Patents

Literature

35results about How to "Improve lap efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

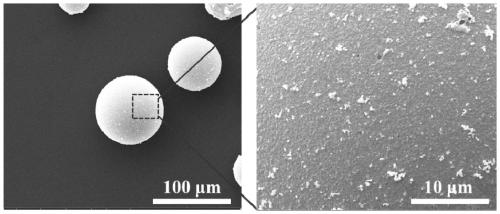

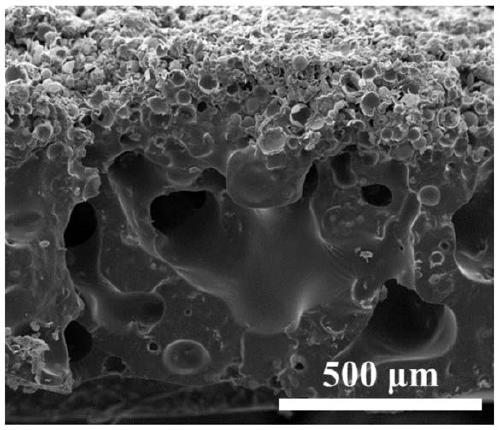

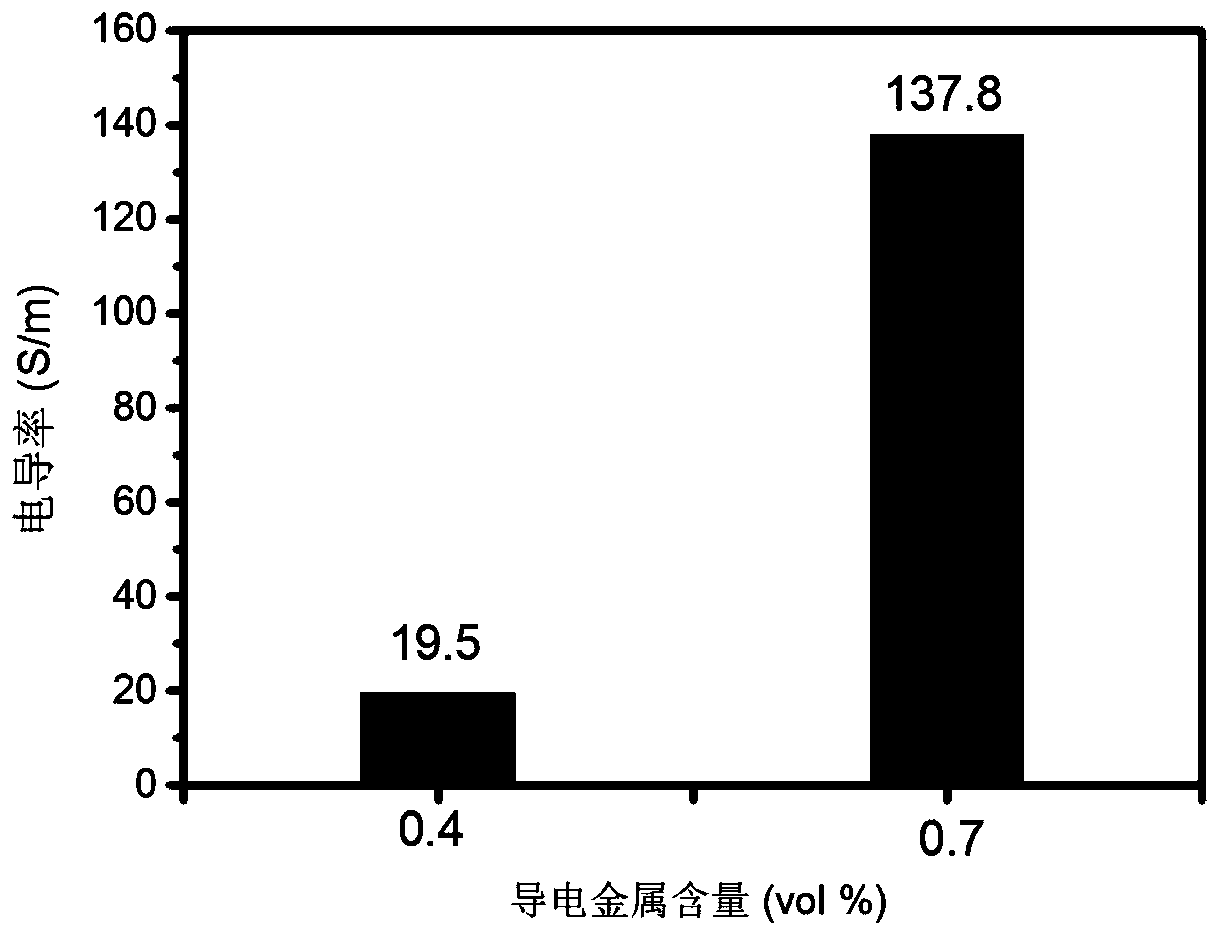

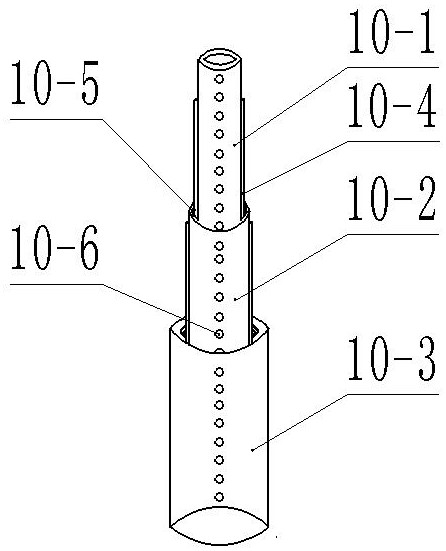

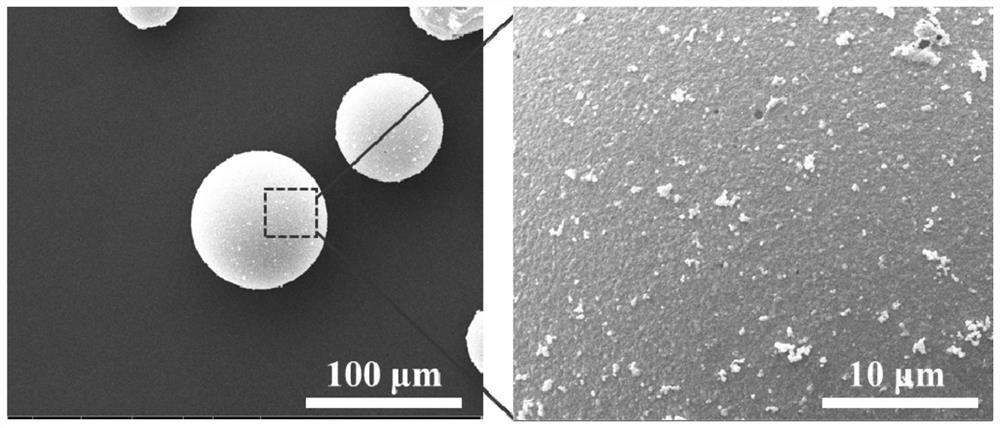

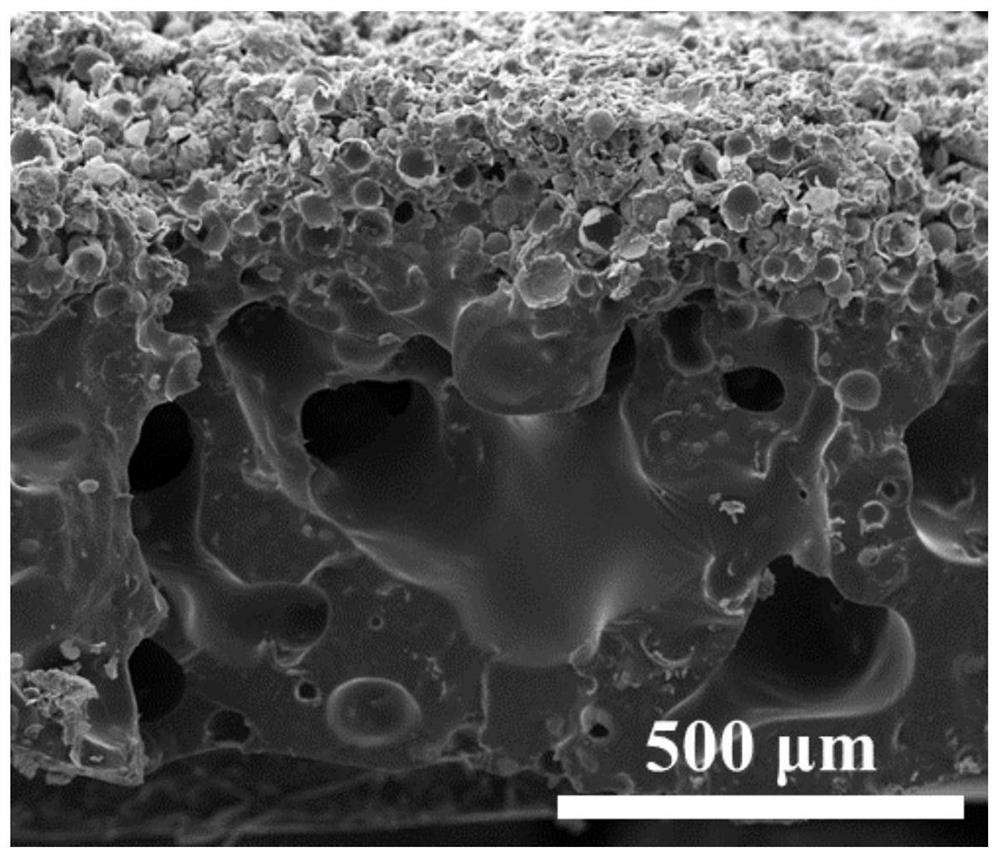

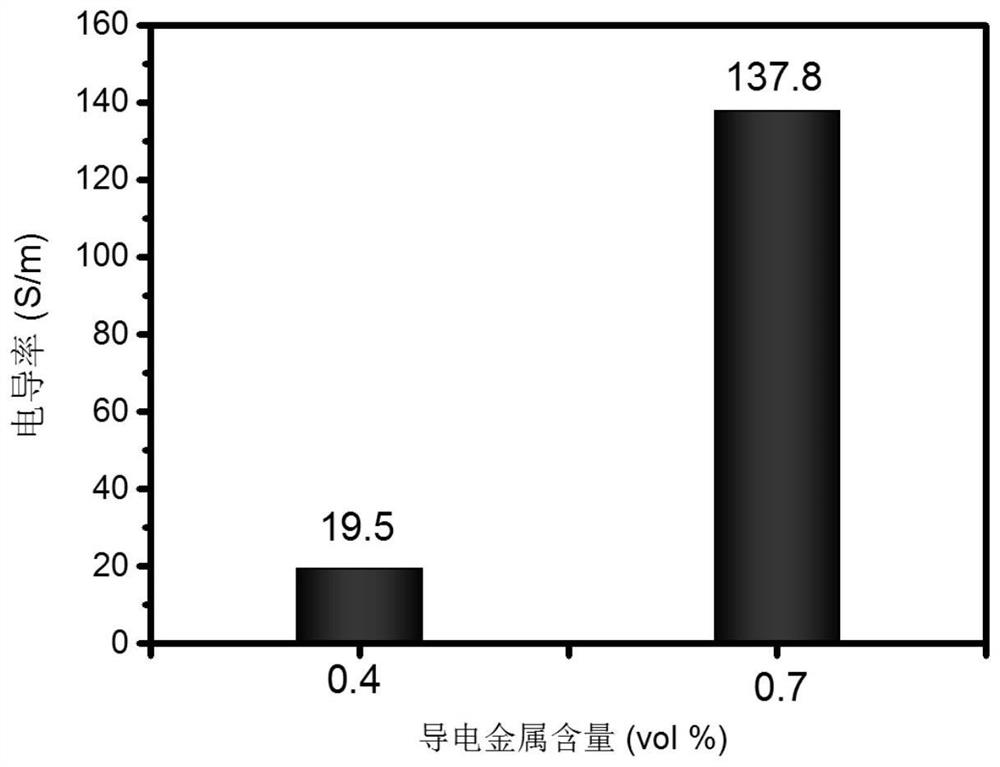

Polymer electromagnetic shielding composite foam with gradient filler structure and preparation method thereof

ActiveCN111138706AAchieving Selective DispersionImprove lap efficiencyMagnetic/electric field screeningMicrosphereElectromagnetic shielding

The invention discloses polymer electromagnetic shielding composite foam with a gradient filler structure and a preparation method thereof. The preparation method comprises the following steps: loading conductive metal on the hollow glass microspheres to obtain low-density conductive particles; then preparing a conductive particle-polymer composite material; and finally, foaming the composite material to obtain the electromagnetic shielding composite foam. By adopting the method disclosed by the invention, the filler consumption of the electromagnetic shielding composite material can be effectively reduced, and the electric conduction and electromagnetic shielding efficiency of the composite foam is improved, so that the prepared foam material has good electric conduction and electromagnetic shielding properties under the condition of low electric conduction filler content.

