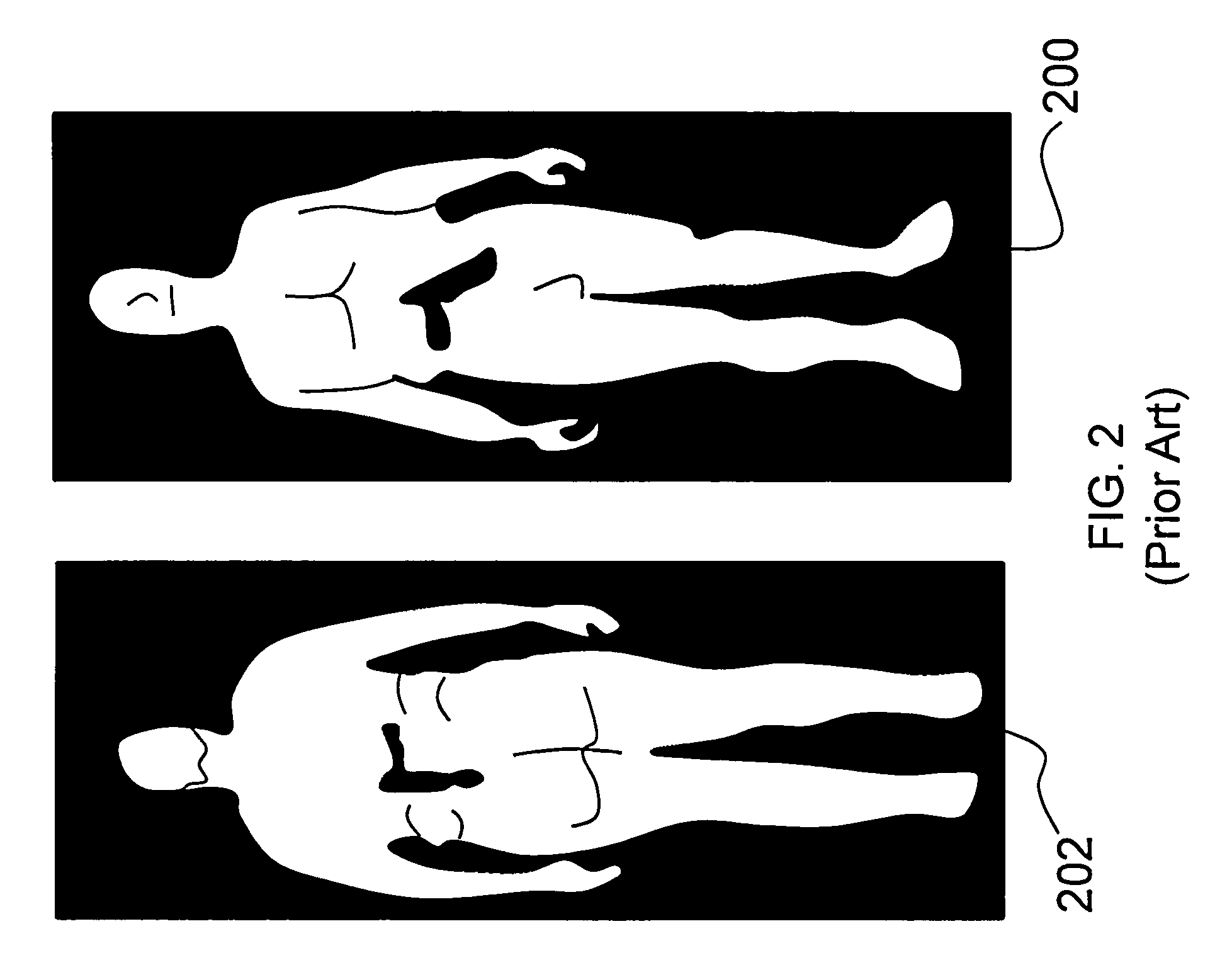

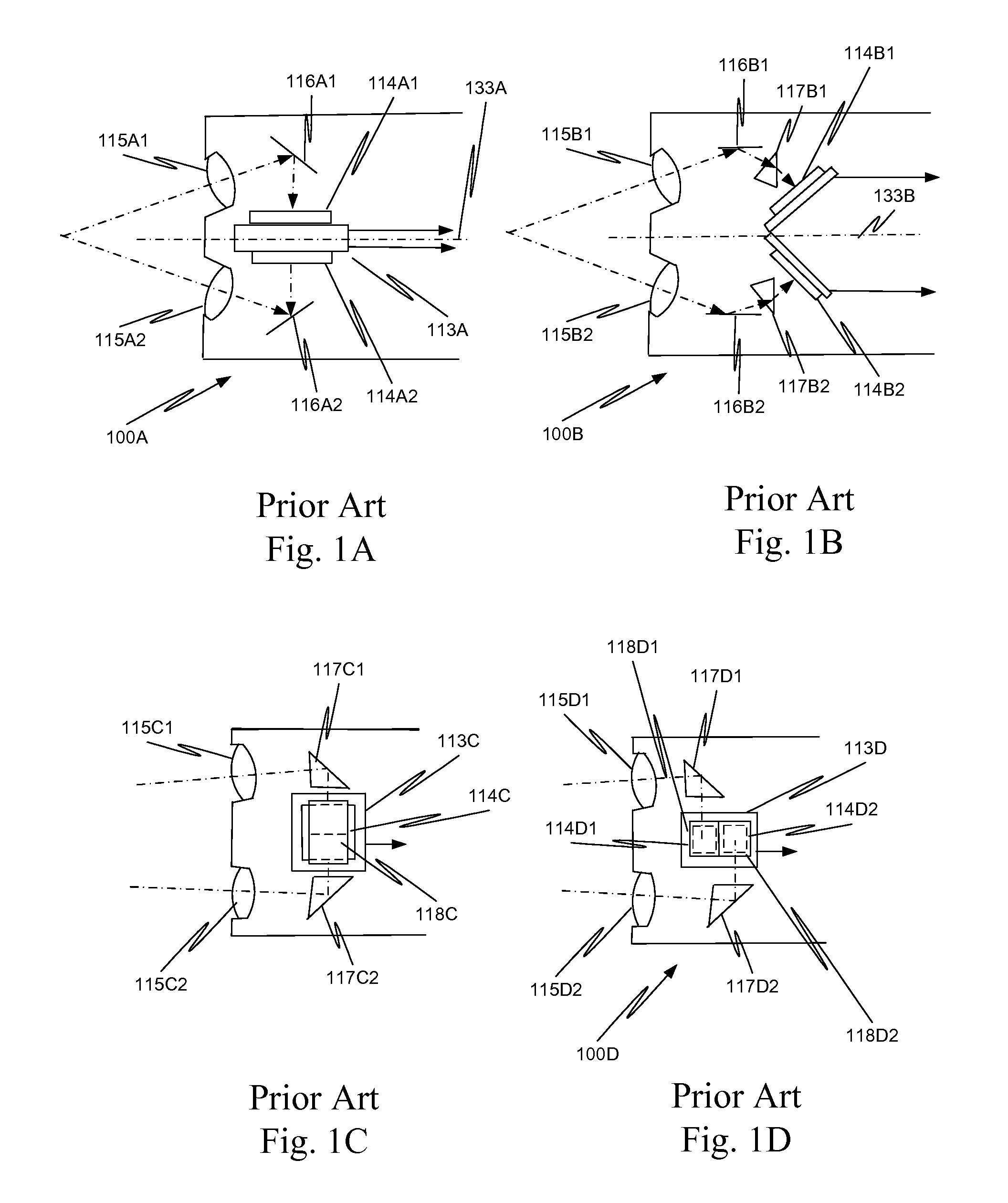

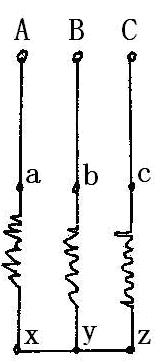

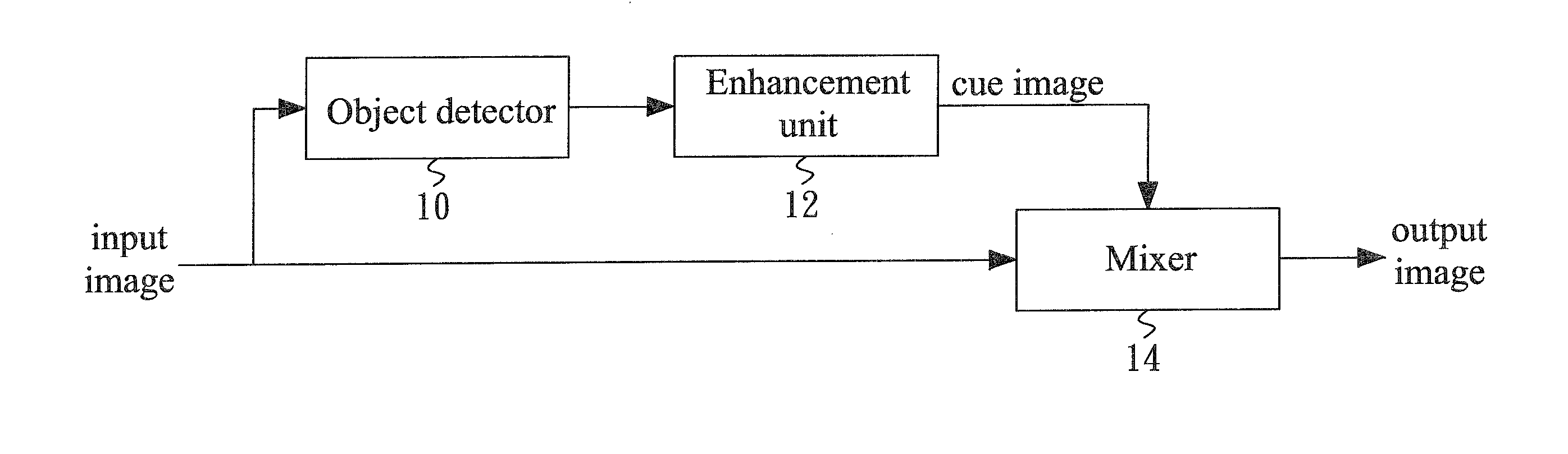

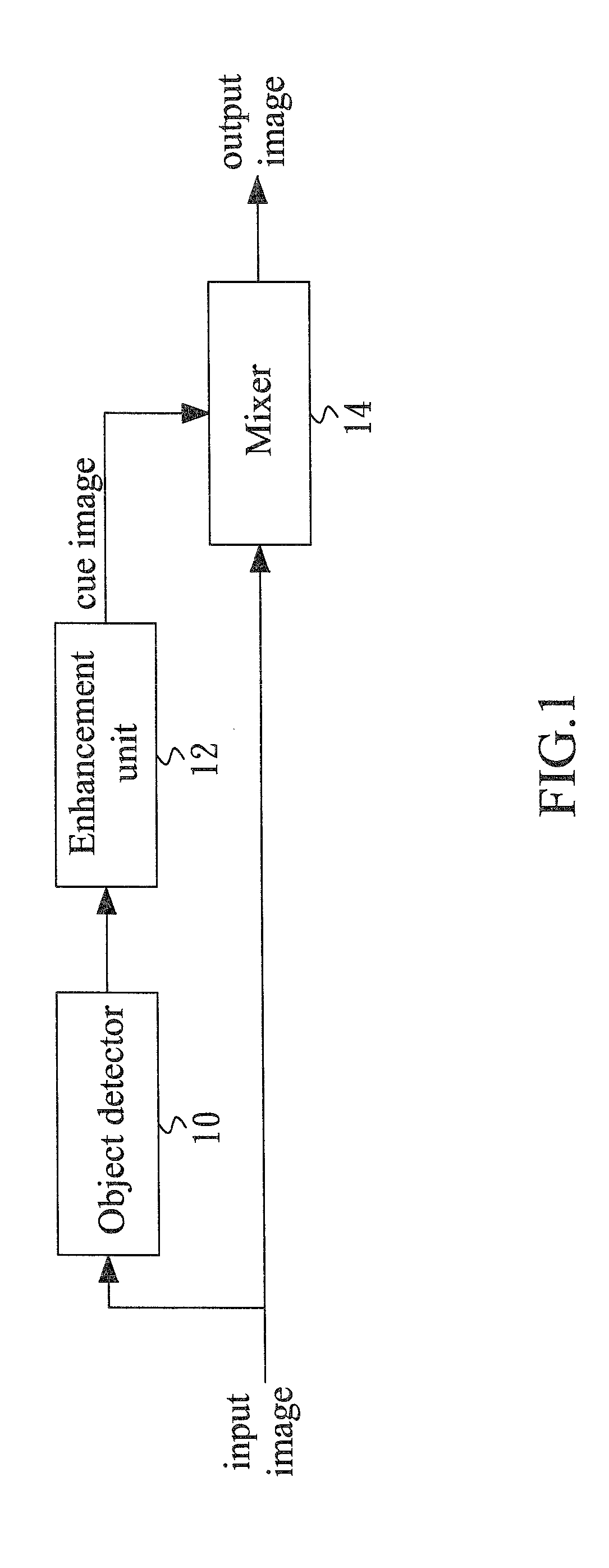

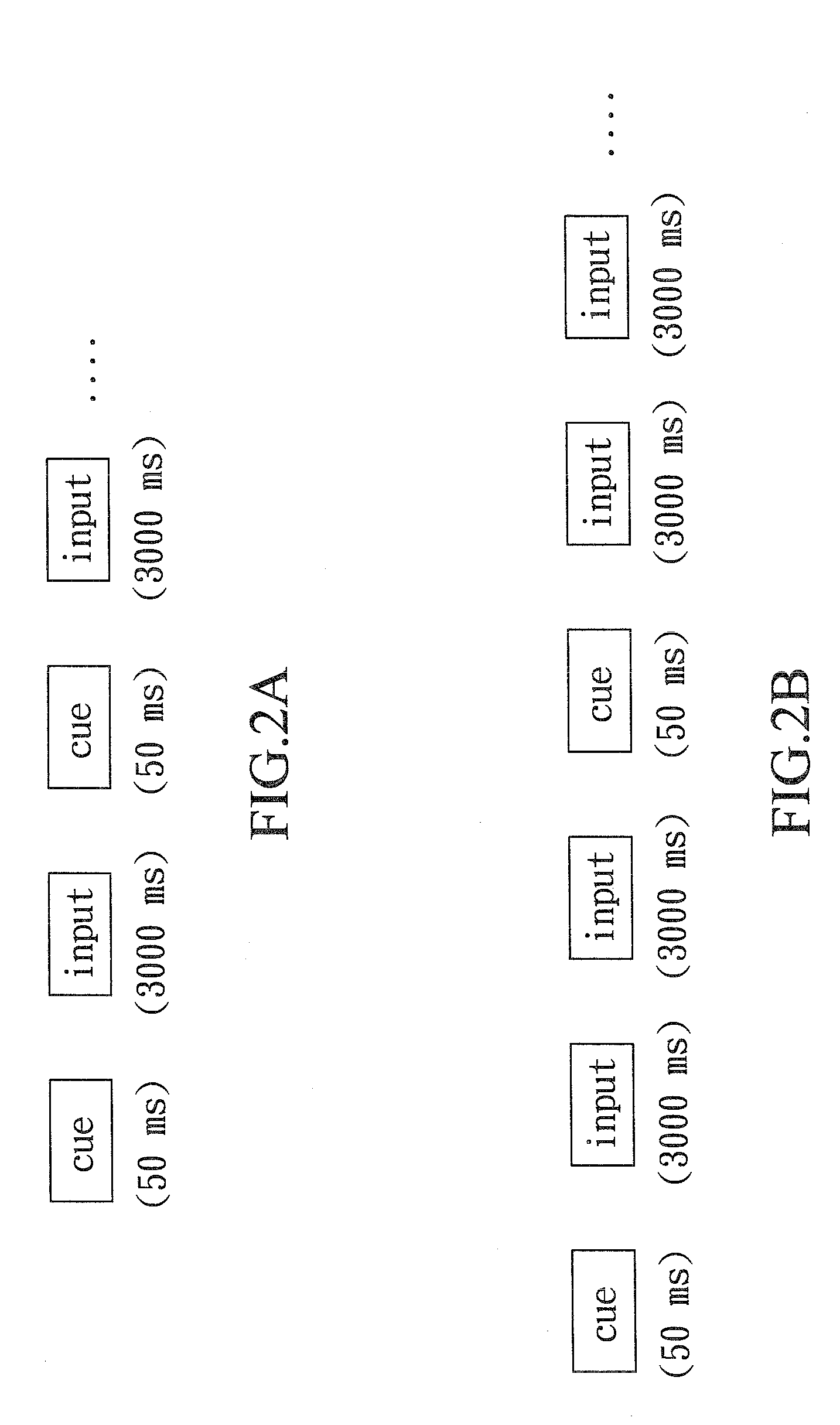

Object-based system and method of directing visual attention by a subliminal cue

ActiveUS8432491B2Effective guidanceEnhance saliency of the cued objectTelevision system detailsColor signal processing circuitsObject basedObject detector

An object-based system and method of directing visual attention by a subliminal cue is disclosed. An object detector detects an object in an input image, thereby resulting in a cued object served as an object-based subliminal cue. An enhancement unit enhances saliency of the cued object in the input image by respectively and differently adjusting image characteristic of the cued object and an area other than the cued object, thereby generating a cue image. A mixer selects between the cue image and the input image, thereby resulting in a sequence of output images composed of the input images and the cue images, each of which is interposed between the adjacent input images.

