Soft-magnetic ferrite with high saturation magnetic induction and preparation method thereof

A technology of magnetic induction and soft ferrite, applied in the field of soft ferrite, can solve problems such as inability to guarantee mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

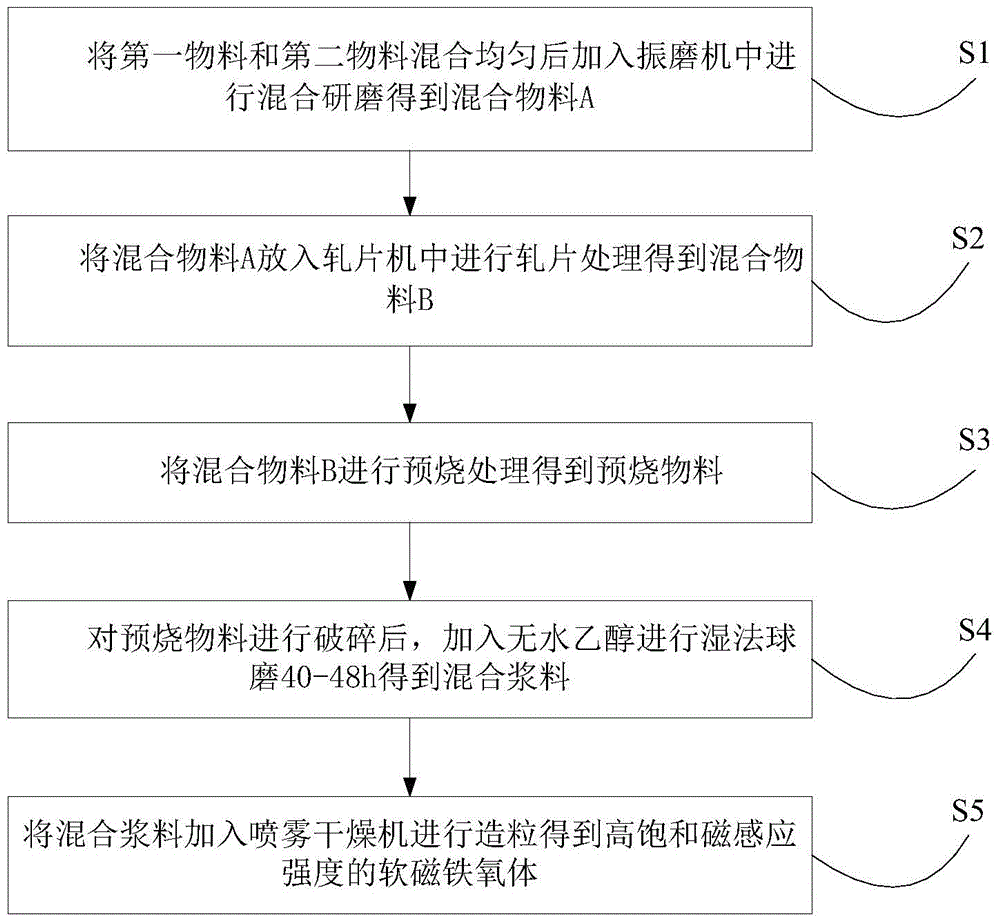

[0023] refer to figure 1 , a kind of preparation method of the soft magnetic ferrite of high saturation magnetic induction proposed by the present invention, comprises the following steps:

[0024] S1. Mix the first material and the second material evenly, and then add them to a vibrating mill for mixing and grinding to obtain a mixed material A;

[0025] S2. Put the mixed material A into a flaking machine to perform flaking treatment to obtain the mixed material B;

[0026] S3. Pre-burning the mixed material B to obtain the pre-burned material;

[0027] S4. After crushing the calcined material, add absolute ethanol to carry out wet ball milling for 40-48 hours to obtain a mixed slurry;

[0028] S5, adding the mixed slurry into a spray dryer for granulation to obtain soft ferrite with high saturation magnetic induction.

Embodiment 1

[0031] A kind of soft magnetic ferrite with high saturation magnetic induction proposed by the present invention, its raw material includes the first material and the second material; wherein the first material includes: iron oxide: 52.0 mol%, manganese oxide: 42.0 mol%, Zinc oxide: 6.0mol%; based on the total mass of the first material, the second material includes: silicon oxide: 100ppm, calcium oxide: 300ppm, niobium oxide: 700ppm, zirconium oxide: 300ppm, nickel oxide: 3000ppm.

[0032] The preparation method of the above-mentioned soft ferrite with high saturation magnetic induction proposed by the present invention comprises the following steps:

[0033] S1. Mix the first material and the second material evenly, and then add them to a vibrating mill for mixing and grinding to obtain a mixed material A;

[0034] S2. Put the mixed material A into a flaking machine to perform flaking treatment to obtain the mixed material B;

[0035] S3. Pre-calcining the mixed material B ...

Embodiment 2

[0039]A kind of soft magnetic ferrite with high saturation magnetic induction proposed by the present invention, its raw material includes the first material and the second material; wherein the first material includes: iron oxide: 53.0mol%, manganese oxide: 39.0mol%, Zinc oxide: 8.0mol%; based on the total mass of the first material, the second material includes: silicon oxide: 50ppm, calcium oxide: 700ppm, niobium oxide: 400ppm, zirconium oxide: 450ppm, nickel oxide: 2600ppm, cobalt oxide: 400ppm.

[0040] The preparation method of the above-mentioned soft ferrite with high saturation magnetic induction proposed by the present invention comprises the following steps:

[0041] S1. Mix the first material and the second material evenly, and then add them to a vibrating mill for mixing and grinding to obtain a mixed material A;

[0042] S2. Put the mixed material A into a flaking machine to perform flaking treatment to obtain the mixed material B;

[0043] S3. Pre-calcining th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com