Owner:SICHUAN UNIV

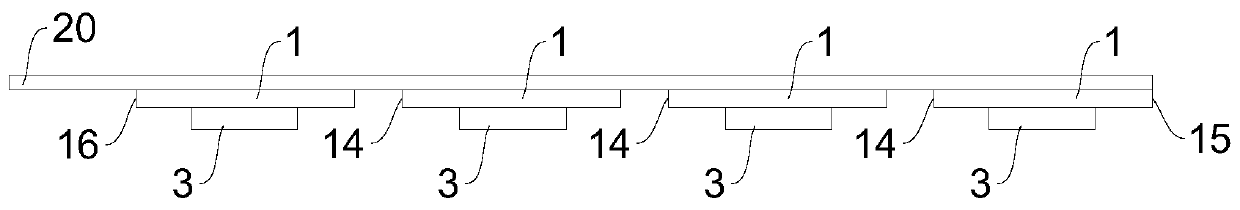

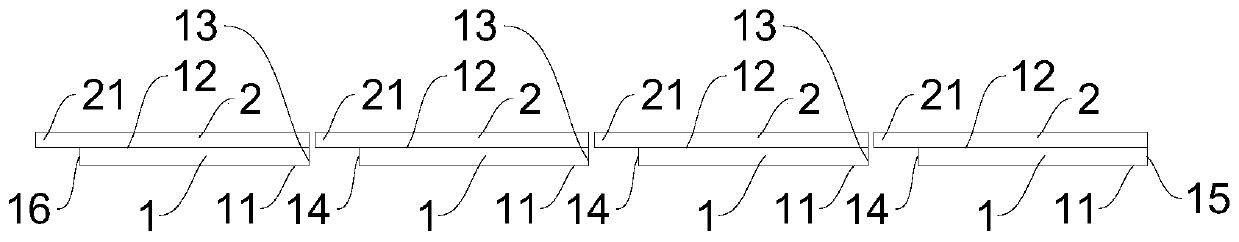

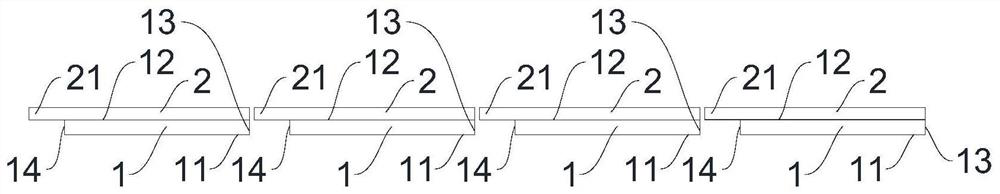

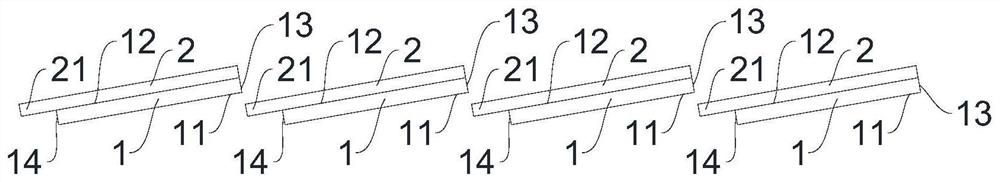

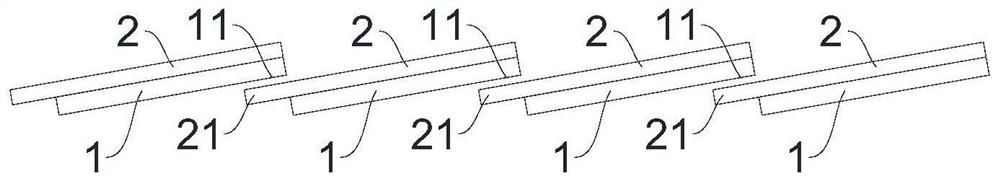

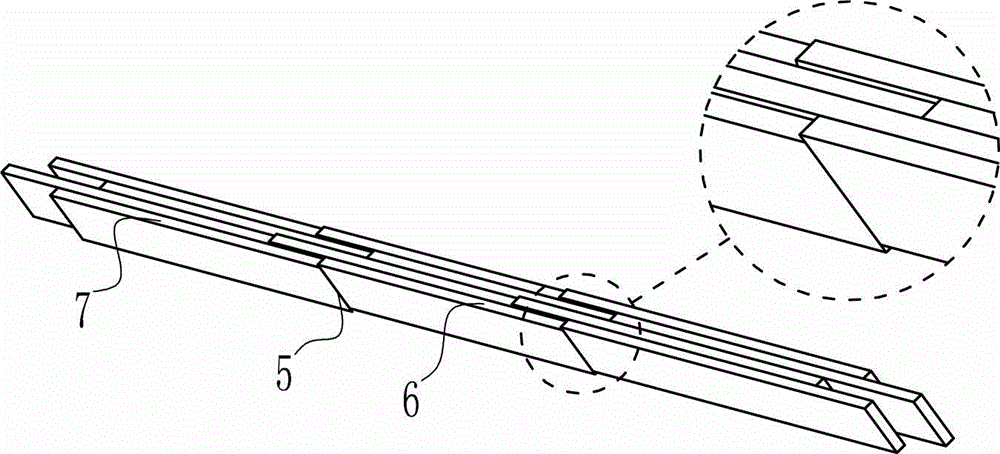

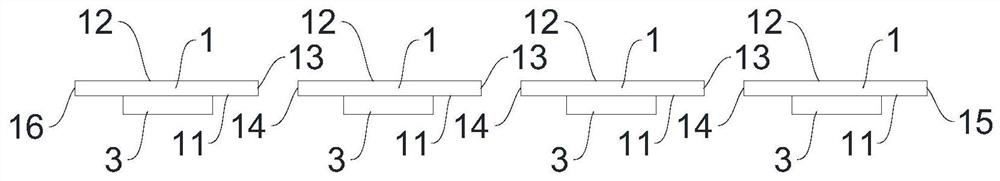

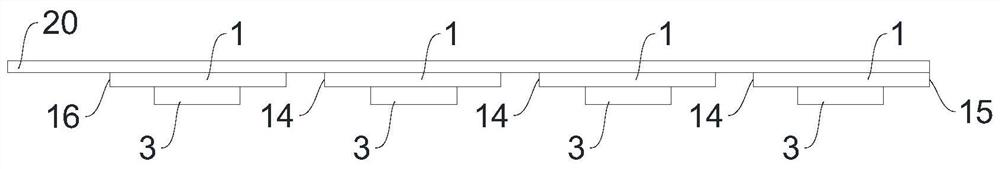

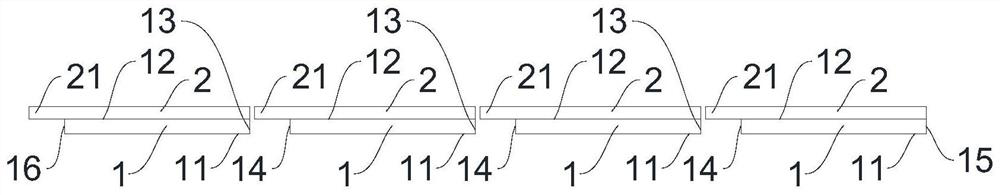

Preparation method of cell string

ActiveCN110649126AImprove cutting efficiencyGuaranteed cutting accuracyFinal product manufacturePhotovoltaic energy generationLap jointSolar battery

The invention discloses a preparation method of a cell string, comprising the following steps: (1) arranging cells; (2) lapping a cell string; and (3) welding the cell string. The cutting efficiency of connecting pieces can be greatly improved, the cutting precision of the connecting pieces can be guaranteed, the lap joint efficiency of the cell string can be improved, the welding efficiency of the cell string can be improved, the preparation efficiency of the cell string can be improved, and the productivity of the cell string and a solar cell module can be improved.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

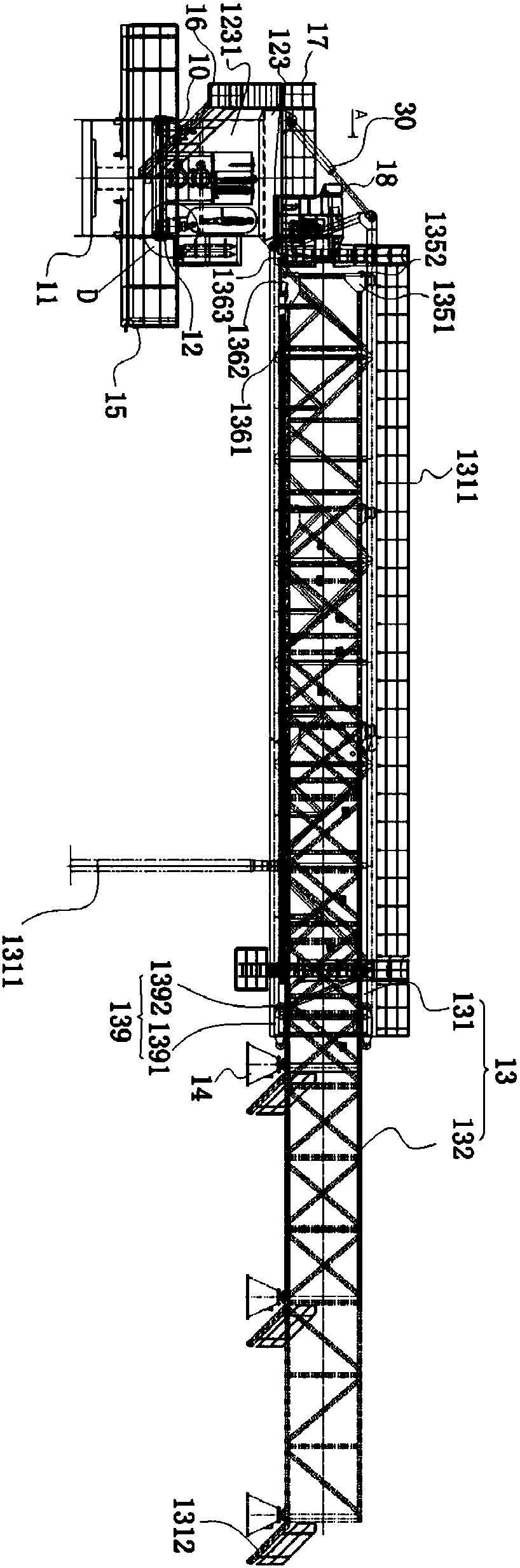

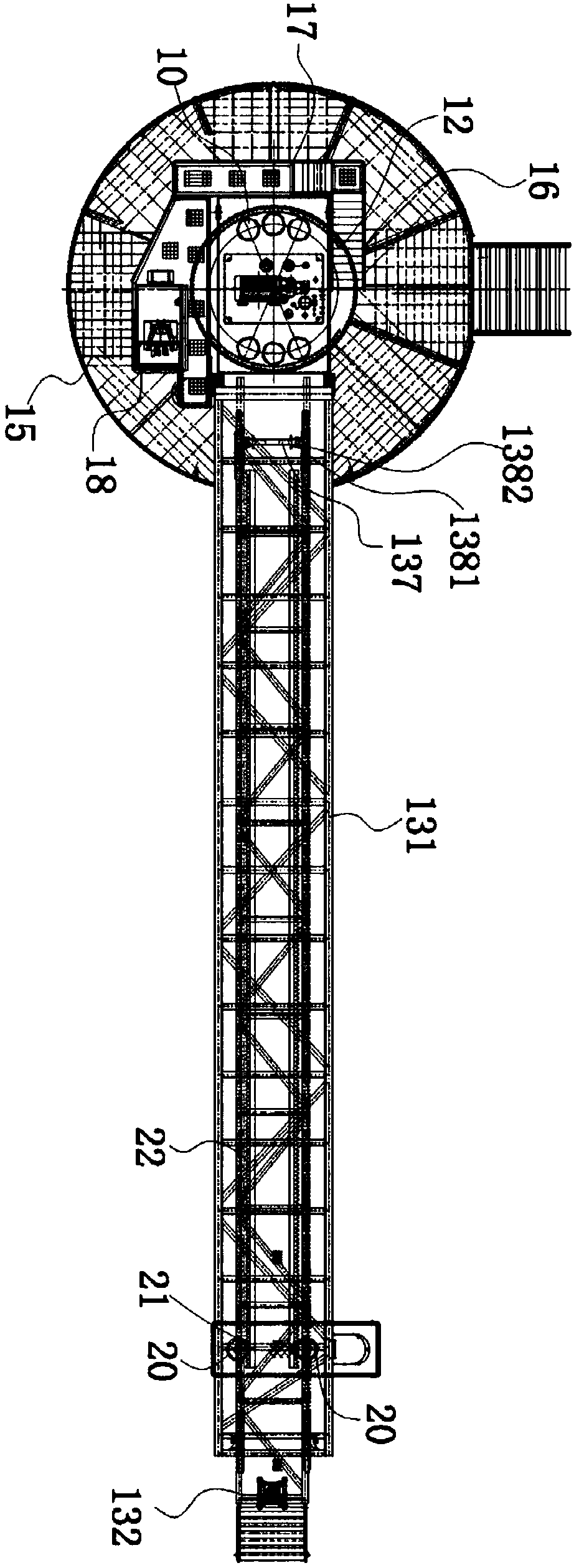

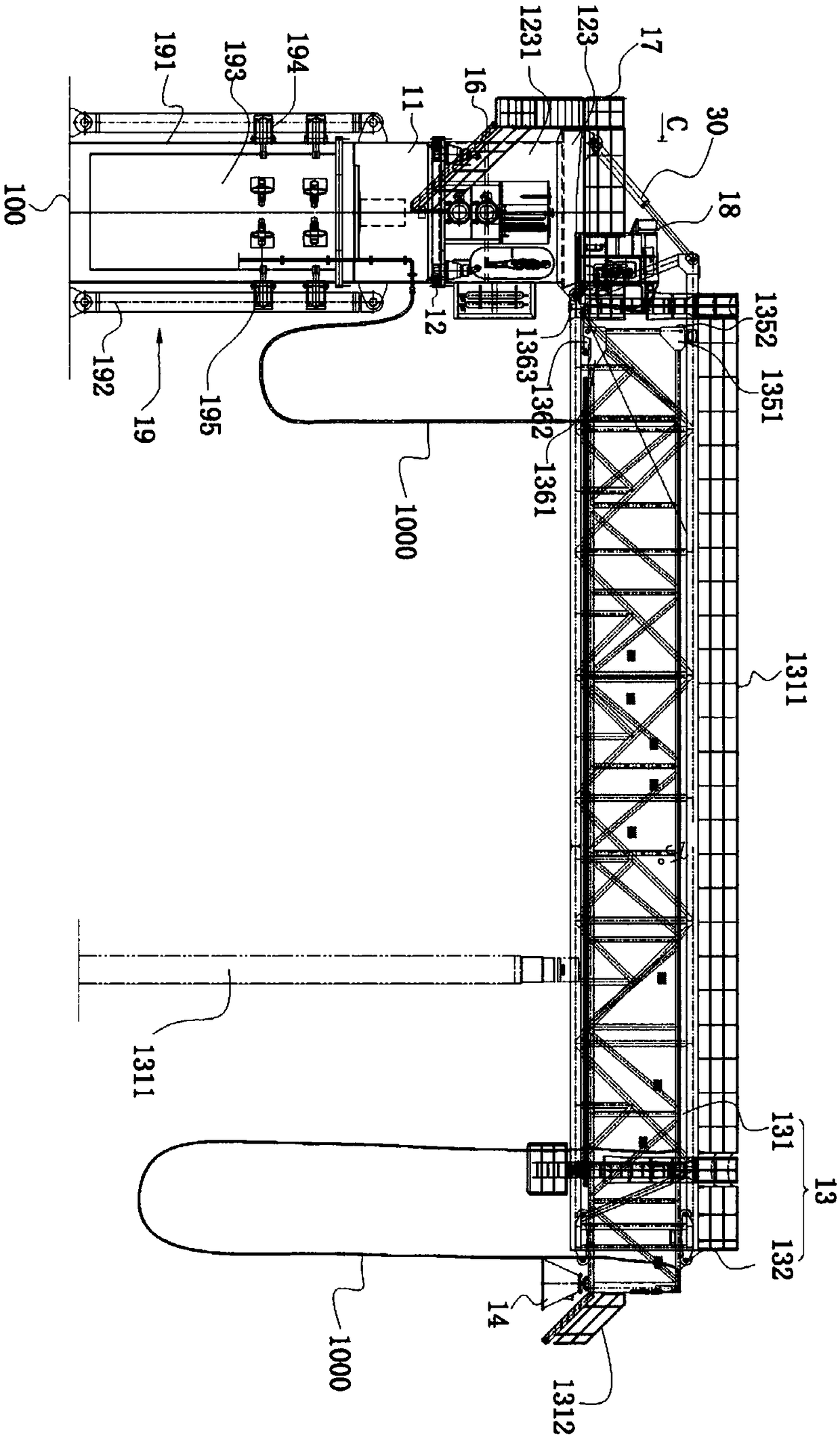

Working method for retractable ship-boarding trestle bridge with function of position compensation

ActiveCN108438150AEasy accessImprove lap efficiencyCargo handling apparatusPassenger handling apparatusActive compensationControl system

Provided is a working method for a retractable ship-boarding trestle bridge with a function of position compensation. The working method comprises an overlap-joint method, a servo-compensation methodand a disengagement method. The overlap-joint method comprises a manual overlap-joint method and an active compensation overlap-joint method. The manual overlap-joint method is to control a handle such that the handle is controlled to send a signal to a control system. The control system controls a rotary hydraulic system, a retractable hydraulic system and an amplitude varying hydraulic system such that the retractable trestle bridge can move within the overlap-joint range. When the overlap-joint range is reached, the active compensation overlap-joint method is applied. Concretely speaking, asignal is detected through a sensor and a DP system. The control system controls the rotary hydraulic system, the retractable hydraulic system and the amplitude varying hydraulic system according tothe signal. Ultimately, overlap-joint is achieved. After overlap-joint is finished, the servo-compensation method is switched. With the working method, the trestle bridge is reliably, safely and efficiently overlapped. After overlap-joint is finished, servo movement of the retractable trestle bridge is achieved. Therefore, people and transport material can smoothly and stably pass. Meanwhile, loads applied to overlap-joint points are minimized.

Owner:SOUTH CHINA MARINE MACHINERY

High-conductivity graphene flexible compound membrane and preparation method therof

The invention discloses a method for preparing a high-conductivity graphene flexible compound membrane. The method for preparing the high-conductivity graphene flexible compound membrane disclosed by the invention comprises the following steps: 1) treating graphene powder for increasing the conductivity: performing solvent peeling, thermal expansion and high-temperature thermal treatment on the graphene powder, thereby increasing the conductivity; 2) compounding: mixing the graphene powder acquired in the step 1), elastic macromolecular grain and solvent, thereby acquiring a mixture, and then adding thixotropic agent and viscosity modifier for controlling the dynamic viscosity to 6000-8000mpa; 3) forming a membrane: preparing the mixture into the membrane. The invention also discloses the high-conductivity graphene flexible compound membrane prepared according to the method disclosed by the invention.

