Patents

Literature

126results about How to "Increase top speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

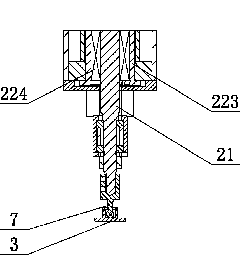

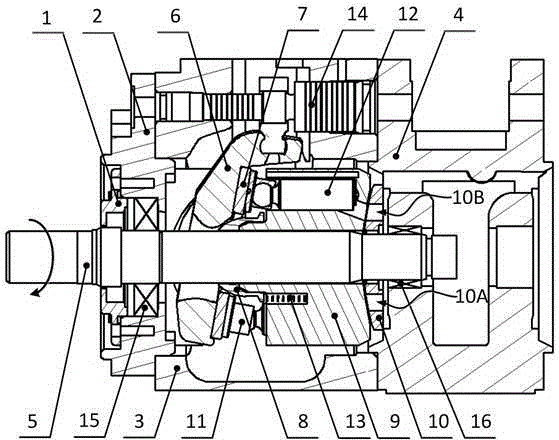

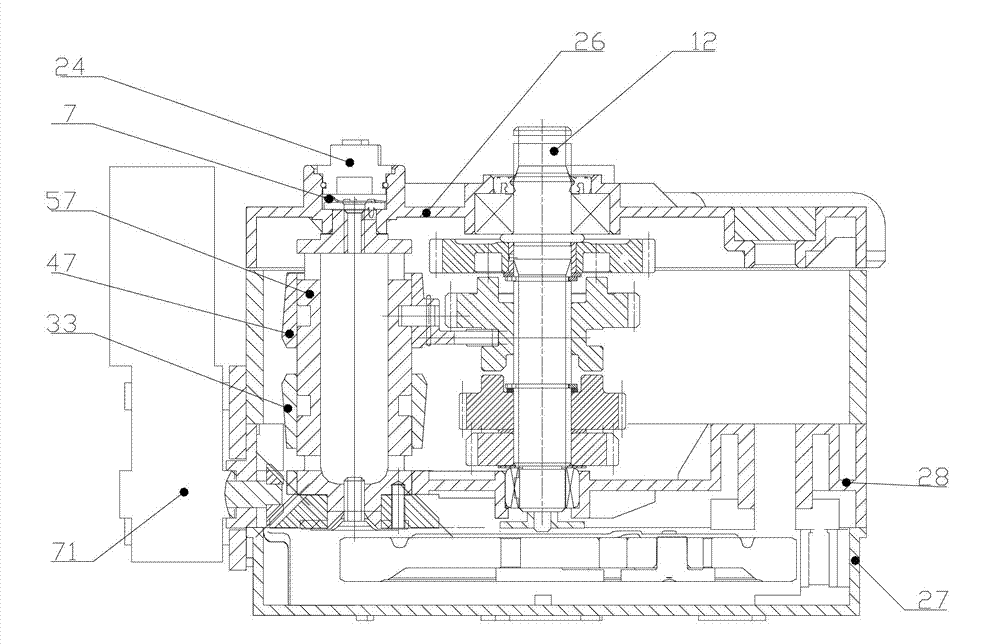

Planetary wheel numerical control polishing removal function generator

InactiveCN101823224AImprove rotation movementDoes not affect rotationOptical surface grinding machinesNumerical controlEngineering

The invention discloses a planetary wheel numerical control polishing removal function generator, which comprises a revolution shaft system, a rotation shaft system, a polishing disk, an eccentric adjusting mechanism and a slewing mechanism. The revolution shaft system is connected above the eccentric adjusting mechanism; the slewing mechanism is connected to the bottom end of the eccentric adjusting mechanism; the rotation shaft system is connected below the slewing mechanism; the polishing disk is arranged at the lower end of the rotation shaft system; the rotation shaft system comprises a rotation shaft, a rotation motor, a rotation transmission mechanism and a rotation shaft base; the rotation shaft base is connected to the slewing mechanism; the rotation shaft is arranged in the rotation shaft base; the rotation motor is fixed to the rotation shaft base; and the output end of the rotation motor is connected with the rotation shaft through the rotation transmission mechanism. The planetary wheel numerical control polishing removal function generator has the advantages of high rigidity for the transmission of the rotation shaft system, balanced rotation and capability of acquiring stable removal functions.

Owner:NAT UNIV OF DEFENSE TECH

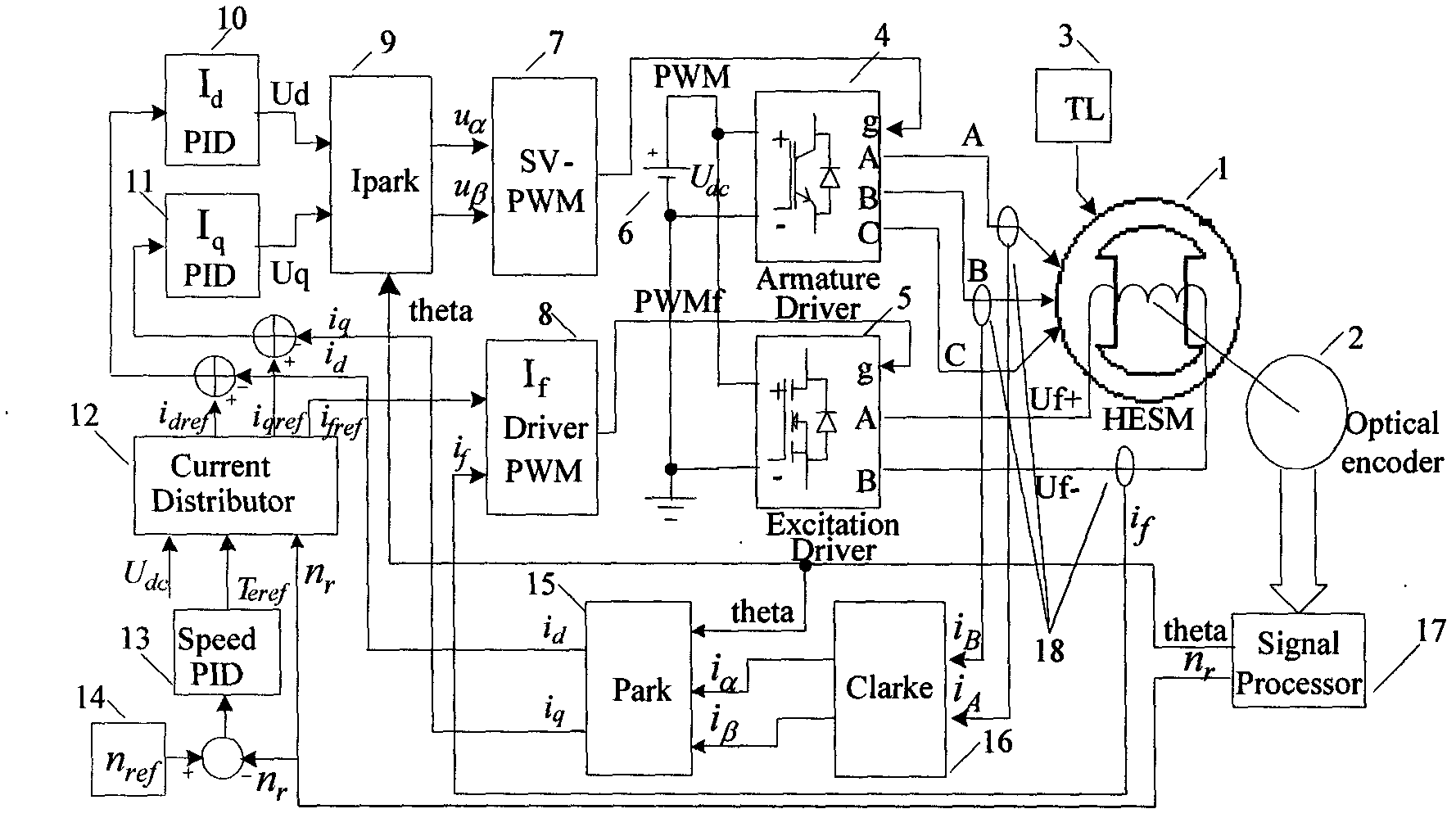

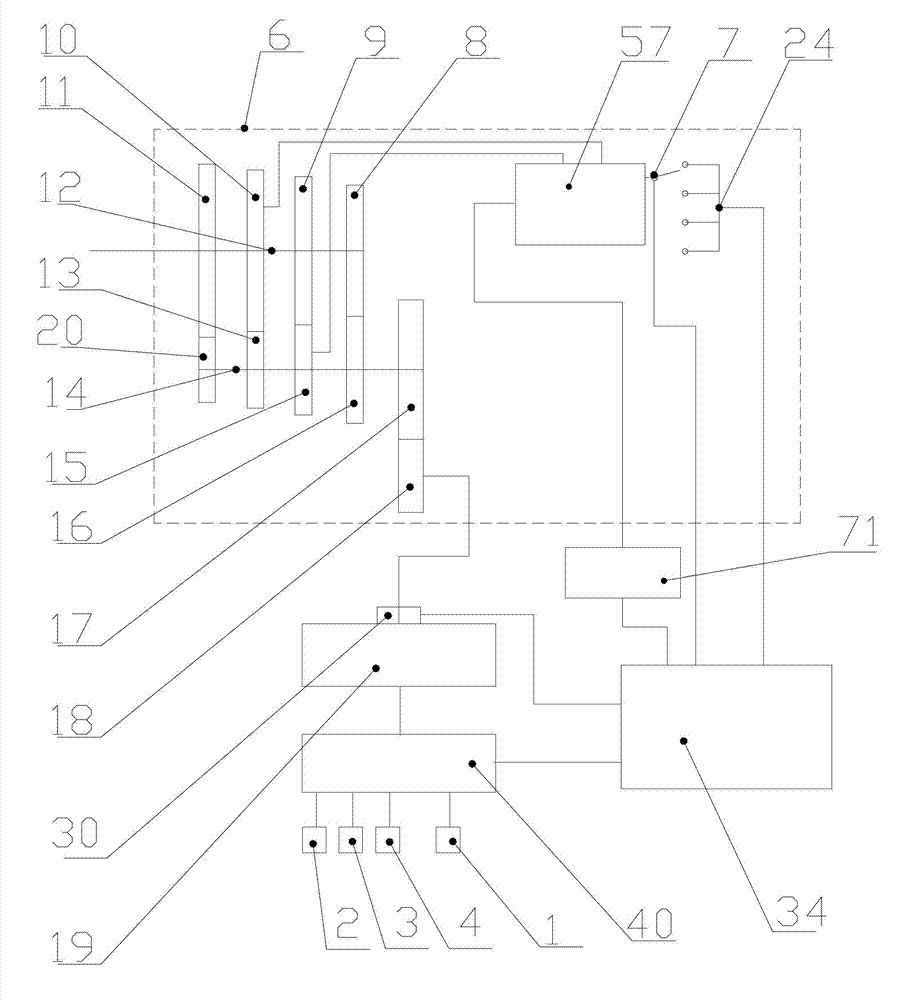

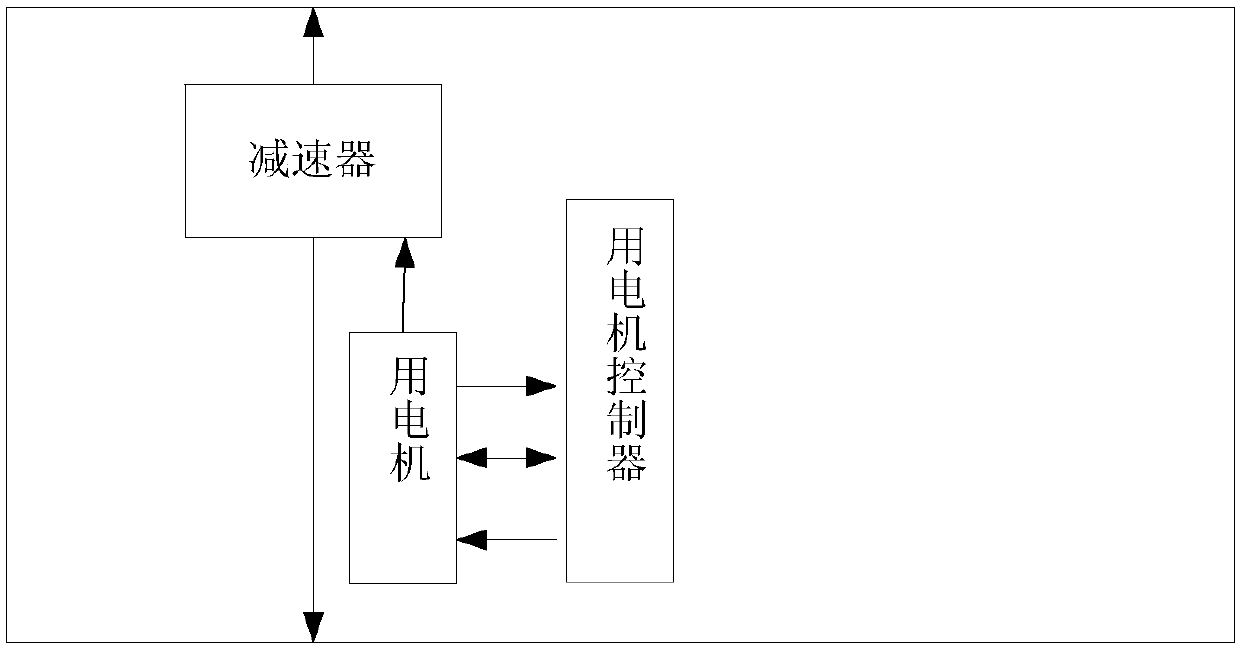

Novel speed regulating system suitable for driving electric automobile and current distributing method

InactiveCN102545766ANo risk of permanent demagnetizationThe risk of permanent demagnetization will notElectronic commutation motor controlVector control systemsPhase currentsProportion integration differentiation

The invention discloses a novel speed regulating system suitable for driving an electric automobile, which comprises the following steps: collecting phase currents iA, iB and exciting current if from an HESM (hybrid excitation synchronous machine) motor main circuit; collecting a real-time rotating speed nr from the HESM motor; obtaining d-q-axis currents id and iq after transforming the collected phase currents; comparing d-q-axis currents id and iq respectively with d-axis reference current idref and q-axis reference current iqref obtained from a current distributer and carrying out PID (proportion integration differentiation) operation, carrying out a reverse Park transformation and a space vector voltage pulse width modulation and outputing a pulse signal to control conduction and disconnection of a power tube corresponding to a armature driving module, and outputing the exciting current if and the exciting reference current ifref through an exciting driving signal generating module to control conduction and disconnection of the power tube corresponding to the exciting driving module, wherein the HESM motor adopts a dual-stator structure, an armature winding is arranged on an outer stator, and an inner stator is provided with an exciting winding; the motor rotor is configured as a claw pole shape, a permanent magnetic steel and a magnetizing iron core are in staggered arrangement on the claw pole, and the area rate of the permanent magnetic steel to the magnetizing iron core is 2:1.

Owner:HENAN INST OF ENG

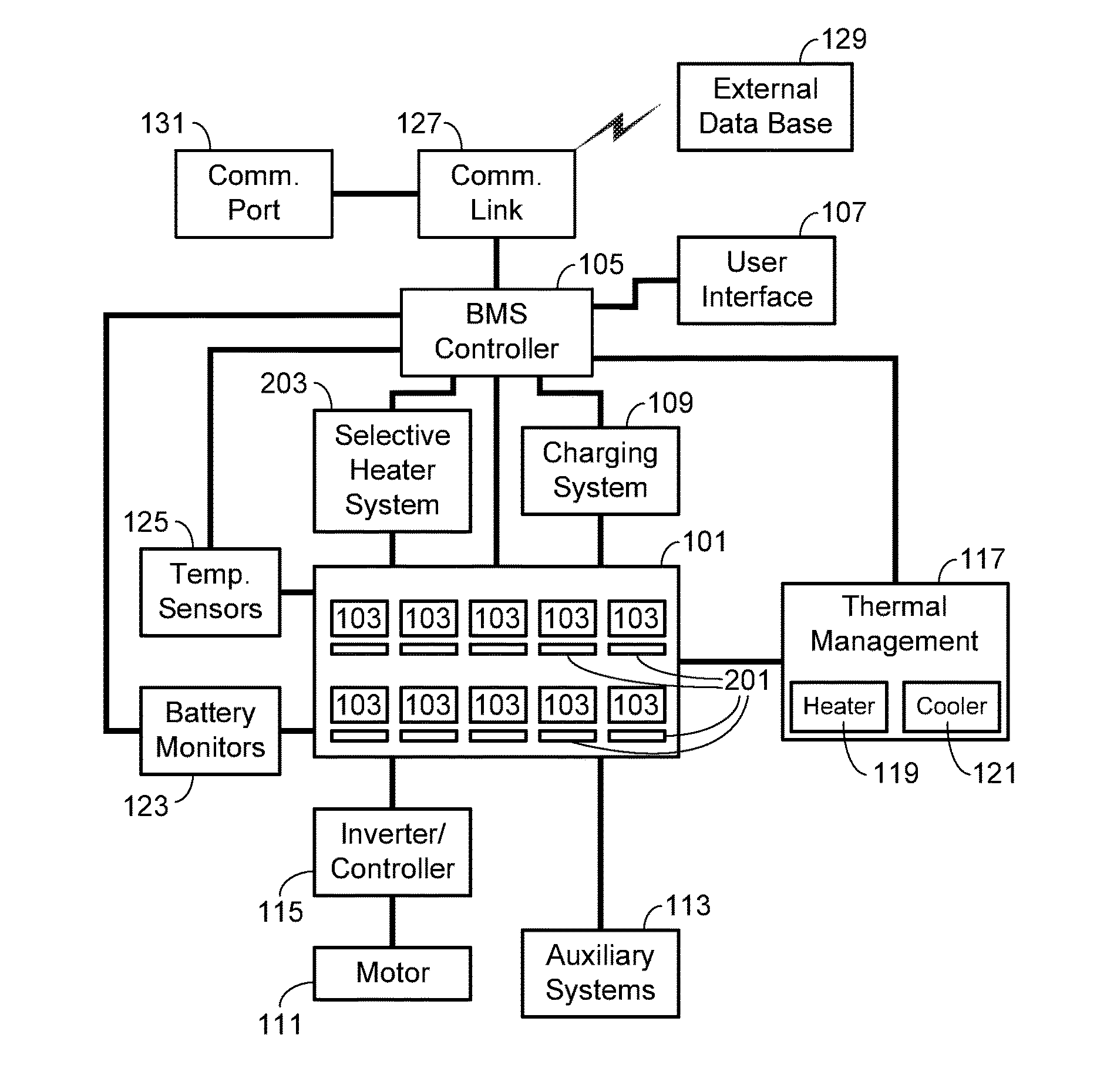

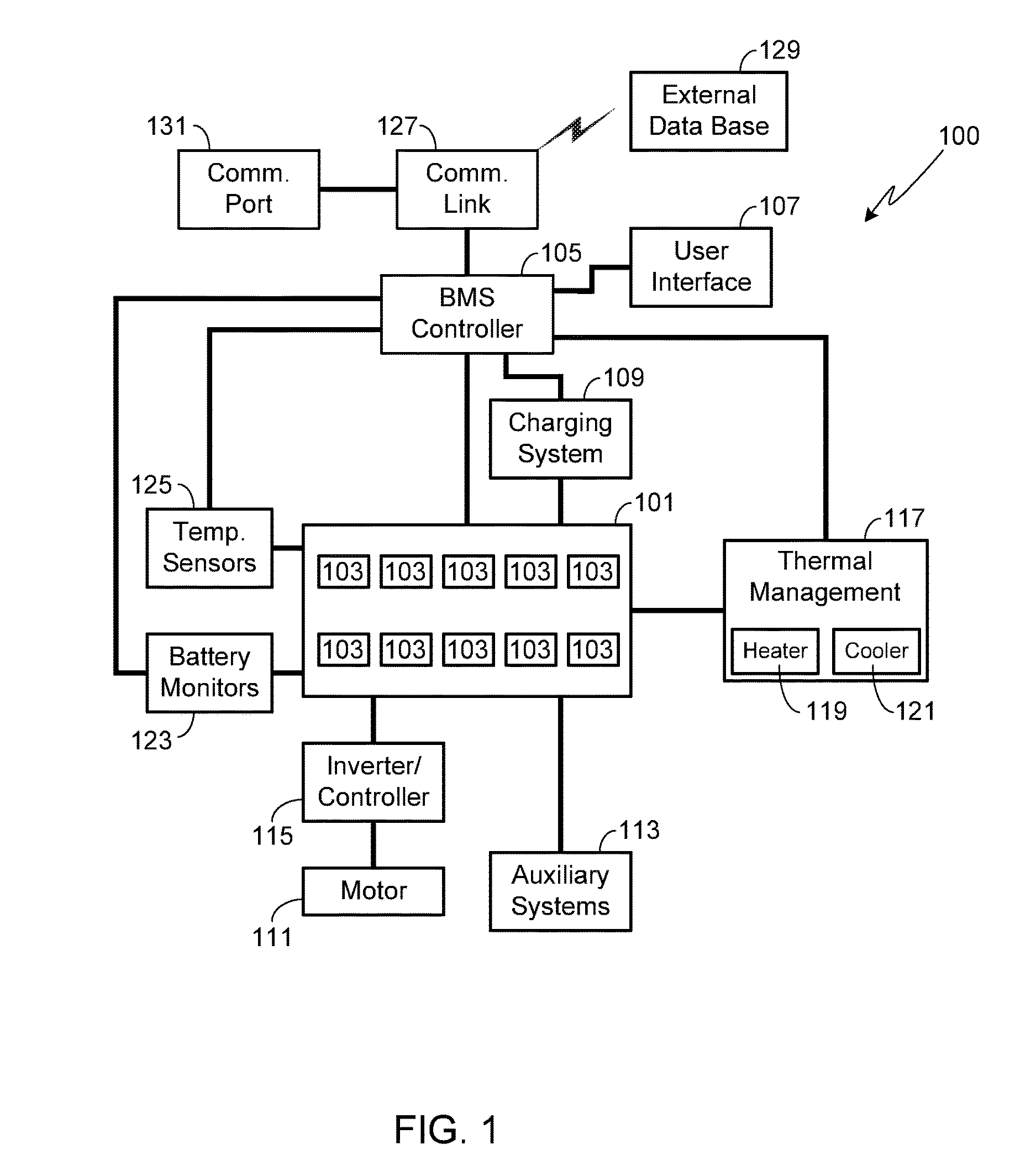

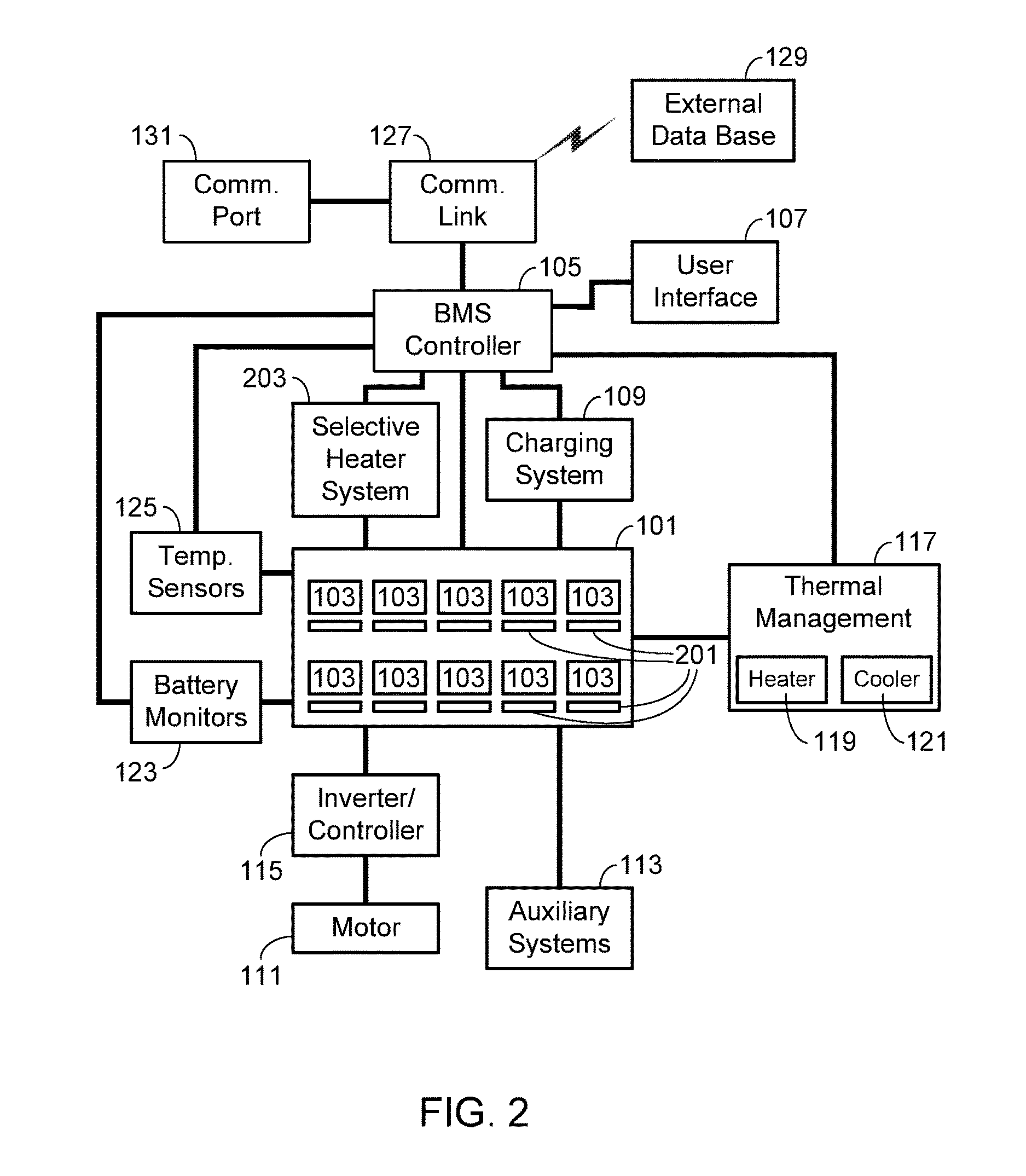

Method and Apparatus for Selectively Heating Individual Battery Modules Within a Battery Pack

ActiveUS20170008419A1Reduce loadIncrease top speedCharging stationsCells structural combinationLow voltageElectrical battery

A system and method are provided which, when the battery pack is at a low charge level, selectively heat the battery or battery module with the lowest voltage, thereby decreasing the internal resistance and mitigating the magnitude of the voltage drop of the affected battery / battery module. As a result, termination of the battery pack's discharge cycle is delayed and the driving range of the vehicle is increased, thereby giving the driver a little more time and driving range to reach a charging station.

Owner:ATIEVA USA INC

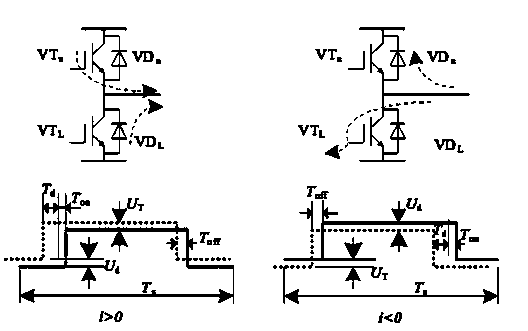

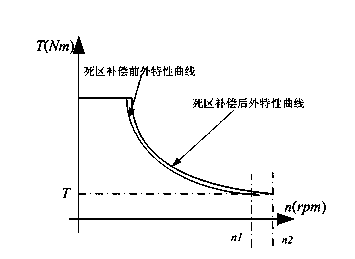

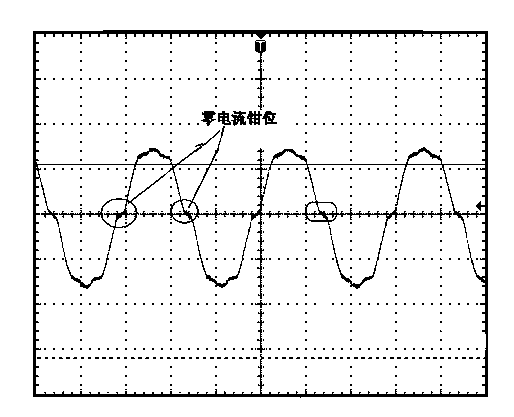

Compensation voltage algorithm of inverter dead zone in motor control system and interpolation method

ActiveCN103888005AIncrease top speedFast dynamic responseElectronic commutation motor controlAC motor controlPower inverterControl system

The invention discloses a compensation voltage algorithm of an inverter dead zone in a motor control system and an interpolation method. The compensation voltage algorithm calculates the inverter dead zone effect error time Terr, equivalent error time Tave caused by conduction and voltage reduction of a power transistor and a diode in one PWM cycle is included, U-phase output end voltage error Vao_err caused by the Tave equivalent error time in one PWM cycle is calculated, three-phase voltage error of the inverter is thus obtained, and the compensation voltage of the inverter dead zone is obtained by the phase voltage error. According to the interpolation method, through sampling three-phase current of the inverter and carrying out filter processing by a current sensor, clark conversion, park conversion, inverted park conversion and inverted clark conversion are respectively carried out on the three-phase current after filter, three-phase current signals after filter are obtained, a zero-crossing threshold is set, and inverter compensation voltage interpolation can be carried out when the absolute value of the three-phase current is more than the threshold. With the algorithm, the compensation voltage can be obtained, and by adopting the interpolation method, the inverter dead zone effect can be avoided.

