Patents

Literature

56results about How to "Reduce work injuries" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

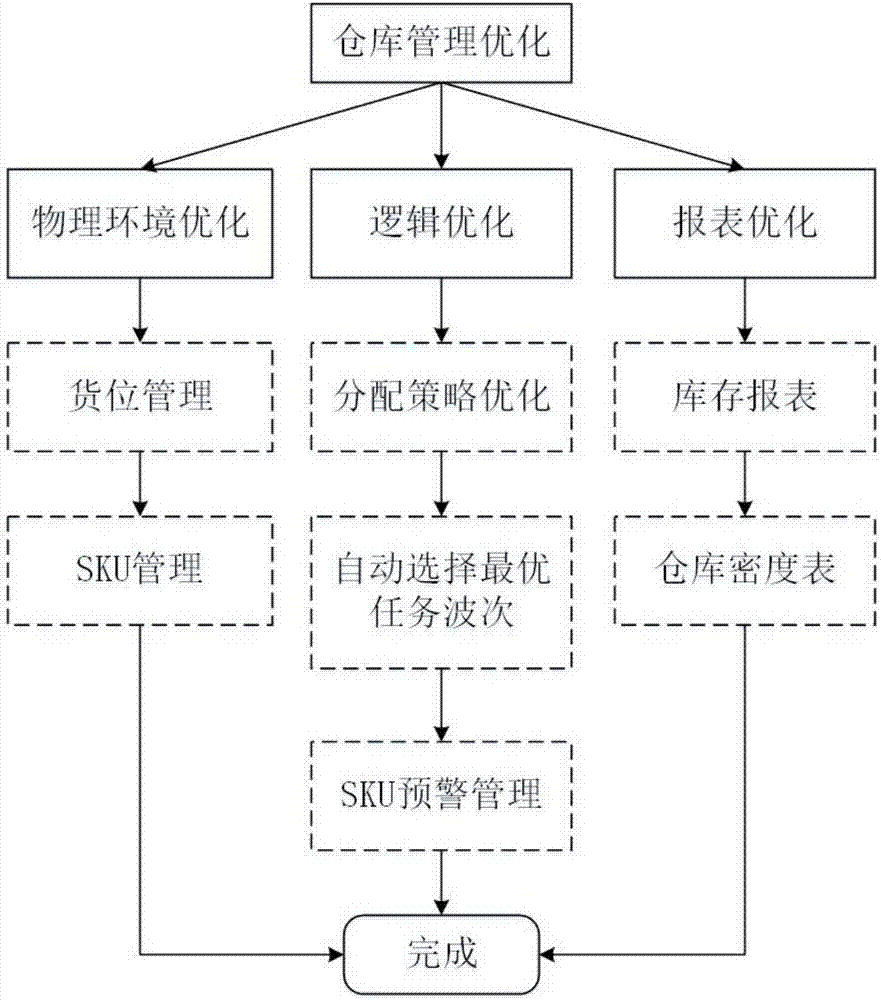

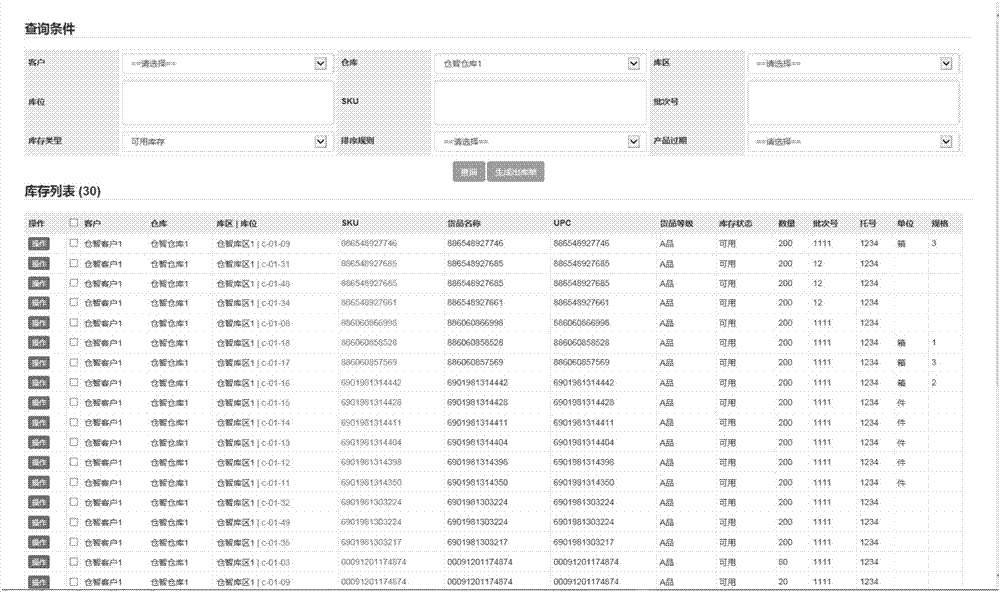

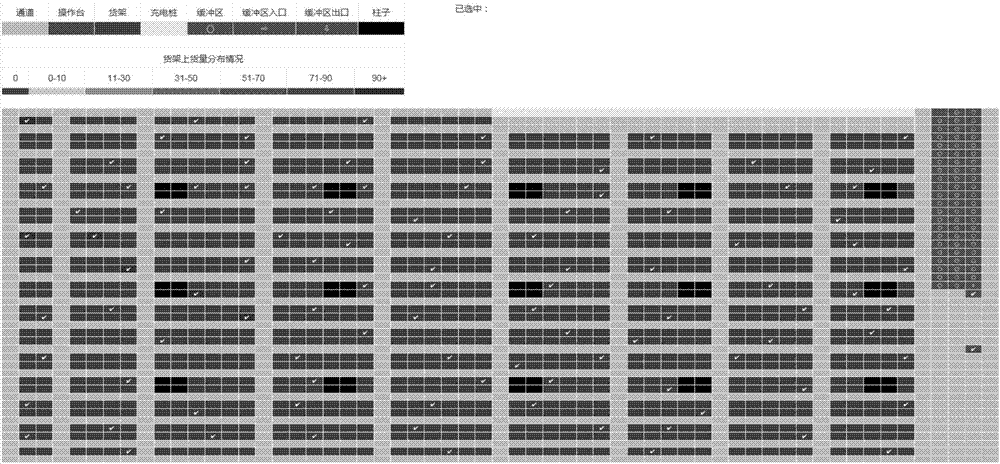

Store management optimization method

The invention discloses a store management optimization method. The store management optimization method comprises the steps of: optimizing the physical environment of cargoes and logistics at first, then, logically optimizing optimized information according to requirements of customers, and finally, making store information into a report to perform report optimization, wherein the physical environment optimization content includes cargo management and SKU logistics management; the logic optimization content includes distribution strategy optimization, automatic selection of an optimal task wave order and SKU forewarning management; and the report optimization content includes an inventory report and a store density table. The invention provides the store management optimization method, which integrates cargo allocation, distribution and loading strategy, transport capacity resource, logistics network and task wave order logistics management optimization algorithms into a whole, and can realize seamless joint with a logistics supply chain information system.

Owner:仓智(上海)智能科技有限公司

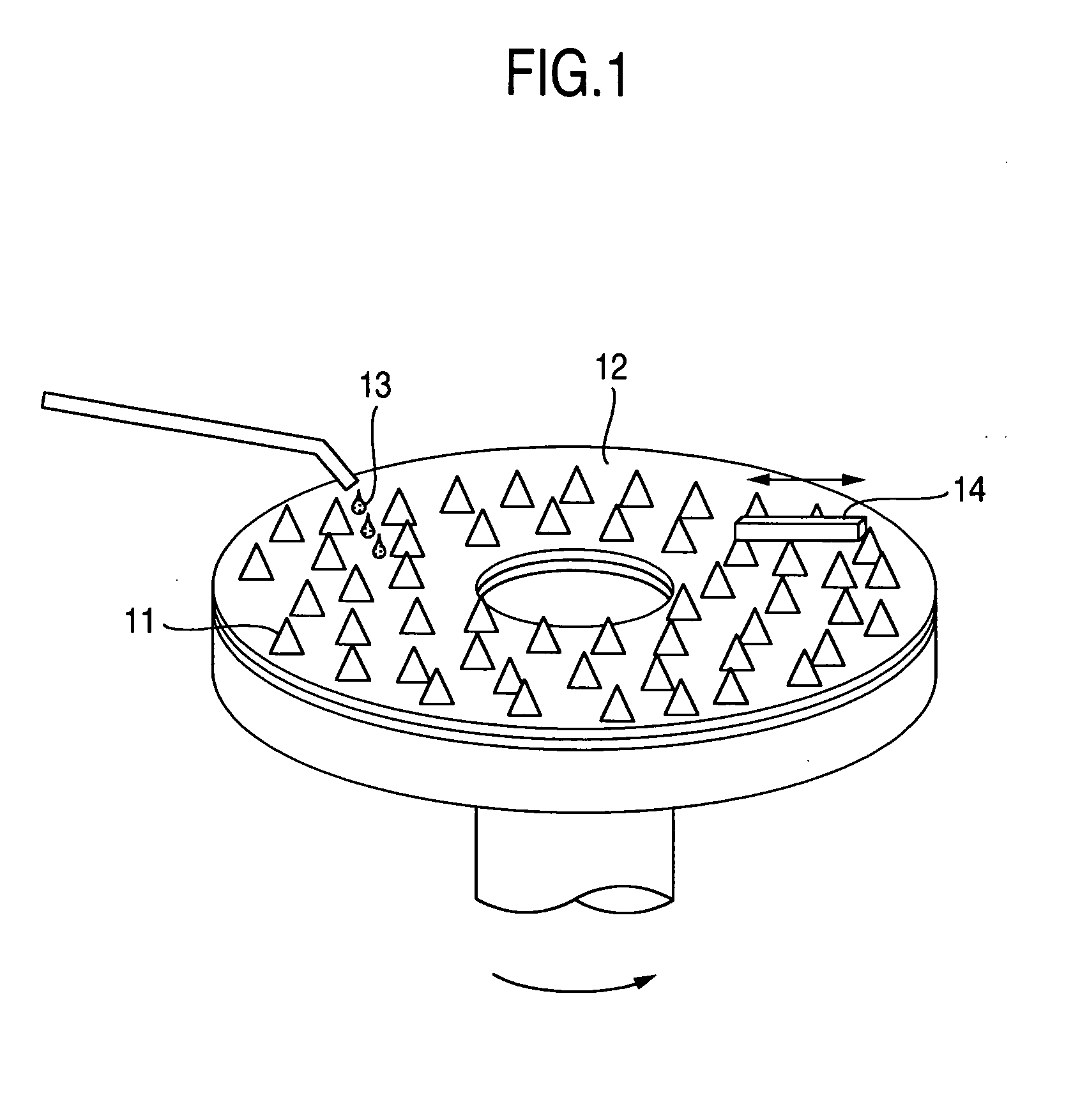

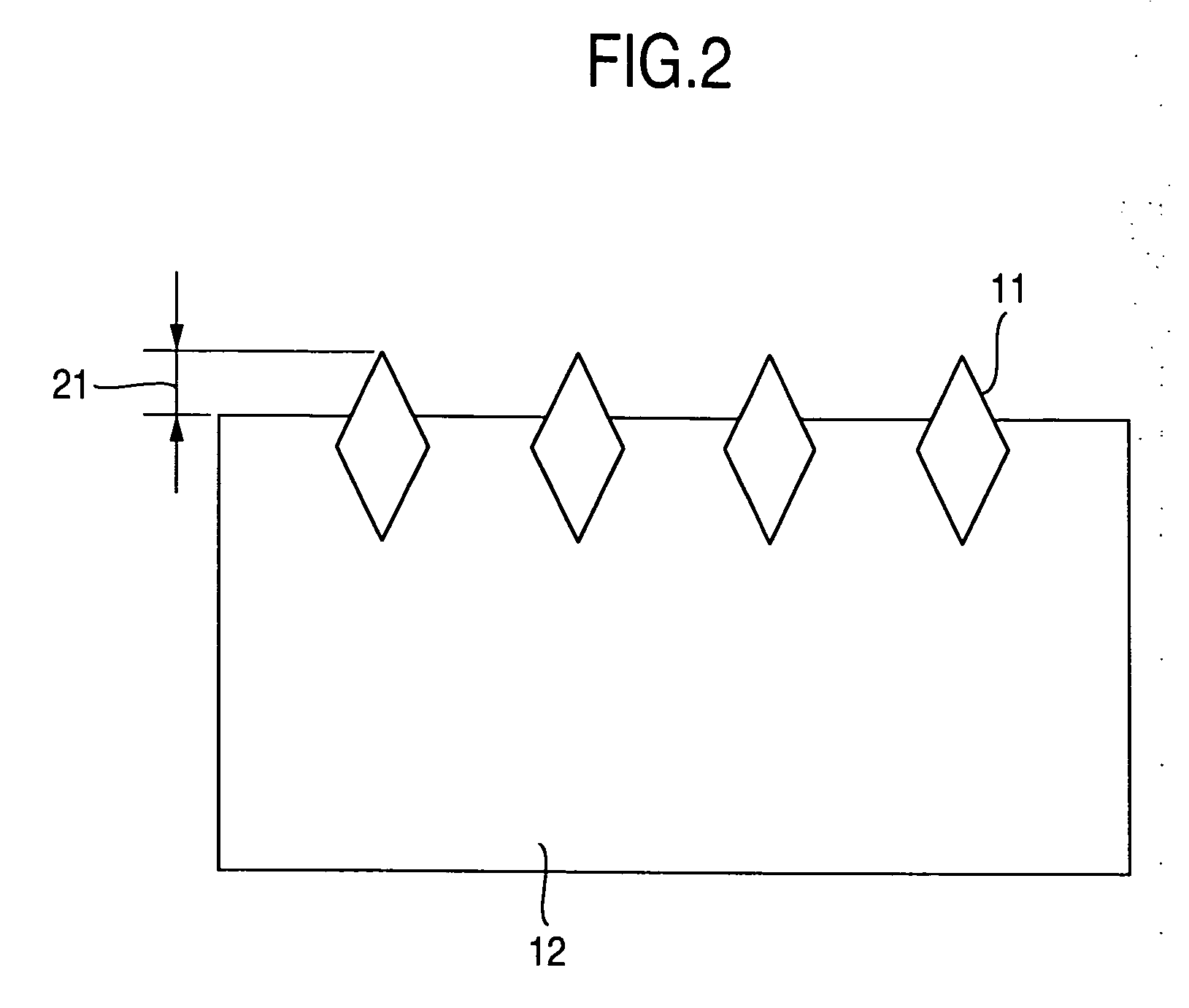

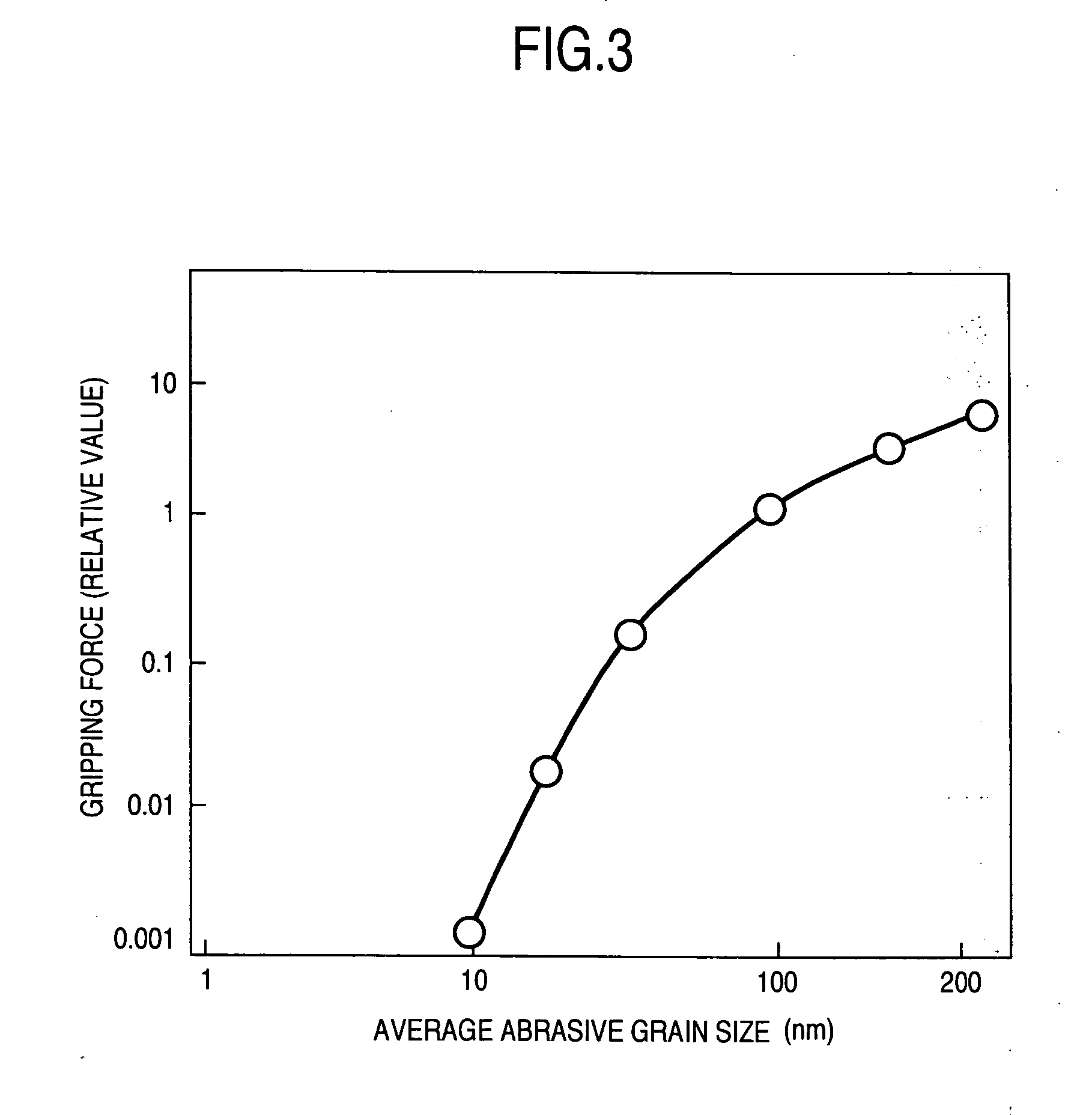

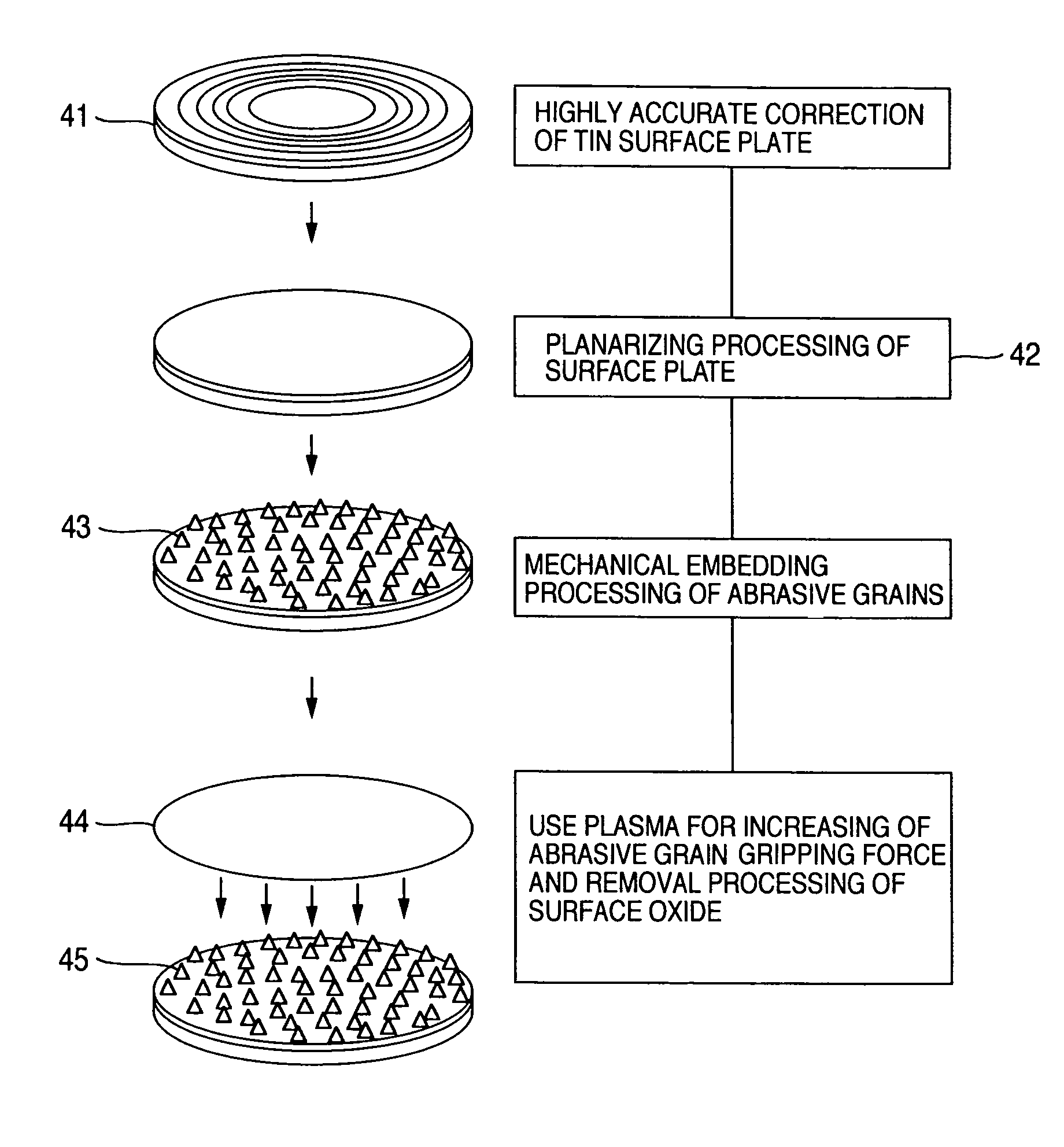

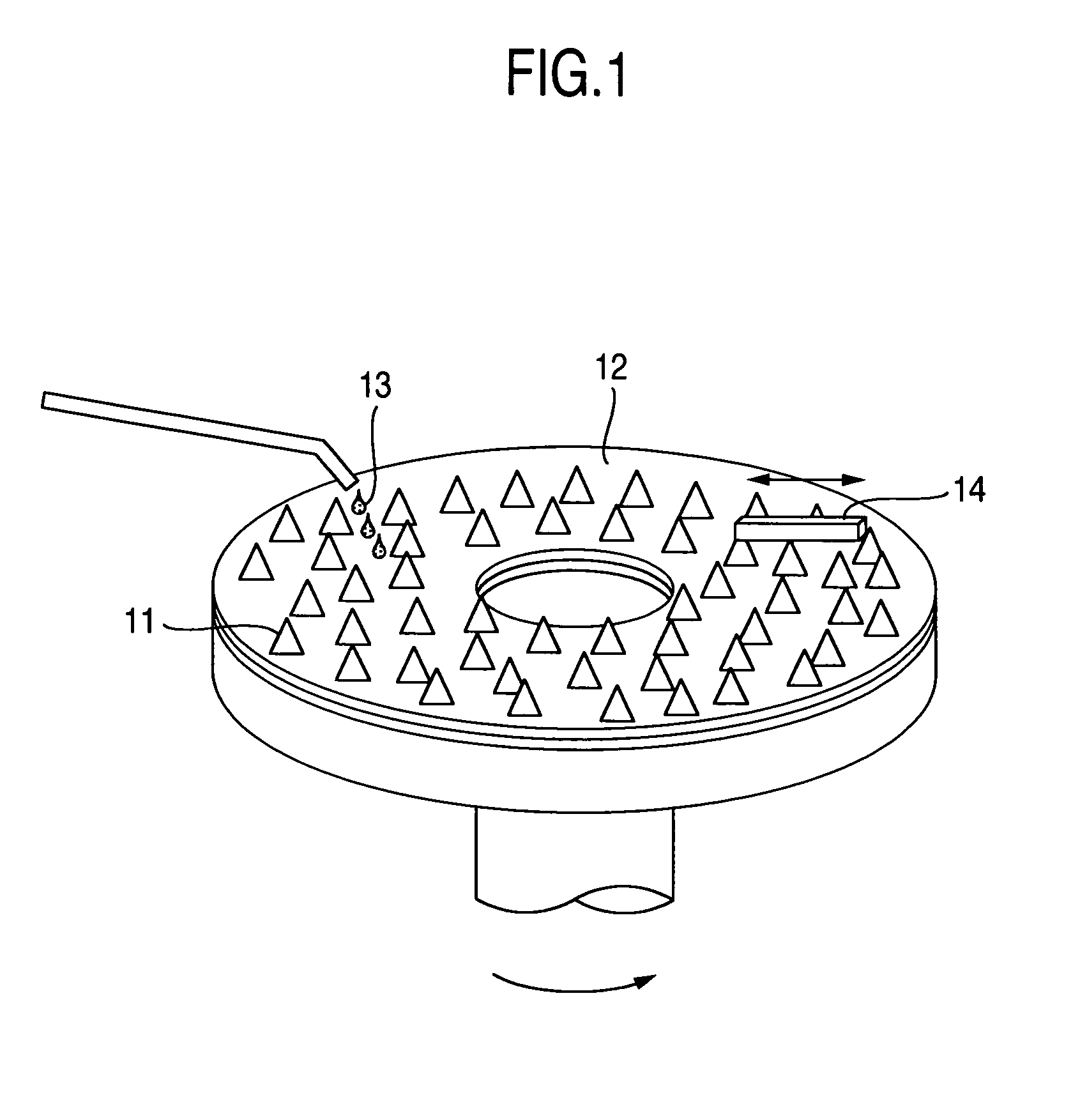

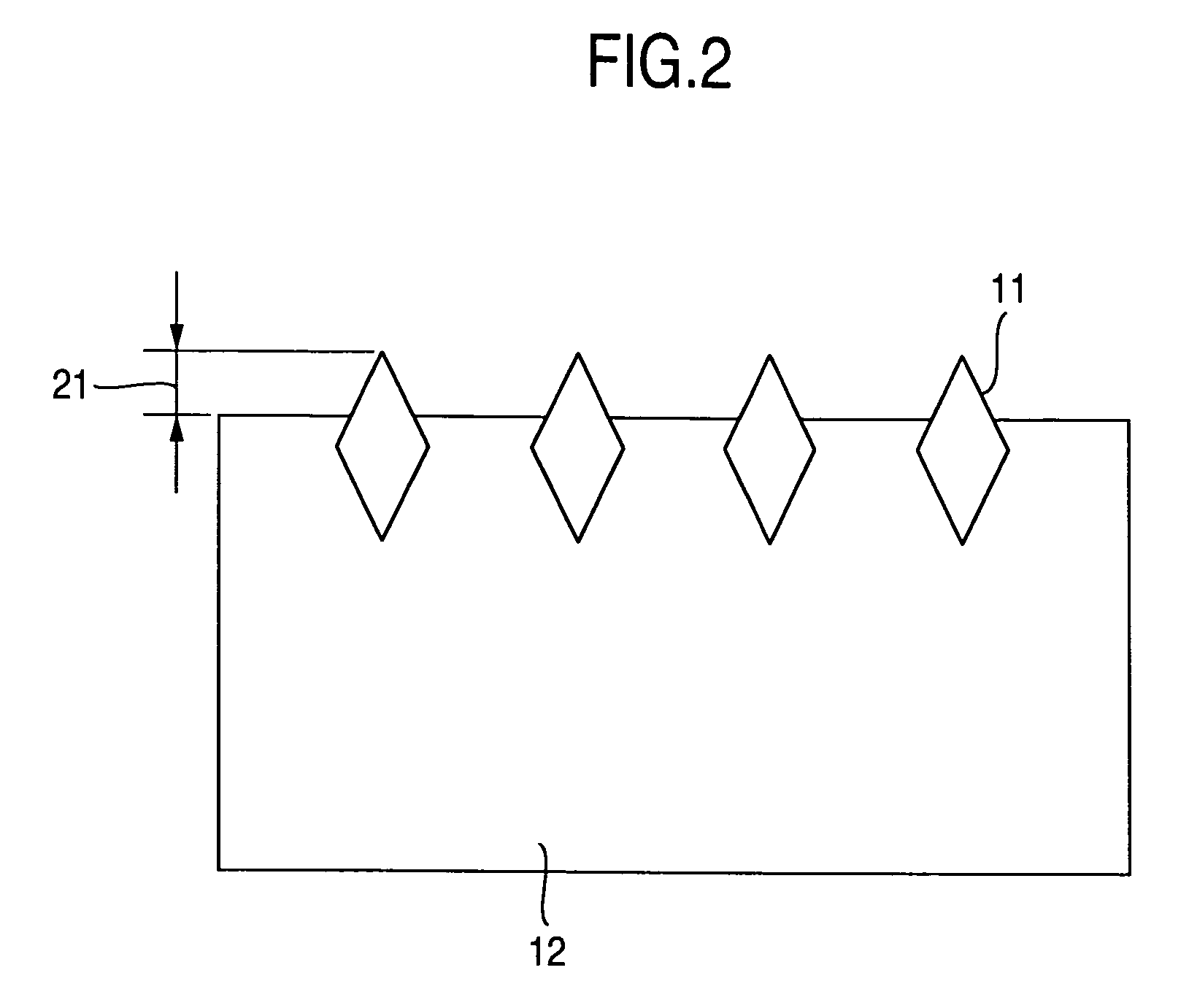

Lapping tool and method for manufacturing the same

InactiveUS20070122548A1Improve lap efficiencyEasy loadingLiquid surface applicatorsOther chemical processesMulti materialHardness

Since structural portions of a device made of a plurality of materials are different from one another in mechanical hardness, it is very difficult to uniformly lap the structural portions. This is attributable to generation of machining recessions due to differences in lapped amount when large fixed abrasive grains are used, and generation of lapping marks caused by that the dropped abrasive grains rotate. Accordingly, in order to cope with the disadvantage, it is essential to surely grip abrasive grains of small size to a surface of a surface plate. [Solving Means]Abrasive grains are fixedly forced into a surface of a lapping tool with mechanical pressure and then the surface of the lapping tool including the abrasive grains is subjected to plasma processing, whereby an improvement in adhesion between the abrasive grains and a surface plate and reduction in the number of loose abrasive grains, which are dropped from the surface of the lapping tool, can be achieved, so that it is possible to realize lapping, in which a surface of a device made of a plurality of materials is made very plane.

