Flat copper wire formed stator coil high-reluctance torque outer rotor type permanent magnet drive motor

A stator coil and permanent magnet drive technology, which is applied to the rotating parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, the shape/style/structure of the winding conductor, etc., can solve the inconvenient operation of the robot and the irreversible demagnetization of the permanent magnet , low energy conversion rate and other issues, to achieve the effect of large reluctance torque, small water resistance and good cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

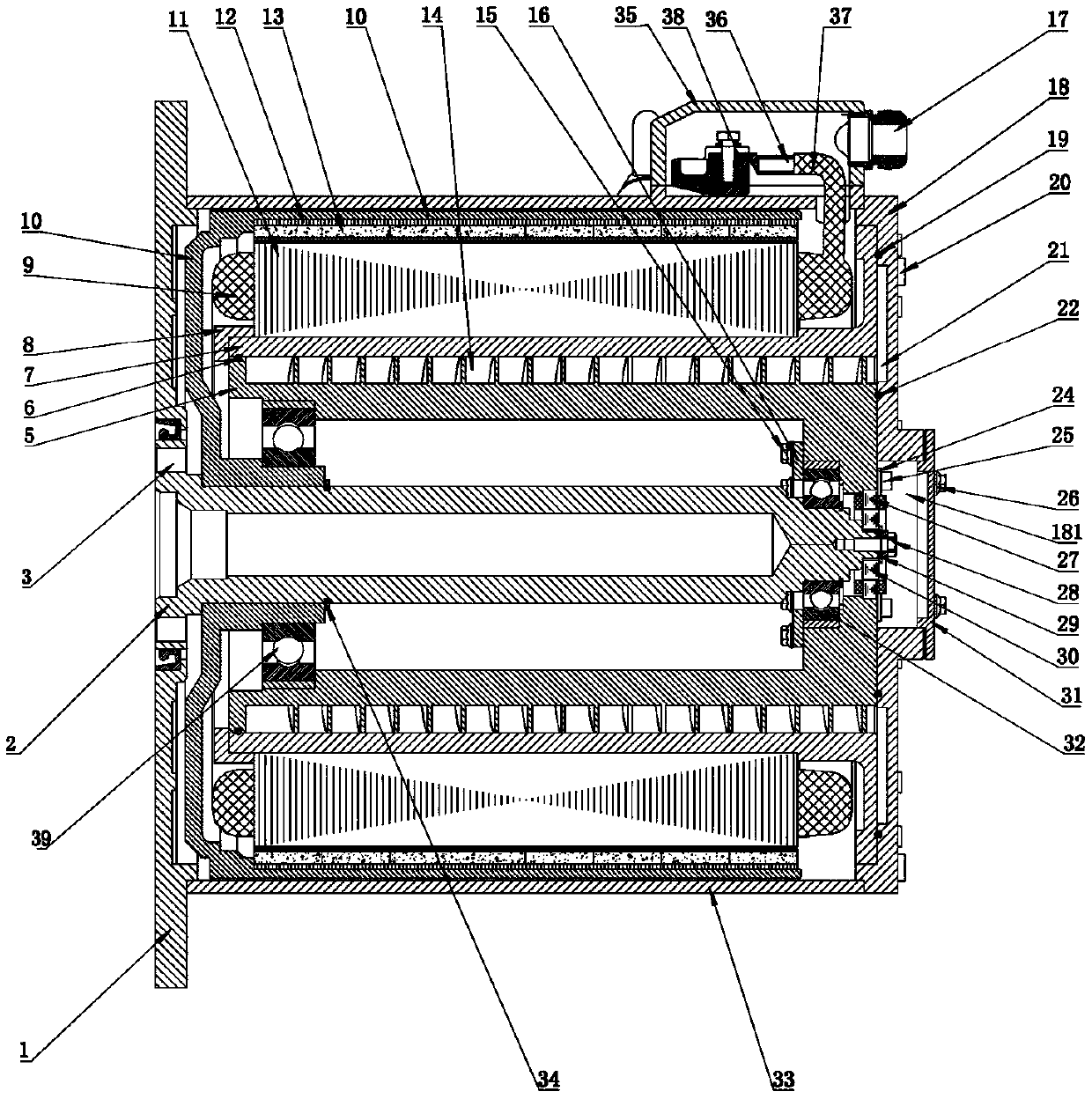

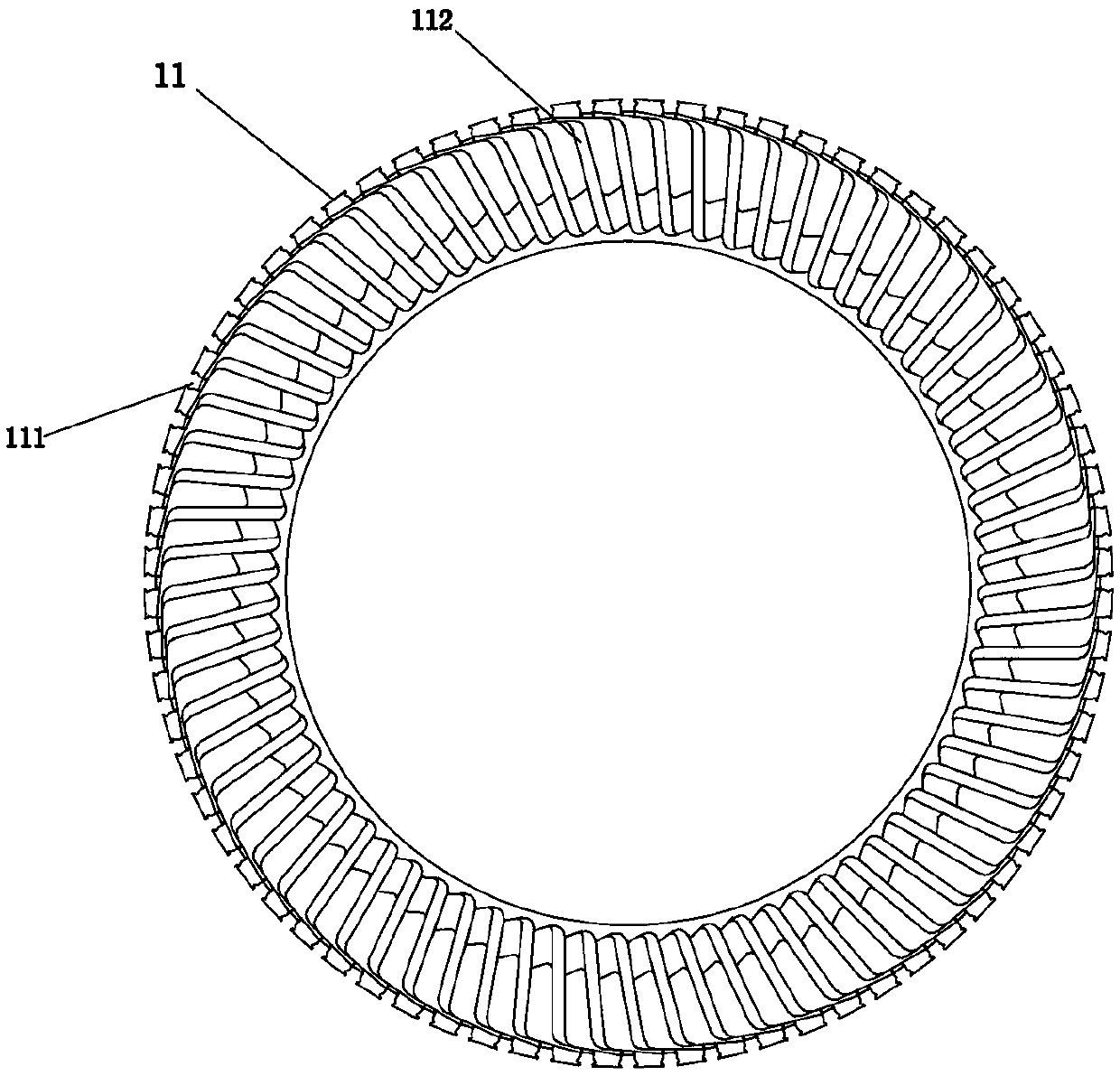

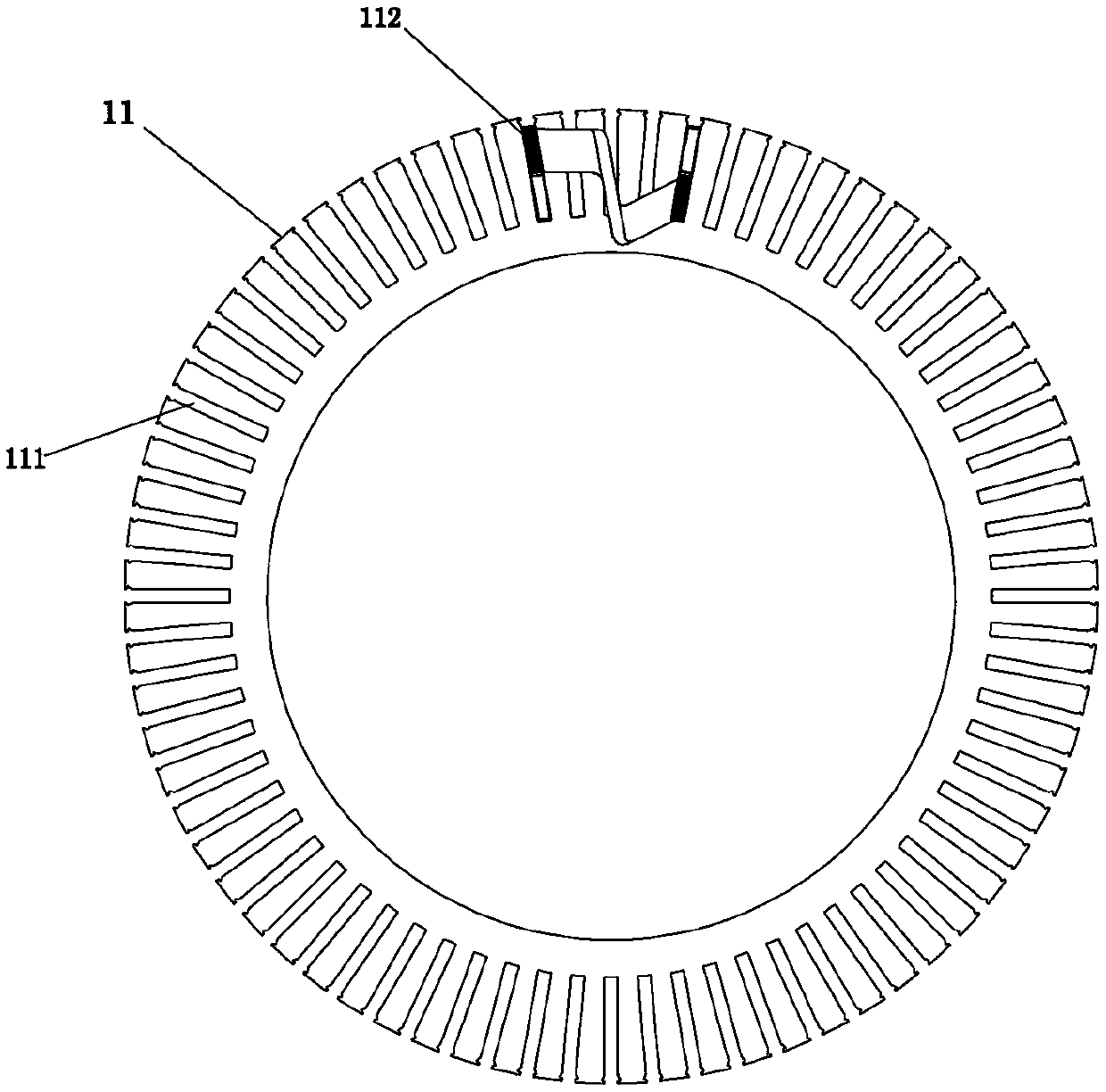

[0026] A flat copper wire formed stator coil high reluctance torque outer rotor permanent magnet drive motor, such as Figure 1-Figure 7As shown, it includes a coupling shaft 2, and the left and right sides of the coupling shaft 2 are respectively connected with a front end cover 1 and a double spiral waterway ring 5 through a front bearing 3 and a rear bearing 32; The fixed retaining ring 16 is arranged on the double-helix waterway ring 5, and the fixed retaining ring 16 of the rear bearing is fixed on the double-helix waterway ring 5 by the rear bearing retaining ring fixing screw 17; the outer ring of the double-helix waterway ring 5 is connected to There is a waterway outer ring 7 matched with the double helix waterway ring 5, and the double helix waterway ring 5 cooperates with the waterway outer ring 7 to form a double helix waterway 14; the outer side of the double helix waterway ring 5 is provided with a stator waterway rear end cover 18 The rear end cover 18 of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com