A polymer electromagnetic shielding composite foam with gradient filler structure and preparation method thereof

An electromagnetic shielding and composite foam technology, applied in the fields of magnetic field/electric field shielding, electrical components, etc., can solve the problems of increasing the cost of material preparation and processing difficulty, increasing the overall density of composite materials, and restricting applications, so as to broaden the potential use field and reduce Density, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

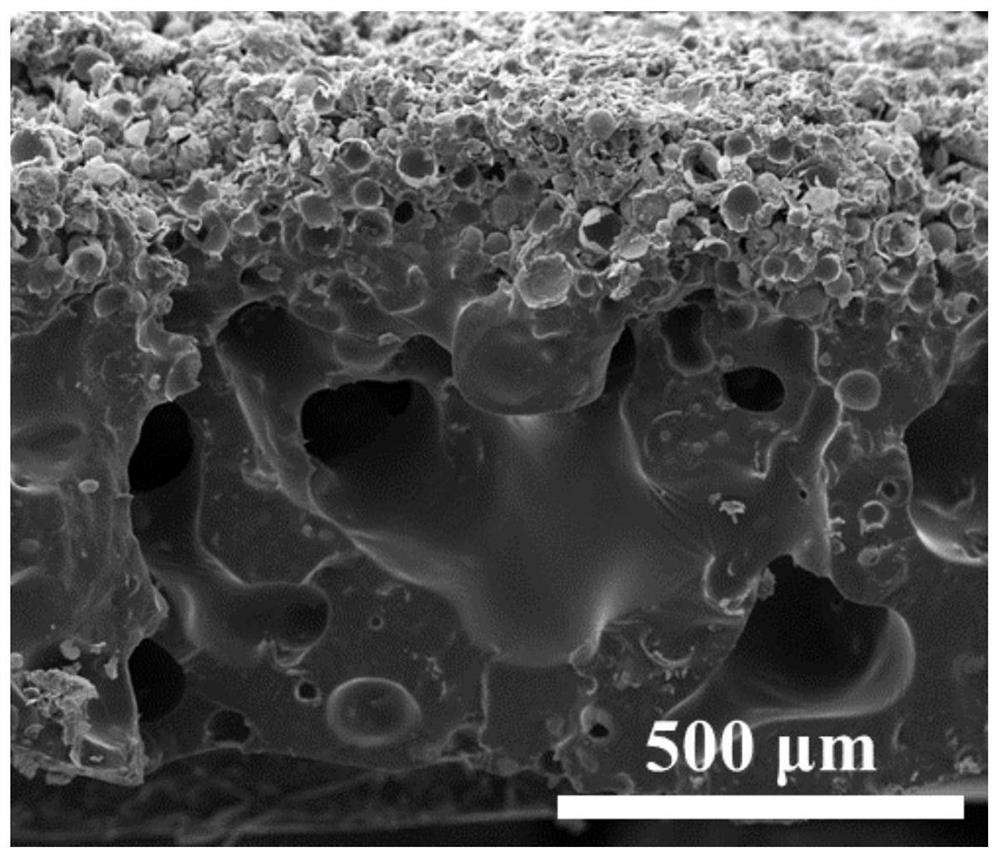

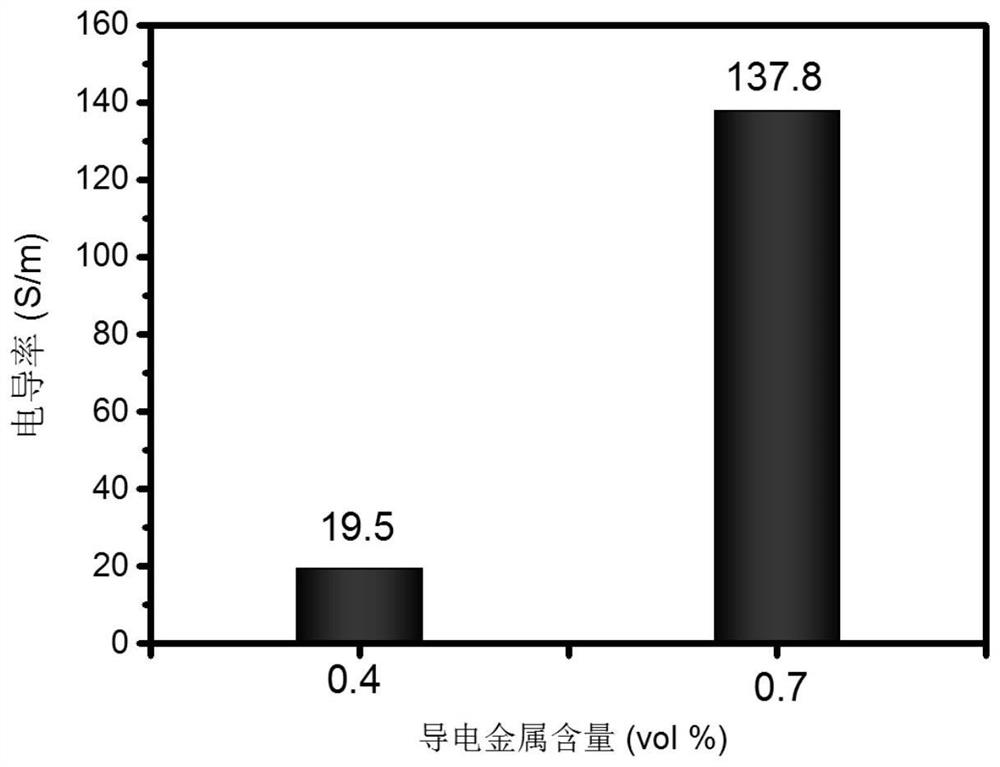

[0030] A preparation method of polymer electromagnetic shielding composite foam with gradient filler structure, comprising the following steps:

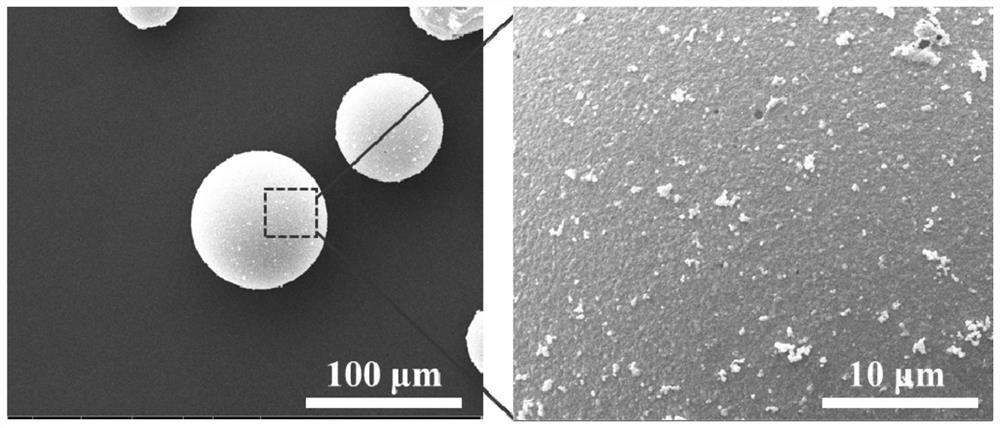

[0031] (1) Preparation of conductive metal-loaded hollow glass microspheres

[0032] Add 2g of hollow glass microspheres to 20mL of dilute sulfuric acid, mechanically stir for 10min, wash with distilled water, then filter with suction, then treat and wash with stannous chloride, and finally add the product to 10mL of electroless tungsten plating solution (sodium tungstate 20g / L, sodium hypophosphite 20g / L), add dropwise the mixed solution that sodium citrate and ammonium sulfate are formed, the concentration of sodium citrate in the mixed solution is 20g / L, the concentration of ammonium sulfate is 50g / L, machine React for 5 minutes under stirring conditions, wash, filter with suction, and dry to obtain metal tungsten-loaded hollow glass microspheres.

[0033] (2) Preparation of glass microsphere-epoxy resin composite body

[0034] ...

Embodiment 2

[0038] A preparation method of polymer electromagnetic shielding composite foam with gradient filler structure, comprising the following steps:

