Motor rotor, motor, compressor and air conditioner

A motor rotor and compressor technology, which is applied in the fields of compressors, air conditioners, motor rotors, and motors. It can solve the problems of non-adjustable excitation of permanent magnet motors, limitation of maximum operating speed, and decline in energy efficiency ratio of the whole machine to achieve magnetic field weakening. Reinforcement, reluctance torque increase, and the effect of improving high-speed operation capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

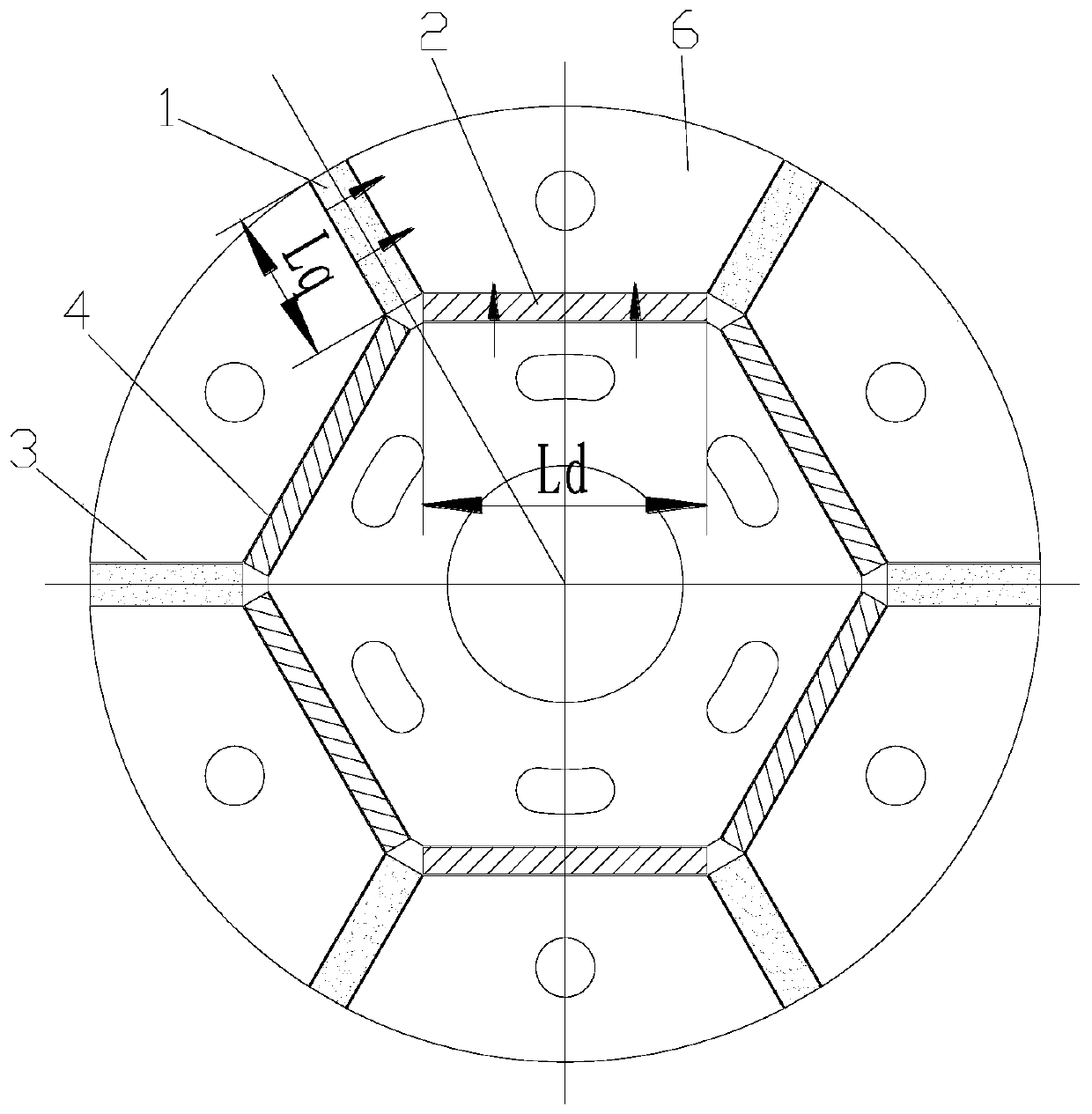

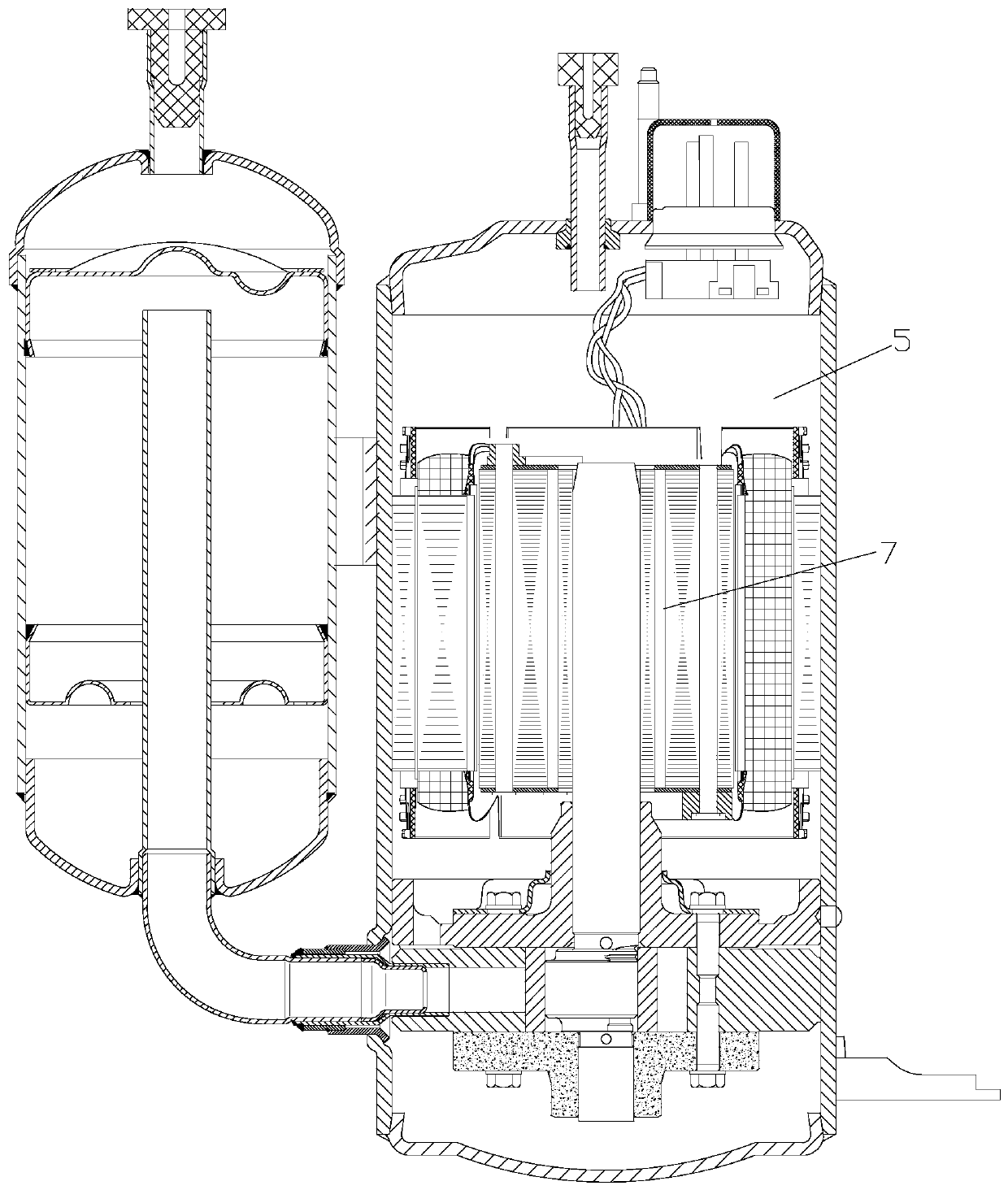

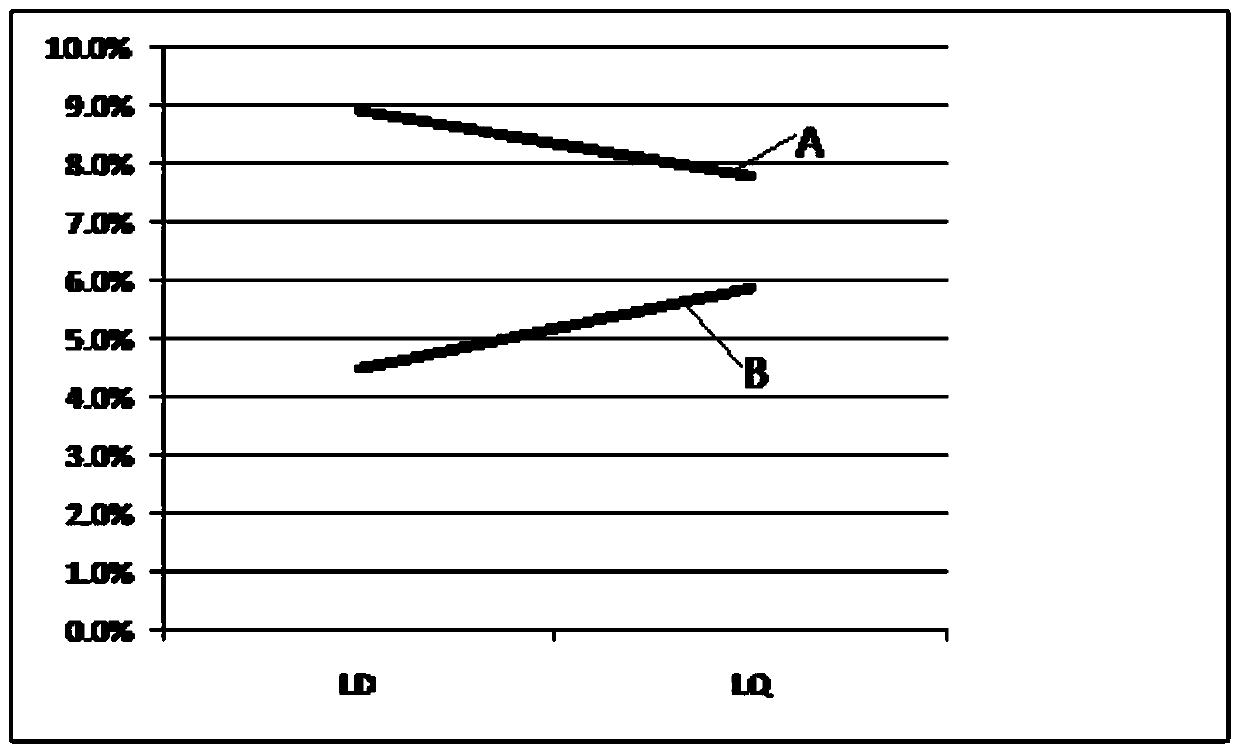

[0023] see in conjunction Figure 1 to Figure 2 As shown, according to the embodiment of the present application, the motor rotor includes a plurality of magnetic poles arranged in the circumferential direction, each magnetic pole includes a first permanent magnet 1 and a second permanent magnet 2, and the first permanent magnet 1 is located on the d-axis of the motor , the second permanent magnet 2 is located on the q-axis of the motor, the first permanent magnet 1 is radially magnetized, the second permanent magnet 2 is tangentially magnetized, and the coercive force temperature coefficient α of the first permanent magnet 1 d Greater than the coercivity temperature coefficient α of the second permanent magnet 2 q .

[0024] At least two kinds of permanent magnets are used in each magnetic pole of the motor rotor, and the coercive force temperature coefficient α of the permanent magnets located on the d-axis d Greater than the coercivity temperature coefficient α of the per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com