Stator used in brushless direct current motor and used for reducing fundamental wave cogging torque

A technology of brush DC motor and cogging torque, which is applied in the direction of electrical components, electromechanical devices, magnetic circuit shape/style/structure, etc., and can solve the problems of large fundamental wave cogging torque and reduction of fundamental wave cogging torque, etc. , to achieve the effects of reducing reluctance torque, improving reliability and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

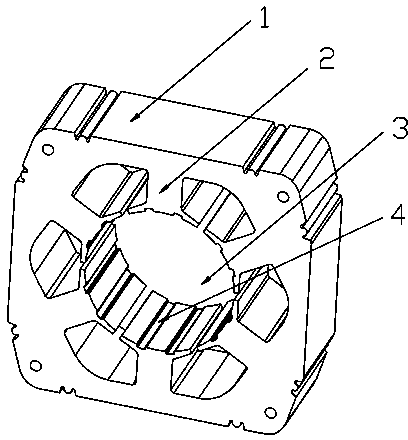

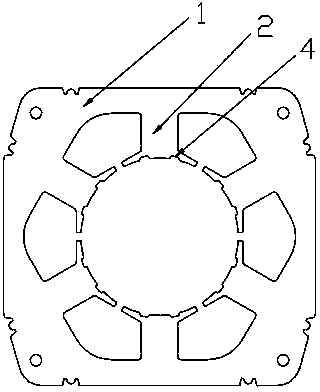

[0013] Example 1: one of the structures of the present invention, see figure 1 , 2 , it has a stator core 1 formed by stacking multiple silicon steel punches, on which windings are provided (the windings are not shown in the figure, which is a conventional technology), and a central hole 3 is also provided in the stator core, around the center The hole is provided with 6 tooth crowns 2, especially: 2 axial grooves 4 are opened on the arc end face of each tooth crown 2, which is mainly suitable for motors with an odd number of slots ZO in the unit motor (1 Axial grooves, suitable for motors with an even number of motor slots ZO).

[0014] In this embodiment, the groove 4 on the tooth crown 2 of the stator core is a full-length through groove.

[0015] In this embodiment, the groove 4 on the tooth crown 2 of the stator core has a rectangular structure.

example 2

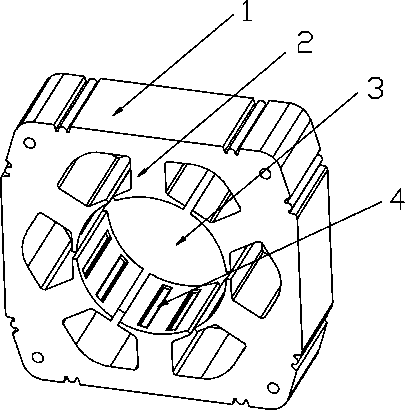

[0016] Example 2: two structures of the present invention, see image 3 , it has a stator core 1 formed by stacking multiple silicon steel punches, on which windings are provided (the windings are not shown in the figure, which is a conventional technology), and a central hole 3 is provided in the stator core, surrounding the central hole There are several tooth crowns 2 structures, especially: two axial grooves 4 are opened on the circular arc end surface of each tooth crown 2 .

[0017] In this embodiment, ribs are provided at both ends of the groove 4 on the tooth crown 2 of the stator core (it is also possible that only one end is provided with a rib, and the other end runs through).

[0018] In this embodiment, the groove 4 on the tooth crown 2 of the stator core is semicircular.

[0019] The analysis of the design principle of the present invention is as follows: a brushless DC motor with grooves on the crown of the stator adopts silicon steel stamping crowns of the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com