Patents

Literature

49results about How to "Increase the number of hydroxyl groups" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

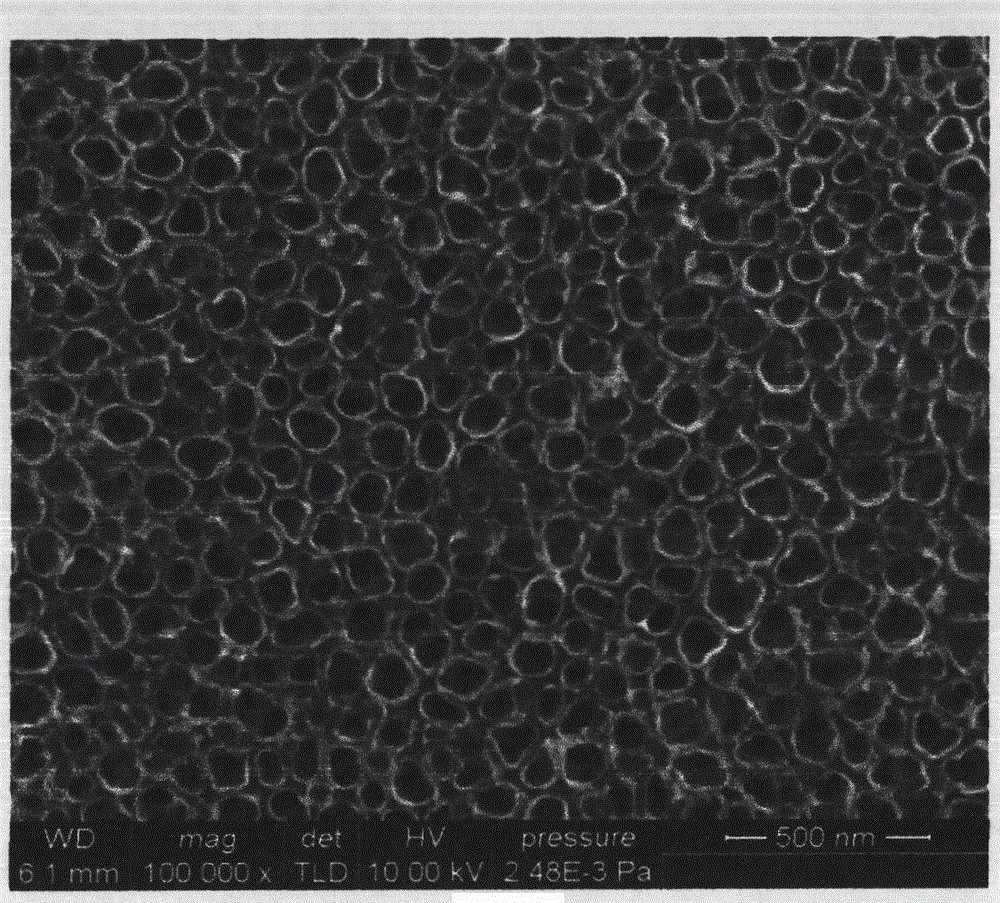

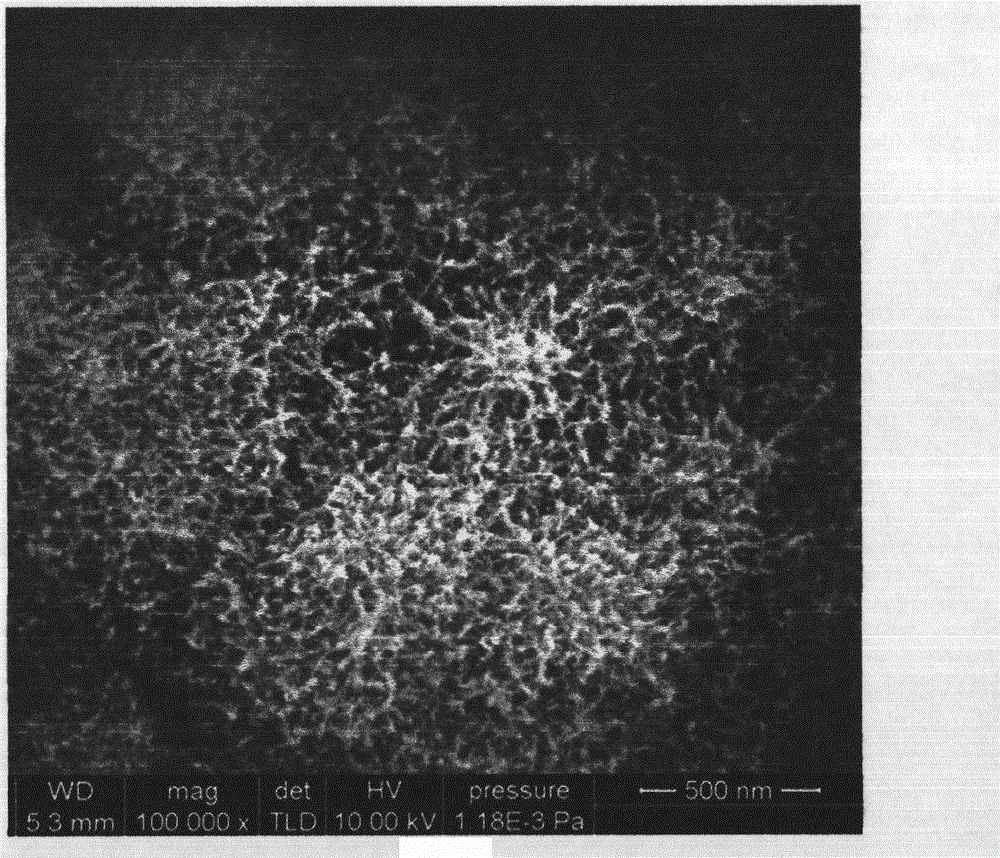

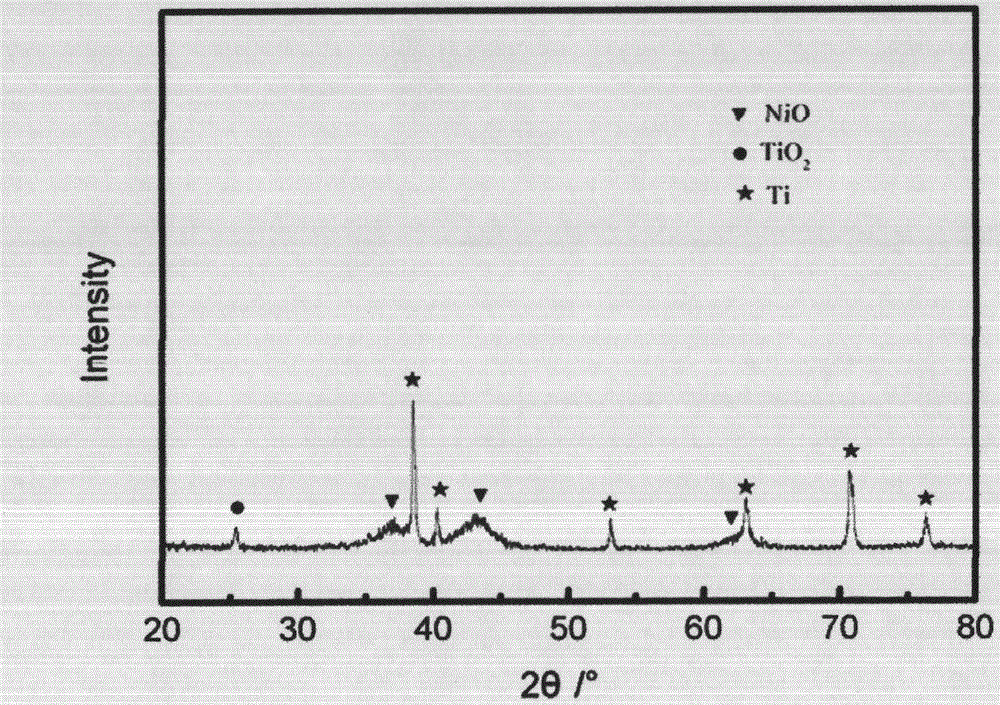

Method for directly growing nickel oxide and cobalt oxide and complex energy storage material thereof on titanium substrate

InactiveCN102719811AReduced precision requirementsExperimental conditions are simpleSurface reaction electrolytic coatingLiquid/solution decomposition chemical coatingHigh energyNanotube

The invention discloses a method for directly growing nickel oxide and cobalt oxide and a complex energy storage material thereof on a titanium substrate. The method comprises the following steps of: growing a titanium dioxide nanotube on the surface of the titanium substrate by an anodic oxidation method; soaking in a citric acid solution to further increase the hydroxyl concentration of the wall of the titanium dioxide nanotube; putting the prepared transition metal solution and the treated titanium substrate into a reaction kettle, and performing hydrothermal reaction; and roasting the reacted titanium substrate in N2 atmosphere to obtain a product. Experimental conditions are simple, the requirement on the precision of an experimental instrument is low, the method is easy to operate, and the grown product film is uniform, is stably combined with the titanium substrate and has high energy storage performance, so the method is suitable for preparing the energy storage material taking metal titanium as the substrate.

