Built-in permanent magnet rotor disc and disc type motor

A technology for permanent magnet rotors and disc motors, which is applied to rotating parts of magnetic circuits, synchronous motors with stationary armatures and rotating magnets, magnetic circuits, etc. Instability and other problems, to achieve the effect of obvious salient pole effect, less permanent magnet consumption and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

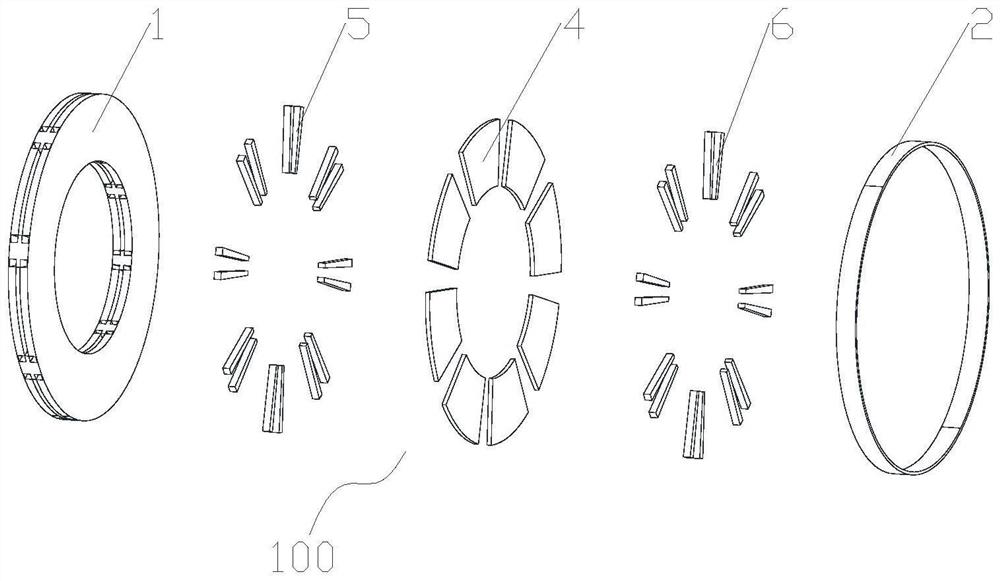

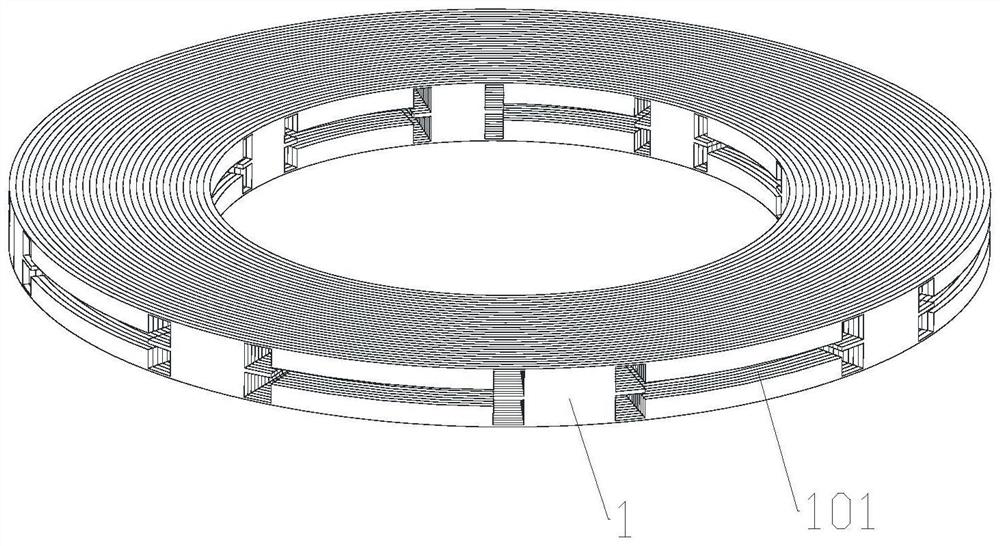

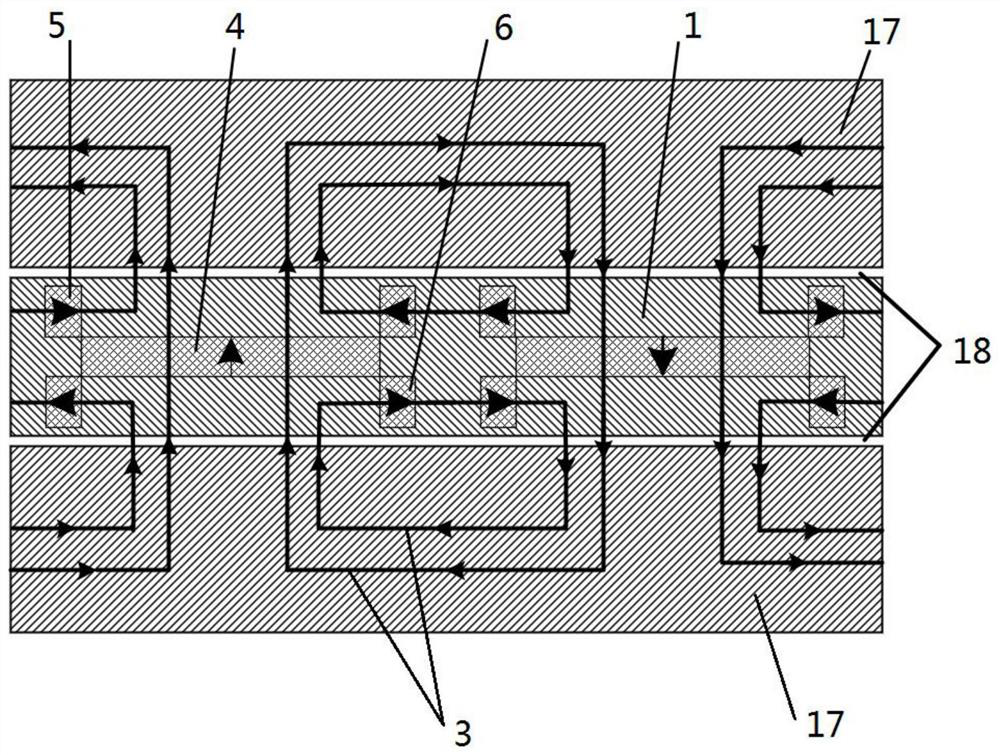

[0032] refer to Figure 1-Figure 8 As shown, the built-in permanent magnet rotor disk 100 provided by this embodiment includes: an annular rotor core 1, a non-magnetic protective cover 2 and a plurality of first permanent magnet groups, and the plurality of first permanent magnet groups are arranged along the annular rotor core. The circumferential direction of 1 is evenly arranged, and there is a gap between any two adjacent first permanent magnet groups, each first permanent magnet group is embedded in the inner of the annular rotor core 1, and the annular rotor core 1 is sleeved on the motor. On the non-magnetic support 12, the non-magnetic protective cover 2 is arranged on the outer wall of the annular rotor core 1, and the non-magnetic protective cover 2 restricts the radial direction of the first permanent magnet group when the annular rotor core 1 rotates. The direction of magnetization of any two adjacent first permanent magnet groups is opposite, and the first permane...

Embodiment 2

[0043] refer to Figure 4 As shown, this embodiment includes some or all of the features of Embodiment 1. The difference is that any two adjacent first permanent magnet groups of the built-in permanent magnet rotor disk 100 provided in this embodiment share a first Tangential permanent magnet 5 and a second tangential permanent magnet 6.

Embodiment 3

[0045] refer to Figure 5 As shown, this embodiment includes some or all of the features of Embodiment 1. The difference is that the first permanent magnet group of the built-in permanent magnet rotor disk 100 provided by this embodiment includes a symmetrically arranged first U-shaped permanent magnet and a second permanent magnet. Two U-shaped permanent magnets, the first U-shaped permanent magnet includes a second axial permanent magnet 7 and two third tangential permanent magnets 8 symmetrically arranged on both sides of the second axial permanent magnet 7, the second U-shaped permanent magnet It includes a third axial permanent magnet 9 and two fourth tangential permanent magnets 10 symmetrically arranged on both sides of the third axial permanent magnet 9 .

[0046] Further, as Figure 5 As shown, in this embodiment, the magnetization directions of the second axial permanent magnet 7 and the third axial permanent magnet 9 are the same in the axial direction; the magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com