Medium-voltage high-rotation-speed brushless direct-current motor driver

A brushless DC motor, high-speed technology, applied in the direction of AC motor control, single motor speed/torque control, electrical components, etc., can solve the problem of controlling the motor speed is not high, the inverter efficiency is low, high-speed brushless DC motor driver There are not many problems such as research, to achieve the effect of simple structure, good control characteristics, and improved stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

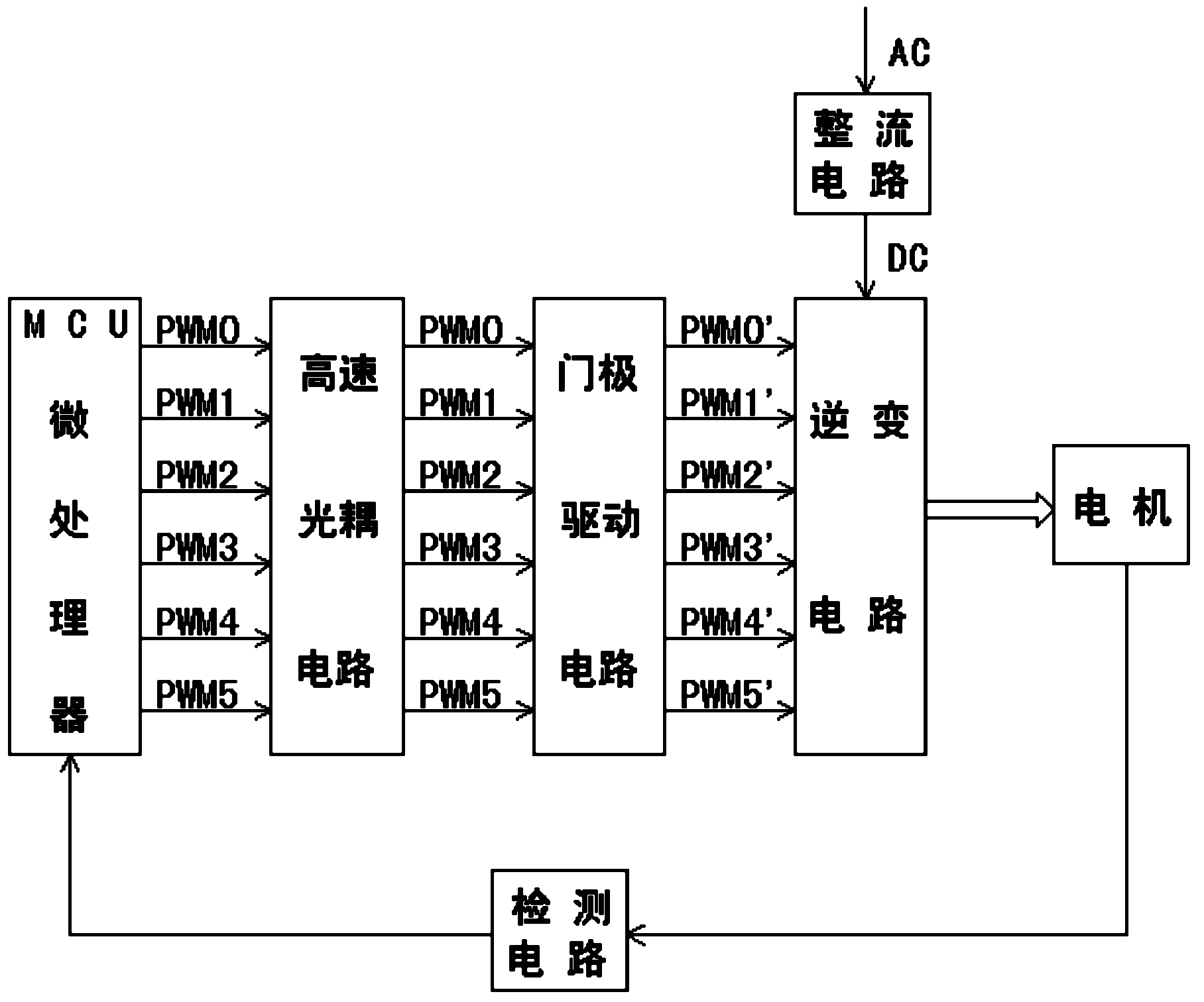

[0016] The medium-voltage high-speed brushless DC motor driver described in this embodiment includes an MCU microprocessor, a high-speed optocoupler circuit, a gate drive circuit, an inverter circuit, a motor, a detection circuit, and a rectifier circuit. The pulse width modulation signal sent by the device is sent to the high-speed optocoupler circuit, the high-speed optocoupler circuit is used to isolate the gate drive circuit from the MCU microprocessor, and the gate drive circuit sends a drive control signal according to the received pulse width modulation signal , the drive control signal is sent to the inverter circuit, the AC power is rectified by the rectifier circuit and then input to the inverter circuit, and the inverter circuit sends a drive voltage according to the received drive control signal and sends it to the motor to drive the motor to work. The detection circuit detects the motor speed signal and the motor rotor position signal and sends the obtained signal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com