High and weak magnetic performance halbach array permanent magnet synchronous motor

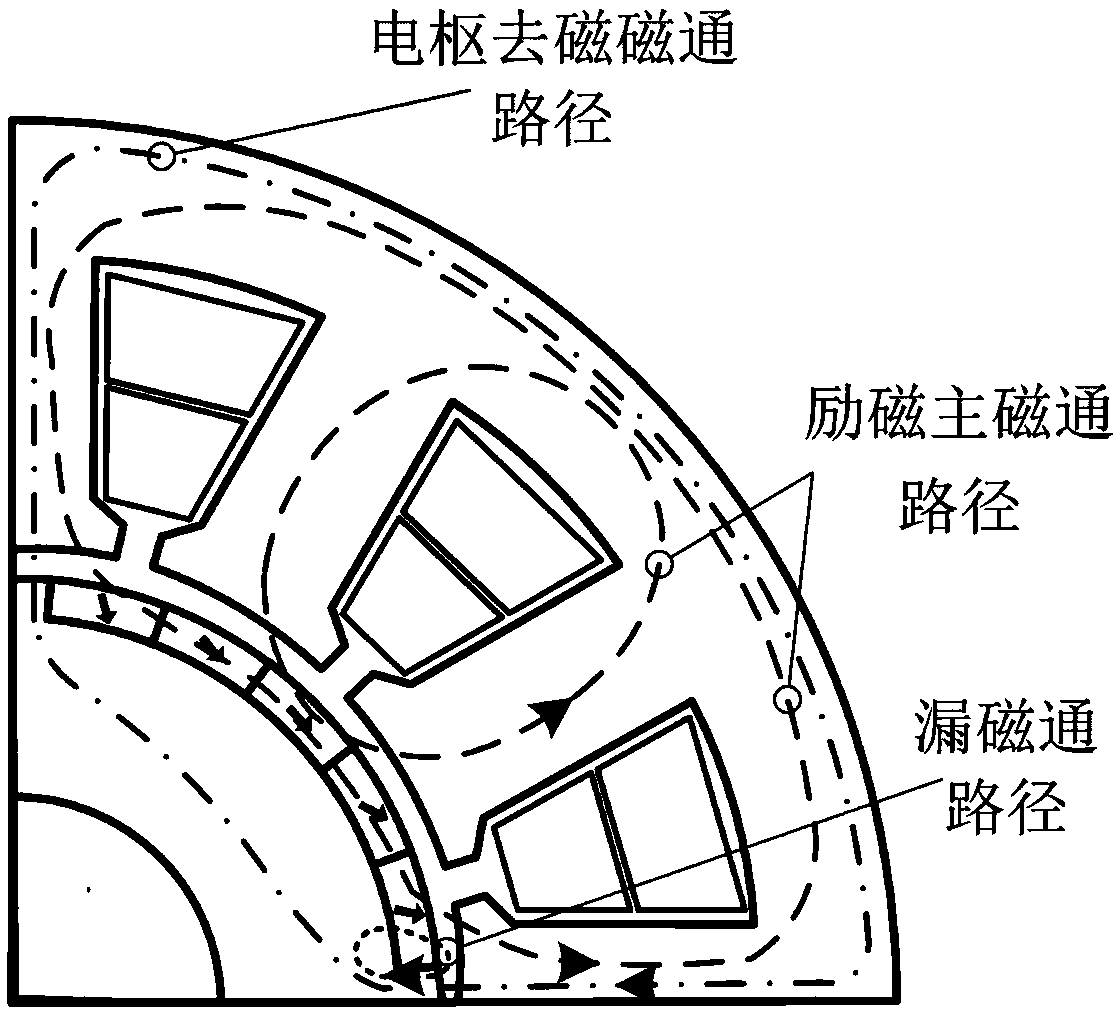

A technology for permanent magnet synchronous motors and magnetic properties, applied in the direction of magnetic circuits, electromechanical devices, electrical components, etc., can solve the problems of difficulty in obtaining weak magnetic effects, irreversible demagnetization of permanent magnets, and difficulty in adapting to applications, etc., to achieve improved weak magnetic expansion Speed performance, avoid irreversible demagnetization failure, optimize the effect of air gap magnetic field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