Owner:常州二维暖烯科技有限公司

Manufacturing method of bamboo laminated material

ActiveCN103144154AEasy to operateIncrease profitCane mechanical workingWood veneer joiningStructural engineeringMechanical engineering

Owner:熊晓晶

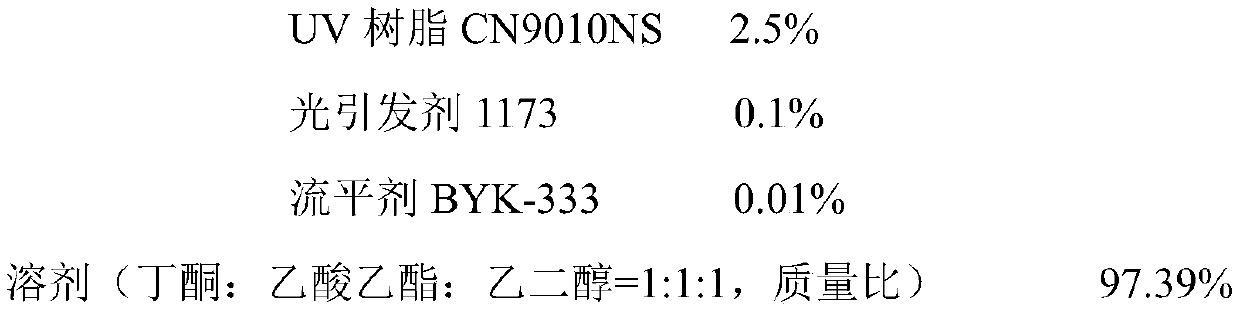

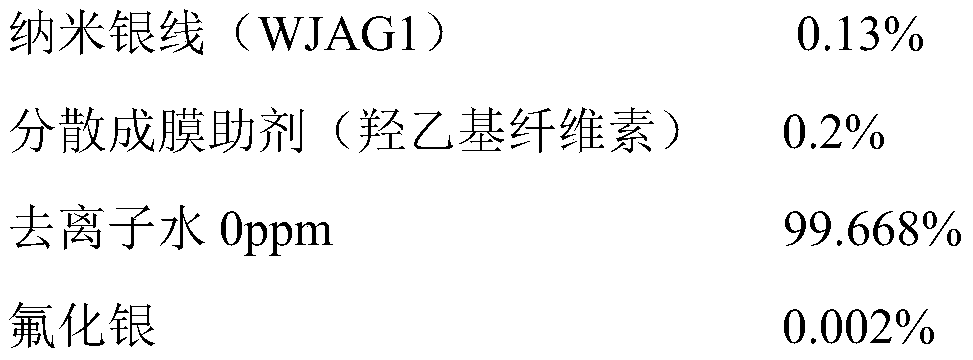

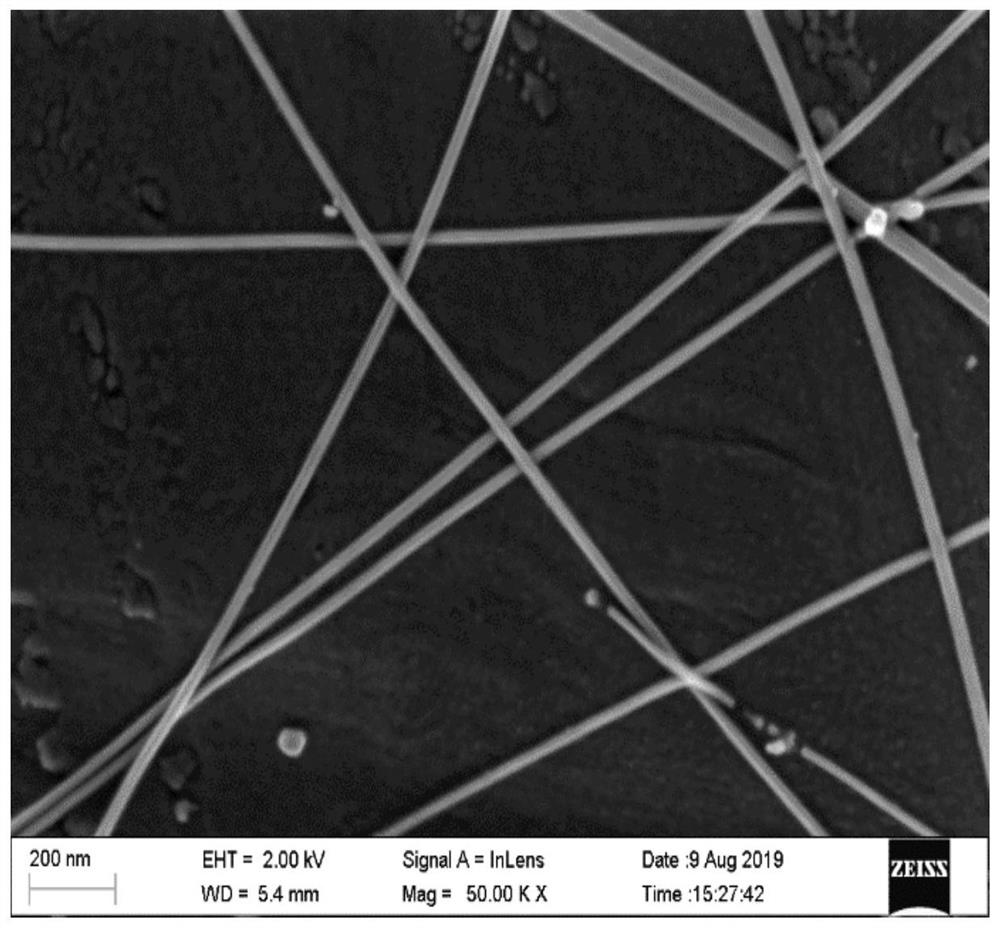

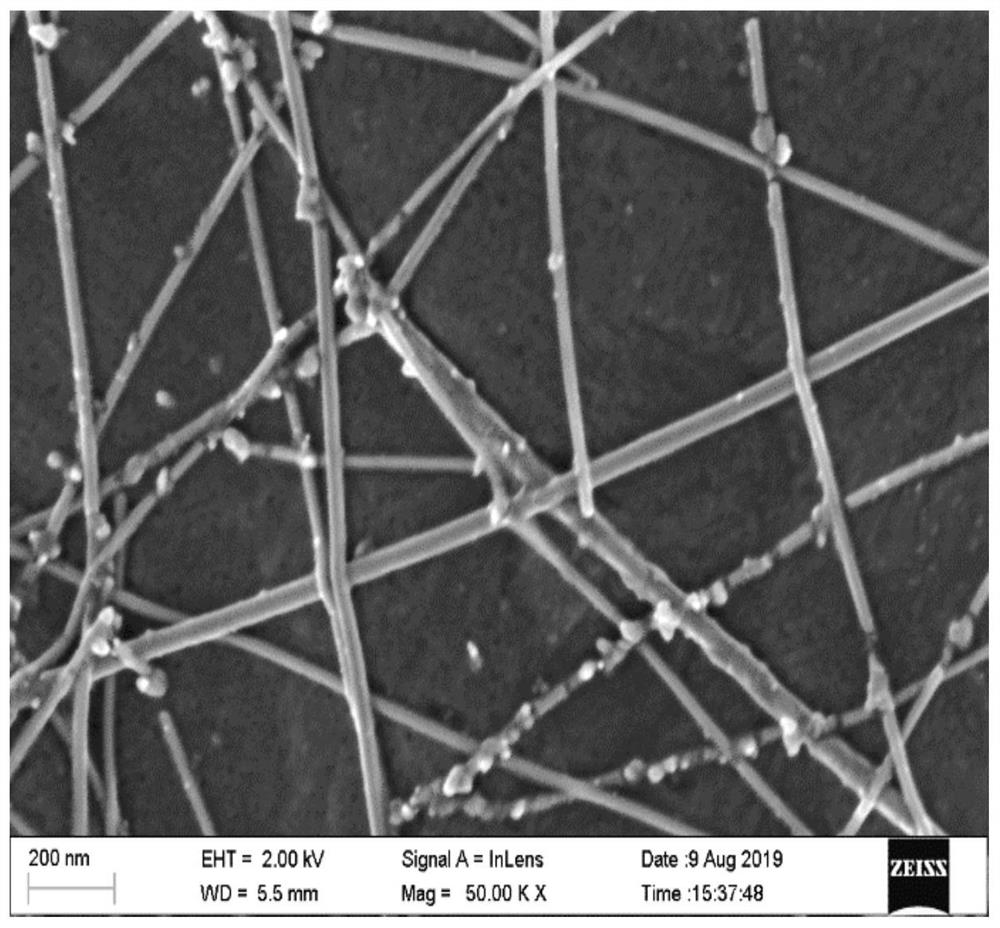

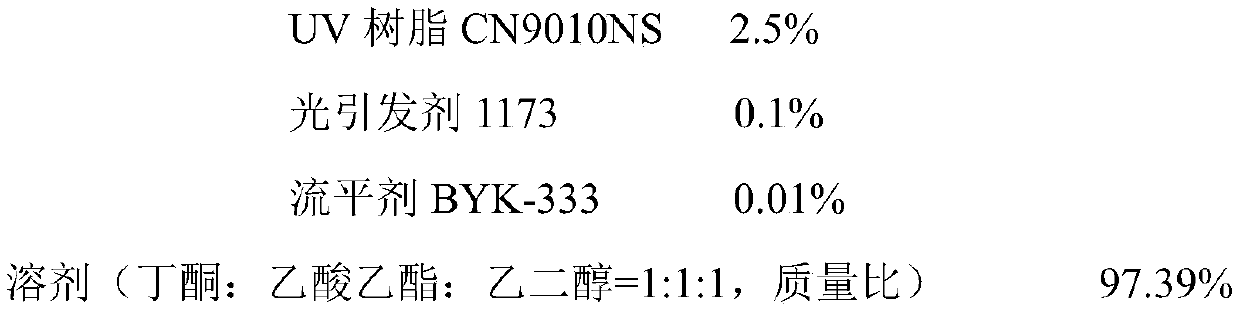

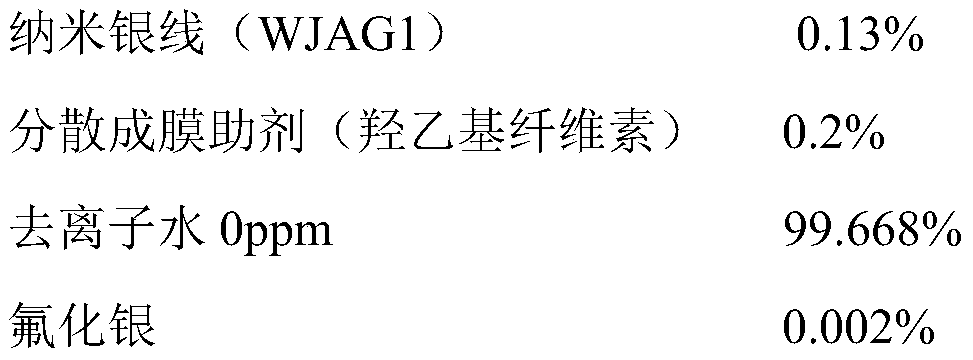

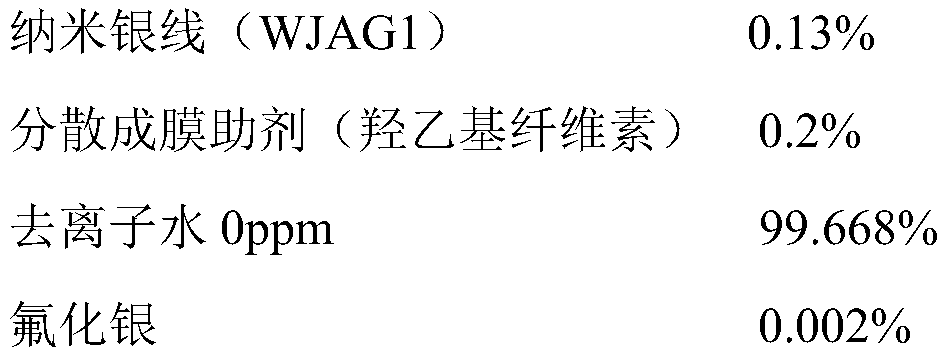

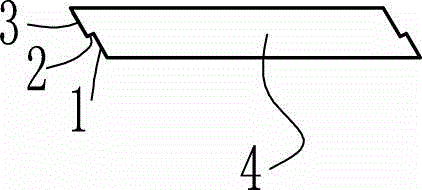

Nano silver wire flexible transparent conductive film with high lapping efficiency and excellent bending resistance

ActiveCN110444318AImprove efficiencyImprove bending resistanceConductive layers on insulating-supportsInsulated cablesUv protectiveTransparent conducting film

The invention discloses a nano silver wire flexible transparent conductive film with high lapping efficiency and excellent bending resistance. The flexible transparent conductive film is prepared by firstly coating the surface of a substrate with nano silver wire conductive ink to form a conductive layer, then coating the surface of the conductive layer with an optimization liquid for optimization, and finally coating the surface of the optimized conductive layer with a UV protective liquid to form a UV protective layer. The nano silver wire surface PVP of the flexible transparent conductive film of the invention is removed, and the nano silver wire network nodes are soldered so that it requires a small number of nano silver wires to prepare the conductive film. The obtained conductive film has excellent optical performance, low square resistance, and excellent bending resistance, and is suitable for large-size display and flexible display.

Owner:合肥微晶材料科技有限公司

Segmentation series welding process for photovoltaic cells

ActiveCN111129233AImprove cutting efficiencyImprove segmentation efficiencyFinal product manufacturePhotovoltaic energy generationLap jointSolar cell

The invention discloses a segmentation series welding process for photovoltaic cells. The invention discloses a segmentation series welding process of a solar cell. The process comprises the followingsteps of: segmenting a conductive connecting piece into a plurality of connecting piece small sections, paving a whole cell on the connecting piece small sections, segmenting the whole cell into a plurality of fragments, and performing lap joint series welding on the fragments to form a cell string. The cutting efficiency of the conductive connecting piece can be improved; according to the invention, the segmentation efficiency of the whole battery piece can be improved, and the fragmentation productivity is improved; and according to the invention, the overlapping efficiency, the welding efficiency and the productivity of the battery string can be improved.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

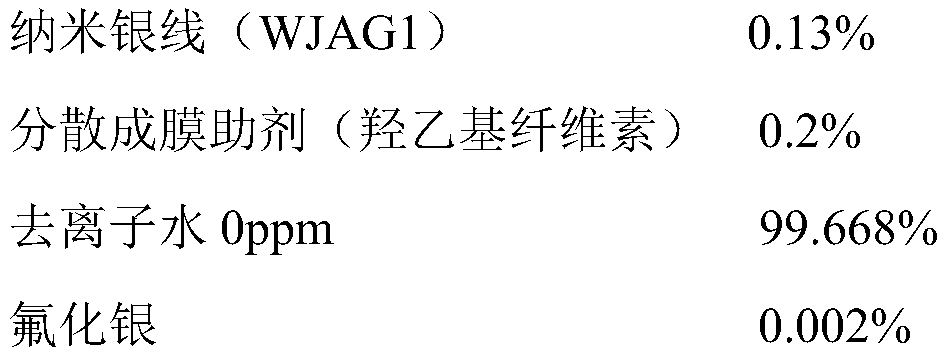

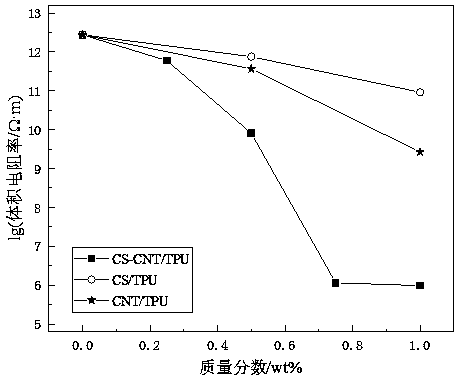

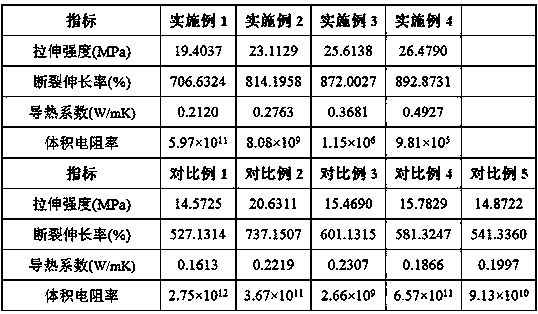

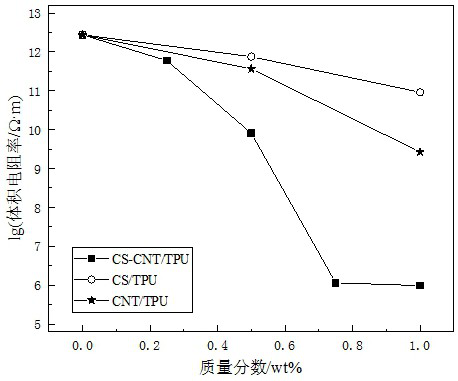

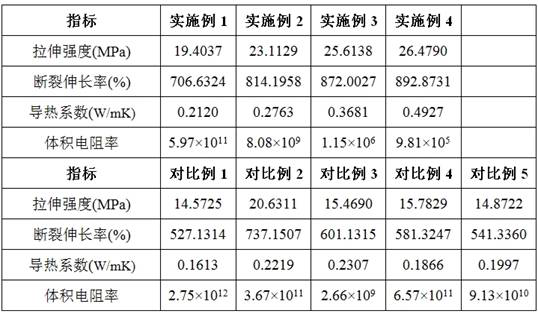

Preparation method of electric conduction and heat conduction functionalized carbon nanotube/TPU composite material