Owner:HITACHI LTD

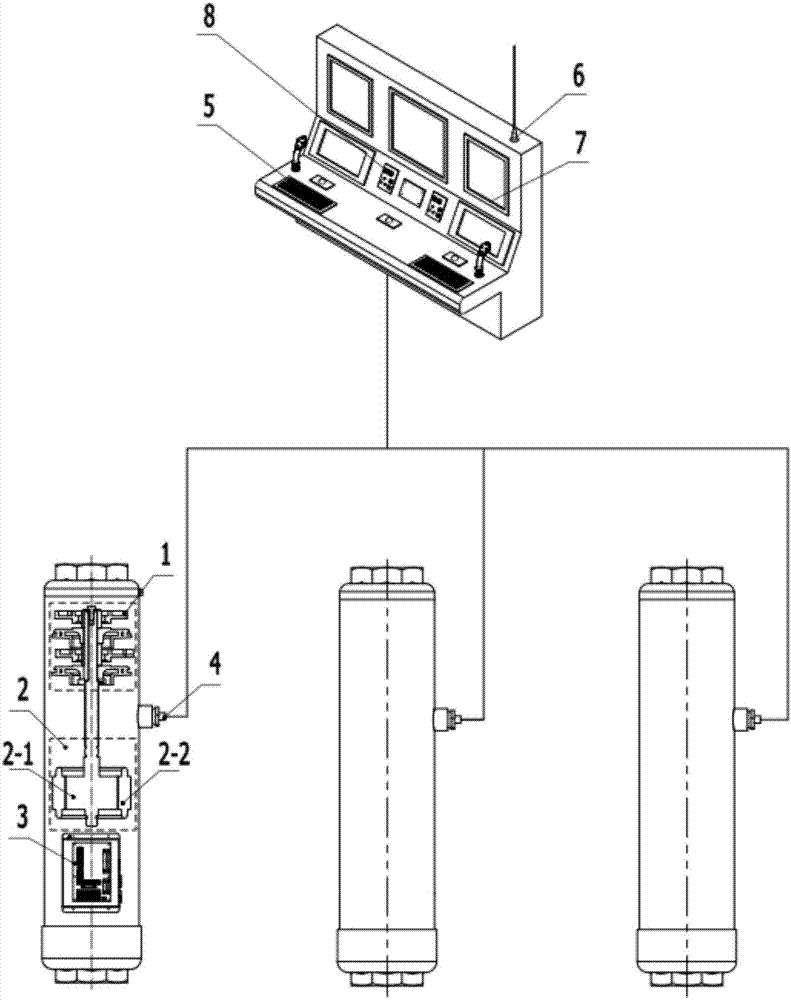

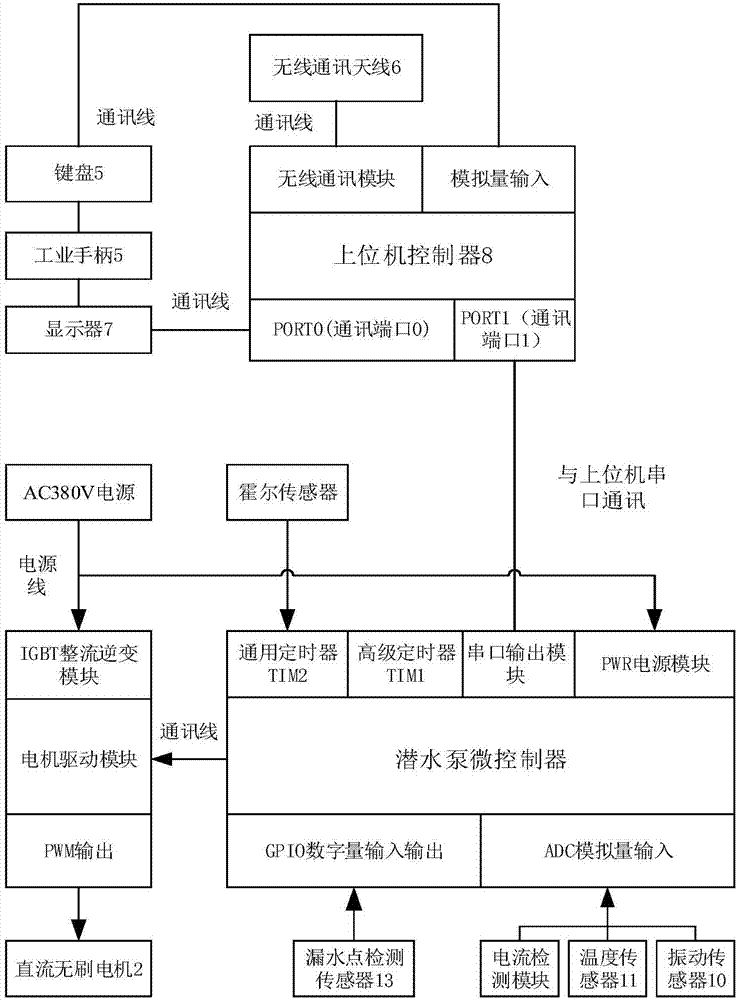

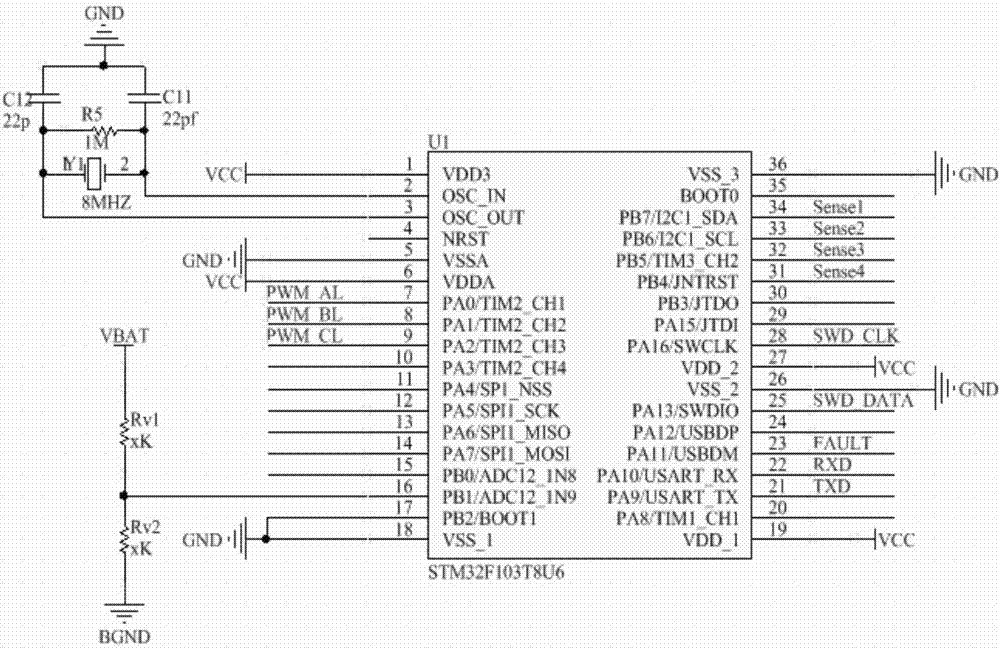

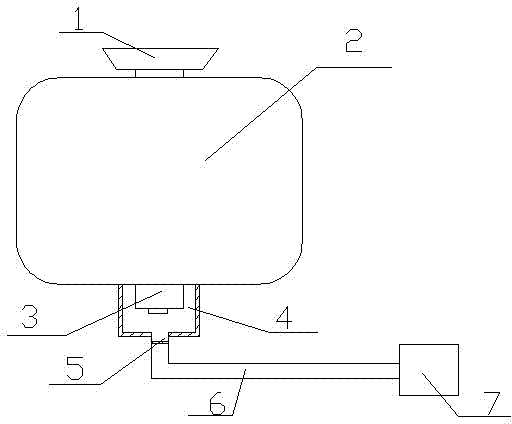

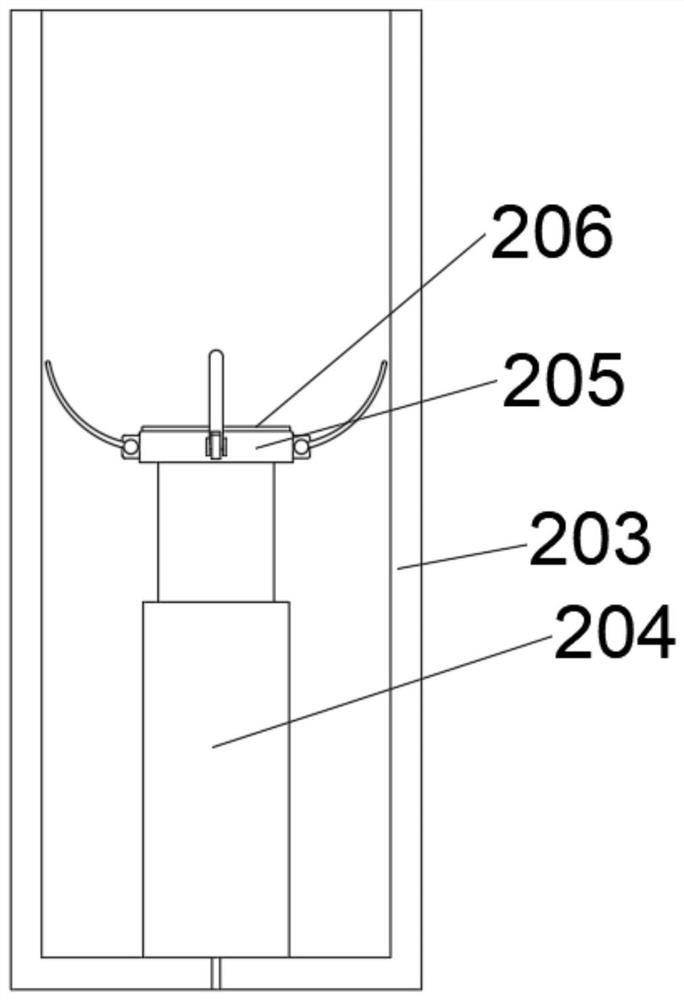

Intelligent integrated control system and intelligent integrated control method based on serial communication for submerged pump

InactiveCN107575401AWork reliablyReduce work injuriesMultiple motor speed/torque controlPump controlImpellerAutomatic control

The invention discloses an intelligent integrated control system and an intelligent integrated control method based on serial communication for a submerged pump, and belongs to the technical field ofintelligent control for submerged pumps. The control system comprises a shore-based upper computer system and underground submersible pump systems which are connected through serial communication wirecables. Each underground submersible pump system is composed of an impeller assembly, a motor and a printed circuit board, wherein the printed circuit board is integrated with an IGBT rectification-inversion module, a motor drive module, a sensor input module and a serial communication port. Each underground submersible pump system sends the internal vibration data, temperature and humidity dataand leakage-point detection sensor data to an upper computer controller in real time, and receives the instructions of the upper computer controller. The intelligent integrated control system is highin integration degree, convenient to install and automatic in control, thereby greatly lowering the labor intensity of personnel, and increasing the working efficiency. The intelligent integrated control method based on serial communication for the submerged pump is based on a multi-sensor fusion technology, and a PID control technology for the rotational speeds and the currents of the motors, thereby meeting the requirements of independent variable-frequency speed regulation and fault detection for the submerged pump.

Owner:JIANGSU UNIV ZHENJIANG RES INST OF FLUID ENG EQUIP TECH

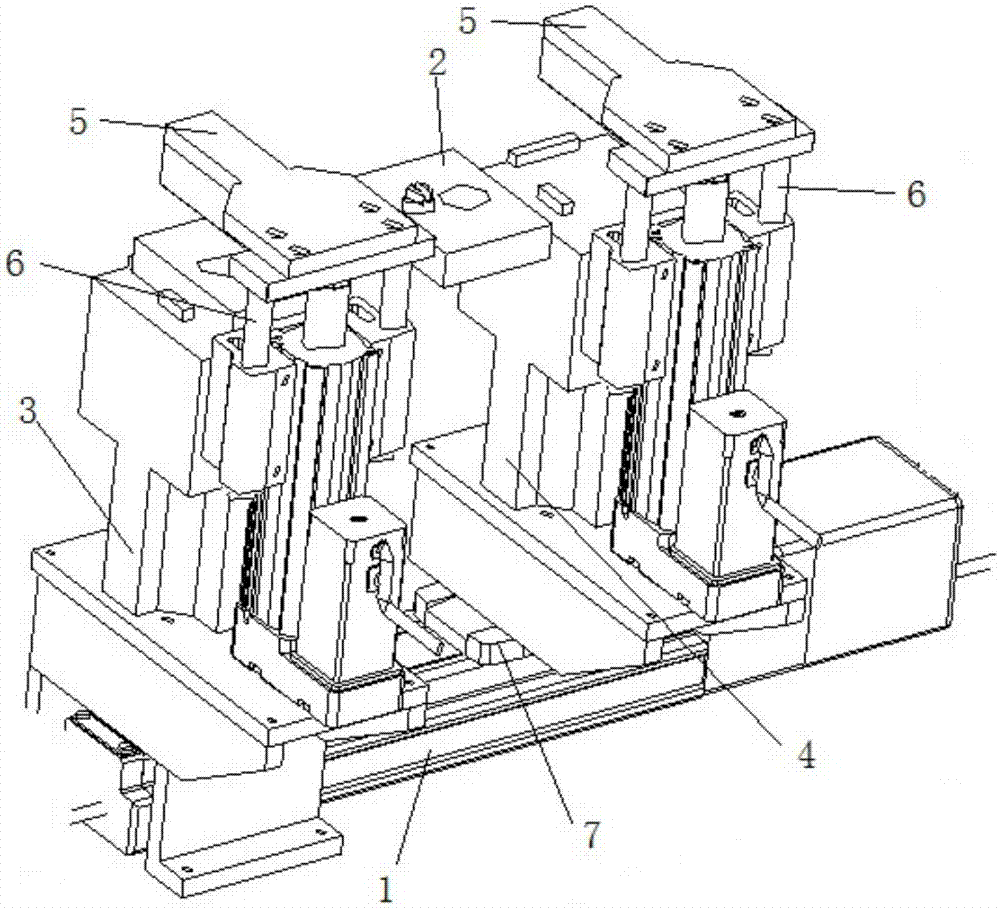

Waste slice removing mould

InactiveCN102699955AQuality assuranceReduce work injuriesMetal working apparatusPulp and paper industrySupport plane

The invention discloses a waste slice removing mould comprising an upper mould plate, a lower mould plate and a lower mould baffle plate, wherein the upper mould plate is provided with a waste removing knife; the lower mould plate is internally provided with a blanking hole; the waste removing knife and the blanking hole correspond to each other in positions; the waste removing knife extrudes finished waste slices out of the blanking hole to achieve the purpose of waste removal; the upper mould plate and the lower mould plate are respectively provided with positioning holes; positioning supports are arranged in the positioning holes to keep the waste removing knife and the blanking hole to correspond to each other in the positions; a ladder-shaped opening is arranged on the lower end of the blanking hole, a small round chamfer is arranged on the edge of the upper end of the blanking hole, and the width of the upper end is less than that of the lower end so that desquamated waste slices are convenient to discharge; the lower mould baffle plate is positioned on the periphery of the lower mould plate and encloses finished products with wastes to be removed to prevent the finished products from generating displacements in a horizontal direction; and a support frame is connected to the bottom of the lower mould plate to support and fix the lower mould plate. When the waste slice removing mould is in use, the upper mould plate and the lower mould plate are respectively arranged on a support capable of moving up and down, and then a waste removal function is achieved; and in addition, the invention is ensured in product quality, increased in production efficiency and saved in cost.

Owner:ZHEJIANG KAISHI LASER TECH CO LTD

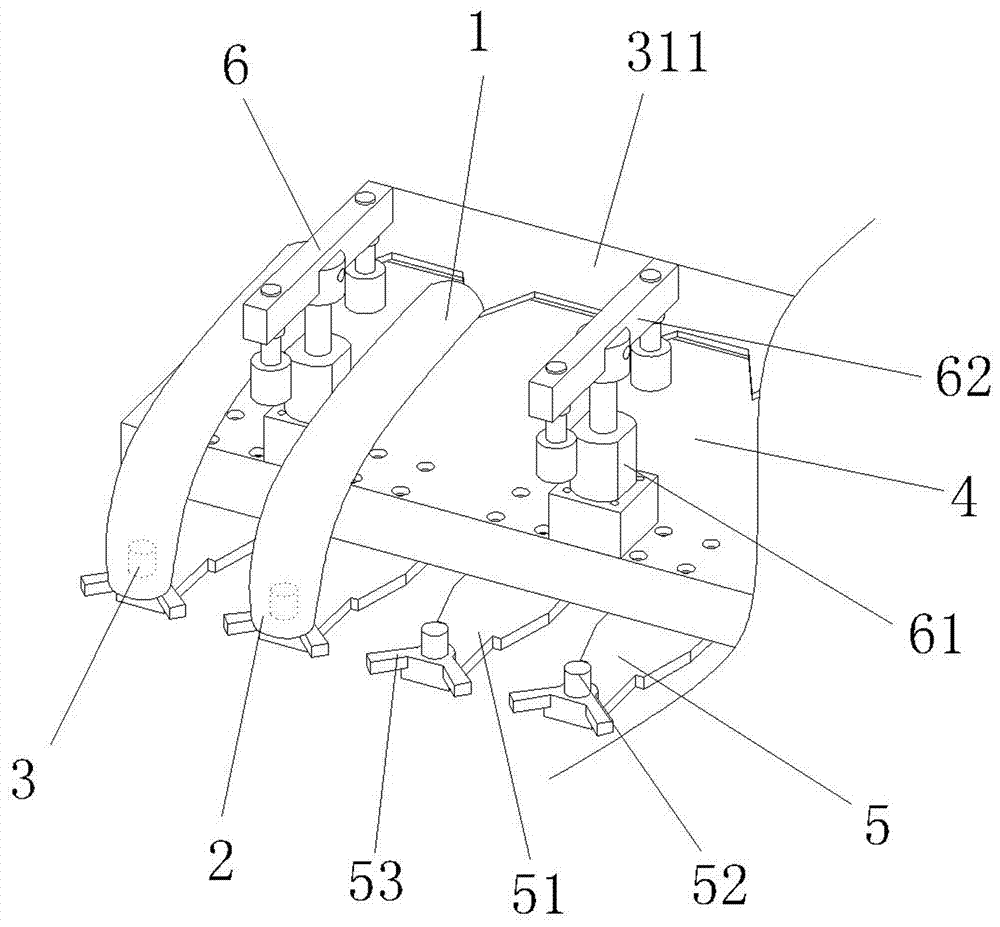

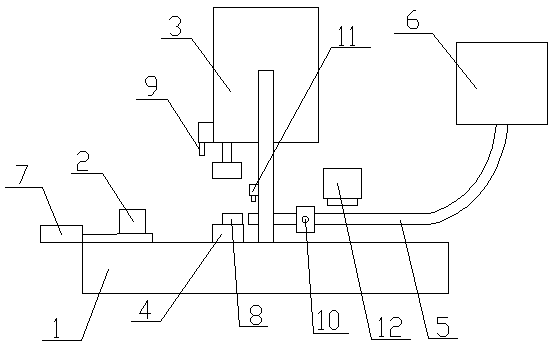

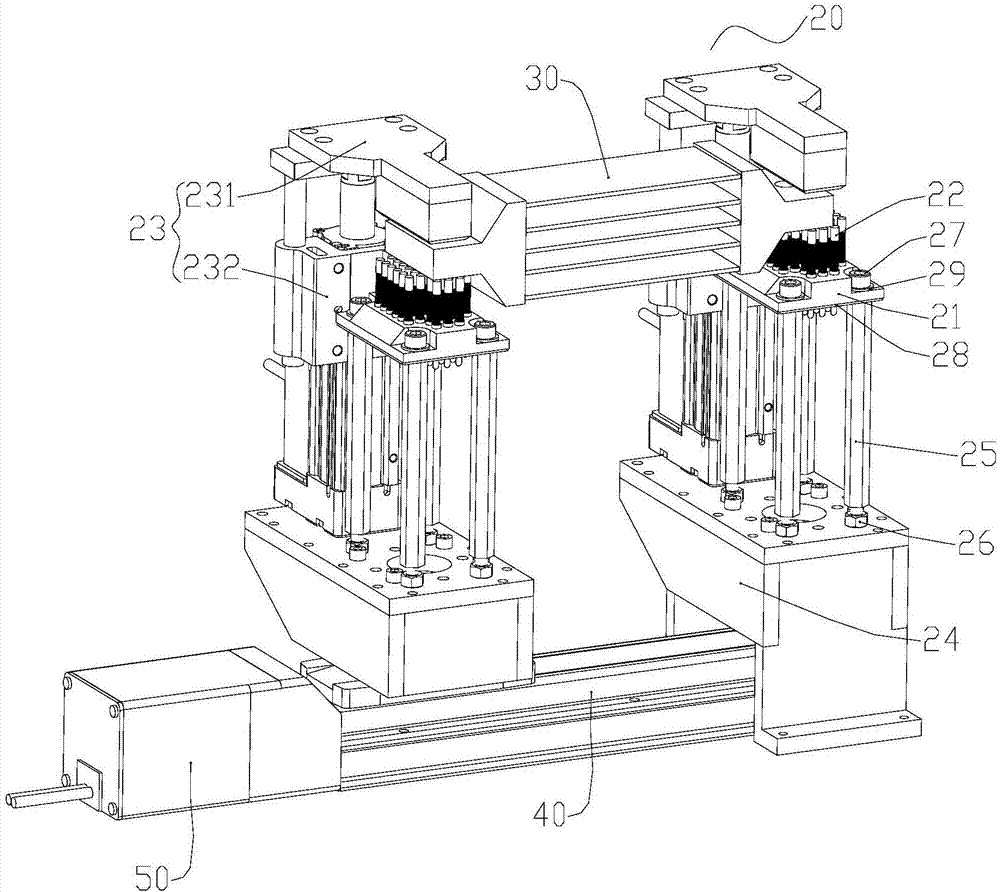

Casting head remover

InactiveCN103111610AReduce laborReduce labor intensityWork related injuriesProgrammable logic controller

Disclosed is a casting head remover which comprises a lathe bed, a table top, a translation module arranged on the table top, an auxiliary guide rail module arranged on the table top and used for resisting grinding force, a control cabinet and a grinder. Multiple workstations are arranged on the translation module, processing is performed at one workstation while feeding and discharging operations can be performed at other workstations, a feeding unit and a clamp unit are disposed at each workstation, and a sensor used for measuring sizes before and after casting head removal is disposed on each feeding unit. Sensor detection is adopted, so that changes of the size of a casting head and a grinding wheel can be effectively detected; the casting head remover is controlled by adopting a PLC (programmable logic controller) integrally, casting head removal can be automatically completed, and only feeding and discharging processes need manual participation, so that labor power can be reduced, labor intensity can be lowered, and risks of work-related injuries and suffering from occupational diseases are reduced.

