Anti-electromagnetic interference manganese zinc ferrite material and preparation method thereof

A manganese-zinc ferrite, anti-electromagnetic interference technology, applied in the field of ferrite materials and its preparation, can solve the problems of high cost, environmental pollution, low resistivity of manganese-zinc ferrite, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

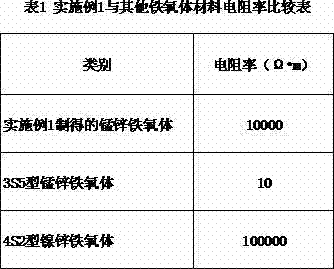

Embodiment 1

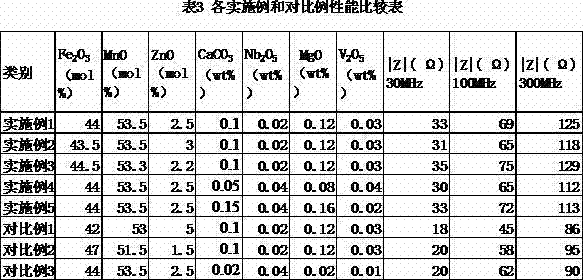

[0023] with Fe 2 o 3 44mol%, MnO 53.5mol% and ZnO 2.5mol% as the main components, weighed the raw materials, added deionized water and put them into a sand mill for sand milling, and the sand milling time was 40 minutes to obtain a slurry. Secondly, the slurry is subjected to spray granulation to prepare granular material. Thirdly, pre-burn the above pellets in a rotary kiln at a temperature of 950° C. and a time of 7 hours. Fourth, add the auxiliary component raw materials weighed in proportion to the above-mentioned calcined material, in terms of the total weight of the main component: CaCO 3 0.1wt%, Nb 2 o 5 0.02wt%, MgO 0.12wt% and V 2 o 5 0.03wt%, and then add deionized water to the mixture and put it into a sand mill for secondary sand grinding. The secondary sand grinding time is 2 hours to obtain a secondary sand abrasive with an average particle size of solid particles of 1.0-1.1 μm. Fifth, after adding PVA and defoamer n-octanol at a weight ratio of 20:1 to...

Embodiment 2

[0032] The difference from Example 1 is that Fe 2 o3 43.5mol%, MnO53.5mol% and ZnO 3mol% are the main components.

[0033] The obtained manganese zinc ferrite material is tested with RM-220 resistivity meter to have a resistivity of 10 4 Ω·m.

[0034] The prepared manganese zinc ferrite material is passed through an X fluorescence analyzer to detect whether the final composition of the ferrite is consistent with the design composition. After the composition test is correct, use the ferrite material to make a magnetic ring with a size of 5mm×2mm×10mm, and use the IWATSU-4291B impedance analyzer to test the impedance of the ferrite under the conditions of 25°C, 30MHz, 100MHz, and 300MHz. 30MHz, impedance |Z| is 31Ω; 100MHz, impedance |Z| is 65Ω; 300MHz, impedance |Z| is 118Ω.

Embodiment 3

[0036] The difference from Example 1 is that Fe 2 o 3 44.5mol%, MnO53.3mol% and ZnO 2.2mol% are the main components.

[0037] The obtained manganese zinc ferrite material is tested with RM-220 resistivity meter to have a resistivity of 10 4 Ω·m.

[0038] The prepared manganese zinc ferrite material is passed through an X fluorescence analyzer to detect whether the final composition of the ferrite is consistent with the design composition. After the composition test is correct, use the ferrite material to make a magnetic ring with a size of 5mm×2mm×10mm, and use the IWATSU-4291B impedance analyzer to test the impedance of the ferrite under the conditions of 25°C, 30MHz, 100MHz, and 300MHz. 30MHz, impedance |Z| is 35Ω; 100MHz, impedance |Z| is 75Ω; 300MHz, impedance |Z| is 129Ω.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com