Anti-flux leakage low-loss driving motor design

A low-loss technology for driving motors, applied in the manufacture of motor generators, magnetic circuit rotating parts, magnetic circuits, etc., can solve the problems of increased loss, increased volume and weight of motors, and higher costs, and achieve high saturation flux density , The effect of driving the motor with high torque and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

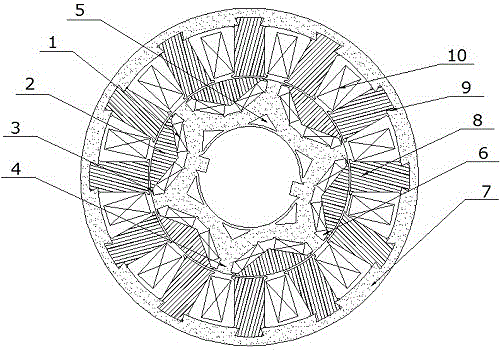

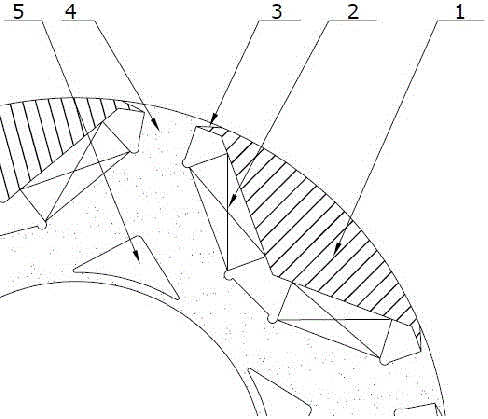

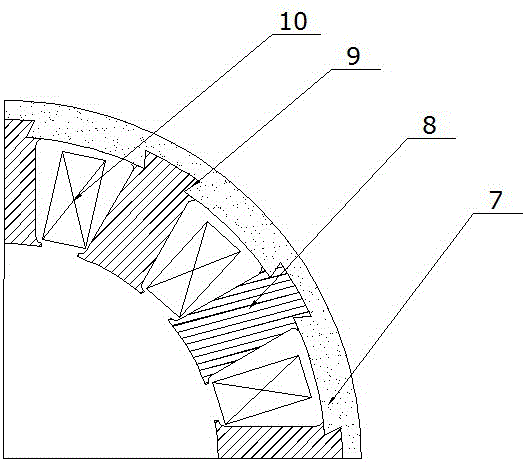

[0031] see figure 1 , see also Figure 2-Figure 11 , The anti-magnetic leakage low-loss drive motor of the present invention includes a stator and a rotor; the stator includes a stator iron core and a stator winding 10 , and the rotor includes a rotor iron core and a rotor magnetic steel 1 .

[0032] The stator core in the present invention includes an annular stator core base 7 composed of stator non-oriented silicon steel laminations and a plurality of stator core inserts 8 composed of stator oriented silicon steel laminations, and the plurality of stator core inserts are evenly spaced Connected to the inner guillotine of the stator core base, the plurality of stator windings 10 respectively pass between adjacent stator core inserts.

[0033] The rotor core in the present invention includes an annular rotor core base 4 composed of rotor non-oriented silicon steel laminations and a plurality of rotor core inserts 2 composed of rotor oriented silicon steel laminations, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com