Owner:SHANGHAI DAJUN TECH

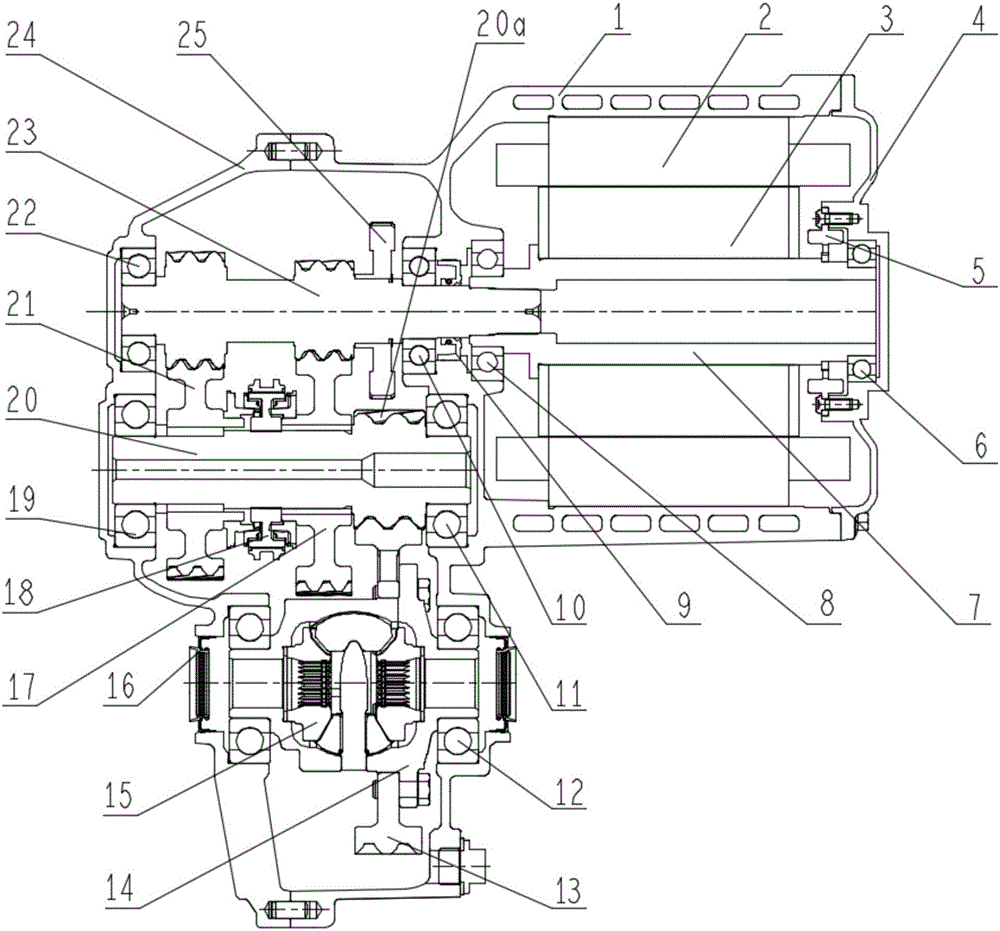

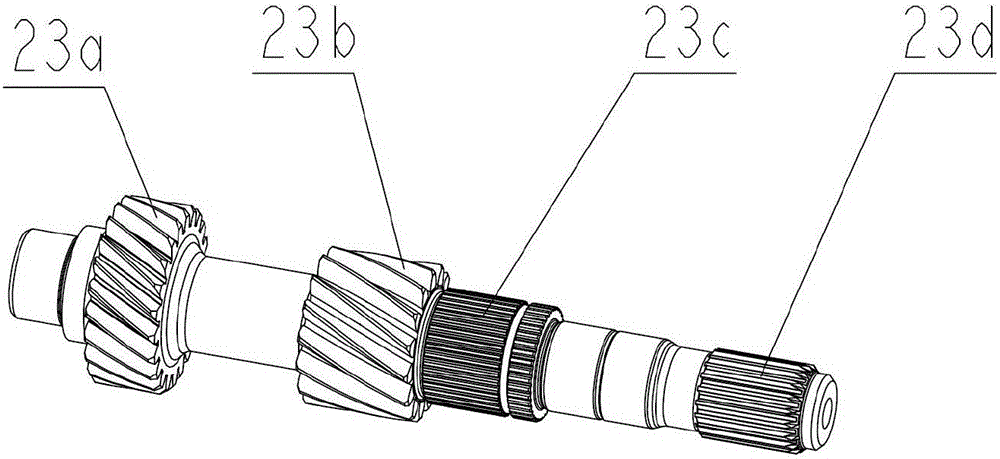

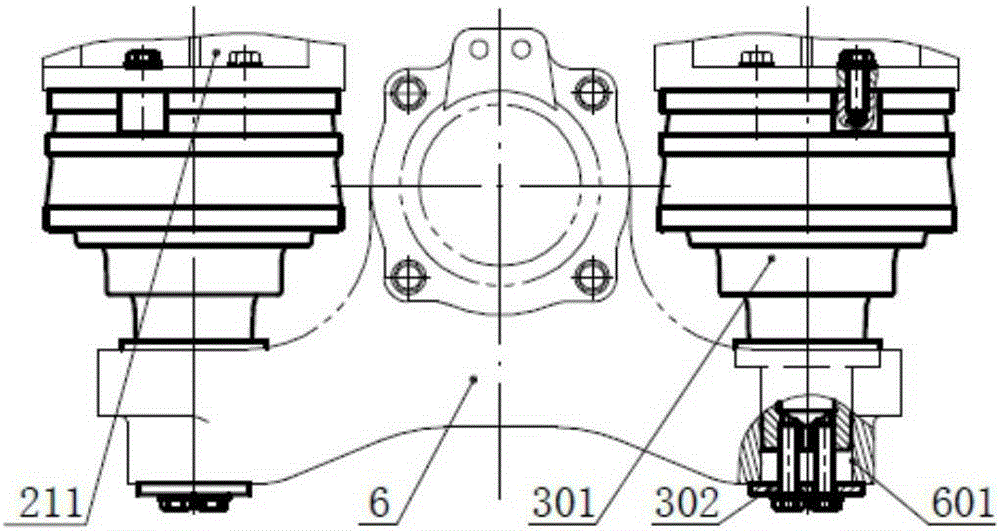

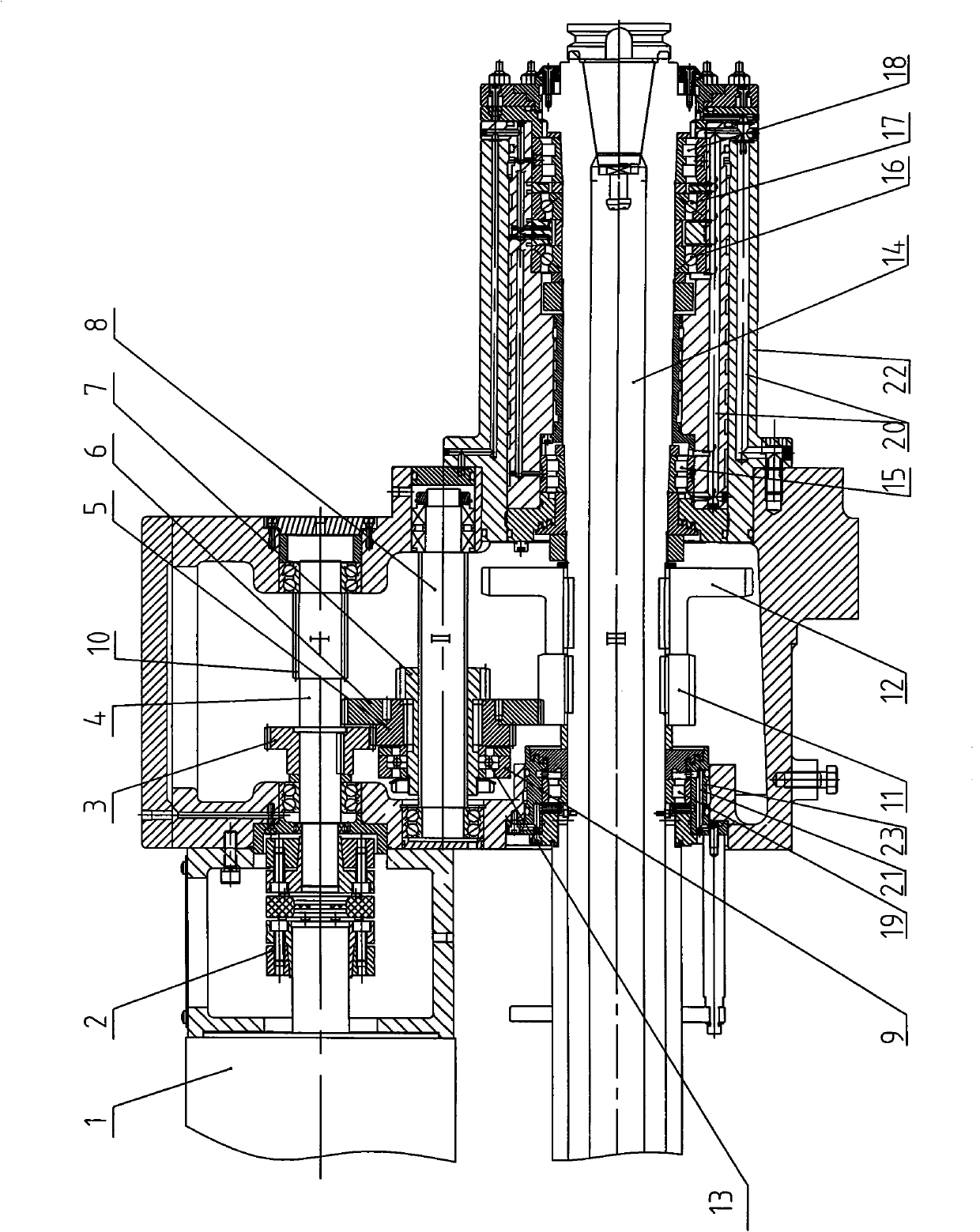

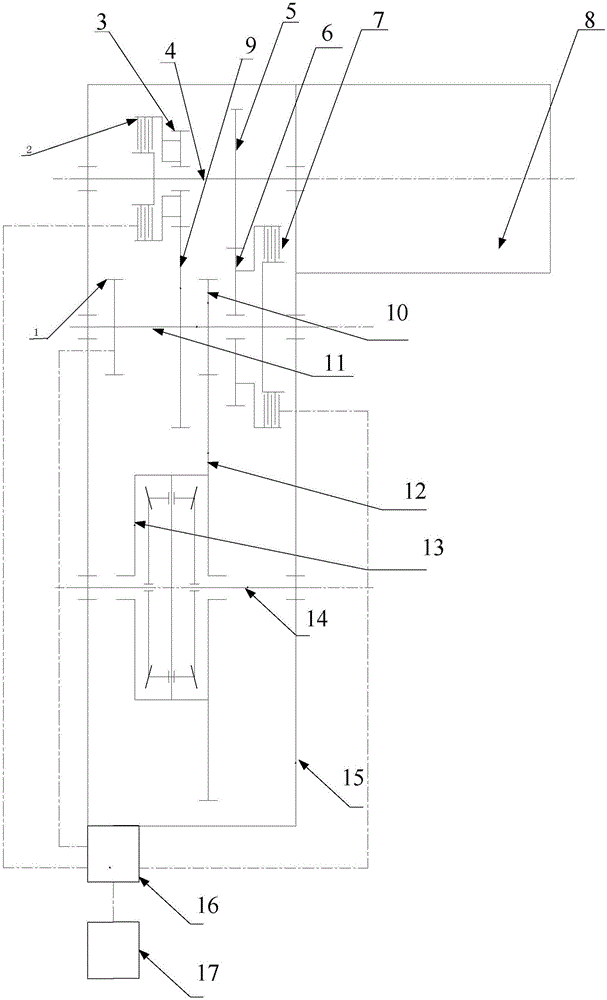

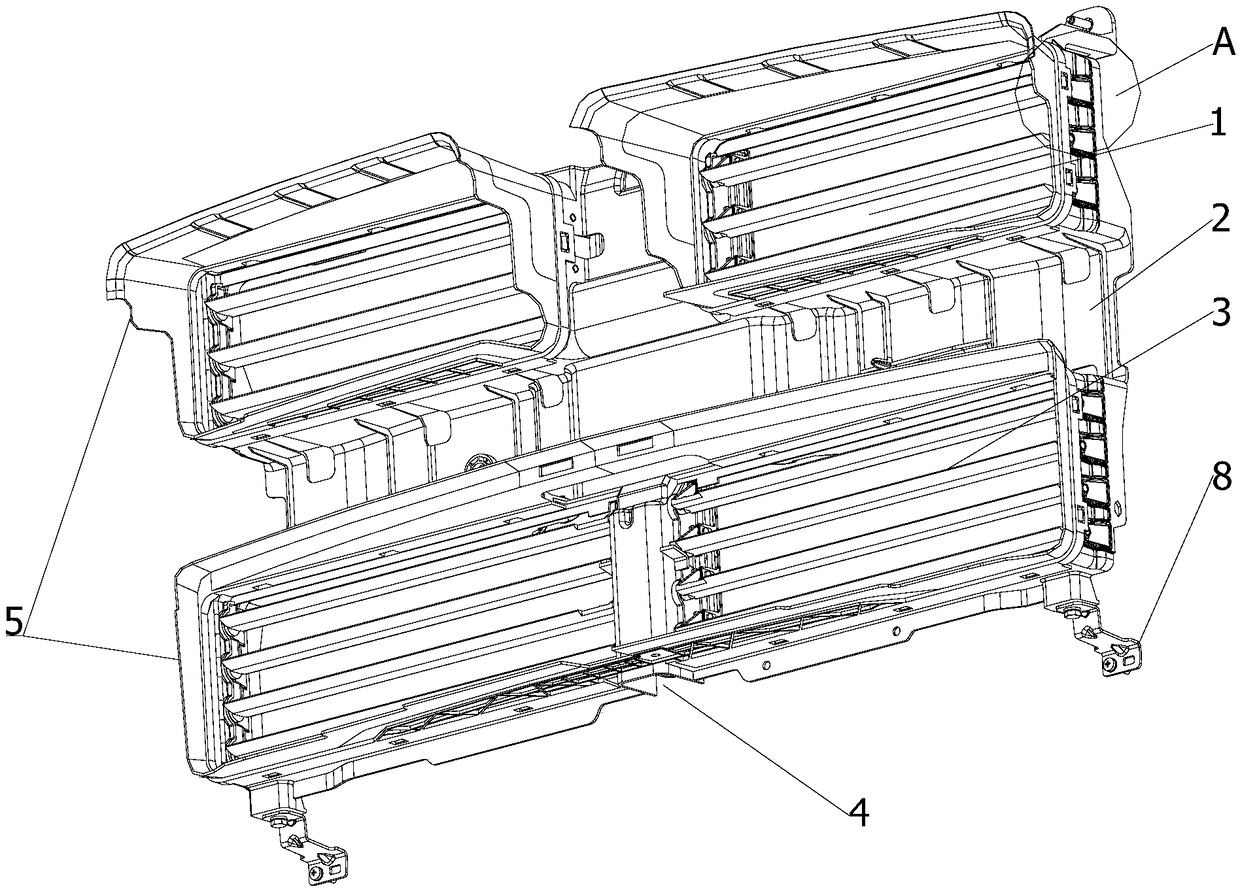

Integrated driving device for two-level electric vehicle

InactiveCN105757210AImprove acceleration performanceImprove climbing abilityGearboxesGearingElectric machineDrive motor

The invention relates to an integrated driving device for a two-level electric vehicle. The integrated driving device is composed of a driving motor, a transmission and a differential mechanism. The transmission comprises an input shaft and an intermediate shaft. An intermediate shaft gear, a first-level reduction gear, a synchronizer and a second-level reduction gear are sequentially arranged on the intermediate shaft from right to left. A first spline, a second spline, a first-level gear and a second-level gear are sequentially arranged on the input shaft from right to left. An output shaft of the driving motor is connected to the first spline of the input shaft of the transmission. The second spline is fixedly sleeved with a parking gear. The first-level reduction gear is meshed with the first-level gear. The second-level reduction gear is meshed with the second-level gear. The second-level reduction gear and the differential mechanism are integrated. The second-level reduction gear is fixedly arranged on a differential mechanism shell in a sleeving mode and meshed with the intermediate shaft gear. Two axle shaft gears are fixedly into the differential mechanism shell. The axle shaft gears are connected with vehicle axle shaft splines. The integrated driving device has the advantages of being compact in structure and high in integration, and the performance of the electric vehicle is greatly improved.

Owner:CHINA FIRST AUTOMOBILE

Hybrid power coupled transmission device

InactiveCN106114185AImprove recycling efficiencyUniform load distributionHybrid vehiclesGas pressure propulsion mountingMotor speedLow speed

The invention provides a hybrid power coupled transmission device. The hybrid power coupled transmission device comprises a power output system and a mechanical transmission system, wherein the power output system comprises an engine, an engine output shaft, a transmission auxiliary motor, a transmission auxiliary motor output shaft, a driving motor and a driving motor output shaft; and the mechanical transmission system comprises an engine output shaft gear, a shock absorber, an engine brake, a planet gear row, a transmission auxiliary motor speed reducing gear, a transmission auxiliary motor brake, a driving motor speed reducing gear and an output shaft. The hybrid power coupled transmission device aims at solving the problems of vibration and noise caused by low speed large torque and medium and high speed of double planet gears in the power and transmission systems, the motor cooling problem and the lubrication problem of the transmission system, the overall efficiency of the power system and the transmission system is improved, and the service life of the power system and the transmission system is prolonged.

Owner:湖州伊立机械有限公司

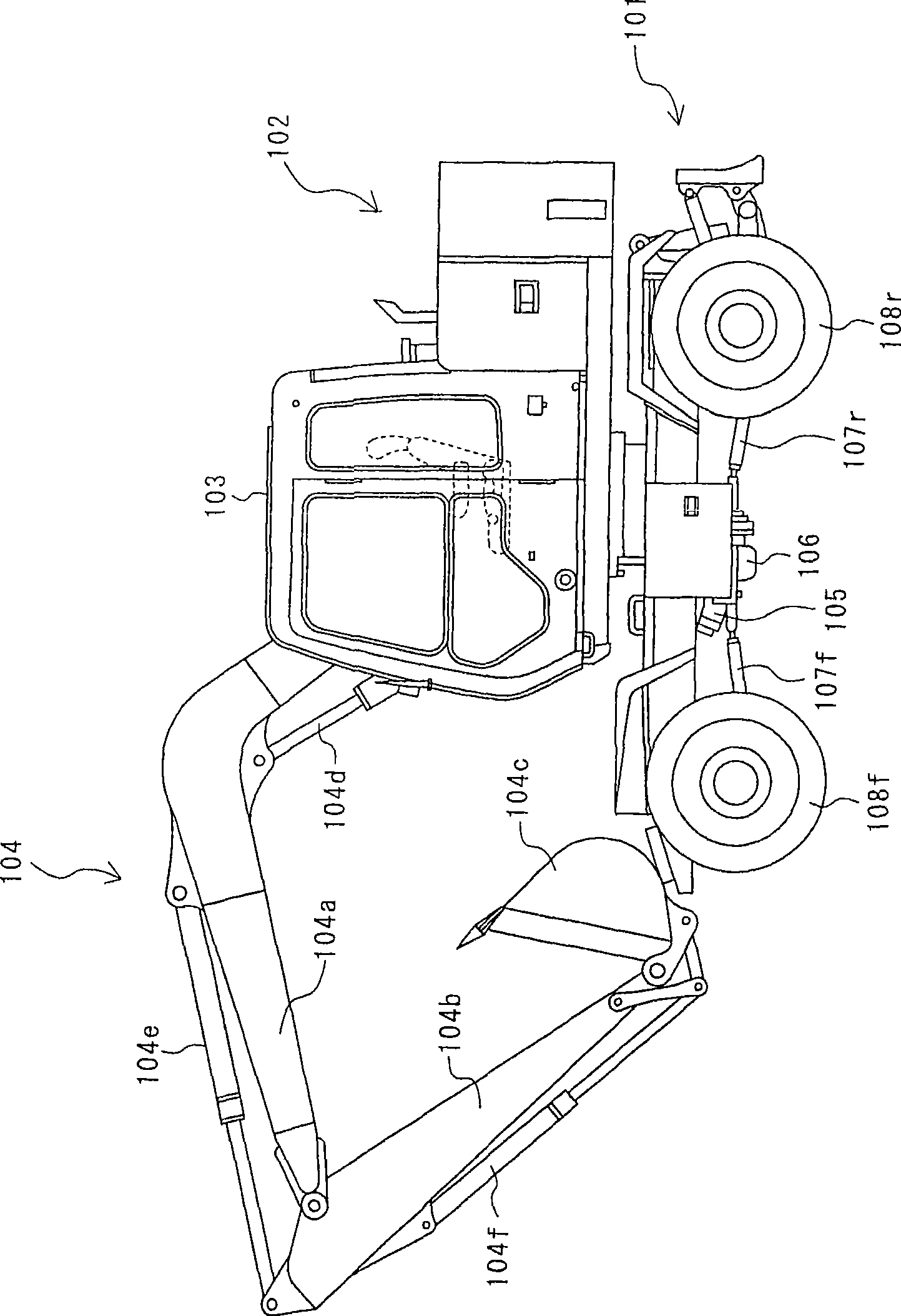

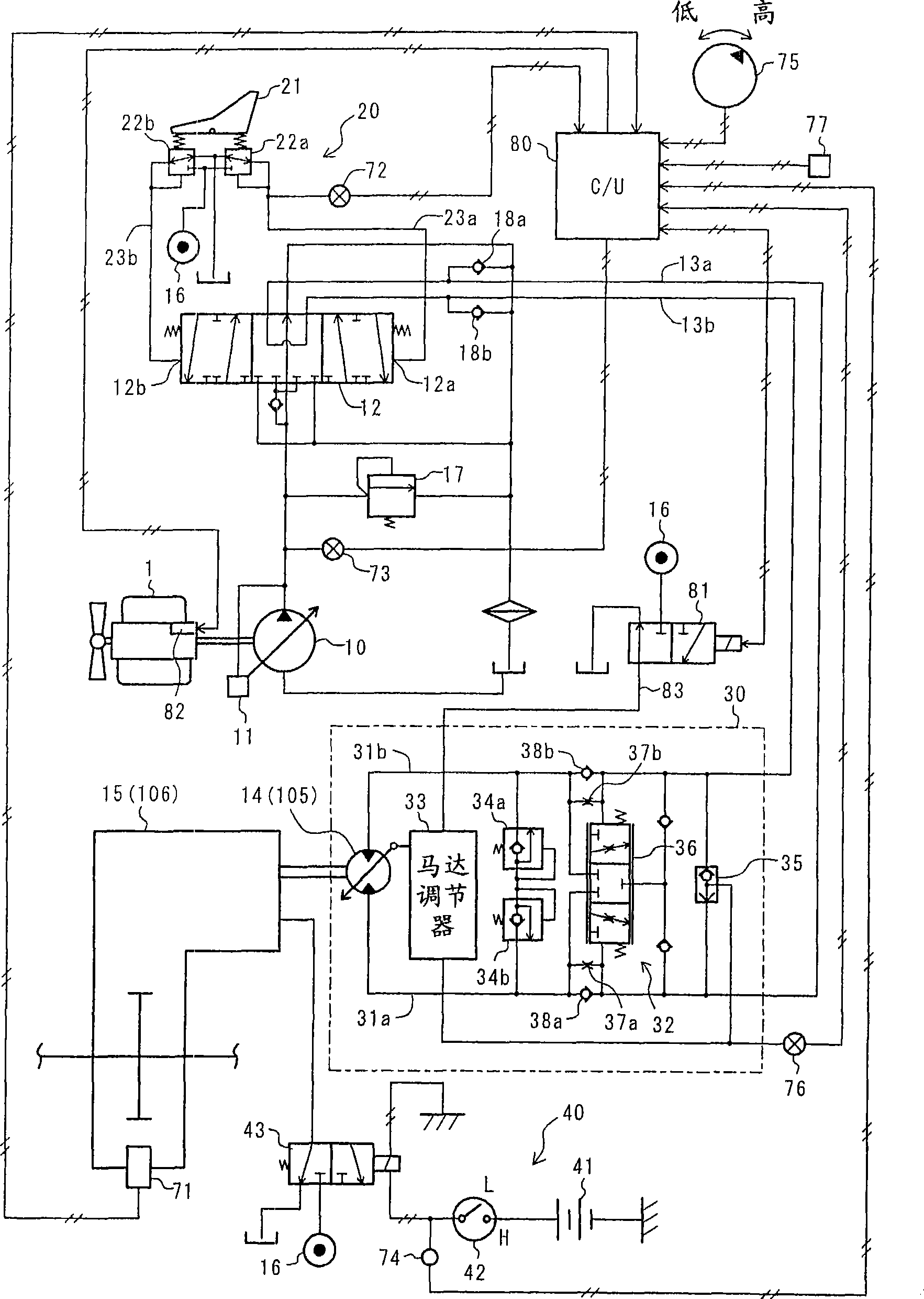

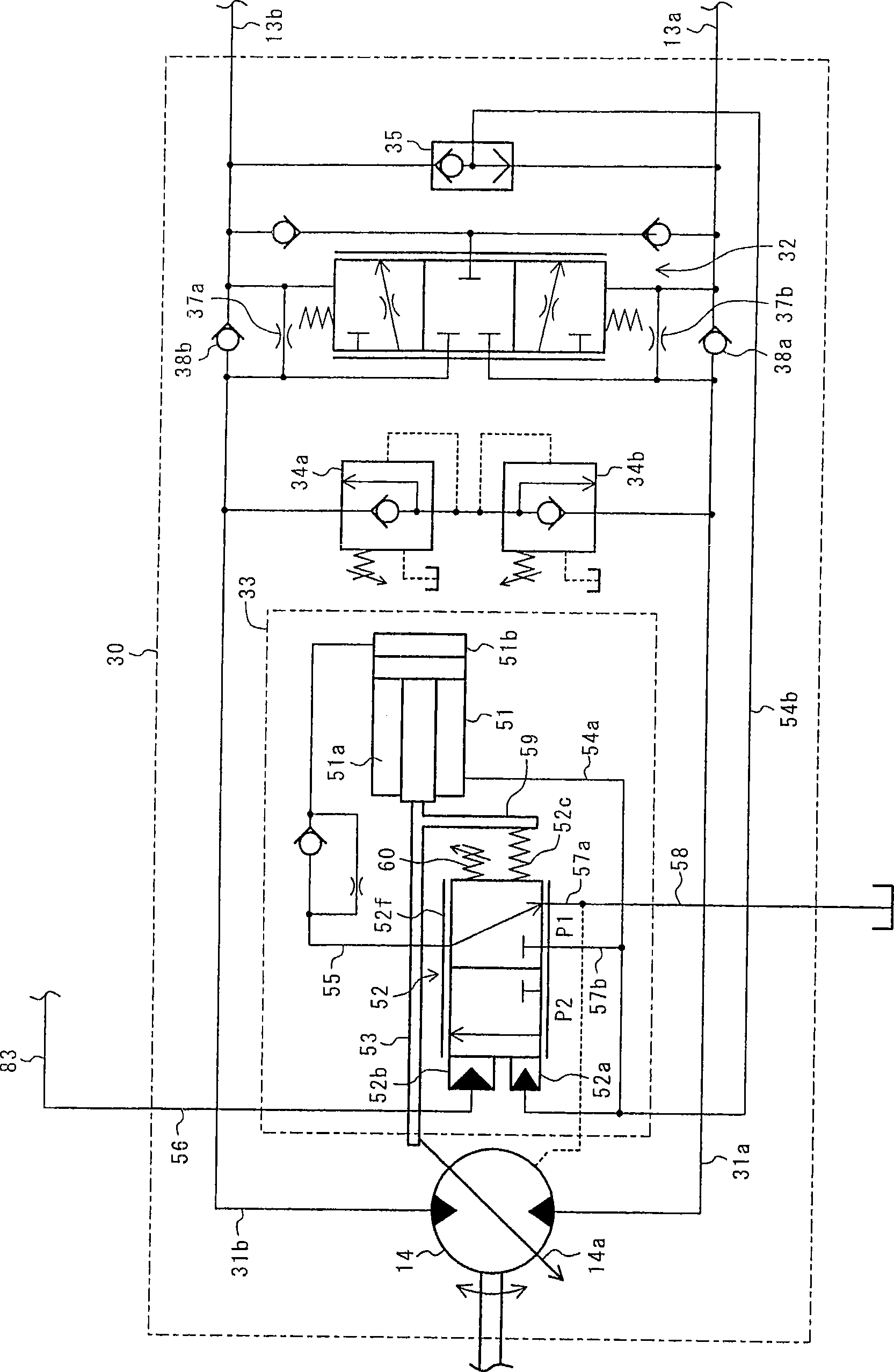

Travel control device for hydraulic traveling vehicle

InactiveCN101535687AIncrease equivalent capacityIncrease maximum flowRoad transportGearing controlTraffic volumeTraffic capacity

A rotational speed pickup 71 (traveling speed detection means), a hydraulic pressure sensor 72 (traveling operation detection means), a hydraulic pressure sensor 73 (drive status detection means), and a voltage sensor 74 (transmission shift position detection means) detect parameters regarding the traveling state of a hydraulic traveling vehicle. A control unit 80, a solenoid proportional valve 81, an engine control system 82, and a motor regulator 33 determine the operating state of the hydraulic traveling vehicle based on the parameters regarding the traveling state, and control the equivalent displacement of the traveling system including a hydraulic traveling motor 14 and the maximum flow rate supplied to the hydraulic traveling motor 14 according to the result of determination. The pump flow rate and motor displacement are controlled according to the traveling state in this way, thereby ensuring favorable traveling performance without degrading the fuel efficiency.

