Mixing torque motor and traction machine adopting same

A technology of torque motors and motors, applied in the field of motors, can solve the problems of increased overall cost, difficulty in processing and installation, and low work efficiency, and achieve the effects of reducing the cost of the whole machine, saving the amount of magnetic steel, and reducing the cost of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the purpose, technical solution and beneficial technical effect of the present invention clearer, the content and specific implementation methods of the present invention will be further described in detail below in conjunction with the accompanying drawings.

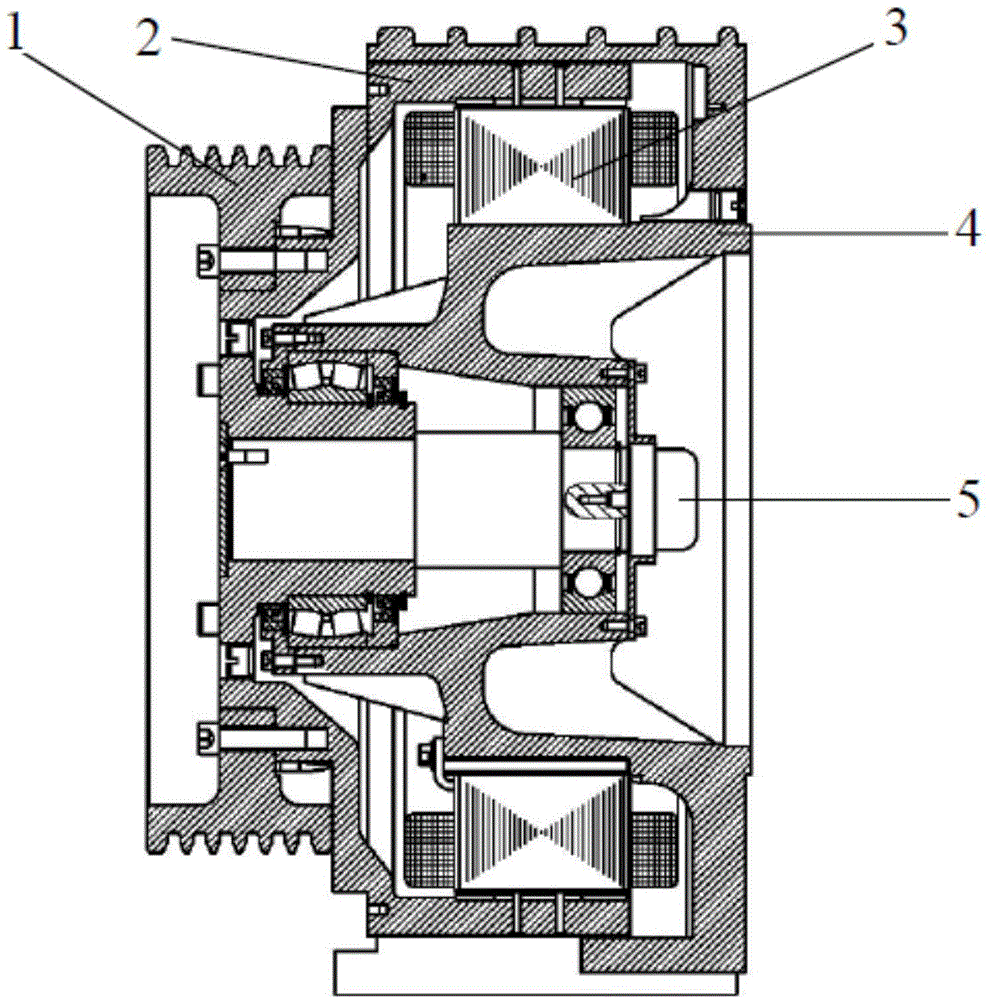

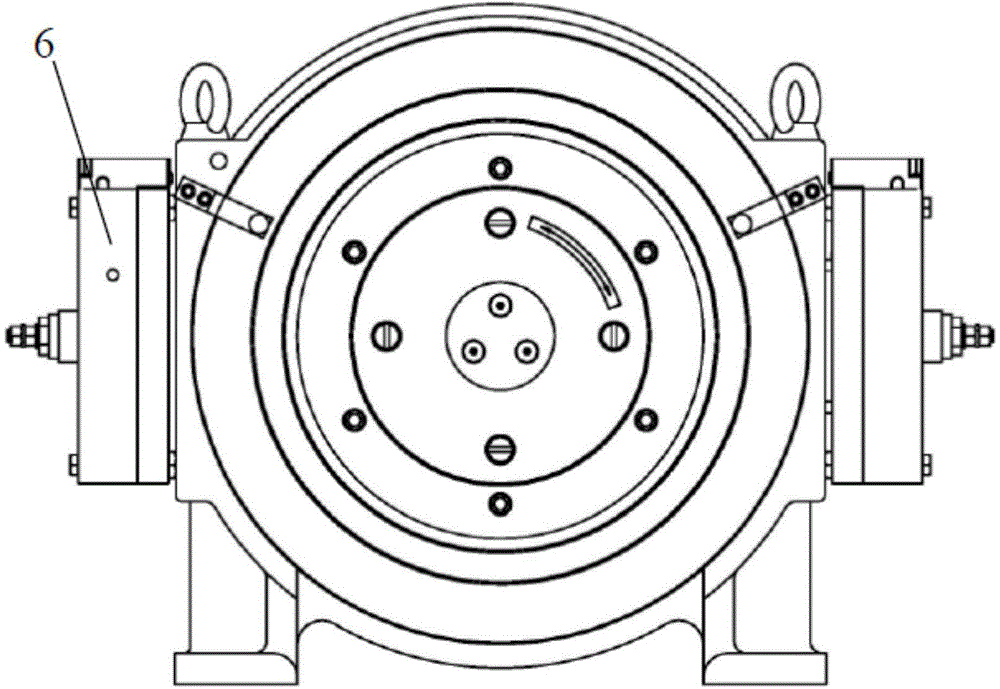