Owner:CHONGQING UNIV

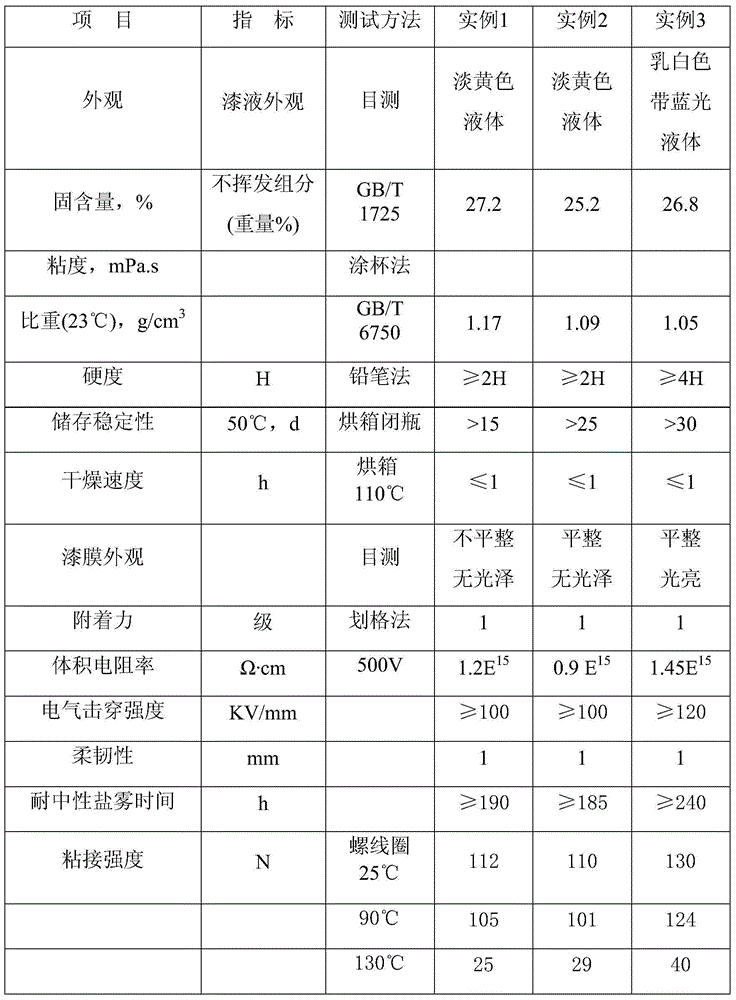

Waterborne epoxy/acrylic resin emulsion with core-shell structure as well as preparation method and application thereof

ActiveCN104788627AExtended epoxy chainIncrease the number of hydroxyl groupsAnti-corrosive paintsEpoxyAdjuvant

The invention discloses a waterborne epoxy / acrylic resin emulsion with a core-shell structure as well as a preparation method and application of the waterborne epoxy / acrylic resin emulsion as a waterborne epoxy / acrylic amino baking paint. The method comprises the following steps: performing graft copolymerization reaction on the prepolymer of acrylic monomer and vinyl monomer and a modified epoxy resin under the effect of a solvent, emulsifying to obtain the epoxy / acrylic amino resin emulsion with the core-shell structure with the solid content of 20-30%; mixing the following components in parts by weight: 100 parts of the epoxy / acrylic resin emulsion with the core-shell structure, 90-200 parts of water, 90-200 parts of waterborne curing agent and 0.01-0.5 part of waterborne adjuvant. The environment-friendly waterborne epoxy / acrylic amino baking paint with high paint film mechanical strength can be obtained to substitute the solvent type epoxy paint as a base coat. The waterborne epoxy / acrylic resin emulsion is wide in application scope, suitable for the protective coating of the metal frame structures such as a circuit coil, a PCB and a building automobile in the electronic field.

Owner:WUHAN UNIV

Water-locking antibacterial material for diapers and preparation method of water-locking antibacterial material

The invention discloses a water-locking antibacterial material for diapers and a preparation method of the water-locking antibacterial material, and belongs to the field of baby products. The water-locking antibacterial material for diapers comprises the following raw materials: polyether sulfone resin, corn starch, polylactic acid, chitosan, alpha-L-guluronic acid, beta-D-mannuronic acid, gelatin, lignin, phtheirospermum japonicum, sodium hydroxide, cholic acid, polyaspartamide, herba andrographis, radix cordylines fruticosae, fructus forsythiae, rhizoma anemarrhenae, rhizoma polygoni cuspidati, silk fibroin, acrylic acid, sodium alginate gel, hydroxyethyl acrylate, glycerol, polyacrylamide, potassium persulfate, sodium sulfite, N, N-methylene bisacrylamide, modified antibacterial additives, and water-locking and reinforcing materials. The invention discloses specific steps of a preparation method of the water-locking antibacterial material for diapers. The water-locking antibacterialmaterial for diapers provided by the invention has excellent antibacterial and water-locking properties.

