Punching machine with automatic discharge

A technology of automatic discharging and punching machine, applied in the field of punching machine, can solve the problems of operator pressing, time-consuming and labor-intensive, work-related injuries, etc., and achieve the effect of simplifying actions, facilitating collection and management, and enhancing safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, the present invention will be further described in detail with reference to the accompanying drawings and specific embodiments.

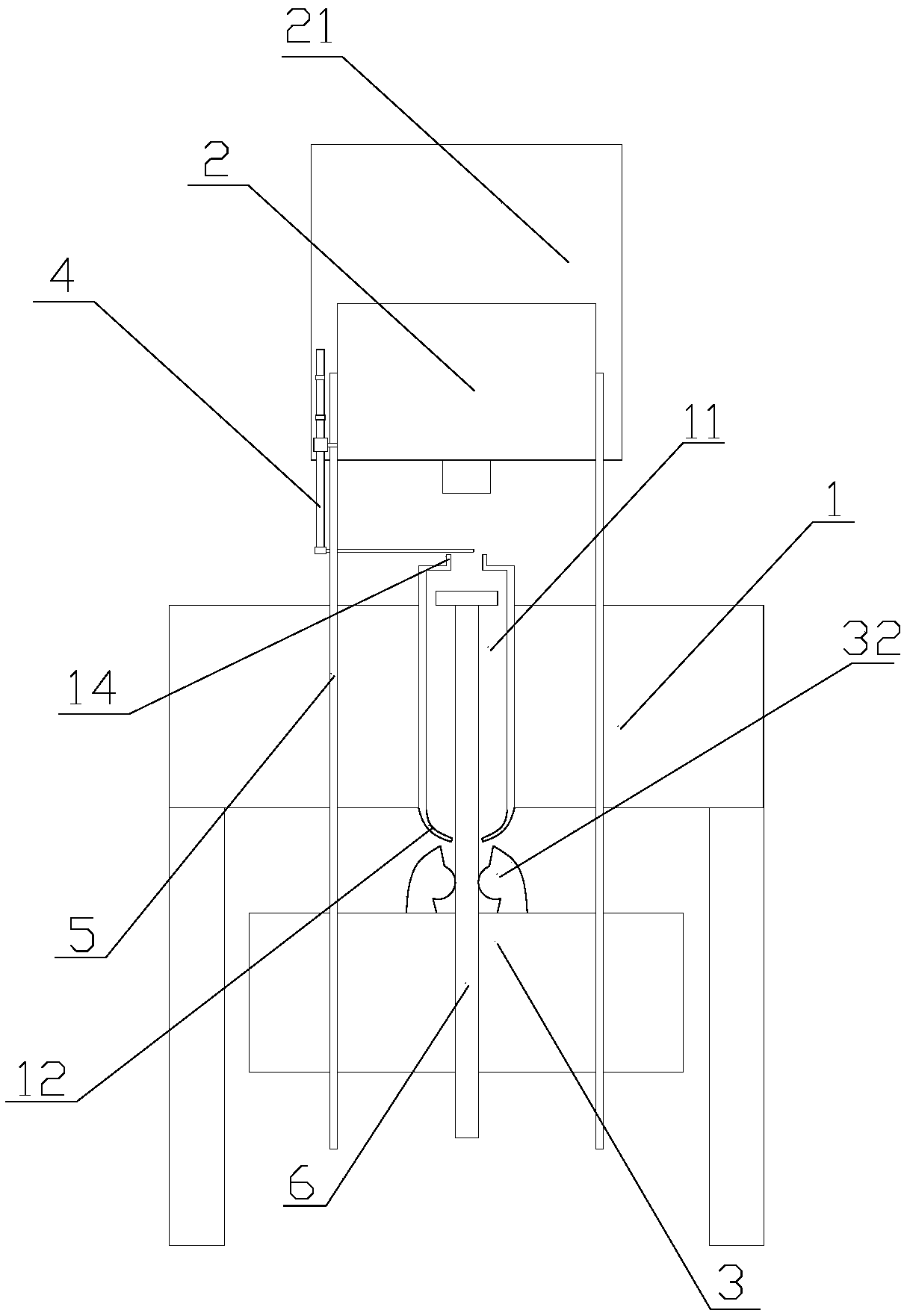

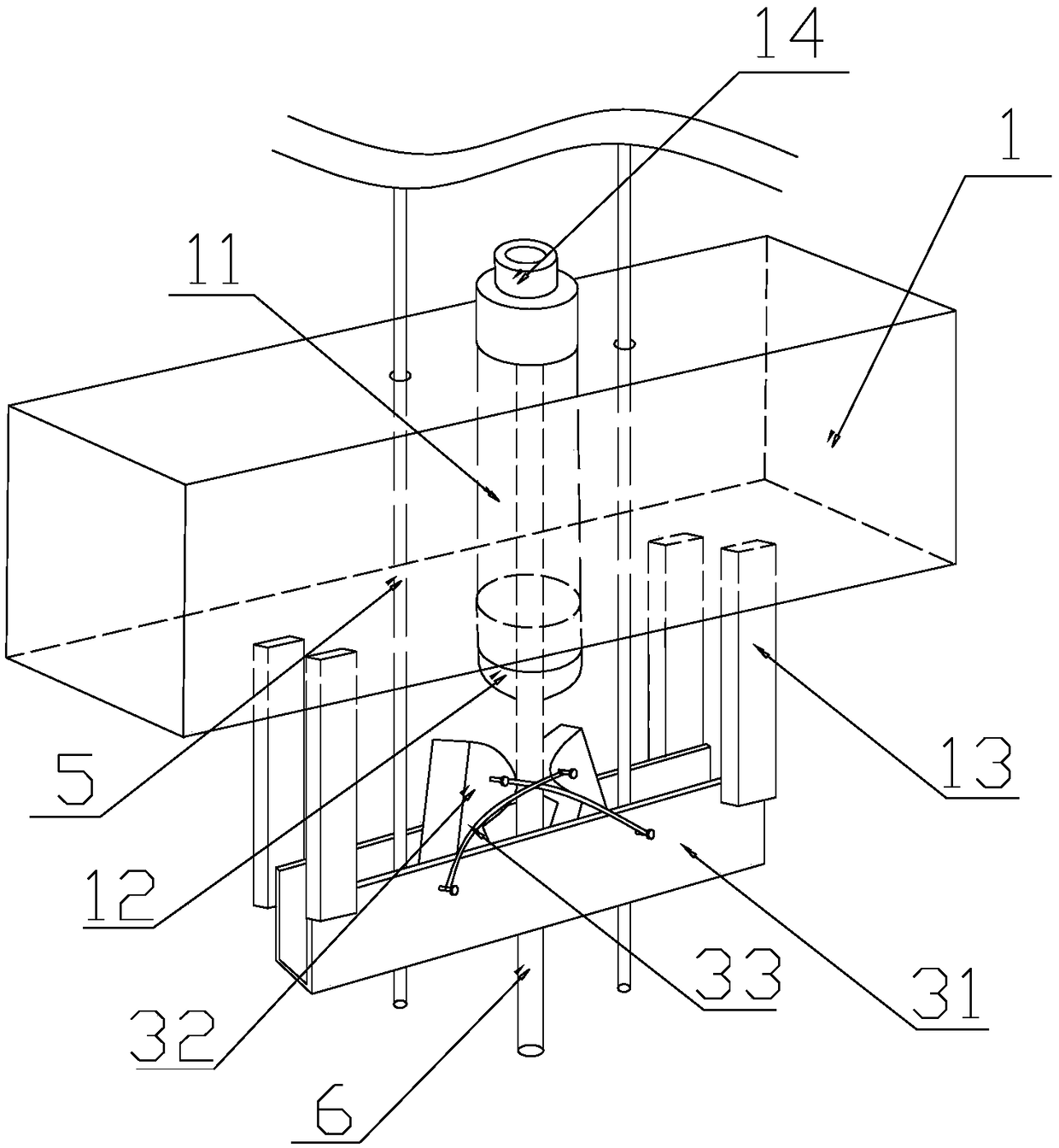

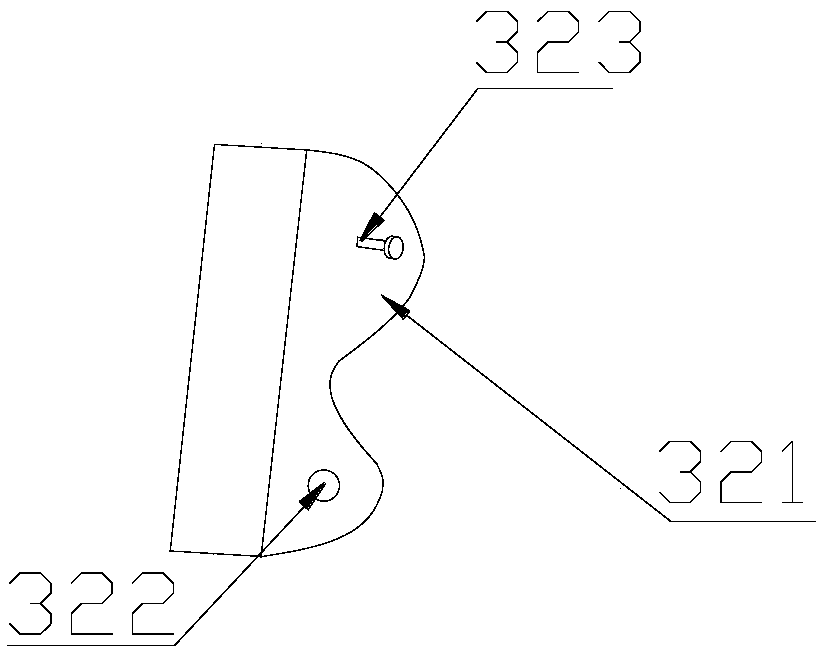

[0021] Such as figure 1 As shown, the automatic discharge punching machine of the present invention includes a workbench 1, a punch 2, a clamping mechanism 3, a swing mechanism 4 and a push rod 6, the punch 2 is located directly above the workbench 1, and the clamp The clamping mechanism 3 is located directly under the workbench 1, the clamping mechanism 3 is connected with the punch 2 through the connecting rod 5, and the connecting rod 5 runs through the workbench 1, so that the clamping mechanism 3 and the punch 2 are linked, so The through hole 11 provided in the workbench 1, the through hole 11 runs through the entire workbench 1, the table surface of the workbench 1 is provided with a placement groove 14 for placing workpieces, and the placement groove 14 is connected to the through hole 14. The holes 11 are connected, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com