Permanent magnet motor concentrated winding modulation method and adjustable winding

A technology of concentrated winding and modulation method, which is applied to the shape/style/structure of winding conductors, windings, electric components, etc., can solve the problems of large winding coil width, long winding end length, and increased winding copper consumption. Small motor volume, improved salient pole rate, and improved magnetic circuit asymmetry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

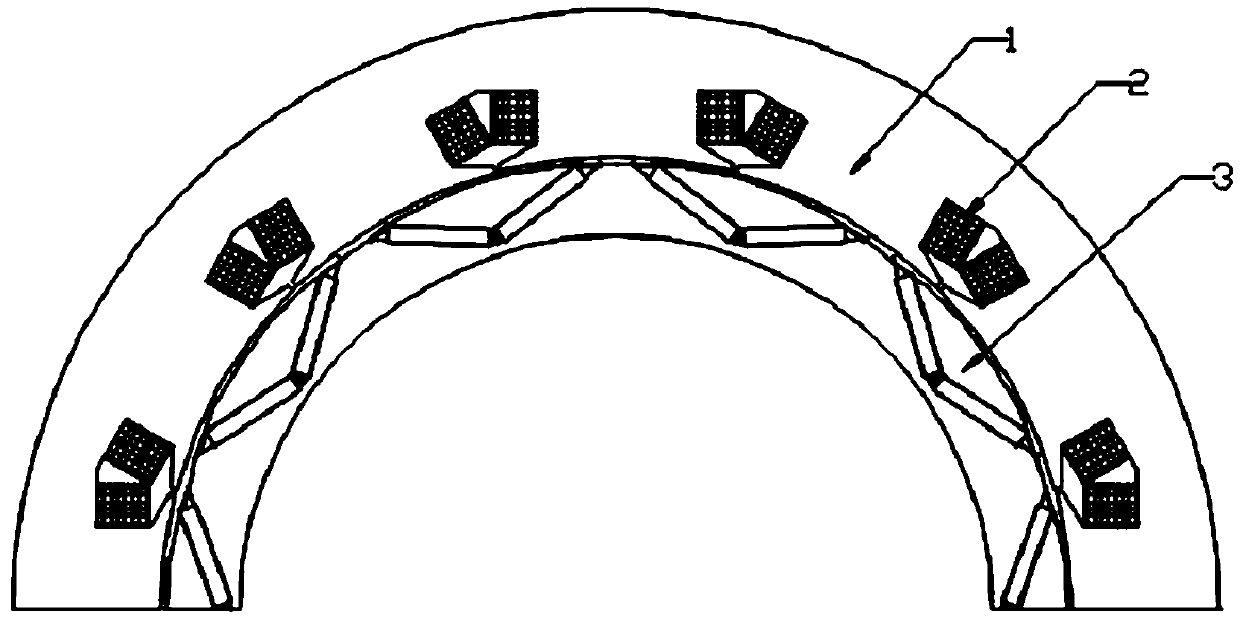

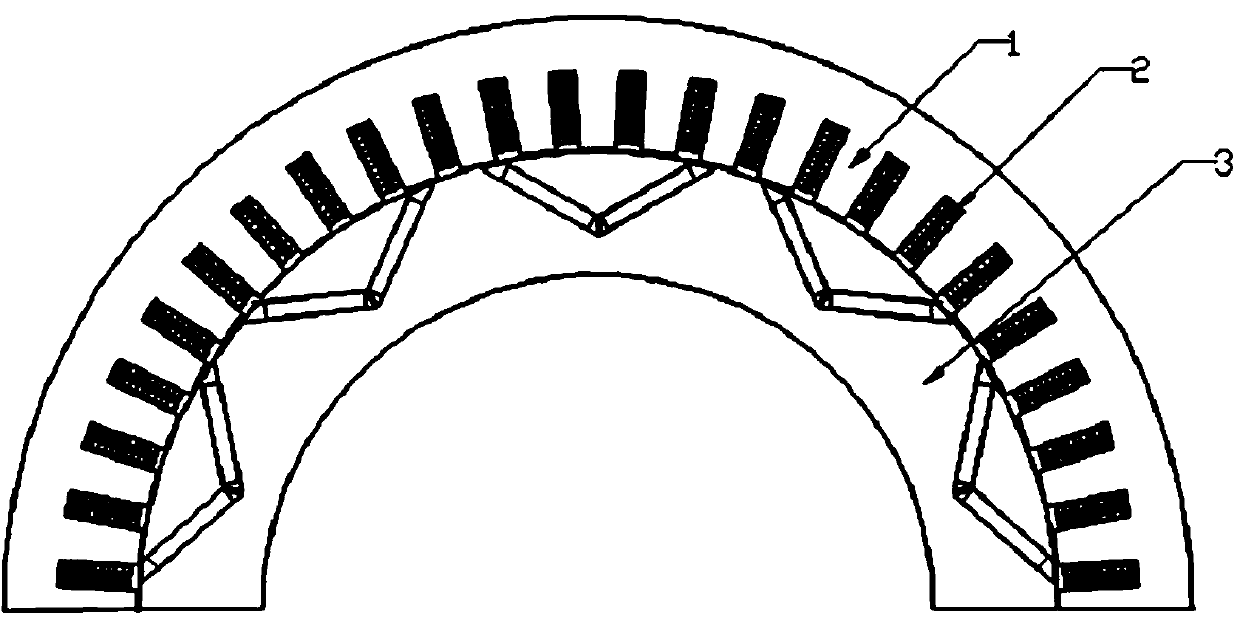

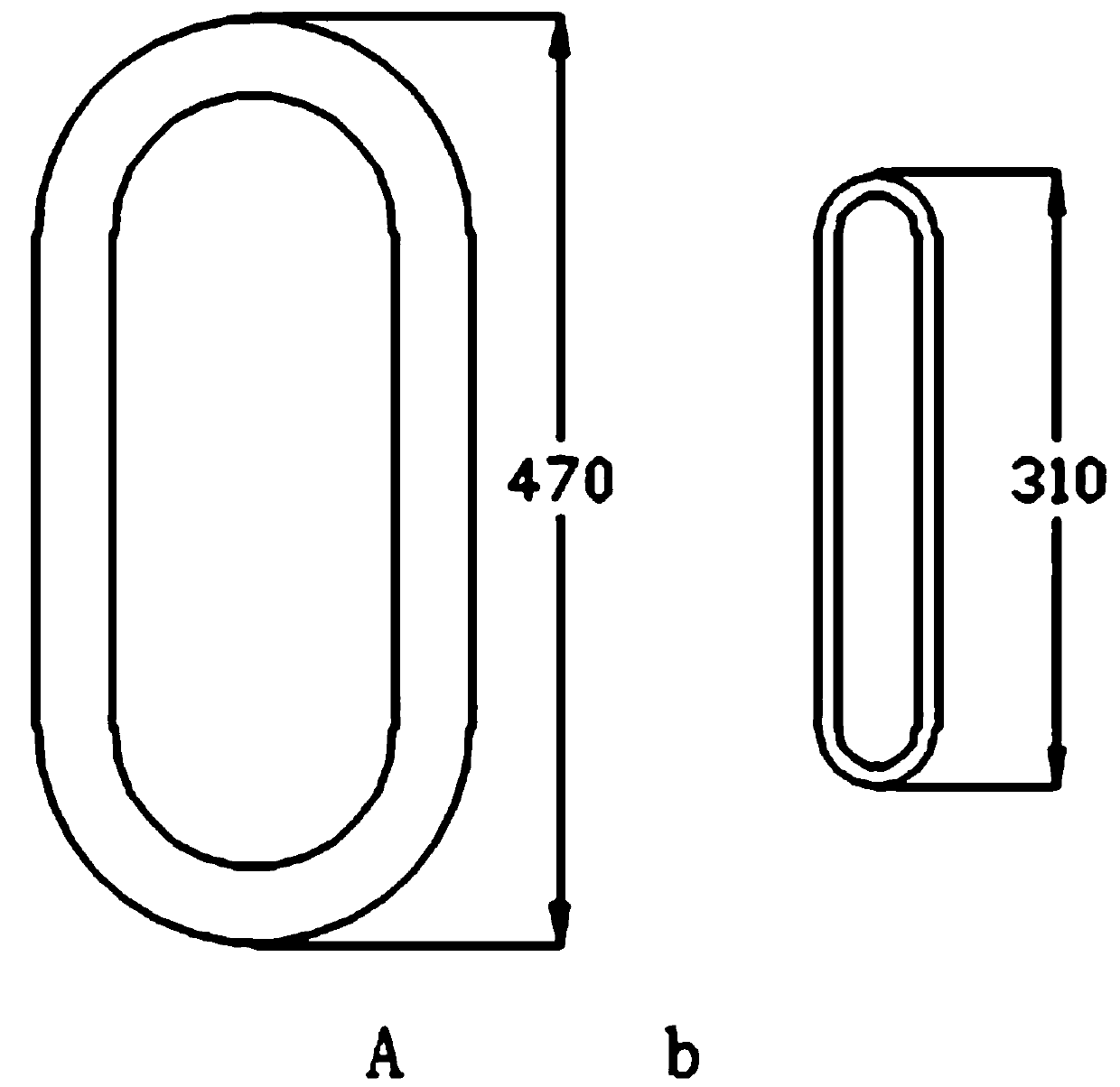

[0043] Modulated concentrated winding of permanent magnet motor. It is characterized in that each phase winding is composed of several coils wound on one tooth in series and in parallel according to a certain connection rule. Each coil is wound on a stator tooth. Single-layer or double-layer armature windings are placed in the stator slots. There is an air gap between the stator and the rotor. The permanent magnetic field provided by the rotor poles is coupled with the rotating magnetic field of the stator armature winding in the air gap, thereby realizing the conversion of electrical energy into mechanical energy.

[0044] Such as Figure 1-12 Shown, the present invention will be further described below in conjunction with accompanying drawing:

[0045] The invention provides a concentrated winding, which can realize various numbers of armature poles under the selection of various numbers of stator slots. The modulation function can be realized, and the modulation ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com