A kind of nano-silver wire flexible transparent conductive film with low square resistance and excellent bending resistance and preparation method thereof

A technology of transparent conductive film and nano-silver wire, applied to the conductive layer on the insulating carrier, equipment for manufacturing conductive/semiconductive layer, cable/conductor manufacturing, etc., can solve the problems of high equipment requirements and achieve optical performance Good, the effect of improving lap joint efficiency and improving mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The composition of each component by mass percentage in the welding fluid used in this embodiment is:

[0048] Stabilizer 0.015% (mass ratio of sodium silicate to magnesium sulfate 1:1)

[0049] Hydroxylamine Hydrochloride 0.01%

[0050] Solvent (ethanol / water mass ratio 1:1) 99.965%

[0051] Specific preparation method: add copper nitrate, sodium silicate, magnesium sulfate, and solvent in turn to the dispersion tank, stir at a speed of 500r / min for 50min, then add hydroxylamine hydrochloride, and mechanically stir for 20s to obtain the welding solution.

[0052] This embodiment prepares nano-silver wire flexible transparent conductive film as follows:

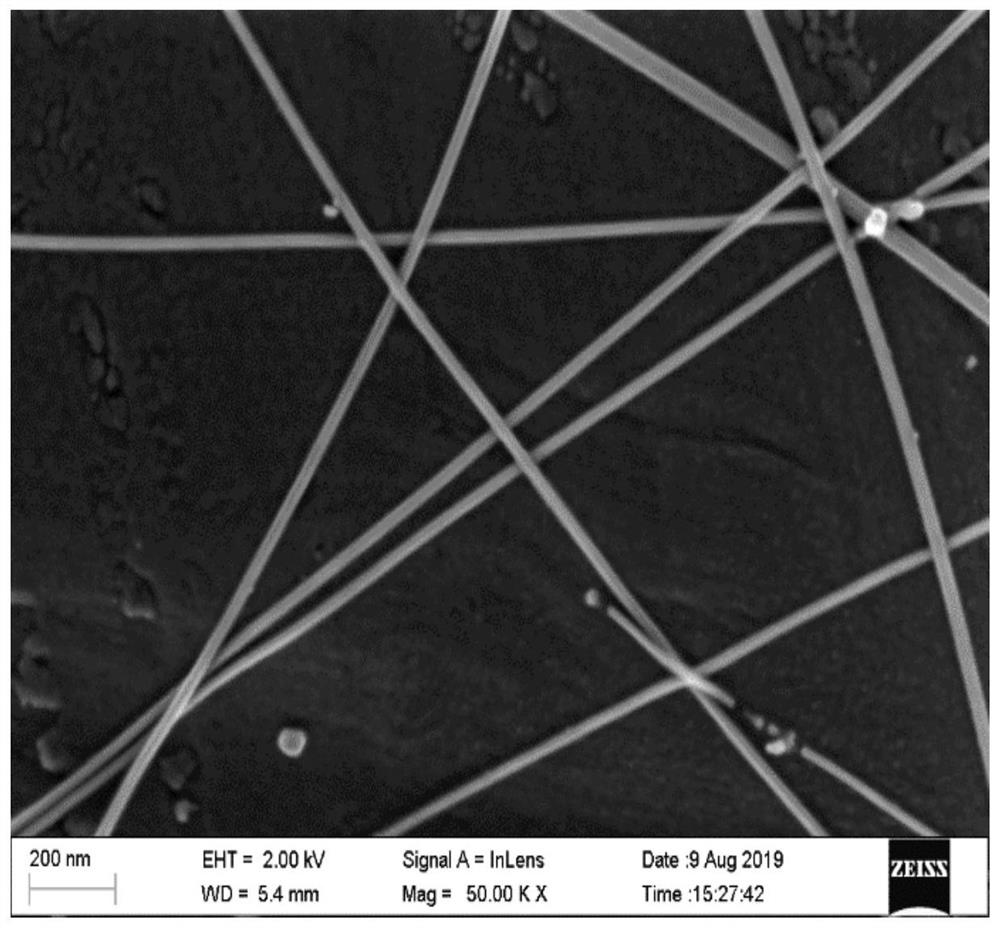

[0053] (1) Coat the conductive ink on the surface of the flexible substrate through the dimple coating process, and then dry it in a tunnel furnace at 130°C for 2 minutes to form a conductive layer of silver nanowires;