The invention discloses a preparation method of an electric conduction and heat conduction functionalized carbon nanotube / TPU composite material. The preparation method comprises the following steps:modifying a functionalized carbon nanotube with chitosan to obtain a functionalized carbon nanotube (CS-CNT), carrying out a reaction on the functionalized carbon nanotube (CS-CNT) with 4,4'-diphenylmethane diisocyanate, adding polytetramethylene ether glycol, 1,4-butanediol and a catalyst, and carrying out a pre-polymerization-chain extension reaction to synthesize the electric conduction and heat conduction functionalized carbon nanotube / TPU composite material. A hydrogen bond interaction and an electrostatic adsorption effect between chitosan and a carbon nano tube exist in a CS-CNT molecule, wherein a large number of hydrogen bonds and covalent bonds exist between the CS-CNTs, between the CS-CNTs and the TPU monomer, and between the CS-CNTs and the TPU matrix at the same time, so thatthe bonding force between the TPU composite material and a TPU matrix is enhanced, the crosslinking degree is increased, a complete and compact conductive network and a more efficient heat conductionnetwork are formed, and the conductive performance and the heat conduction performance of the TPU composite material are greatly improved.

Owner:FUZHOU UNIV

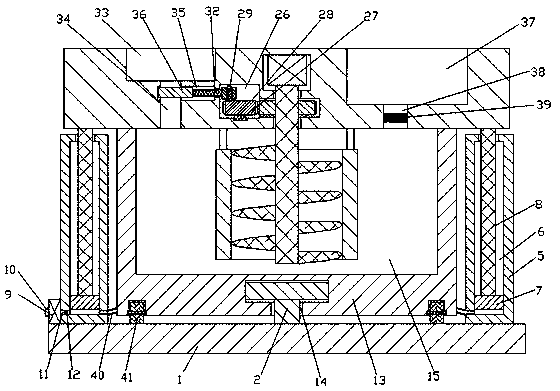

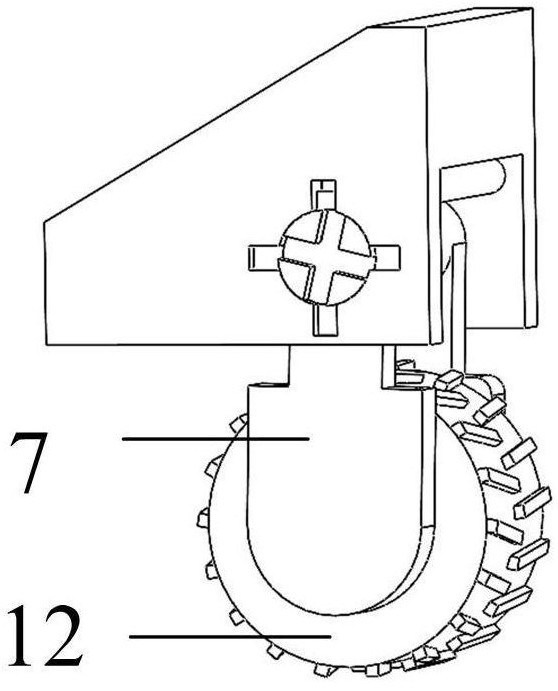

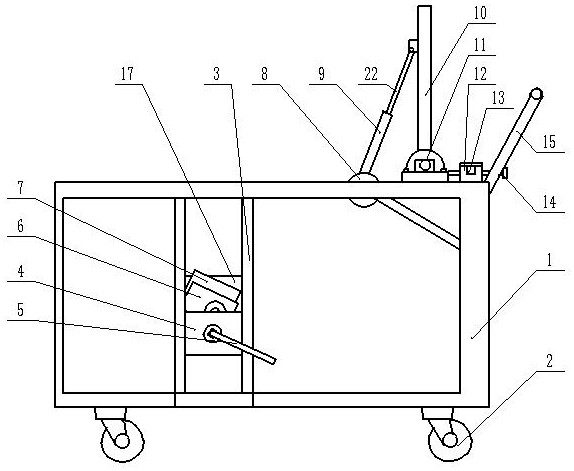

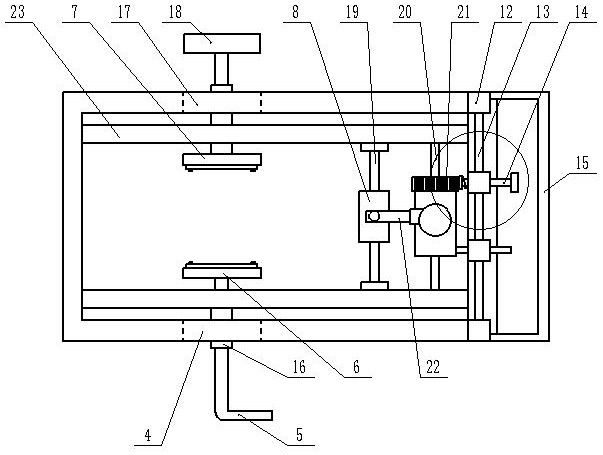

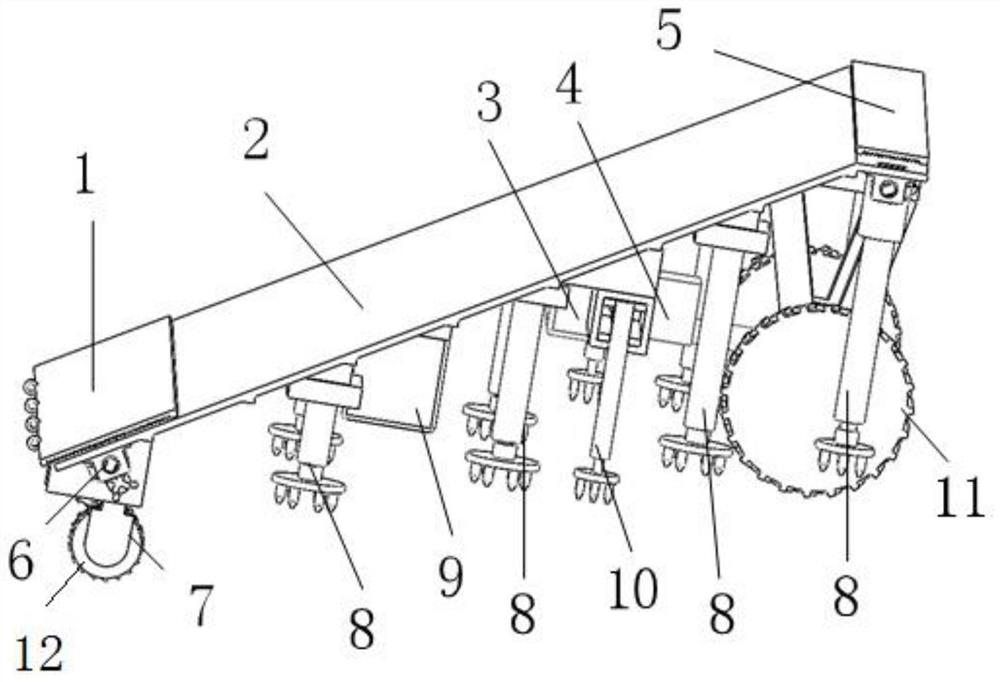

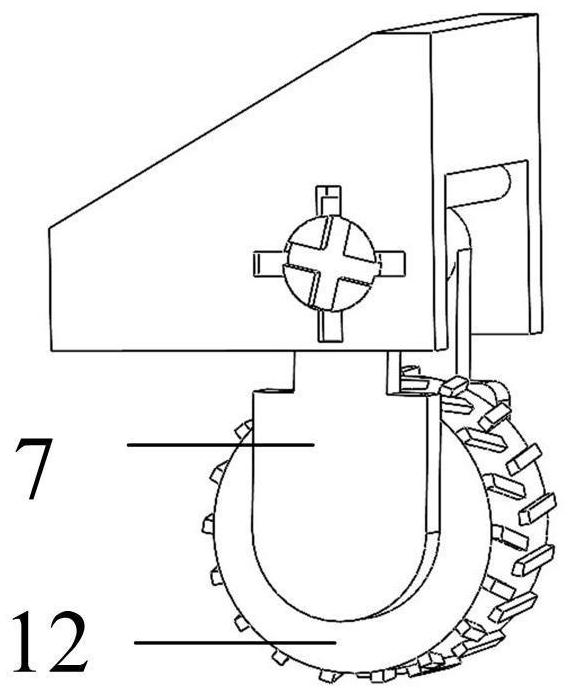

Wood fiber roll-cutting and overlapping device and using method thereof

InactiveCN109249536AReduce wastePrevent overflowMixing operation control apparatusWood working apparatusEngineeringMechanical engineering

The invention discloses a wood fiber roll-cutting and overlapping device and a using method thereof. The wood fiber roll-cutting and overlapping device comprises a base; a T-shaped sliding rail extending forwards, backwards and rightwards is arranged in the middle of the upper end face of the base; a lifting plate is arranged on the upper portion of the rear side of the base; a loading shell is arranged below the lifting plate and slidably mounted on the T-shaped sliding rail through a T-shaped sliding groove which penetrates through the lower end face of the loading shell in a front-rear direction; a mixing overlapping space with an upward opening is formed in the loading shell; a driving space is formed in the middle in the lifting plate; a powder storage space with an upward opening isformed in the left side of the upper end face of the lifting plate; and a water storage space with an upward opening is formed in the right side of the upper end face of the lifting plate. During working of the wood fiber roll-cutting and overlapping device, the same power source is used, stirring and mixing are simultaneously conducted, wood fibers and mortar are advantageously roll-cut and thusare evenly mixed, and the water retention effect after the wood fibers and the mortar are overlapped is enhanced.

