High-quality three-phase alternating current permanent magnet servo synchronous motor

A synchronous motor, three-phase AC technology, applied in the field of servo motors, to achieve the effect of improving saliency, increasing saliency, and improving the sensitivity of servo

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

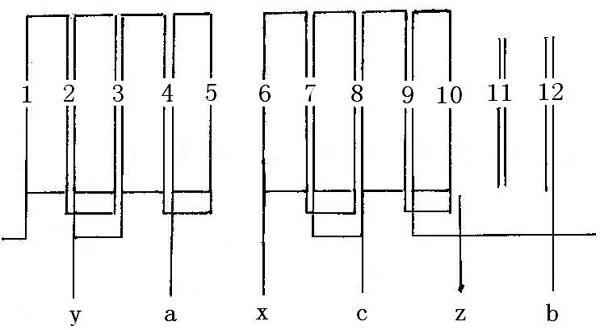

[0030] The stator core of the embodiment of the present invention is inclined by 7 / 32 tooth pitches. After comprehensive calculation, the harmonic content of the opposite electromotive force of the winding is less than 1%. Compared with an imported product with 12 slots, 8 poles, 3 phases, q=1 / 2 fractional slot pitch of 1 concentrated winding, its opposite electromotive force harmonic content is as high as 24.5%. The harmonic content of the reverse electromotive force is reduced by 95.92%, accounting for only 4% of the original harmonic. It can be seen that the reverse potential waveform of the embodiment of the present invention is a highly sinusoidal waveform.

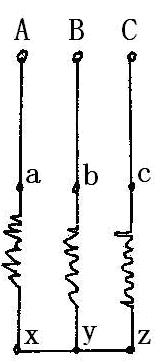

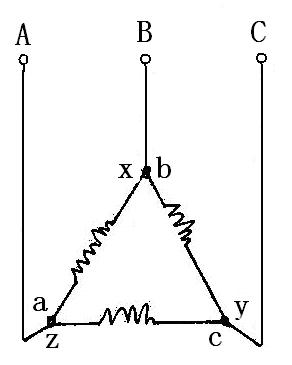

[0031] The stator windings of the embodiments of the present invention are Y-connected at low speeds, thereby increasing the low-speed torque; delta-connected at high speeds, thereby reducing high-speed overvoltage, ensuring safety, and expanding the high-speed operating range.

[0032] Since the stator iron core has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com