Built-in hybrid permanent magnet motor

A hybrid permanent magnet, built-in technology, applied in the direction of magnetic circuits, electrical components, electromechanical devices, etc., can solve the problems of reducing torque ripple, unreasonable, unable to improve motor performance, etc., to reduce magnetic flux leakage and improve utilization , Improving the effect of anti-demagnetization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

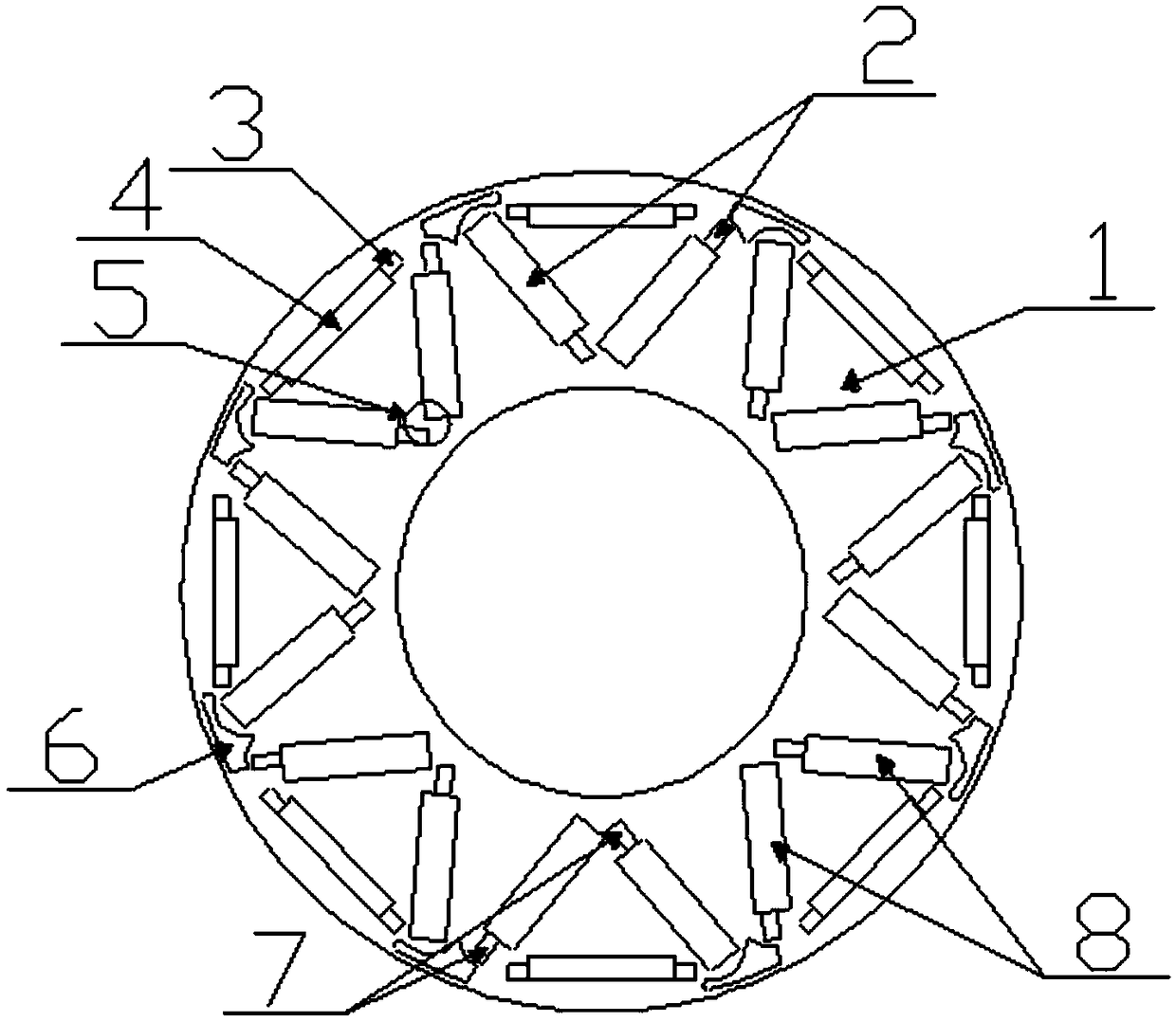