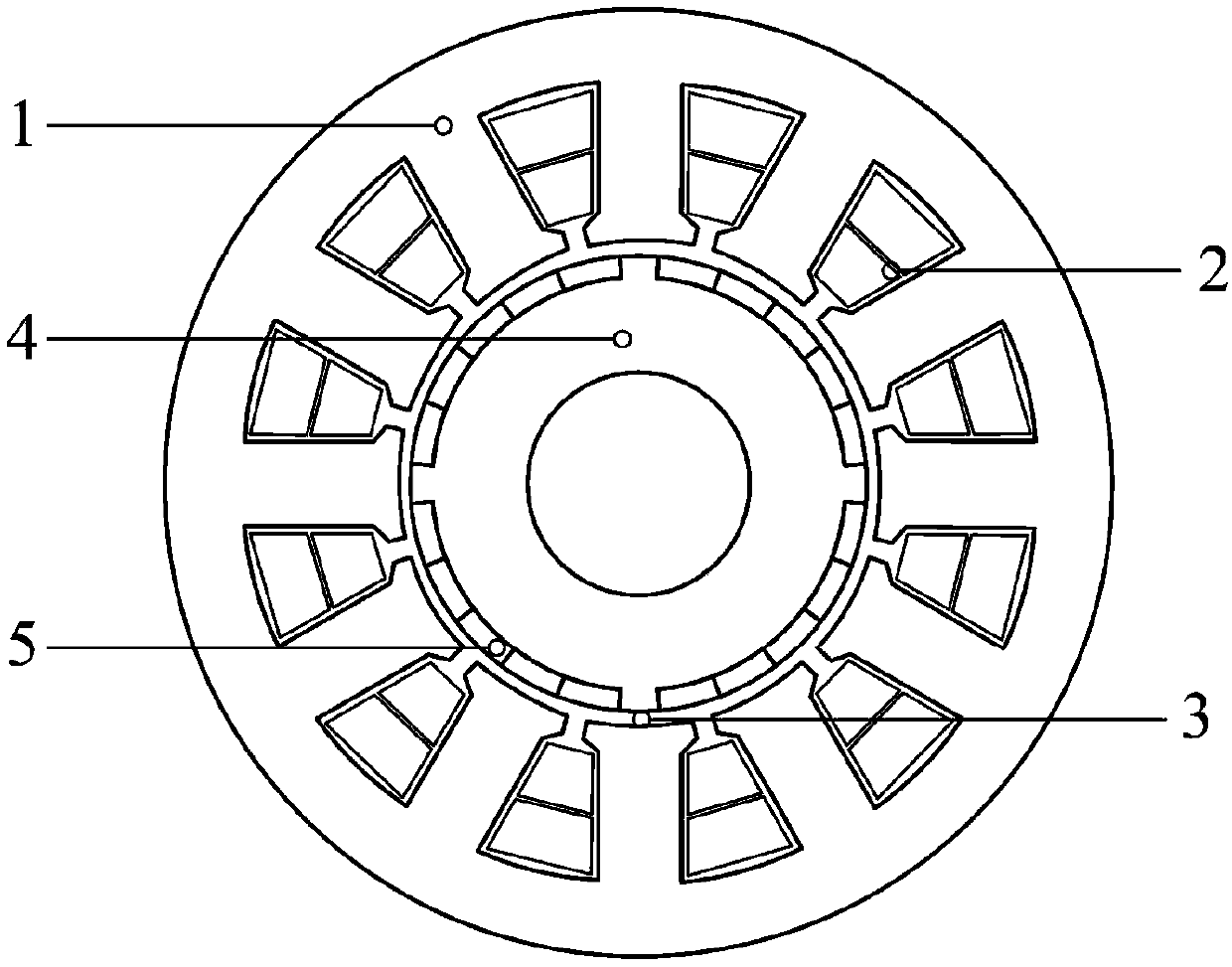

[0030] The structure of the Halbach array permanent magnet synchronous motor with inner rotor structure and high field weakening performance described in this embodiment is as follows figure 1 As shown, it includes an outer stator core, a three-phase armature winding, an air gap, an inner rotor core, and segmented Halbach array permanent magnet poles.

[0031] In this embodiment, the number of stator slots of the motor is 12, the number of rotor pole pairs p is 2, and each pole is composed of 5 permanent magnets of the same size. The salient poles of the rotor core occupy an angle of 10° (that is, the pole arc coefficient α Fe Is 0.11), the angle occupied by each permanent magnet is 16°, and its pole arc coefficient is 0.178.