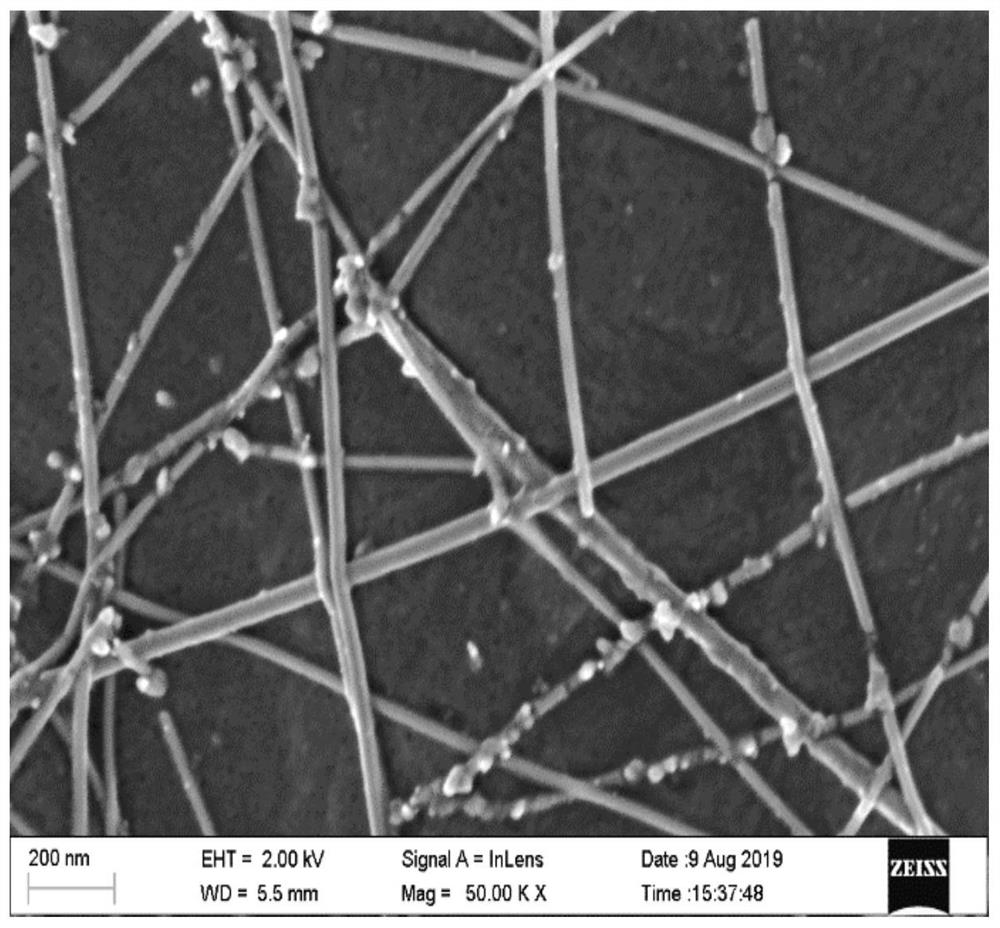

[0054] (2) Apply the soldering liquid on the surface of the condu...

Embodiment 2

[0057] The composition of each component by mass percentage in the welding fluid used in this embodiment is:

[0058] Silver nitrate 0.01%

[0059] Stabilizer 0.015% (mass ratio of sodium silicate to magnesium sulfate 1:1)

[0060] Hydroxylamine Hydrochloride 0.01%

[0061] Solvent (ethanol to water mass ratio 1:1) 99.965%

[0062] Specific preparation method: add silver nitrate, sodium silicate, magnesium sulfate, and solvent in turn to the dispersion tank, stir at a speed of 500r / min for 50min, then add hydroxylamine hydrochloride, and mechanically stir for 20s to obtain the welding solution.

[0063] This embodiment prepares nano-silver wire flexible transparent conductive film as follows:

[0064] (1) Coat the conductive ink on the surface of the flexible substrate through the dimple coating process, and then dry it in a tunnel furnace at 130°C for 2 minutes to form a conductive layer of silver nanowires;

[0065] (2) The welding liquid is coated on the surface of the ...

Embodiment 3

[0068] The composition of each component by mass percentage in the welding fluid used in this embodiment is:

[0070] β-Cyclodextrin 0.01%

[0071] Hydroxylamine Hydrochloride 0.01%

[0072] Solvent (ethanol / water mass ratio 1:1) 99.97%

[0073] Specific preparation method: add copper nitrate, β-cyclodextrin, and solvent in sequence to the dispersion tank, stir at a speed of 500r / min for 50min, then add hydroxylamine hydrochloride, and mechanically stir for 20s to obtain the welding solution.

[0074] This embodiment prepares nano-silver wire flexible transparent conductive film as follows:

[0075] (1) Coat the conductive ink on the surface of the flexible substrate through the dimple coating process, and then dry it in a tunnel furnace at 130°C for 2 minutes to form a conductive layer of silver nanowires;

[0076] (2) The welding liquid is coated on the surface of the conductive layer through a dimple coating process, and then naturally air-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com