Owner:马洁

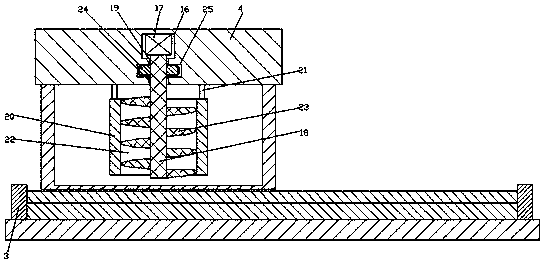

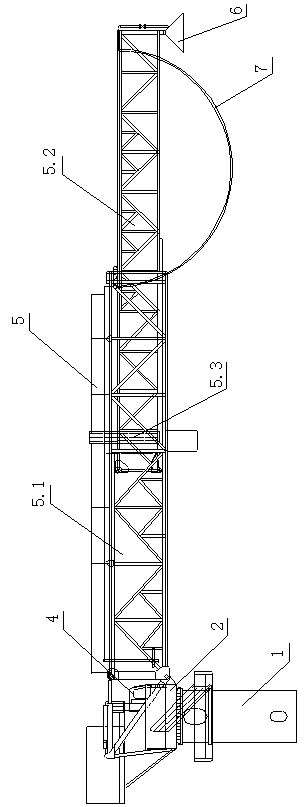

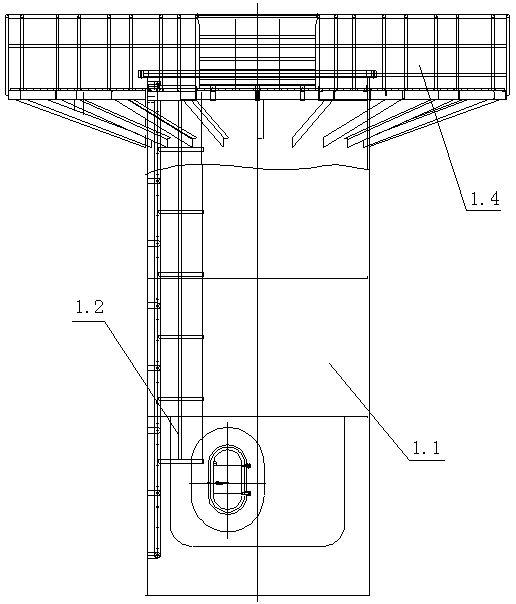

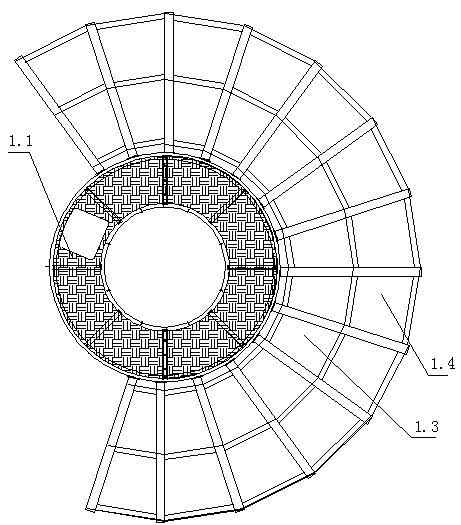

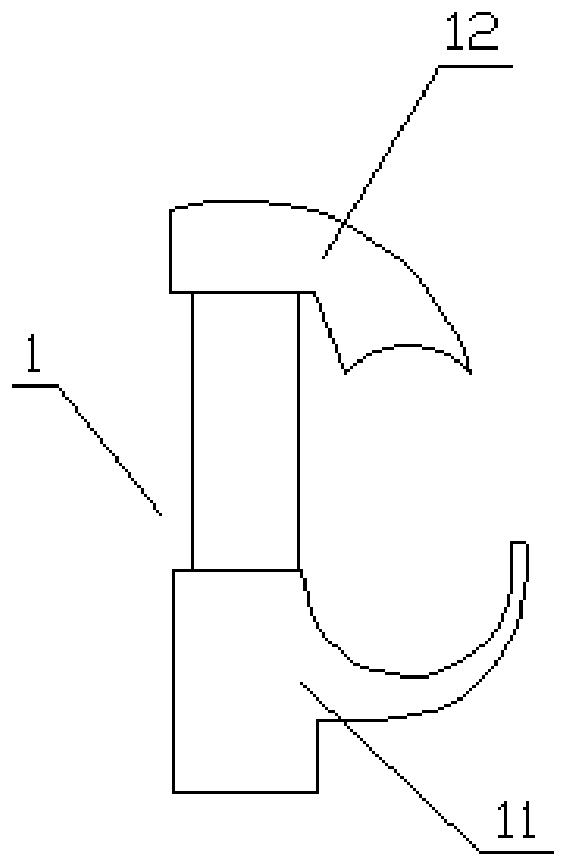

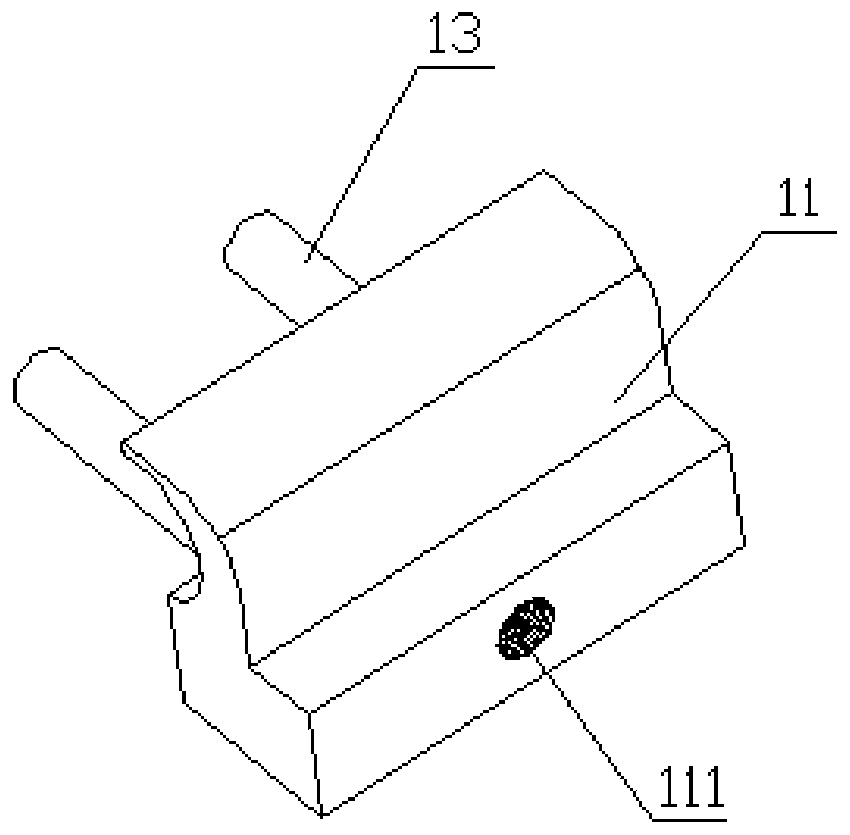

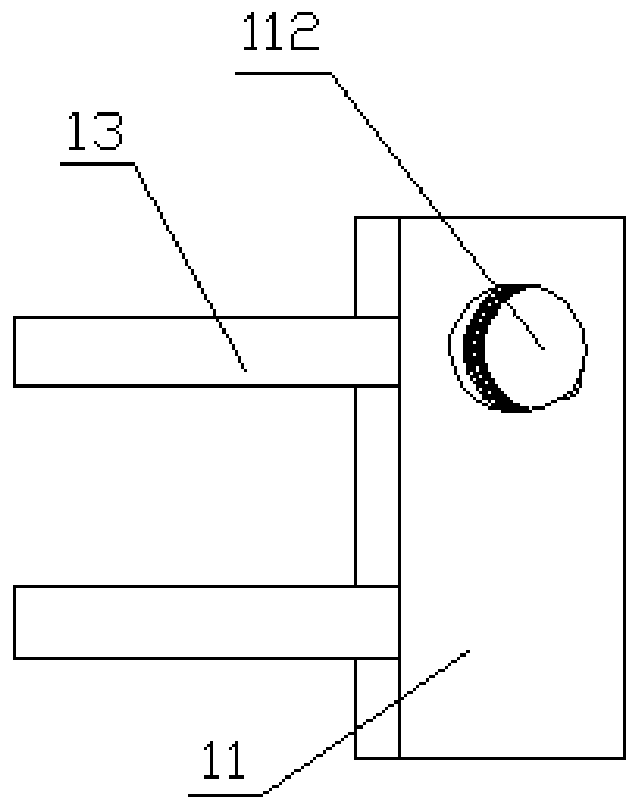

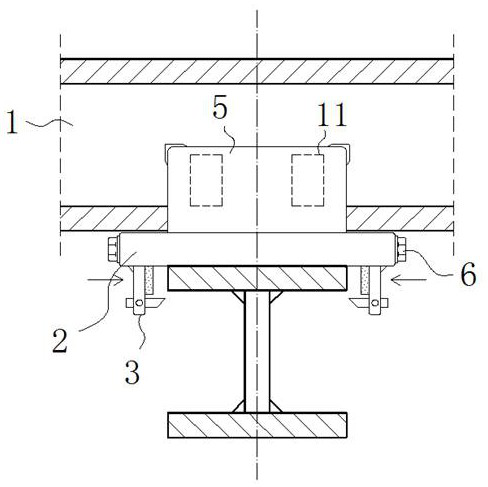

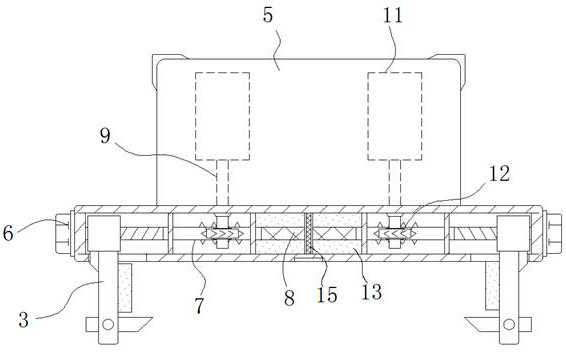

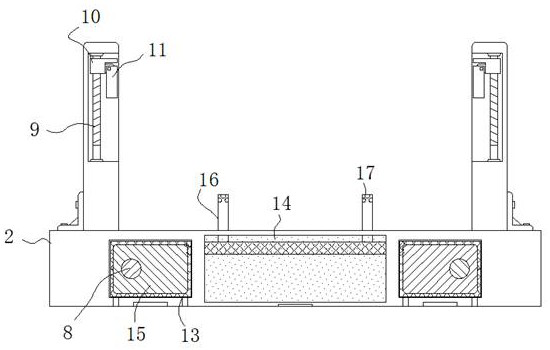

Safe and reliable full-rotation retractable gap bridge

ActiveCN102900017BSmall shock and vibrationExtend the service life of the bridgeCargo handling apparatusSwing bridgesClassical mechanicsStructural engineering

The invention relates to a safe and reliable full-rotation retractable gap bridge, which is characterized by comprising a base frame (1), wherein a rotation support (2) is arranged on the base frame (1); a gap bridge (5) is hinged to one end of the rotation support (2) and comprises a fixing gap bridge (5.1) and a movable gap bridge (5.2); the movable gap bridge (5.2) is connected with the fixing gap bridge (5.1) through a retractable device (5.3); a landing support (6) is fixed at one end, which is away from the fixing gap bridge (5.1), of the movable gap bridge (5.2); and a supply system (7) is also arranged on the safe and reliable full-rotation retractable gap bridge. By the safe and reliable full-rotation retractable gap bridge, supplies are conveyed safely and conveniently, personnel are transferred quickly, the dropping impact of the gap bridge is reduced, the service life of the gap bridge is prolonged, and the gap bridge is convenient to operate and repair.

Owner:JIANGYIN HUANGSHAN MARINE FITTING

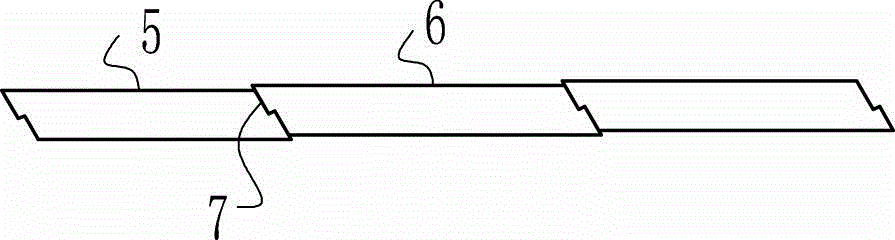

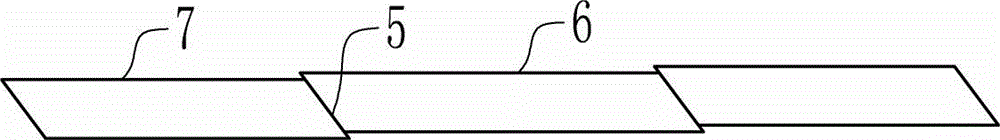

Segmentation series welding process of solar cell

InactiveCN111180543AImprove cutting efficiencyImprove lap efficiencyFinal product manufacturePhotovoltaic energy generationElectrical batteryLap joint

The invention discloses a segmentation series welding process of a solar cell, which comprises the following steps of: segmenting the whole solar cell into a plurality of segments, paving and segmenting conductive connecting pieces on the segments, and performing lap joint series welding on the segments to form a cell string. Thus, the segmentation efficiency of the whole solar cell can be improved, and the fragmentation productivity is improved; the cutting efficiency of the conductive connecting piece can be improved; and the overlapping efficiency, the welding efficiency and the productivity of the cell string can be improved.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