Owner:SUZHOU UNIV

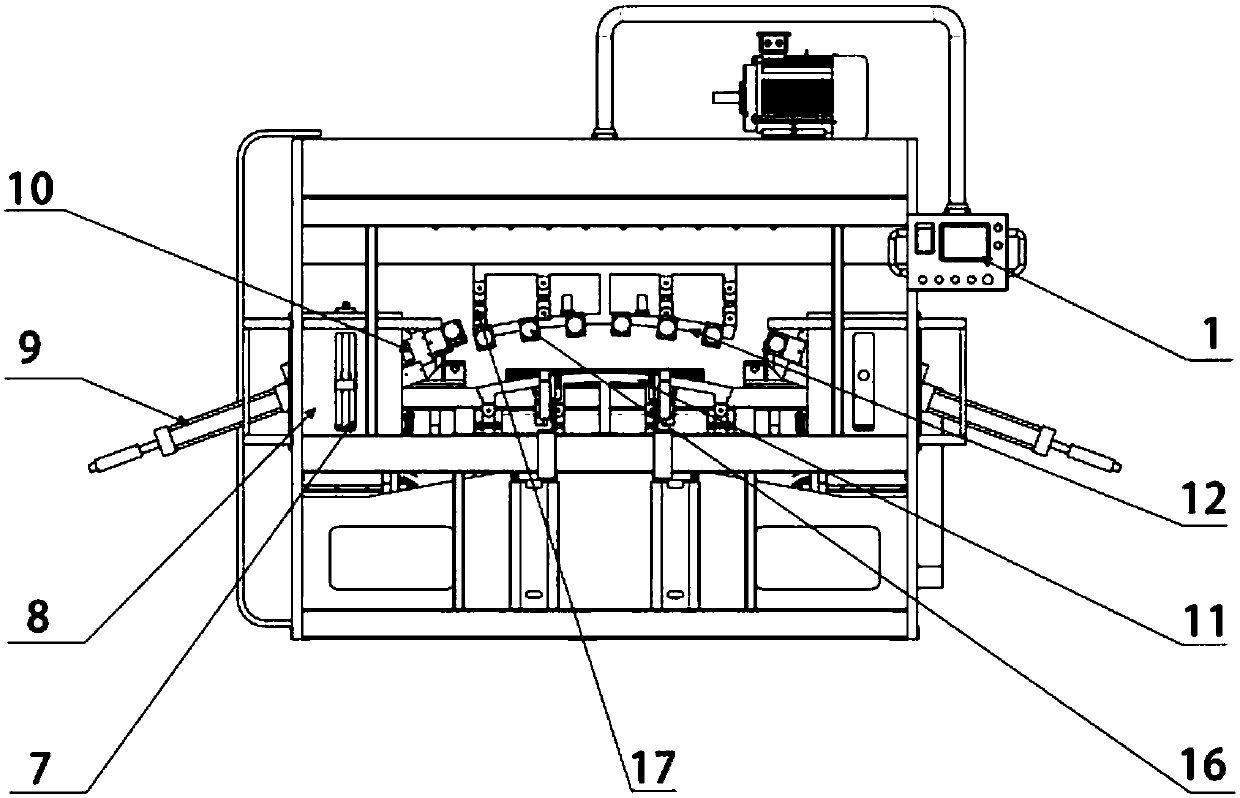

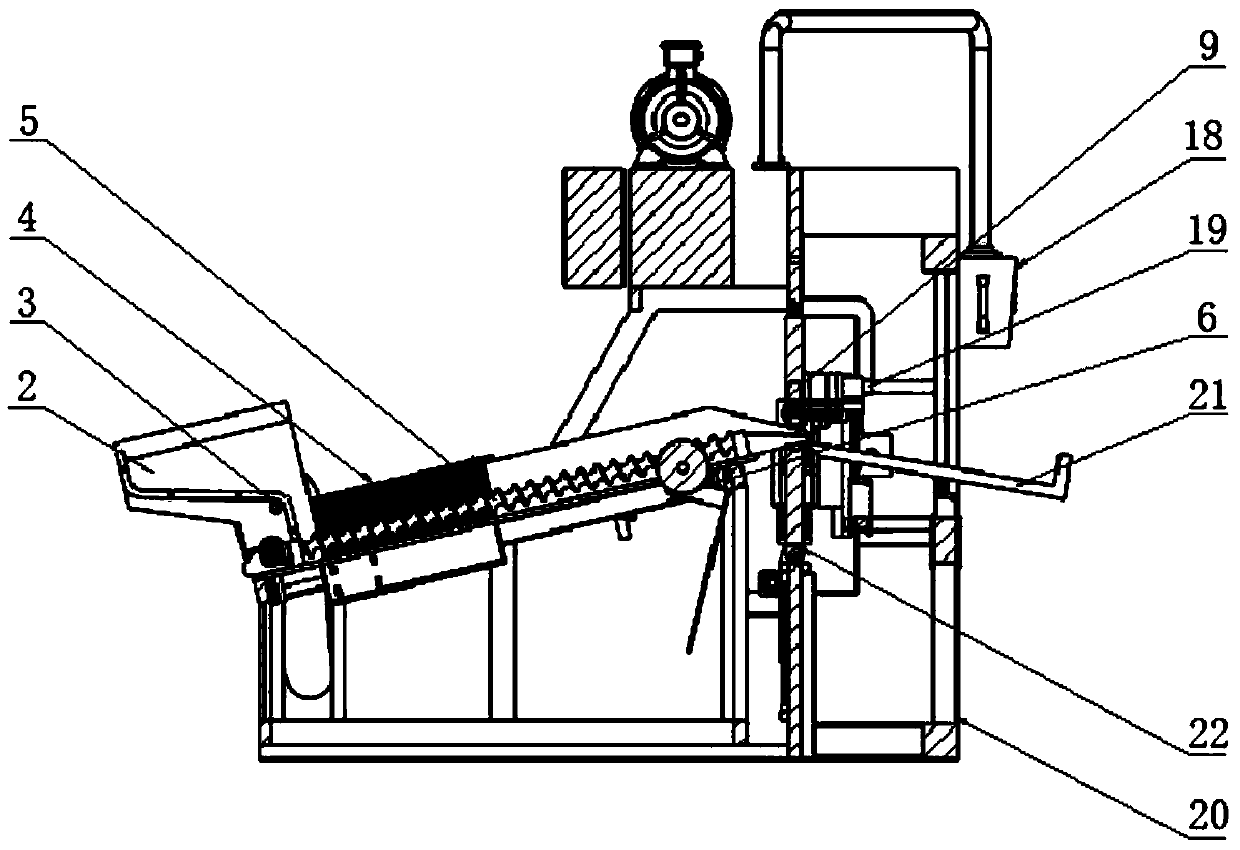

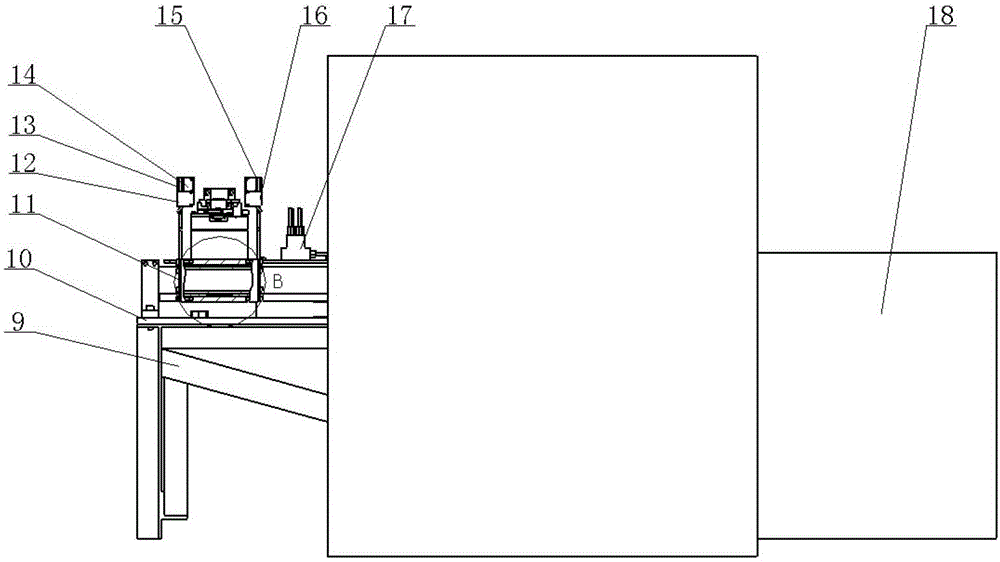

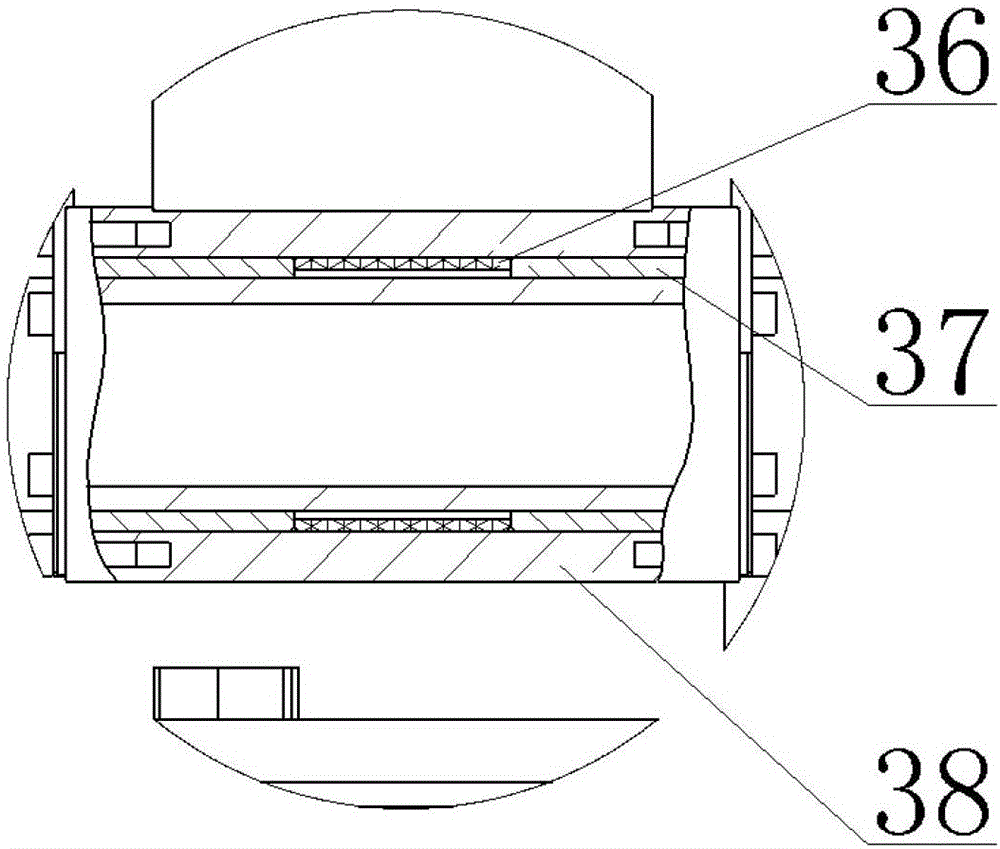

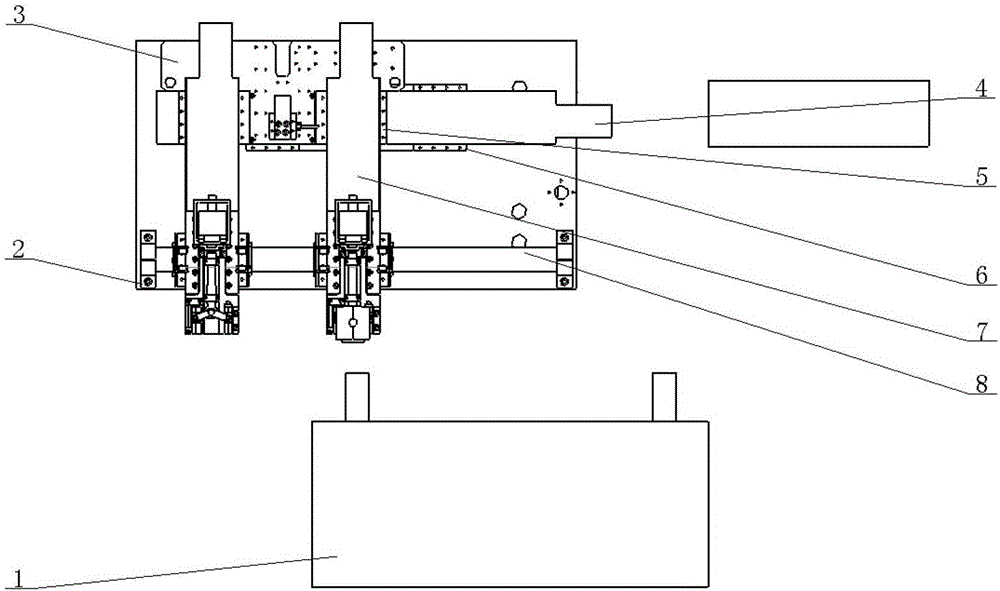

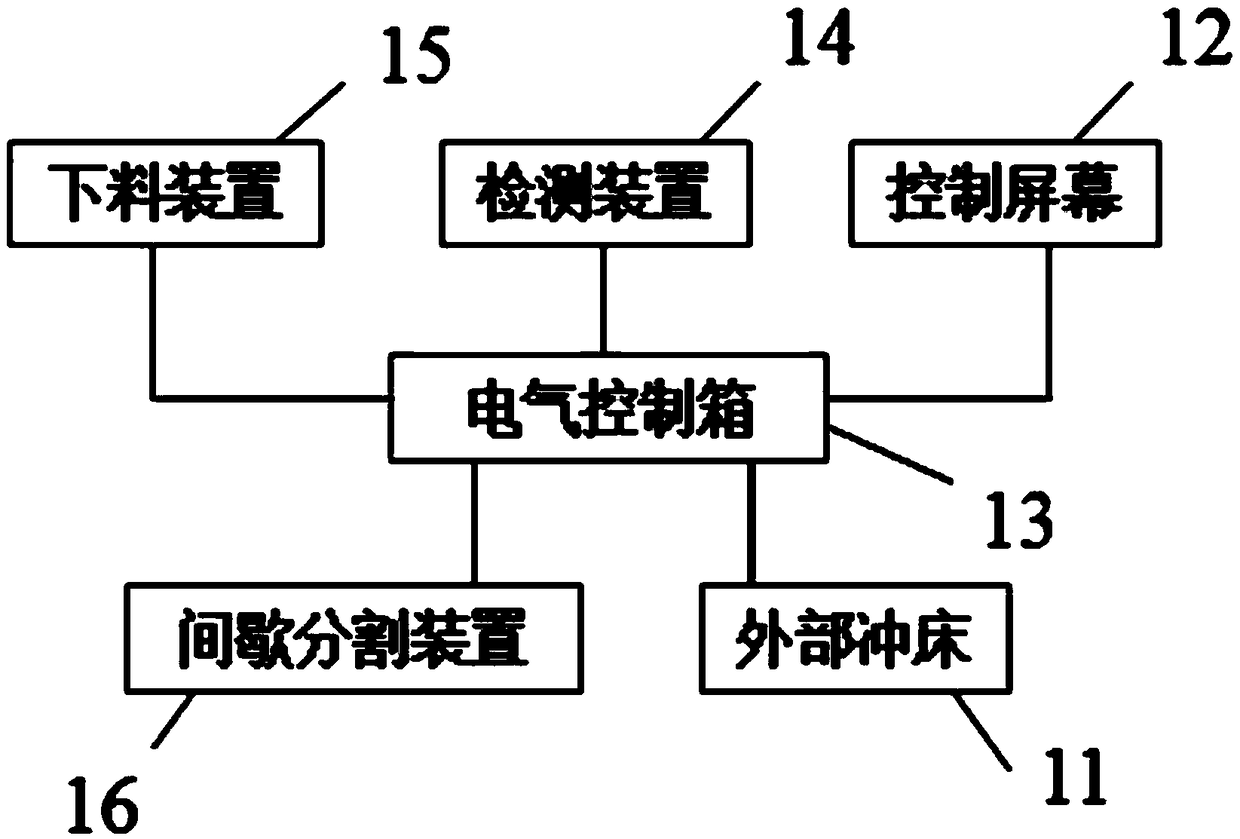

Full-automatic bent pipe and shrunk pipe punching machine

InactiveCN107755530AComplete and compact structural designEasy to controlEdge grinding machinesMetal-working feeding devicesPunchingWork related injuries

The invention discloses a fully automatic bending and shrinking punching machine, which includes a touch screen control electric box, a loading bin, a feeding screw, a brush for wiping pipes, an adjustable oil cylinder for shrinking dies, a bending die and a main body of the punching machine. A touch screen control electric box is installed on one side of the main body of the punching machine, an electric motor is installed on the upper end of the main body of the punching machine, a bent pipe is installed on one side of the electric motor, one end of the bent pipe is connected with the touch screen control electric box, and the other end of the bent pipe is provided with a bent pipe. Pipe mold, pipe bending mold includes elbow upper clamping die and elbow lower clamping die. Both sides of the mold are equipped with shrinking mold mounting seats, and shrinking molds are installed inside the shrinking mold mounting seats. Compared with manual processes from milling tubes to bending, punching and shrinking, the entire processing process saves time and improves The production capacity reduces work injuries, and the invention has a simple structure and a reasonable design, is more humanized, and is suitable for popularization and use.

Owner:深圳市永顺通用机械有限公司

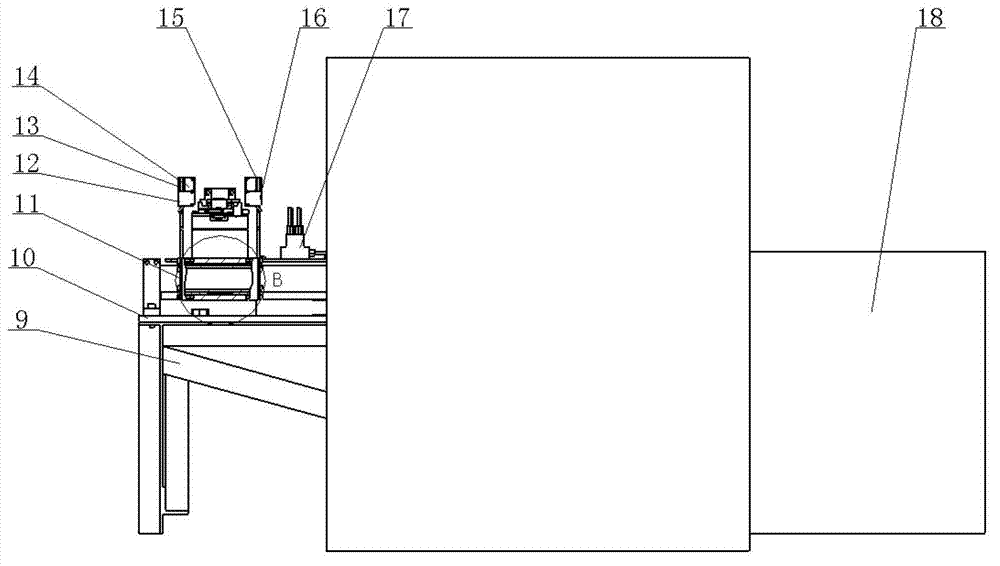

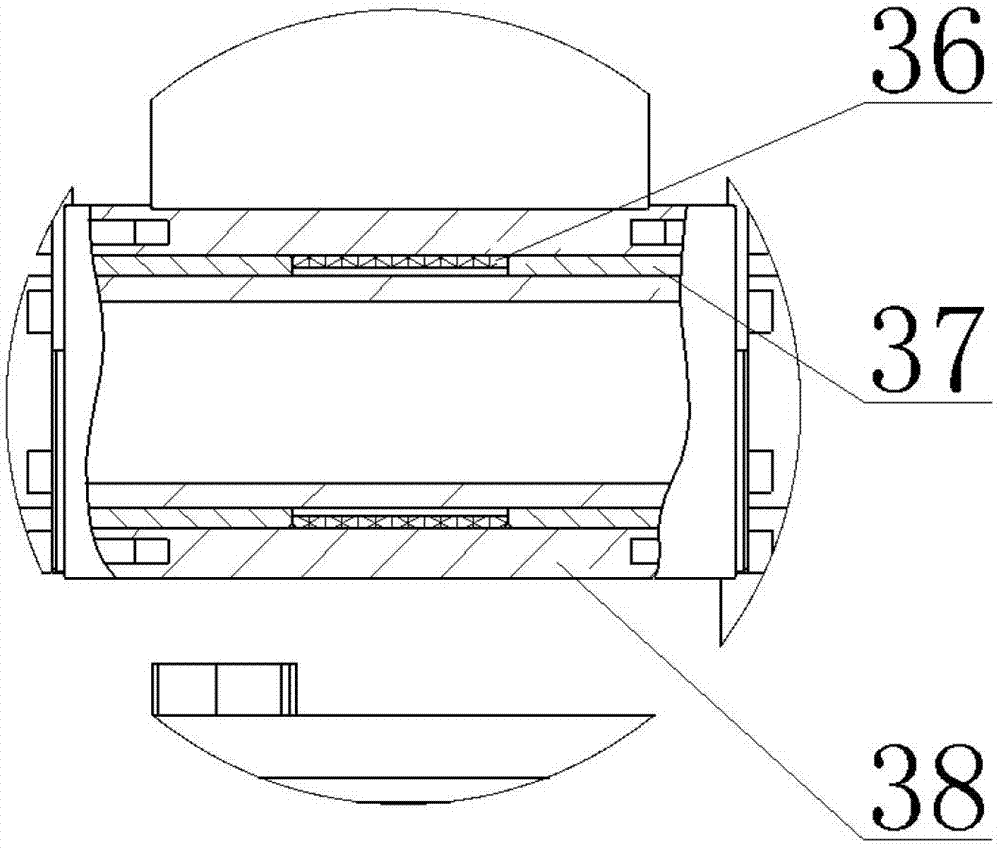

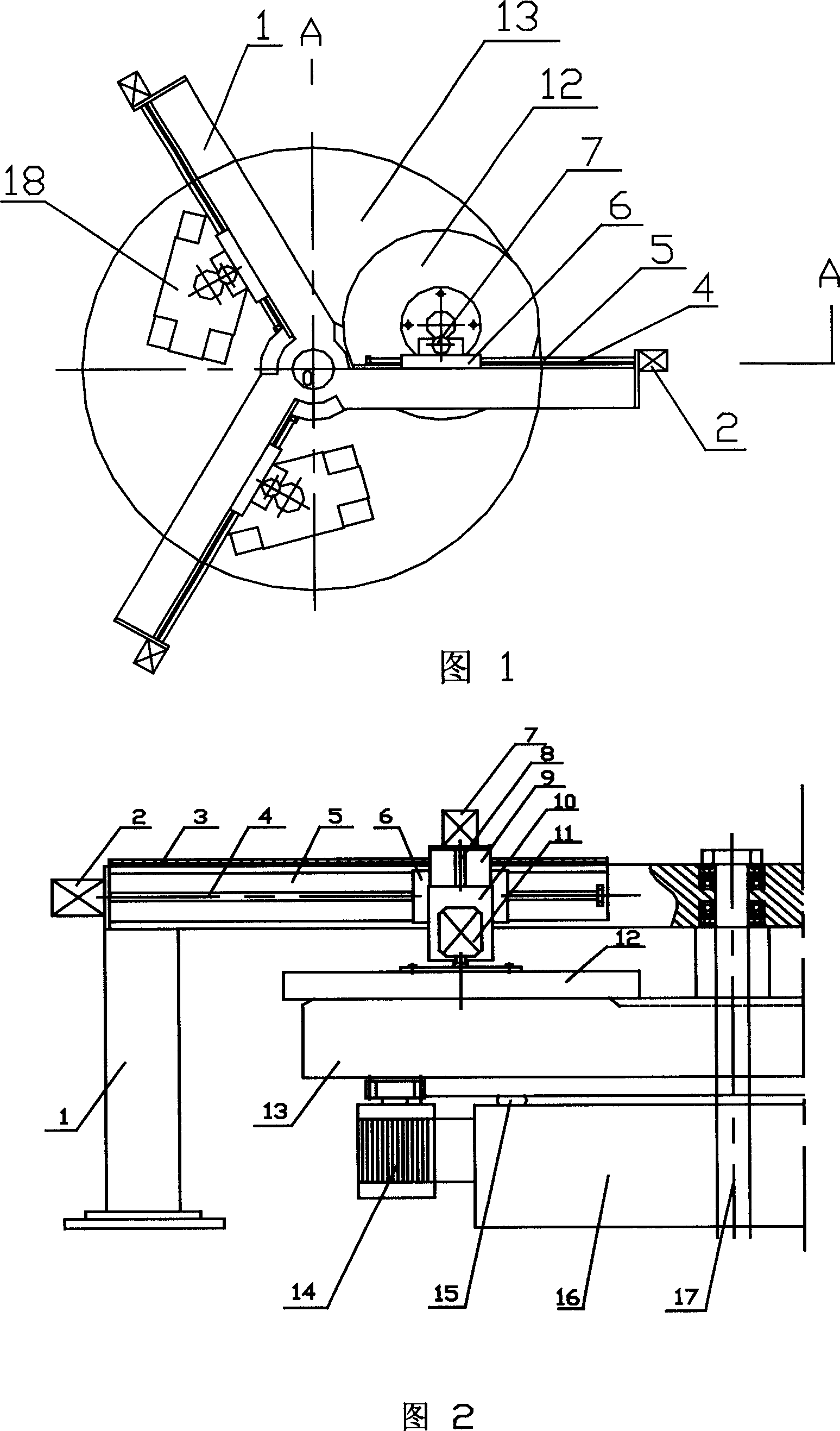

Automatic plate moving mechanism of large-diameter high-accuracy glass polishing machine

ActiveCN101096074ASmooth temperature changeSolve the deformationEdge grinding machinesGrinding machine componentsEngineeringMechanical engineering

The invention relates to an automatic disk-moving mechanism of large-diameter high-accuracy glass polisher, mainly comprising a large rotary disk. On the disk face of large rotary disk rubber disk is set and on the rubber disk finishing disk and workpeice disk are set. A three-foot scaffold is set at outside of the large rotary disk. Three horizontal beams of the scaffold are located above the large disk and are intersected with the large disk at the center. Radial disk-moving mechanism is set on each horizontal beam. The mechanism comprising a radial screw, a radial guide rail, a radial seat frame and step motor. Vertical lifting mechanism is set on each radial seat frame. The mechanism comprises a vertical screw, a vertical guide rail, a vertical seat frame and step motor, wherein a vertical seat frame is fixed with the center frame of finishing disk and other two vertical seat frame are fixed with the center frame of workpeice disk. Transmission mechanism for driving the finishing disk or the workpeice disk rotate is set on each vertical seat frame. The invention can improve producing efficiency and decrease industrial injury. The invention also conquers the deformation problem of rubber disk face and improves machining quality.

Owner:上海中晶企业发展有限公司

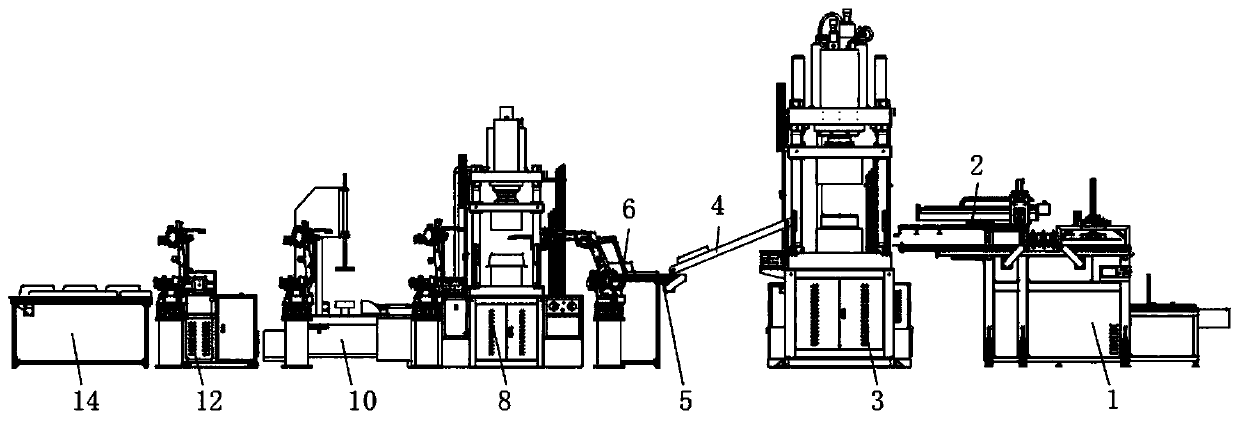

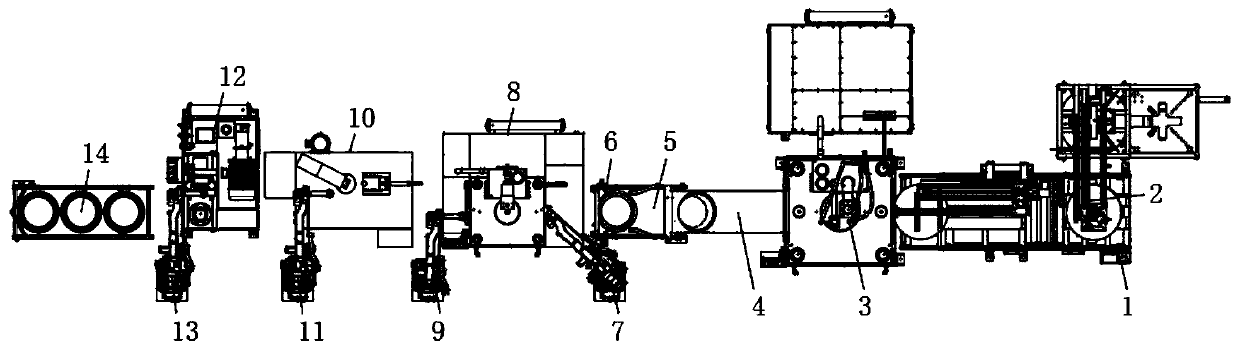

Inner container deep-stretching automatic line

InactiveCN110814161AShorten the processing cycleThe control process is stable, safe and reliableMetal-working feeding devicesMetal working apparatusRobot handProcess engineering

The invention relates to the technical field of electric rice cooker production lines, in particular to an inner container deep-stretching automatic line. The inner container deep-stretching automaticline comprises a loading and oil coating integrated machine, a feeding manipulator, a first stretcher, an unloading oblique bucket, a first conveyor, a clamping positioning mechanism, a first four-axis robot, a second stretcher, a second four-axis robot, a curling machine, a third four-axis robot, a labeling machine, a fourth four-axis robot and a second conveyor, the feeding manipulator is located on the left side of the top of the loading and oil coating integrated machine, the first stretcher is located on the left side of the loading and oil coating integrated machine, and one end of theunloading oblique bucket fixedly communicates with a discharging outlet in the left side of the first stretcher. According to the inner container deep-stretching automatic line, the purposes that a control process is stable, safe and reliable, the production takt can be closely matched, and the production efficiency is ensured are achieved, compared with traditional manual operation, the machiningcycle of an inner container can be shortened greatly through cooperative machining of the robots and an oil press, the machining circulating time is shortened, and production efficiency is improved.

Owner:FOSHAN CHENGDA HYDRAULIC EQUIP CO LTD

Manufacturing method of pressing mould turner, turning device and turning method

The invention provides a pressing mould turner which comprises a clamp hoop, four clamp rings, two wire ropes, two T-shaped hanging blocks and a screw rod, wherein two clamp rings clamp the clamp hoop and are screwed through screws to obtain a T-shaped groove sliding block and fixed with one ends of the wire ropes; the other ends of the wire ropes are tightly locked by the T-shaped hanging blocks; and the T-shaped groove sliding block is fastened with the screw rod. The invention also provides a mould turning method which comprises the following steps of: (1) adjusting the position of the T-shaped groove sliding block; (2) locking the mould with a tightening lock on the screw rod; (3) starting a driver, and pulling the mould upwards; and (4) pushing the turning mould. The method is simple and safe to operate, and solves the problems that the conventional manual mould turning operation needs large working space, is time-consuming and labor-consuming, easily causes industrial injury and the like.

Owner:广东新志密封技术有限公司

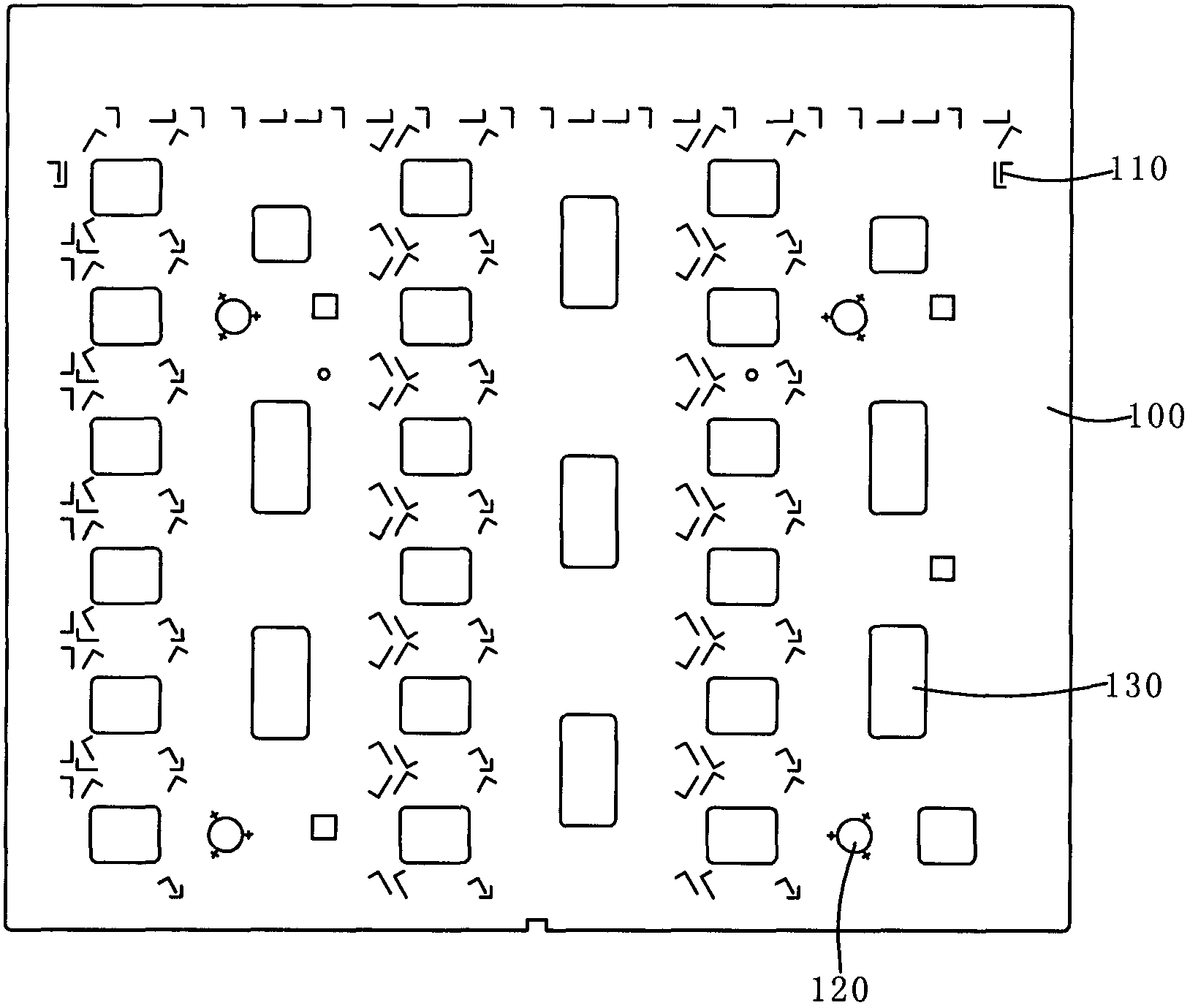

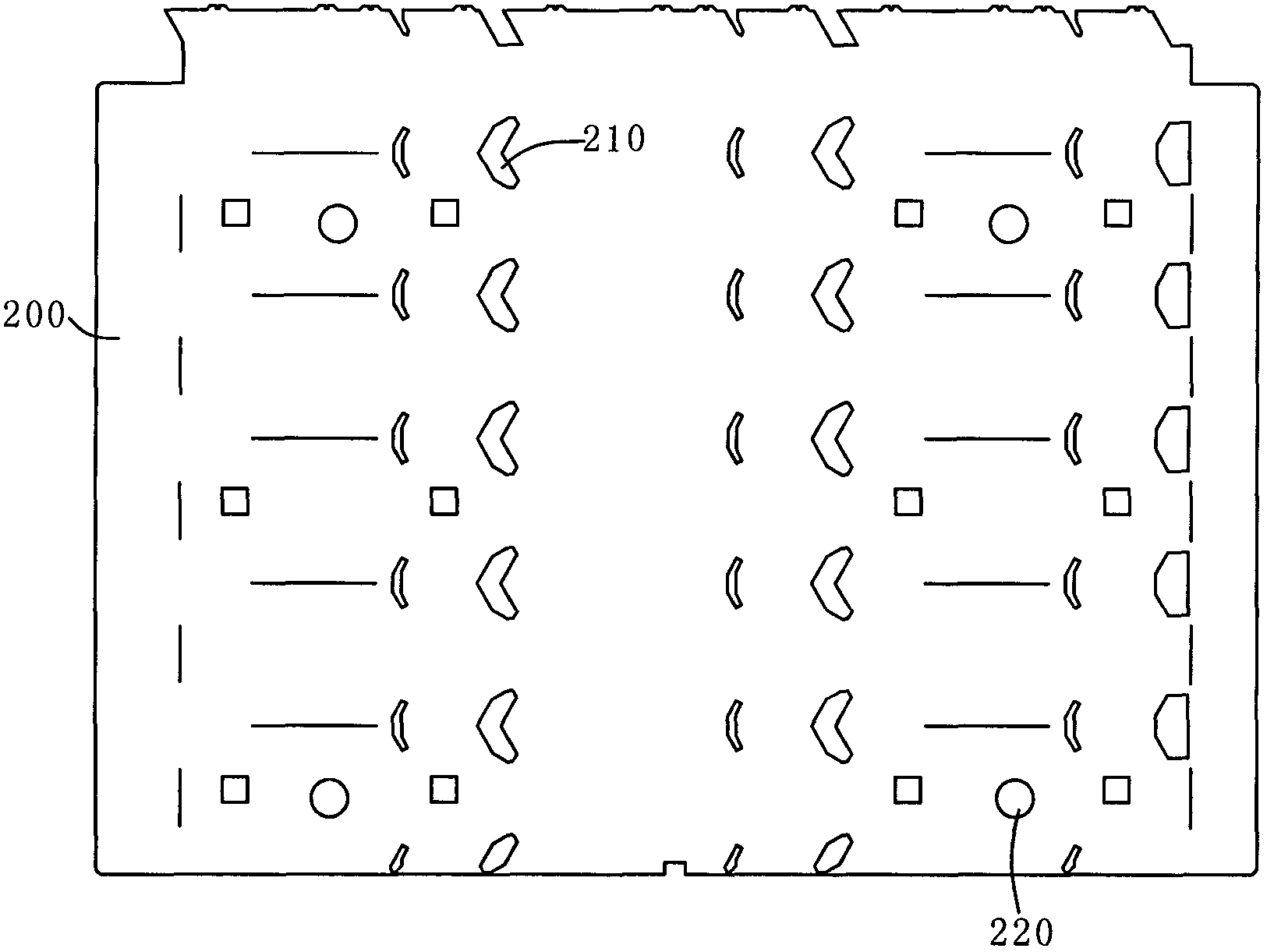

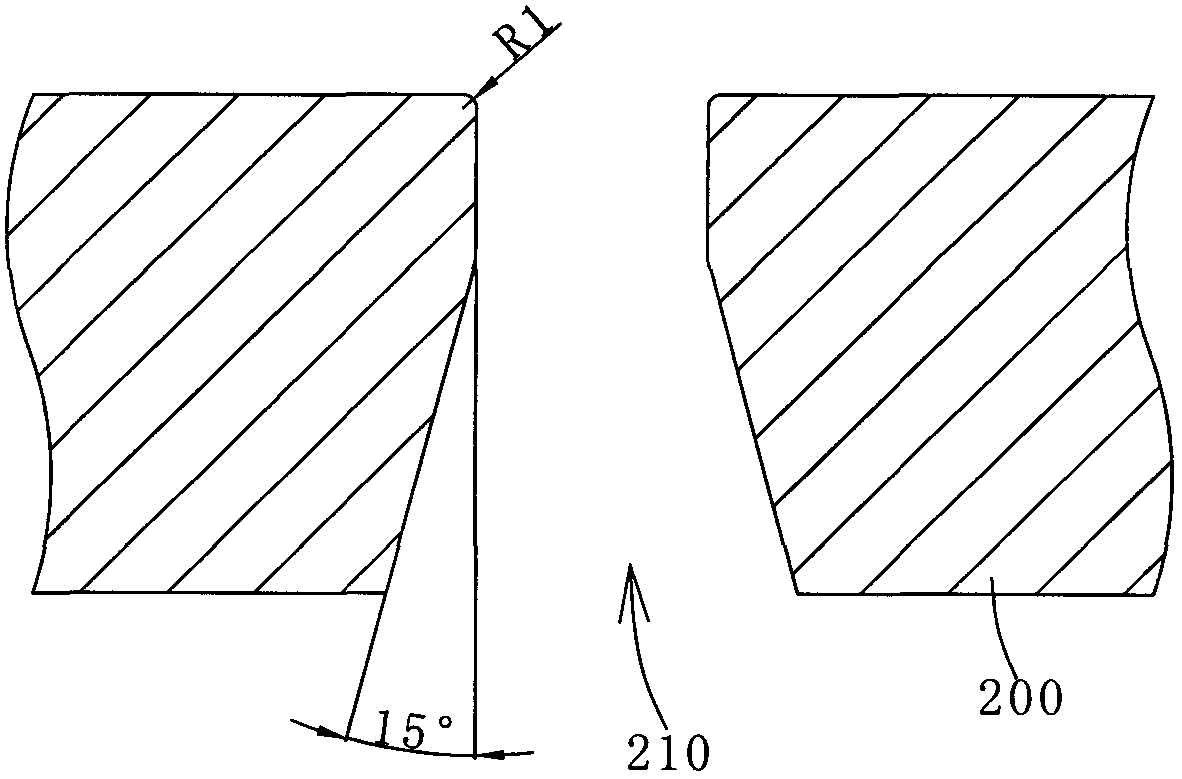

Lapping tool and method for manufacturing the same

InactiveUS8092560B2Avoid damageReduce roughnessCellsLiquid surface applicatorsHardnessMechanical pressure

Since structural portions of a device made of a plurality of materials are different from one another in mechanical hardness, it is very difficult to uniformly lap the structural portions. This is attributable to generation of machining recessions due to differences in lapped amount when large fixed abrasive grains are used, and generation of lapping marks caused by that the dropped abrasive grains rotate. Accordingly, in order to cope with the disadvantage, it is essential to surely grip abrasive grains of small size to a surface of a surface plate.[Solving Means]Abrasive grains are fixedly forced into a surface of a lapping tool with mechanical pressure and then the surface of the lapping tool including the abrasive grains is subjected to plasma processing, whereby an improvement in adhesion between the abrasive grains and a surface plate and reduction in the number of loose abrasive grains, which are dropped from the surface of the lapping tool, can be achieved, so that it is possible to realize lapping, in which a surface of a device made of a plurality of materials is made very plane.