Owner:CHANGSHA XIAORU INFORMATION TECH CO LTD

Modified polypropylene fiber-steel fiber doping high-intensity concrete and preparation method thereof

The invention discloses a preparation method of modified polypropylene fiber-steel fiber doping high-intensity concrete. The preparation method is characterized in that waste and old tires are mechanically crushed and sieved to obtain waste and old rubber powder; silane coupling agents are added into an alcohol solution; after the hydrolysis, the material is uniformly sprayed onto the surface of the rubber powder; the material is sufficiently mixed; after the treatment in microwaves, a sodium hydroxide solution is used for soaking; then, drying is performed in a baking oven; the modified rubber powder is obtained; polyvinyl alcohol and distilled water are mixed; water bath heating melting is performed; polypropylene fiber is added; uniform ultrasonic dispersion is performed; soaking treatment is performed; drying is performed to obtain the surface treatment polypropylene fiber; a gelling material is finely ground through machinery and is then mixed with Portland cement, steel fiber andnaphthalene-based efficient water reducing agents; the mixture is added into a stirring machine; the obtained material is added; then, sand and tap water are added; stirring is performed for uniformscattering; slurry is obtained; slurry is poured into a mold; scraping leveling is performed by a scraper; after the shaping, still standing is performed; then, mold stripping is performed; standard maintenance is performed; the drying is performed in the ventilation drying place; high-intensity concrete is obtained.

Owner:ANHUI HONGSHI OPTOELECTRONICS HIGH TECH CO LTD

Preparation method of high-strength high-barrier TPU composite material

ActiveCN111138631AIncrease the number of hydroxyl groupsIncreased reactive sitesPrepolymerComposite material

The invention discloses a preparation method of a high-strength high-barrier TPU composite material, and belongs to the technical field of polymer composite material synthesis. According to the method, carrying out a reaction between polytetramethylene ether glycol and 4, 4 '-methylenediphenyl diisocyanate to obtain an isocyanate-terminated TPU prepolymer, adding modified graphene oxide into the TPU prepolymer, and taking the modified graphene oxide and 1, 4-butanediol as a compound chain extender to participate in an in-situ polymerization process, so as to complete a chain extension reaction, thereby obtaining the high-strength and high-barrier TPU composite material. The modified graphene oxide enables reaction sites of a reaction system to be increased; the crosslinking degree of the composite material is improved, and a large number of covalent bonds and hydrogen bonds exist in the prepared TPU composite material, so that the dispersity of the modified graphene oxide in a TPU matrix is good, the interface bonding force with the TPU matrix is enhanced, and the barrier property and the mechanical property of the TPU composite material are improved.