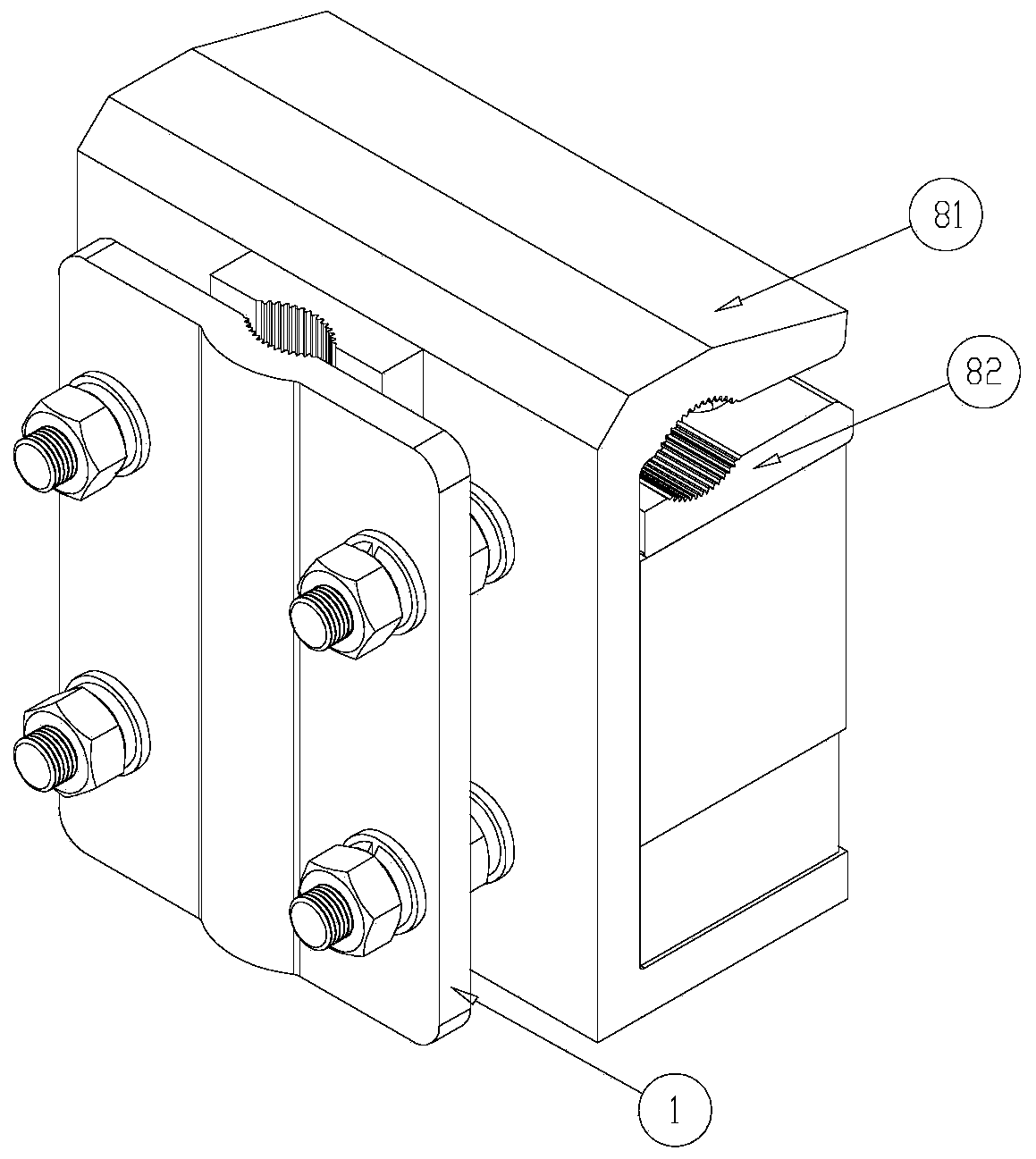

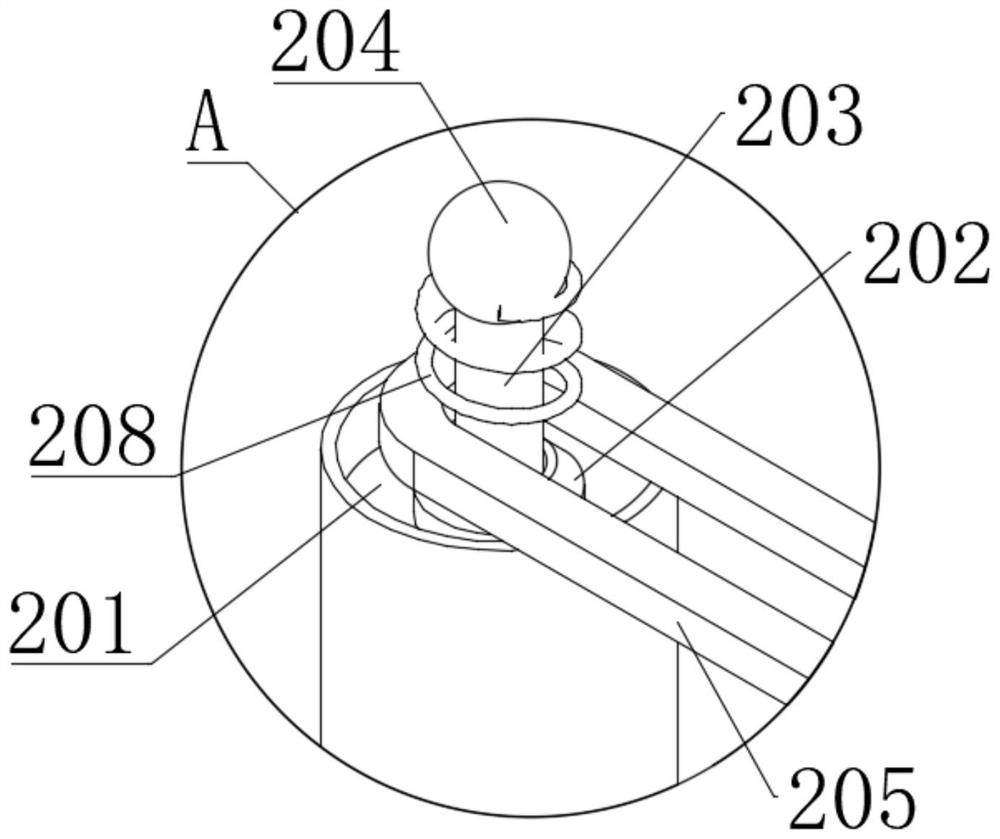

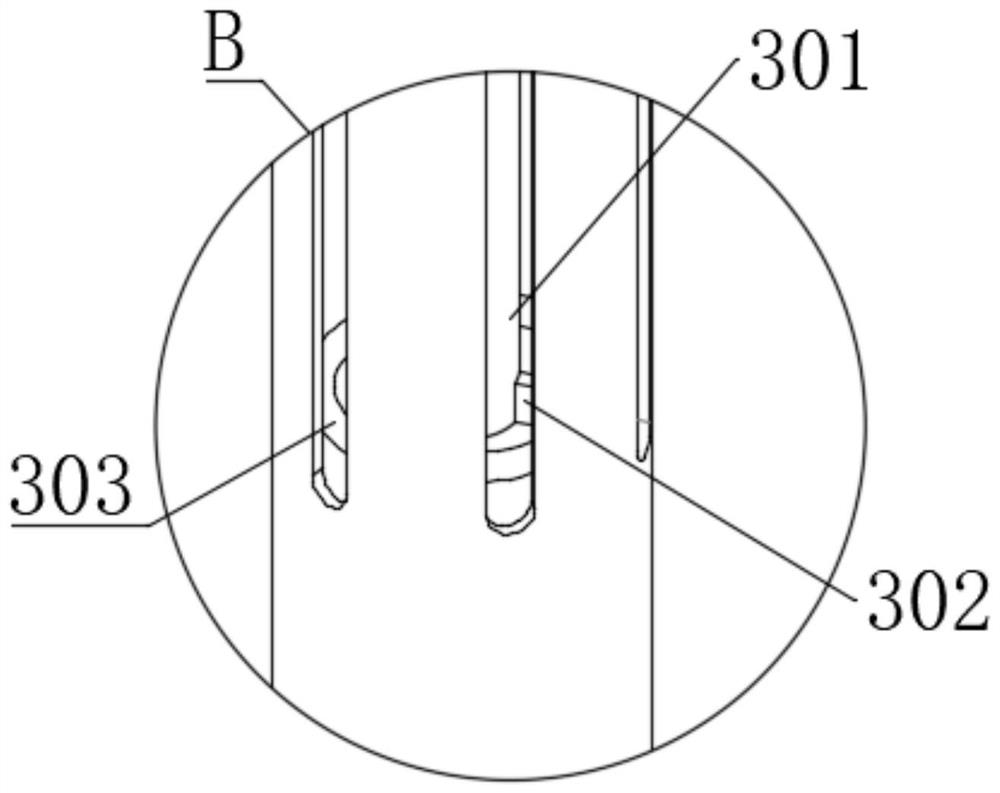

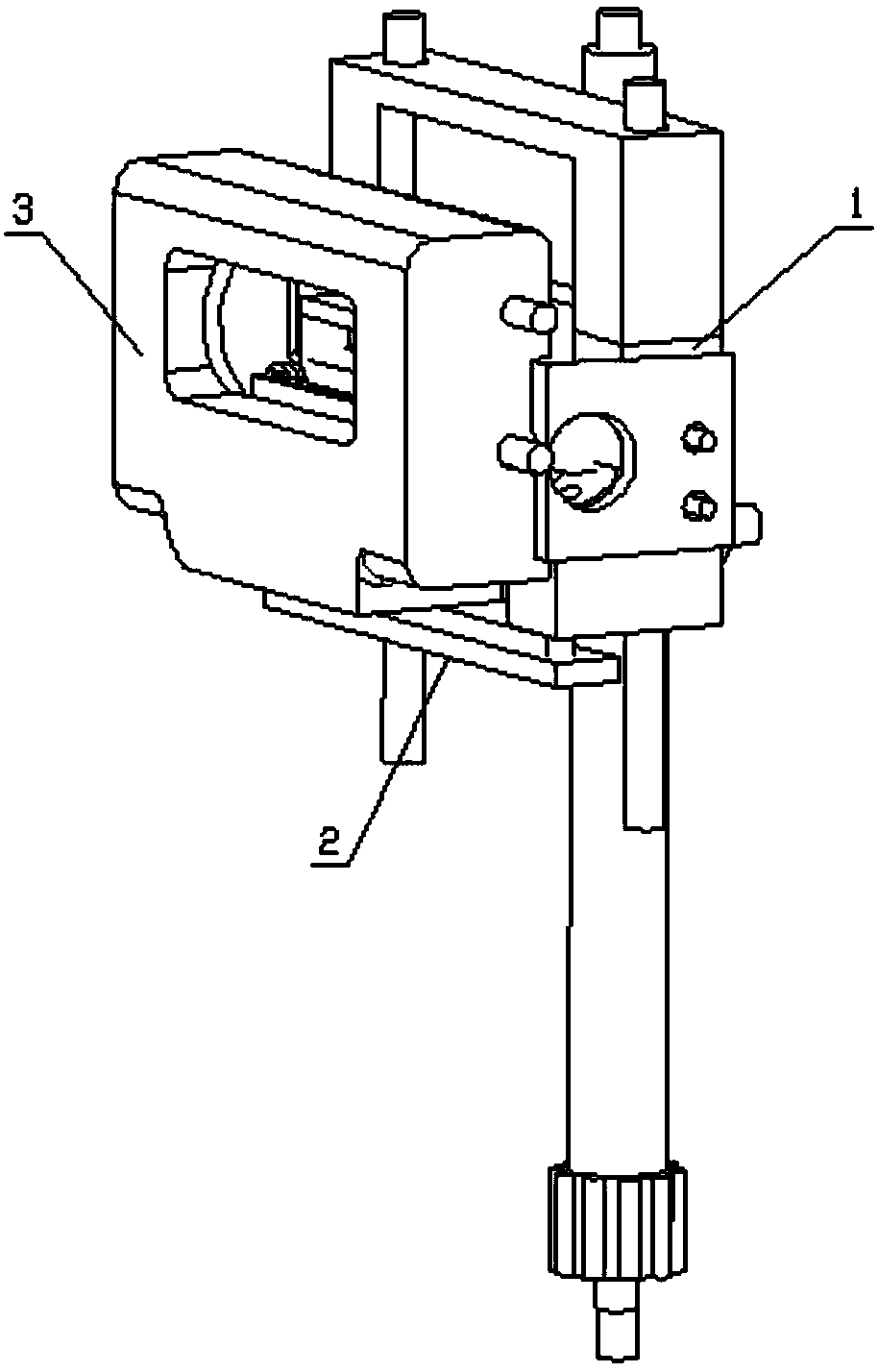

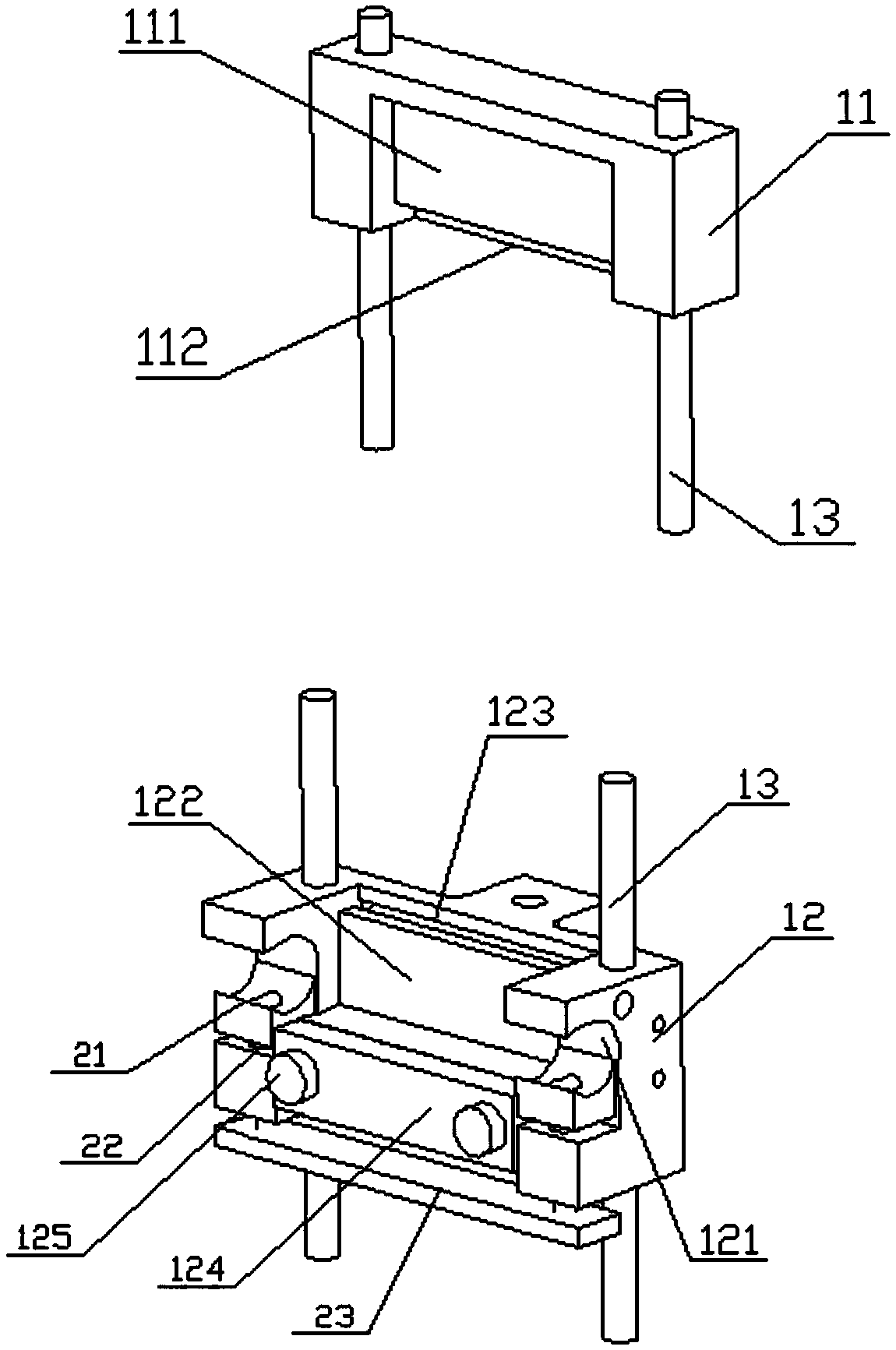

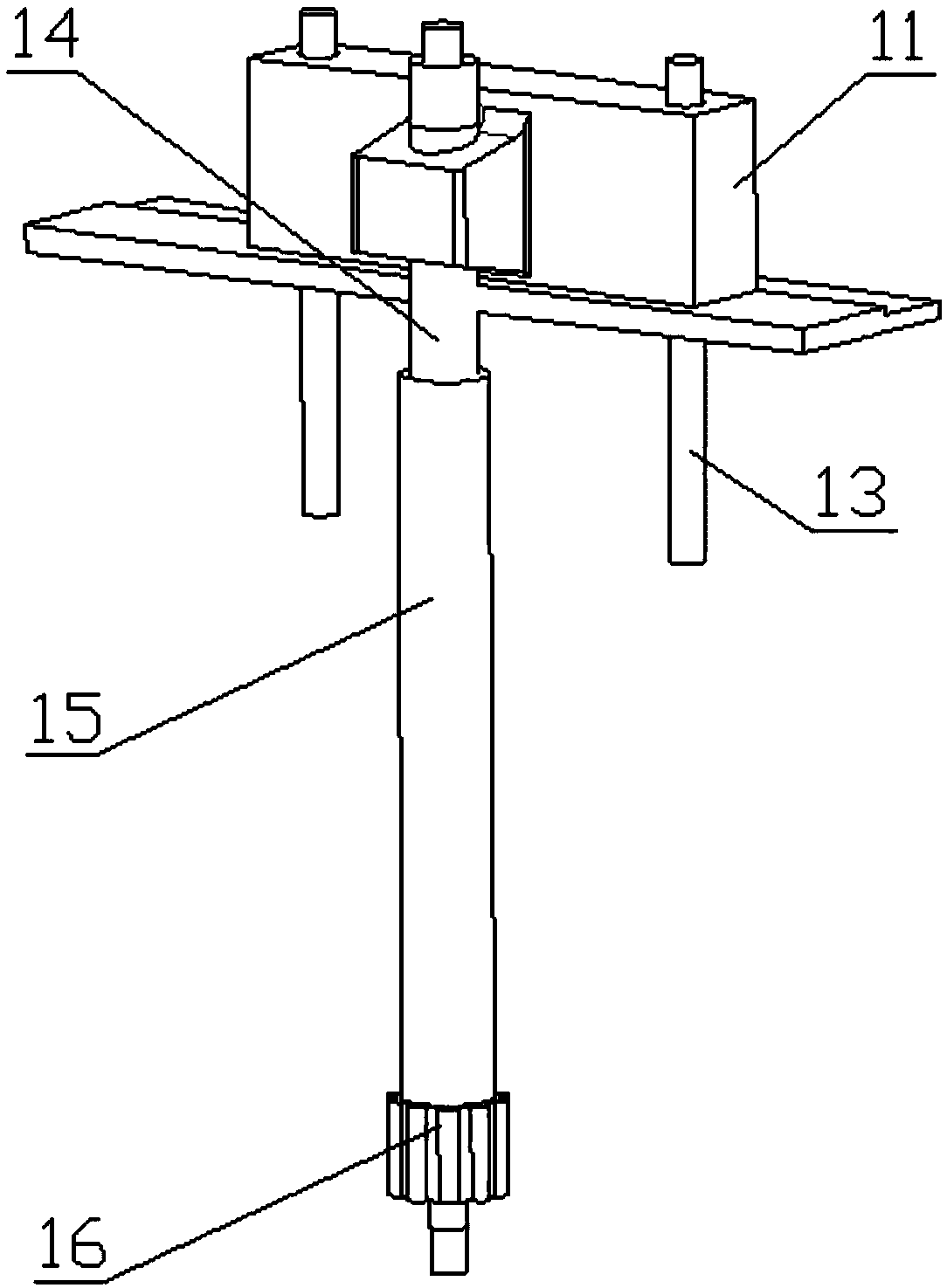

Movable heavy lapping device and lapping method thereof

ActiveCN113562428AQuick dockingImprove lap efficiencyControl devices for conveyorsSupporting framesEngineeringMechanical engineering

Owner:北京东方威特称重设备系统有限公司

A kind of nano-silver wire flexible transparent conductive film with low square resistance and excellent bending resistance and preparation method thereof

ActiveCN110634593BReduce contact resistanceImprove mechanical stabilityConductive layers on insulating-supportsApparatus for manufacturing conducting/semi-conducting layersUv protectiveOptical transmittance

The invention discloses a nano-silver wire flexible transparent conductive film with low square resistance and excellent bending resistance and a preparation method thereof. Firstly, a nano-silver wire conductive layer is formed on the surface of a flexible substrate, and then the nano-silver wire is formed on the surface of the nano-silver wire through welding liquid. The joints are welded, and finally a UV protective layer is provided on the surface of the conductive layer after welding, so as to obtain. The present invention realizes welding at the nodes of nano silver wires, and the square resistance of the conductive film is reduced by about 20% to 40%, while the optical transmittance and haze do not change significantly, and the prepared conductive film has low square resistance and excellent optical performance , Excellent bending resistance, suitable for large-size displays and flexible displays.

Owner:合肥微晶材料科技有限公司

A kind of preparation method of electrical and thermal conductivity functionalized carbon nanotube/tpu composite material

The invention discloses a method for preparing a conductive and thermally conductive functionalized carbon nanotube / TPU composite material. Firstly, the functionalized carbon nanotube (CS-CNT) is obtained by modifying the functionalized carbon nanotube with chitosan, and then combined with 4, 4'-diphenylmethane diisocyanate reaction, then adding polytetramethylene ether glycol, 1,4-butanediol and a catalyst to synthesize the conductive and thermally conductive functionalized carbon nanotube / TPU composite through pre-polymerization-chain extension reaction Material. There are hydrogen bonds and electrostatic adsorption between chitosan and carbon nanotubes in the CS‑CNT molecule, between CS‑CNT, between CS‑CNT and TPU monomer, and between CS‑CNT and TPU matrix A large number of hydrogen bonds and covalent bonds lead to an enhanced binding force with the TPU matrix, an increased degree of crosslinking, and the formation of a complete and dense conductive network and a more efficient heat conduction network. The electrical and thermal conductivity of the TPU composite material have been greatly improved. promote.

Owner:FUZHOU UNIV

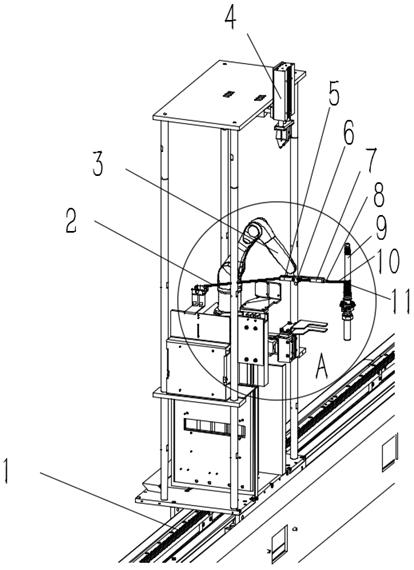

Substation grounding wire mobile operation device and grounding wire connection method

ActiveCN113725770ASolve messy linesResolve distortionCable installation apparatusSwitchgearControl theoryMechanical engineering

The invention belongs to the technical field of substation ground wire operation devices, and particularly relates to a substation grounding wire mobile operation device and a grounding wire connection method. The device comprises a support, two vertical supporting rods arranged separately are arranged on the two side faces of the support respectively, a handle is arranged on the support, grounding wire take-up frame rotating devices are arranged on the two vertical supporting rods respectively, and a grounding wire supporting device and a hydraulic rod lifting device for adjusting the grounding wire supporting device are fixedly arranged on the support. When the device is used for grounding wire connection, movement is flexible, the device is suitable for various operation conditions, and the problems that a conventional grounding wire is often disordered, twisted, damaged by dragging, inconvenient to use and inconvenient to store in use are solved.

