Permanent magnet motor structure for cryogenic pumps

A technology for permanent magnet motors and cryopumps, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit, synchronous machine, etc., can solve the problems of permanent magnet motors such as magnetic flux leakage, slow heat dissipation, difficult start, etc., to reduce magnetic flux leakage, The effect of increasing the saliency ratio and increasing the starting torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

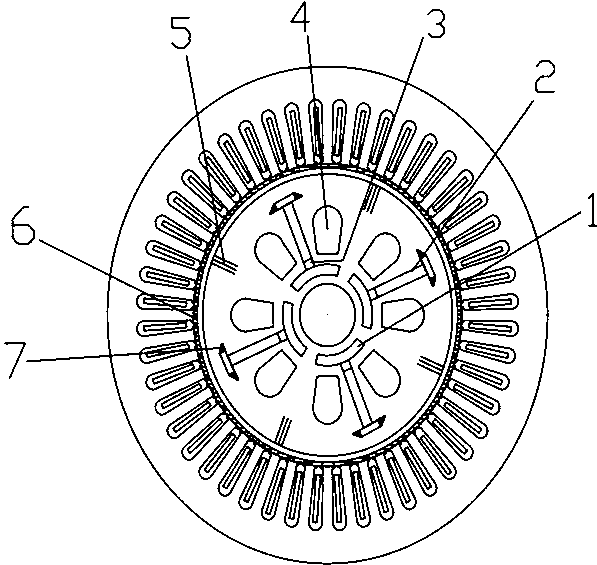

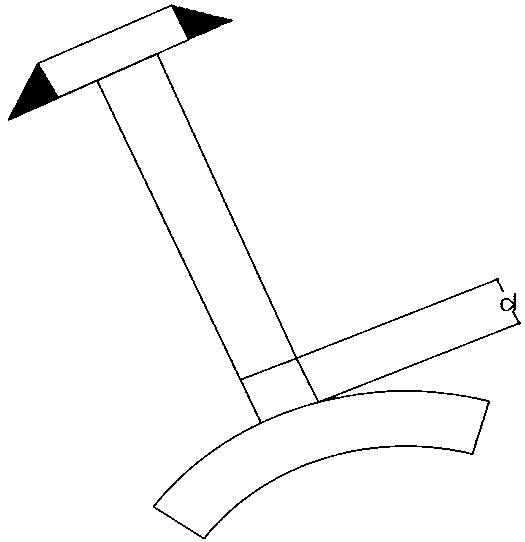

[0014] Refer to the attached figure 1 , 2 , a permanent magnet motor structure for a cryopump, characterized in that the structure includes an air isolation tank (1), a permanent magnet (2), a magnetic isolation sleeve (3), a leaf-shaped hole (4), and a starting cage bar (5), shielding sleeve (6), auxiliary groove (7), the air magnetic isolation groove (1) is a circular structure, and the permanent magnet (2) is a "T" type combined structure, the The magnetic isolation sleeve (3) is located at the junction of each group of permanent magnets and the air magnetic isolation slot, the leaf-shaped holes (4) are evenly distributed along the circumference, and the starting cage bars (5) are symmetrically distributed in three clusters On the edge of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com