Owner:HITACHI LTD

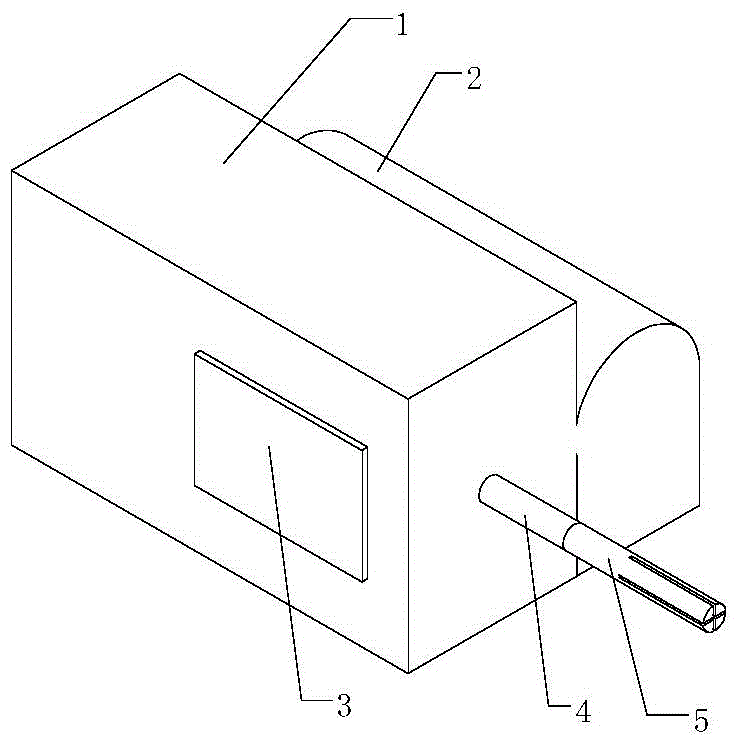

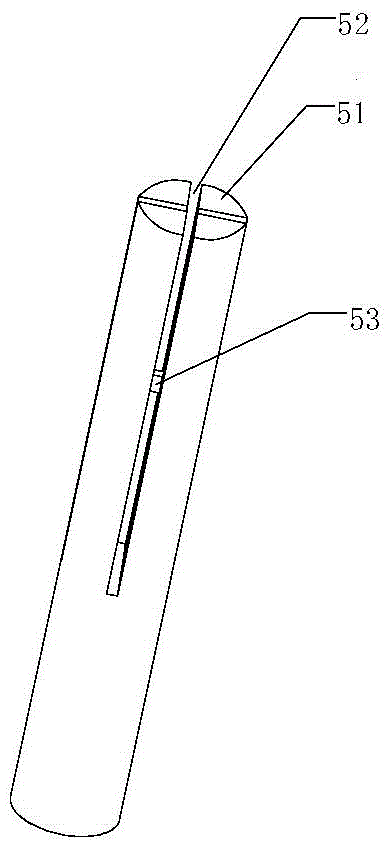

Transformer wire winding stripping machine

InactiveCN104966609ALow costReduce manufacturing costConnection formation by deformationCoils manufactureWinding machineTransformer

The invention discloses a transformer wire winding stripping machine. The transformer wire winding stripping machine comprises an automatic wire winding machine and an engine; an operation panel and a rotating shaft are arranged on the automatic wire winding machine, and a paint removing terminal is installed on a rotating shaft; the paint removing terminal is in a cylinder shape, and a terminal head is equally divided into four cutting knives; gaps are formed between every two adjacent cutting knives and the center positions of the four cutting knives. The transformer wire winding stripping machine is low in cost, a worker does not need to make contact with virulent pain remover, the safety is improved, and the possibility of occupational injuries or occupational diseases is reduced. The environmental protection is better achieved, and the use of the paint remover causing great pollution on the environment is avoided.

Owner:WUXI JINGLEI ELECTRONICS

Sweet persimmon stem removing device

ActiveCN113317535AAvoid destructionReduce the likelihood of damageFood treatmentAir blowerMechanical engineering

The invention discloses a sweet persimmon stem removing device which comprises a working basket and further comprises a conveying mechanism, a correcting mechanism, a feeding mechanism, a stem removing mechanism and a discharging mechanism; the correcting mechanism is arranged in the conveying mechanism, the feeding mechanism is fixedly installed at one end of the conveying mechanism and located over the conveying mechanism, the stem removing mechanism is fixedly installed at the top end of the conveying mechanism, the stem removing mechanism is located over the end, away from the feeding mechanism, of the conveying mechanism, and the discharging mechanism is erected on one side of the working basket. According to the sweet persimmon stem removing device, by arranging the stem removing mechanism, fruit stems of sweet persimmons can be fully automatically removed, an air blower can blow off the cut-off fruit stems, the situation that the fruit stems are piled to affect subsequent work is prevented, by arranging the correcting mechanism, the sweet persimmons can be adjusted in advance, the ends, with the fruit stems, of the sweet persimmons face upwards, and the fruit stems can be conveniently cut off subsequently.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Efficient U-shaped bolt manufacturing device

PendingCN112024759AHigh speedReduce work injuriesMetal-working feeding devicesNutsInductorHydraulic pressure

The invention provides an efficient U-shaped bolt manufacturing device which is used for automatic feeding and bending of U-shaped bolts of an automobile chassis. The manufacturing device comprises abending device, the bending device comprises a bending frame, a shaping wheel, two bending wheels, a track guide plate, a bending inductor and a hydraulic power system, the bending frame is a hollow frame body, and the shaping wheel is a sheet body with an arc groove. Arc grooves are formed in the positions, corresponding to the arc groove of the shaping wheel, of the bending wheels, the two bending wheels are connected with the hydraulic power system, and during work, the two bending wheels move along the two arc side edges of the track guide plate. The bending inductor is used for inductingwhether a bolt exists or not. According to the device, through automatic discharging, the production efficiency is improved, and the labor intensity of staff is relieved.

Owner:ZHEJIANG CHANGHUA AUTO PARTS

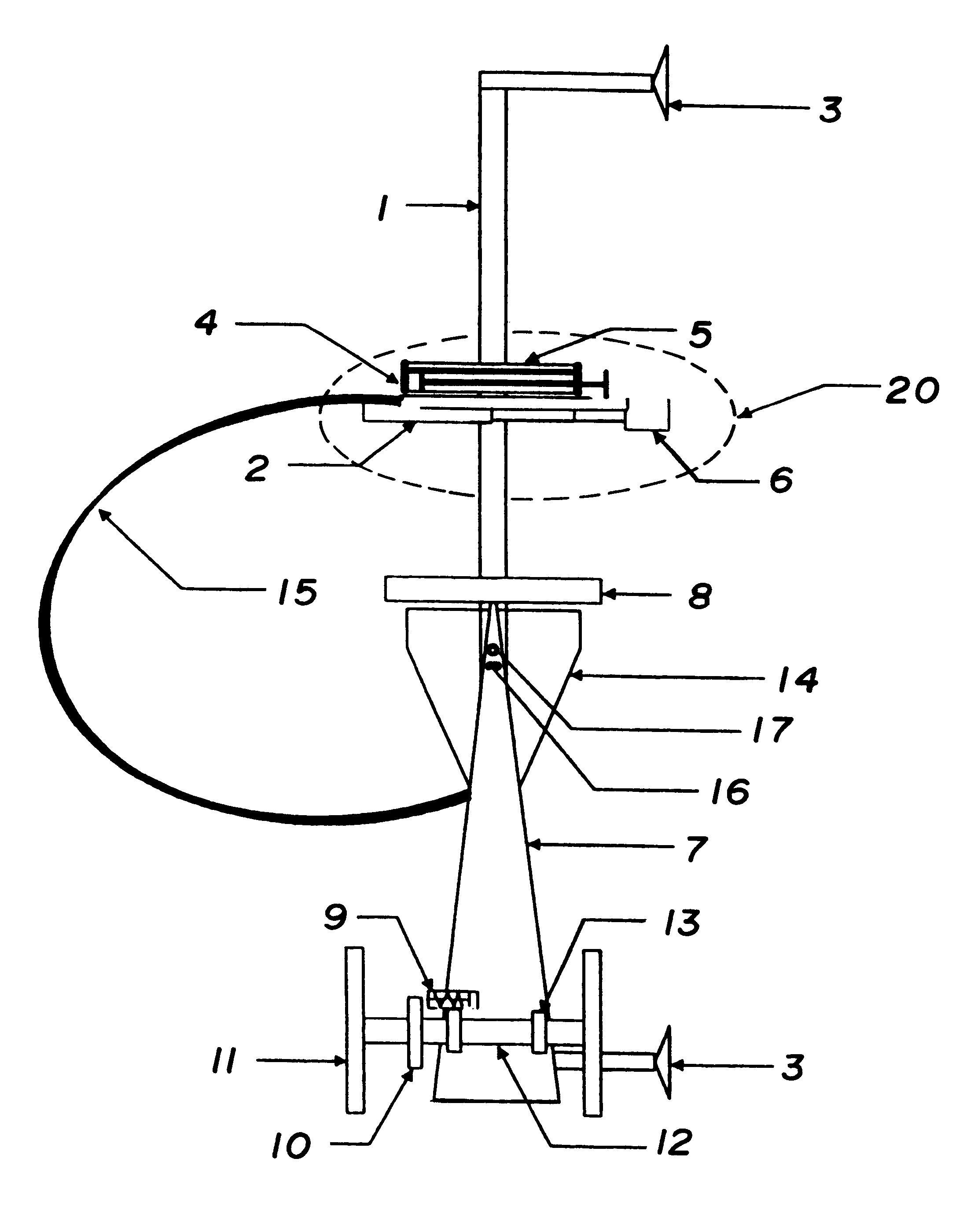

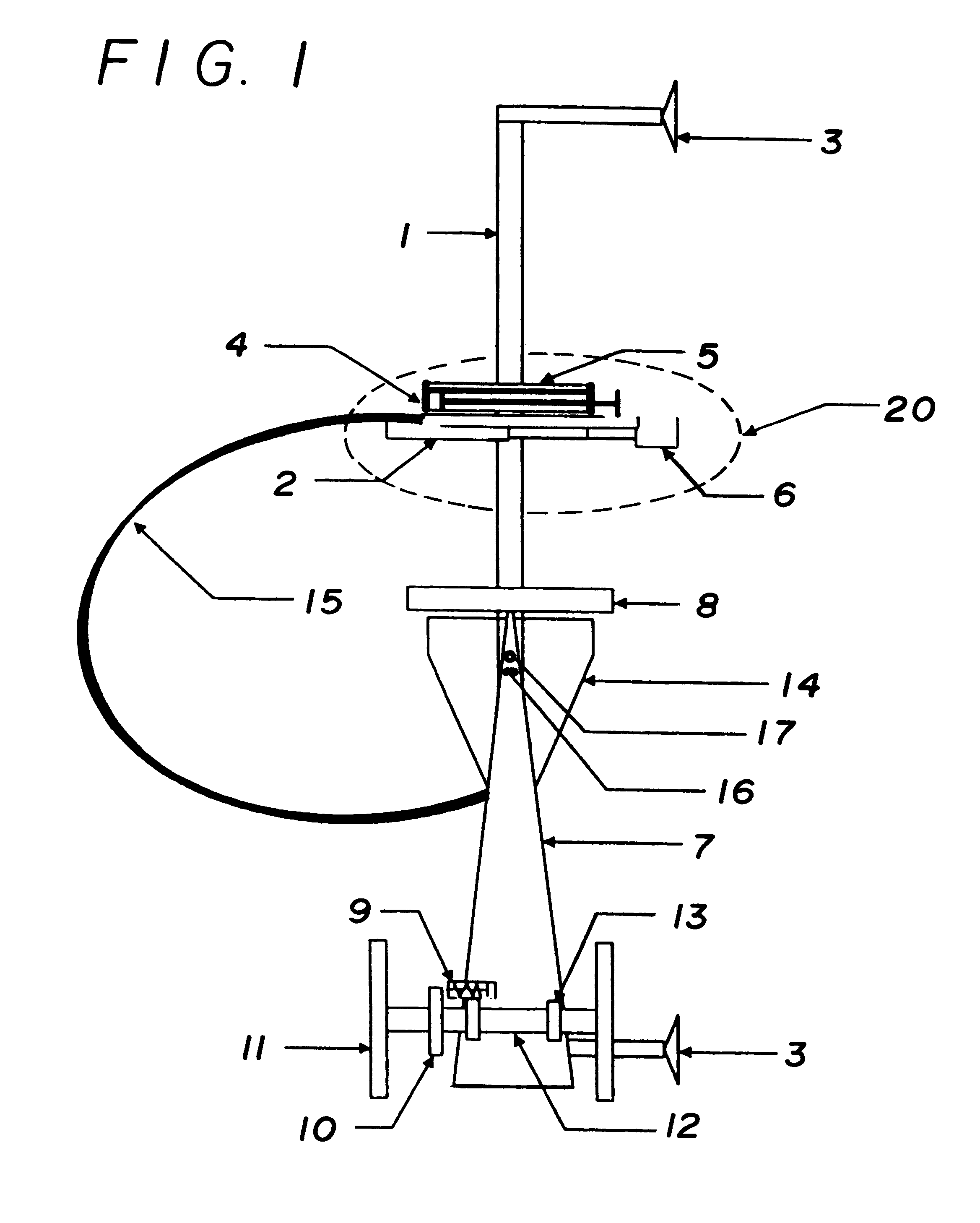

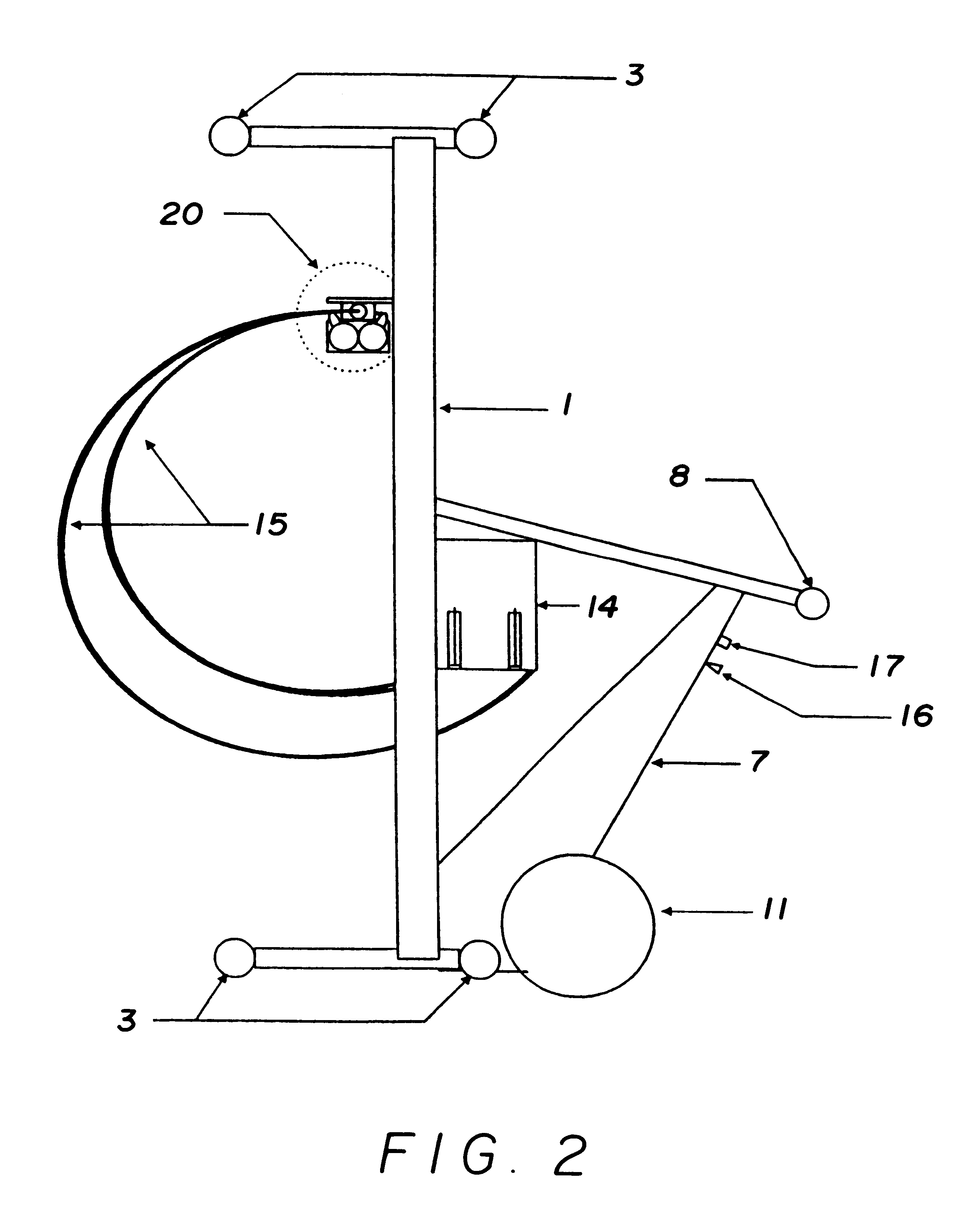

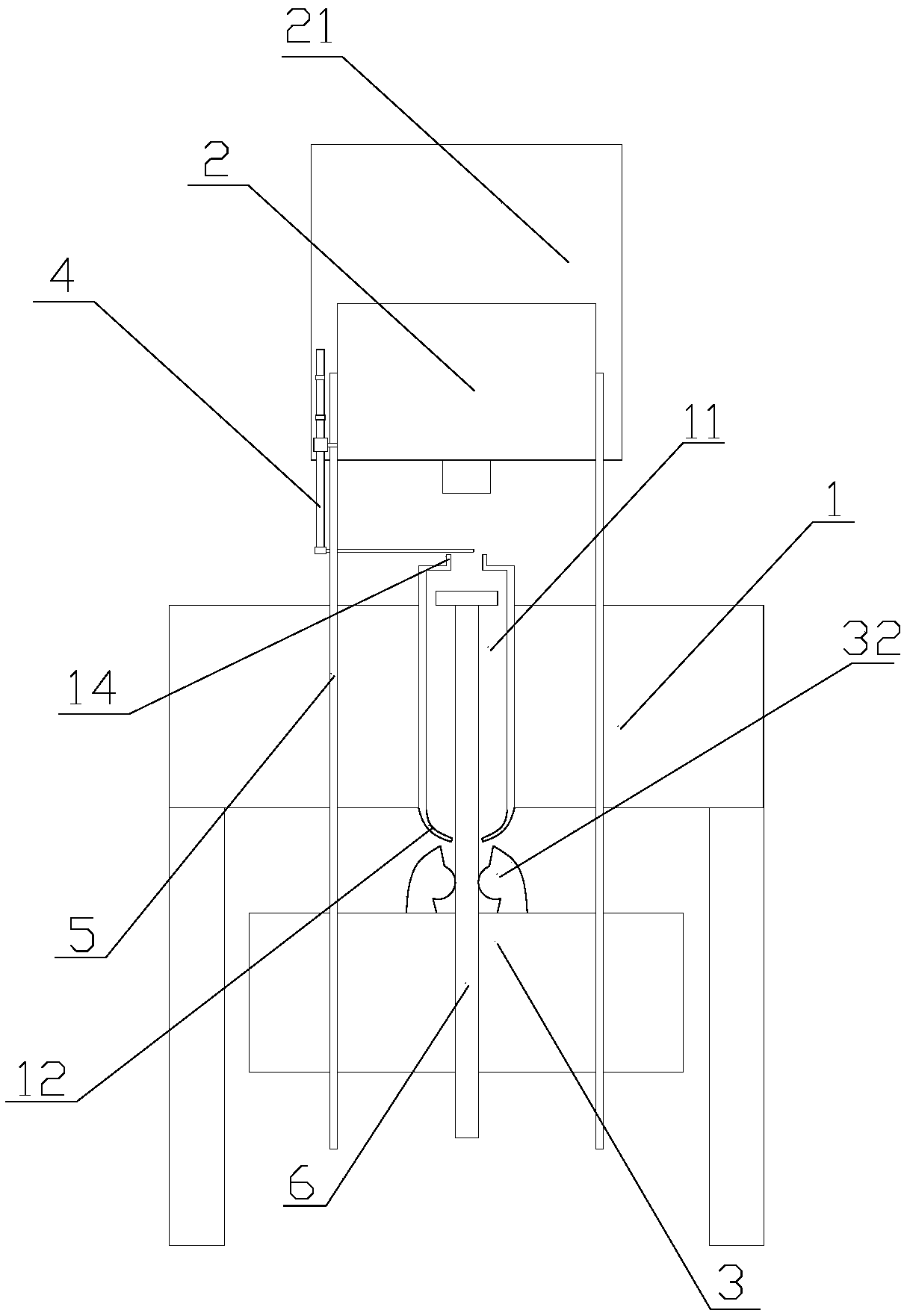

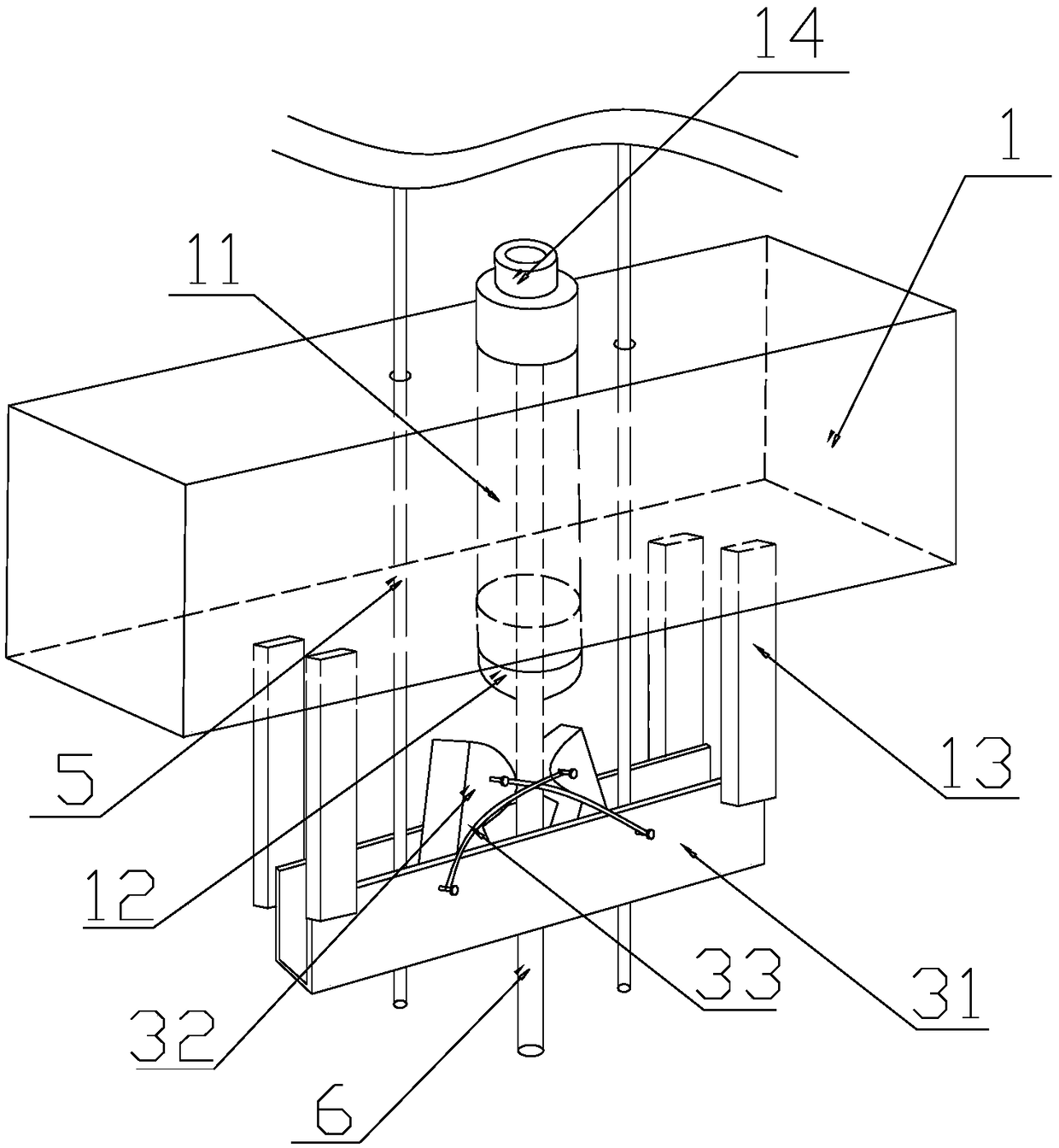

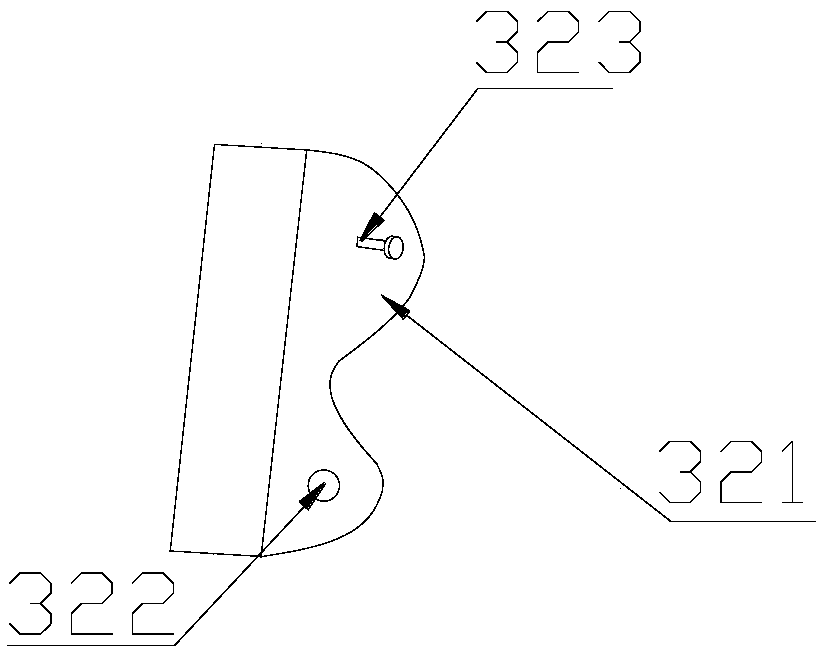

Mobile automatic machine for fastening of fasteners

A mobile automatic machine for fastening fasteners which includes a rod mounted on wheels (11) and is attachable to and held in contact with a workpiece by a vacuum in suction cups (3) is disclosed. The fasteners are blown from a fastener feeder (14) through hoses (15) to a fastener driver (20) which includes a fastener holder (6). The fastener driver engages fasteners held by the fastener holder (6) and drives them into the workpiece under the control of a controller. The fastener driver (20) is slidably mounted on the rod and moves linearly at repeatable intervals or at a uniform speed along the entire length of rod (1) under the control of a controller. Other tools, such as drills or milling devices can substituted for the fastener driver.