Owner:FUZHOU UNIVERSITY

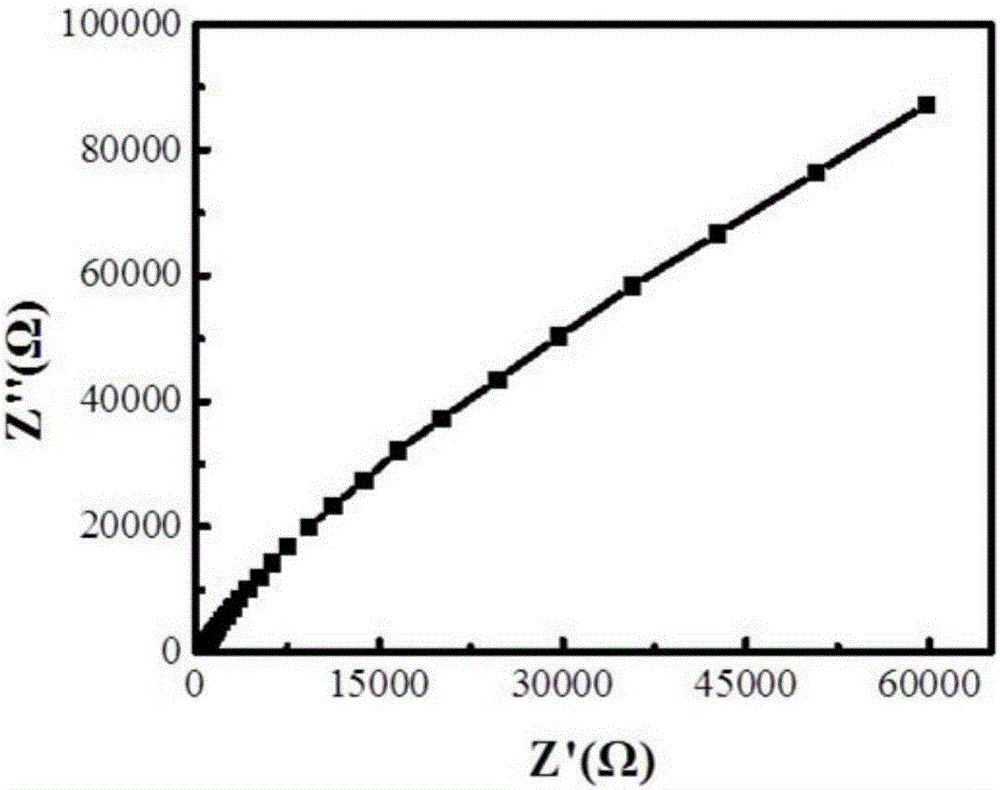

Preparation method of polyvinyl acetal based solid electrolyte

The invention provides a preparation method of a polyvinyl acetal solid electrolyte. The preparation method comprises the steps of respectively reacting polyvinyl formal or a homologue of polyvinyl formal and polyvinyl alcohol with boric acid, oxalic acid and lithium salt in an organic solvent system step by step, performing mixing in proportion, performing washing, suction filtration and drying, synthesizing high-purity polymer lithium salt with a lithium mono(oxalato) borate structure grafted on a polymer molecular chain, dissolving the high-purity polymer lithium salt in an organic solvent to form a settled solution, and finally preparing the solid electrolyte. The solid electrolyte prepared by the method has lithium ion migration number approximate to 1, excellent room-temperature conductivity greater than or equal to 10<-4>S / cm, a wide electrochemical stability window greater than or equal to 6V(vs.Li / Li<+>), outstanding thermal stability, high tensile strength greater than or equal to 35MPa, and excellent comprehensive performance for an all-solid battery system.