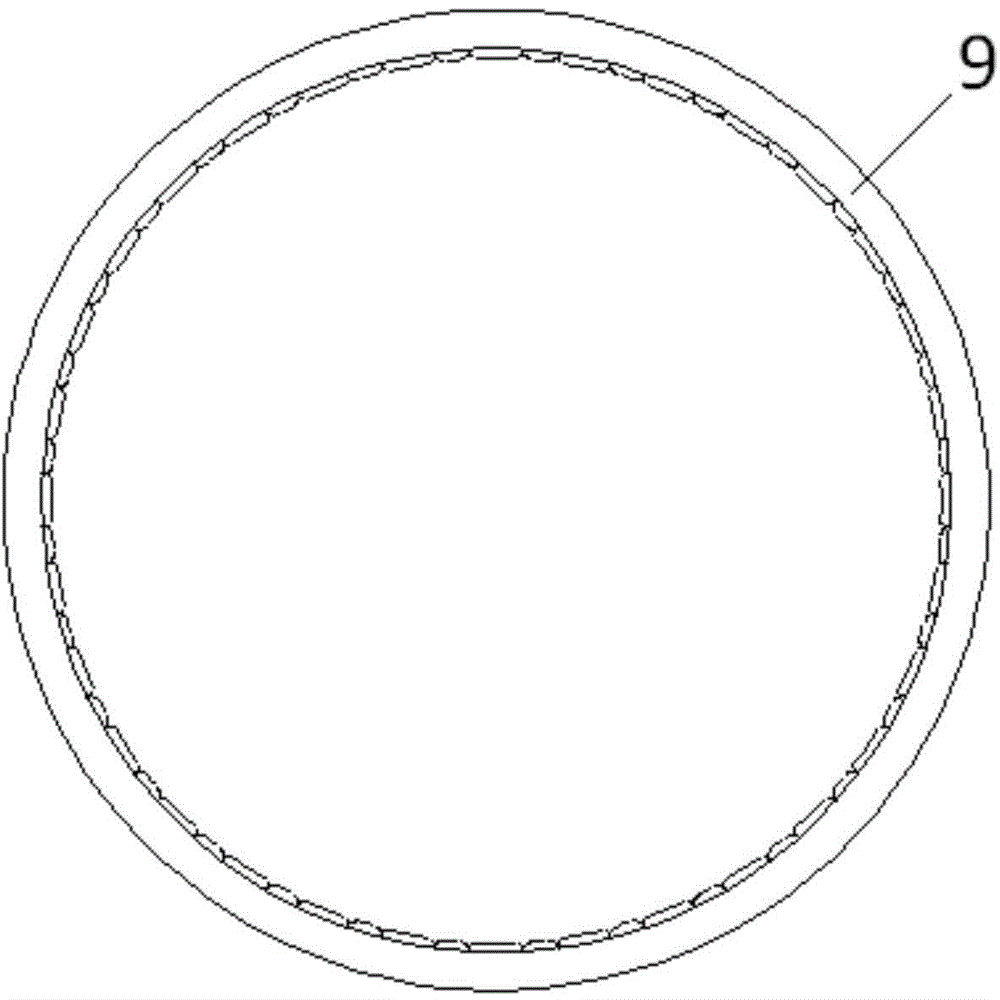

[0037] Such as figure 1 with figure 2 As shown, the hybrid torque elevator traction machine includes a relatively rotatable rotor 2 and a stator 3. There are multiple tooth poles on the stator core, which are made of laminated silicon steel sheets. Located on the periphery of the stator 3, the stator 3 and the rotor 2 can rotate relative to each other, the traction wheel 1 is connected to the rotor 2, the rotor 2 and the stator 3 are installed on the frame 4, and the frame 4 is integrated with the overall base of the traction machine. The overall structure is simple and convenient. The sensor 5 is installed in the base 4, the controller detects the position of the rotor 2 according to the sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com