Owner:NAT TAIWAN UNIV +1

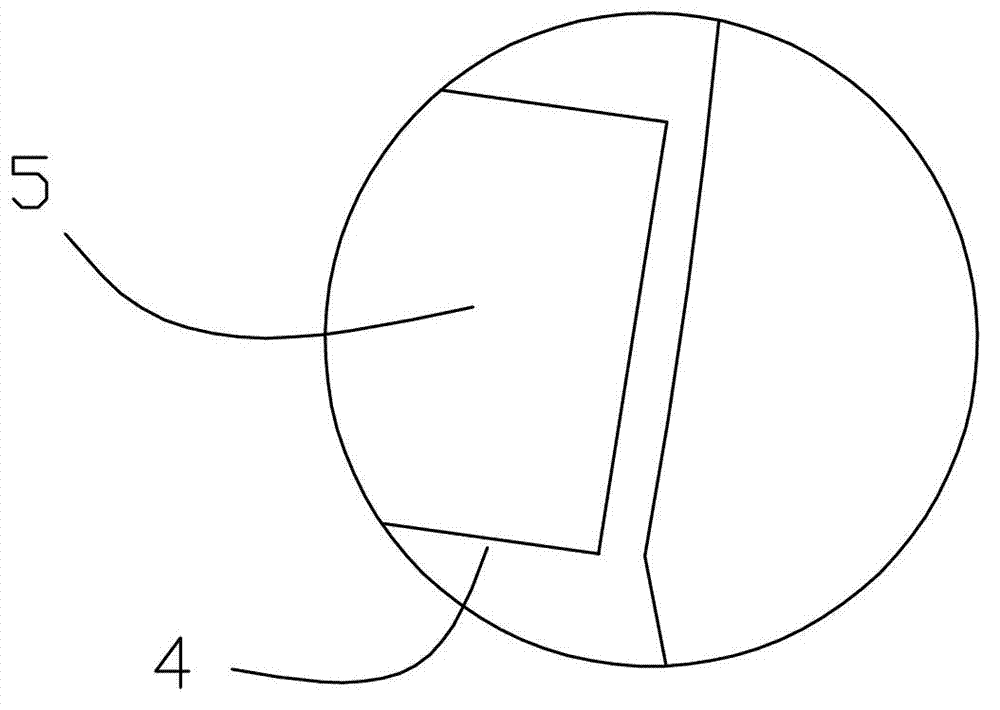

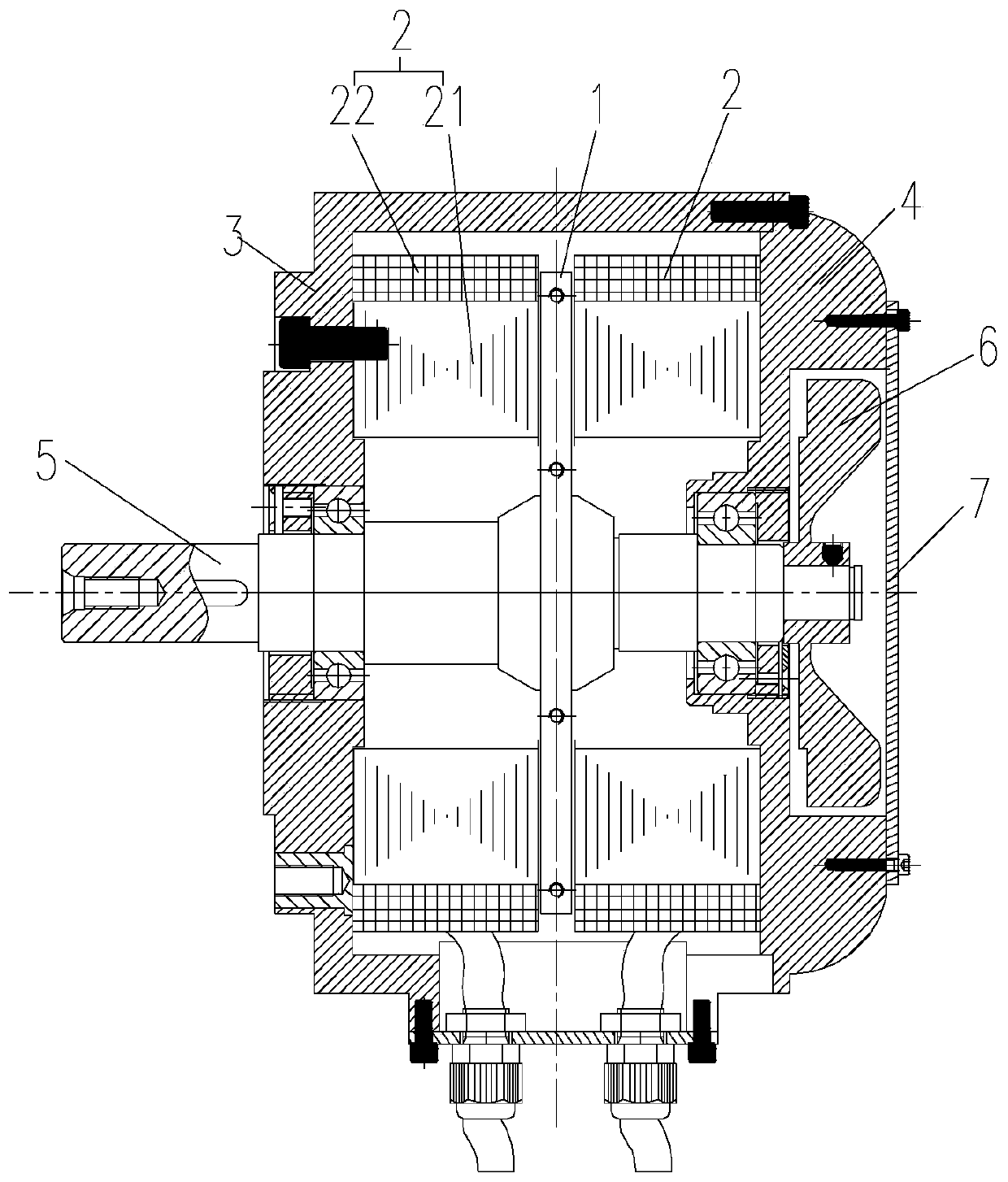

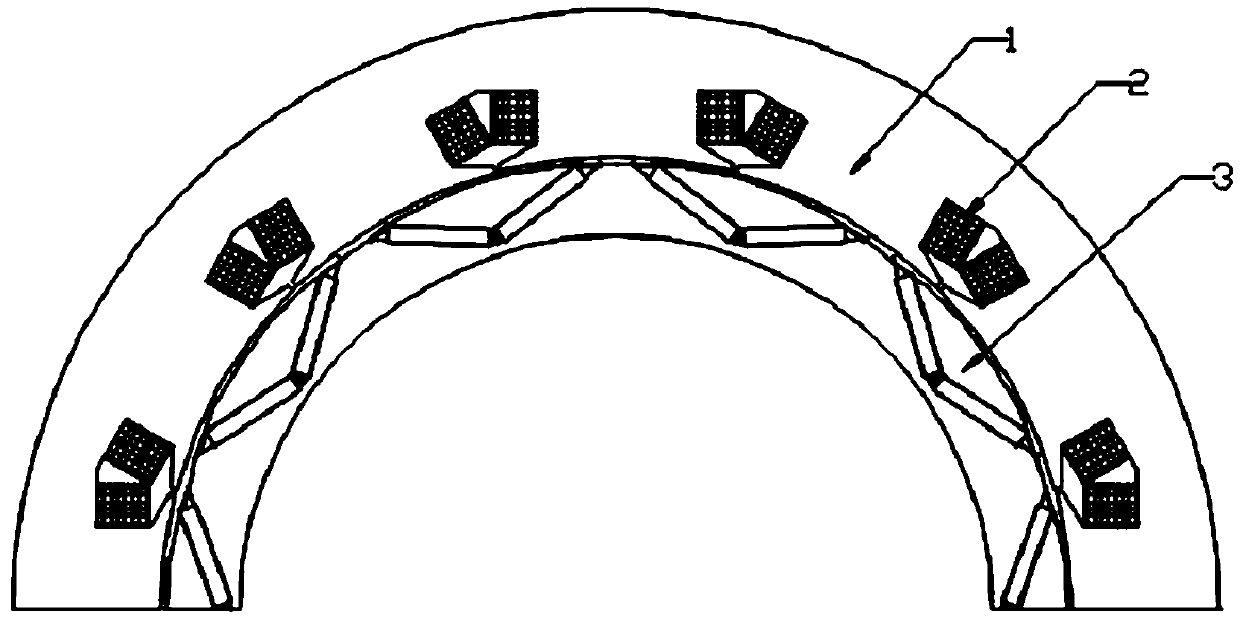

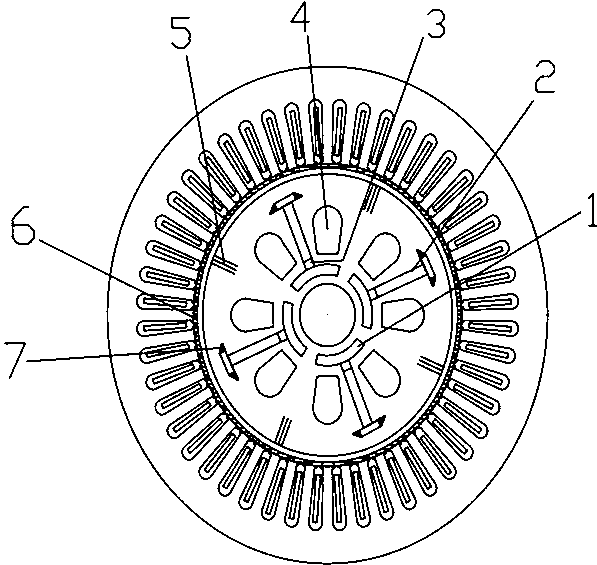

A rotor structure for improving flux-weakening performance of permanent magnet motor

PendingCN109067044ASmooth rotationIncrease saliencyMagnetic circuit rotating partsPermanent magnet motorHigh intensity

The invention relates to a rotor structure of a permanent magnet motor for improving the performance of magnetic field weakening speed expansion. The rotor body comprises a rotor iron core, a ventilation hole and a permanent magnet. The rotor iron core is carbon steel with high strength, The ventilation holes are uniformly distributed in the rotor core along the circumferential direction, and thepermanent magnet is composed of a V-shaped permanent magnet, a type of permanent magnet and an inverted V-shaped permanent magnet. Three kinds of permanent magnet are sequentially embedded in the rotor core along the radial direction. The technical essentials are that the rotor core is made of high-strength carbon steel, which is favorable for high-speed rotation and expansion of the motor. The ventilation holes