Owner:UNIV OF SCI & TECH BEIJING

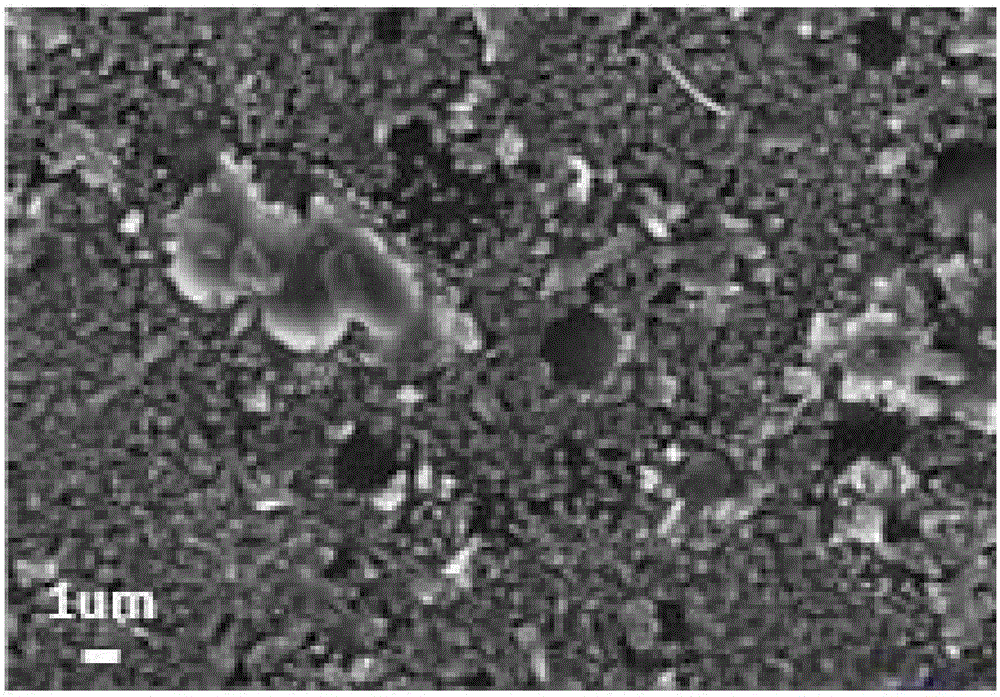

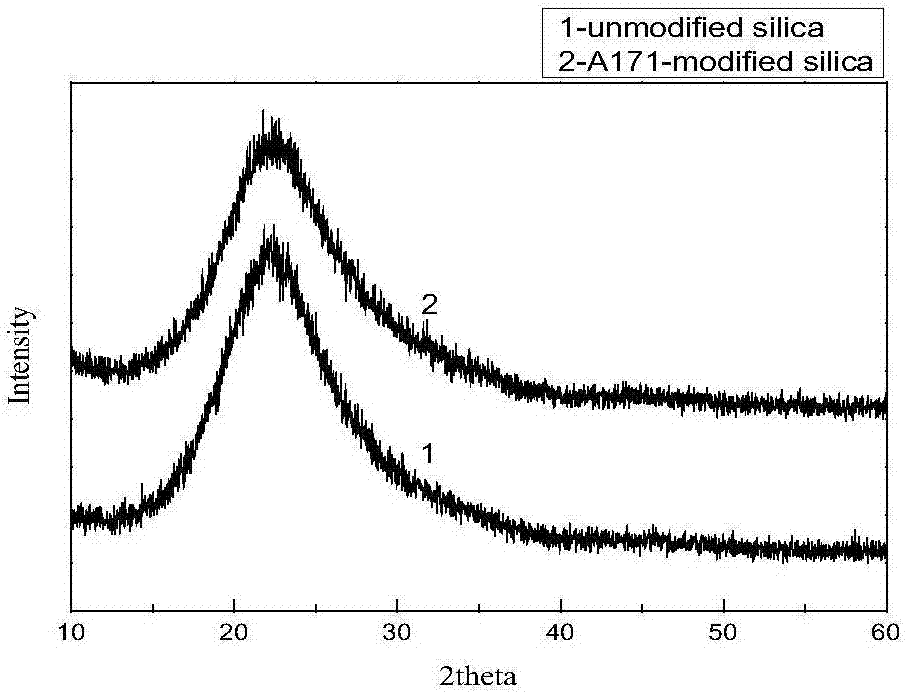

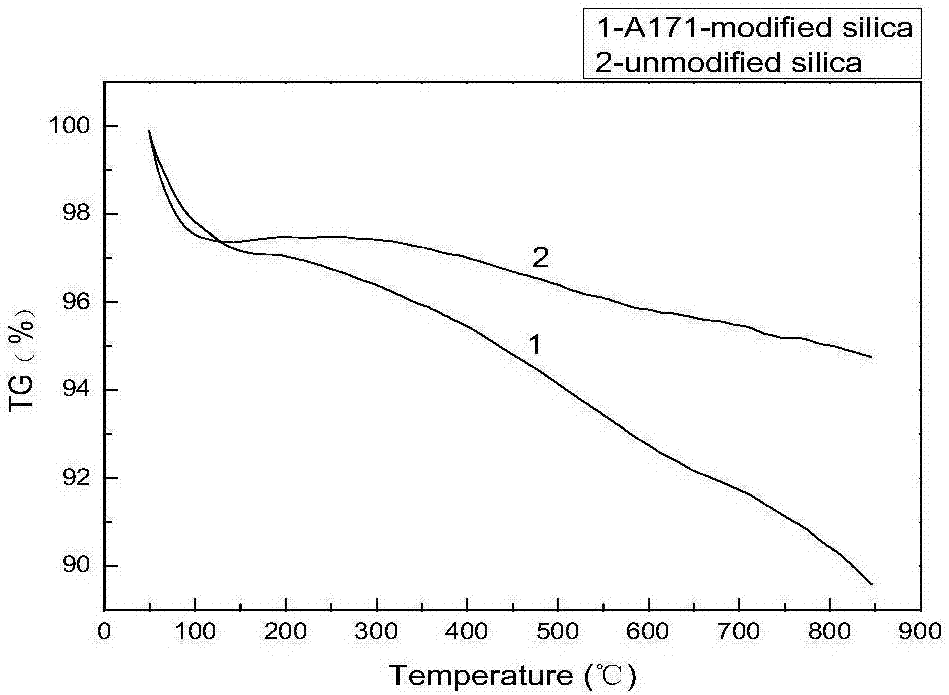

Preparation method of hydrophobic high-reinforcing white carbon black

InactiveCN107337810AHydroxyl number reductionImprove hydrophobicityButadiene-styrene rubberMechanical properties of carbon nanotubes

The invention relates to a preparation method of hydrophobic high-reinforcing white carbon black. According to the preparation method, a SiO2 wet gel is used as a raw material and A171 is used as a modifier to prepare the hydrophobic high-reinforcing white carbon black; and the modification temperature is 80-95 DEG C, the modification time is 60-150 min, the pH value of the modification solution is 2.2-3.1, and the use amount of the modifier is 2.2-3.4% of the total mass of the reaction solution. According to the present invention, the problems that the traditional white carbon black has many silanol groups on the surface and has poor compatibility with rubbers are solved through the white carbon black of the present invention, and the hydrophobicity of the traditional white carbon black is improved; with the application of the white carbon black of the present invention in the styrene-butadiene rubber, the processing performance of the rubber is improved, the vulcanization time of the rubber is reduced, the wear resistance, the tensile strength, the tensile stress at a given elongation, and other mechanical properties of the vulcanized rubber are improved, and the reinforcing property of the traditional white carbon black is improved; and the preparation method has advantages of simple process, good product stability, easy industrialization, and good technical economy.