Owner:NIHON KENKI CO LTD

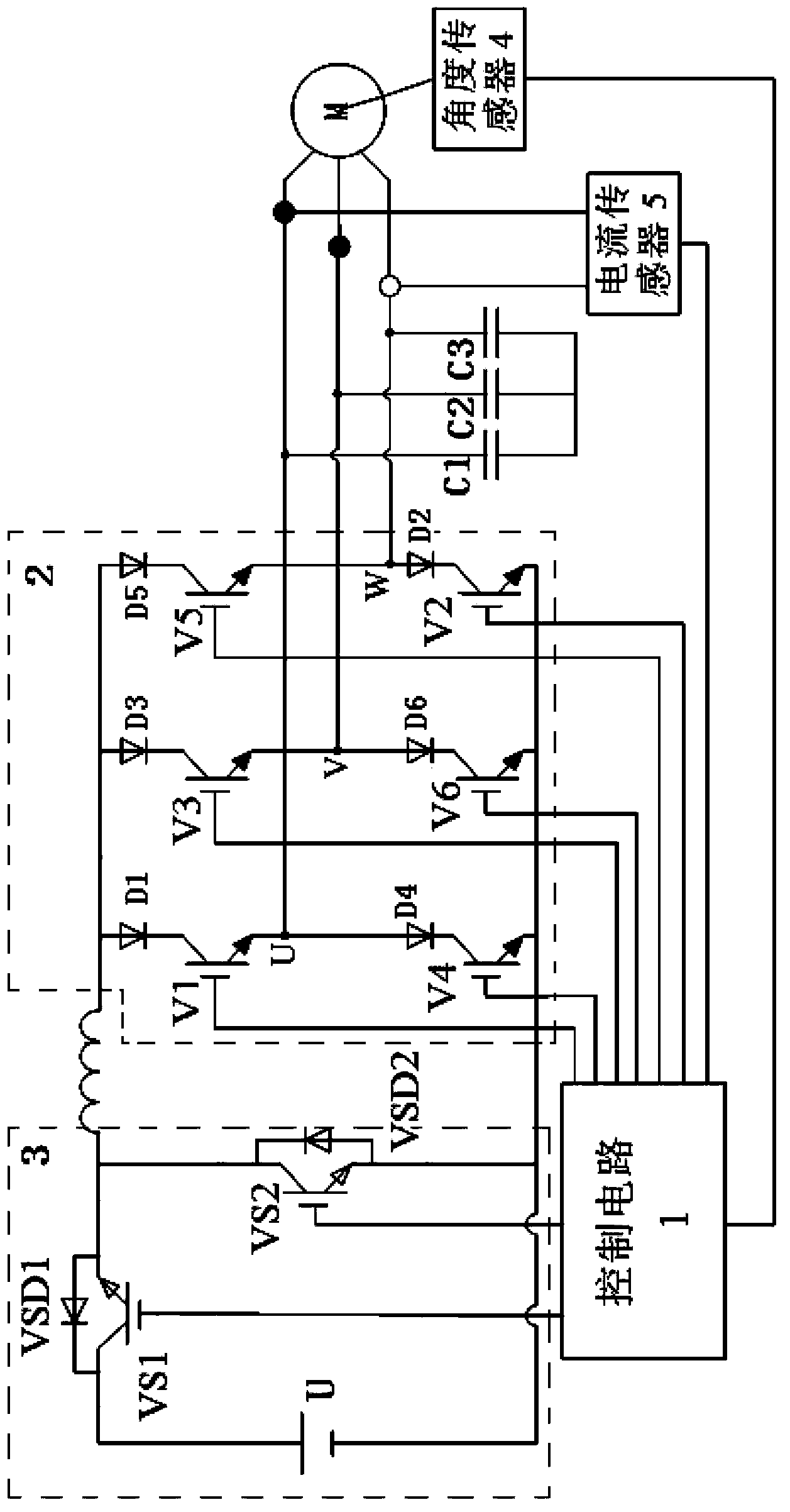

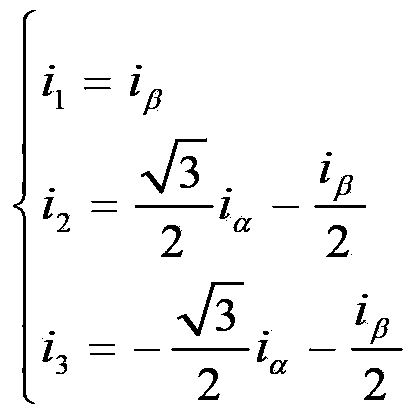

Disc-type coreless permanent-magnet synchronous motor controller based on current inverter and method

InactiveCN103401499ARealize speed controlIncrease top speedElectronic commutation motor controlAC motor controlControl signalPermanent magnet synchronous motor

The invention relates to a disc-type coreless permanent-magnet synchronous motor controller based on a current inverter and a method. The disc-type coreless permanent-magnet synchronous motor controller comprises a control circuit, a three-phase inverting circuit and a step-down chopper circuit, wherein the three-phase inverting circuit is used for driving a disc-type coreless motor, and the signal input end of the three-phase inverting circuit is connected with the signal output end of the control circuit; the control signal input end of the step-down chopper circuit is connected with the signal output end of the control circuit, and the current output end of the step-down chopper circuit is connected with the current input end of the three-phase inverting circuit through an inductor L; the output shaft of the disc-type coreless motor is connected with the signal input end of the control circuit through an angle sensor; and the three-phase current outputs of the three-phase inverting circuit are respectively connected with the signal input end of the control circuit through a current sensor. The controller controls the speed regulation of the disc-type coreless permanent-magnet synchronous motor and increases the maximum speed of the motor. The controller has the characteristics of small current pulsation, good sinusoidal performance, convenience in energy feedback and the like.

Owner:TIANJIN UNIV

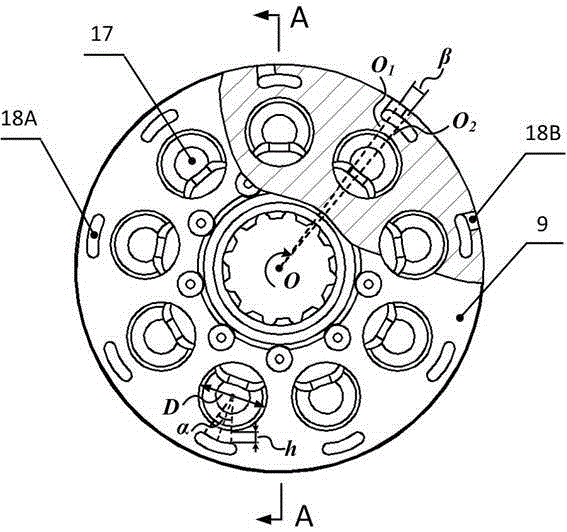

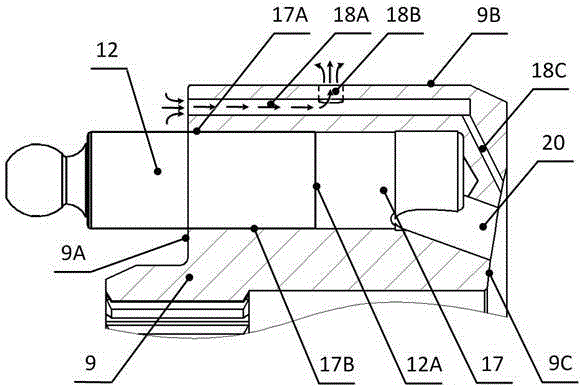

Self-cooling structure for cylinder of swashplate type plunger pump

InactiveCN105201816ADoesn't break smoothnessLow rotational resistancePositive displacement pump componentsPositive-displacement liquid enginesDifferential pressureCentrifugal force

The invention relates to a self-cooling structure for a cylinder of a swashplate type plunger pump. The self-cooling structure comprises the cylinder and a flow-distribution plate, wherein plunger cavities are formed in the front end surface of the cylinder, kidney-shaped holes communicated with the plunger cavities are formed in the back end surface of the cylinder, the back end surface of the cylinder is closely attached to the flow-distribution plate, axial cooling oil channels are formed in the cylinder, radial cooling oil channels for communicating the axial cooling oil channels with the outer circumferential surface of the cylinder are formed in the circumferential side of the cylinder, flow-distribution cooling oil channels for communicating the axial cooling oil channels with the back end surface of the cylinder are formed in the back end surface of the cylinder, an arc through hole-shaped low-pressure oil sucking area and high-pressure oil discharge areas are formed in two sides of a same end surface of the flow-distribution plate, oil grooves are formed between the low-pressure oil sucking area and the high-pressure oil discharge areas, and the plunger cavities are communicated with the low-pressure oil sucking area and the high-pressure oil discharge areas through the kidney-shaped holes. Under the action of the rotating centrifugal force of the cylinder and the pressure difference of the outer circumferential surface of the cylinder, the cooling efficiency is effectively improved; the specific oil grooves of the flow-distribution plate and the cooling oil channels of the cylinder are formed, and the cooling efficiency and reliability are further improved.

Owner:FUZHOU UNIV

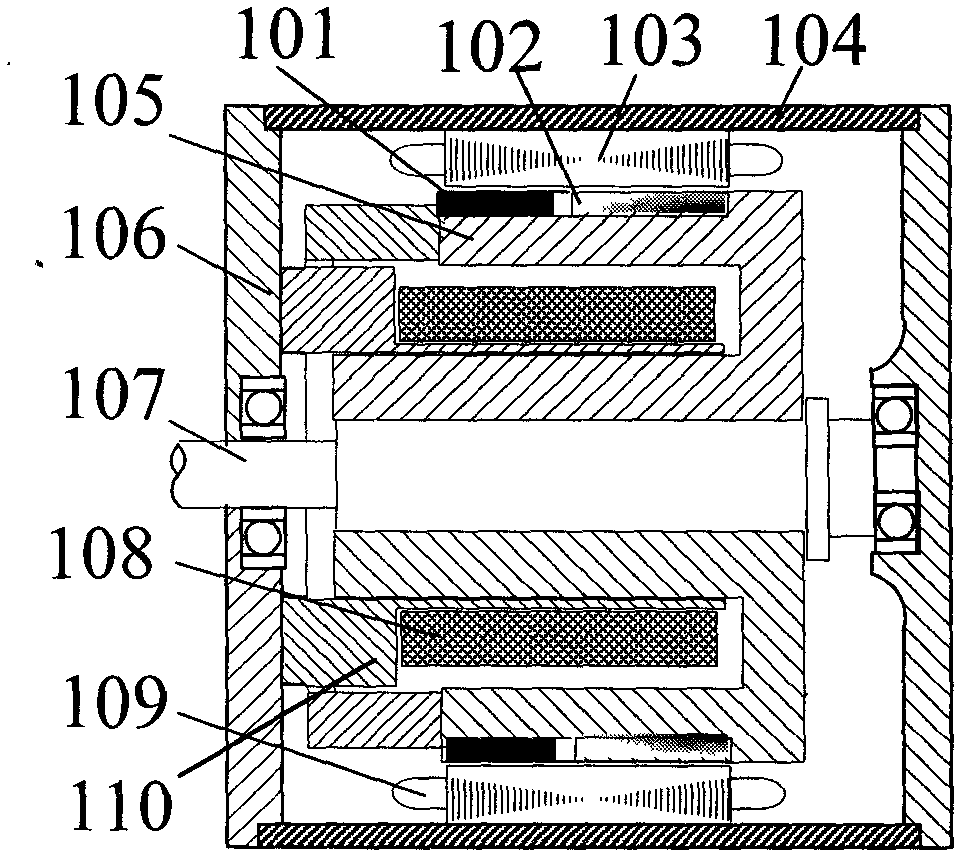

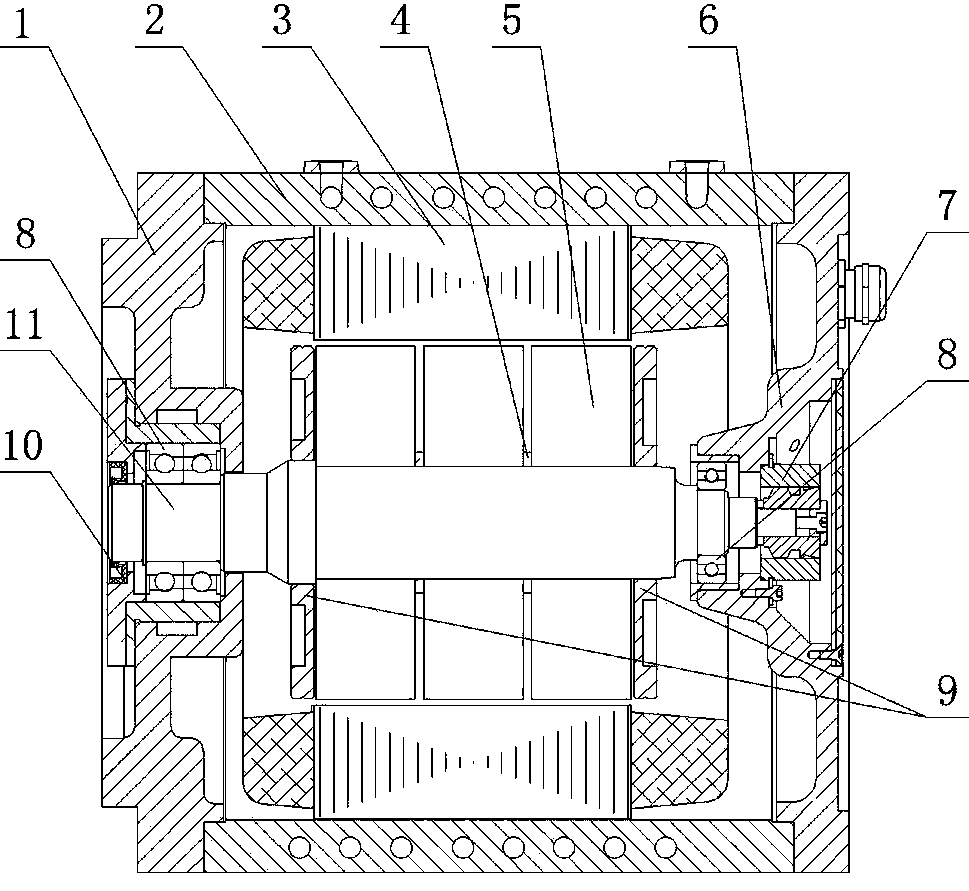

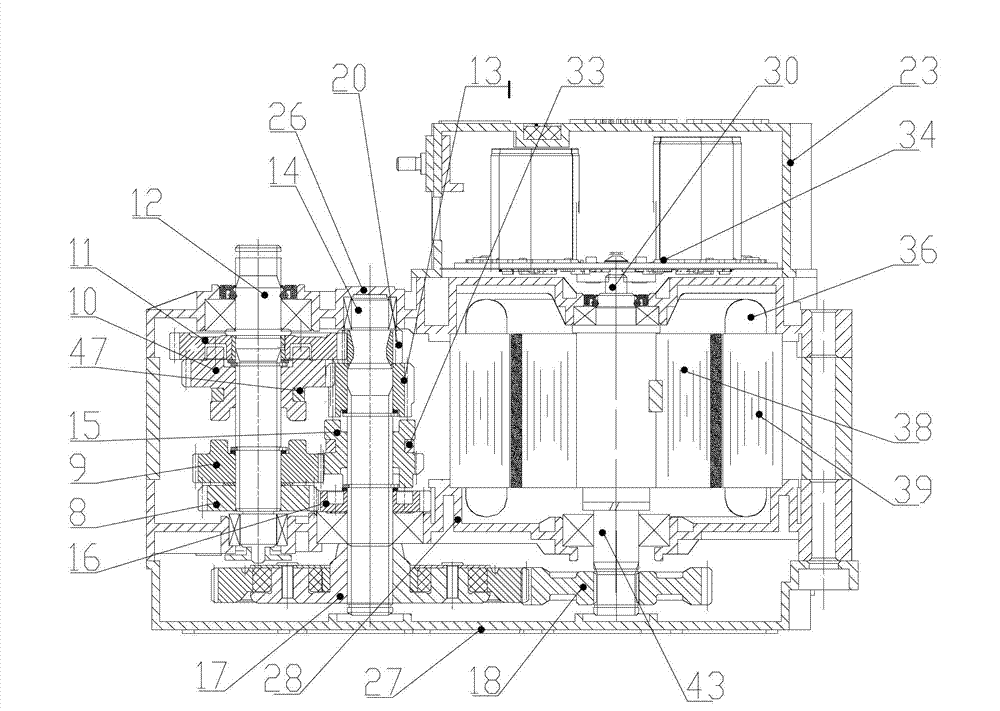

Wide-range speed control permanent magnet synchronous motor used for electric vehicle

InactiveCN103580410AIncrease output torque and powerImprove compatibilityMagnetic circuit rotating partsElectric machinesElectric vehiclePermanent magnet synchronous motor

The invention discloses a wide-range speed control permanent magnet synchronous motor used for an electric vehicle. The wide-range speed control permanent magnet synchronous motor used for the electric vehicle comprises a shell body, wherein a front end cover and a rear end cover are installed at the two ends of the shell body respectively, a stator is installed inside the shell body, a rotor shaft is installed between the front end cover and the rear end cover, at least two rotor modules are installed on the rotor shaft in a sleeved mode, a spacing ring is installed between the rotor modules, a balancing ring is installed between each rotor module and the front end cover, and a balancing ring is installed between each rotor module and the rear end cover. Due to the fact that the at least two rotor modules are installed on the rotor shaft, the output torque and power of the motor can be increased by increasing the number of the rotor modules and the length of the stator on the premise that the radial size is not changed, and compatibility of the motor is improved greatly; by optimizing the magnetic structure, reducing air-gap field strength and weakening permanent magnet resistance, the maximum speed of revolution of the motor is increased and the speed control range of the motor is widened finally, and the constant-power range of the permanent magnet synchronous motor is widened greatly.

Owner:CHENGDU LAINTEM MOTORS CONTROL TECH

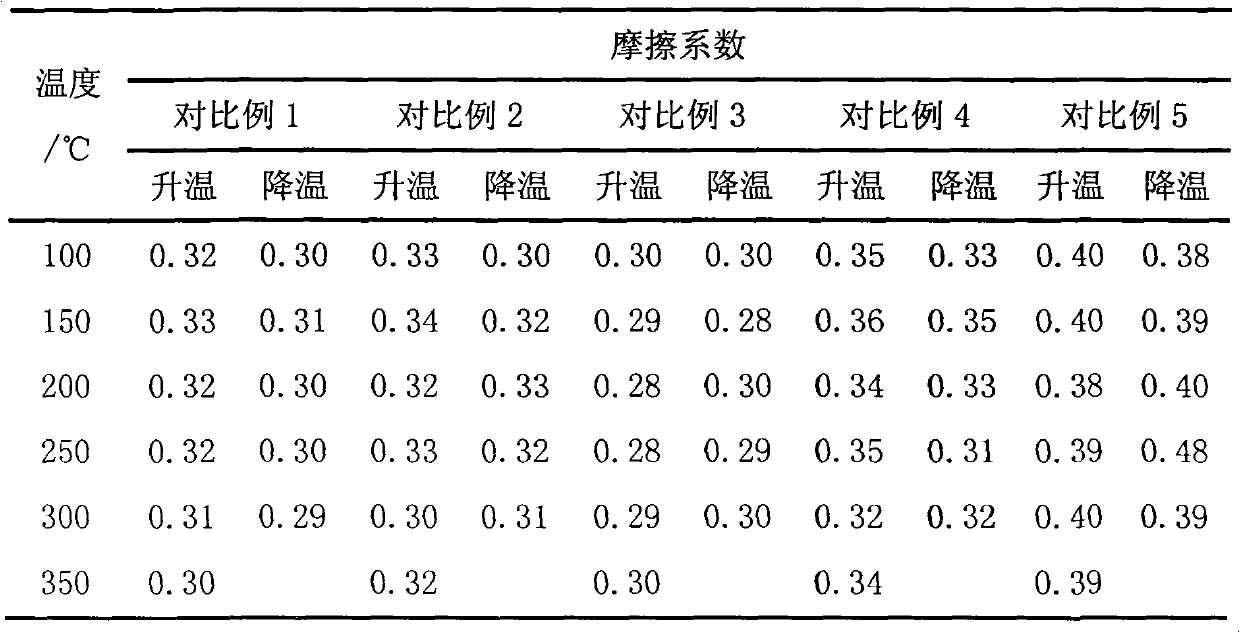

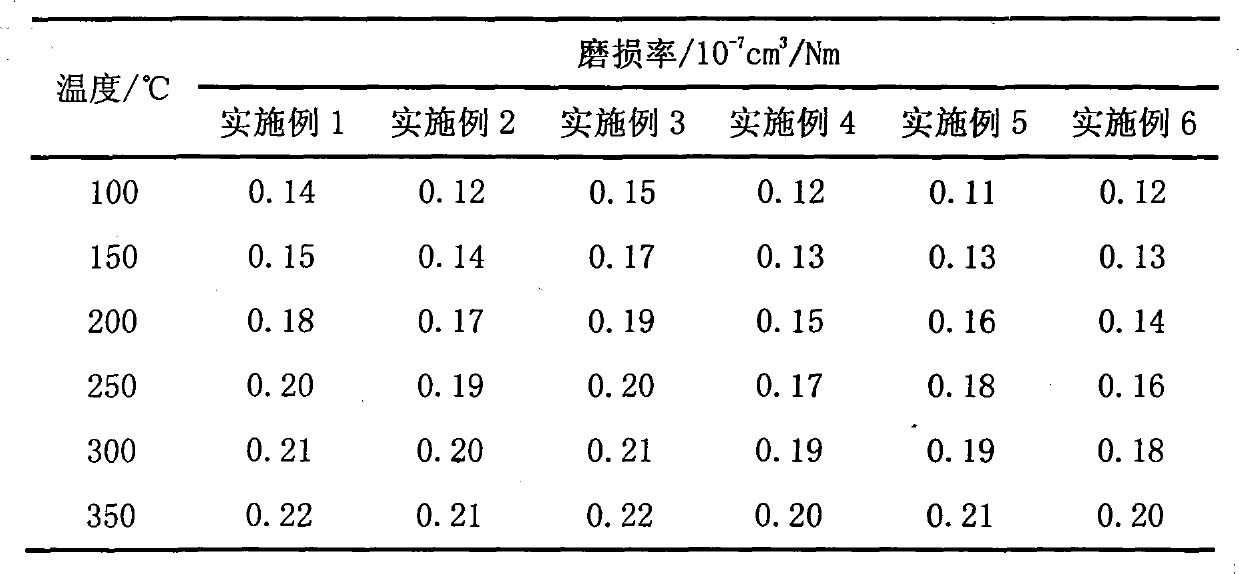

Copper-free ceramic type friction material and preparation method thereof

InactiveCN101948673AImprove thermal conductivityImprove friction performanceOther chemical processesCeramic shaping apparatusFiberAlkaline earth metal

The invention discloses a copper-free ceramic type friction material and a preparation method thereof. The friction material at least comprises 2 to 30 mass percent of alkaline earth-based metallic compound and 2 to 30 mass percent of carbon fiber, wherein the alkaline earth-based metallic compound is MxFeyTiOz, M is alkaline earth metallic element, namely Be, Mg, Ca, Sr or Ba, x is 0.2 to 2, y is 1 to 2, and z is 4 to 16. The friction material prepared by the method has the advantages of: high friction and wear property, higher heat conductivity, high performance of resisting high-temperature recession, and capacity of efficiently reducing the temperature of a friction surface in the braking process.