are uniformly distributed in the rotor core along the circumferential direction, which is favorable for heat dissipation, preventing permanent magnet demagnetization and facilitating weak magnetic field expansion; Permanent magnet is composed of V-shaped permanent magnet, one-shaped permanent magnet and inverted V-shaped permanent magnet. Three kinds of permanent magnet are embedded in the rotor core in turn along the radial direction to reduce magnetic flux leakage, increase the saliency of the motor and improve the ability of weak magnetic field speed expansion. The rotor structure of the permanent magnet motor of the invention has the advantages of good heat dissipation, compact structure, and strong magnetic field weakening and speed expanding ability of the motor.

Owner:HARBIN UNIV OF SCI & TECH

Motor

PendingCN110768497AImprove insulation performanceReduce generationMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsElectric machineEddy current

The invention relates to a motor and particularly relates to the motor. The motor comprises a rotor and a stator which are matched with each other, the rotor includes a rotor bracket, neodymium iron boron permanent magnets, ferrite magnets and pole shoes, the neodymium iron boron permanent magnets are circumferentially distributed on the rotor bracket, the ferrite magnets cover axial side surfaces, close to the stator, of the neodymium iron boron permanent magnets, the pole shoes are arranged on the rotor bracket, and every two adjacent neodymium iron boron permanent magnets are separated by the corresponding pole shoe. The motor is advantaged in that the ferrite magnets are arranged on the axial side surfaces of the neodymium-iron-boron permanent magnets, the neodymium-iron-boron permanent magnets are far away from a stator iron core, the air-gap magnetic fields of the positions where the neodymium-iron-boron permanent magnets are located are relatively uniform, and therefore eddy currents are reduced. Besides, the position close to the motor stator iron core is replaced by the ferrite magnets, the ferrite magnets have good insulating property, eddy current loss is hardly generated even in a high-frequency rotating magnetic field, problems that in the prior art, a rotor of a disc type motor easily generates eddy currents in a magnetic field, consequently the rotor is demagnetized, and the salient pole rate is low are solved.