Owner:国网河南省电力公司超高压公司 +1

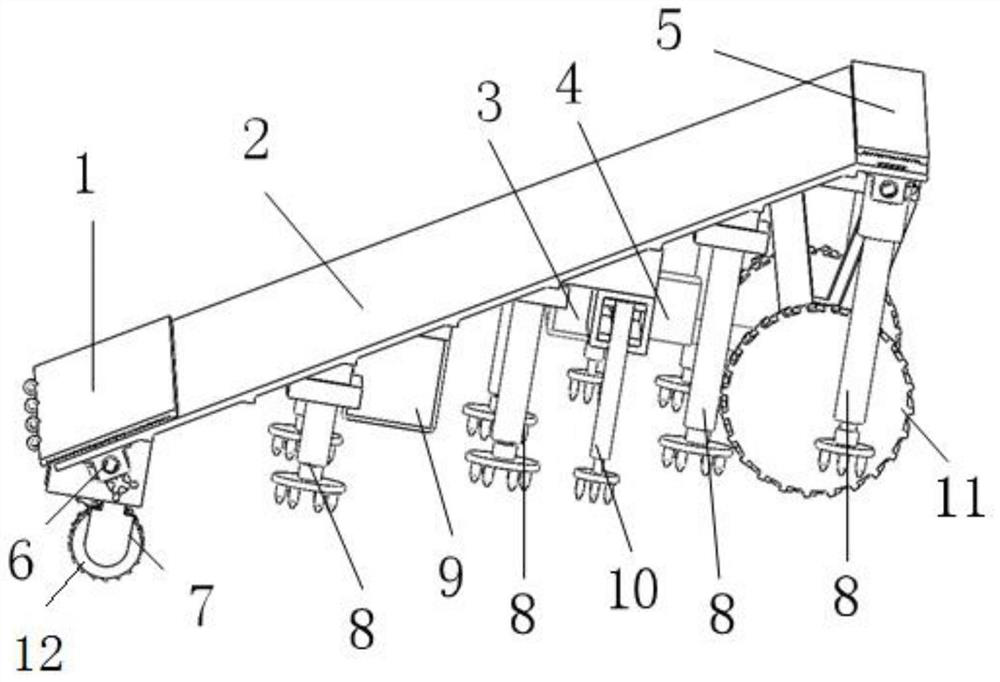

A movable heavy-duty lap joint device and its lap joint method

ActiveCN113562428BQuick dockingImprove lap efficiencyControl devices for conveyorsSupporting framesClassical mechanicsLap joint

The invention discloses a movable heavy-duty lap joint device and its lap joint method, comprising a first conveying platform, a plurality of traveling wheels for supporting the first conveying platform to travel, a plurality of first hydraulic pressures for fixedly supporting the first conveying platform Struts, each traveling wheel is arranged on both sides of the first conveying platform along the transport length direction, a lifting mechanism for driving the first conveying platform to rise and fall is supported between the traveling wheel and the first conveying platform, and each first hydraulic support is close to the corresponding traveling They are symmetrically arranged on both sides of the traveling wheel along the width direction. By setting the traveling wheel on the first conveying platform, the first conveying platform is transported to the corresponding position, and then the first conveying platform is transported to the corresponding position through the lifting mechanism connected with the traveling wheel. The conveying platform is quickly adjusted to a suitable height and inclination to facilitate the rapid extension of the first hydraulic strut to the corresponding length, and then fine-tuned according to the size of the support force to realize the flexible movement and rapid overlap of the first conveying platform .

Owner:北京东方威特称重设备系统有限公司

A polymer electromagnetic shielding composite foam with gradient filler structure and preparation method thereof

ActiveCN111138706BAchieving Selective DispersionImprove lap efficiencyMagnetic/electric field screeningPolymer scienceMicrosphere

The invention discloses a polymer electromagnetic shielding composite foam with a gradient filler structure and a preparation method thereof; during preparation, conductive metal is loaded on hollow glass microspheres to obtain low-density conductive particles; then conductive particle-polymer composite material is prepared ; Finally, the composite material is foamed to obtain an electromagnetic shielding composite foam. The method of the invention can effectively reduce the amount of filler used in the electromagnetic shielding composite material, improve the conductivity and electromagnetic shielding performance of the composite foam, and the prepared foam material has good conductivity and electromagnetic shielding performance at a low content of conductive filler.

Owner:SICHUAN UNIV

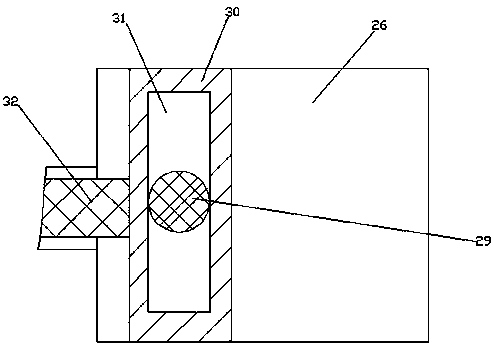

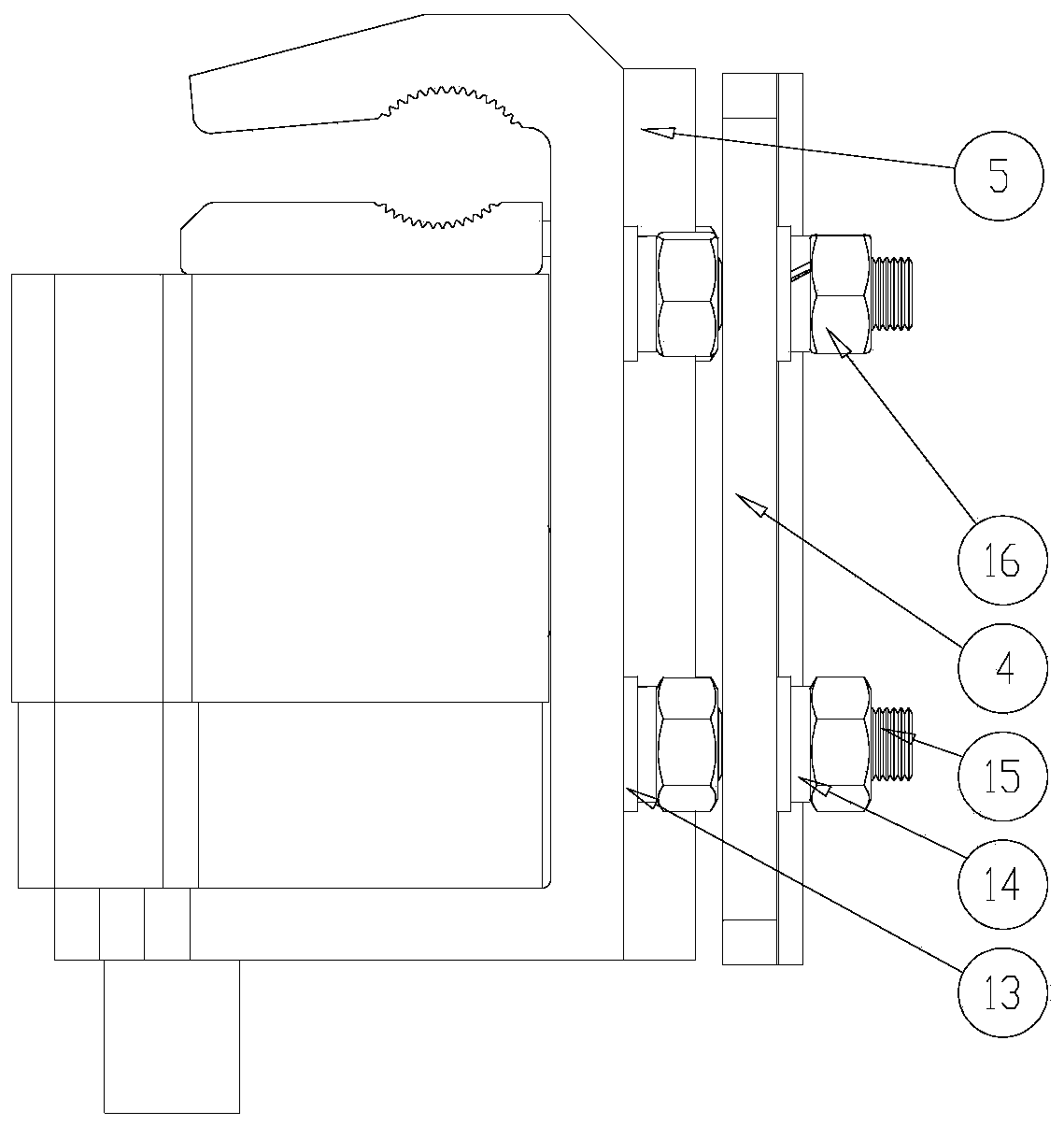

Power distribution network ground potential live line connection T wiring device

InactiveCN110718777ARealize T-connectionImprove lap efficiencyClip conductor connectionClamped/spring connectionsControl theoryMechanical engineering

The invention provides a power distribution network ground potential live line connection T wiring device, which comprises a wiring clamp body, a fixed clamping block, a movable clamping block, a fixed clamping plate, a movable clamping plate, a lifting assembly and an insulating worm and gear assembly. The fixed clamping block is arranged on the wiring clamp body and extends along the horizontaldirection together with the movable clamping block. The fixed clamping block and the movable clamping block are oppositely arranged and form a first wire clamping space. The fixed clamping plate is arranged on the wiring clamp body and extends along the vertical direction together with the movable clamping plate. The fixed clamping plate and the movable clamping plate are oppositely arranged and form a second wire clamping space. The first wire clamping space is located on one side of the wiring clamp body, and the second wire clamping space is located on the other side of the wiring clamp body. The lifting assembly is connected to the lower surface of the movable clamping block. The worm and gear assembly is used for driving the movable clamping block to ascend and descend. The T-shaped wiring clamp can realize live line connection in a live state, and can prevent power failure caused by live line connection from influencing normal power supply to users.

Owner:GUIZHOU POWER GRID CO LTD

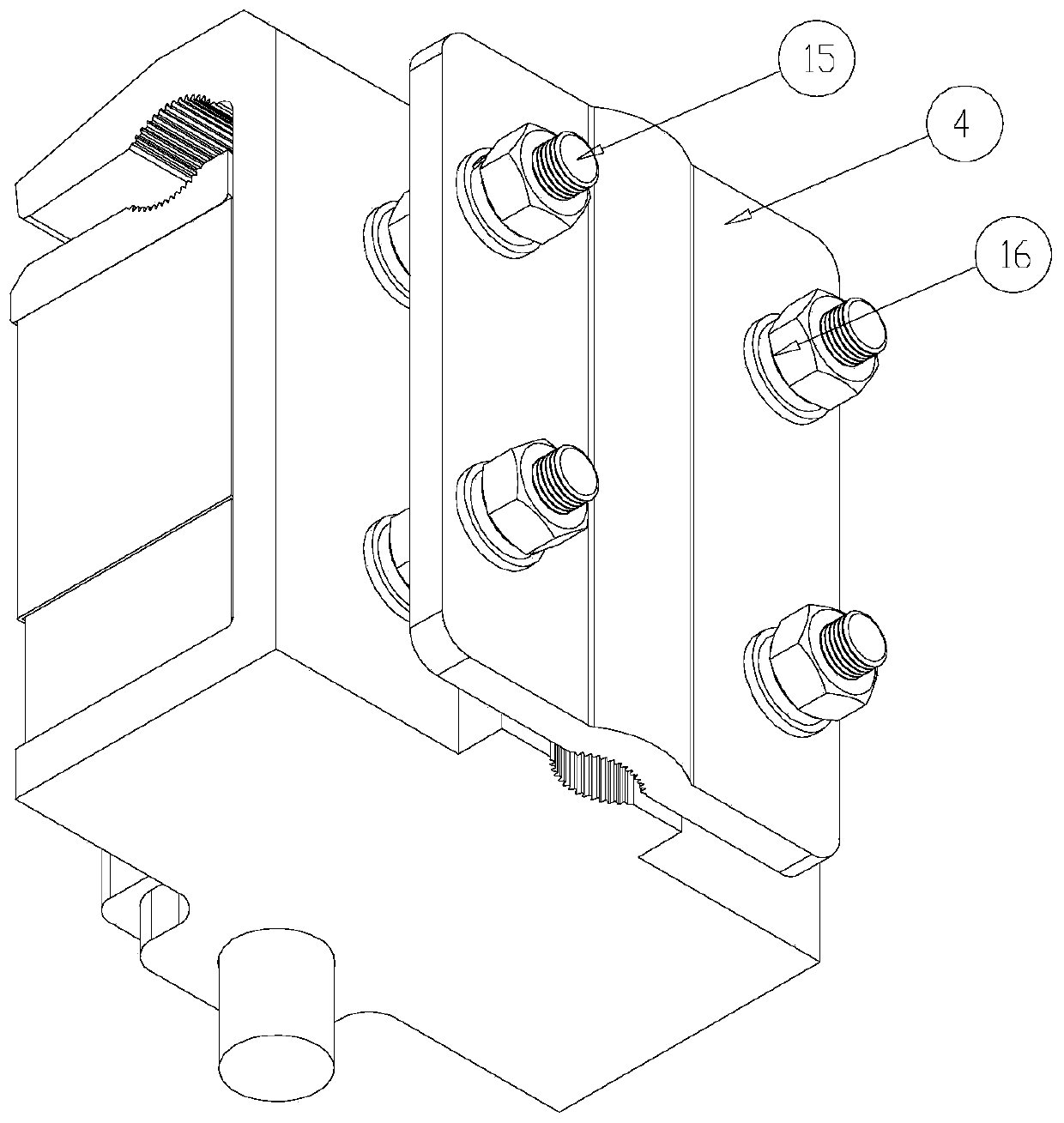

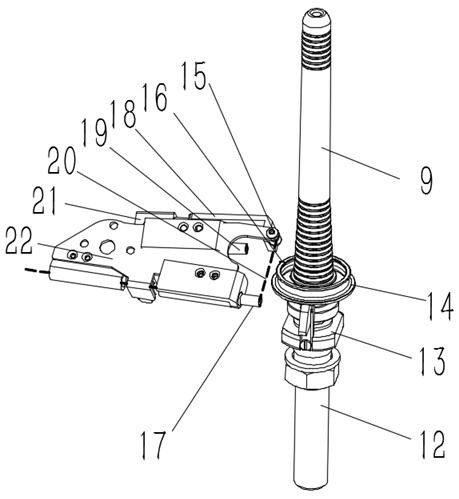

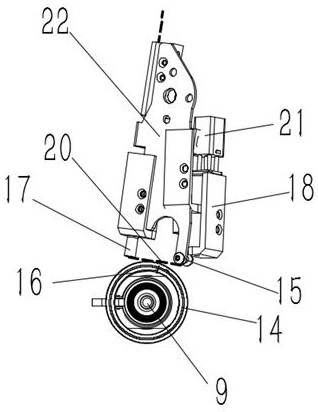

10kV live working insulating rod operation parallel groove clamp quick installer

PendingCN110808487AImprove lap efficiencyEasy to operateElectric connection structural associationsEngineeringScrew thread

The invention discloses a 10kV live working insulating rod operation parallel groove clamp quick installer, which includes a clamp assembly and a lead fixing assembly. The clamp assembly includes a first clamp, a second clamp, guide shafts, and a driving screw. The first clamp and the second clamp are provided with wire clamping grooves for clamping an overhead wire in cooperation and driving screw holes matching the driving screw. The first clamp and the second clamp are rotatably driven by the driving screw to clamp or release the overhead wire. The two guide shafts are arranged side by sidefor guiding the relative movement of the first clamp and the second clamp. The lead fixing assembly includes a lead clamping sleeve for clamping a lead end and a threaded connection component. The threaded connection member is provided with a first threaded segment. The first clamp is provided with a connection threaded hole. The first threaded segment is in threaded connection with the connection threaded hole. On the one hand, the 10kV live working insulating rod operation parallel groove clamp quick installer requires less tools, and on the other hand, can be operated by a single user, which facilitates the operation and improves the lead overlapping efficiency.

