A kind of manufacturing method of bamboo glulam

A manufacturing method and glulam technology, which is applied in the direction of manufacturing tools, wood processing appliances, and the joining of wooden veneers, and can solve the problems of complex buckle shape at the end of finely planed bamboo strips, difficult control of product quality, and high technical requirements for workers. problem, to achieve the effect of low labor intensity, high bamboo utilization rate and low technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

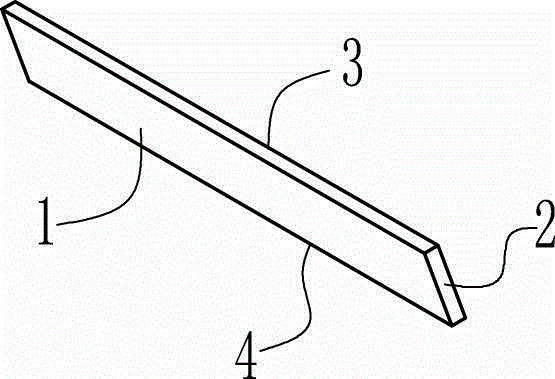

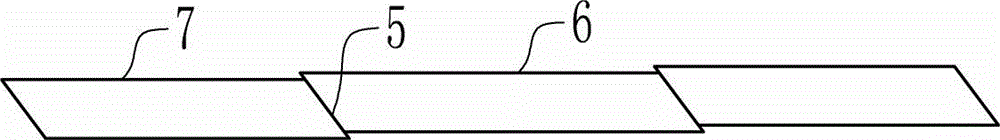

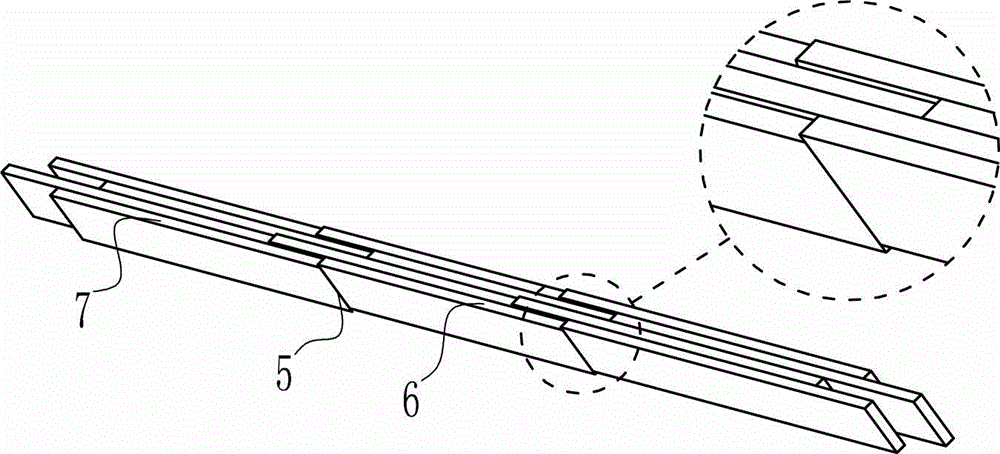

[0024] A method for manufacturing bamboo glulam, comprising end sawing, end sawing, billet formation, and pressing processes, wherein, in the end sawing process, at least one end in the length direction of finely planed bamboo strips is cut into an overlapping inclined surface 2, and the finely planed bamboo strips are combined with The obtuse-angled side of the lapped slope is the bottom surface 3, and the acute-angled side of the lapped slope is the top surface 4, such as figure 1 As shown, the billet assembly process consists of several pieces of finely planed bamboo strips that have been made with overlapping slopes along the length direction. Part 5, the top surface 6 of bamboo strip one is higher than the bottom surface 7 of another bamboo strip, and the connection length of two finely planed bamboo strips in the length direction is as follows: figure 2 As shown, then the bamboo strip groups after the length direction is extended are arranged into groups sequentially al...

Embodiment 2

[0026] A method for manufacturing bamboo glulam, comprising the steps of end sawing, billet formation, and pressing, wherein, in the end sawing process, at least one end of the finely planed bamboo strip in the length direction is sawed into an overlapping inclined surface 2, and the finely planed bamboo strip is connected to the The obtuse side of the overlapping slope is the bottom surface 3, the side forming an acute angle with the overlapping slope is the top surface 4, and the overlapping slope 2 and the top surface 4 form an angle of 30°; The finely planed bamboo strips are lengthened along the length direction, and when two adjacent finely planed bamboo strips are lengthened in the length direction, the lapped inclined surfaces fit together to form a joint part 5, and the top surface 6 of one bamboo strip is higher than the other bamboo strip 7 of the bottom surface, 1mm higher than the distance, and the length of the connection between the two finely planed bamboo strip...

Embodiment 3

[0028] A method for manufacturing bamboo glulam, comprising the steps of end sawing, billet formation, and pressing, wherein, in the end sawing process, at least one end of the finely planed bamboo strip in the length direction is sawed into an overlapping inclined surface 2, and the finely planed bamboo strip is connected to the The obtuse side of the overlapping slope is the bottom surface 3, the side forming an acute angle with the overlapping slope is the top surface 4, and the overlapping slope 2 and the top surface 4 form an angle of 30°; The finely planed bamboo strips are lengthened along the length direction, and when two adjacent finely planed bamboo strips are lengthened in the length direction, the lapped inclined surfaces fit together to form a joint part 5, and the top surface 6 of one bamboo strip is higher than the other bamboo strip The bottom surface of the bottom surface is 7, the distance is 5mm higher, and the connection length of two finely planed bamboo s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com