Owner:CHANGZHOU GOLDEN MOTOR TECH

A high-speed permanent magnet motor rotor including an axially stressed magnetically permeable sheath

ActiveCN108649722BReduce eddy current lossReduce temperature riseMagnetic circuit rotating partsStructural associationElectric machinePermanent magnet motor

The invention discloses a high-speed permanent magnet motor including an axial-forced magnetic-conductive jacket. The high-speed permanent magnet motor comprises a rotating shaft, a front hooped plateand a back hooped plate are arranged on an axial direction of the rotating shaft; two ends of a plurality of magnetic-conductive jacket plate plates are fixedly connected with the front hooped plateand the back hooped plate to form electric insulation; a rotor iron core is arranged between the front hooped plate and the back hooped plate and fixedly connected with the rotating shaft; the permanent magnet is fixedly arranged between the roto iron core and each magnetic conductive jacket plate; the amount of each of the magnetic conductive jacket plate and the permanent magnet is same as the pole number of the rotor; each of the front hooped plate and the back hooped plate is made from non-magnetic conductive material, a first clearance is formed between the adjacent magnetic conductive jacket plates, a second clearance is formed between the adjacent permanent magnets, and the third clearance is arranged among the permanent magnet and the front hooped plate and the third hooped plate.The structure disclosed by the invention can reduce the eddy loss in the jacket, inhibit the rotor temperature rising, and improves the magnetic load and torque output capacity of the motor at the same time.

Owner:SOUTHEAST UNIV

Permanent magnet motor concentrated winding modulation method and adjustable winding

InactiveCN111478540ASmall sizeShorten the axial lengthSynchronous machine detailsMagnetic circuit stationary partsElectric machineMagnetic poles

The invention belongs to the field of motor design, and particularly relates to an armature winding design technology of a permanent magnet motor. Each phase of the windings provided by the inventionrealizes flexible armature magnetic field pole number change through the mutual offset effect of the coils wound on each tooth. According to the scheme, each coil is wound on a stator tooth, each phase winding is formed by connecting a plurality of coils wound on one tooth in series and in parallel according to a certain connection rule, and no matter how many rotor magnetic poles are, the windingcan always keep a single-tooth-winding centralized winding with the pitch of 1.

Owner:SHENYANG POLYTECHNIC UNIV +1

Permanent magnet motor structure for cryogenic pumps

InactiveCN110299812AImprove running characteristicsFeatures do not affectSynchronous machine detailsMagnetic circuit rotating partsElectric machineType distribution

The invention provides a permanent magnet motor structure for cryogenic pumps, which belongs to the technical field of motor structure. The structure includes permanent magnets, auxiliary slots, magnetic isolation sleeves, starting cage bars, leaf-like holes, a shielding sleeve and air magnetic isolation slots. The permanent magnets are distributed in a 'T' shape, and are provided with the auxiliary slots filled with a non-magnetic material at the end. Each permanent magnet is provided with one magnetic isolation sleeve. The starting cage bars are symmetrically distributed at the edge of a rotor in an integrated three-bar way. The leaf-like holes are concentrically distributed on the rotor. The shielding sleeve is located between a stator and the rotor and is close to the stator. Accordingto the motor structure of the invention, the 'T'-type distribution of the permanent magnets improves the saliency ratio, the auxiliary slots at the end are filled with a non-magnetic material to reduce magnetic leakage and fix the permanent magnets, the magnetic isolation sleeves and the air magnetic isolation slots can reduce magnetic leakage, the starting cage bars can improve the starting torque and shorten the starting time, the leaf-like holes can reduce the inertia of the rotor, circulate the low-temperature medium and strengthen heat dissipation, and the shielding sleeve can prevent the medium from corroding the stator core and the windings.

