A magnetic steel built-in double U-shaped fractional slot concentrated winding permanent magnet motor

A concentrated winding, permanent magnet motor technology, applied to synchronous motors with static armatures and rotating magnets, magnetic circuit shape/style/structure, magnetic circuit, etc. Reduce the magnetic capacity, reduce the mechanical strength of the motor rotor, etc., to achieve the effect of improving the field weakening capacity, increasing the reluctance torque, improving the operating efficiency and torque control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with the accompanying drawings.

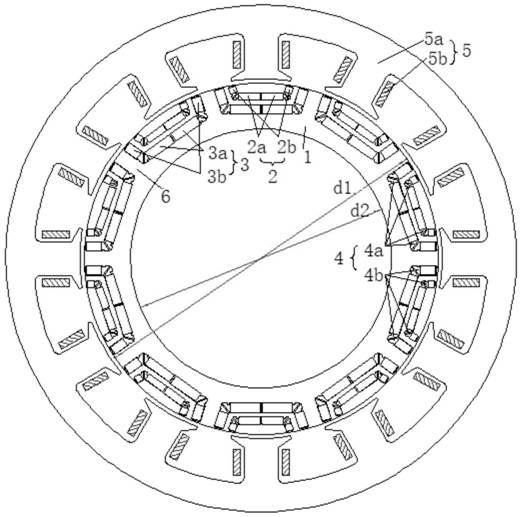

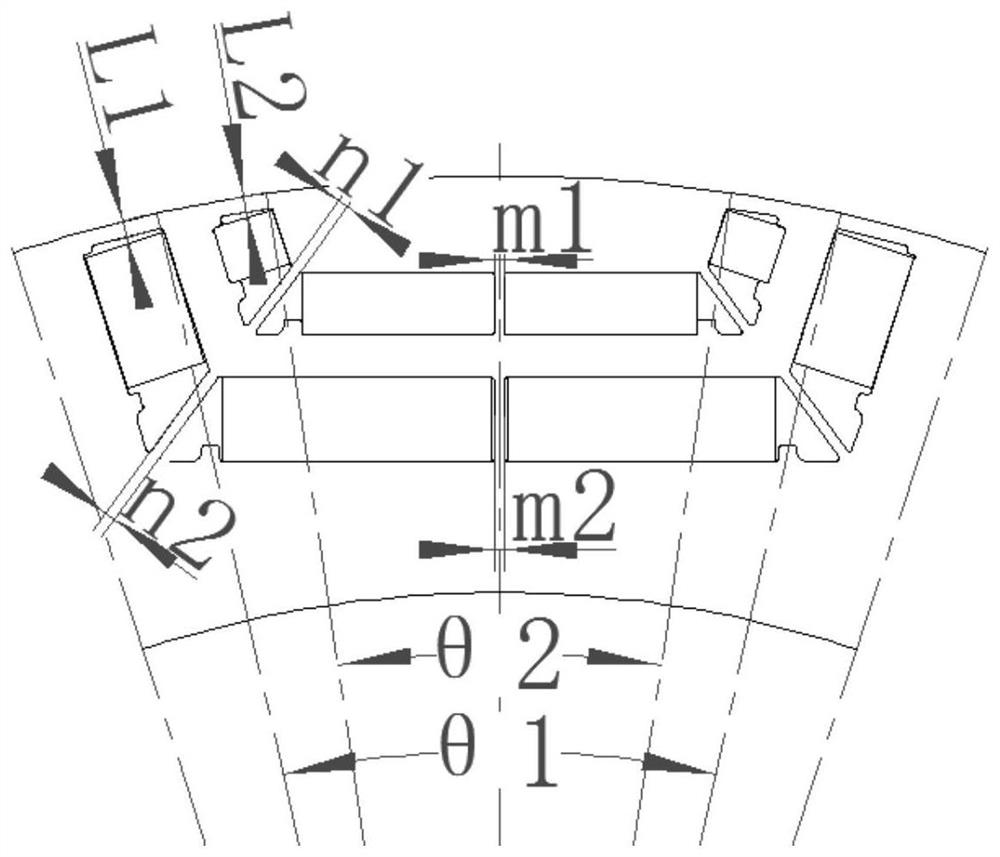

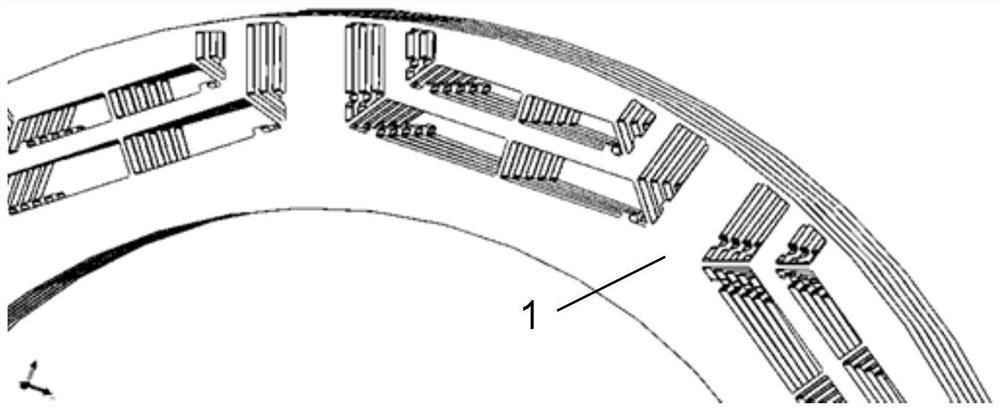

[0020] Such as Figure 1 to Figure 3 As shown, a magnetic steel built-in double U-shaped fractional slot concentrated winding permanent magnet motor includes a stator 5 and a rotor 6 . The stator includes a stator core 5a and a concentrated winding 5b, and the stator core 5a is formed by laminating stator magnetically conductive punching sheets. The rotor 6 includes a rotor core 1 , inside the rotor core 1 there are evenly distributed magnetic steel slots 4 along the circumference. Two radially magnetized magnetic steels 2a and 3a are arranged in the center of the flat bottom magnetic poles of the inner and outer layers of the double-layer U-shaped groove; a piece of tangentially magnetized magnetic steel is respectively arranged on both sides of the inner and outer layers of the double-layer U-shaped groove. Magnets 2b, 3b. A magnetic bridge is provided between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com