Preparation method of battery string

A battery and cell technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems such as low battery string preparation efficiency, and achieve the effects of improving lap efficiency, efficiency and welding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

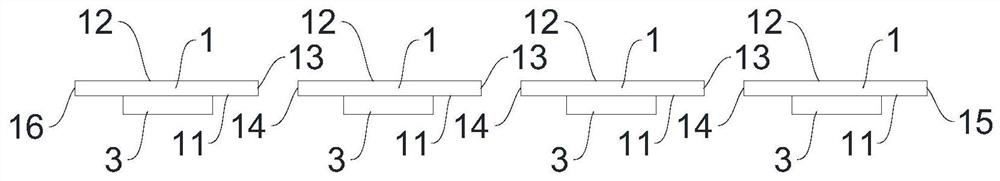

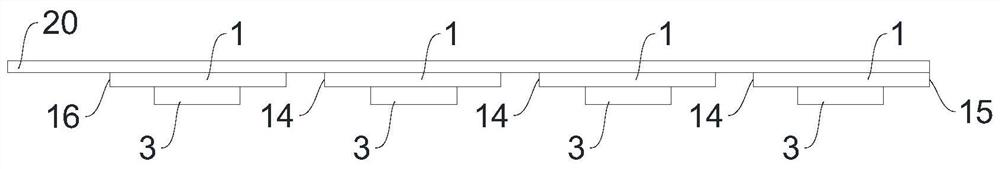

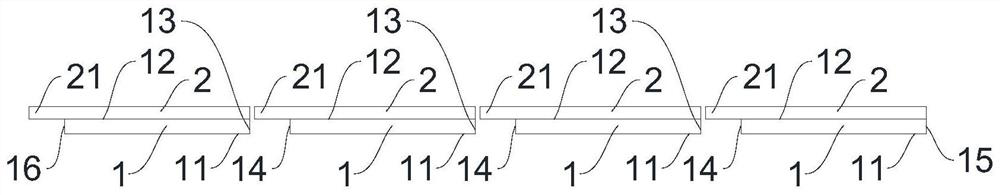

[0039] Such as Figure 1 to Figure 6 As shown, the present invention provides a method for preparing a battery string, comprising the following steps:

[0040] 1) Cell 1 arrangement:

[0041] A plurality of first stages 3 are arranged in sequence along the left and right directions, and a cell 1 with the back facing up is laid flat on each first stage 3; each cell 1 is located at the same height; each cell 1 is provided with a front edge The electrode 11 and the back electrode 12; the front edge electrode 11 is located on the front right edge of the battery sheet 1 where it is located (or the left edge, the right edge is used as an example in each figure); the left and right sides of the same battery sheet 1 , wherein the side edge close to the front edge electrode 11 is the first edge 13, and the side edge far away from the front edge electrode 11 is the second edge 14; the first battery sheet 1 on each first carrier 3 The sidelines 13 are facing the same in the left-right ...

Embodiment 2

[0053] On the basis of implementation 1, the difference is:

[0054] In step 2), each cell is sucked up synchronously by the suction cup manipulator. The suction cup manipulator is equipped with multiple suction cups, which are arranged in sequence along the left and right directions, and each suction cup is at the same height; Suction cup spacing adjustment mechanism for each suction cup spacing, and each suction cup is also equipped with a turning mechanism; each suction cup picks up a cell, and the battery slice is rotated by a certain angle through the turning mechanism, and the adjacent two cells are reduced by the suction cup spacing adjustment mechanism. Cell spacing;

[0055] In step 3), the battery strings on the second carrier are heated and welded by a plurality of heating lamp tubes. The heating area of the multiple heating lamp tubes covers the front connection of each battery. The front connection of the battery is the front edge electrode and The joint of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com