Owner:南京钛威科技有限公司 +1

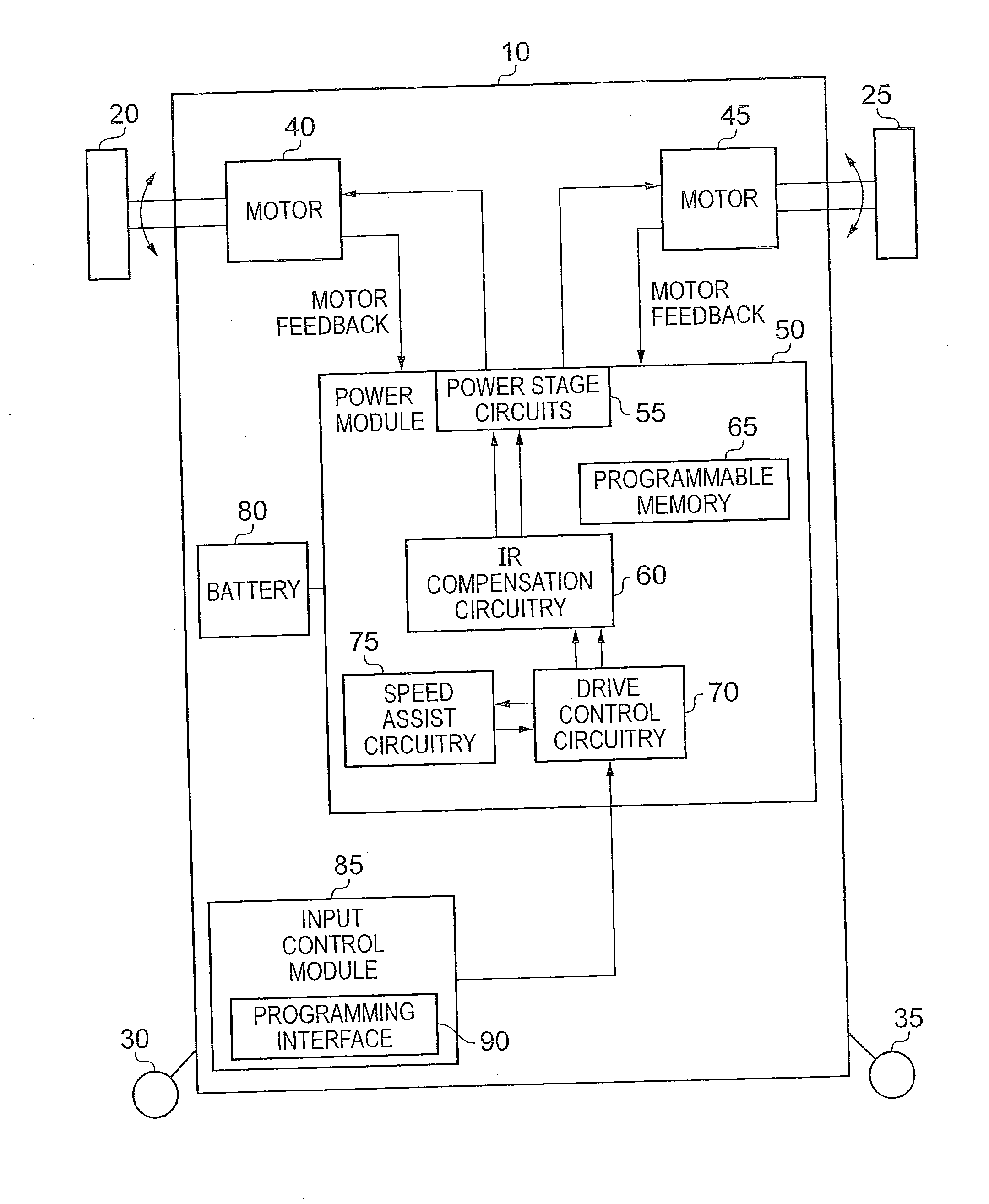

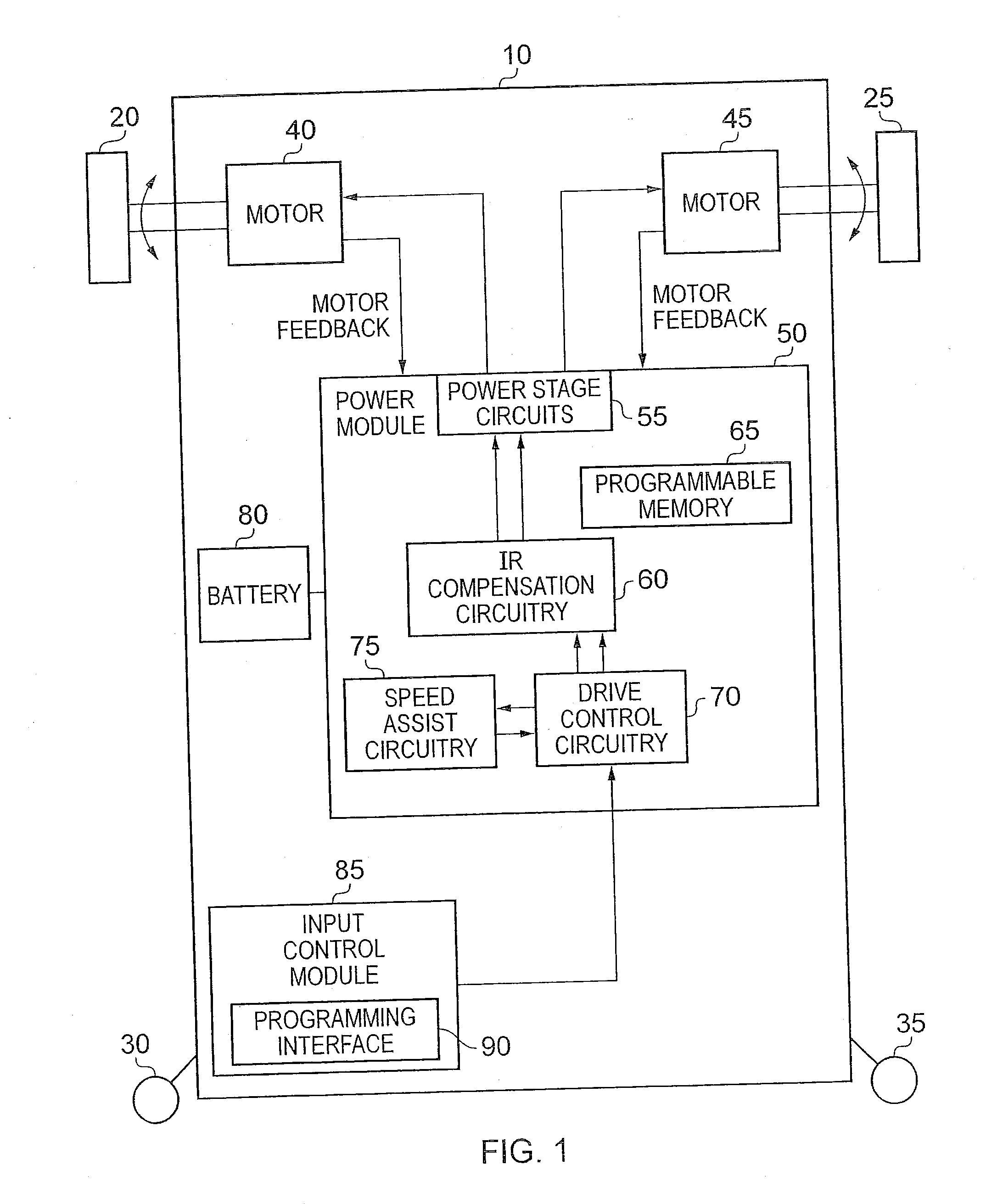

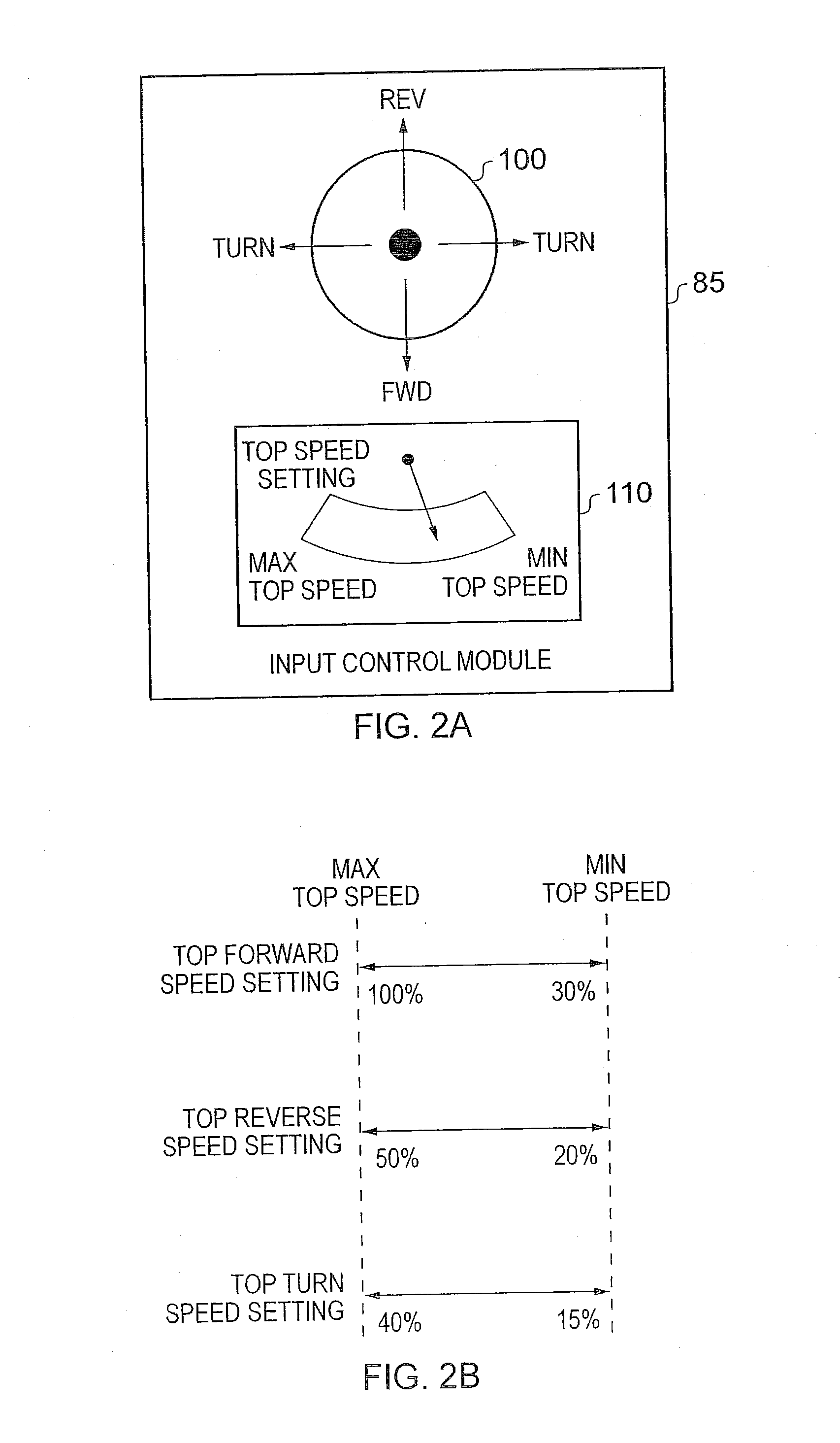

Controller And Control Method For A Motorised Vehicle

ActiveUS20110071711A1Compensate for such errorMaintaining stability and controlSpeed controllerDigital data processing detailsLow speedWheelchair

A controller and control method for a motorised vehicle such a wheelchair are provided. The motorised vehicle has at least two driven wheels driven independently by a motor arrangement, and the controller receives a number of input signals from a user input device of the motorised vehicle. The controller comprises drive control circuitry for generating control signals for controlling the driving of the driven wheels by the motor arrangement, the control signals being dependent on the input signals. Speed assist circuitry is responsive to an indication of current consumed in driving the driven wheels to detect occurrence of a loading condition. On detection of occurrence of a loading condition, the speed assist circuitry is then arranged to boost at least one of the input signals in order to boost top speed in the presence of the loading condition. This significantly improves the control of the motorised vehicle in situations where the occurrence of the loading condition may otherwise prevent the vehicle from moving, as for example may occur when seeking to turn the vehicle at low speed.

Owner:PENNY & GILES CONTROLS

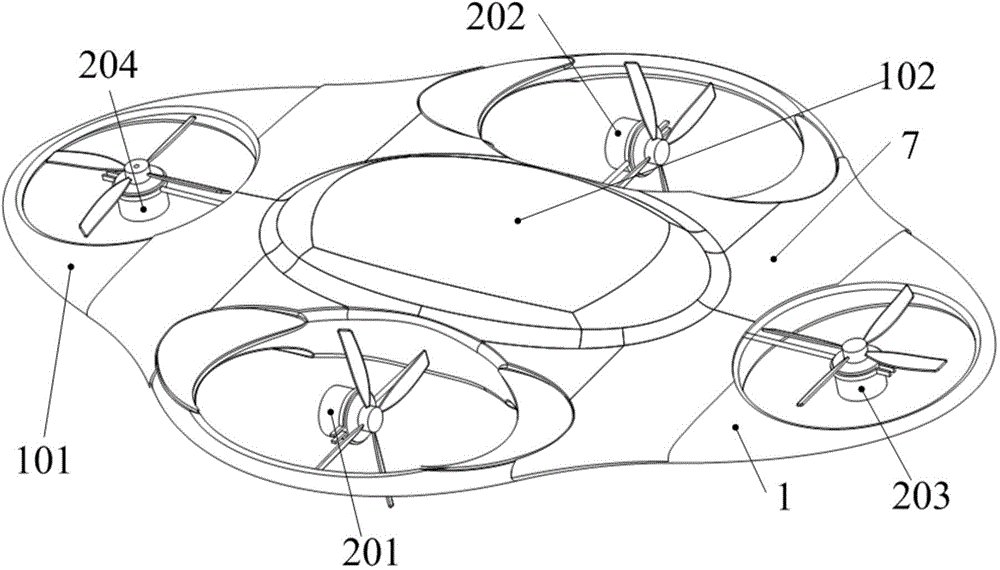

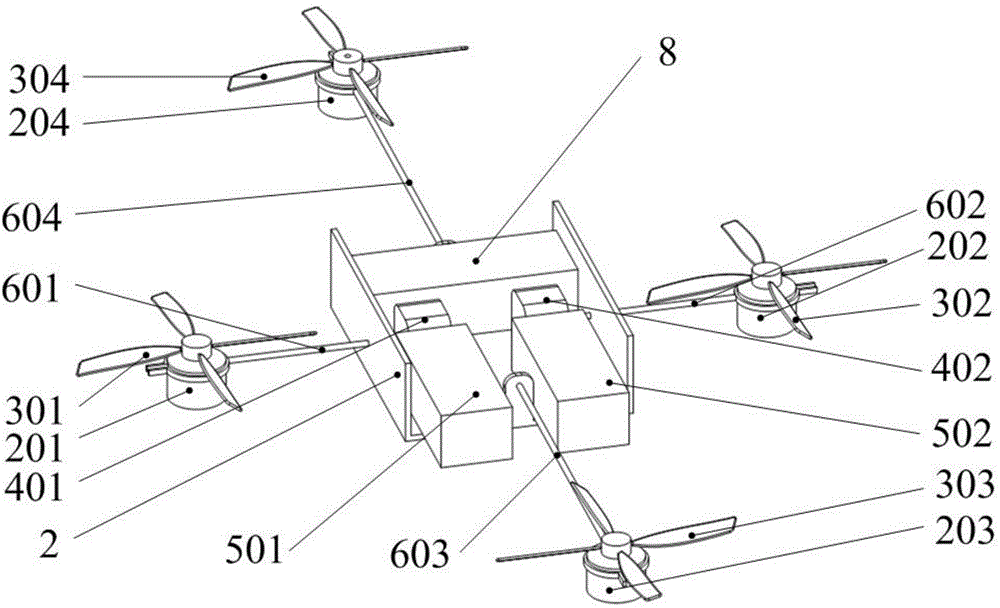

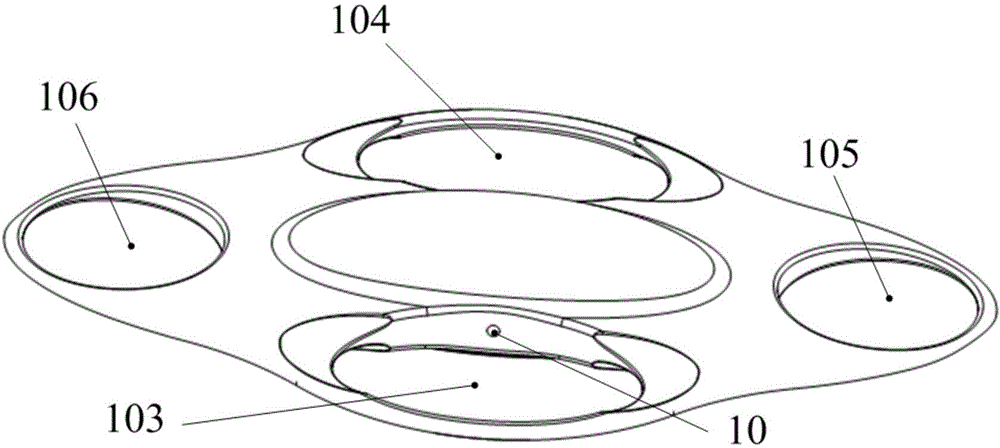

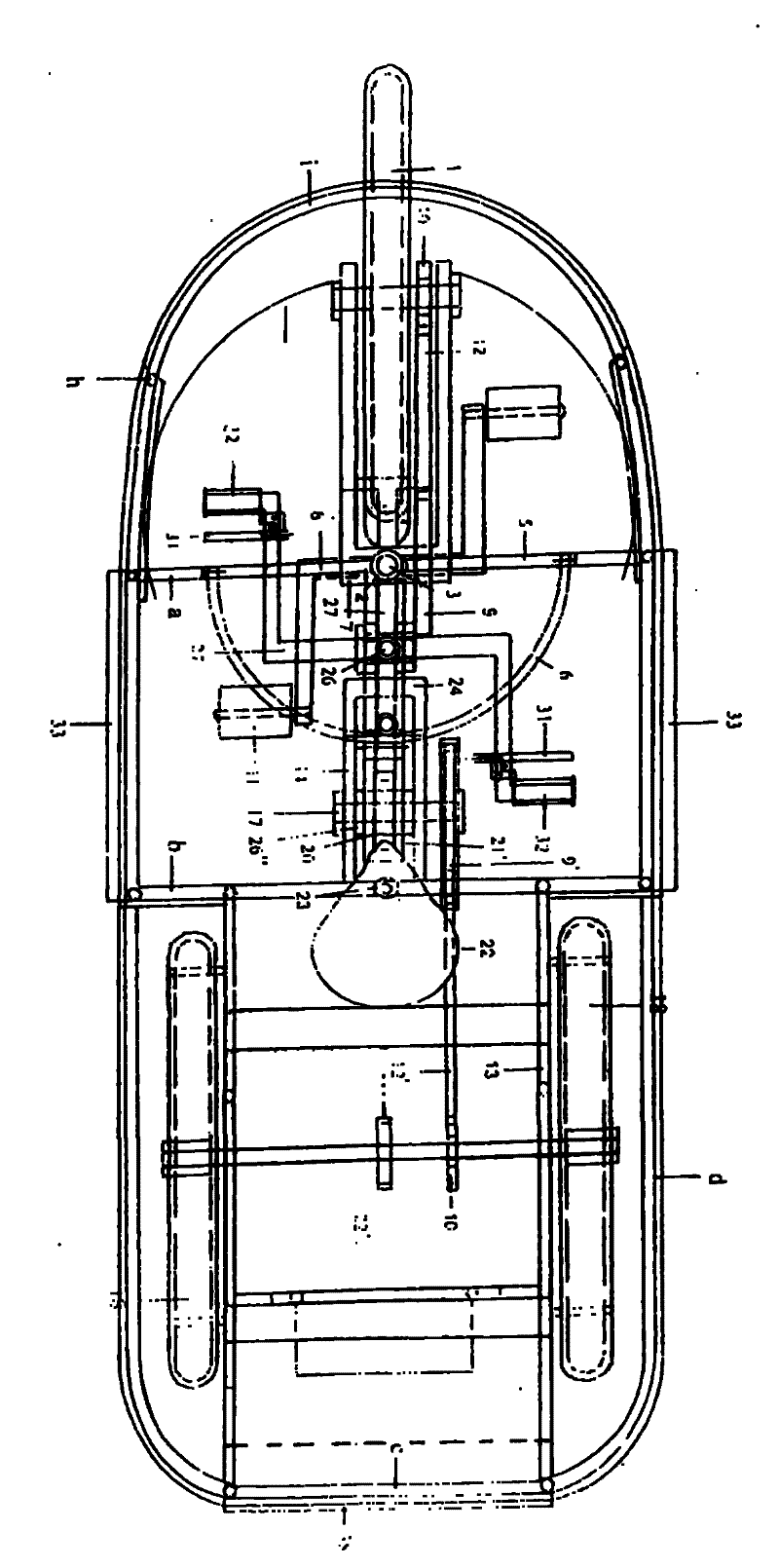

Solar aircraft

InactiveCN104401486AIncrease top speedImprove battery lifeAircraft power plant componentsEnergy efficient board measuresBrushless motorsSolar cell

The invention discloses a solar aircraft and aims to solve the problems that the cruising capability of a conventional aircraft is limited, the flight attitude is single, the aircraft cannot hover, and the safety is low. The solar aircraft comprises a housing (1), a power device and an energy unit, wherein the housing (1) comprises a lower housing (101) and an upper housing (102); an elliptical hole is formed in the center of the top end face of the lower housing (101); a first wing through hole, a second wing through hole, a third wing through hole and a fourth wing through hole are formed in four corners of the lower housing (101); the upper housing (102) is buckled on the elliptical hole of the lower housing (101) and is glued by waterproof glue; a first direct current brushless motor, a second direct current brushless motor, a third direct current brushless motor and a fourth direct current brushless motor of the power device are mounted at the end parts of a first short shaft, a second short shaft, a first long shaft and a second long shaft in the first wing through hole, the second wing through hole, the third wing through hole and the fourth wing through hole of the housing (1); a thin-film-type solar cell panel (7) of the energy unit is attached to the surface of the housing (1); a first storage battery pack (501) and a second storage battery pack (502) are fixed at one end of a bottom plate (901) in a base (2) of the power device.

Owner:JILIN UNIV

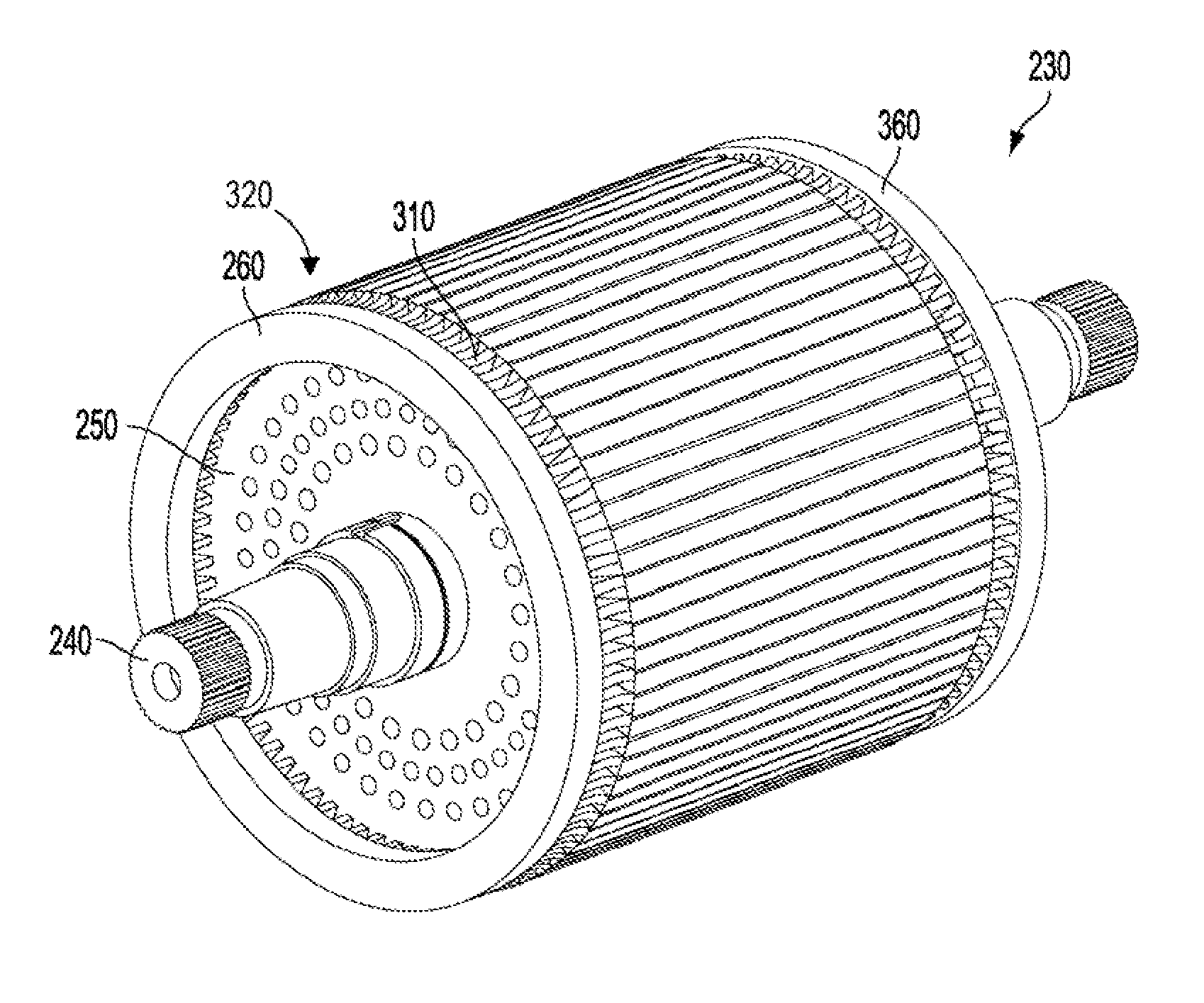

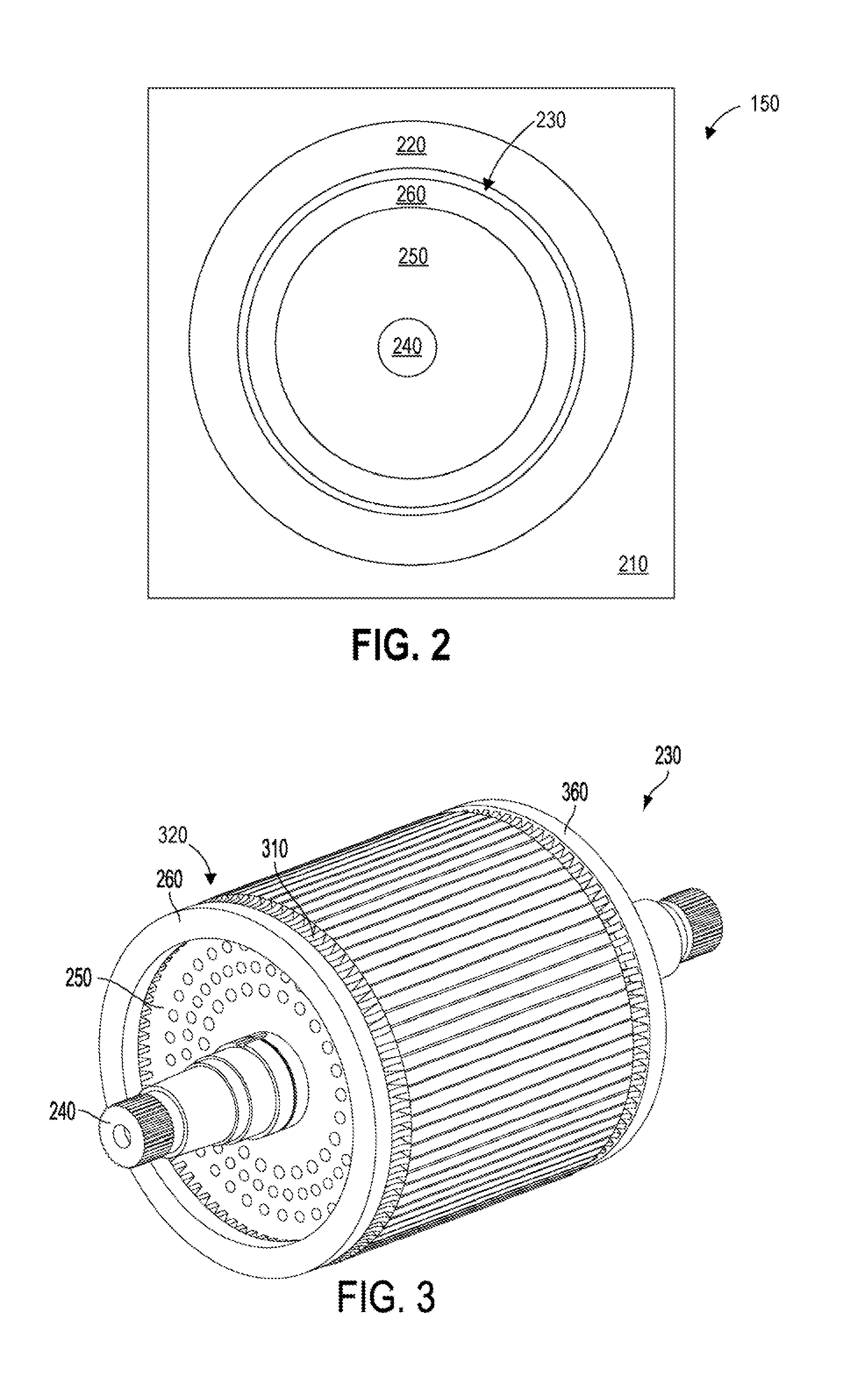

Traction motor

ActiveUS20110254400A1Ring stress can be reducedMean timeMagnetic circuit rotating partsSynchronous motorsPunchingInduction motor

In one embodiment, a rotor for an induction motor comprises a punching assembly, a plurality of conductive bars, and an end-ring. The plurality of conductive bars may be substantially parallel to an axis of the rotor and connected to the punching assembly at a periphery of the punching assembly. Each conductive bar includes an end connected to the end-ring. The end-ring comprises a punching side having a surface facing the punching assembly and a housing side having a surface opposite the punching surface. The end-ring may be thicker on the punching side than the housing side. In this manner, the peak end ring stresses may be reduced at higher speeds and the mean time between failures of the rotor may be increased. Alternatively, the threshold speed may be increased and the top-speed of the off-highway vehicle may be increased for a given expected mean time between failures of the rotor.