[0039] (1) Preparation of conductive metal-loaded hollow glass microspheres

[0040] Add 2g of hollow glass microspheres to 50mL of dilute sulfuric acid, mechanically stir for 30min and wash with distilled water, then suction filter, then treat and wash with sensitization solution, and finally add the product to 50mL of electroless iron plating solution (iron sulfate 15g / L , gentiobiose 2g / L), a sodium borohydride solution with a concentration of 1.5g / L was added dropwise, reacted for 1h under the condition of mechanical stirring, washed, suction filtered, and dried to obtain metal iron-loaded hollow glass microspheres.

[0041] (2) Preparation of glass microsphere-polyethylene composite body

[0042] Add 10 g of polyethylene into the trichlorethylene solvent, heat and mechanically stir to fully dissolve the polyethylene, then add 2...

Embodiment 3

[0046] A preparation method of polymer electromagnetic shielding composite foam with gradient filler structure, comprising the following steps:

[0047] (1) Preparation of conductive metal-loaded hollow glass microspheres

[0048] 2g of hollow glass microspheres were added to 80mL of dilute sulfuric acid, mechanically stirred for 1h and washed with distilled water, then suction filtered, then treated with stannous chloride and washed, and finally the product was added to 100mL of electroless aluminum plating solution (aluminum chloride 5g / L, sodium hypophosphite 25g / L), dropwise adding a lithium hydride solution with a concentration of 1g / L, reacted for 2h under the condition of mechanical stirring, washed, suction filtered, and dried to obtain metal aluminum-loaded hollow glass microspheres.

[0049] (2) Preparation of glass microsphere-polyphenylene sulfide composite body

[0050] Add 10 g of polyphenylene sulfide to the α-chloronaphthalene solvent, raise the temperature a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com