Owner:CHANGZHOU UNIV

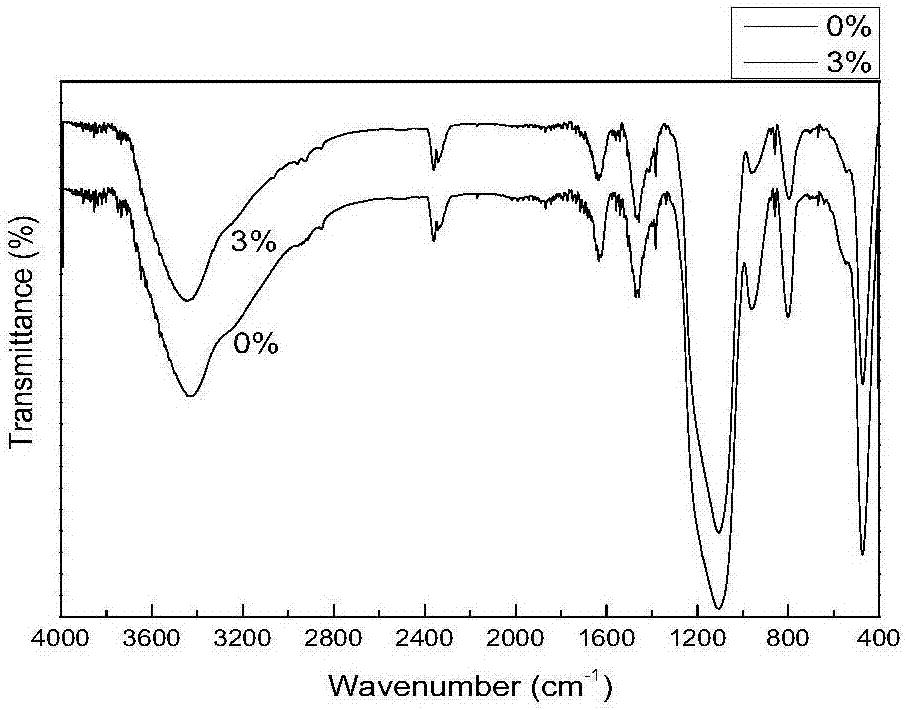

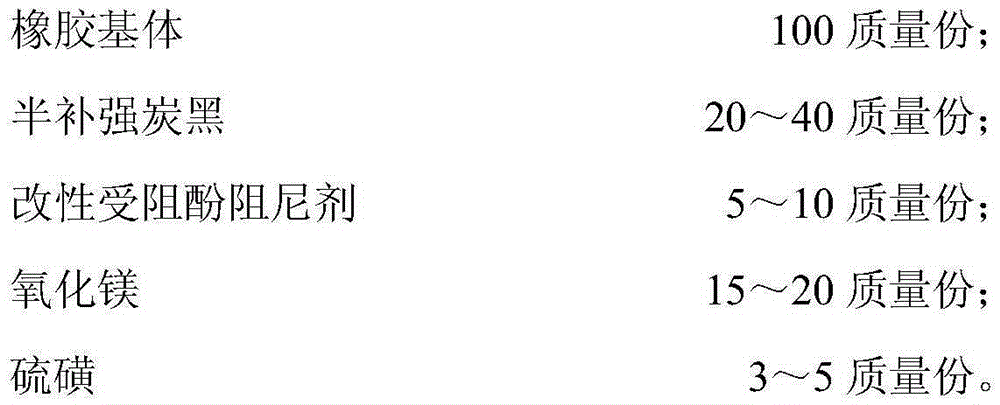

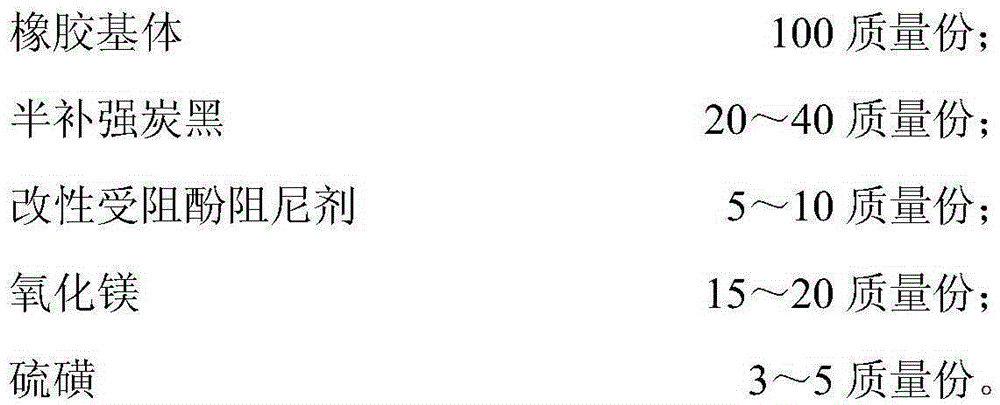

Modified hindered phenol damping agent, and preparation method and applications thereof

ActiveCN105399961AEnhanced hydrogen bondingOvercome the defect of easy migrationRubber materialWear resistance