Owner:GE GLOBAL SOURCING LLC

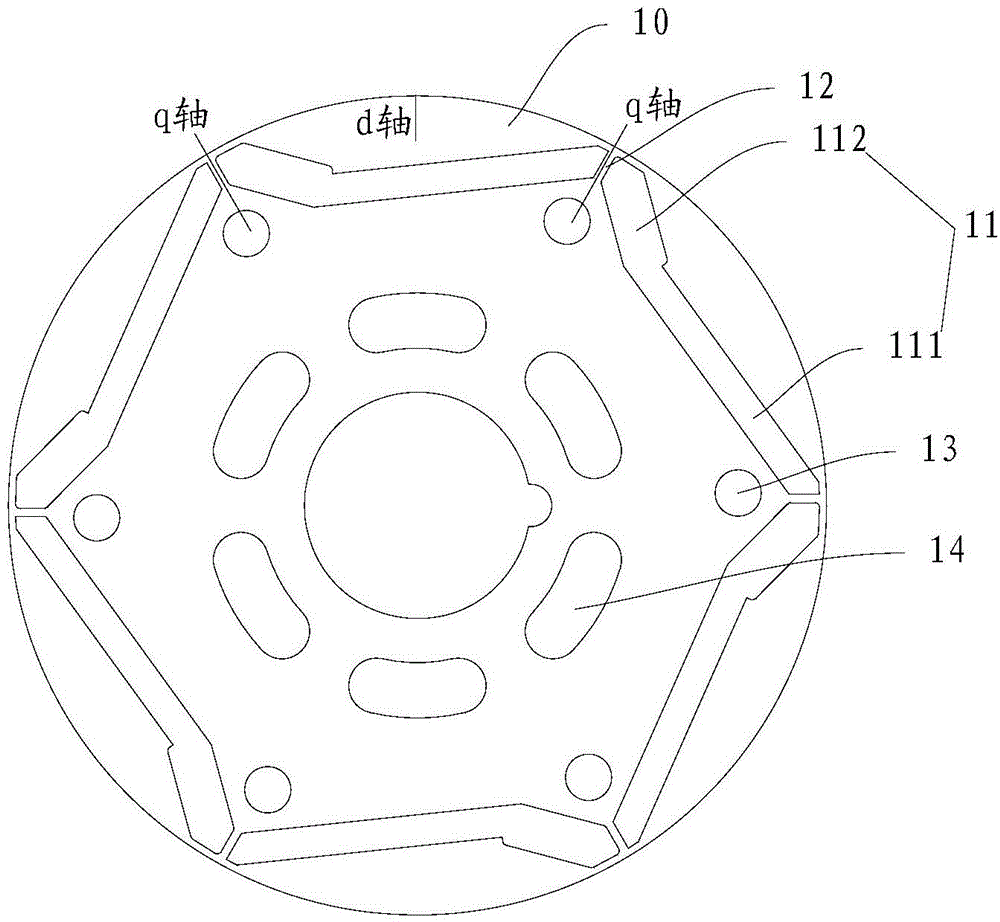

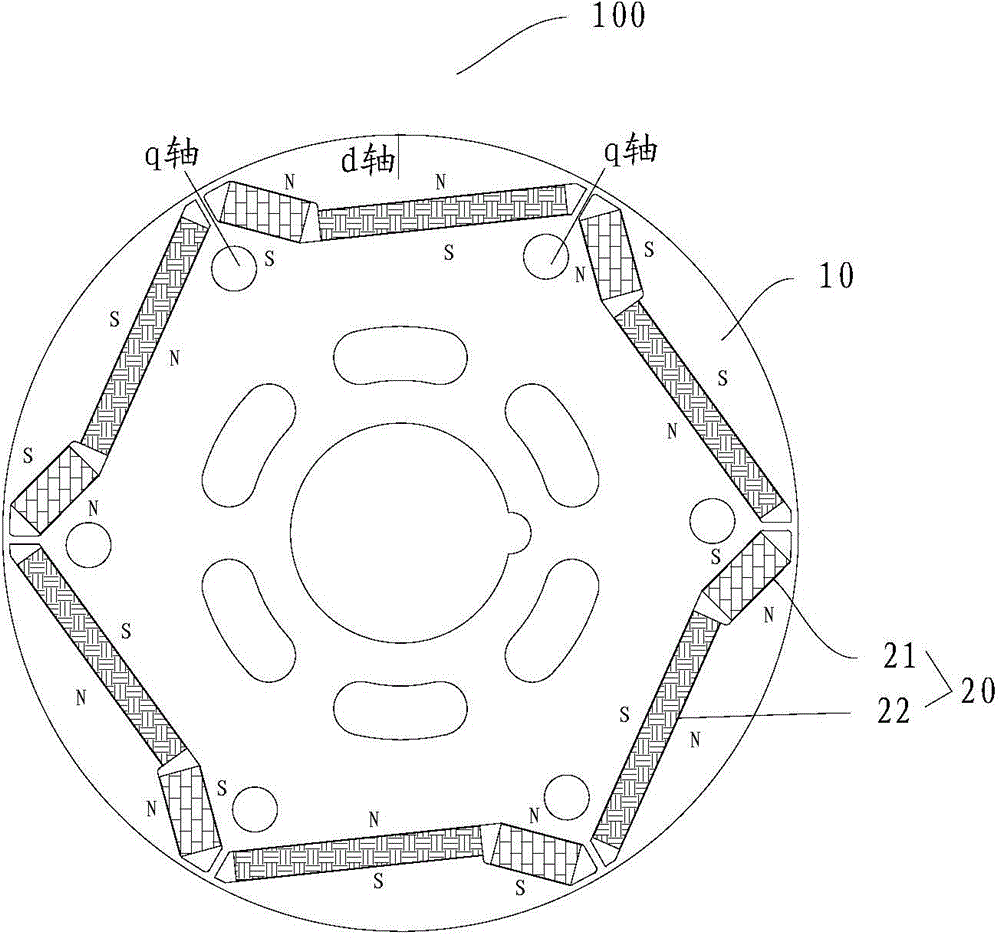

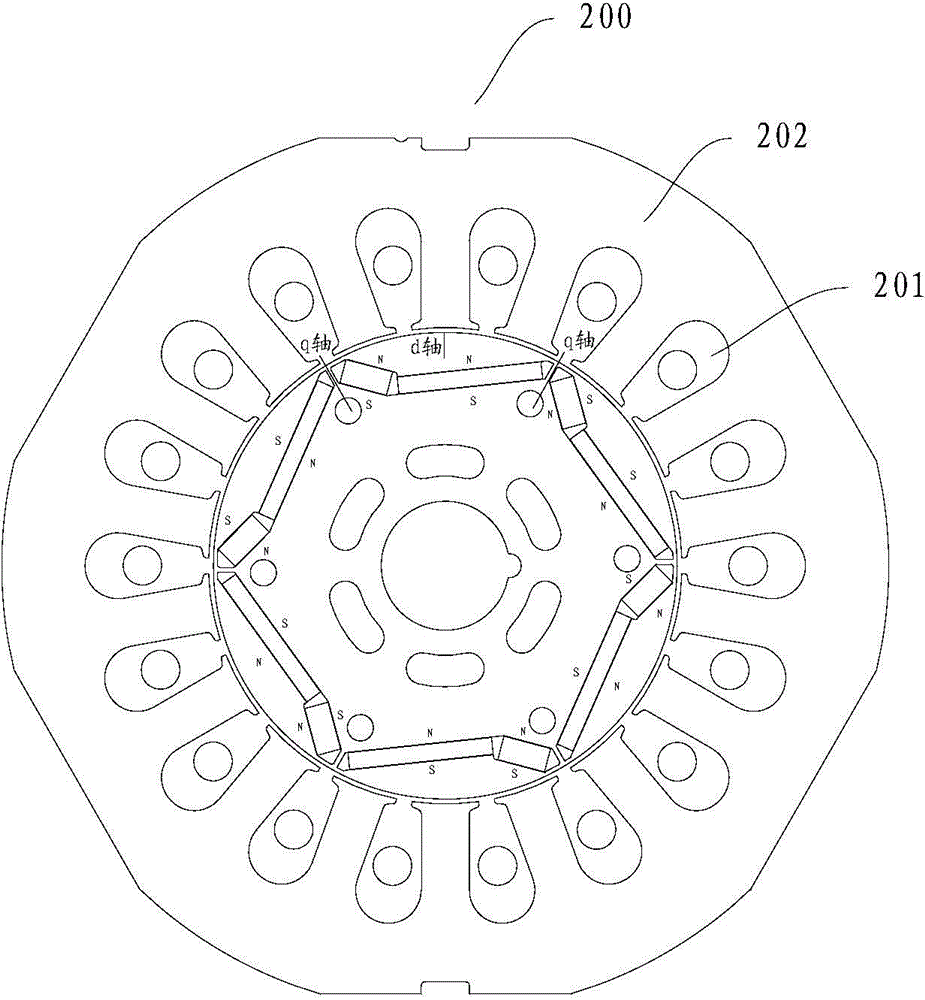

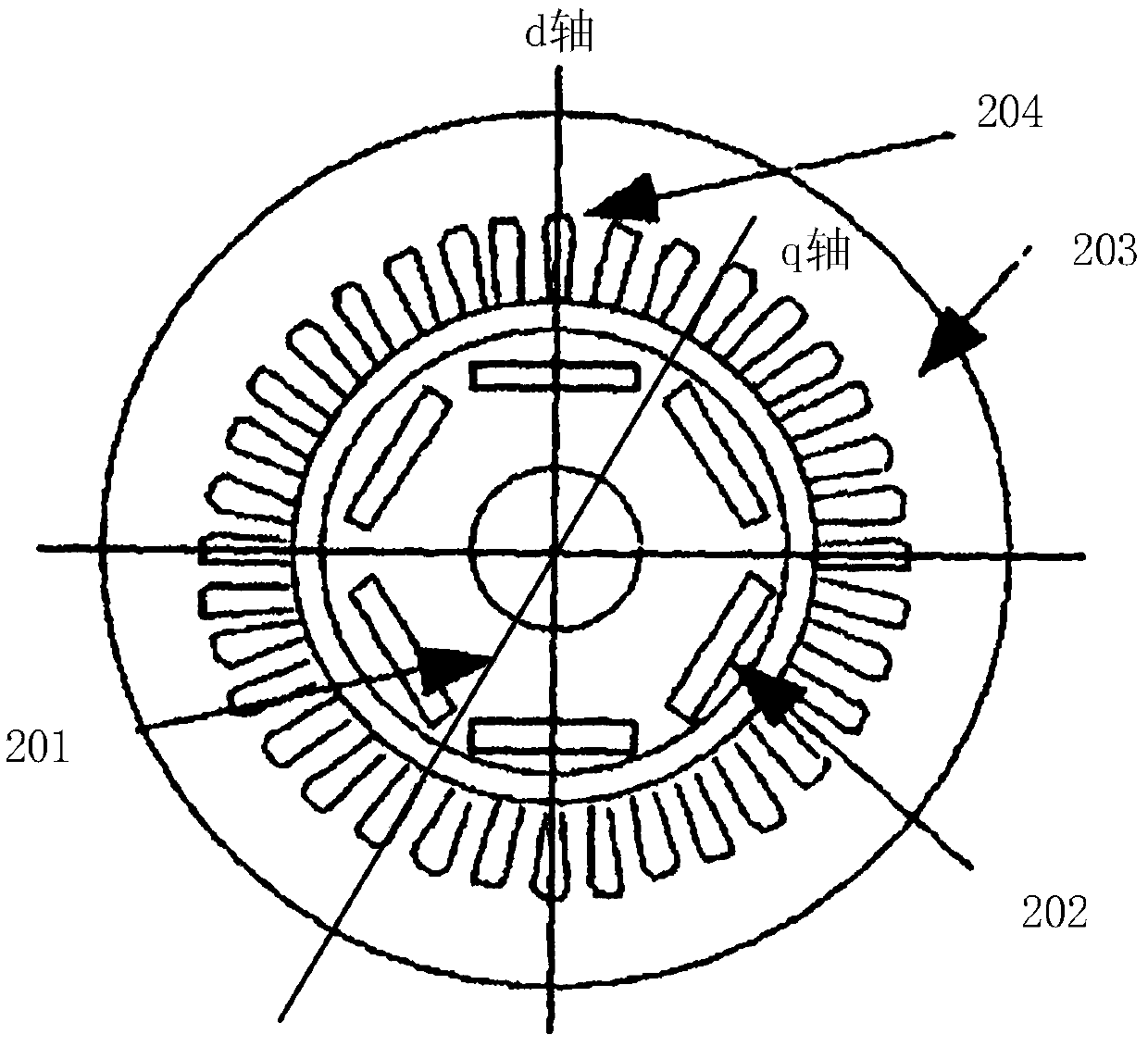

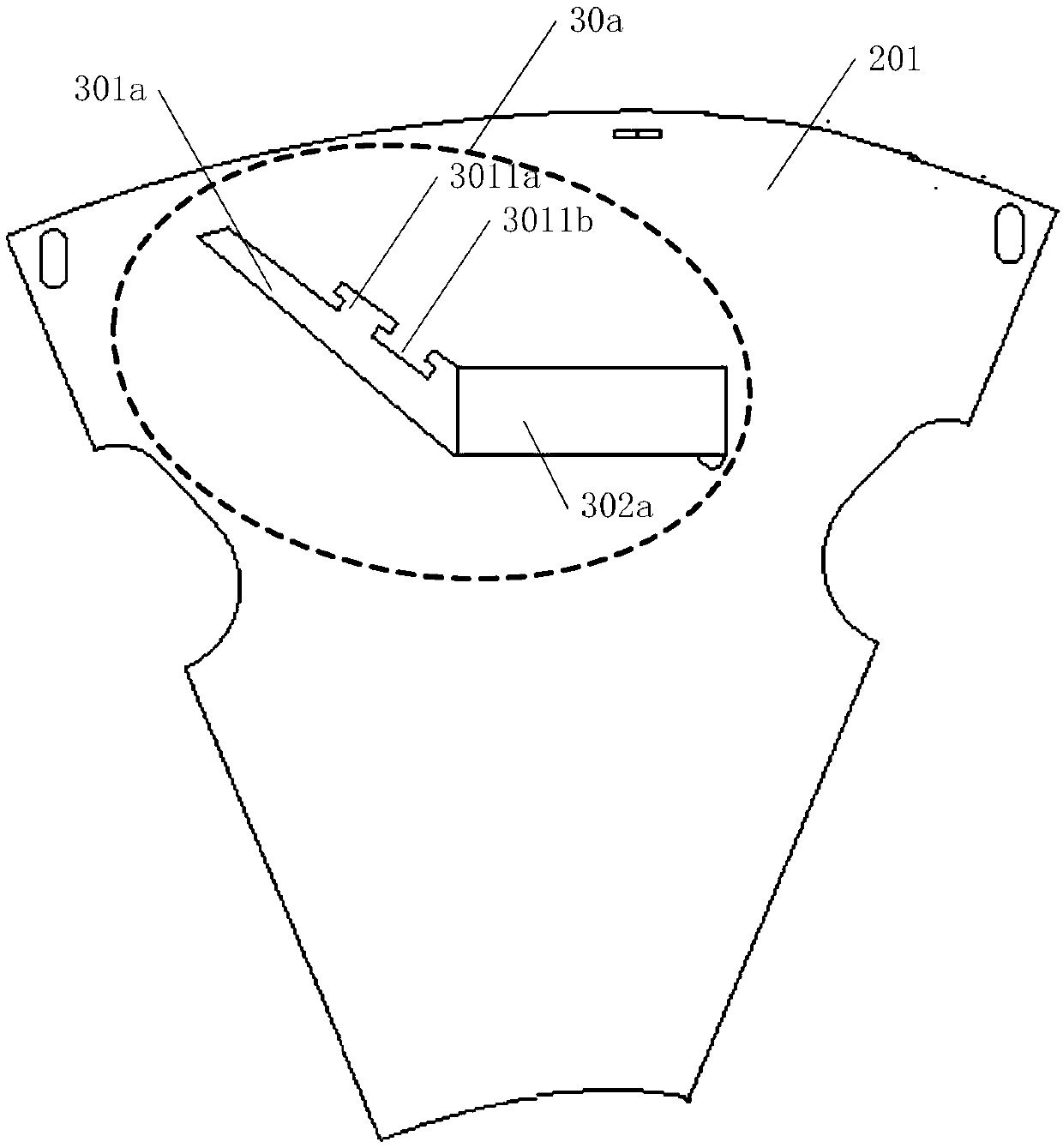

Rotor of rotary motor, permanent magnetic motor, compressor and air-conditioning system

ActiveCN104836355ABack EMF Coefficient DecreaseImprove efficiencyMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsElectric machineMagnetic poles

The invention discloses a rotor of a rotary motor, a permanent magnetic motor, a compressor and an air-conditioning system. The rotor of the rotary motor comprises a body, the body is provided with multiple magnetic poles arranged to be spaced along a circumferential direction, the multiple magnetic poles are rotationally symmetrical relative to the rotation center of the body, each magnetic pole comprises a first permanent magnet and a second permanent magnet, and the coercive force of each first permanent magnet is more than two times that of each first permanent magnet. According to the rotor of the rotary motor provided by one embodiment of the invention, the counterelectromotive force coefficient of the motor can be flexibly adjusted according to the need of the operation speed of the rotor, the motor always runs at a high-efficiency state, and at the same time, the rotating speed scope of a conventional motor can also be enlarged.

Owner:GUANGDONG MEIZHI COMPRESSOR

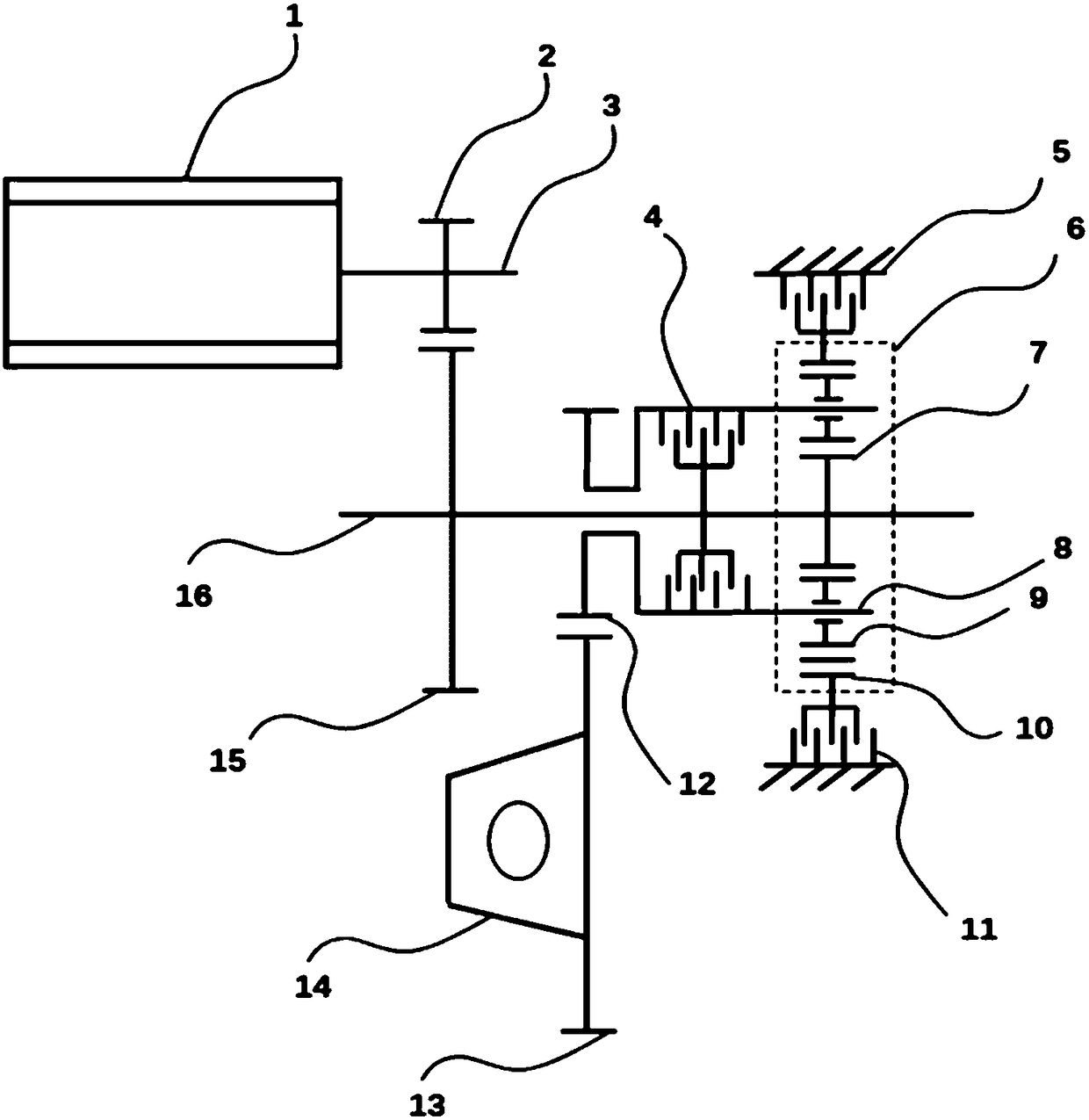

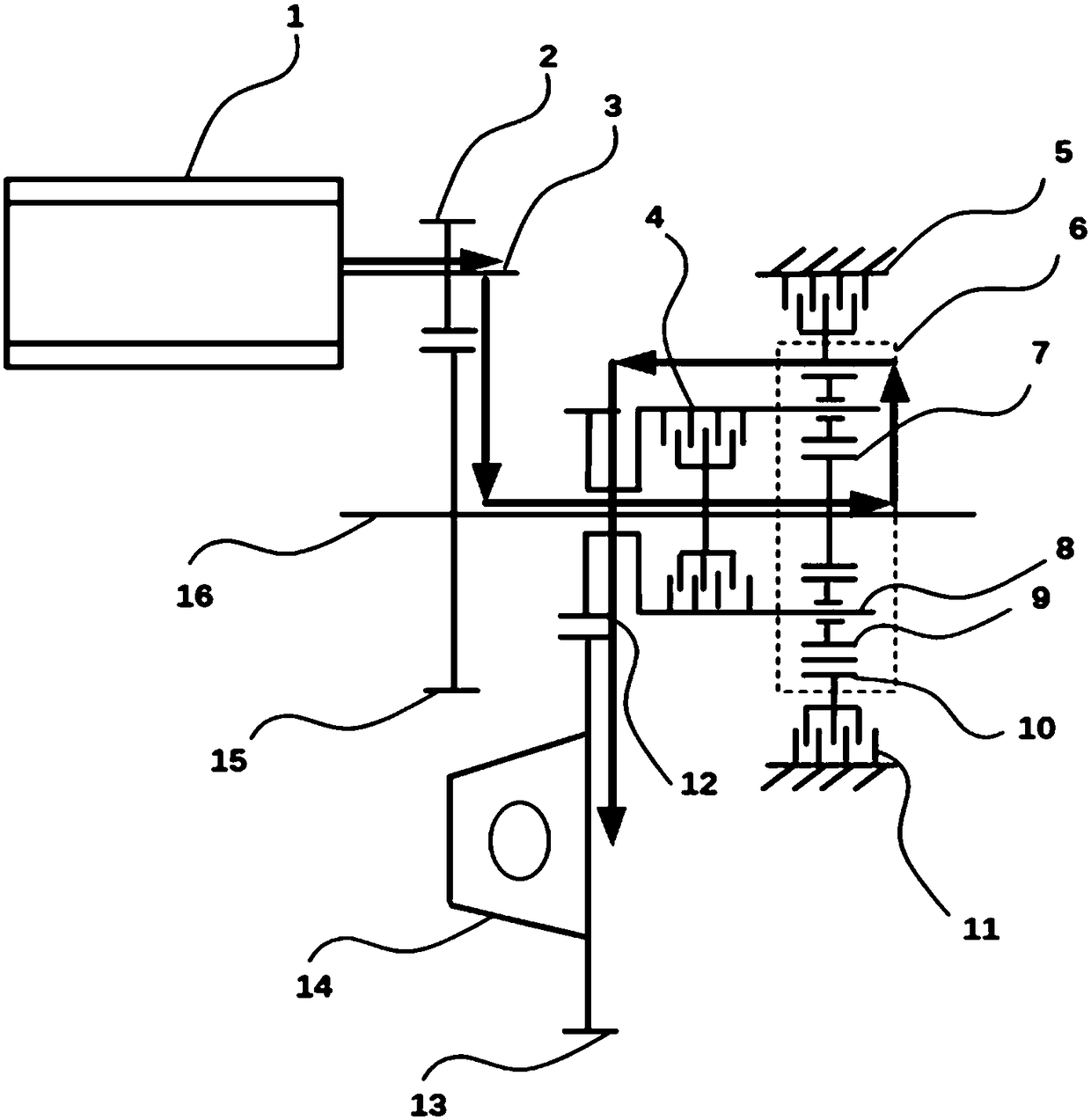

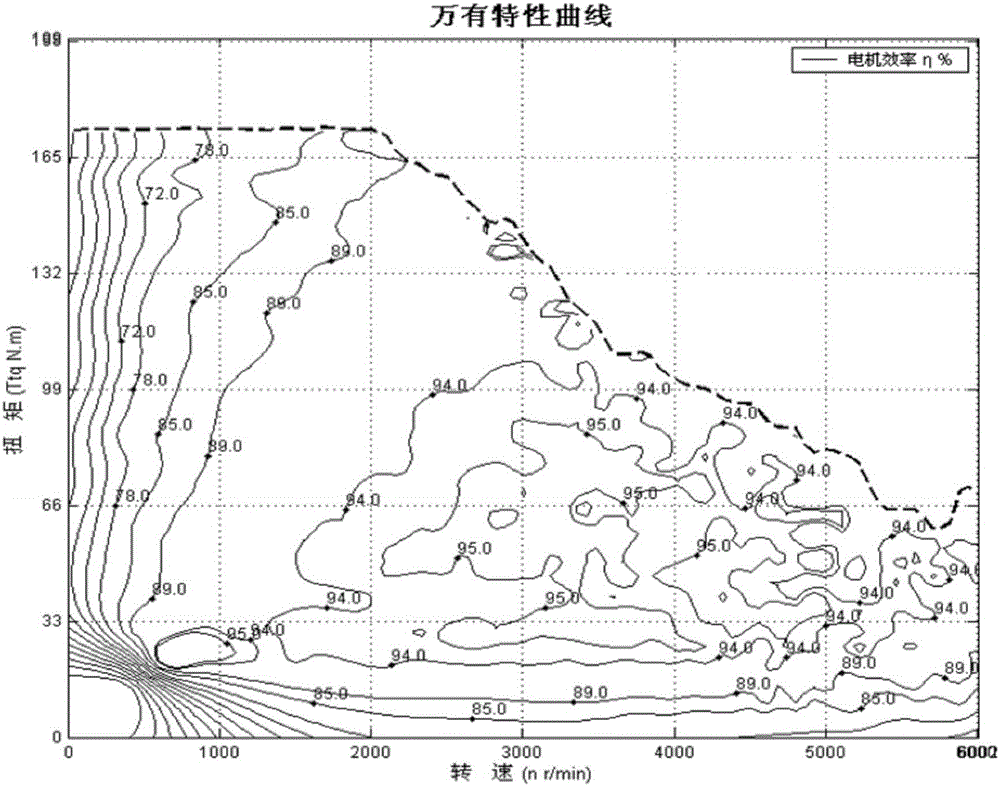

Electromobile variable speed driving system and automatic variable speed control method

The invention discloses an electromobile variable speed driving system and an automatic variable speed control method. The electromobile variable speed driving system comprises a driving motor, a motor controller, a gear shifting controller and a multi-gear transmission, wherein a main shaft of the multi-gear transmission is connected with a rotating shaft of the driving motor through a gear transmission mechanism; one end of a variable speed hub of the multi-gear transmission is electrically connected with the gear shifting controller through a gear contact switch, and the other end of the variable speed hub is connected with a shaft of a gear shifting motor; and the gear shifting controller is electrically connected with the gear shifting motor, a rotating speed sensor of the driving motor, the gear contact switch and the motor controller. The automatic variable speed control for the electromobile variable speed driving system is realized through presetting the lower limit eta min of the working efficiency of the driving motor in a program of the gear shifting controller, comparing the calculated real-time operational efficiency eta c of the driving motor with the set lowest working efficiency eta min of the driving motor, and then controlling the gear shifting motor to drive the variable speed hub to drive the transmission to finish gear-up and gear-down actions.