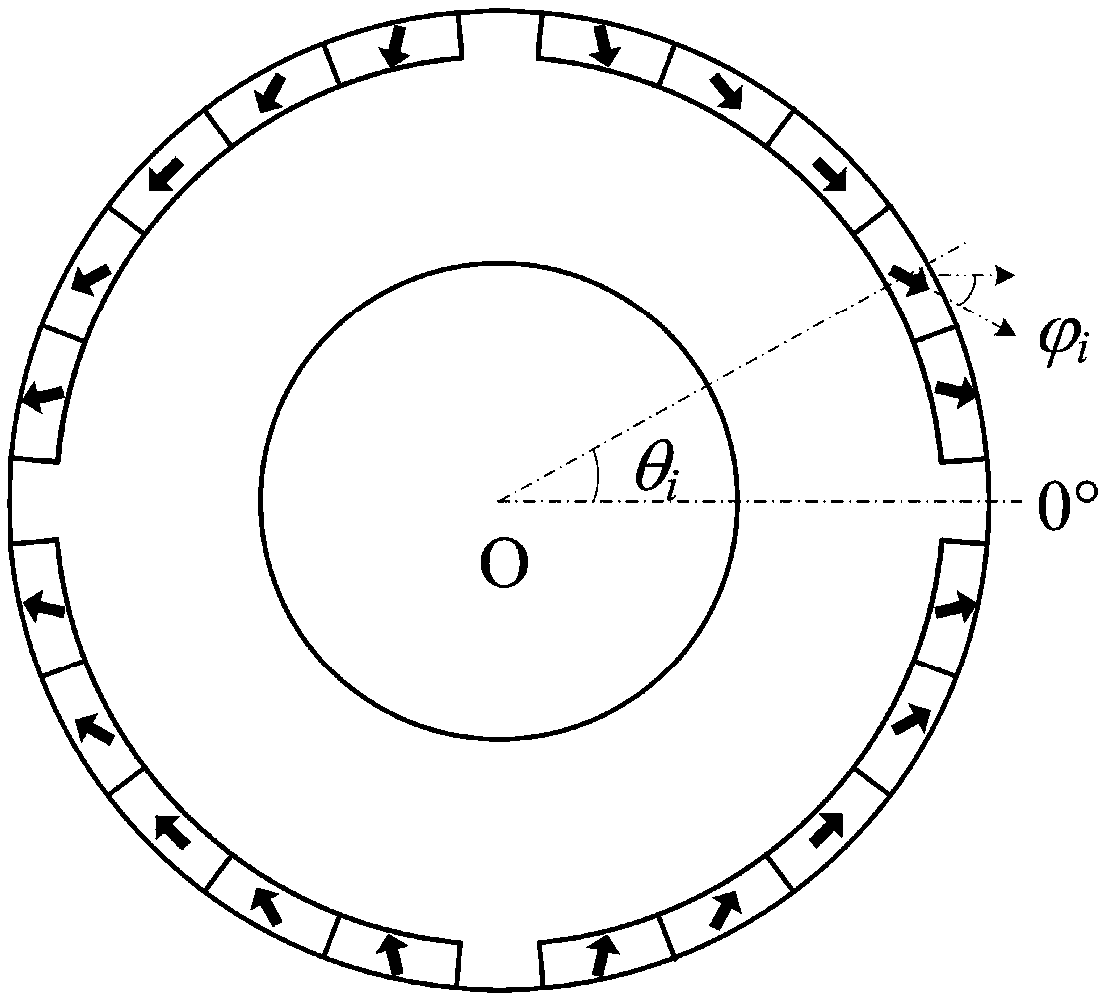

[0032] According to the size of the permanent magnet and the salient pole of the rotor core, the position angle of each permanent magnet and its corresponding magnetization angle can be calculated, as shown in Table 1.

[0033] Table 1 Permanent magnet positi...

specific Embodiment 2

[0036] The structure of the Halbach array permanent magnet synchronous motor with an outer rotor structure and high field weakening performance described in this embodiment is as Figure 4 As shown, it includes an inner stator core, a three-phase armature winding, an air gap, an outer rotor core, and segmented Halbach array permanent magnet poles.

[0037] Same as the first embodiment, the number of stator slots of the motor in this embodiment is 12, the number of rotor pole pairs is 2, and each pole is composed of 5 permanent magnets of the same size. The salient poles of the rotor occupy an angle of 10° (that is, the pole arc Coefficient α Fe Is 0.11), the angle occupied by each permanent magnet is 16°, and its pole arc coefficient is 0.178.

[0038] According to the size of the permanent magnet and the salient pole of the rotor core, the position angle of each permanent magnet and its corresponding magnetization angle can be calculated, as shown in Table 2.

[0039] Table 2 Perma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com