Owner:HARBIN UNIV OF SCI & TECH

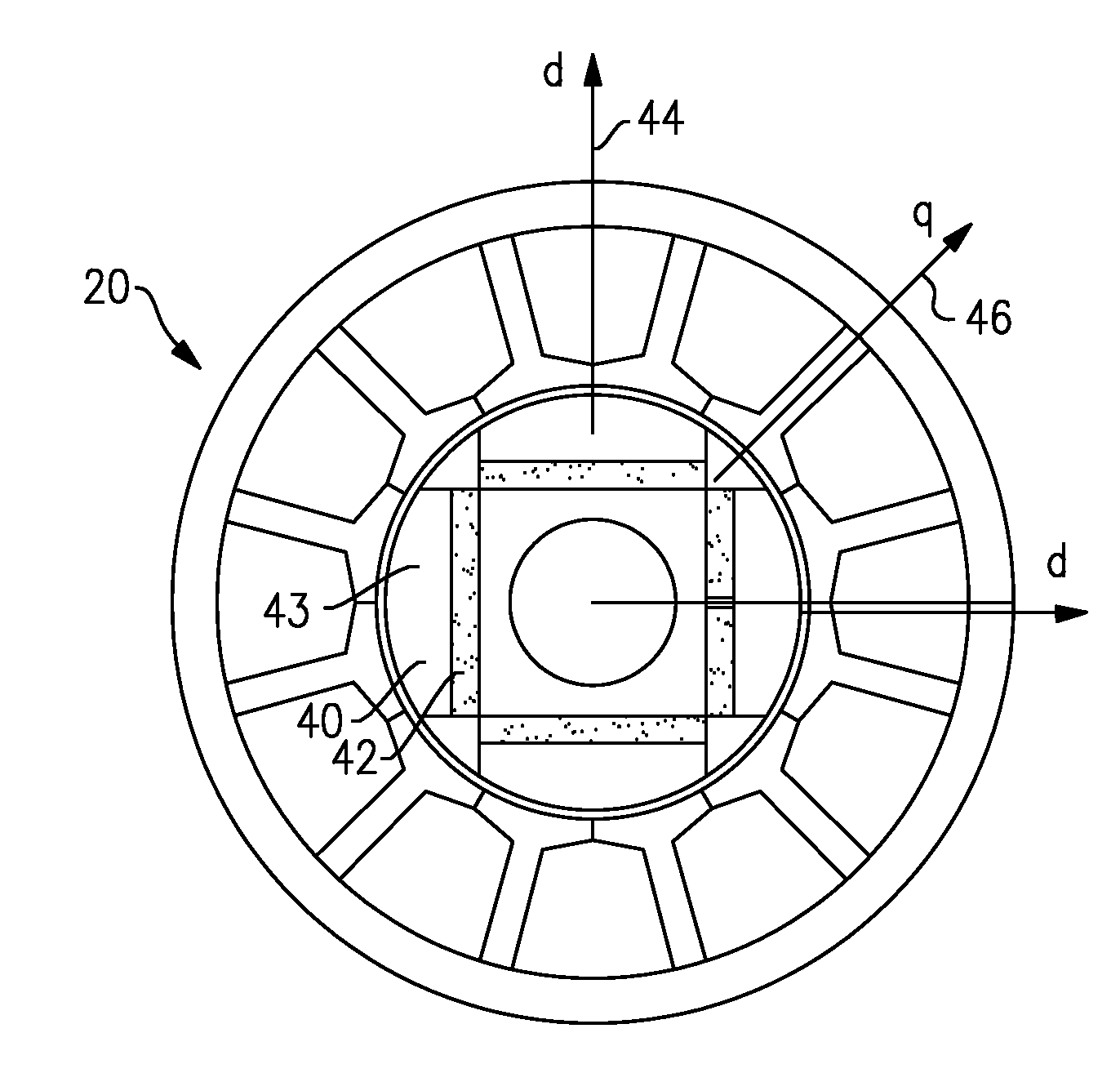

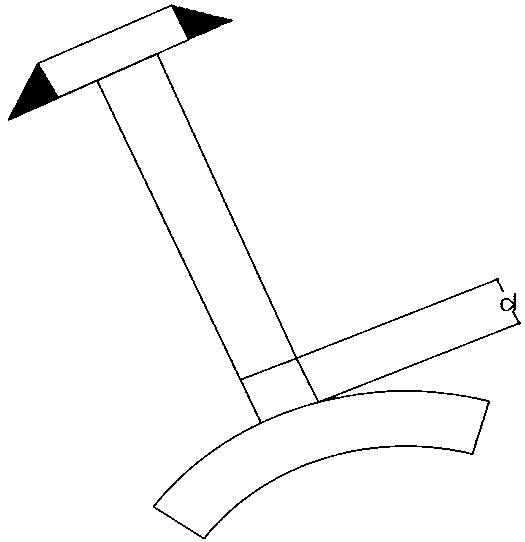

Rotor of a rotating electrical machine

ActiveCN107431397BIncrease saliencyMagnetic circuit rotating partsSynchronous motorsElectric machineMagnetic poles

The present invention provides a rotor of a rotating electric machine, comprising a cylindrical rotor core disposed radially inside a stator around which coils are wound, and an outer peripheral surface of the rotor core faces the stator via a gap. The rotor core has a plurality of magnetic pole regions in the circumferential direction, and has a magnetic flux barrier extending along the q-axis magnetic circuit in each magnetic pole region. The inner wall of the flux barrier has a radially outer wall surface and a radially inner wall surface, the radially inner wall surface expanding toward an adjacent magnetic pole region compared to a position along the q-axis magnetic circuit.

Owner:TOYOTA IND CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com