Rotor of a rotating electrical machine

A technology of rotating electrical machines and rotors, which is applied in the field of rotors of rotating electrical machines, which can solve the problems of increased reluctance torque and achieve the effect of increasing the salient pole ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

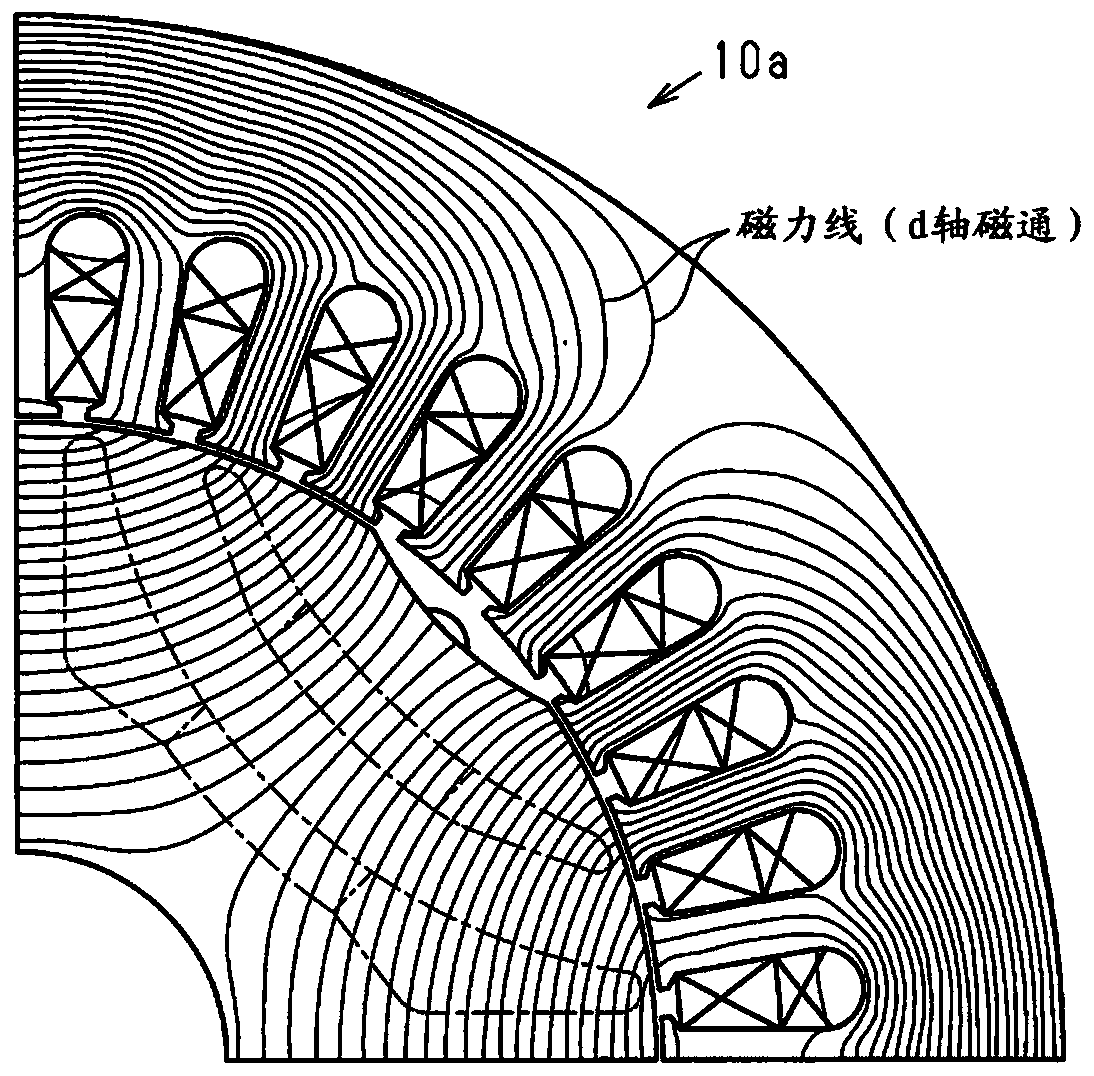

[0023] Hereinafter, one embodiment of the present invention will be described with reference to the drawings.