Owner:STATE GRID ZHEJIANG XINCHANG POWER SUPPLY +3

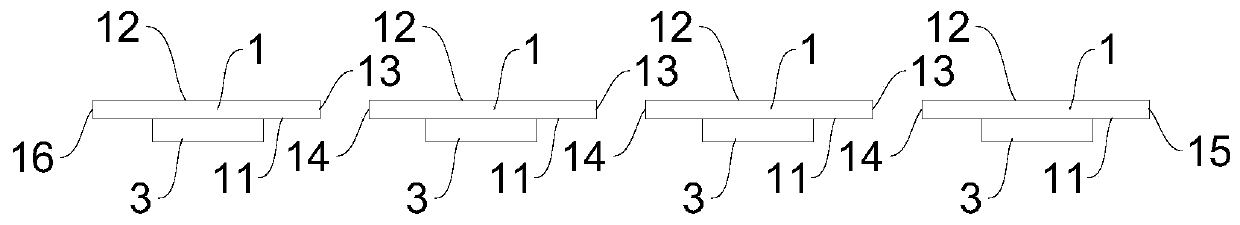

How to connect battery strings

ActiveCN110649125BImprove lap efficiencyFinal product manufactureSemiconductor devicesLap jointFront edge

The invention discloses a lap joint method of cell strings, comprising the following steps: multiple cells which are horizontally arranged and have upward backs are sequentially arranged in the left-right direction; the cells are sucked up synchronously, then the cells are rotated by a certain angle, the rotation directions of the cells are that first side lines face upwards and second side linesface downwards, and the cells are inclined at a small angle; the distance between two adjacent cells is reduced, so that front edge electrodes are positioned right above the external sections of adjacent connecting pieces; and all the cells are synchronously placed on a certain plane, so that the front edge electrodes are pressed on the external sections of the connecting pieces located under thefront edge electrodes, and lap joint of the cell strings is completed. According to the invention, multiple cells can be synchronously in lap joint, and the lap joint efficiency of cell strings can beimproved.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

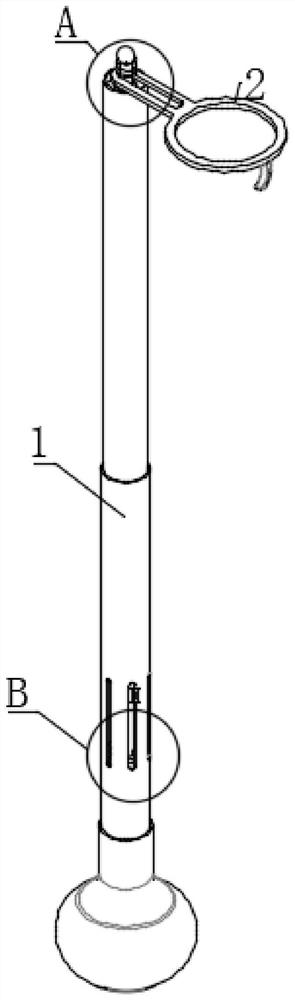

Wire lapping device for circuit breaker opening and closing test and use method of wire lapping device for circuit breaker opening and closing test

PendingCN114460332AConvenient for the second step of lappingAvoid safety accidentsMeasurement instrument housingLap jointCircuit breaker

The invention discloses a wire lapping device for breaker opening and closing tests. The wire lapping device comprises a telescopic rod piece; the wire lapping structure is arranged at the top of the telescopic rod piece; and the wire structure is located on the inner side of the telescopic rod piece, and one end of the wire structure is electrically connected with the wire lapping structure. The invention relates to a high-altitude line lap joint device, and aims to solve the problems that a ladder is inconvenient to use, safety accidents are easy to occur, and the lap joint efficiency is relatively low when lap joint is carried out directly through a supporting rod when lap joint is carried out with a high-altitude line.

Owner:GUIZHOU ELECTRIC POWER DESIGN INST

Parallel Ditch Clamp Lap

The invention discloses a parallel groove clamp lap-joint device, which comprises a clamp fixing device, a lead locking device and a pressure cylinder fixing device, wherein the clamp fixing device comprises a first clamp fixing block, a second clamp fixing block arranged at the lower side of the first clamp fixing block, a guide connecting rod connecting the first clamp fixing block and the second clamp fixing block and a clamp fixing device control structure which enables the first clamp fixing block and the second clamp fixing block to clamp or loosen a parallel groove clamp, the second clamp fixing block is provided with a lead pass-through slot provided for a lead to transversely pass through, the lead locking device comprises a locking block arranged in the lead pass-through slot anda lead locking device control structure which controls the locking block to move so as to lock or loosen the lead, and the pressure cylinder fixing device comprises a pressure cylinder fixing block connected with the second clamp fixing block and pressure cylinder clamping pieces arranged at the left and right sides of the pressure cylinder fixing block respectively. The parallel groove clamp lap-joint device can be operated by one person, and can complete lap joint through one set of tools, thereby greatly improving the lap-joint efficiency of the parallel groove clamp.

Owner:STATE GRID ZHEJIANG XINCHANG POWER SUPPLY +3

A kind of highly conductive graphene flexible composite film and preparation method thereof

ActiveCN107474520BImprove conductivityFull play of electrical conductivityThermal dilatationPolymer science

The invention discloses a method for preparing a high-conductivity graphene flexible compound membrane. The method for preparing the high-conductivity graphene flexible compound membrane disclosed by the invention comprises the following steps: 1) treating graphene powder for increasing the conductivity: performing solvent peeling, thermal expansion and high-temperature thermal treatment on the graphene powder, thereby increasing the conductivity; 2) compounding: mixing the graphene powder acquired in the step 1), elastic macromolecular grain and solvent, thereby acquiring a mixture, and then adding thixotropic agent and viscosity modifier for controlling the dynamic viscosity to 6000-8000mpa; 3) forming a membrane: preparing the mixture into the membrane. The invention also discloses the high-conductivity graphene flexible compound membrane prepared according to the method disclosed by the invention.

Owner:常州二维暖烯科技有限公司

Fabricated building steel structure lap joint component

The invention discloses a fabricated building steel structure lap joint component which comprises I-shaped steel, a positioning plate is arranged between the adjacent lap joint outer walls of the I-shaped steel, side baffles are movably installed on the left side and the right side of the bottom of the positioning plate, limiting hooks are hinged to the lower ends of the side baffles, and limiting components are arranged at the bottoms of the I-shaped steel at the joints of the side baffles and the limiting hooks; the rotating rod pieces are rotationally installed on the front side and the rear side of the interior of the positioning plate piece, and the rotating rod pieces are in threaded connection with the side baffles; the vertical lead screw is rotationally installed on the inner side of the edge plate in an embedded mode, and a positioning sleeve is installed on the outer wall of the vertical lead screw in a threaded mode; the first liquid cavity and the second liquid cavity are sequentially formed in the positioning plate from the edge to the middle. According to the assembly type building steel structure lap joint component, stable connection between steel structure I-shaped steel is facilitated through the lap joint component, the lap joint efficiency is improved, and follow-up position adjustment and disassembly of the I-shaped steel can be facilitated.

Owner:曾顺义

A flexible transparent conductive film with silver nanowires with high lapping efficiency and excellent bending resistance

ActiveCN110444318BReduce contentImprove bending resistanceConductive layers on insulating-supportsInsulated cablesUv protectiveTransparent conducting film

Owner:合肥微晶材料科技有限公司

Separation and stringing process of photovoltaic cells

ActiveCN111129233BImprove cutting efficiencyImprove segmentation efficiencyFinal product manufacturePhotovoltaic energy generationElectrical batteryEntire cell

The invention relates to the field of photovoltaics, and discloses a process for splitting and stringing solar cells. Firstly, the conductive connector is divided into a plurality of connector segments, and then the entire cell is laid on the connector segment, and then the entire segment is Divide into multiple slices, and then weld the overlapping strings of the slices into battery strings. The present invention can improve the cutting efficiency of the conductive connector; the present invention can improve the segmentation efficiency of the whole battery sheet, and increase the production capacity of the slice; the present invention can improve the overlapping efficiency, welding efficiency and production capacity of the battery string.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

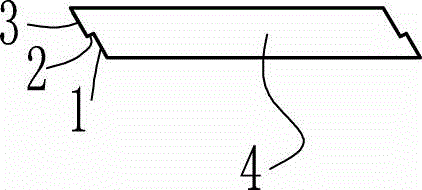

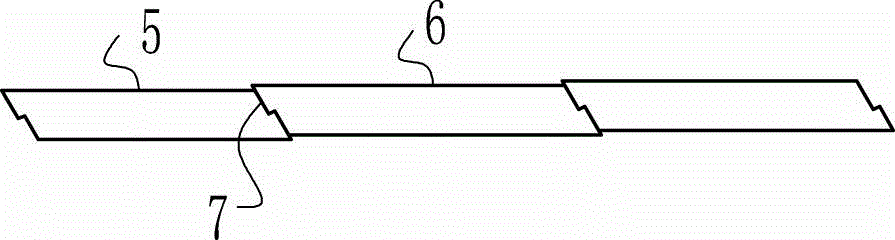

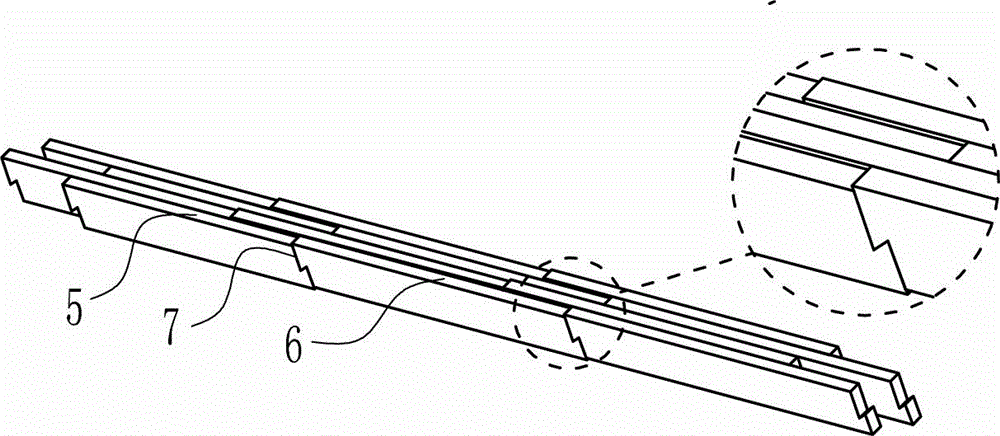

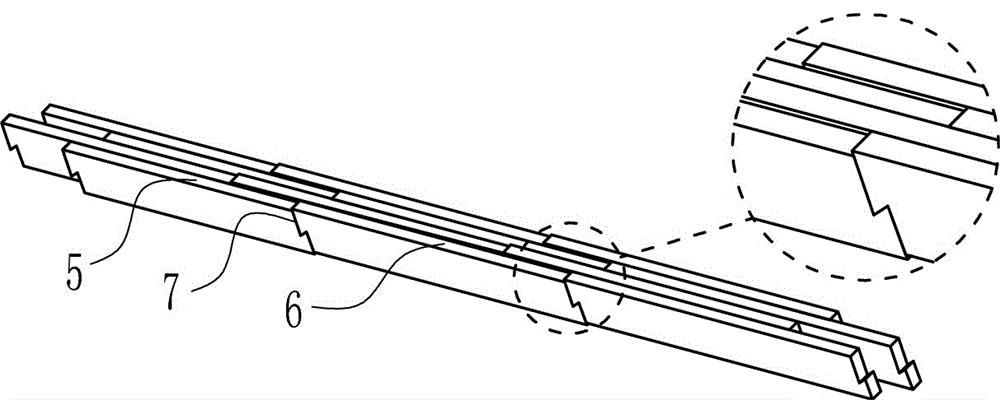

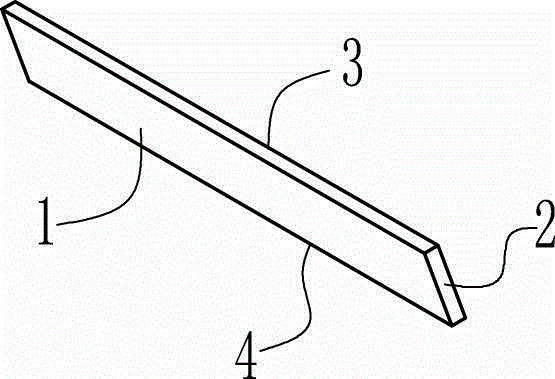

A kind of manufacturing method of bamboo lamella

ActiveCN103144154BEasy to operateIncrease profitCane mechanical workingWood veneer joiningLap jointPulp and paper industry

The invention relates to a method for manufacturing bamboo glulam. It specifically includes the production of positioning overlapping parts, blank assembly, and pressing processes. The positioning overlapping part manufacturing process processes at least one end of the length direction of the finely planed bamboo strips with a positioning overlapping part; The length direction is sequentially overlapped to form an overlapping area. After overlapping, the top surfaces of two adjacent bamboo strips are automatically staggered from each other. Staggered; the pressing process extrudes the finished bamboo strip group along the height and width directions until the top surfaces of the two bamboo strips are even. The invention has simple lap joint process and high lap joint efficiency, avoids the problem of lap joint gaps in the pressing process, and greatly improves the work efficiency and product qualification rate of bamboo laminated wood production.

Owner:熊晓晶

A kind of manufacturing method of bamboo glulam

ActiveCN103112059BIncrease profitLow technical requirementsWood veneer joiningEngineeringMechanical engineering

The invention relates to a manufacturing method of bamboo glulam, which specifically includes the steps of end sawing, blank assembly, and pressing, wherein, in the end sawing process, at least one end of the finely planed bamboo strip in the length direction is sawed into a slope, and the slope is used as the blank assembly process The overlapping slopes; the billet assembly process consists of several pieces of finely planed bamboo strips that have been made with lapping slopes along the length direction. The joint part, the top surface of one bamboo strip in the joint part is higher than the bottom surface of the other bamboo strip, forming a dislocation, and then the bamboo strip groups lengthened in the length direction are arranged into groups sequentially along the width or height direction, and the joint part is staggered; The pressing process extrudes the finished bamboo strip group along the height and width directions, so that the finely planed bamboo strips overlapping each other in the length direction slide along the overlapping inclined plane until the dislocation disappears. The method has the advantages of simple processing technology, reduced processing amount and high processing efficiency.

Owner:熊晓晶

A kind of automatic threading method and threading device for traveler of ring spinning frame

The invention discloses an automatic threading device for a traveler of a ring spinning frame, comprising a thread feeder for arranging the yarn into a linear tension state, the thread feeder comprising at least two yarn clamps separated from each other The two clamping devices are fixed on the same fixing base, the fixing base is provided with a connecting part fixed on the mechanical arm, and the two yarn clamping devices respectively clamp the two ends of the yarn to form the threading part of the yarn , a circulation generator for forming a surrounding airflow at the ring; the beneficial effect of the present invention is: the surrounding airflow makes the traveler can be blown at any position of the ring, and rotates around the ring, through the threading part and the steel ring. The axis of the collar forms an included angle a to ensure that the threading part of the traveler hangs in the traveler.

Owner:PINTER YUHUA CHINA TECH CO LTD

Preparation method of battery string

ActiveCN110649126BImprove cutting efficiencyGuaranteed cutting accuracyFinal product manufacturePhotovoltaic energy generationLap jointEngineering

The invention discloses a preparation method of a cell string, comprising the following steps: (1) arranging cells; (2) lapping a cell string; and (3) welding the cell string. The cutting efficiency of connecting pieces can be greatly improved, the cutting precision of the connecting pieces can be guaranteed, the lap joint efficiency of the cell string can be improved, the welding efficiency of the cell string can be improved, the preparation efficiency of the cell string can be improved, and the productivity of the cell string and a solar cell module can be improved.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com