Owner:刘厚荣

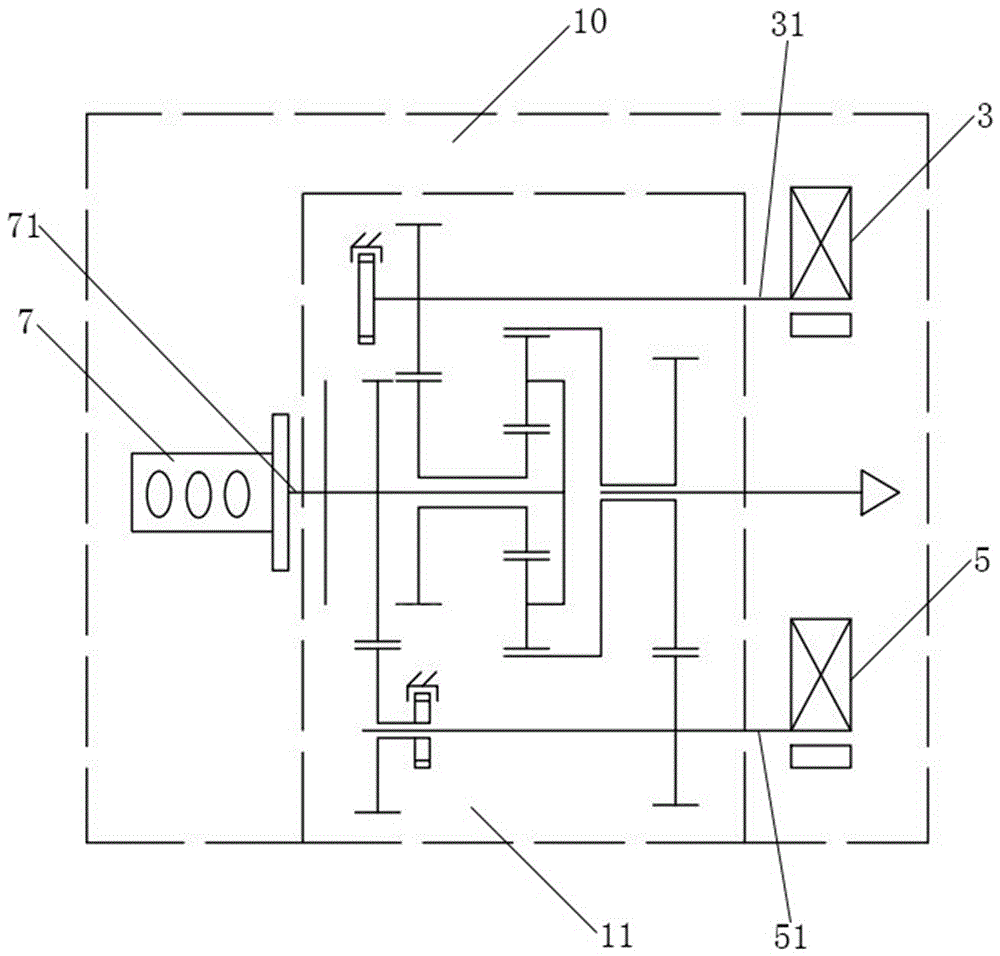

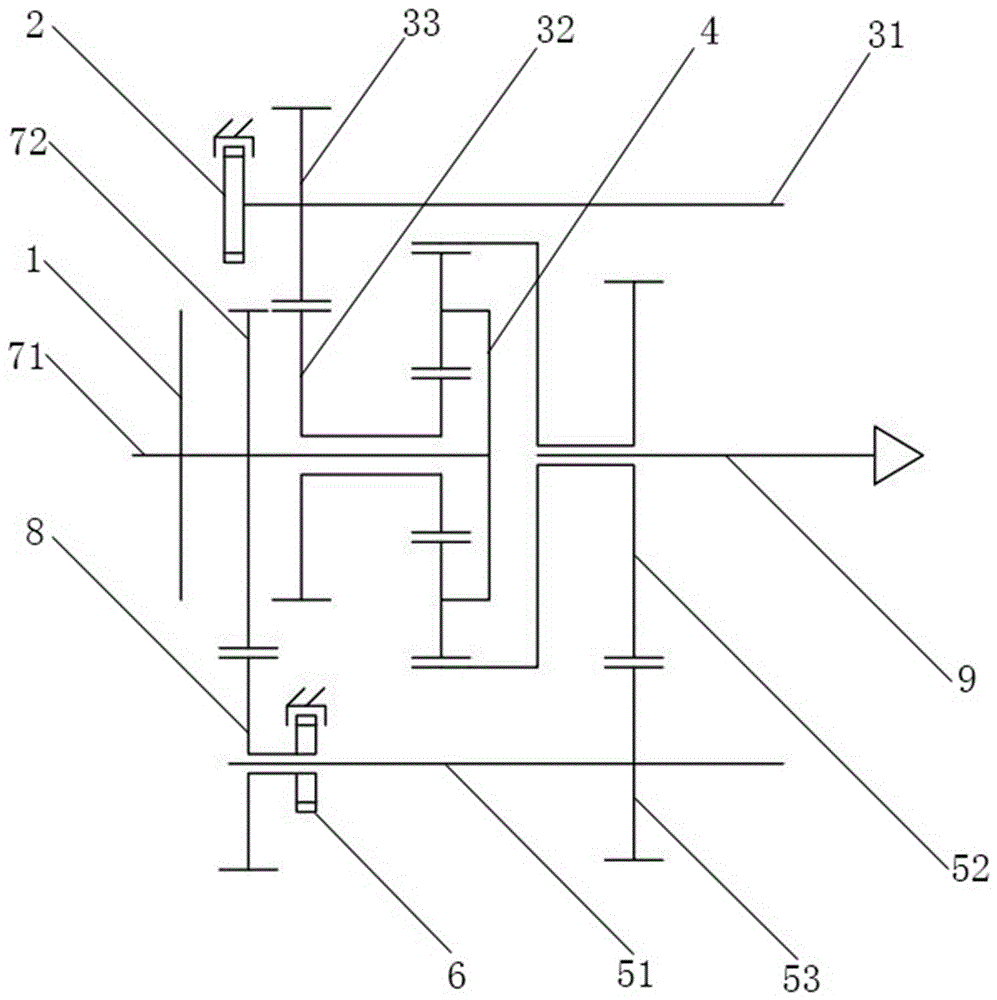

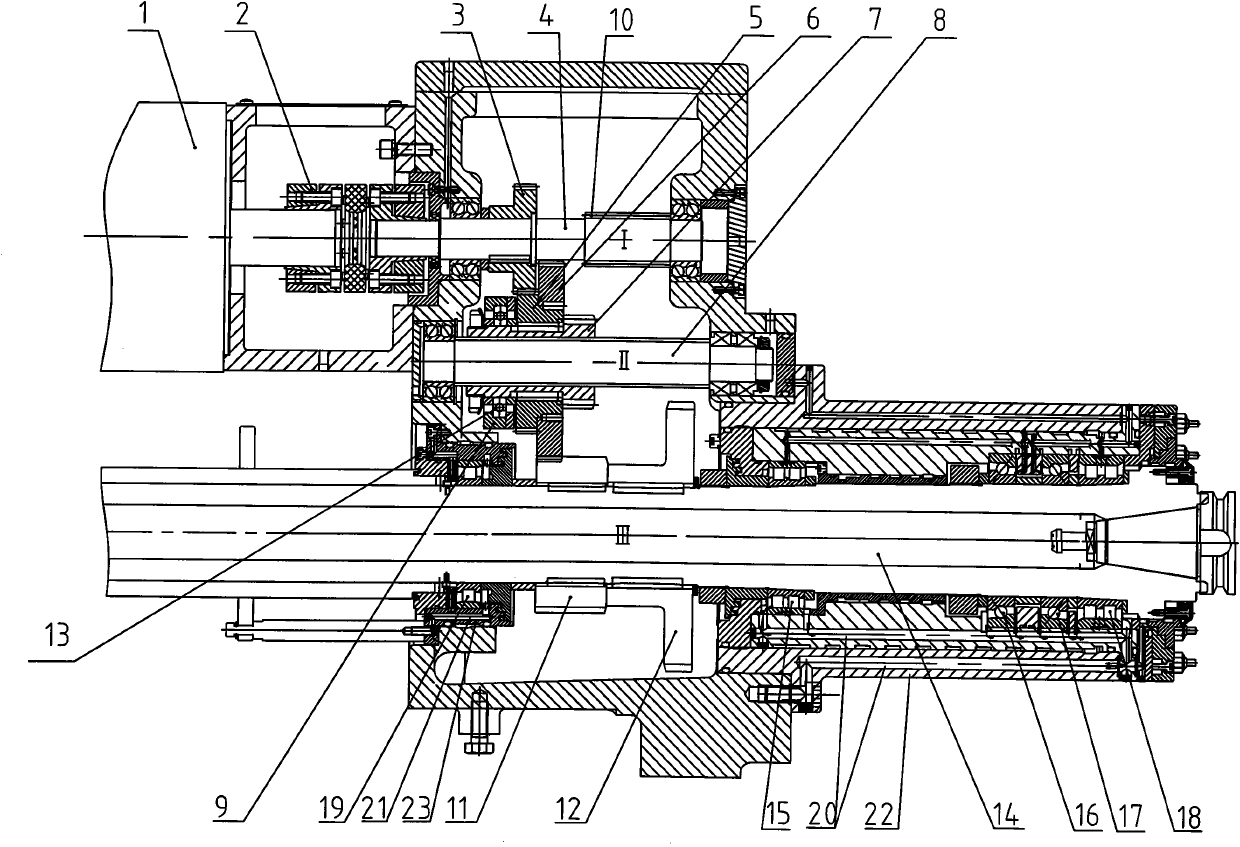

Two-speed transmission for pure electric vehicle and speed changing method

PendingCN109442014AFlexible and efficient torque transmissionImprove powerGearingGear wheelEngineering

The invention discloses a two-speed transmission for a pure electric vehicle. The two-speed transmission for the pure electric vehicle comprises a transmission shell. The transmission comprises a drive motor, an input gear, an input shaft, an intermediate shaft, an intermediate gear, a planetary gear train, a first power module, a second power module and a differential mechanism. The drive motor is in spline connection with an input shaft. The input shaft is provided with the input gear. The intermediate shaft is provided with the intermediate gear and a sun gear. The intermediate gear is meshed with the input gear. The planetary gear train comprises a planetary rack, a sun gear, a planet gear and a gear ring. The first power module comprises a first clutch and a sun gear. The second powermodule comprises a second clutch, a main speed reduction input gear and a main speed reduction output gear. The main speed reduction input gear is meshed with the main speed reduction output gear. The differential mechanism is fixedly connected with the main speed reduction output gear through a bolt. The two-speed transmission for the pure electric vehicle can meet the requirements for the vehicle power performance, highest vehicle speed and the like, the transmission efficiency of the power system is higher, power gear shifting is free of interruption, the comfort of passengers is improved,and the market application prospect is broad.

Owner:上海伊控动力系统有限公司

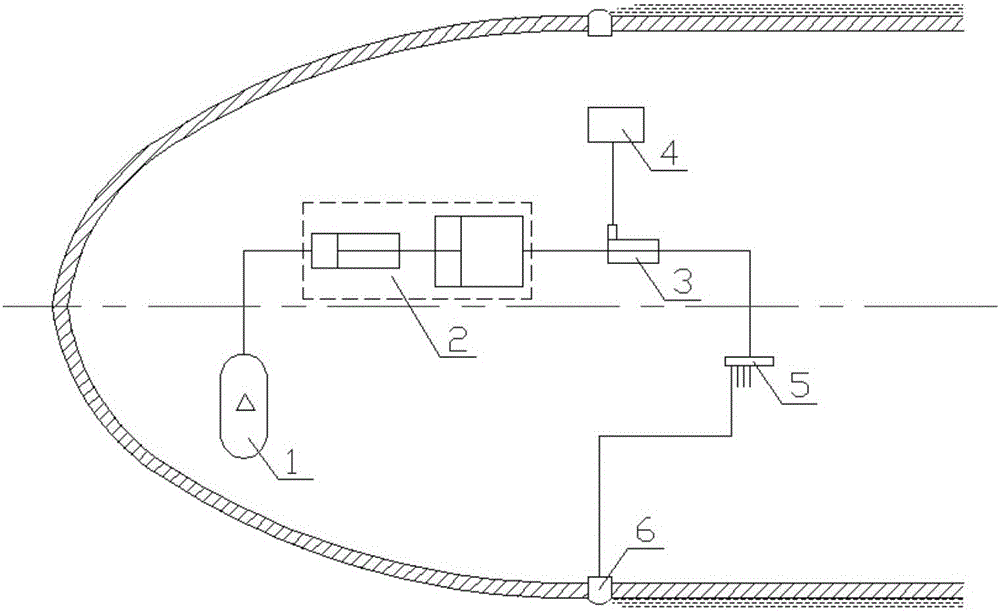

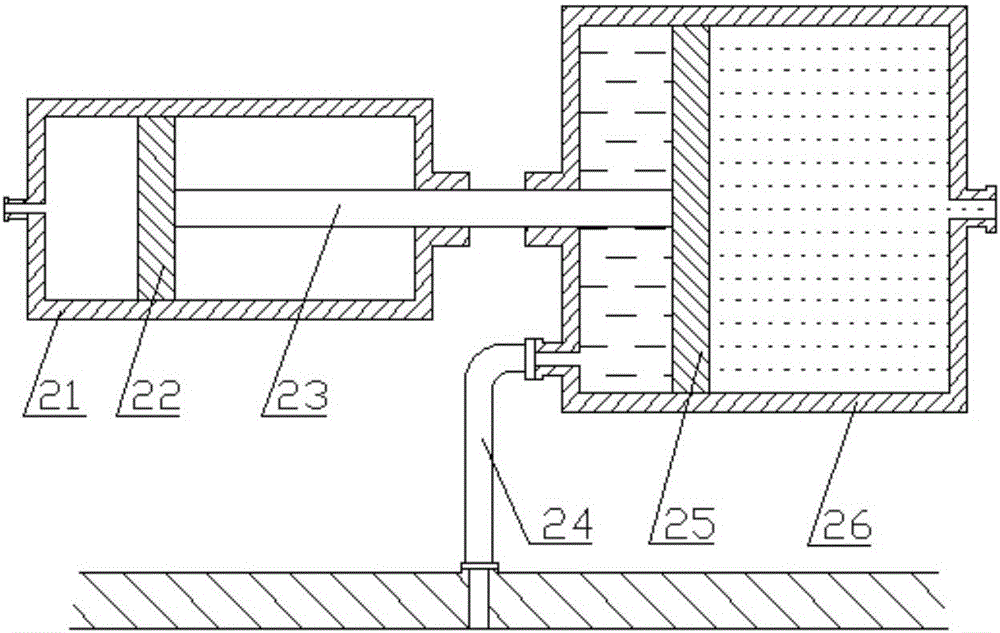

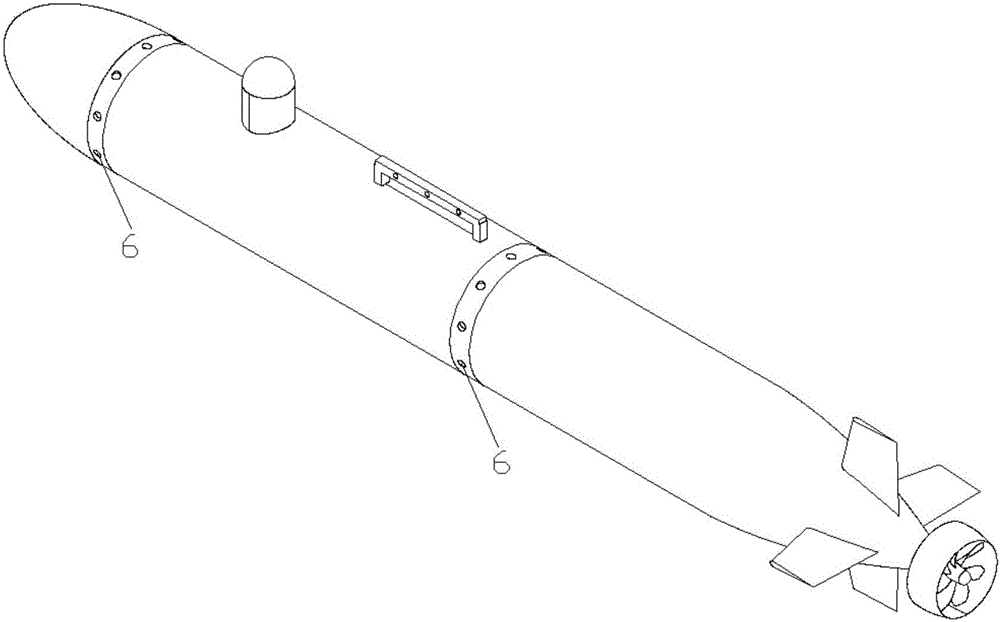

Mucus drag reduction device for underwater vehicle

ActiveCN105947105AReduce frictional resistanceImprove mobilityWatercraft hull designHydrodynamic/hydrostatic featuresPistonPiston cylinder

The invention discloses a mucus drag reduction device for a underwater vehicle, which belongs to the technical field of ship drag reduction and efficiency increasing. The mucus drag reduction device for the underwater vehicle comprises an air cylinder, a piston cylinder, a flow control valve, a controller, a joint, mucus, an air pipe and liquid pipes. The cavity of the piston cylinder is divided into two parts through a piston; the cavity on one side is connected with the air cylinder through the air pipe; the mucus is within the cavity on the other side; the cavity, full of the mucus, of the piston cylinder is connected with an inlet of the joint through the liquid pipe with the flow control valve; more than one outlets of the joint are respectively connected with mucus releasing holes in a underwater vehicle housing through the liquid pipes; and the controller is connected with the flow control valve. According to the invention, the drag reducing mucus releasing speed can be automatically adjusted according to the navigational speed of the underwater vehicle so that the drag reducing mucus uniformly and persistently cover most external surface of the underwater vehicle to increase the maximum navigational speed of the underwater vehicle and energy consumption can be also reduced at equivalent navigational speed.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

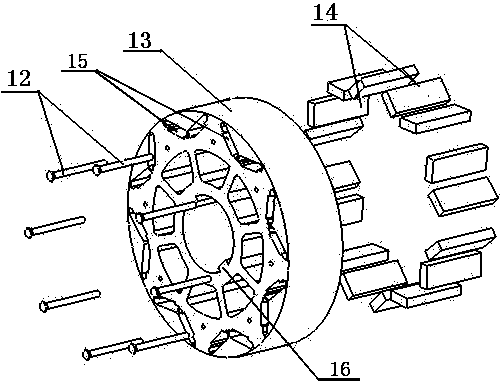

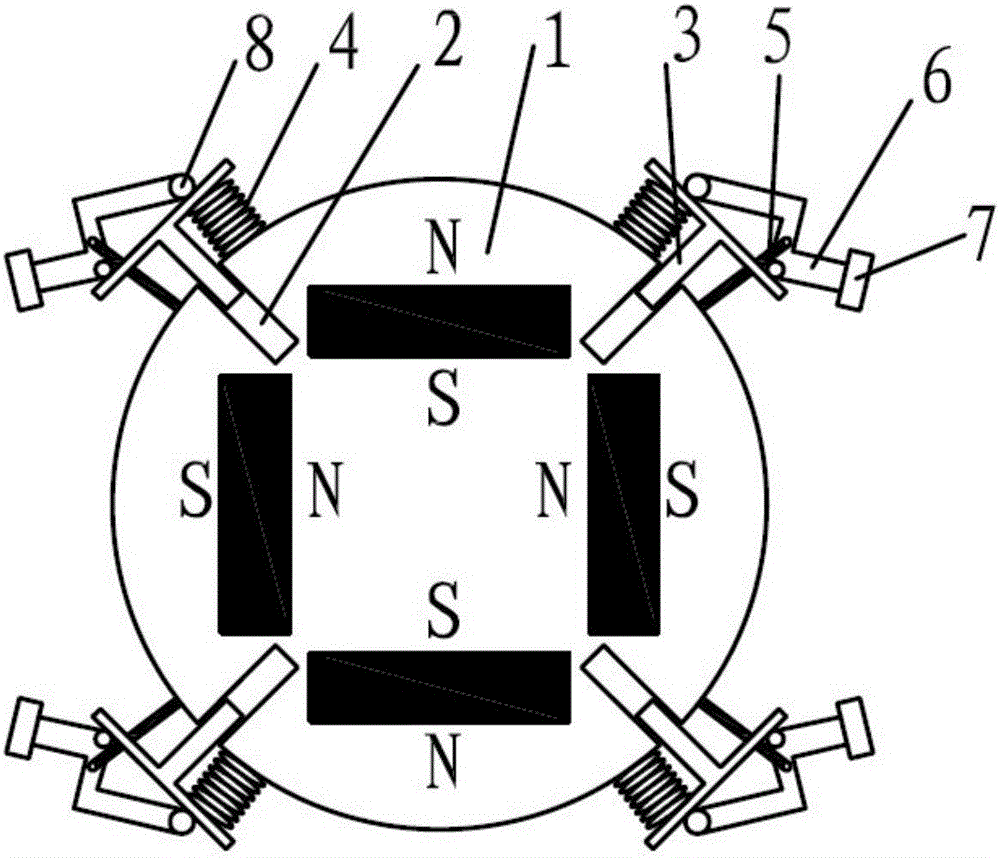

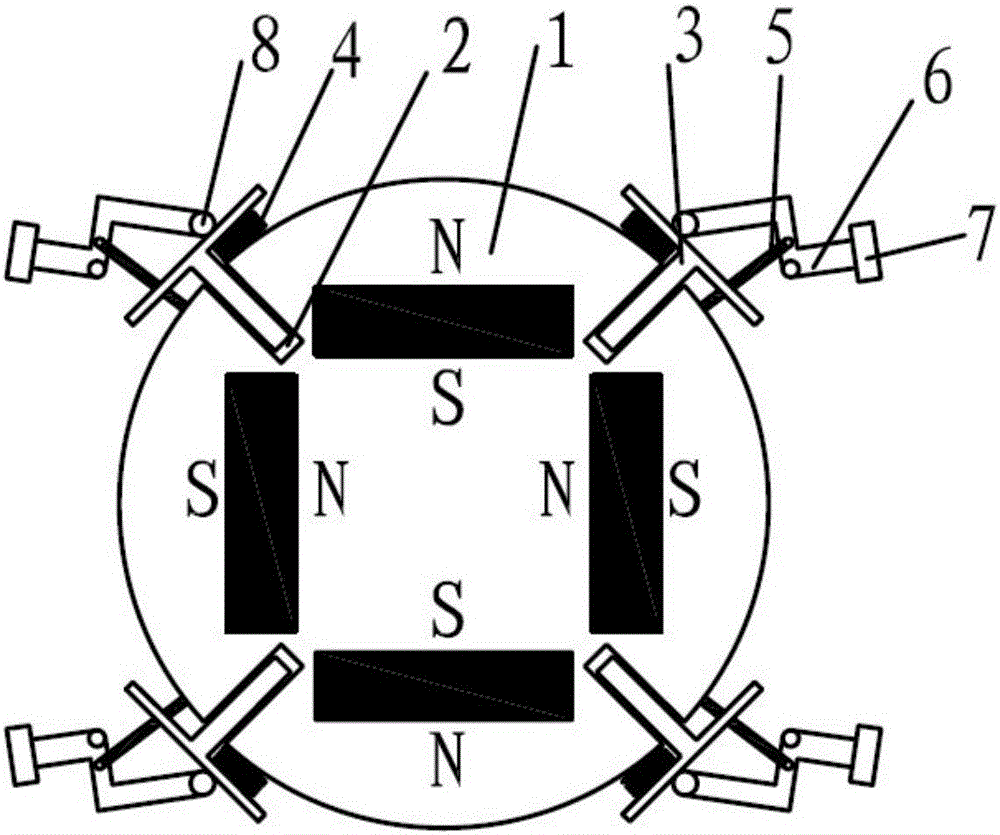

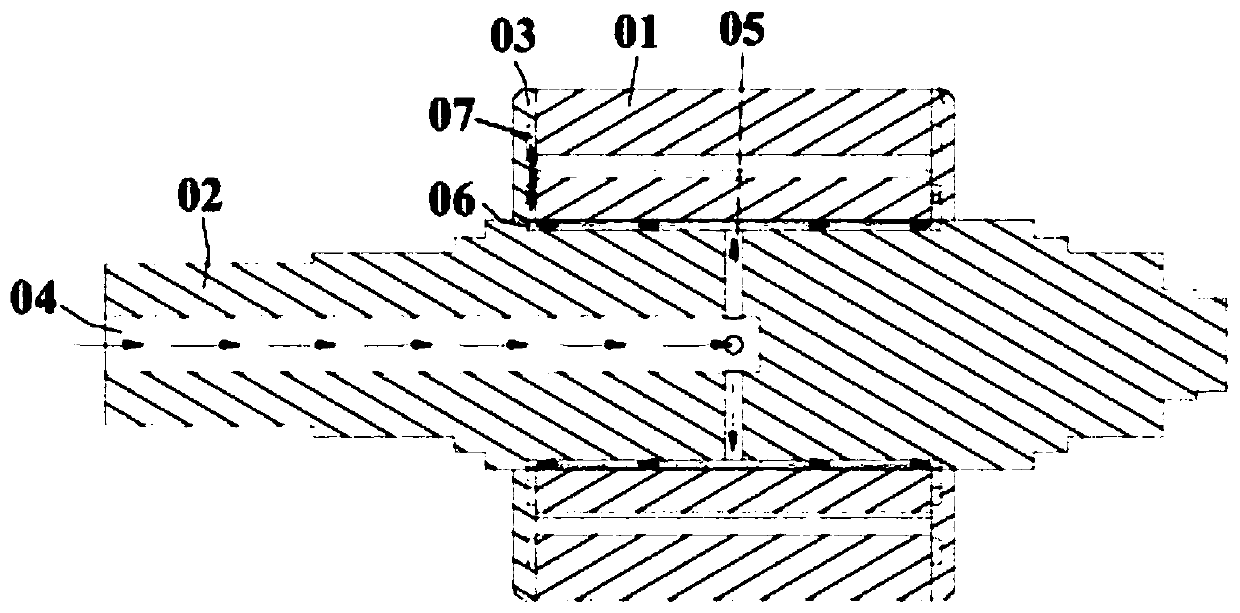

Rotor structure of variable excitation permanent magnet synchronous motor

InactiveCN105720719AIncrease top speedRun fastMagnetic circuit rotating partsSynchronous machine detailsLow speedElectric machine

The invention discloses a variable excitation permanent magnet synchronous motor rotor structure, belonging to a motor rotor. In the present invention, slots are evenly opened in the middle of adjacent permanent magnets in the rotor along the radial direction of the rotor, and several sets of field-weakening adjustment mechanisms are installed around the rotor; The soft iron block slides radially, a spring is installed between the rotor and the soft iron block, and a connecting rod counterweight mechanism is installed corresponding to each soft iron block; the link counterweight mechanism includes a bracket integrated with the rotor, and is installed on the bracket A connecting rod, the connecting rod is installed on the rotor through the bracket and can swing around the bracket; a counterweight is installed at one end of the connecting rod, and a roller is installed at the other end, and the connecting rod leans against the soft iron block through the roller. Advantages: At low speed, the effective excitation magnetic field is strong, which ensures the torque output capability at low speed; at high speed, the effective excitation magnetic field is weakened, which improves the maximum operating speed of the permanent magnet synchronous motor.

Owner:XUZHOU COLLEGE OF INDAL TECH

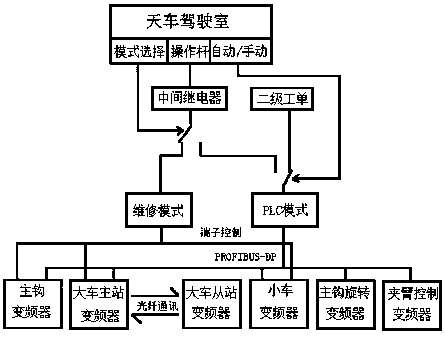

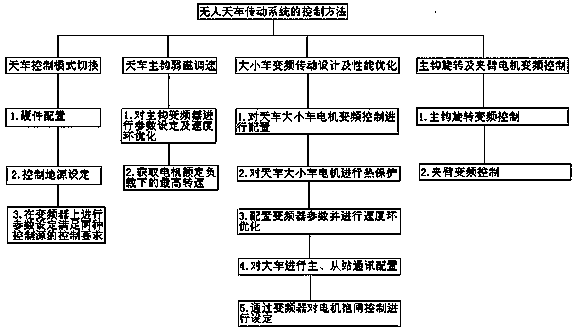

Method for frequency conversion transmission control of crown block unmanned system

ActiveCN109734000ASuppress swingImprove work efficiencyAC motor controlElectric motor speed/torque regulationFrequency changerElectric machine

The invention relates to a method for frequency conversion transmission control of a crown block unmanned system, and belongs to the technical field of unmanned crown block equipment. According to thetechnical scheme, the method includes the four steps of crown block control mode switching, flux weakening speed regulating under crown block main hook frequency conversion control, large and small vehicle frequency conversion transmission performance optimization and main hook rotating and clamping arm motor frequency conversion control. The method has the beneficial effects that various controlmodes of crown block running are achieved, the highest rotating speed of a motor is increased, the work efficiency of a crown block is improved, the swinging angle of a main hook during running of the crown block is effectively inhibited, and accurate positioning of the crown block is achieved; during main hook rotating, due to set adjustment on a speed increasing and decreasing slope of a frequency converter, hook head swinging caused by rotation can be effectively inhibited; and a clamping arm motor achieves accurate positioning of the clamping arm width through frequency conversion controlduring opening and closing of a clamping arm. According to the method, due to reasonable design and configuration of a transmission system and optimization of frequency conversion speed regulation, the control performance of the crown block unmanned system is improved.