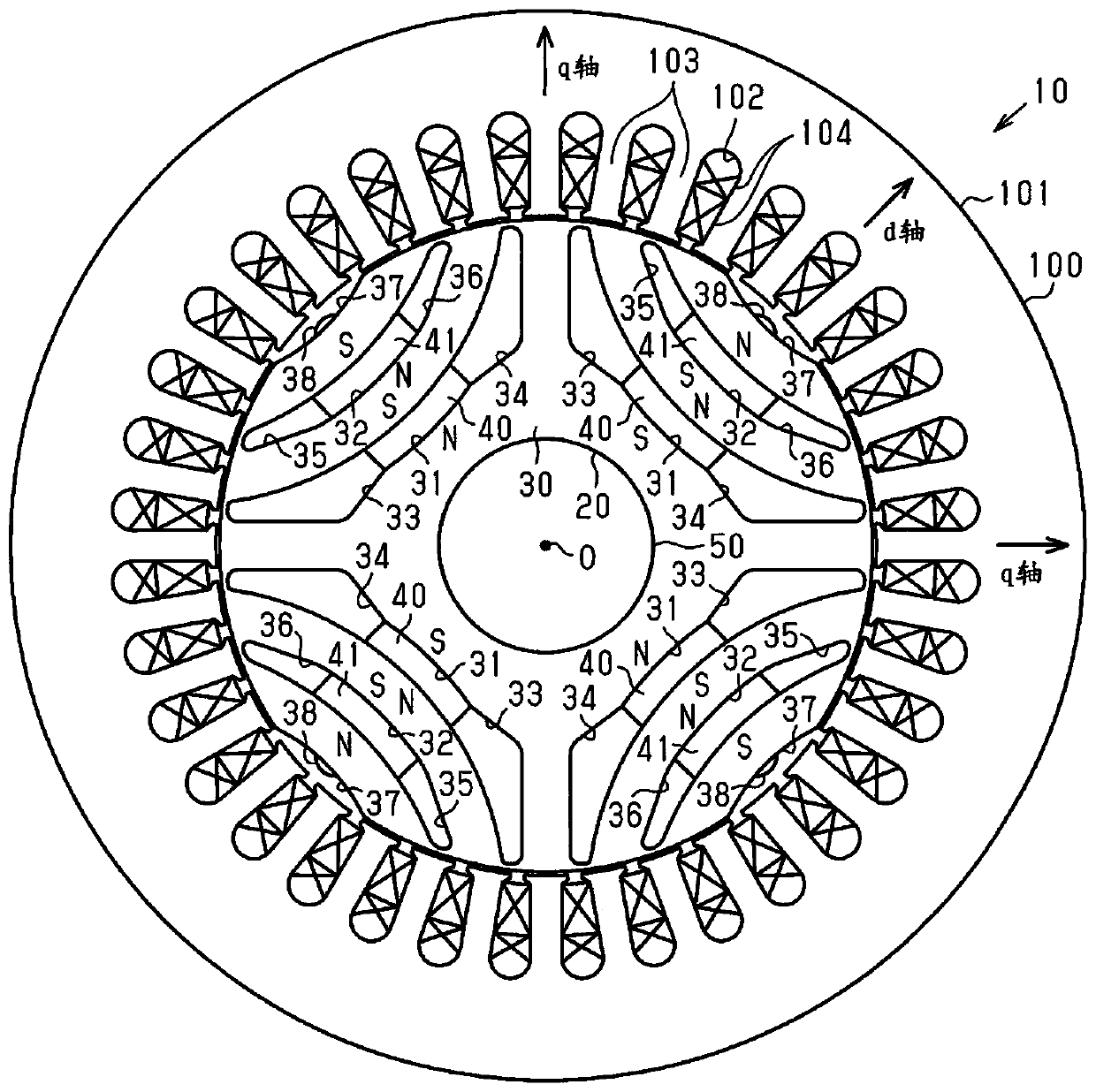

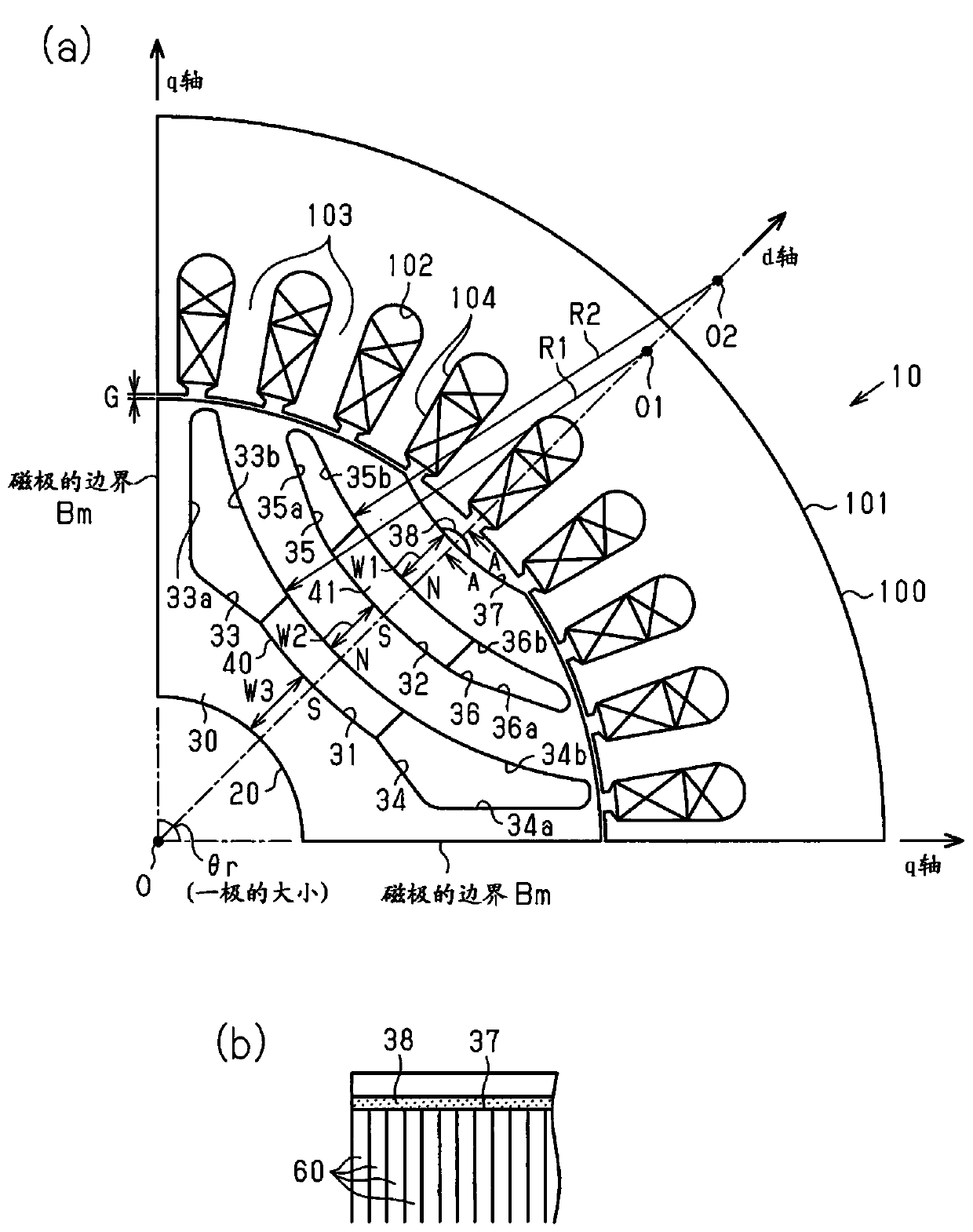

[0024] Such as figure 1 As shown, the rotating electrical machine 10 is a magnet-embedded rotating electrical machine, and includes a rotor 20 and a stator 100 . The stator 100 is disposed on the outer peripheral side of the cylindrical rotor 20 . The inner peripheral surface of the stator 100 passes through the gap G (refer to figure 2 (a)) faces the outer peripheral surface of the rotor 20 . In addition, the figure is all a schematic diagram, and describes it emphatically about a shape. The number of poles of the rotating electric machine 10 of this embodiment is "4".

[0025] Such as figure 1 as well as figure 2 As shown in (a), the stator 100 has a cylindrical stator core 101 , and a plurality of (36 in this embodiment) slots 102 are formed inside the stator core 101 so as to line up in the circumferential direction. Each slot 102 opens on the inner pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com