Owner:SODERLUND ROGER

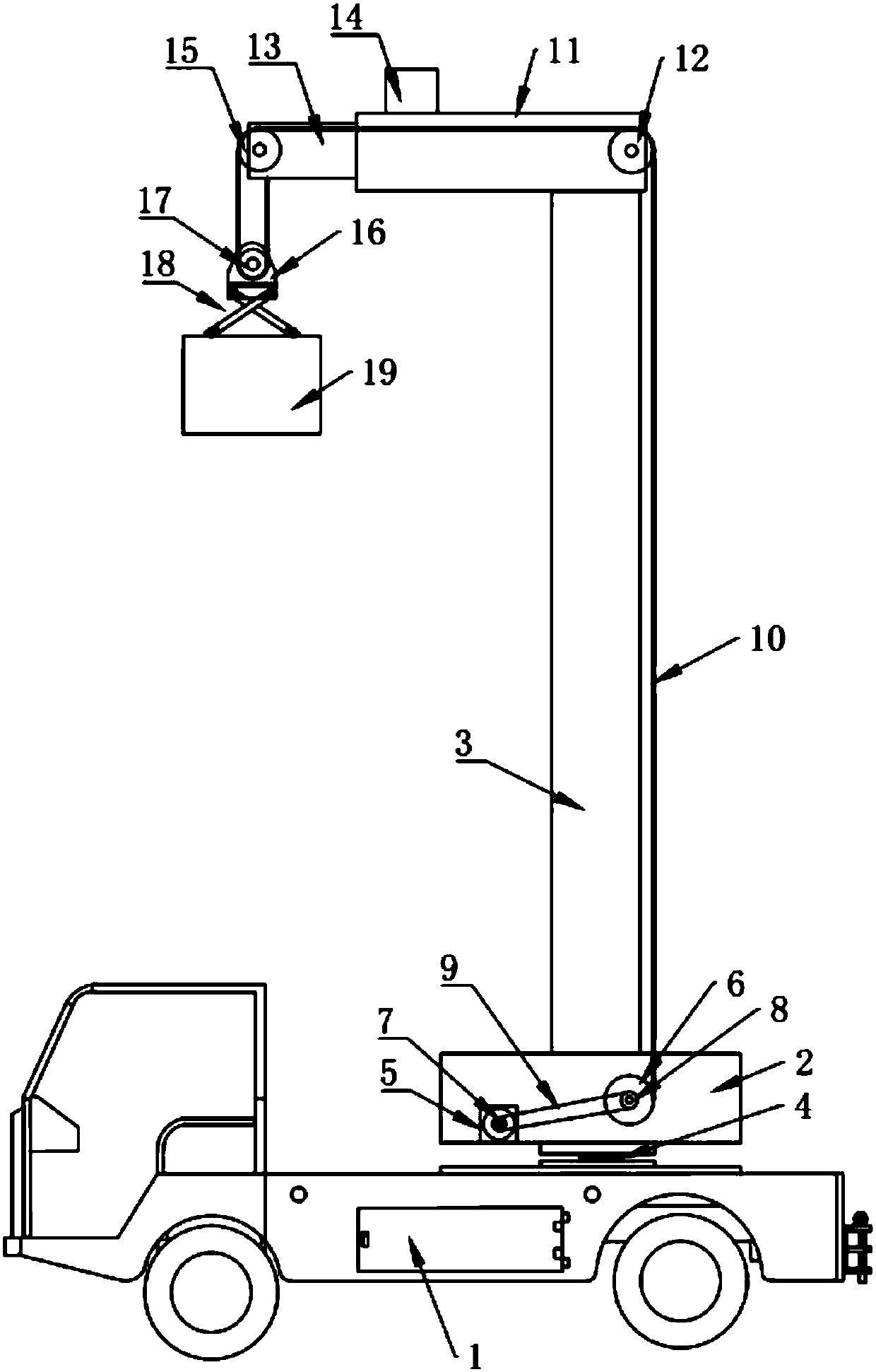

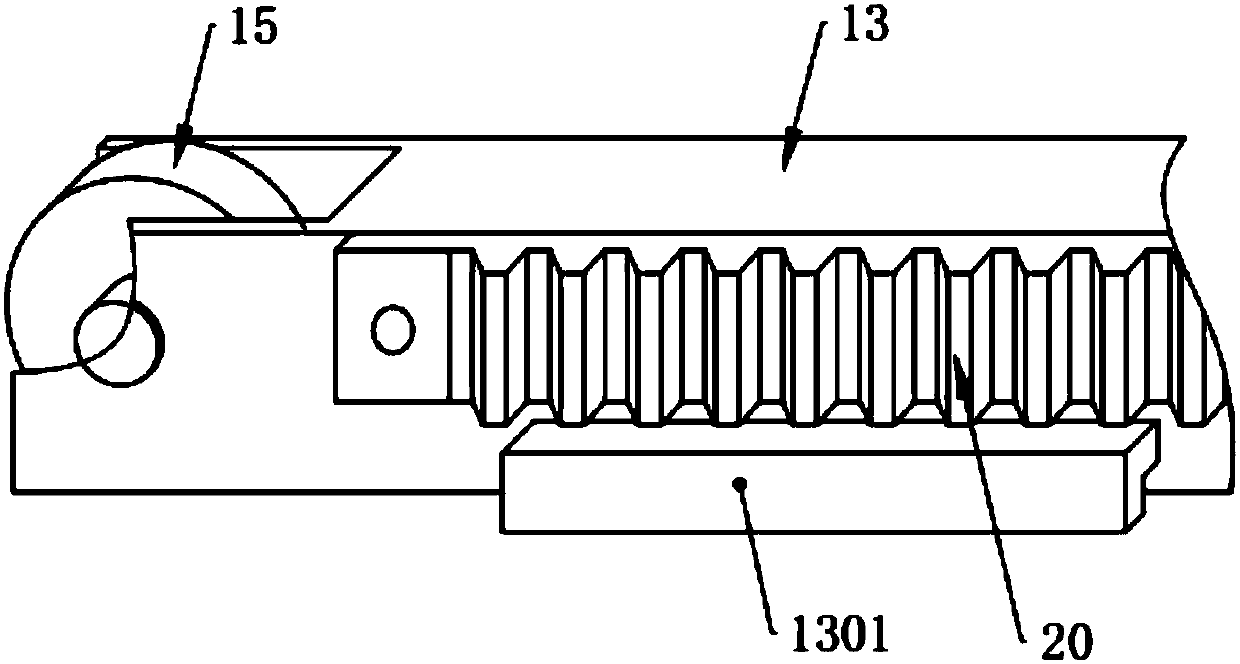

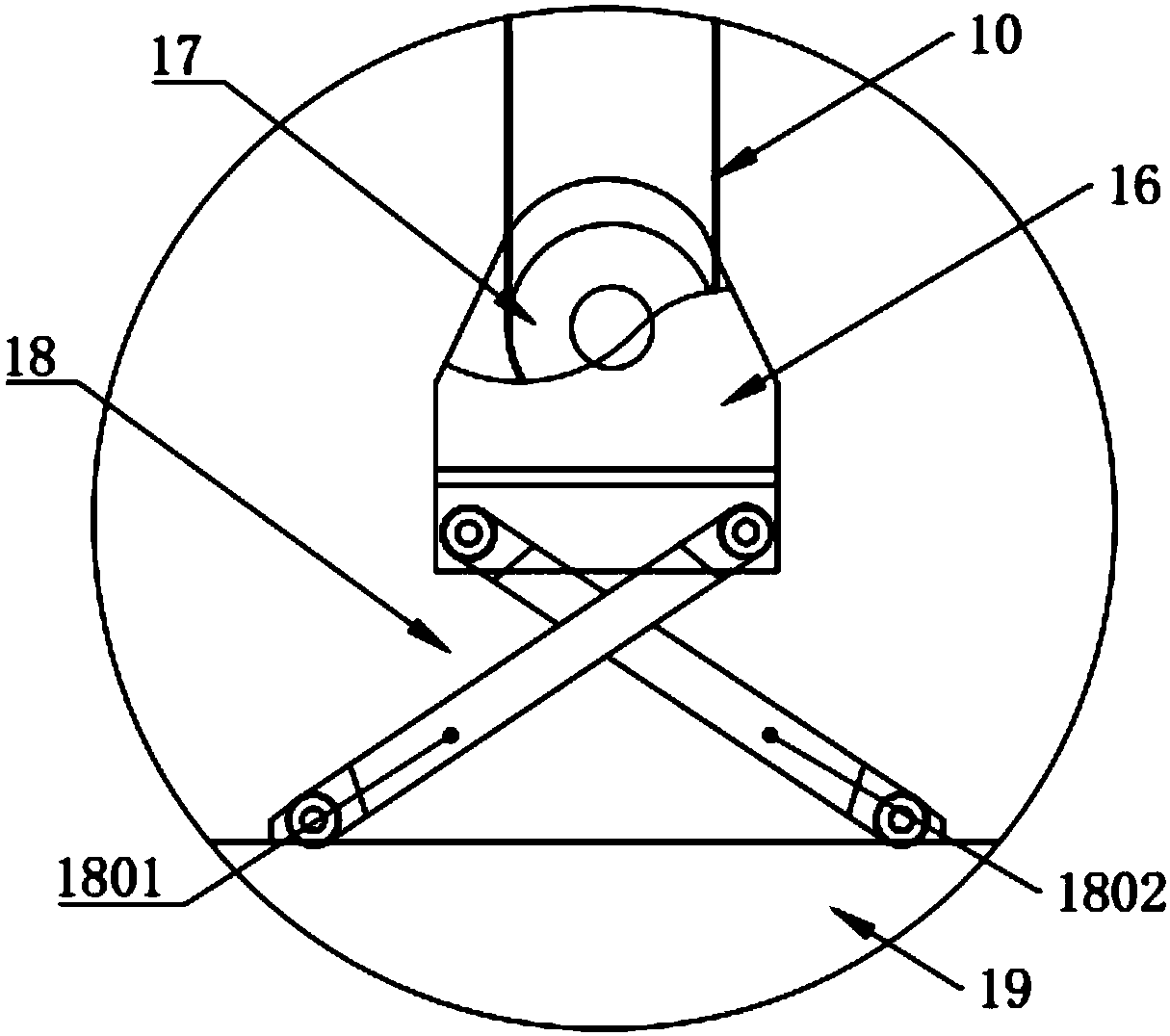

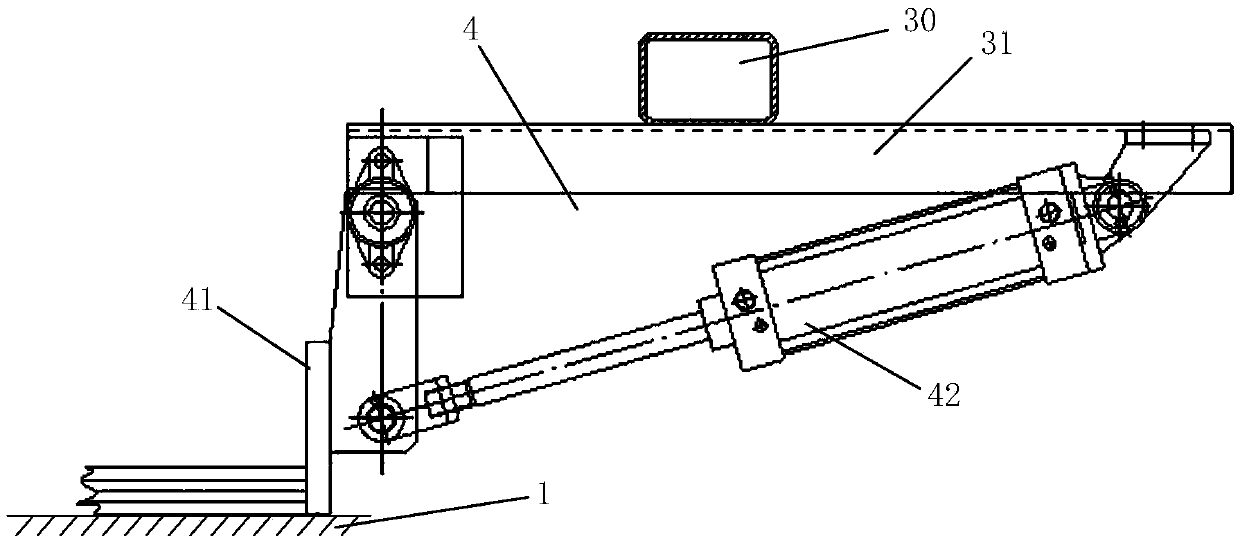

Electrical operation vehicle

InactiveCN107915178AConditions to reduce or counteract transition offsetsAvoid large-scale shakingLifting devicesEngineeringPower apparatus

The invention belongs to the technical field of high-altitude operation equipment and provides an electrical operation vehicle. The vehicle comprises a vehicle body; a mounting platform is rotationally mounted on the vehicle body; a supporting frame and a steel cable winding roller driven by a first power device are arranged on the mounting platform; a steel cable winds around the steel cable winding roller; a cross beam is mounted at the top end of the supporting frame; a steel cable wheel is rotationally mounted at one end of the cross beam; a telescopic rod driven by a second power device is glidingly mounted at the other end of the cross beam; a fixed pulley is rotationally mounted at one end of the telescopic rod; a movable pulley is rotationally mounted on a lifting lug; the steel cable winds around the steel cable wheel, the fixed pulley and the movably pulley sequentially; the end of the steel cable is fixedly connected onto the cross beam; two groups of connecting rod mechanisms comprising first connecting rods and second connecting rods are arranged between the lifting lug and a working lifting basket; the first connecting rods and the second connecting rods are arrangedin the scissor-fork shape; and two ends of each of the first connecting rods and the second connecting rods are hinged to the lifting lug and the working lifting basket respectively. By the aid of thevehicle, the working range and the working efficiency are increased, movement of the working lifting basket or the phenomenon of swaying during working can be effectively avoided, and the safety performance is higher.

Owner:李秀荣

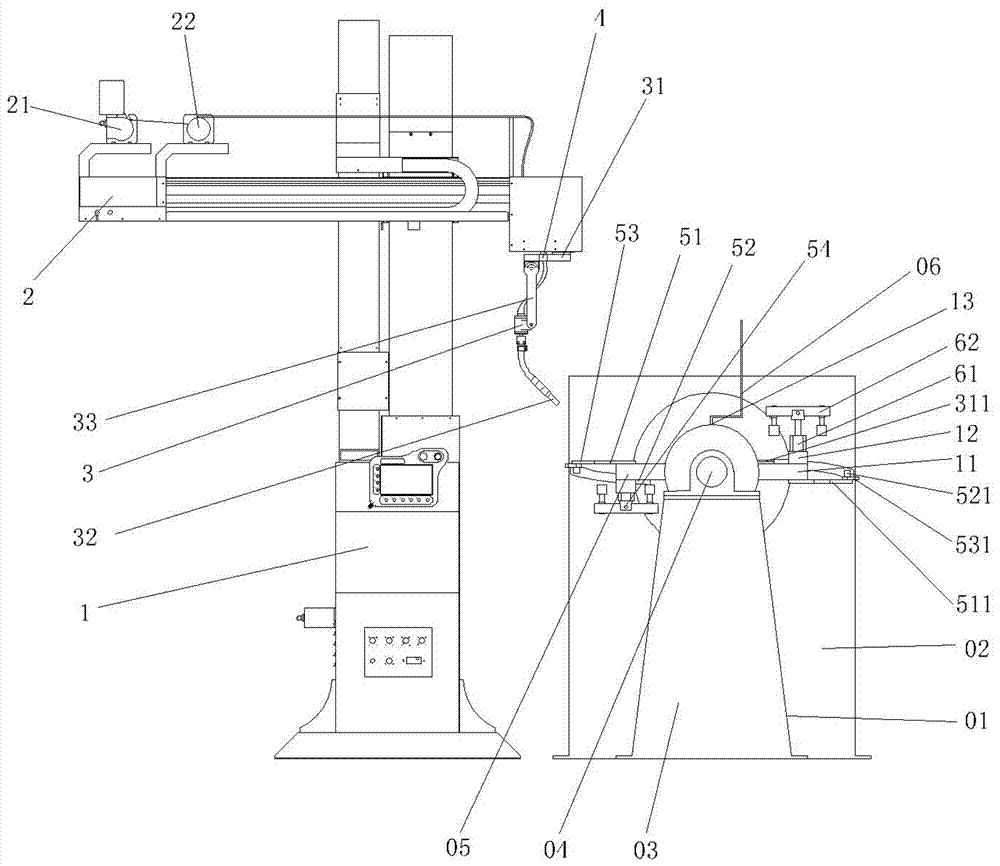

Efficient automatic spot welding device for upper longitudinal beam support

PendingCN112171035AHigh speedReduce work injuriesWelding/cutting auxillary devicesAuxillary welding devicesGear wheelClassical mechanics

The invention provides an efficient automatic spot welding device for an upper longitudinal beam support. The efficient automatic spot welding device comprises an upper longitudinal beam support turnover device. The upper longitudinal beam support turnover device turns over the upper longitudinal beam support by 180 degrees. The upper longitudinal beam support turnover device comprises a limitingplate, a fixed rack, a turnover connecting block, a turnover sliding block, a turnover gear, a clamping block and a clamping air cylinder. The turnover connecting block is an L-shaped body. One end ofthe turnover connecting block is connected with a feeding air cylinder, and the other end of the turnover connecting block is arranged on one side of the limiting plate and connected with the turnover sliding block. The fixed rack is arranged on the other side of the limiting plate. The turnover gear is arranged above the fixed rack. A center shaft of the turnover gear penetrates a through hole of the turnover sliding block and then is fixedly connected with the clamping block. The clamping air cylinder is arranged on the clamping block. The efficient automatic spot welding device is reliablein structure, convenient to use, easy to maintain and high in universality, safety production is achieved, and the market competitiveness of enterprises is improved.