Owner:WEIER AUTOMATION CO LTD TANGSHAN IRON & STEELGRP

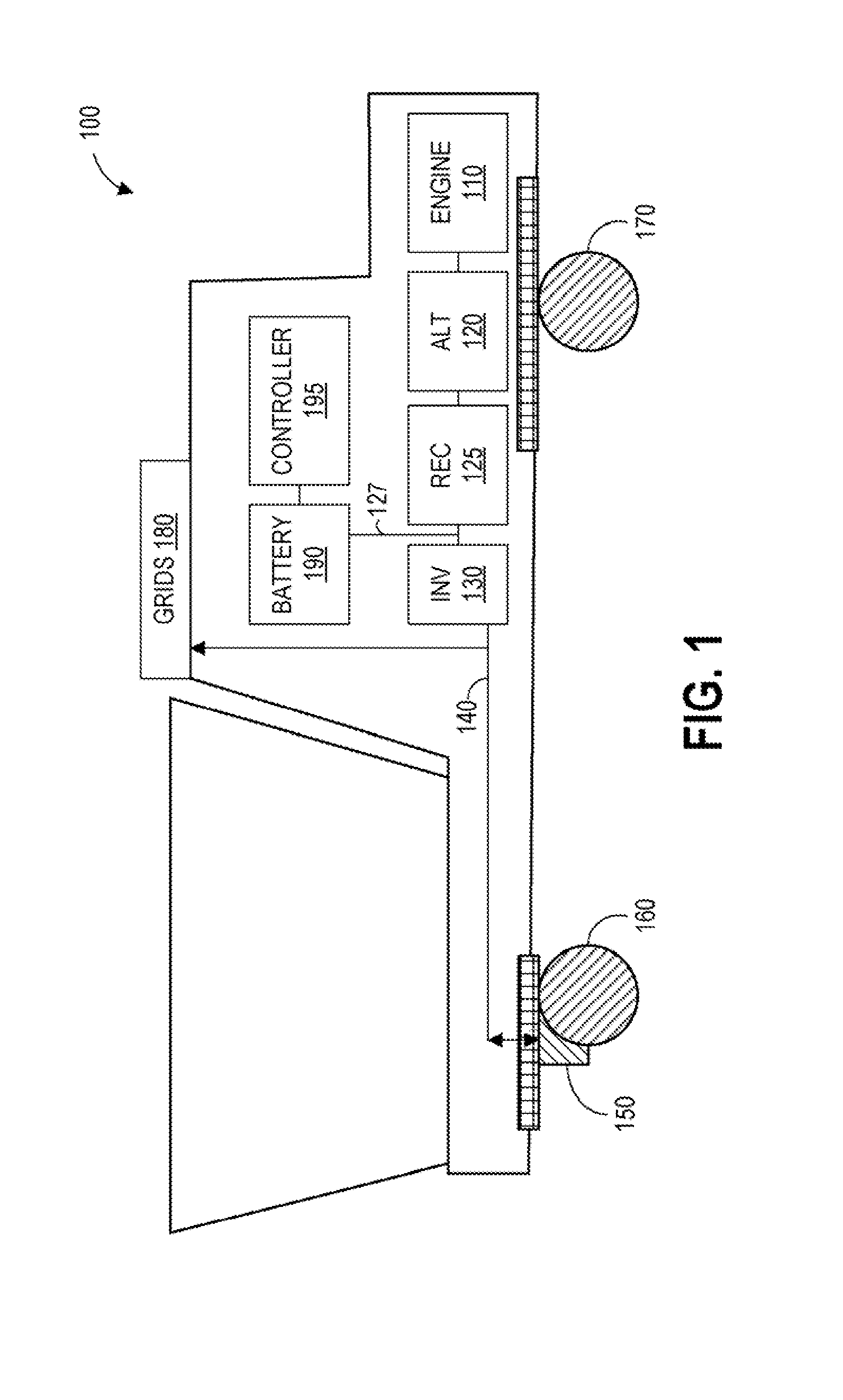

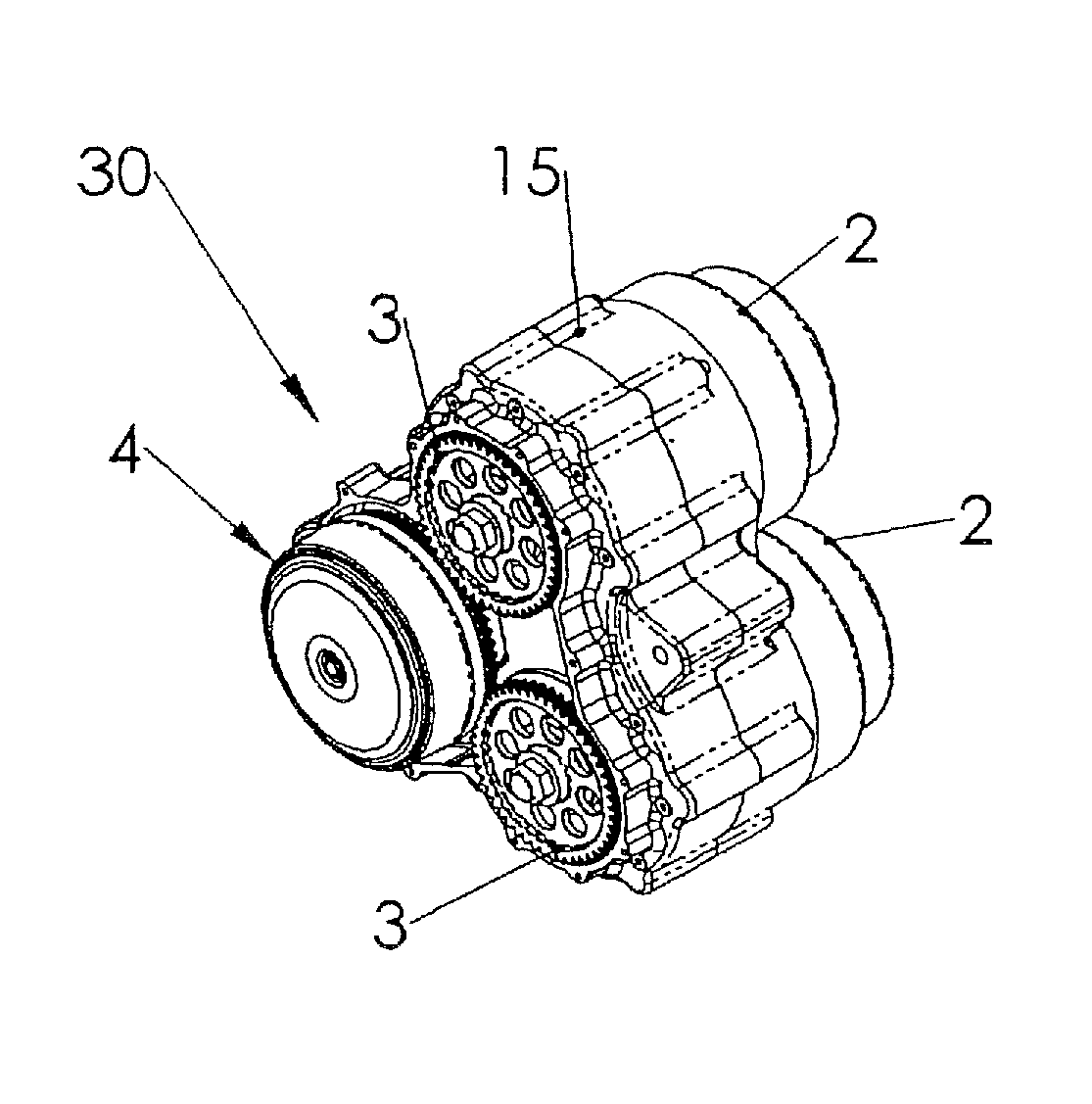

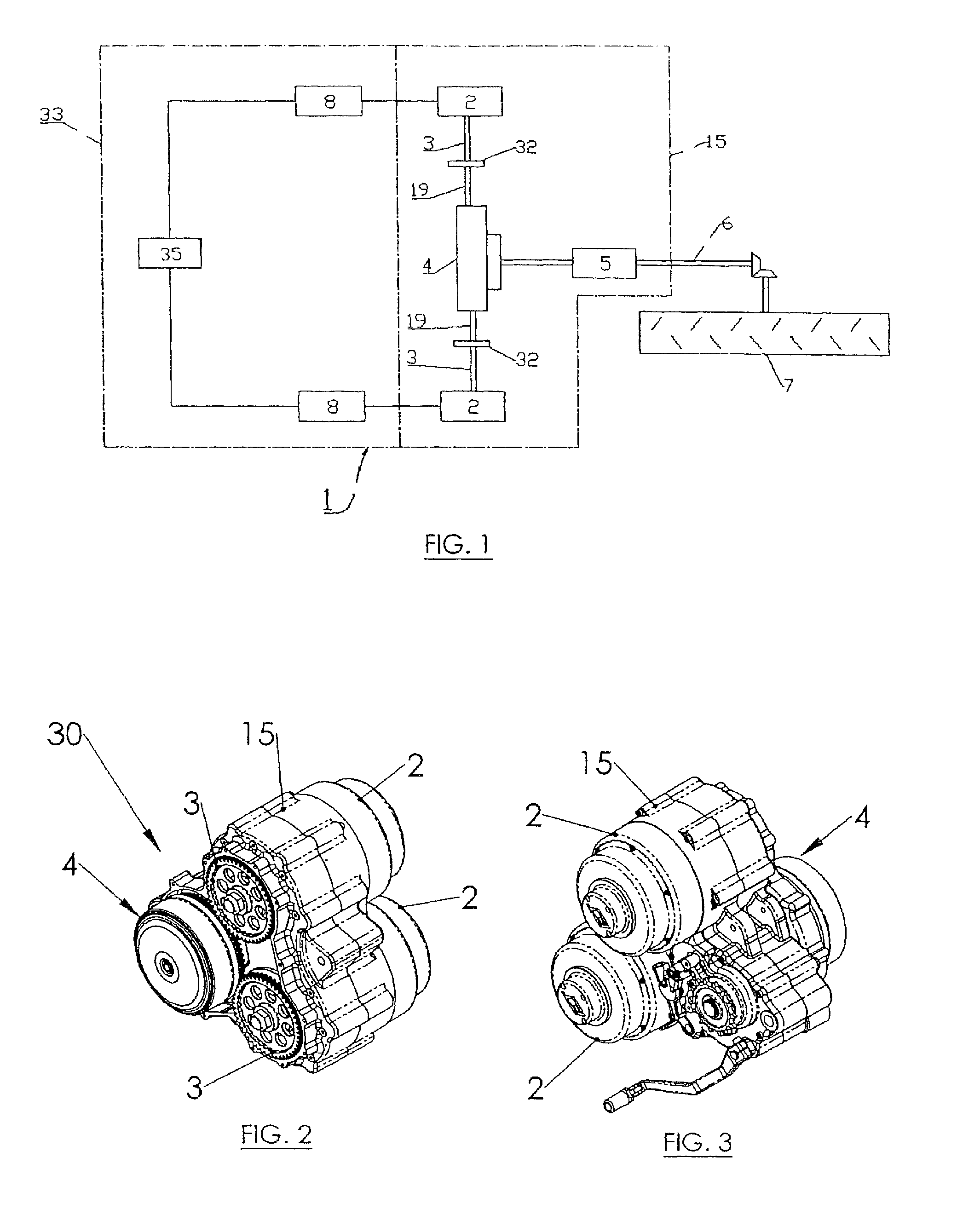

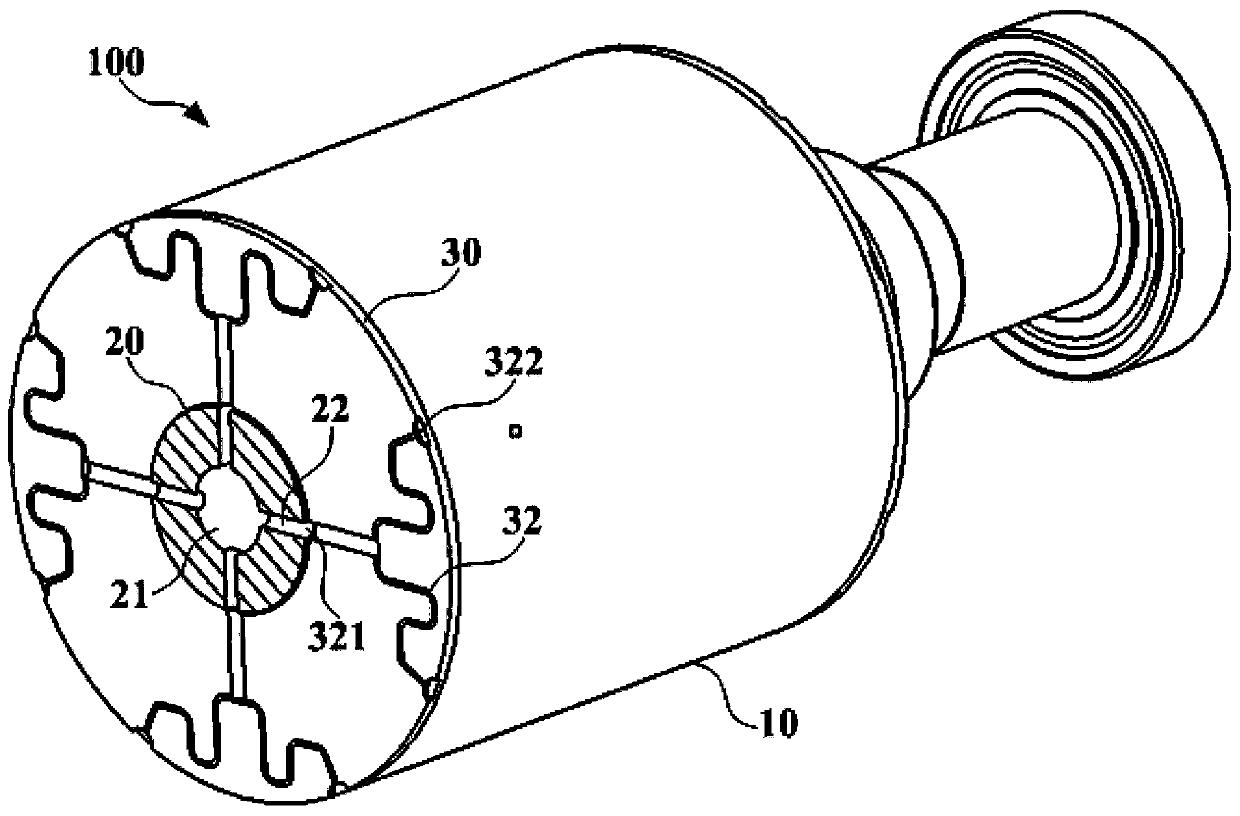

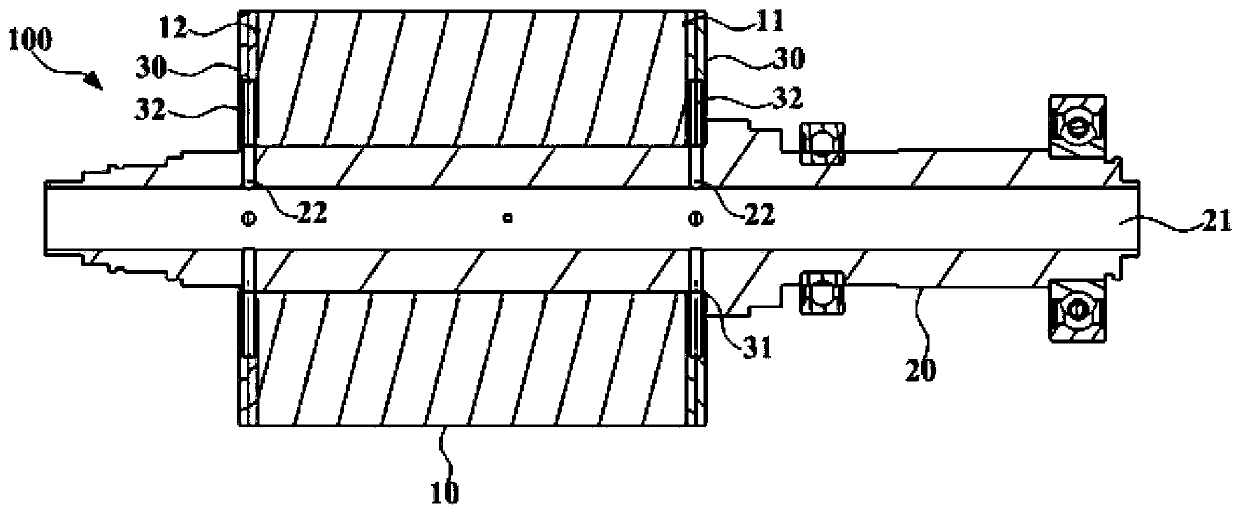

Propulsion system for a self-propelled vehicle with multiple electric drive units

ActiveUS9038756B2Increase autonomyLow cost of executionMechanical apparatusElectric devicesBrushless motorsComing out

A propulsion system for a self-propelled vehicle comprises a motor body which is associated with a mechanical transmission conveying motion to the driving wheels of the vehicle, and which integrates and contains in a single body electric propulsion means, comprising at least several components of a brushless rotary motor; a clutch coupling located downstream of and mechanically connected to the electric propulsion means; and a gearbox with discontinuous gear ratios, having an input shaft connected to the clutch coupling and an output shaft coming out to the outside of the motor body and connecting to the mechanical transmission. The electric propulsion means comprise the components of at least two brushless motors, each equipped with a respective driving shaft provided with a pinion which is coupled by meshing with a predetermined ratio to a clutch coupling.

Owner:SOLAREDGE TECH LTD

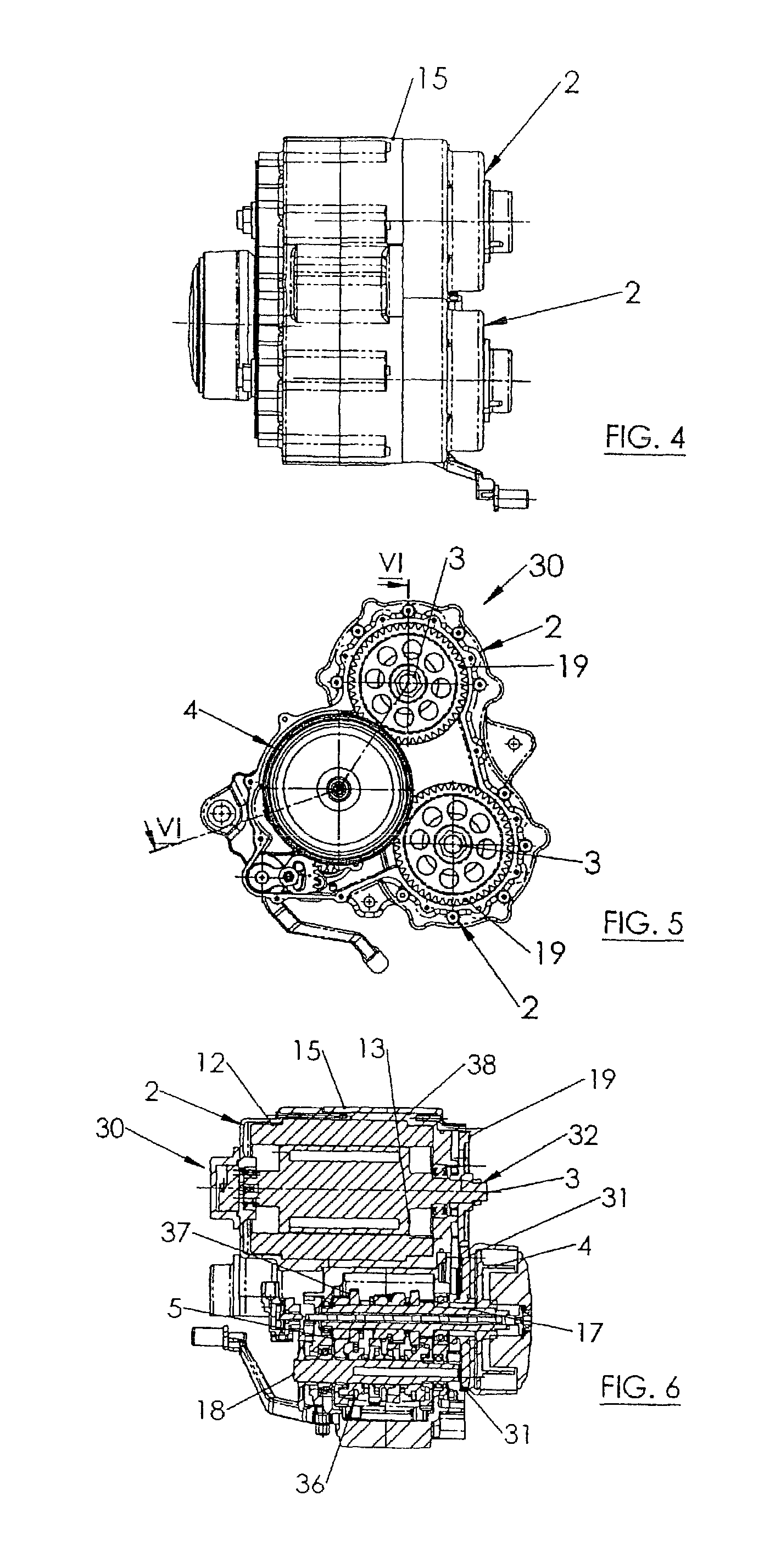

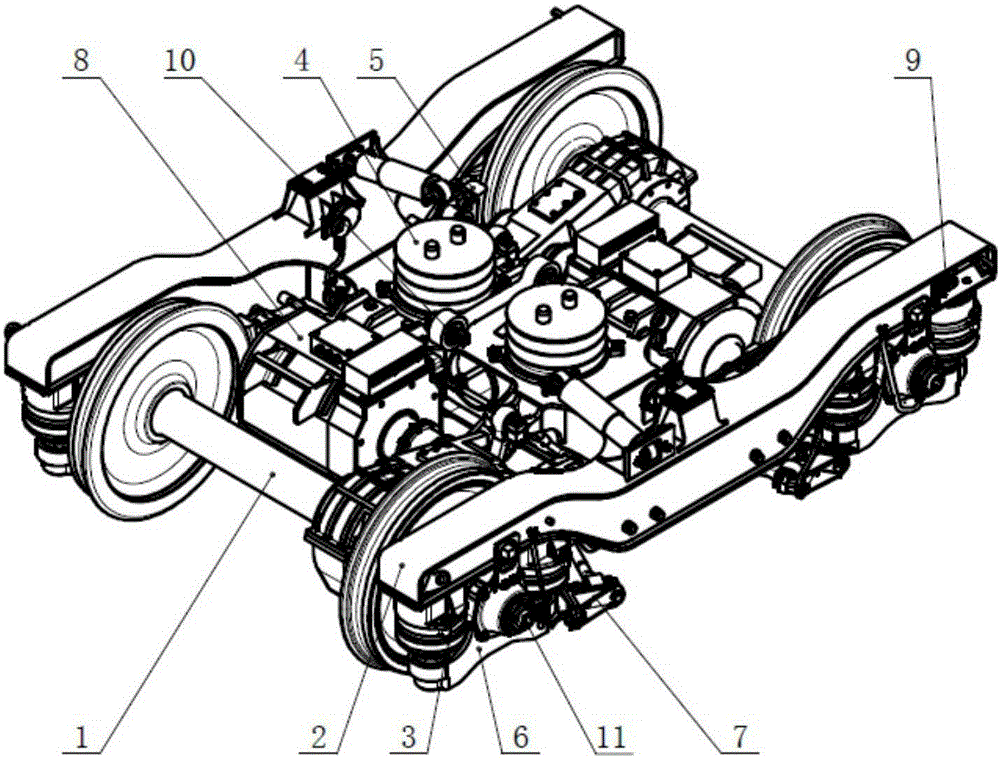

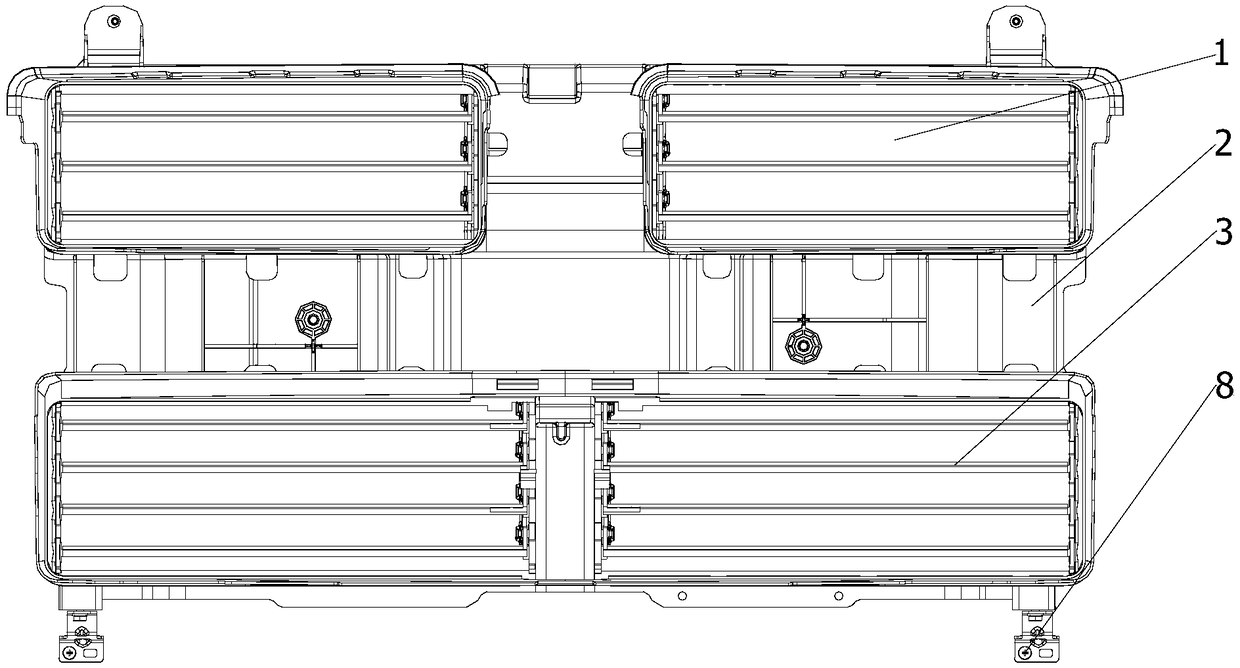

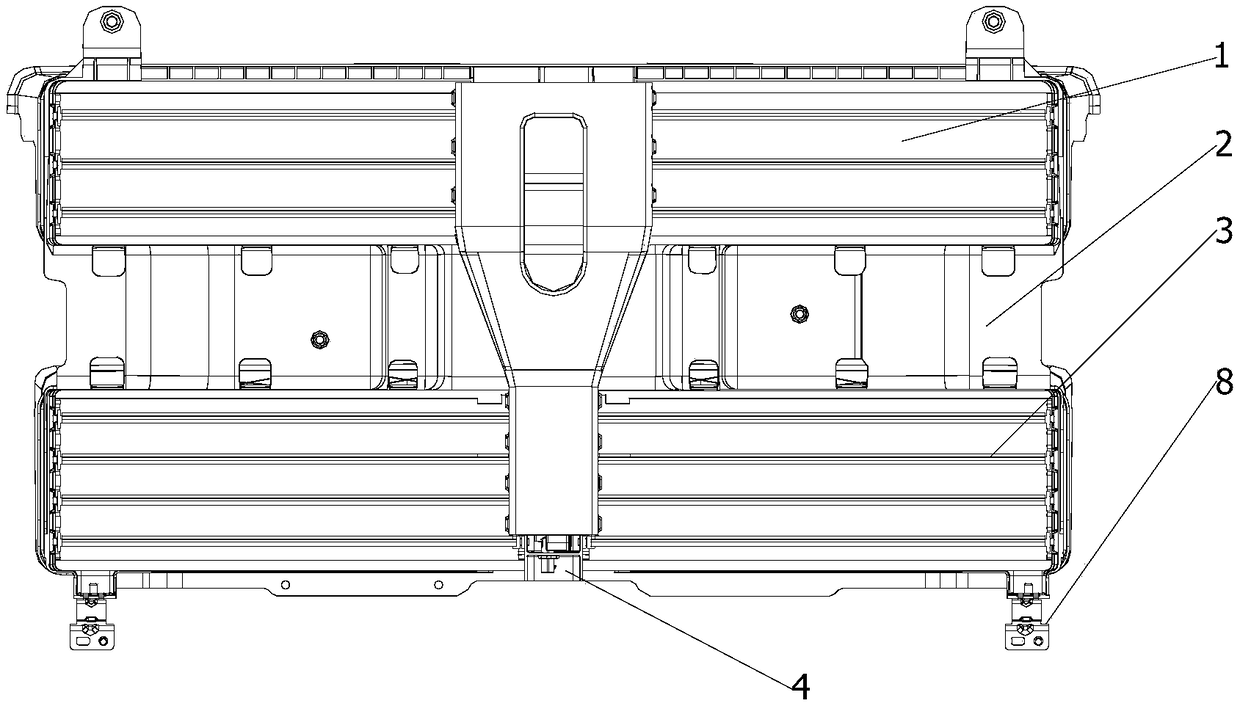

Electric driving bogie for subway engineering vehicle

ActiveCN105151069ACompact structureIncrease top speedElectric motor propulsion transmissionBogiesAir springStructural pattern

The invention discloses an electric driving bogie for a subway engineering vehicle. The electric driving bogie comprises a framework, two pairs of wheel sets, an axle box, a plurality of primary suspension systems, a secondary suspension system, a driving device, a traction device, an axle box connecting device, a braking device, a weighing device and a grounding device. The electric driving bogie has the beneficial effects that problems such as center plate bearing and longitudinal impact of traction are solved by adopting a rubber-metal pad bearing plus traction rod traction pattern; by adopting a unit braking device for replacing a conventional lever braking device, the daily maintenance free is realized, and the maintenance amount is reduced; compared with the structure of a substrate coach bogie, the structure of the bogie is simple; the structural pattern of the bogie is optimized according to the requirements of the subway engineering vehicle; rubber-metal pad bearing is used for replacing air spring bearing and is supplemented by a device for preventing the side rolling of a vehicle body; a single traction rod is used for replacing a Z-shaped double traction rod and a center pin; an interface of the vehicle body and the structure of the bogie are simplified; and the manufacturing manufacturability is improved.

