Disc rotor and disc motor

A disc rotor and rotor support technology, applied in the field of motor parts, can solve problems such as difficulty in fixing a ring 10-shaped iron core 1 and a permanent magnet 9, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

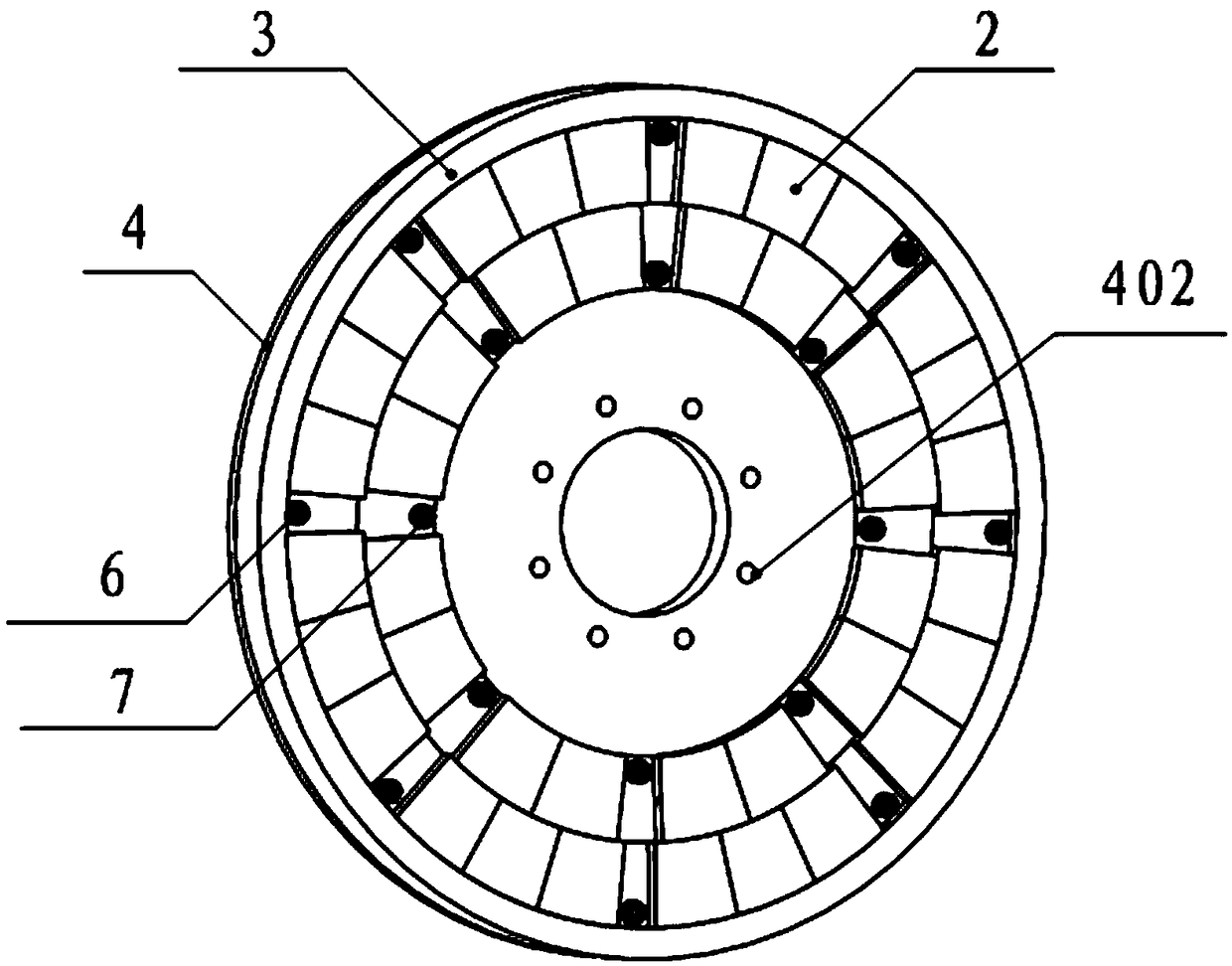

[0057] Such as Figure 2-4 As shown, the present invention provides a disc rotor. The disc rotor structure can be used in the middle stator, two side rotors or single stator, single rotor or cascaded disc motor structures.