Owner:ZHEJIANG CHANGHUA AUTO PARTS

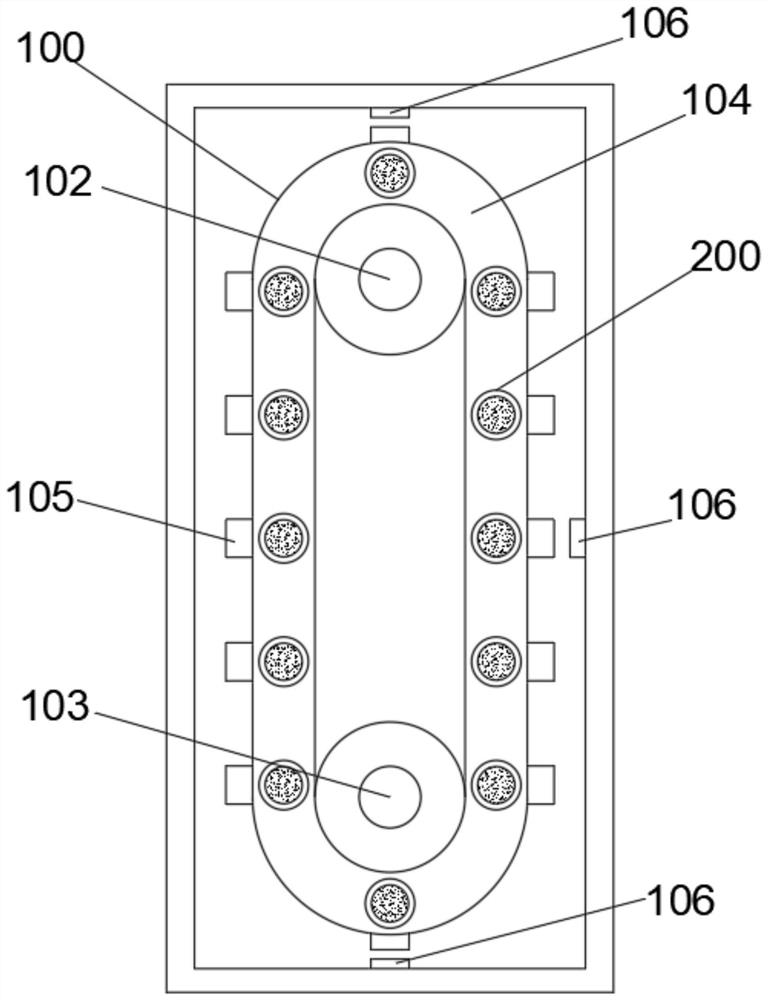

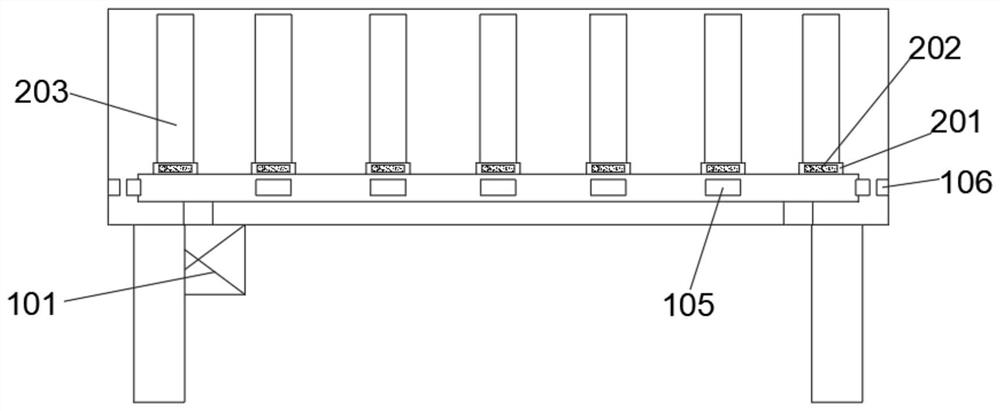

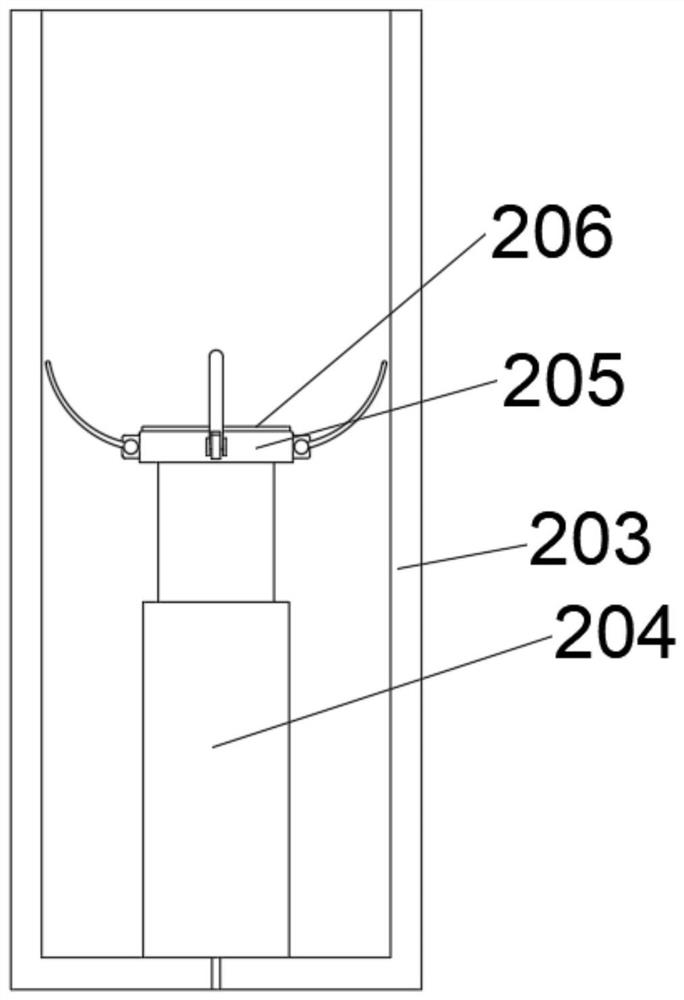

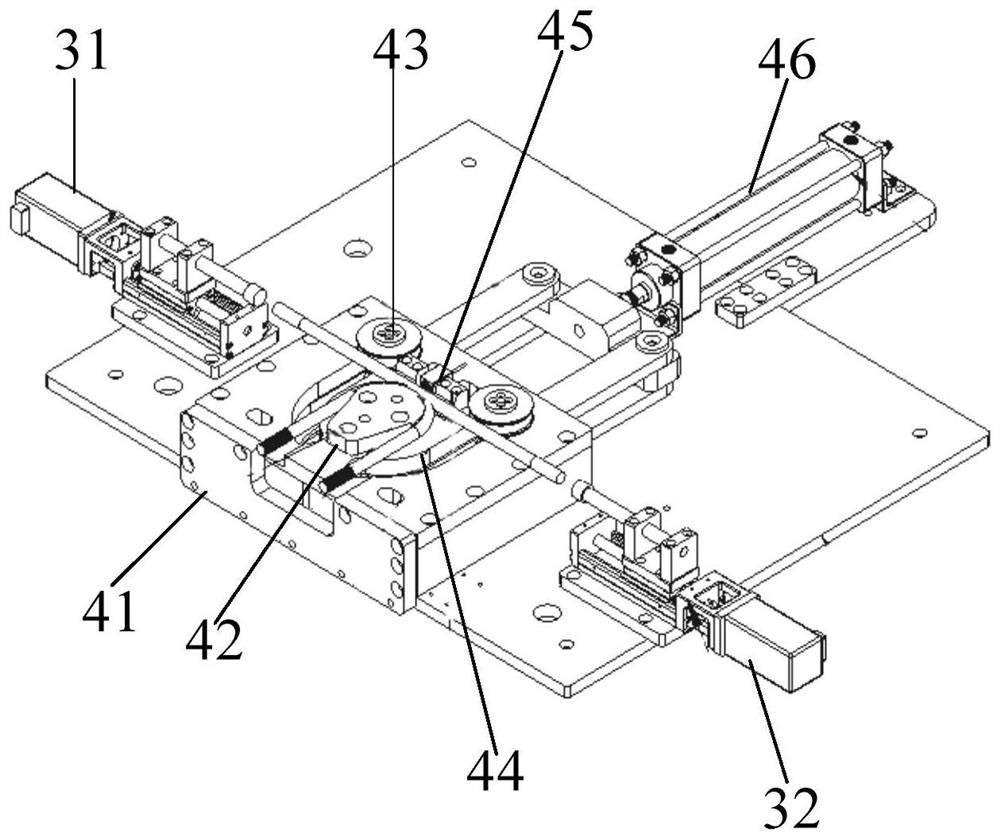

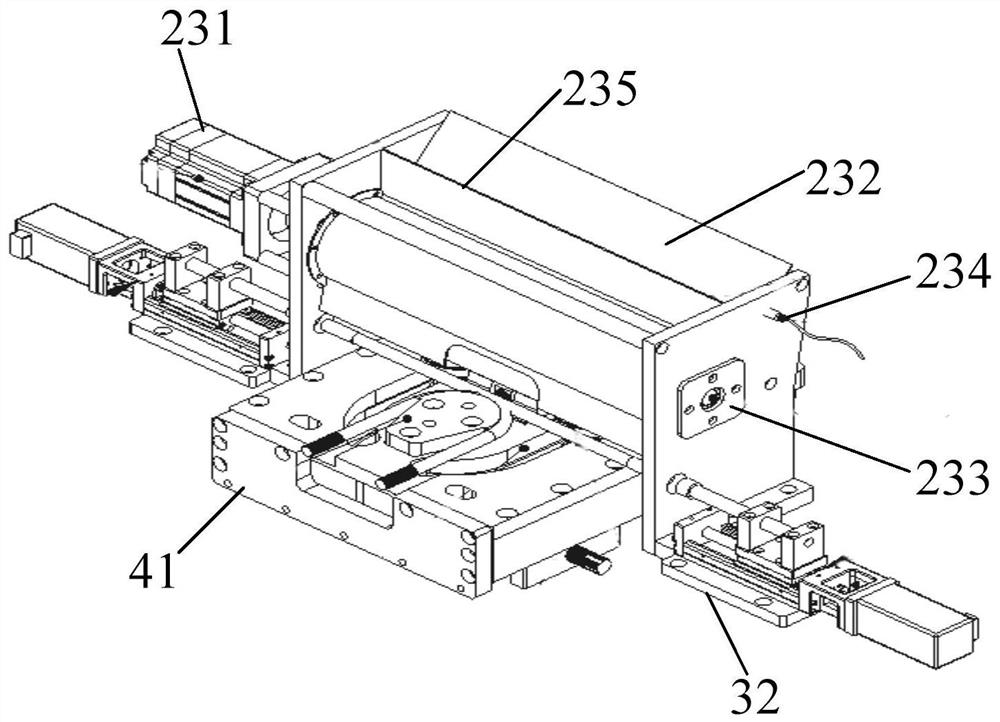

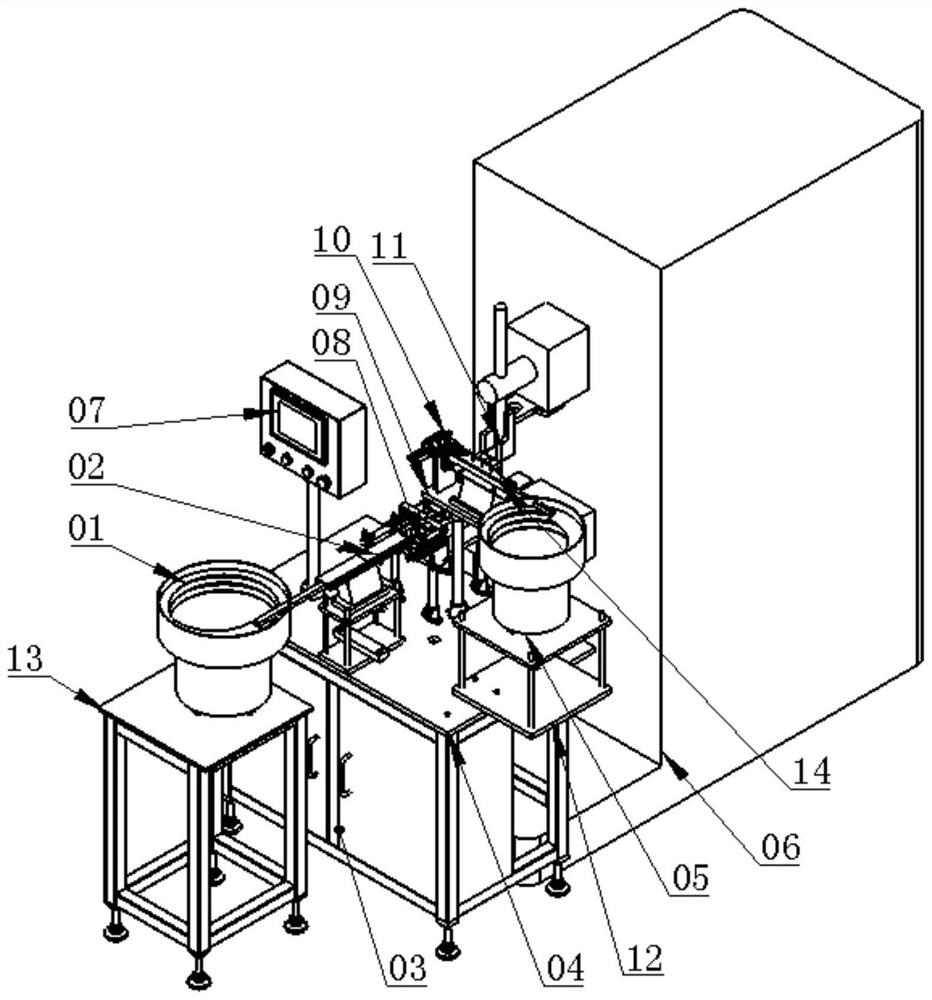

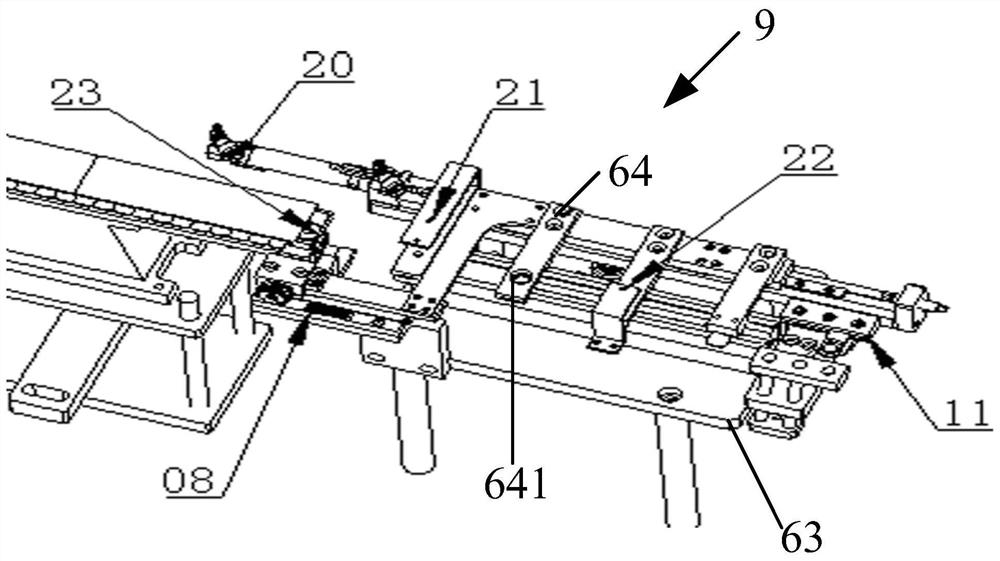

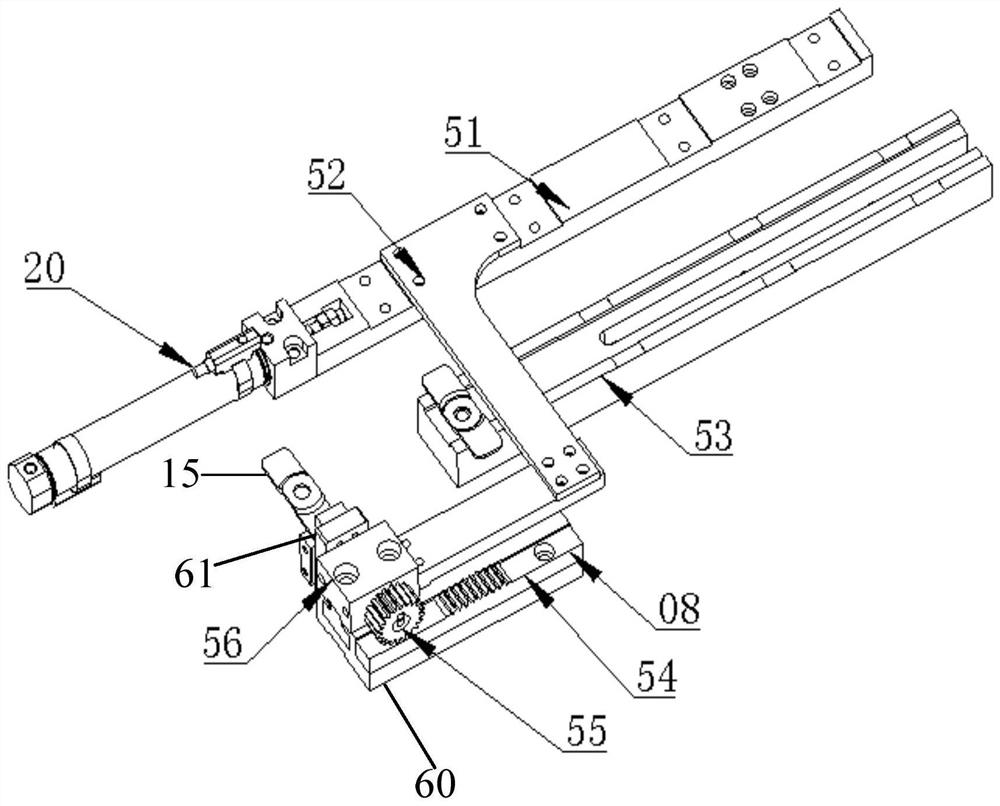

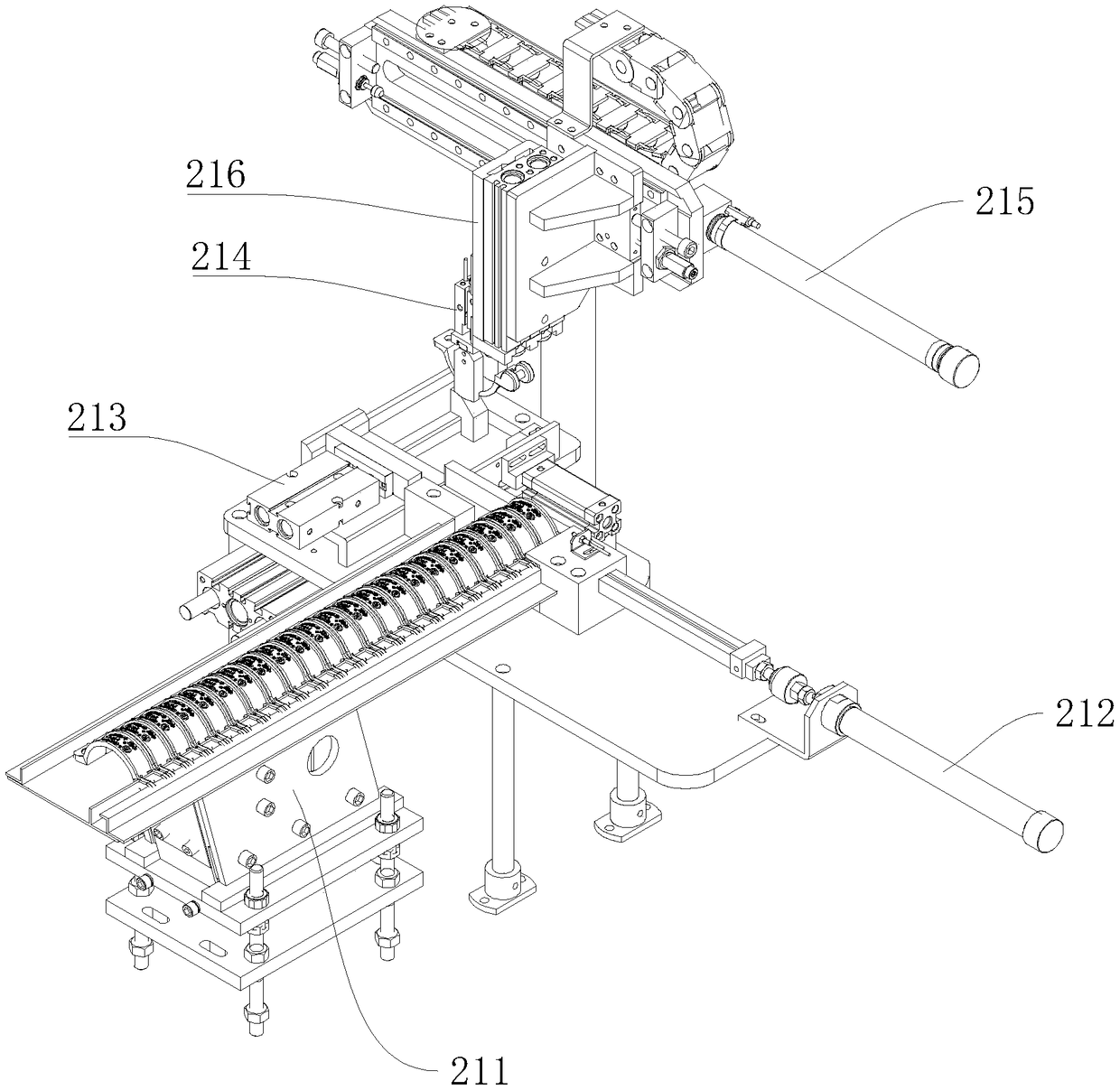

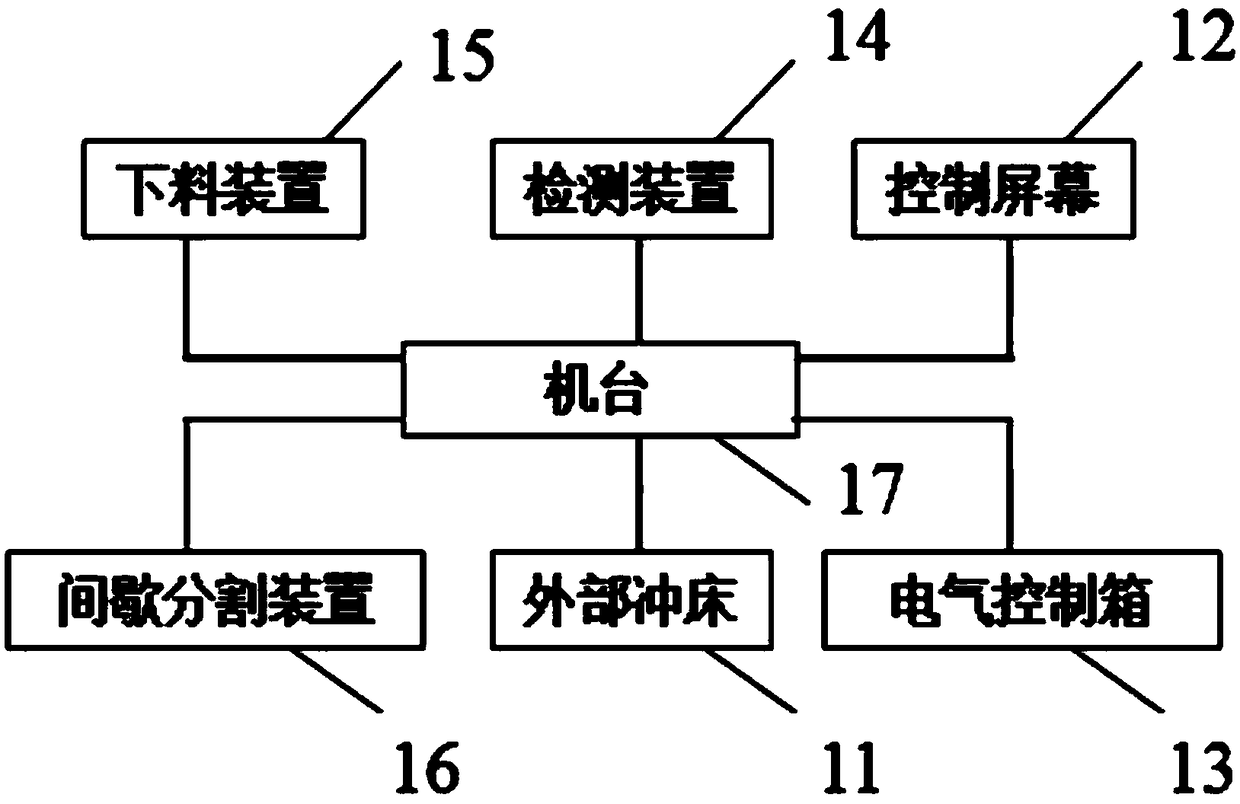

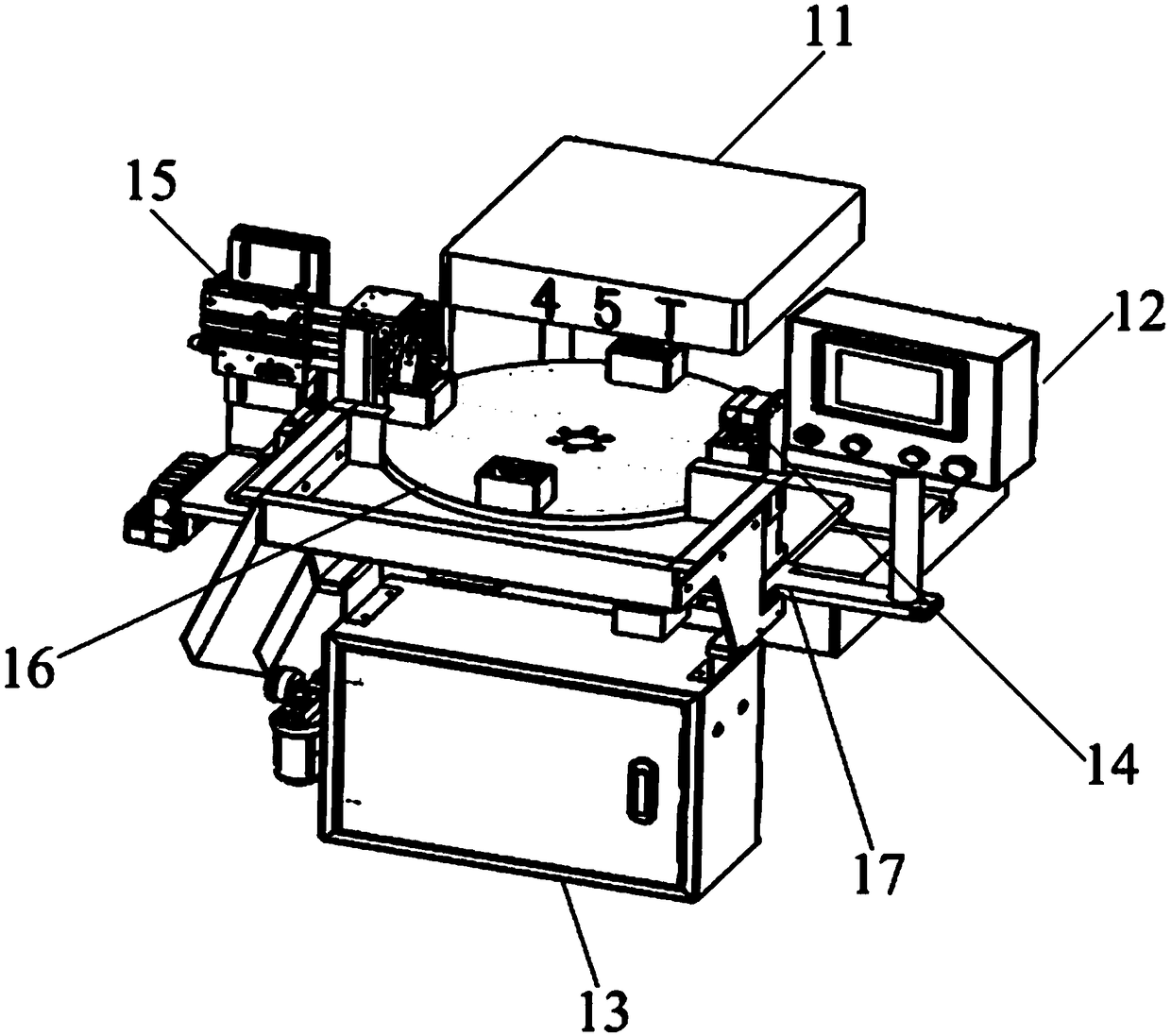

Automatic assembling equipment of self-buckling type pipe clamp, nut and screw

PendingCN109317964AIncrease productivityReduce work injuriesAssembly machinesSelf-bucklingRotating disc

The invention discloses automatic assembling equipment of a self-buckling type pipe clamp, a nut and a screw. The automatic assembling equipment comprises a workbench, a rotating disc, an opening-freepipe clamp feeding station, a nut assembling station, a pipe clamp pressing-in station, a pipe clamp assembling station, a screw loading station and a finished product taking-out station, wherein therotating disc is arranged on the workbench, the opening-free pipe clamp feeding station, the nut assembling station, the pipe clamp pressing-in station, the pipe clamp assembling station, the screw loading station and the finished product taking-out station are arranged on the workbench and are arranged around the rotating disc in sequence, an opening-free pipe clamp feeding mechanism, a nut assembling mechanism, a pipe clamp pressing-in mechanism, a pipe clamp assembling mechanism, a screw loading mechanism and a finished product taking-out mechanism are arranged on the opening-free pipe clamp feeding station, the nut assembling station, the pipe clamp pressing-in station, the pipe clamp assembling station, the screw loading station and the finished product taking-out station correspondingly; the outer ring of the rotating disc is provided with a plurality of opening pipe clamp clamps which align with each station, the inner ring of the rotating disc is provided with a plurality of opening-free pipe clamp clamps which align with all the stations correspondingly, and the opening pipe clamps corresponding to each station and the opening pipe clamps abut against each other in an end-to-end mode. According to the automatic assembling equipment, the full-automatic assembly production of the self-buckling type pipe clamp is realized, the production efficiency is improved, the laborinjury caused by manual assembly is reduced, and a large amount of manpower is saved.

