Automatic assembling equipment of self-buckling type pipe clamp, nut and screw

An automatic assembly and self-fastening technology, which is applied in metal processing equipment, assembly machines, manufacturing tools, etc., can solve the problems of manual picking and placing of raw materials, low assembly efficiency, easy hand injury, etc., to reduce work-related injuries, improve production efficiency, Labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

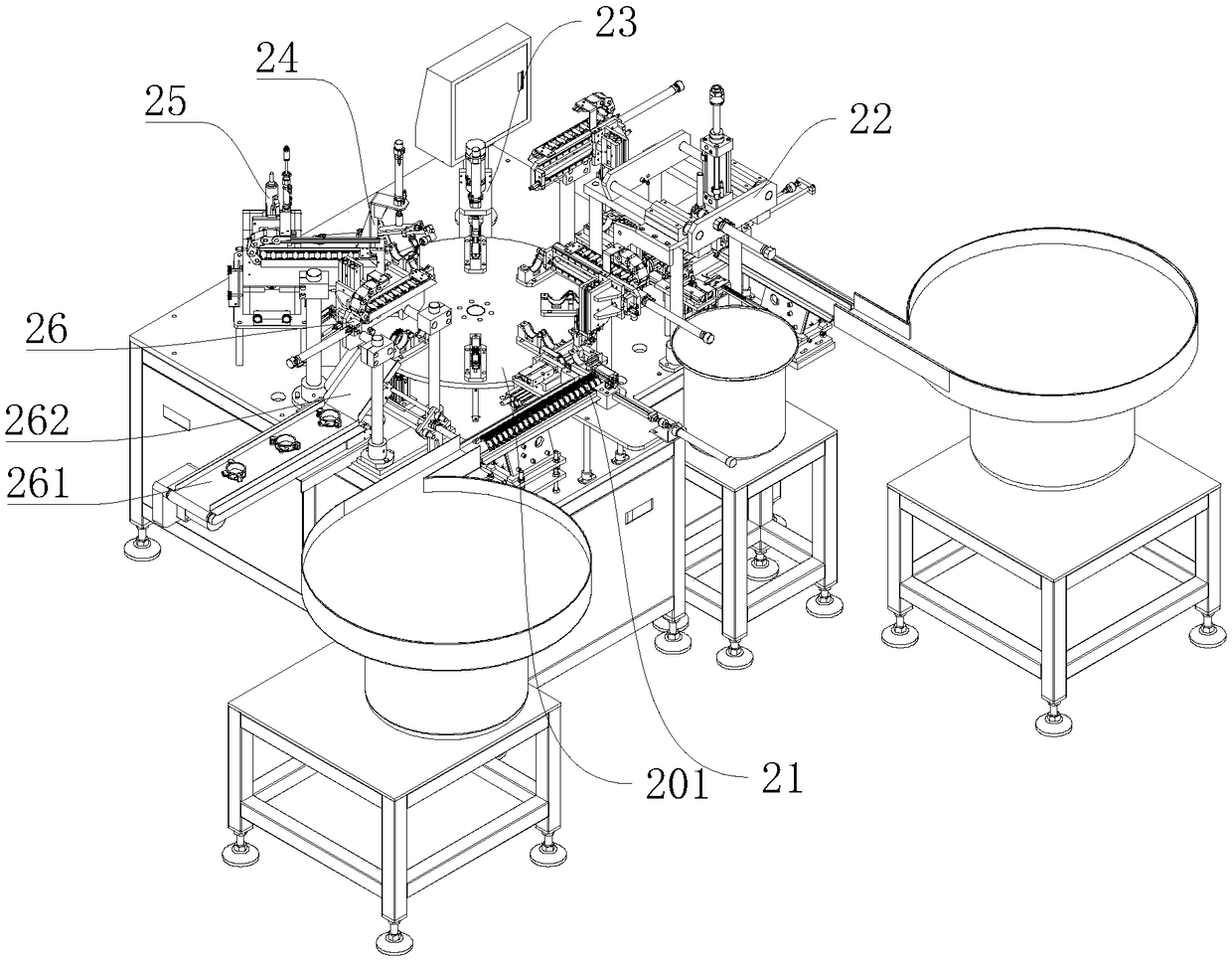

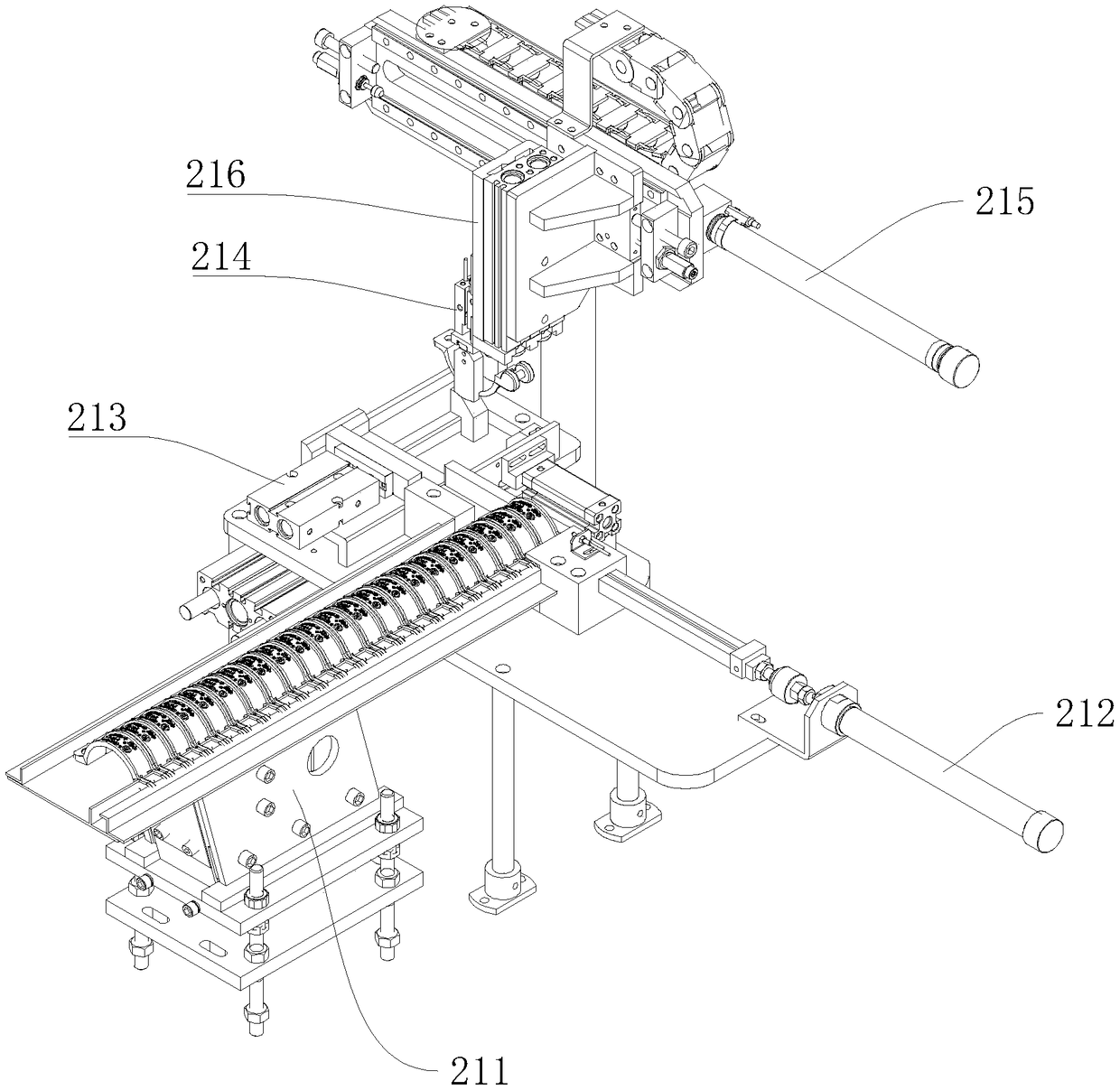