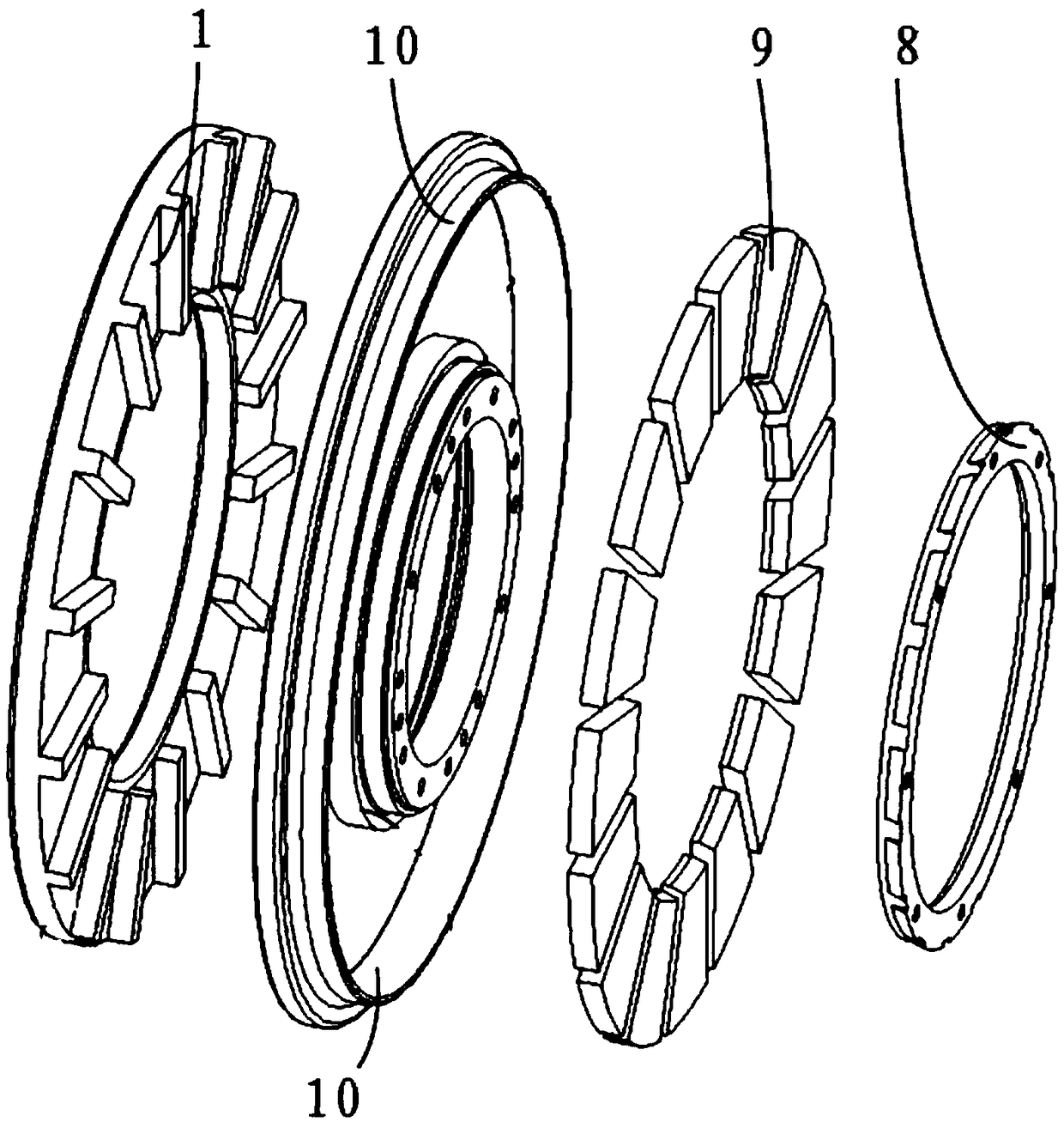

[0058] Wherein, the disc rotor includes an annular iron core 1 , a magnetic steel 2 , a hoop 3 and a rotor bracket 4 .

[0059] The annular iron core 1 is formed by winding silicon steel sheet or amorphous. The annular iron core 1 is provided with a plurality of sets of magnetic steel mounting positions 101, the same set of magnetic steel mounting positions 101 are installed with the same magnetic pole magnets 2, and the adjacent sets of magnetic steel mounting positions 101 are equipped with opposite magnetic pole magnets 2. A buckle device 102 is provided on the magnetic steel mounting position 101 .

[0060] The magnet 2 is installed in the magnet installation position 101 , and the buckle device 102 can buckle the magnet 2 in the magnet installation...