Owner:湖南湘光机械模具有限公司

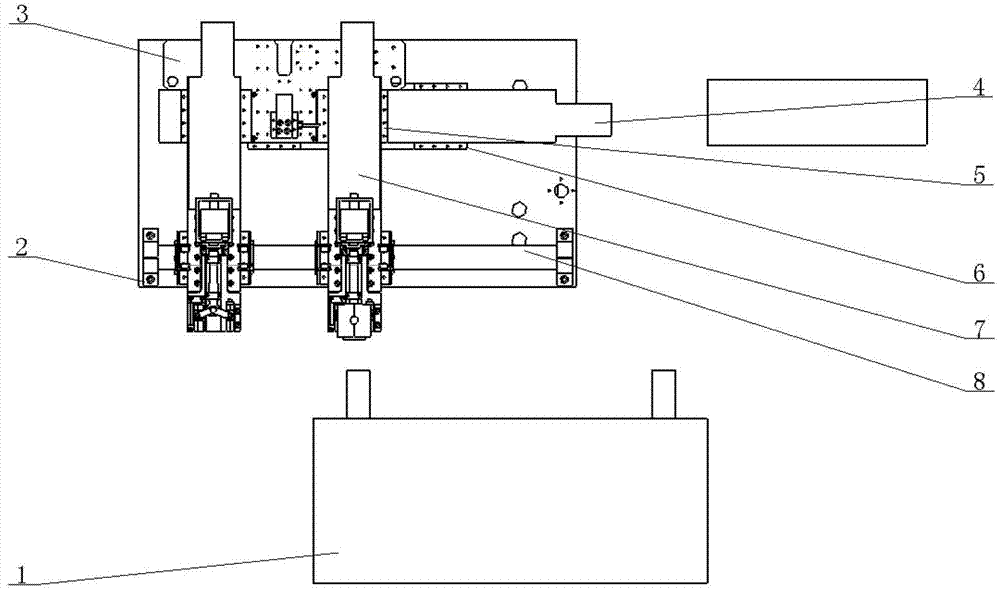

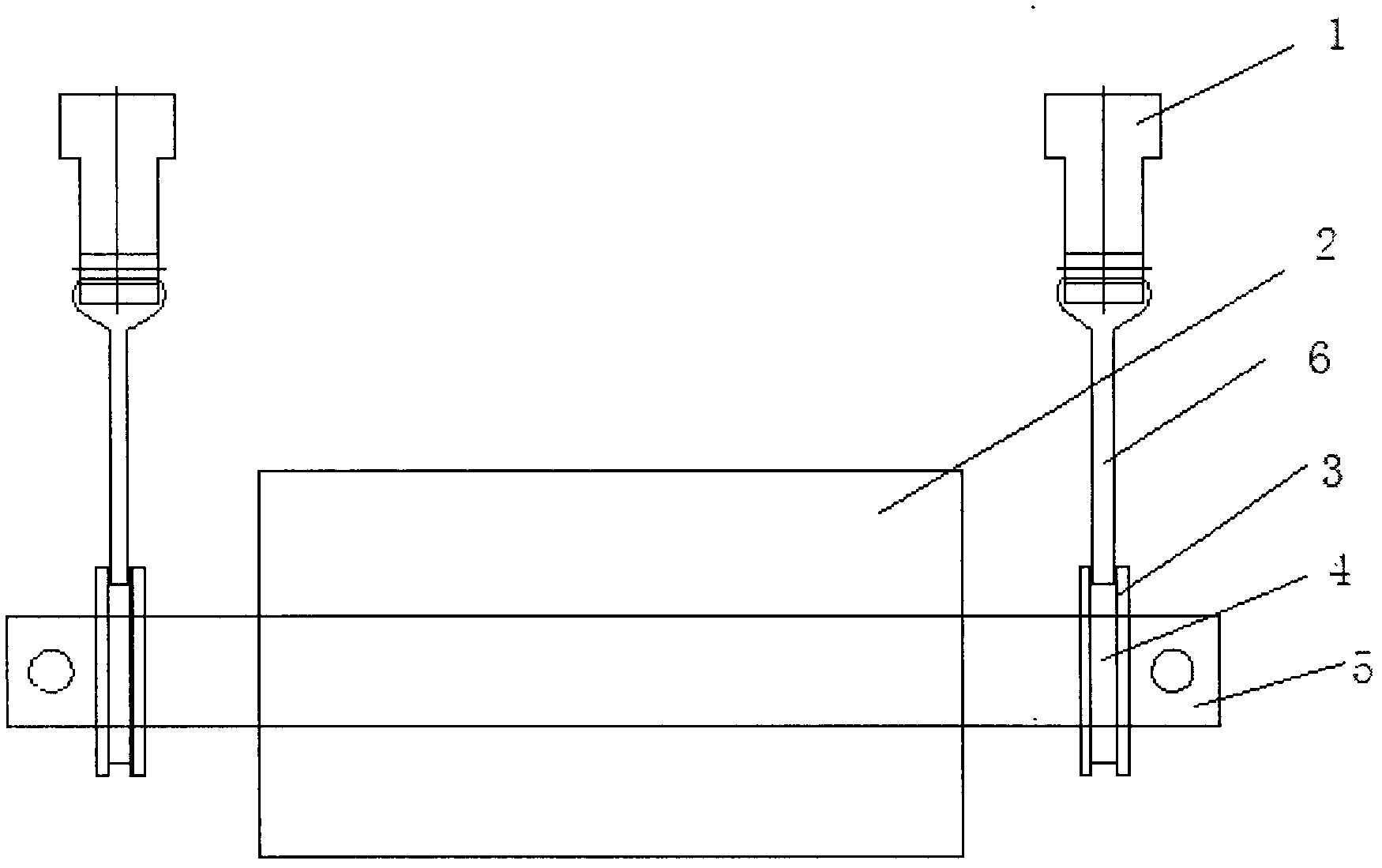

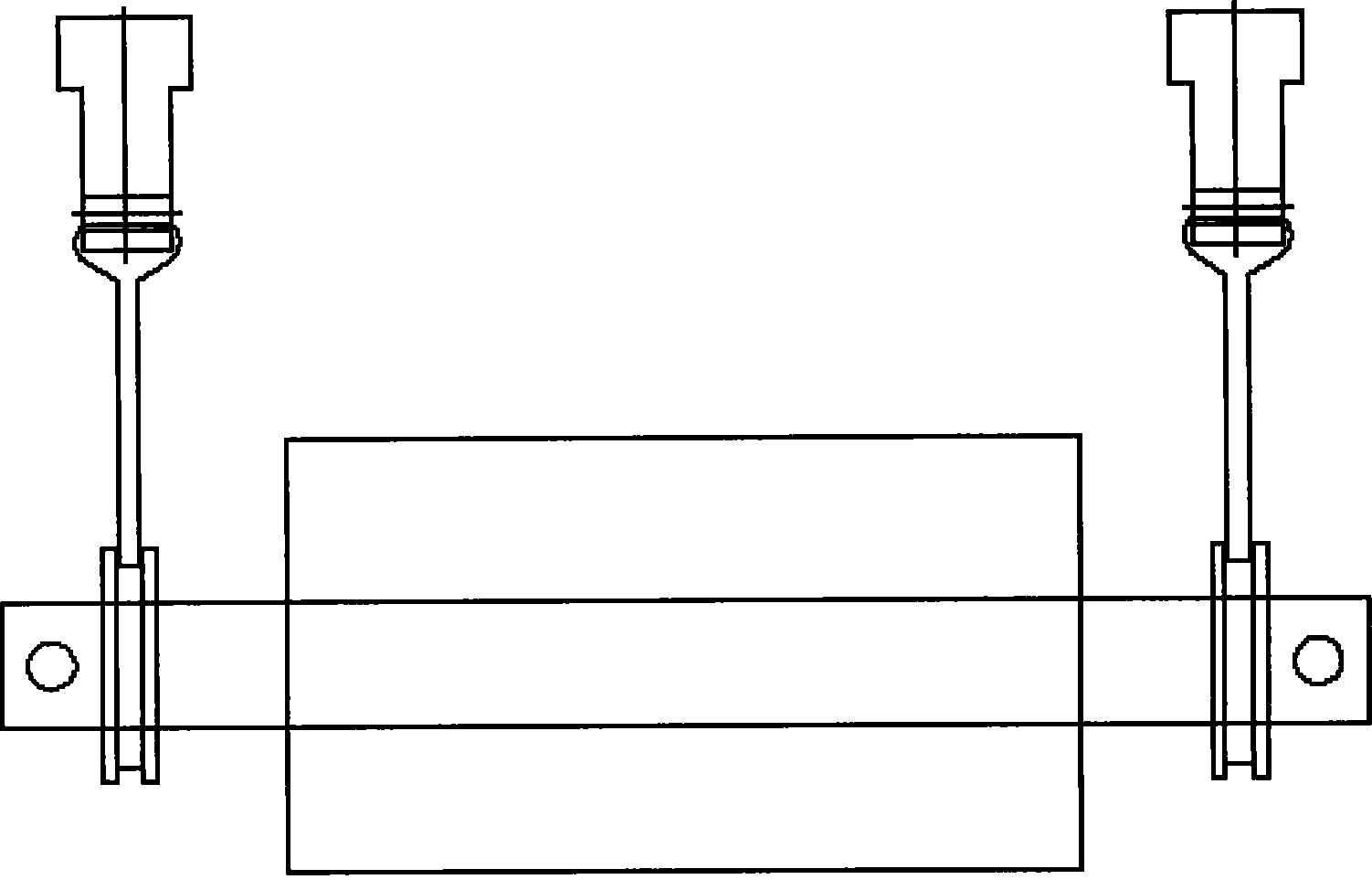

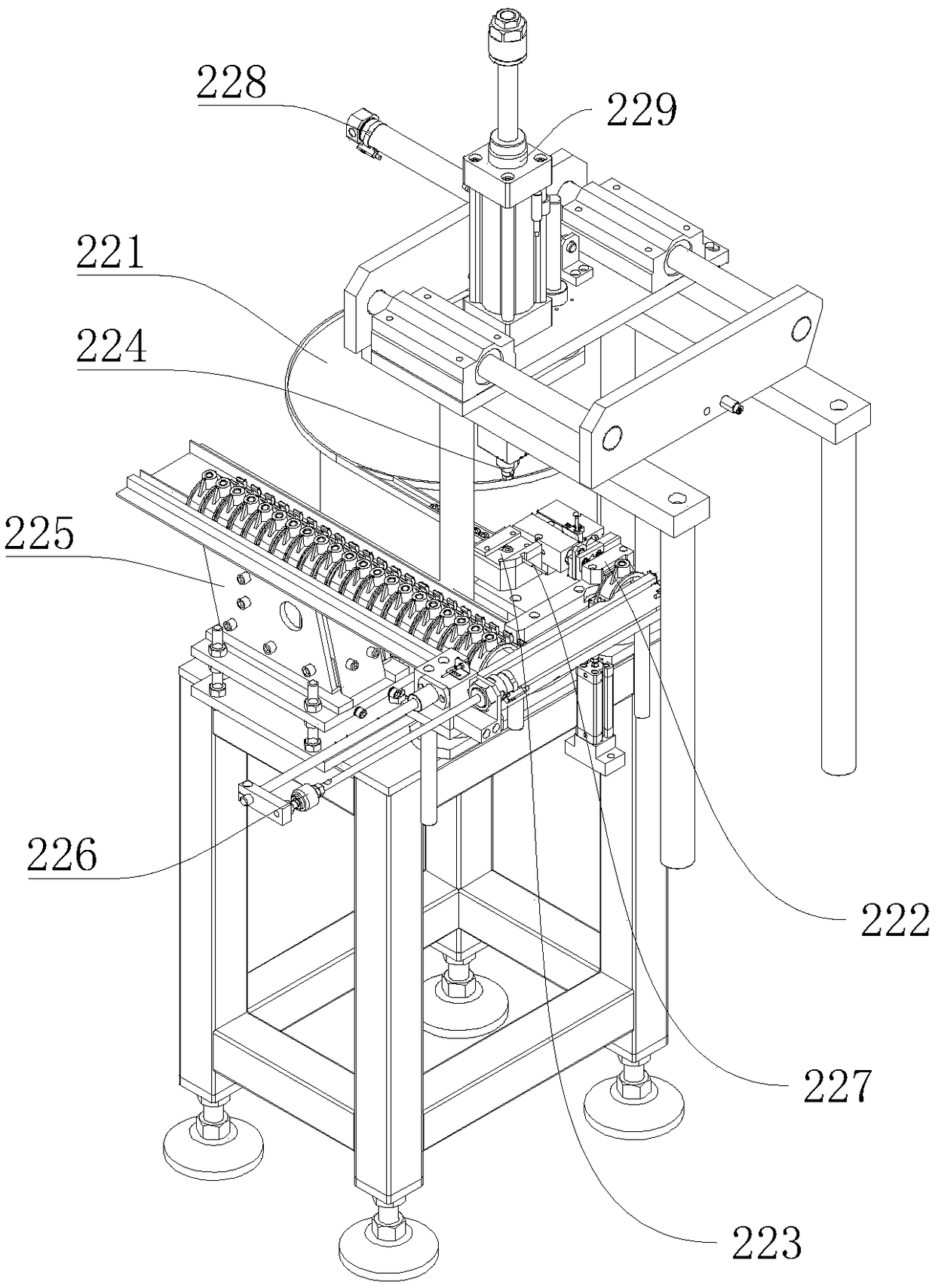

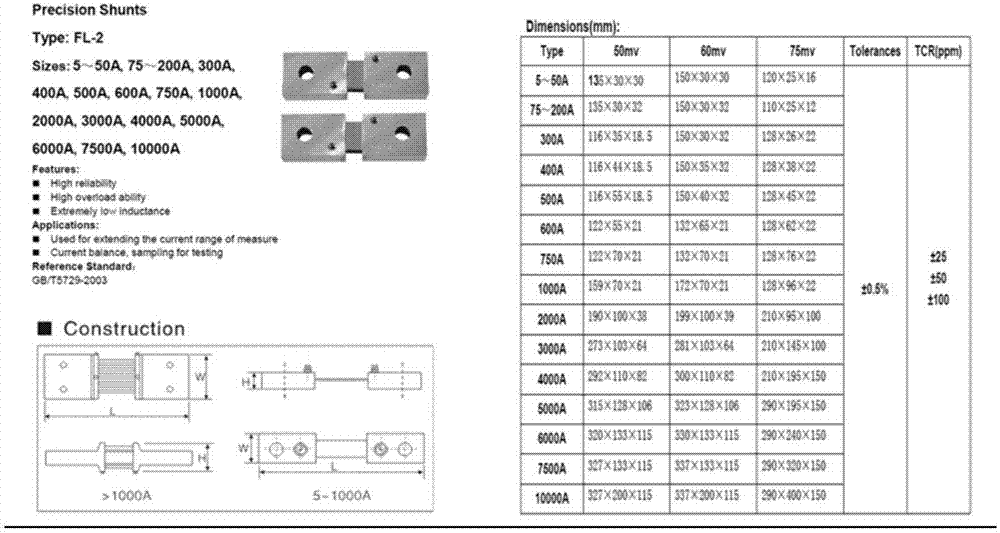

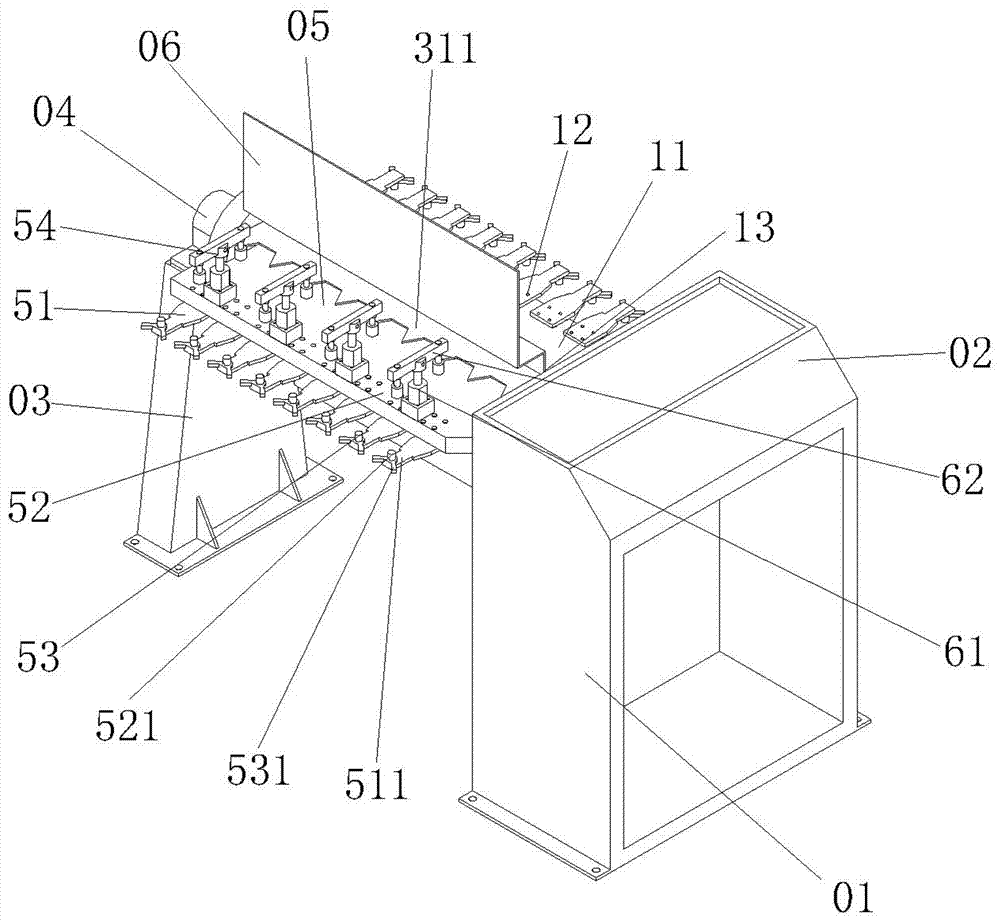

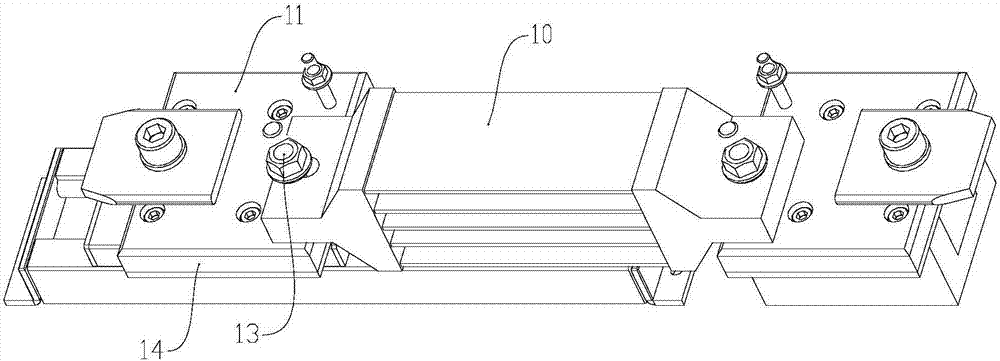

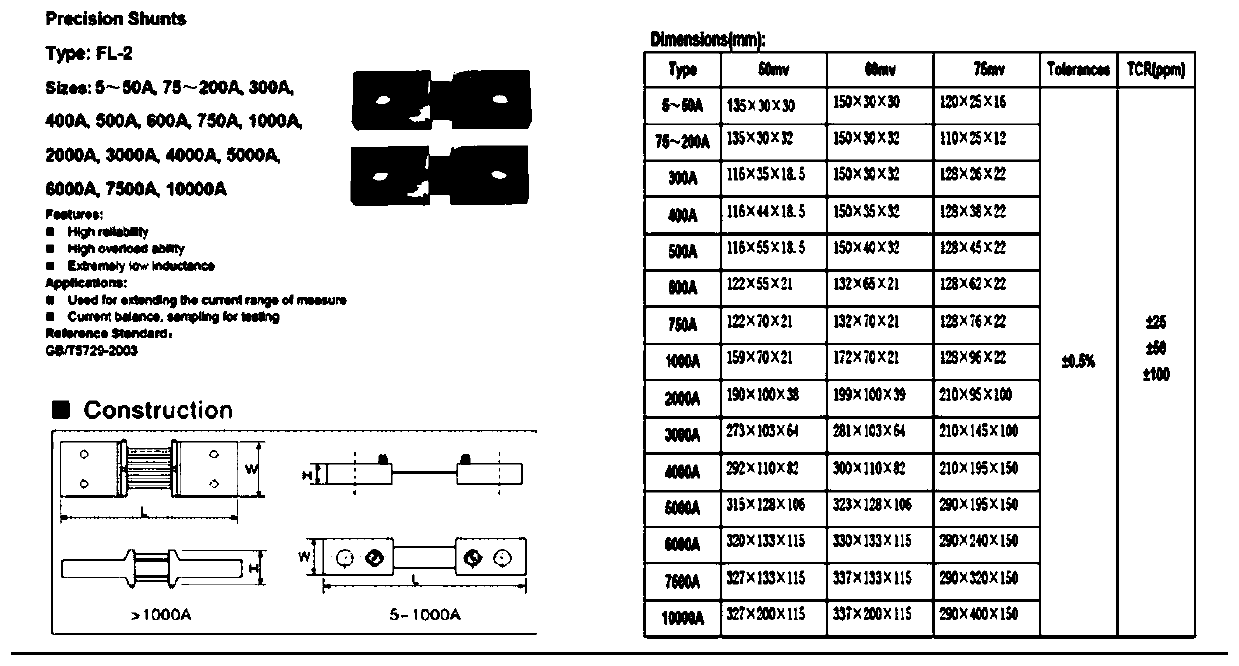

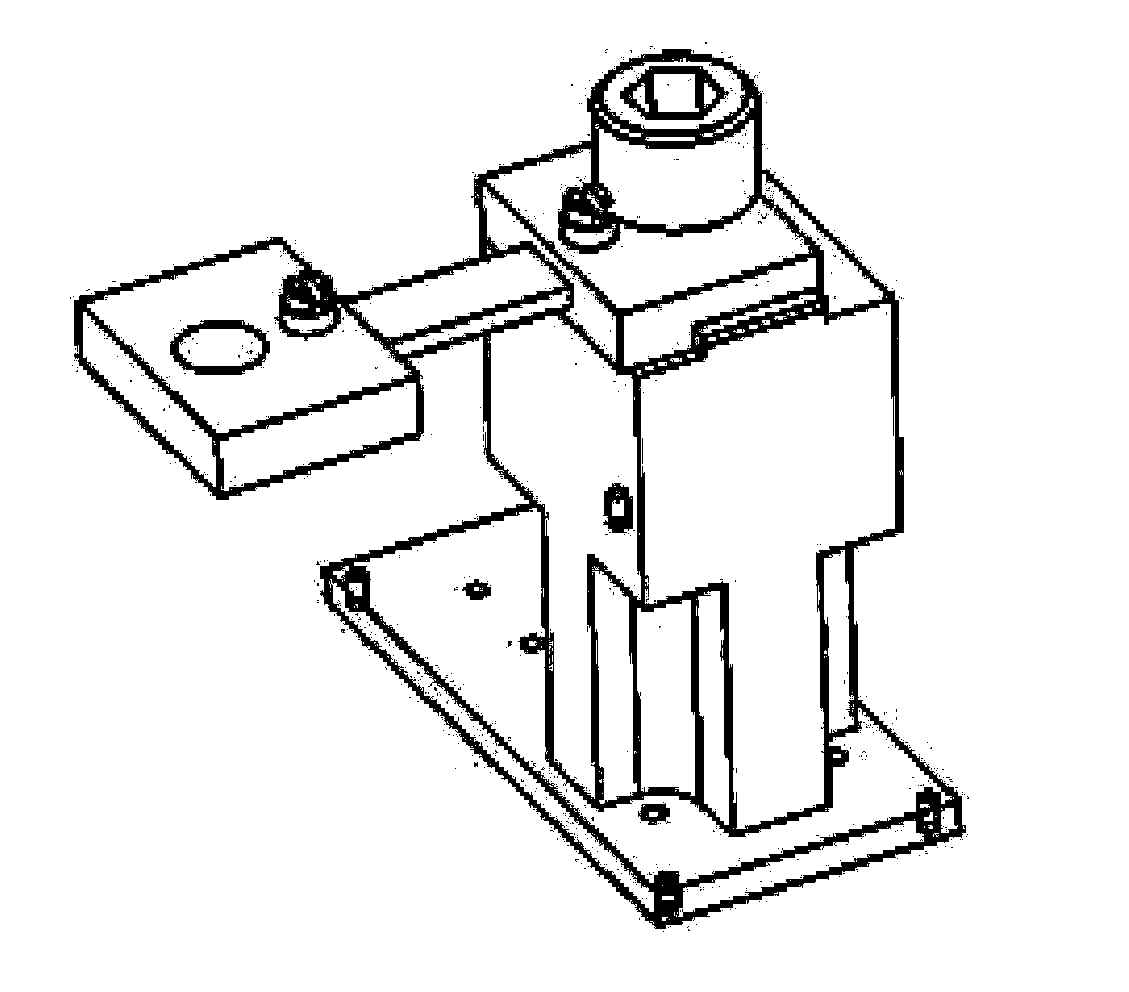

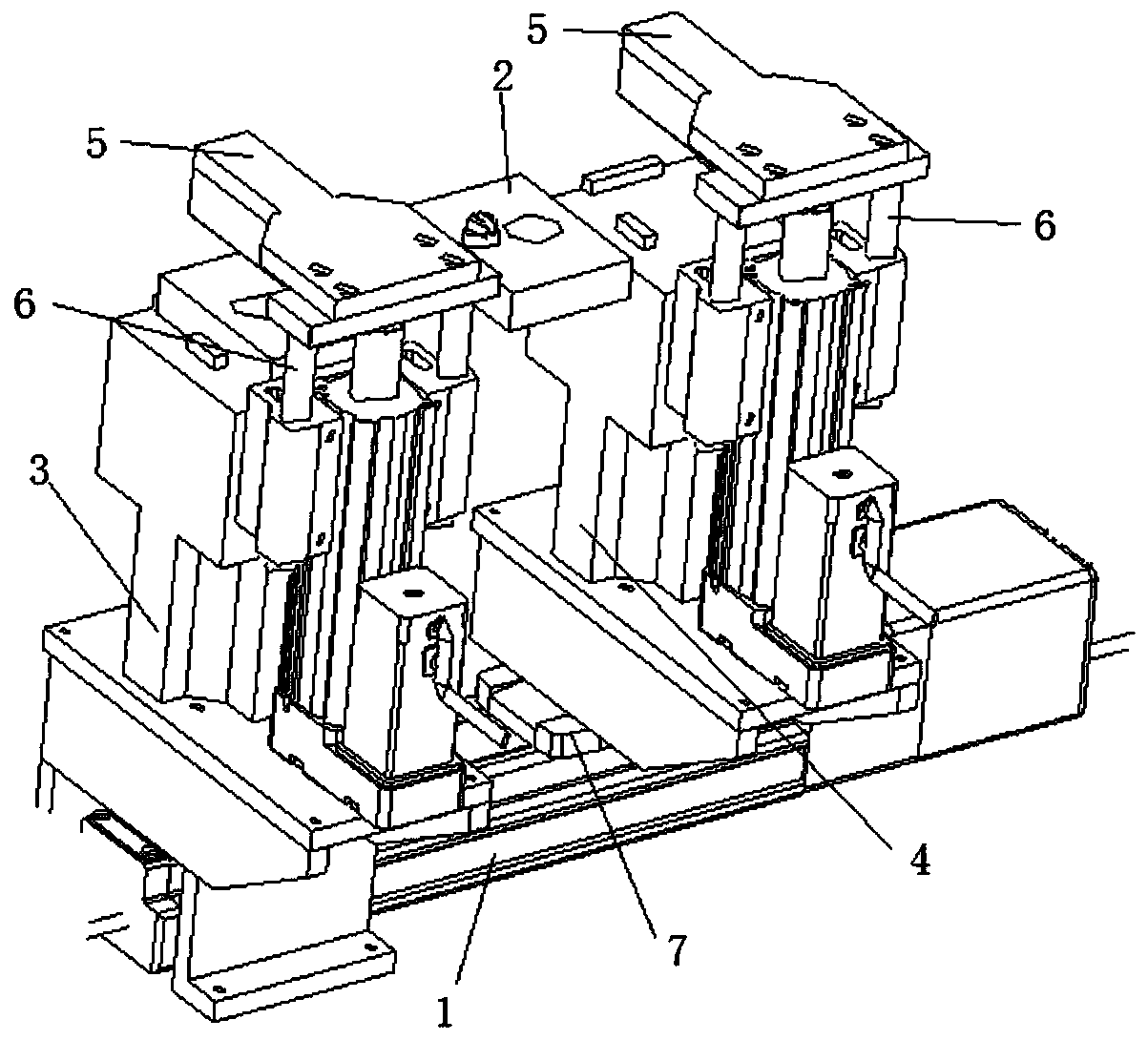

Automatic loading device for heavy current element tests

ActiveCN107356788AGuaranteed contactIncrease contactMeasurement instrument housingCurrent elementEngineering

The invention relates to an automatic loading device for heavy current element tests. The device comprises an electric sliding table used for disposing a fixed supporting device and a moveable supporting device of a tested workpiece, and two compaction devices used for compacting the tested workpiece, wherein the tested workpiece is arranged at a top end of the fixed supporting device and the moveable supporting device, the fixed supporting device is fixed on the electric sliding table, the moveable supporting device is arranged on the electric sliding table and can move on the electric sliding table relative to the fixed supporting device so as to dispose tested workpieces in different sizes, and the two compaction devices are respectively arranged on the fixed supporting device and the moveable supporting device and are used for compacting the tested workpiece from the upper portion. The loading device is advantaged in that automatic adjustment can be carried out according to the sizes of the workpieces, and damage to the tested workpieces can be reduced.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +2

A five-star chair foot welding device

ActiveCN105033526BMaintain stabilityWon't fall offWelding/cutting auxillary devicesAuxillary welding devicesCentral symmetryWelding

The invention relates to a five-star chair leg welding device and belongs to the field of welding equipment. A welding wire pipe fine adjustment part comprises a welding wire pipe, a fine adjustment motor and a welding wire pipe installation groove formed in the output shaft end of the fine adjustment motor. The welding wire pipe is arranged in the welding wire pipe installation groove through circumferential movement and connected with the welding end. The welding end is matched with a support base. The support base comprises a driving support, a driven support and a rotary shaft arranged between the driving support and the driven support. Two welding supporting device bodies which are in central symmetry and utilize the axis of the rotary shaft as the center line are arranged on the rotary shaft. The technical scheme is provided for an existing welding device, the welding pipe can be replaced and maintained conveniently, and a welding wire can pass through the welding wire pipe easily. In addition, the structural strength of the welding wire pipe is high, and the service life of the welding wire pipe is long. A rotary welded object support is further arranged to be matched with a welding gun head.

Owner:QIDONG CHUANGLU NEW MATERIAL CO LTD

Gas storage tank

InactiveCN104514985AEasy to collectImprove securityContainer filling methodsContainer discharging methodsWater treatment systemCold injury

The invention discloses a gas storage tank. The gas storage tank comprises a gas inlet, a tank body, and a gas outlet; the upper part of the tank body is provided with the gas inlet; the gas outlet is arranged on the lower part of the tank body; the bottom of the tank body is provided with a liquid collect box; and a liquid exhaust pipe is arranged below the liquid collect box. The gas storage tank is simple in structure, and is convenient for operation; the bottom of the tank body is provided with the liquid collect box, so that collection of condensate water is more convenient, safety of operation staff is increased, operation staff is protected from cold injury, operation reasonable performance is improved, operators are protected from injuries, occupational injury of employees is reduced, and safe production is ensured; waste condensate water is delivered into a waste water pipe network, so that waste condensate water can be delivered into an enterprise waste water processing system directly for waste water treatment, and then is discharged into a city pipe network; pressure of the city pipe network is reduced, the city pipe network is protected, direct corrosion of pipeline caused by discharged waste water is avoided, and service life of the city pipe network is prolonged.

Owner:扬州三方电器有限公司

Crimping device for wire plug skeleton

InactiveCN107732627AImprove work efficiencyImprove crimping accuracyLine/current collector detailsEngineeringMechanical engineering

The invention provides a crimping device for a wire plug skeleton. The crimping device comprises a pedestal; a wire head placing rack is arranged on the pedestal; a press fitting machine is arranged at one side of the wire head placing rack; a press fitting base is arranged below the press fitting machine; and a plug feeding track is arranged at the rear side of the press fitting machine and a vibrating screen is arranged at the rear end of the plug feeding track. A moving cylinder is arranged at the lower end of the wire head placing rack. And a plug righting block is arranged on the press fitting base. A wire head is arranged by the wire head placing rack and automatic feeding of the wire head is carried out by the vibrating screen and the plug feeding track, the plug is localized by theplug righting block, and a crimping machine completes the crimping work, so that the work efficiency is improved, the labor consumption is reduced, and occupational injuries are reduced. Moreover, with a material blocking cylinder, a plug detector, and a residue detector, plug feeding and residues are controlled, so that the crimping precision is improved.

Owner:WUHU SHUNCHENG ELECTRONICS

A device for removing sweet persimmon stalk

ActiveCN113317535BAvoid destructionReduce the likelihood of damageFood treatmentEngineeringSweetness

The invention discloses a device for removing sweet persimmon stalks, which includes a working basket, and also includes a transport mechanism, a straightening mechanism, a feeding mechanism, a handle removal mechanism and a discharging mechanism; the straightening mechanism is arranged inside the transportation mechanism, and the The feeding mechanism is fixedly installed on one end of the transportation mechanism, and the feeding mechanism is located directly above the transportation mechanism, the handle removal mechanism is fixedly installed on the top of the transportation mechanism, and the handle removal mechanism It is located directly above the end of the transport mechanism away from the feeding mechanism, and the discharging mechanism is erected on one side of the working basket; in the present invention, by setting the handle removing mechanism, the fruit handle of the sweet persimmon can be fully automatically removed. Remove, and the hair dryer can blow off the cut fruit stalks to prevent the piles of fruit stalks from affecting the follow-up work. By setting the correction mechanism, the sweet persimmon can be adjusted in advance so that the end of the sweet persimmon with the stalk is upward, which is convenient for subsequent processing. The fruit stalk is excised.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Punching machine with automatic discharge

ActiveCN107457297BSimple actionAvoid being injured by the punch by mistakeShaping safety devicesNutsPunchingMachine parts

The invention discloses a punching machine capable of automatic discharging. The punching machine comprises a workbench and a punch. The punching machine is characterized by further comprising a clamping mechanism, an oscillating bar mechanism and an ejector rod, wherein the clamping mechanism is connected with the punch by virtue of a connecting rod, a through hole is formed in the workbench, part of the ejector rod is located in the through hole, part of the ejector rod protrudes from the workbench, the oscillating bar mechanism is connected with the punch, the oscillating bar mechanism is driven to rotate in the process that the punch is pressed downwards or is lifted, the ejector rod is clamped by the clamping mechanism so as to drive the ejector rod to move downwards or upwards, and when the punch is lifted to the top, the ejector rod is loosened by the clamping mechanism, so that the ejector rod falls off. According to the punching machine, the punching and automatic discharging operation can be completed, and automatic discharging can be performed after punching is completed, so that collection and management are facilitated, the operation of operating personnel is simplified, the condition that the operating personnel are accidentally hurt by the punch when machined parts are taken is avoided, occupational injuries are reduced, and the safety of the operating personnel is greatly increased.

Owner:DONGTAI DAMING METAL PROD CO LTD

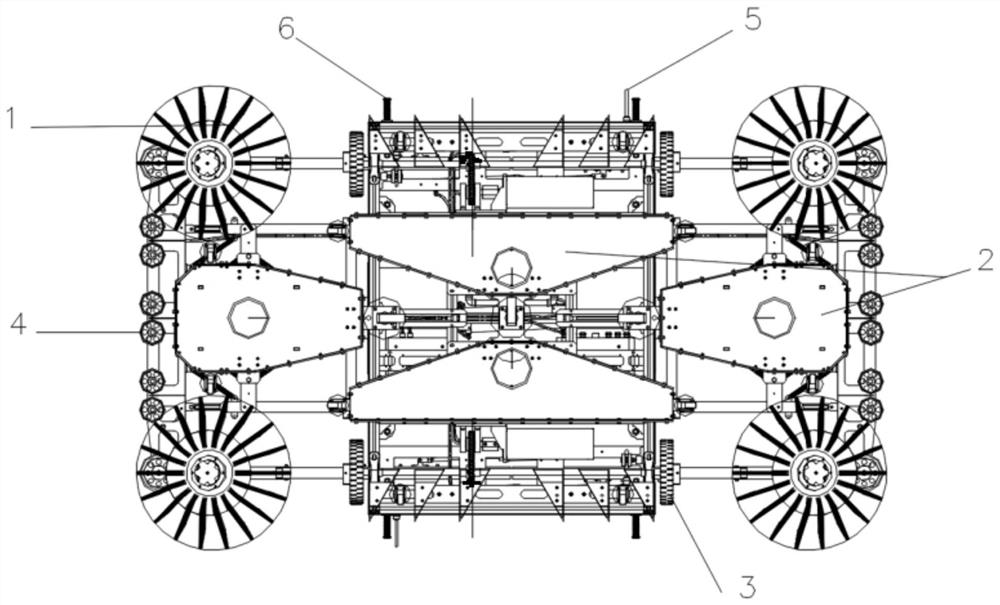

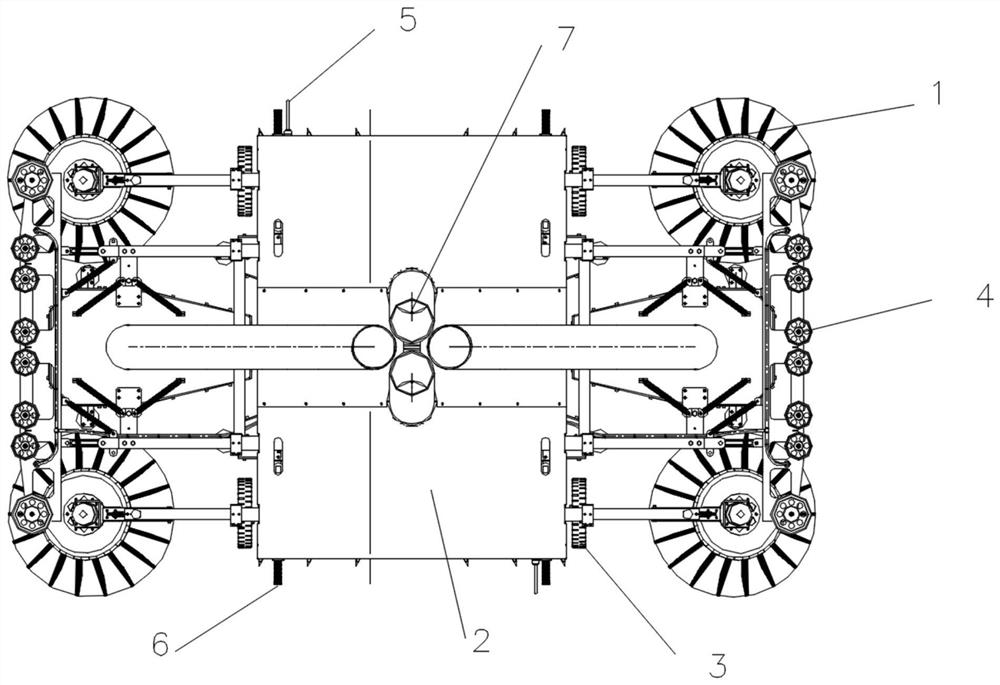

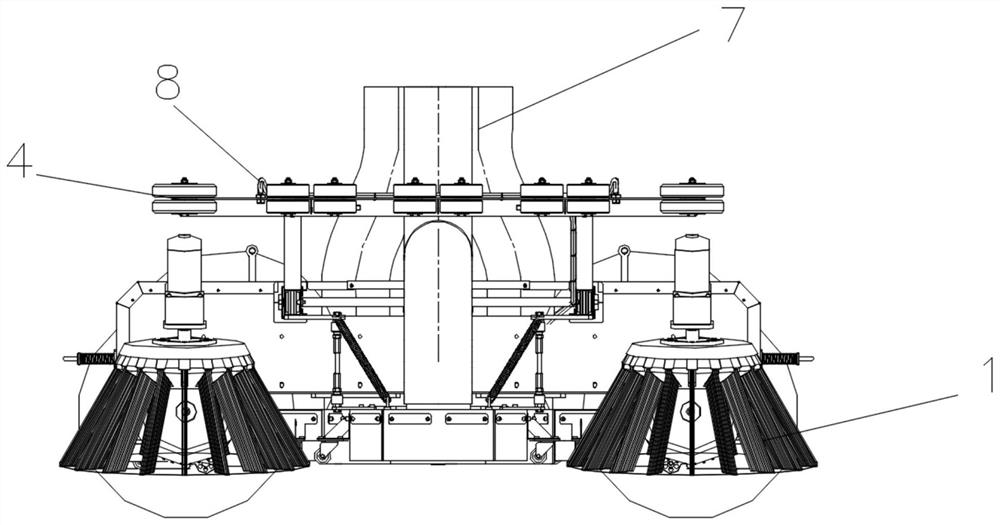

Train coal cinder sweeping equipment and sweeping method thereof

PendingCN112959976AReduce pollutionFast negative pressure suctionCleaning apparatus with conveyorsUsing liquid separation agentBrushControl theory

The invention discloses train coal cinder sweeping equipment and a sweeping method thereof. The train coal cinder sweeping equipment comprises a sweeping trolley in a compartment and a control mother vehicle which can pull the sweeping trolley and is located outside the compartment. The sweeping trolley comprises a rack, a controller, and a rolling brush rotary sweeping module, a suction module, a spraying module, a walking driving module and a limit position sensing module which are arranged on the rack and are controlled by the controller; the rolling brush rotary sweeping modules are arranged on the two sides of the rack, namely the two width sides of the carriage. The walking driving module is used for driving the sweeping trolley to move in the length direction of the carriage. The control mother vehicle is connected with the sweeping trolley through a traction device and is provided with a coal cinder collecting bin and a fan; the suction module performs negative pressure suction on the coal cinder under the action of the fan and feeds the coal cinder into the coal cinder collecting bin; and through full-automatic cleaning of the cleaning trolley, the incidence rate of pneumoconiosis is reduced.