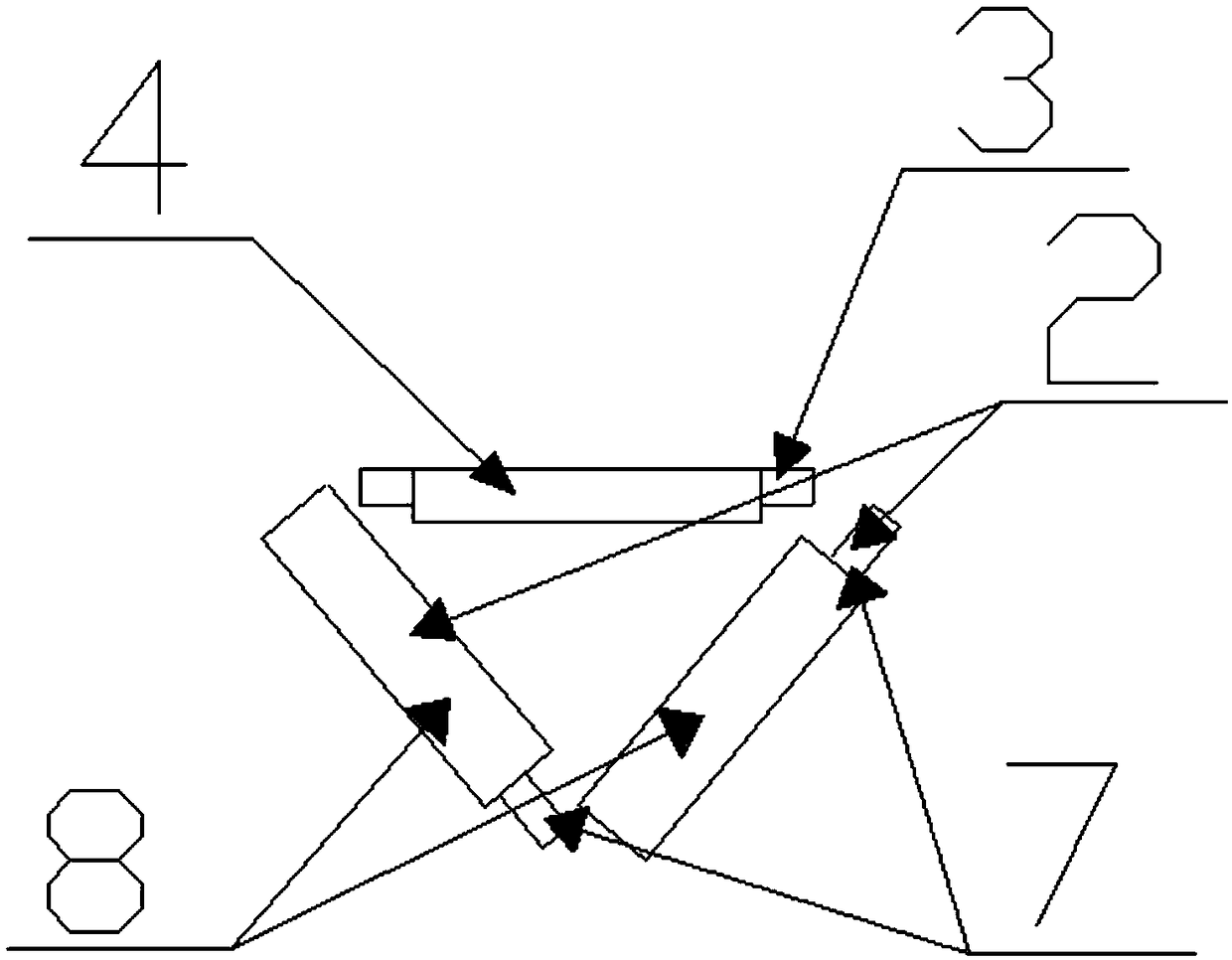

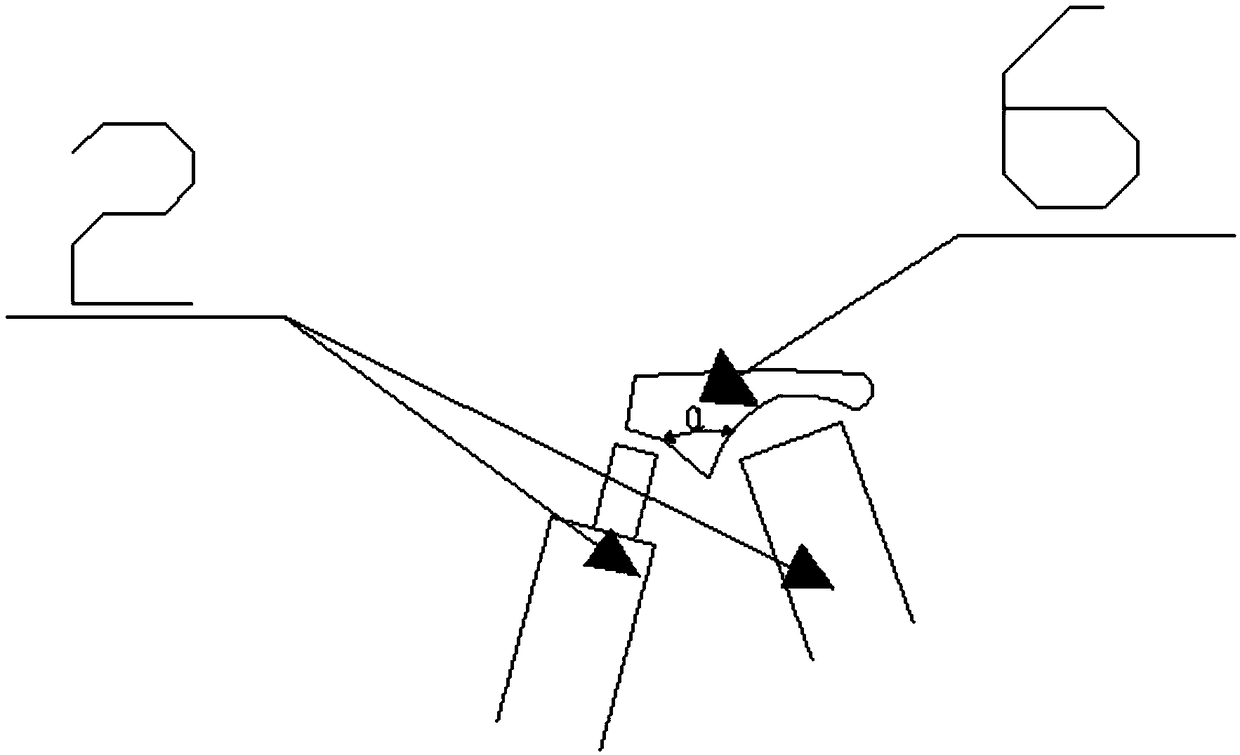

[0025] A built-in hybrid permanent magnet motor, comprising two parts of a rotor and a stator, the rotor (1) is located in the stator (9); the rotor is provided with a V-shaped groove (2) along the circumferential direction; the V An inline groove (3) is arranged between the groove (2) and the outer edge of the rotor; the V-shaped groove and the inline groove form a group of groove structures, and the permanent magnets in the group of grooves have the same polarity; the two groups Sickle-shaped magnetic isolation bridges (6) are arranged between the slot structures.

[0026] Each side of the V-shaped groove is divided into upper and lower parts; the upper and lower parts are two rectangular structures with different widths and lengths, and the two rectangular structures are divided into a large rectangular structure (8) and a small rectangular structure (7), and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com