Embodiment 2

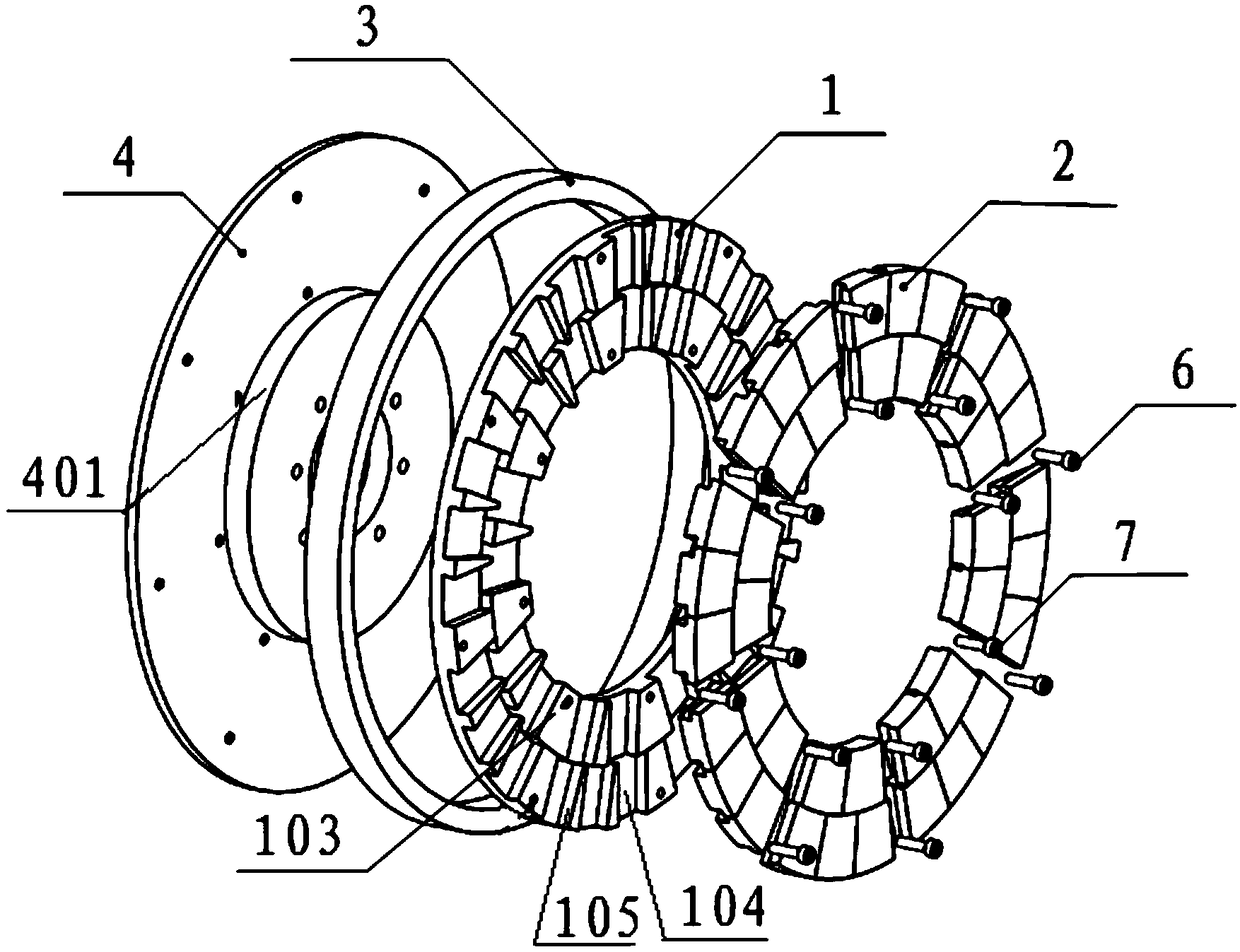

[0065] Such as Figure 5-10 , in the second embodiment provided by the present invention, the structure of the disc rotor in this embodiment is similar to that in the first embodiment, and the similarities will not be repeated, and only the differences will be introduced.

[0066] In this embodiment, the present invention specifically discloses that the annular iron core 1 is provided with first iron core teeth 103 , and the number of the first iron core teeth 103 is multiple, which are used to separate multiple groups of magnetic steel installation positions 101 .

[0067] The present invention discloses two methods for fixing the annular iron core 1 on the rotor bracket 4:

[0068] (1) Open a through hole on the first iron core tooth 103, and fix the annular iron core 1 on the rotor bracket 4 by the first screw 6;

[0069] (2) The disc rotor also includes a claw-shaped support 5, the claw-shaped support 5 includes an annular support portion 501 and a support rib 502, the an...

Embodiment 3

[0096] The present invention provides a disc motor, including the disc rotor in any one of the above embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com