Owner:孙丽洁

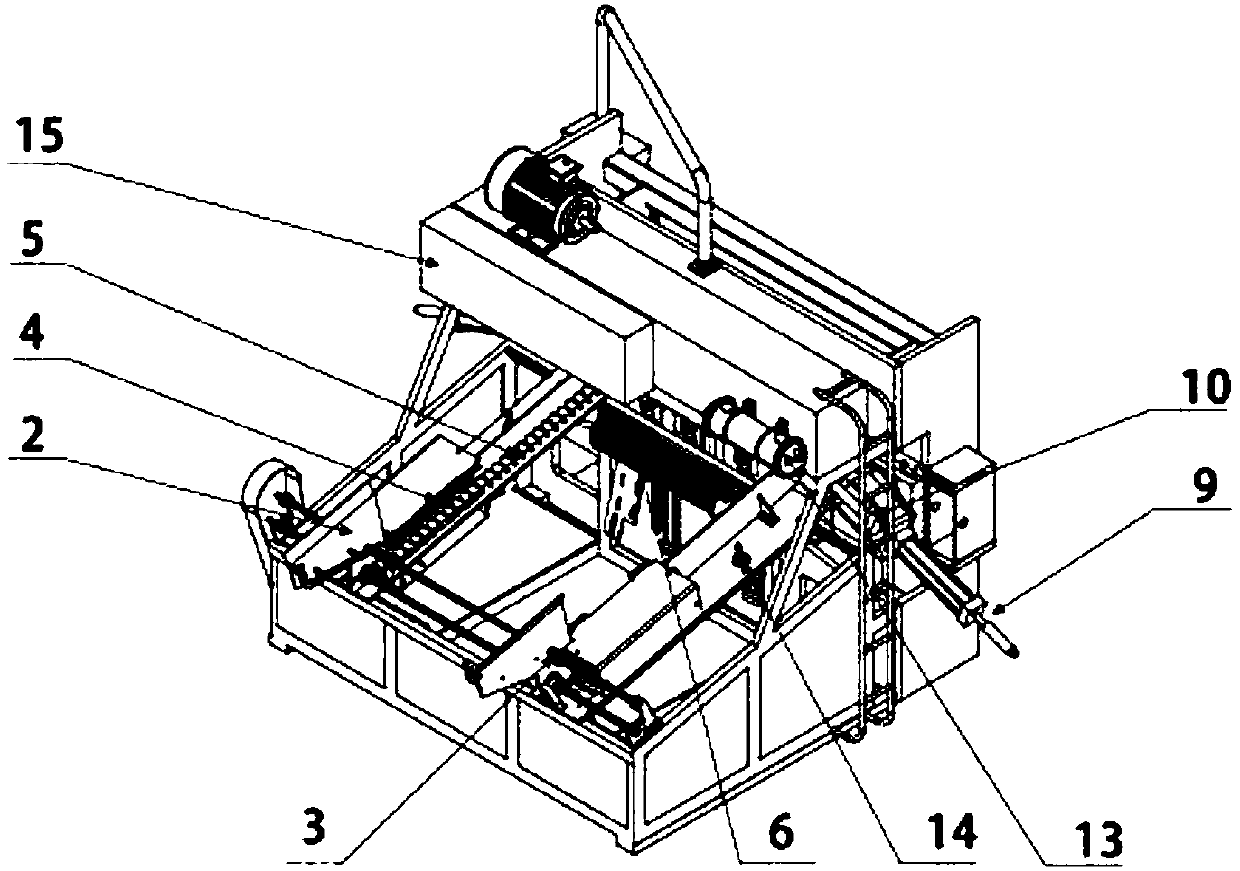

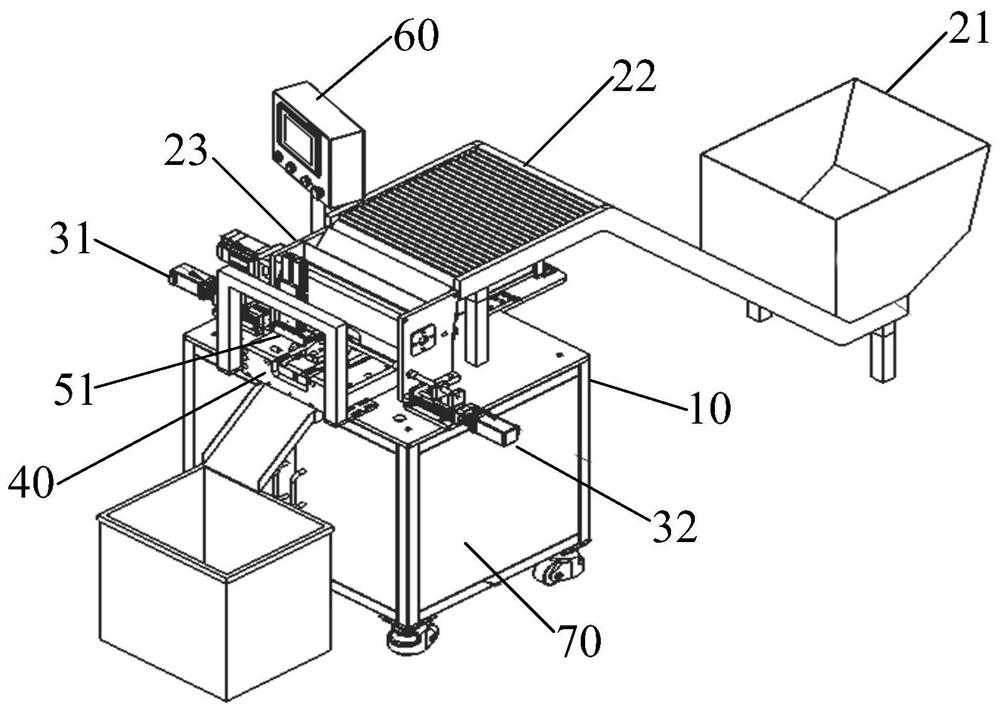

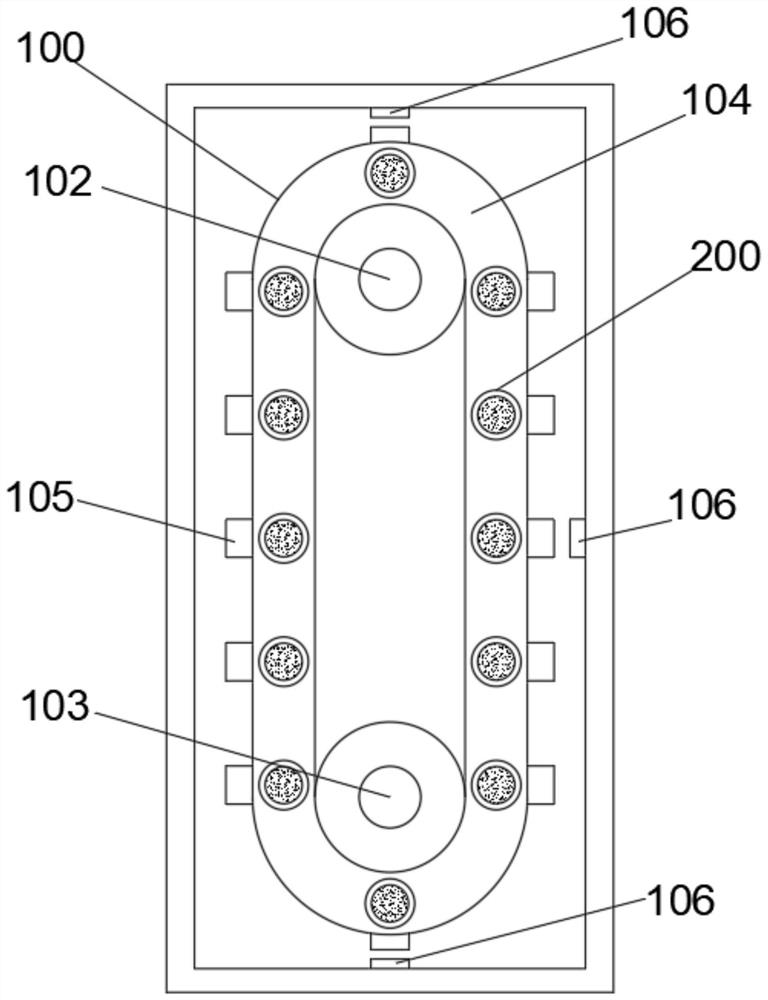

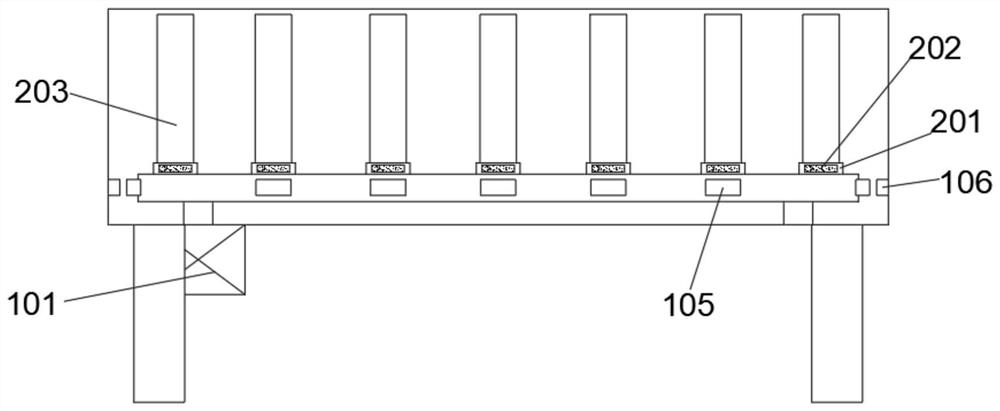

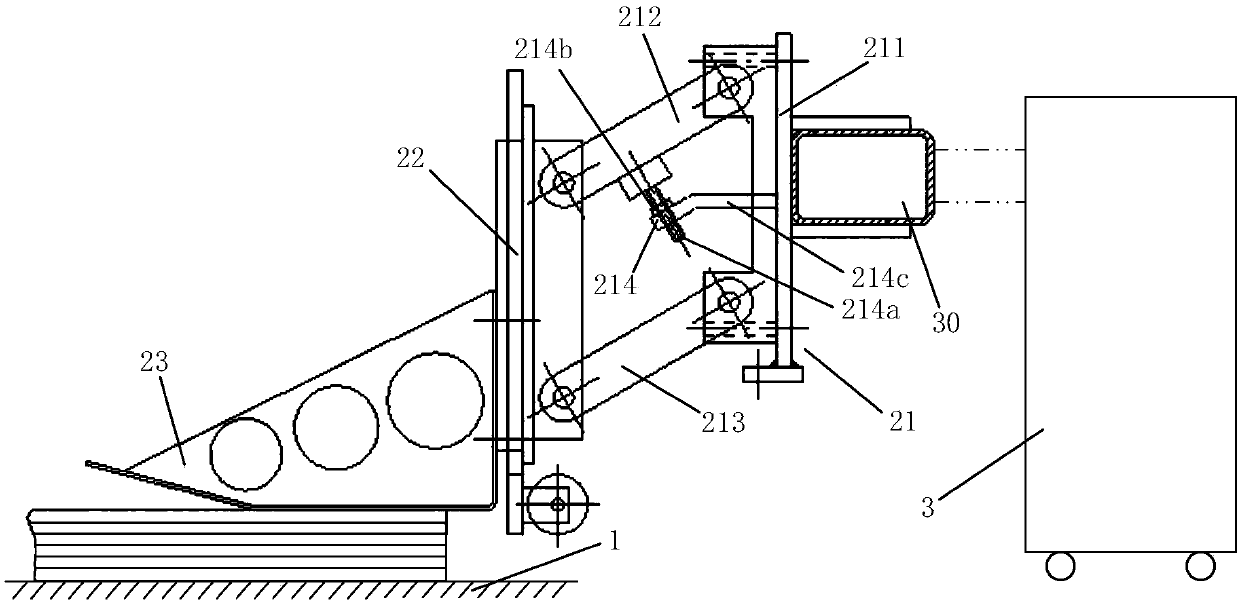

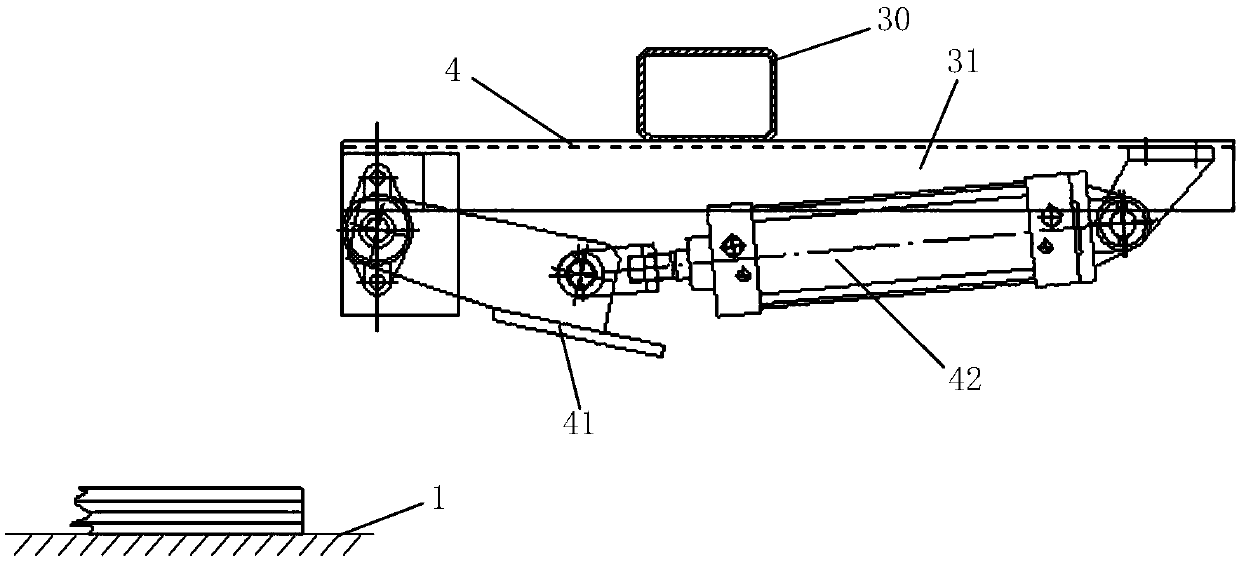

Automatic plate loading equipment

ActiveCN110239961AReduce manual workloadReduce work injuriesStacking articlesDe-stacking articlesElectricityEngineering

The invention provides automatic plate loading equipment. The automatic plate loading equipment comprises a controller, a hydraulic lifting platform, a plate loading mechanism and a moving trolley, wherein the first end of the plate loading mechanism is fixedly connected with the moving trolley, the second end of the plate loading mechanism is positioned above one end of the hydraulic lifting platform, the hydraulic lifting platform and the moving trolley are electrically connected with the controller, the controller controls lifting or lowering of the hydraulic lifting platform, and the controller controls starting and stopping and the moving direction of the moving trolley. The automatic plate loading equipment not only can automatically align stacked gypsum plates, but also can simultaneously load a pair of gypsum plates, thereby reducing labor workload, reducing the possibility of occupational injuries and improving the production automation degree and production efficiency.

Owner:BEIJING NEW BUILDING MATERIALS PLC

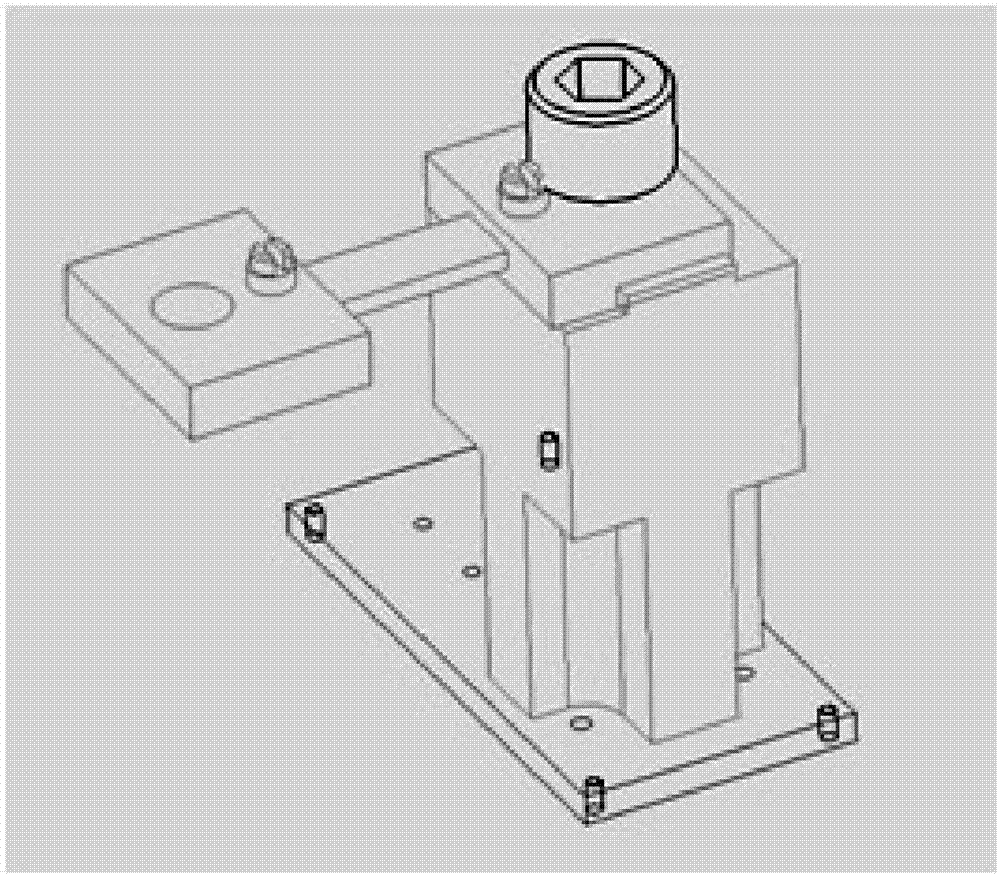

Connecting structure for current element measurement

ActiveCN107422155AAvoid feverNot easy to get hotBase element modificationsCurrent elementEngineering

The present invention discloses a connecting structure for current element measurement, comprising two sets of connecting members for connecting the two ends of a current element arranged in a current flowing direction to a measuring circuit respectively with the two connecting members disposed oppositely at the two ends of the current element. Each set of connecting members includes a mounting plate provided with a plurality of vertical elastic probes with elastic force. The top ends of the elastic probes are used for connecting the end part arranged on the current element correspondingly, and the oppositely arranged bottom ends of the elastic probes penetrate the mounting plate and are connected with the measuring circuit. The connecting structure further comprises a pressing component used for abutting against the end part of the current element to be in contact with the top ends of the plurality of corresponding elastic probes. The connecting structure for current element measurement of the present invention achieves good heat dissipation, is not easy to generate heat, and can keep close contact with the current element all the time. The operation process for the structure is simple, the packaging and clamping efficiency is high, and the connecting structure can be applied widely.

Owner:长沙天恒测控技术有限公司

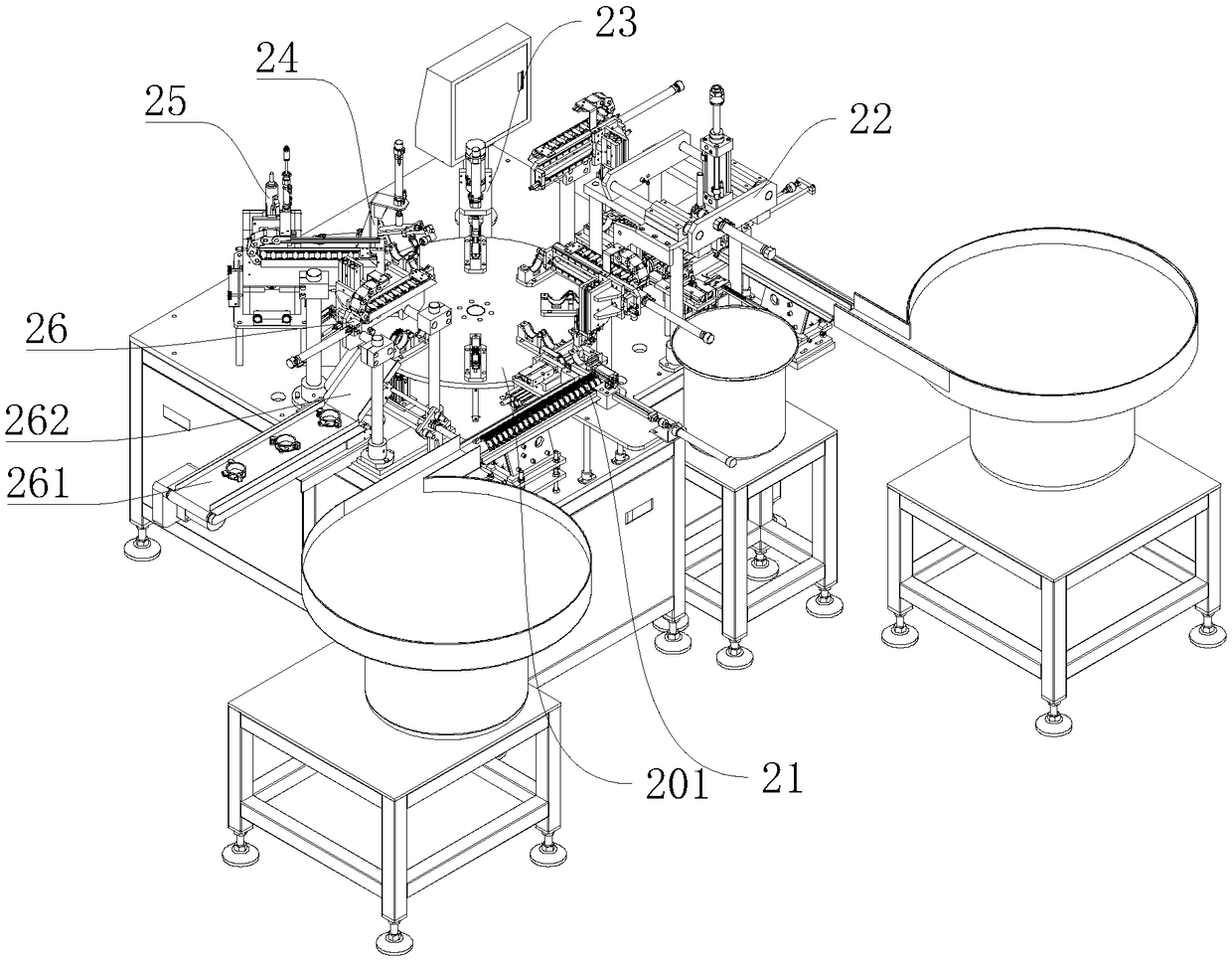

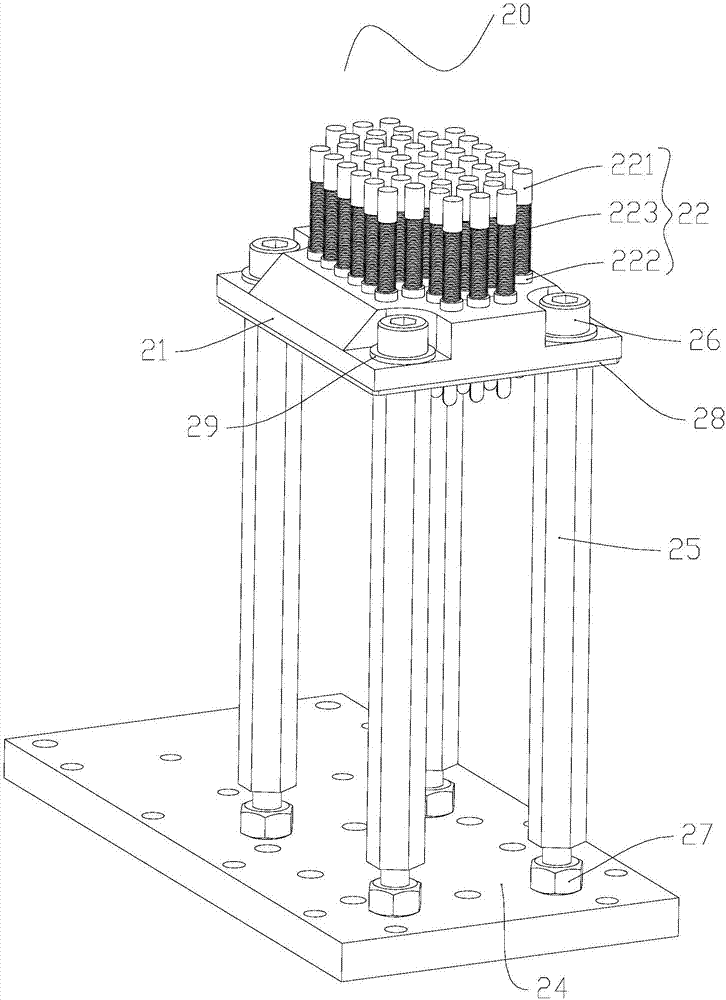

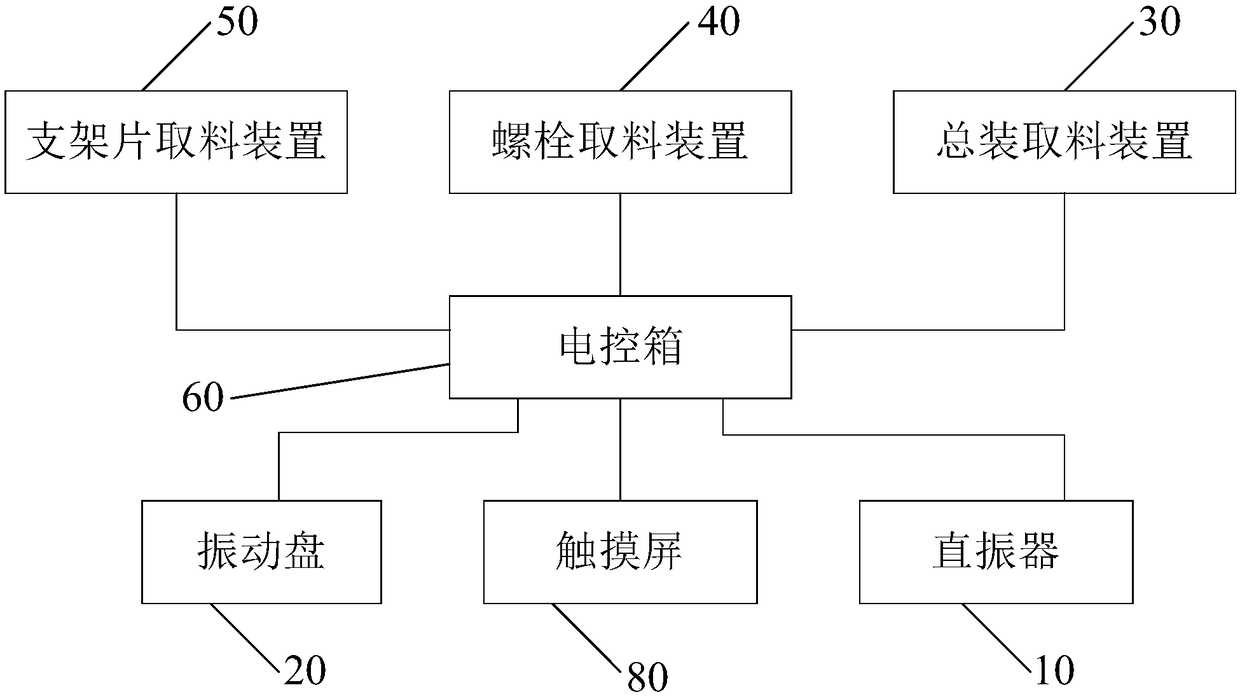

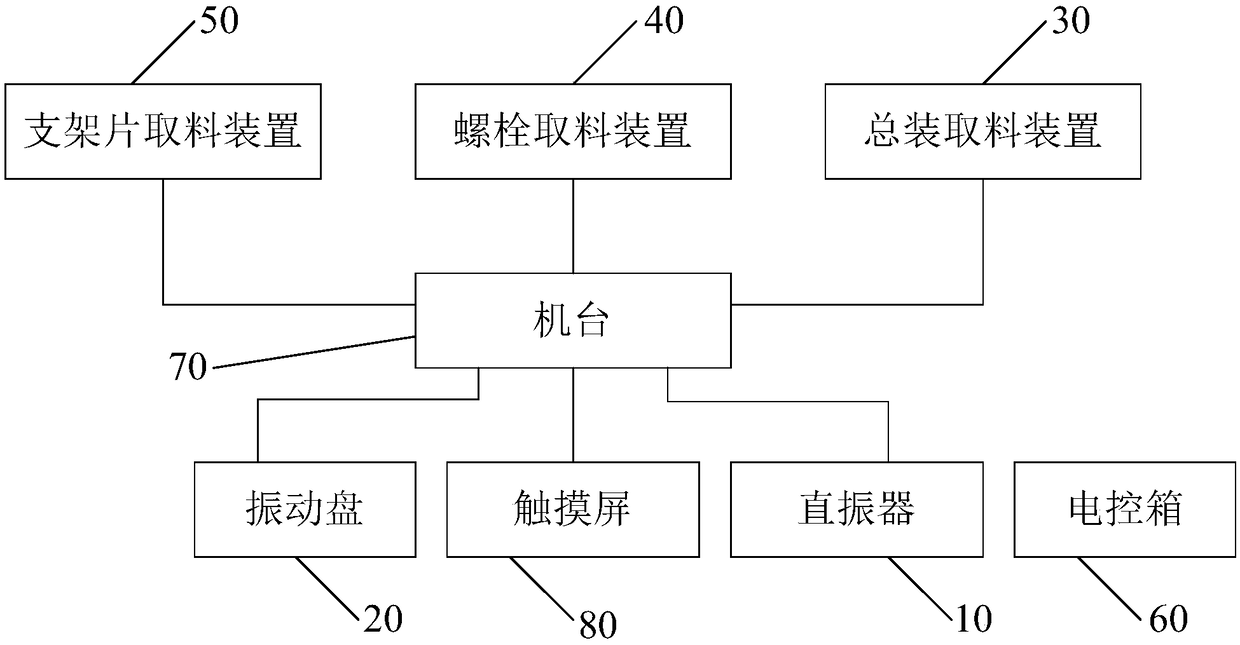

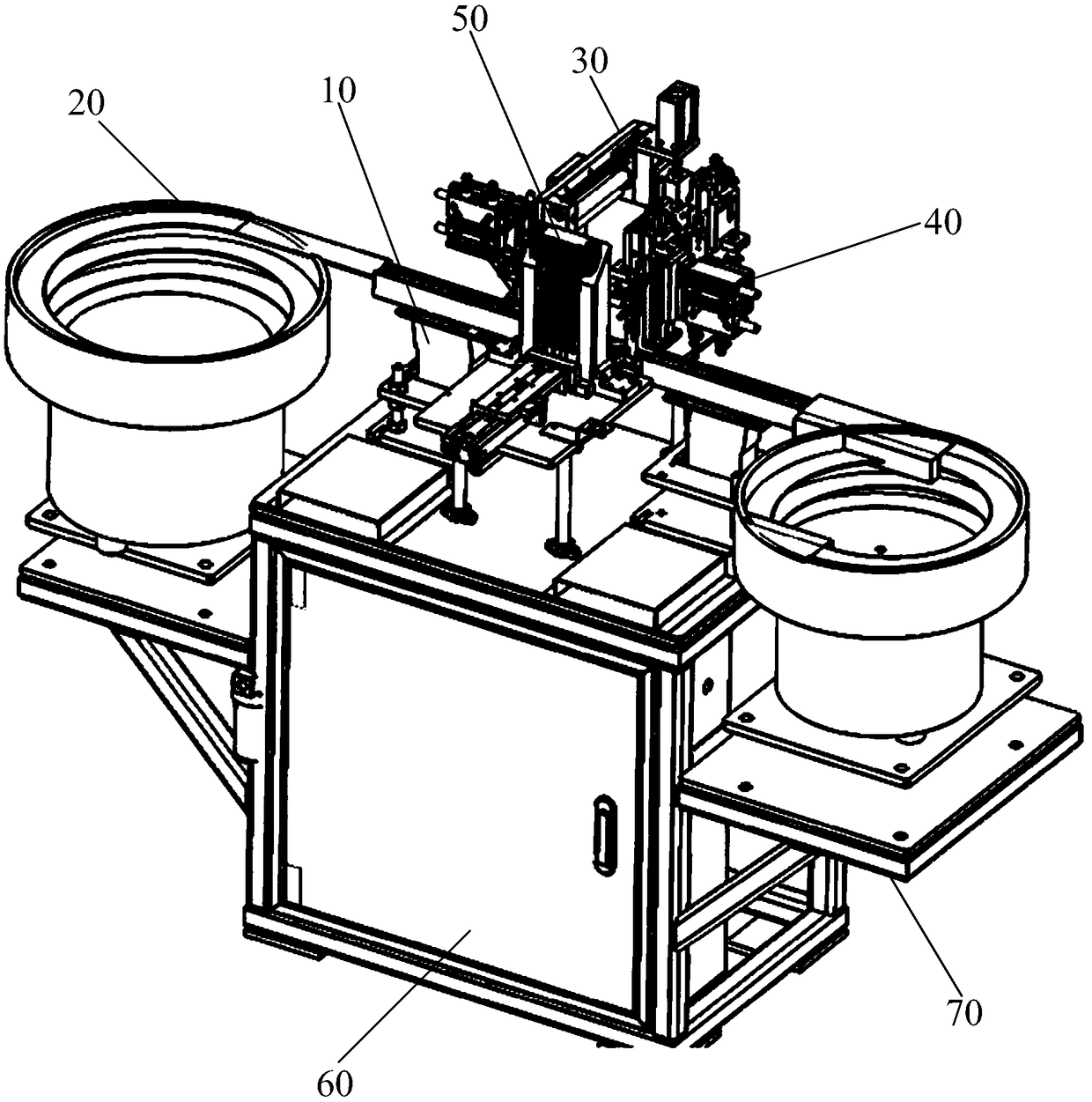

Automatic assembling and feeding device for high-precision bolt and bracket piece

The invention provides an automatic assembling and feeding device for a high-precision bolt and a bracket piece, which comprises a machine platform, a support sheet material taking device, a bolt material taking device, a final assembly material taking device, a vibration disc, a vibration absorber, a touch screen and an electric cabinet; wherein the connection relation is that the support sheet material taking device, the bolt material taking device, the final assembly material taking device, the vibration disc, the vibration absorber, the touch screen and the electric control box are connected with the machine platform; the support sheet material taking device, the bolt material taking device, the final assembly material taking device, the vibration disc, the vibration absorber and the touch screen are respectively electrically connected with the electric control box; the support sheet material taking device comprises a first cylinder, a stack block, a feeding position sensor and a stack block placing table. The device is automatically taken and assembled, replaces manual production, has the advantages of reliable structure, high performance, convenient use, and easy maintenance,and meets safe production and improves market competitiveness of the enterprise.

Owner:ZHEJIANG CHANGHUA AUTO PARTS

A pouring riser removal machine

InactiveCN103111610BEasy to processEffective detection sizeWork related injuriesProgrammable logic controller

Owner:SUZHOU UNIV

High-precision and high-efficiency automobile bolt and eccentric washer riveting device

Owner:ZHEJIANG CHANGHUA AUTO PARTS

Automatic loading device for high current component testing

ActiveCN107356788BGuaranteed contactIncrease contactMeasurement instrument housingCurrent elementEngineering

The invention relates to an automatic loading device for heavy current element tests. The device comprises an electric sliding table used for disposing a fixed supporting device and a moveable supporting device of a tested workpiece, and two compaction devices used for compacting the tested workpiece, wherein the tested workpiece is arranged at a top end of the fixed supporting device and the moveable supporting device, the fixed supporting device is fixed on the electric sliding table, the moveable supporting device is arranged on the electric sliding table and can move on the electric sliding table relative to the fixed supporting device so as to dispose tested workpieces in different sizes, and the two compaction devices are respectively arranged on the fixed supporting device and the moveable supporting device and are used for compacting the tested workpiece from the upper portion. The loading device is advantaged in that automatic adjustment can be carried out according to the sizes of the workpieces, and damage to the tested workpieces can be reduced.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com