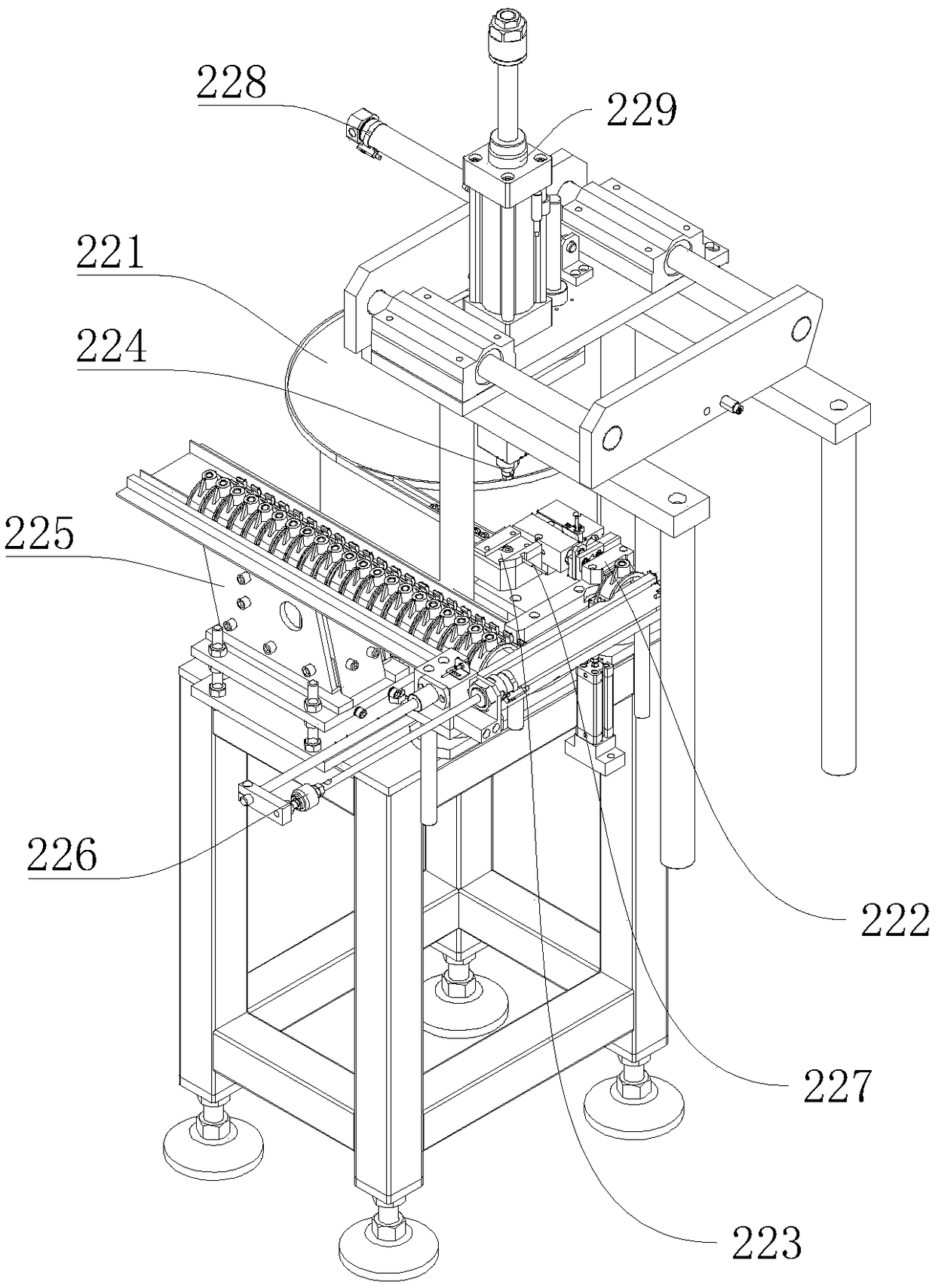

[0028] Such as Figure 1-Figure 6 Shown is a kind of automatic assembly equipment of self-locking type pipe clamp, nut and screw of the present invention, self-locking type pipe clamp such as Figure 7 As shown, it includes a mouthless pipe clamp 11 and a mouthed pipe clamp 12. One end of the mouthless pipe clamp 11 and the mouthed pipe clamp 12 is rotatably connected by a pin shaft, and the other end is detachably connected by a screw 13 and a nut, including: working Table 2, a turntable arranged on the workbench 2, the turntable is used to transport components between the stations, including a turntable body 201, a cam divider 202 arranged at the bottom of the turntable body 201 for driving the turntable body 201 to rotate, and The cam divider 202 is connected to a motor 203 for providing power. Preferably, an eight-degree cam divider 202 is used in this embodiment, and the outer ring of the main body of the turntable 201 is provided with a number of pipe clamps 205 with mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com