Owner:CRRC SHANDONG CO LTD

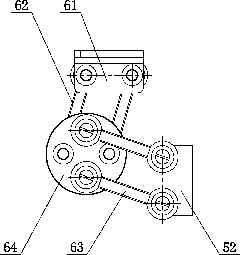

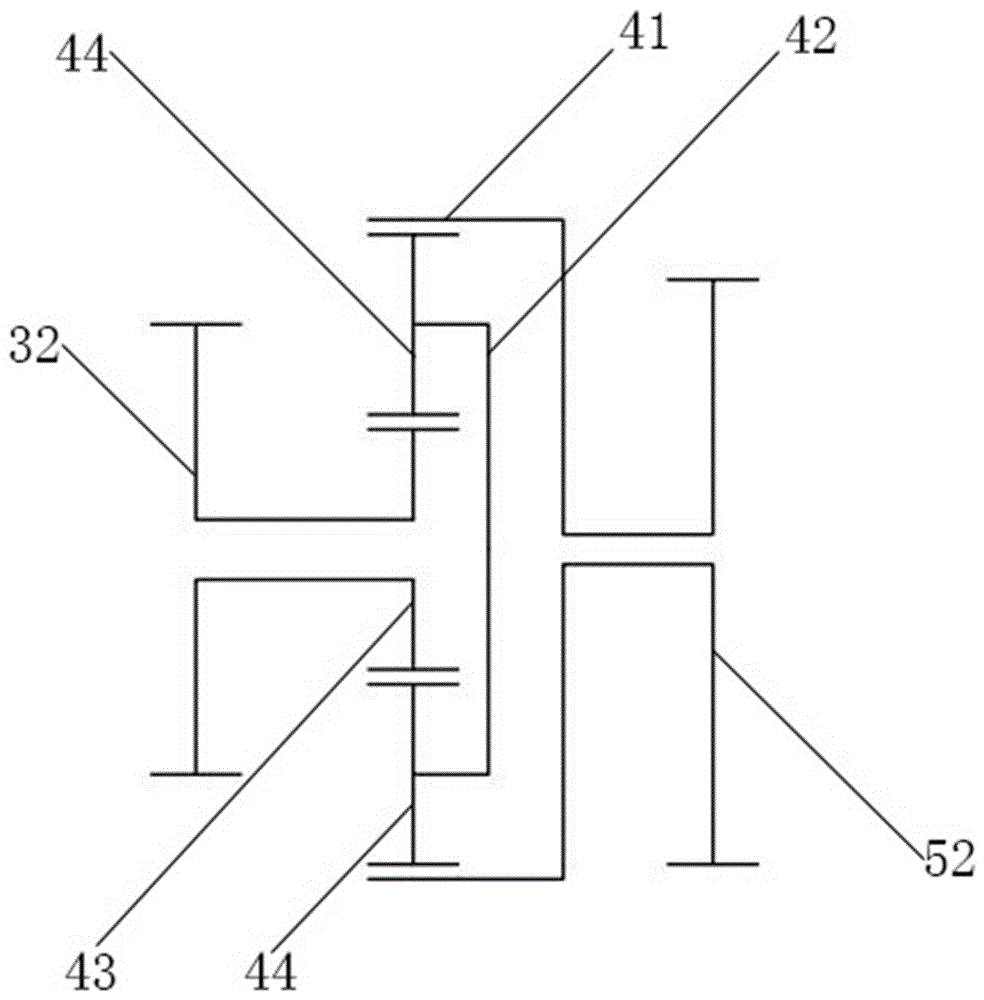

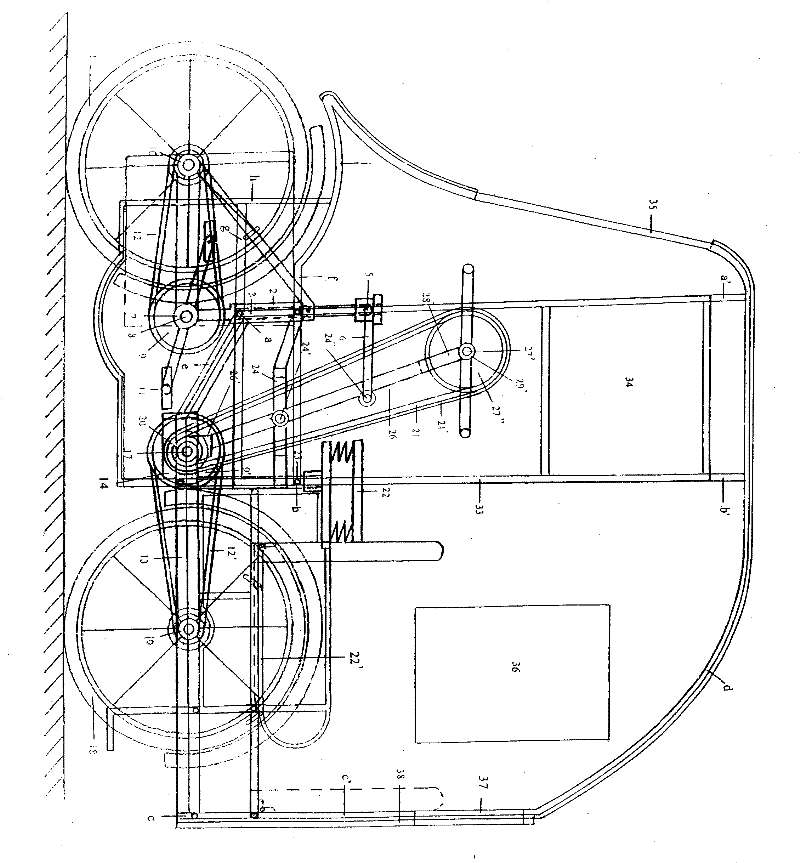

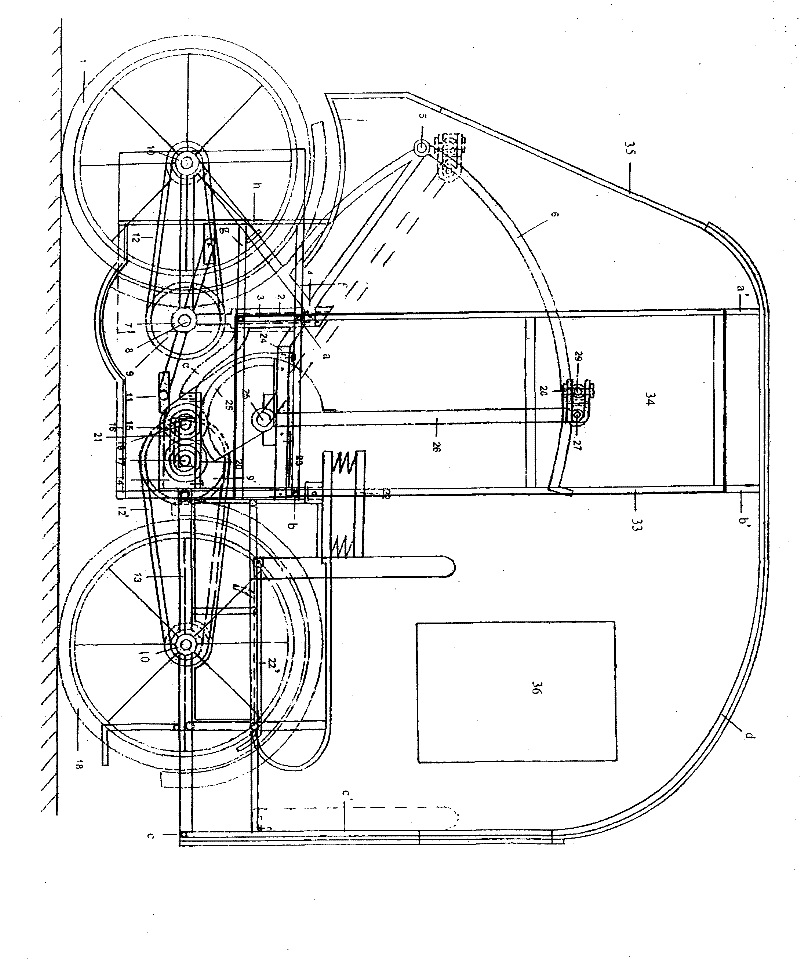

Gear spindle structure for horizontal type machining center

The invention relates to a gear spindle structure for a horizontal type machining center, which comprises a spindle box body, a driving shaft, an intermediate shaft and a spindle, wherein the driving shaft, the intermediate shaft and the spindle are supported on the spindle box body in parallel; a first gear of the driving shaft and a second gear of the driving shaft are fixed on the driving shaft; a first gear of the spindle and a second gear of the spindle are fixed on the spindle; a first gear of the intermediate shaft, a second gear of the intermediate shaft and a third gear of the intermediate shaft, which are capable of axially sliding along the intermediate shaft and are mutually connected to form an integrate are arranged on the intermediate shaft; the first gear of the driving shaft can be engaged with the first gear of the intermediate shaft; the second gear of the intermediate shaft can be engaged with the first gear of the spindle and the second gear of the driving shaft; the third gear of the intermediate shaft can be engaged with the second gear of the spindle; and the first gear of the intermediate shaft, the second gear of the intermediate shaft and the third gear of the intermediate shaft are connected to a push type shifting fork of a cylinder through a shifting fork bearing. The spindle has the advantages that the highest rotating speed is enhanced; the work efficiency is high; and the use range is wide.

Owner:DALIAN HUAGEN MACHINERY

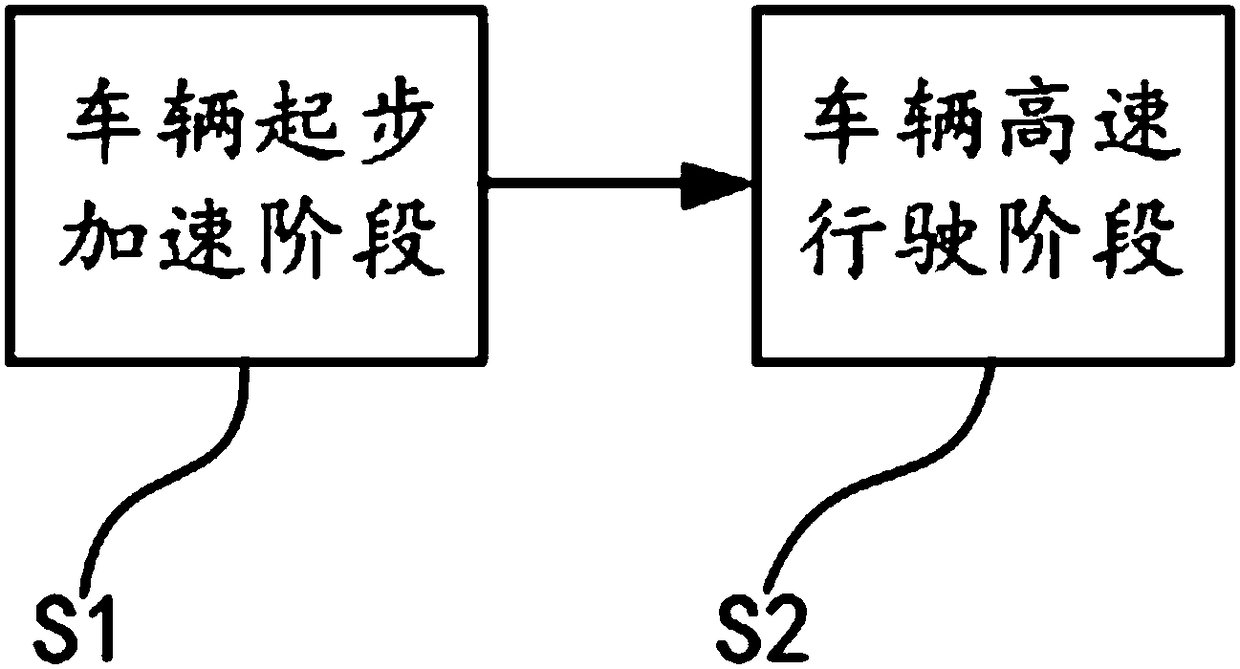

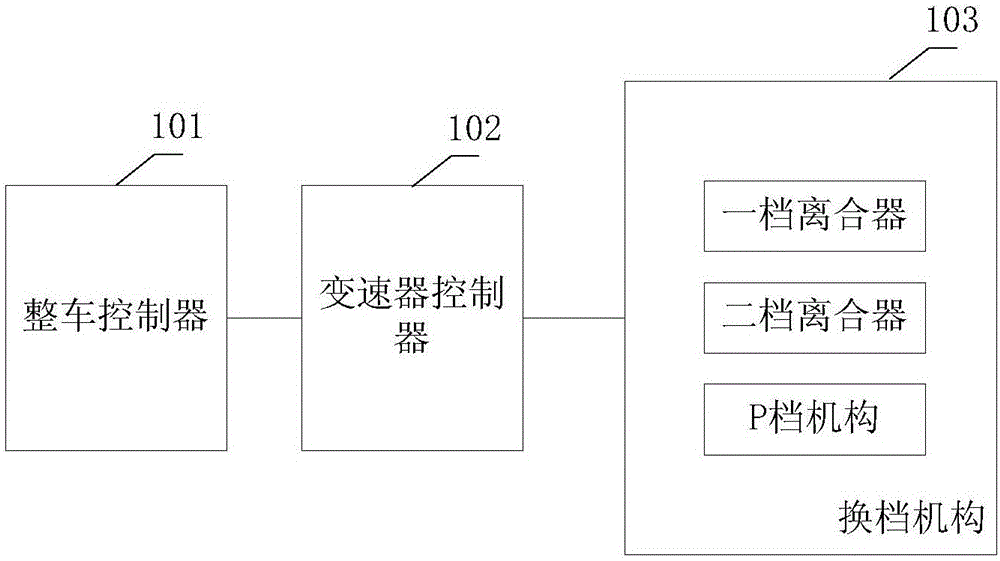

Two-gear speed changing system and method of electric car and electric car

ActiveCN106240570AImprove acceleration performanceHigh torqueGearing controlElectric machineDrive motor

The embodiment of the invention discloses a two-gear speed changing system and method of an electric car and the electric car. The two-gear speed changing system comprises a finished car controller, a speed changer controller and a gear shifting mechanism, wherein the finished car controller is used for collecting the rotation speed of a drive motor; the speed changer controller is used for generating a first-gear start instruction or a second-gear switch instruction or a first-gear switch instruction based on the rotation speed of the drive motor; and the gear shifting mechanism comprises a first-gear clutch and a second-gear clutch, the first-gear clutch is used for achieving engagement based on the first-gear start instruction or the first-gear switch instruction so that the car is switched to the first gear, and the second-gear clutch is used for achieving engagement based on the second-gear switch instruction so that the car is switched to the second gear. Through the implementation mode, the drive motor can work at a high-efficiency rotation speed range continuously, the energy consumption rate of the car is decreased, and accordingly both the acceleration time index and the highest car speed index are taken into consideration.

Owner:CH AUTO TECH CORP CO LTD

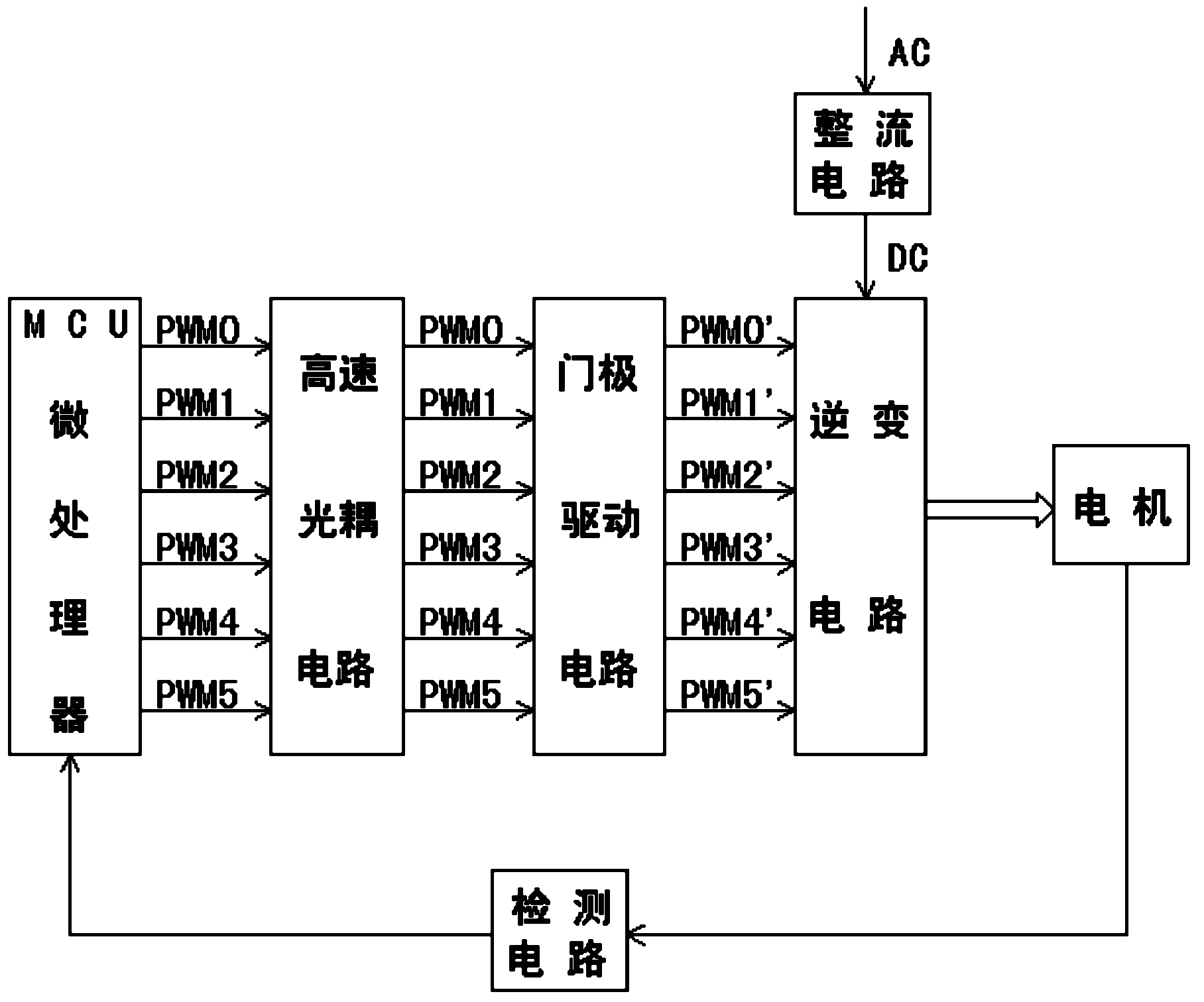

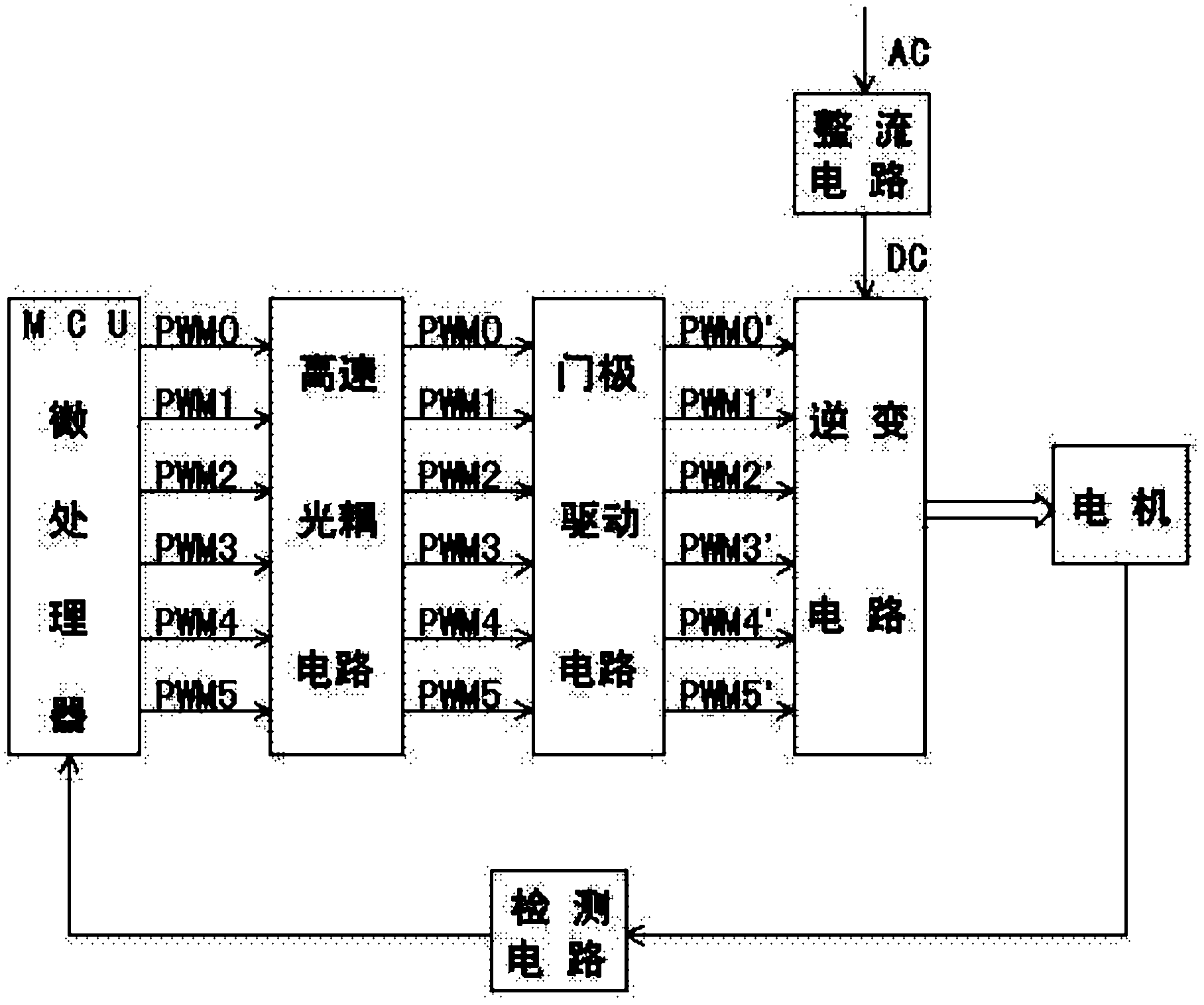

Medium-voltage high-rotation-speed brushless direct-current motor driver

InactiveCN102638209AAccurate speed controlIncrease top speedAC motor controlSingle motor speed/torque controlSwitching frequencyField-effect transistor

The invention discloses a medium-voltage high-rotation-speed brushless direct-current motor driver which drives a motor to rotate through a high-frequency PWM (pulse width modulation) modulation signal. The motor transmits the collected motor rotor information to an MCU (micro controller unit) micro processor through a detection circuit; the MCU micro processor can accurately collect a position signal of a rotor through a sampling signal with the frequency not less than 120KHz and a PWM duty ratio regulating signal with the frequency not less than 1KHz; the system can accurately control the rotation speed of the motor through controlling the duty ratio of the PWM modulation signal; in order to enable an MOSFET (metal oxide semiconductor field effect transistor) device in an inverter circuit to be able to operate normally under the high-switch frequency, a gate pole driving circuit which can rapidly drive the MOSFET to be conducted or switched off is added at the front end of the inverter circuit, thus the MOSFET can be rapidly conducted or switched off under the driving of the high-frequency PWM modulation signal. The medium-voltage high-rotation-speed brushless direct-current motor driver provided by the invention not only is simple in structure, but also has good control characteristic and high working efficiency, thus the highest rotation speed of the motor is improved.

Owner:SUZHOU DAYI EQUIP TECH

Rapid body-building three-wheel mini bus using hands and feet

InactiveCN102126537AAvoid exposureOvercoming the insufficient speed of the maximum driving speedCyclesRider propulsionPush and pullFixed bearing

The invention discloses a rapid body-building three-wheel mini bus using hands and feet. A rotation shaft in a bearing is vertically fixed at the front end of a frame; pedal plates, a transmission gear and a chain are arranged between the lower end of the frame and the rotation shaft of a front wheel; a group of transmission gears, a chain and a hand-rotated gear connected with the transmission gears through the chain, or a hand push-and-pull gear rod linked with the transmission gears in a meshed manner are arranged in front of a rear wheel; or a hand-rotated gear or a hand push-and-pull gear rod, a transmission gear and a chain are arranged between a rod jaw at the upper inclined part of the front wheel and the rotation shaft of the front wheel; and a group of pedal plates, the transmission gear and the chain are arranged in front of the rear wheel; when two feet of a user pedal on the pedal plates, the front wheel or the rear wheel is enabled to obtain forward thrust, and meanwhile, the hand-rotated gear is rotated by two arms of the user or the hand push-and-pull gear rod is pushed and pulled, the rear wheel or front wheel is enabled to obtain the forward thrust. The mini bus provided by the invention has the advantages of high speed and comfort of motor vehicles as well as energy conservation and environmental friendliness of tricycles, thus overcoming the defect of incapability of training hands and feet; and the mini bus is suitable for being used as a rapid body-building vehicle in city, and is especially suitable for the old to ride.

Owner:姜仁滨

Additional variable active intake grille and vehicle

InactiveCN109080445AReduce fuel consumption at constant speedReduce fuel consumptionComponent optimizationPropulsion coolingControl theoryWindage

Owner:GEELY AUTOMOBILE INST NINGBO CO LTD +1

Motor rotor device and motor

ActiveCN110544997AIncrease top speedAbsorb centrifugal forceMagnetic circuit rotating partsEngineeringMechanical engineering

The present application discloses a motor rotor device. The motor rotor device includes a rotor core and an adhesive element, wherein the adhesive element is fitted to the rotor core; a first sub-airgroove is disposed on the rotor core and includes a first convex tooth and a first groove; the adhesive element includes a second convex tooth and a second groove; the first convex tooth and the second convex tooth match each other; and the first groove and the second groove match each other. The structure where the adhesive element cooperates with the first sub-air groove on the rotor core can effectively absorb the centrifugal tensile force generated by the high-speed rotation of the rotor, significantly reduce the tensile stress on a rotor magnetic bridge, ensures the robustness of the rotor during high-speed rotation, and increases the speed of the motor as much as possible.

Owner:HUAWEI TECH CO LTD

Rotor, motor and electric vehicle

ActiveCN110380545AReduce kinetic energy lossEffective coolingMagnetic circuit rotating partsElectric propulsion mountingElectric machineEngineering

The application provides a rotor, a motor and an electric vehicle which are used for reducing the kinetic energy loss of the motor on the premise of effective heat dissipation of the rotor. The rotorincludes a rotor core and a rotor shaft, wherein, the rotor core is cylindrical and is provided with a first end and a second end; at least one end of the rotor core is fixed with a fixing plate, thefixing plate is provided with a through hole and a first flow channel, the first flow channel is a damping flow channel, an inlet of the first flow channel communicates with the through hole, and an outlet of the first flow channel is arranged on the peripheral side surface of the fixing plate; the rotor shaft is fixedly assembled in the rotor core, at least one end of the rotor shaft extends to the outer side of the rotor core from the through hole of the fixing plate, a second flow channel arranged in the axial direction and a third flow channel arranged in the radial direction at least at the position corresponding to one of the through holes are arranged in the rotor shaft, the inlet of the second flow channel is arranged at one end of the rotor shaft, the outlet of the second flow channel communicates with the inlet of the third flow channel, and the outlet of the third flow channel communicates with the inlet of the first flow channel.

Owner:HUAWEI DIGITAL POWER TECH CO LTD

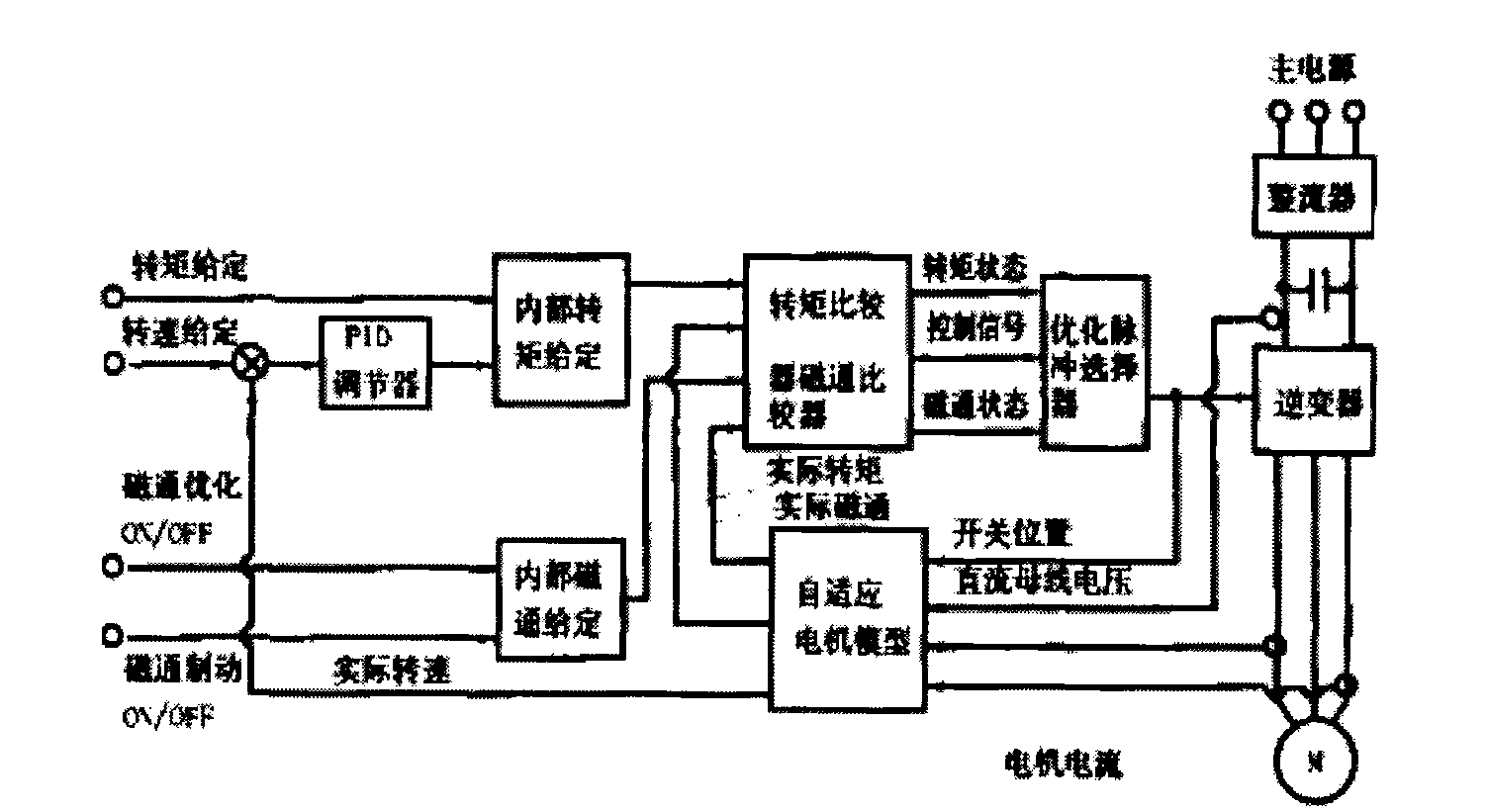

Direct torque control system

InactiveCN103001572AIncrease top speedExpand the range of speed regulationMotor parameters estimation/adaptationProportion integration differentiationControl system

The invention discloses a direct torque control system. An output end of an internal torque giver is connected with an input end of a torque comparator / magnetic flux comparator, rotational speed setup is connected with the internal torque giver through a PID (proportion integration differentiation) adjuster after being compared with actual rotational speed feedback, magnetic flux optimizer and a magnetic flux brake are respectively connected with the internal torque giver, the output end of the internal torque giver and an output end of an adaptive motor model are connected with an input end of the torque comparator / magnetic flux comparator, an output end of the torque comparator / magnetic flux comparator is connected with an input end of an optimized pulse selector, and a main power supply circuit is used for optimizing the whole control system by using a control circuit for controlling and adjusting the torque of a motor. The direct torque control system has the advantages that by means of measurement of torque and magnetic flux, open and closed states of an inversion circuit are adjusted immediately, and then the torque and the magnetic flux are further adjusted so that precise control is achieved.

Owner:WUXI FORE AUTOMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com