The invention discloses a modified hindered phenol damping agent, and a preparation method and applications thereof. The modified hindered phenol damping agent is prepared via hyperbranched modification of hindered phenol with a N,N-dihydroxyethyl-3-amino methyl propionate monomer. The preparation method comprises following steps: hindered phenol, the N,N-dihydroxyethyl-3-amino methyl propionate monomer, and a catalyst are mixed at a certain ratio; and an obtained mixture is subjected to 7 to 9h of stirring reaction at 90 to 110 DEG C under inert gas shielding so as to obtain a finished product. A damping rubber material can be prepared by adding 5 to 10 mass parts of the modified hindered phenol damping agent into 100 mass parts of a rubber matrix. It is shown by experiments that the modified hindered phenol damping agent can be uniformly dispersed into the rubber matrix material, and is capable of improving damping performance, mechanical properties, and wear resistance of the obtained damping rubber material obviously.

Owner:SHANGHAI UNIV OF ENG SCI

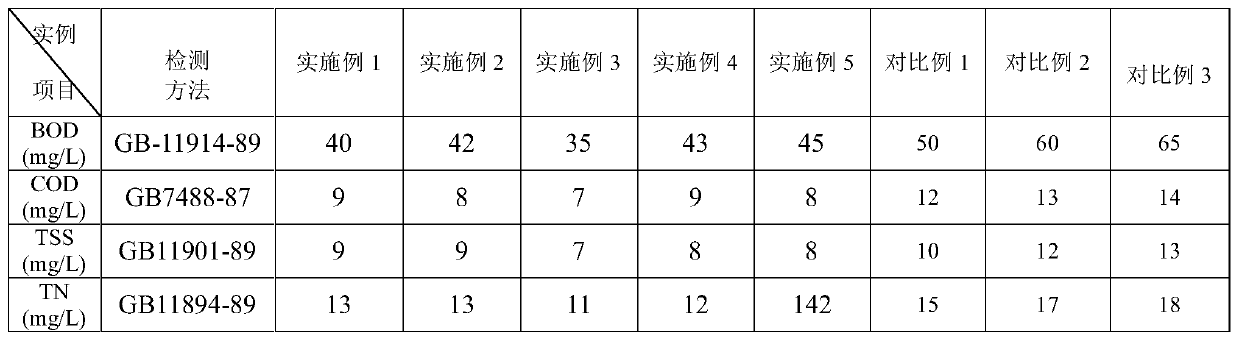

Agricultural sewage treatment agent and preparation method thereof

InactiveCN109912046AEfficient removalEfficient recyclingWater contaminantsBiological water/sewage treatmentCelluloseEutrophication

The invention discloses an agricultural sewage treatment agent and a preparation method thereof. The sewage treatment agent comprises the following raw materials in parts by weight: 30-40 parts of anadsorbent, 15-20 parts of chitosan, 10-20 parts of sodium alginate, 10-20 parts of carbon nanotubes, 10-15 parts of modified beta-cyclodextrin, 10 -15 parts of starch, 10-15 parts of sepiolite, 5-10 parts of cellulose, 5-8 parts of chlorophyll and 3-5 parts of a bactericide. The agricultural sewage treatment agent provided by the invention can effectively remove pesticide residues from sewage, reduces the eutrophication degree of the water quality, and effectively recycles heavy metal pollutants contained in water so as to ensure that after treatment, the water quality meets standards of farmland irrigation and industrial water.

Owner:杨晓飞

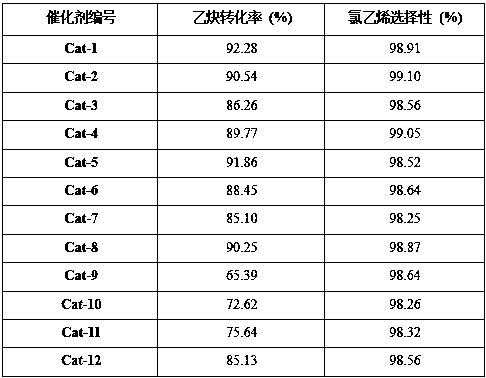

Preparation and application method of metal-free catalyst used for fixed bed acetylene hydrochlorinate preparation of vinyl chloride

ActiveCN108246340AIncrease contentHigh activityMolecular sieve catalystsPreparation by halogen halide additionFixed bedFunction group

The invention relates to a preparation method and an application application method of a metal-free catalyst used for fixed bed acetylene hydrochlorinate preparation of vinyl chloride. Compared with other metal-free catalysts prepared through dipping-calcining method, the metal-free catalyst used for fixed bed acetylene hydrochlorinate preparation of vinyl chloride possesses following advantages:the nitrogen content of the metal-free catalyst used for fixed bed acetylene hydrochlorinate preparation of vinyl chloride is increased through in-suit doping combined ammonia gas treatment; the catalyst specific surface area is increased effectively through calcining of a precursor with polytetrafluoroethylene at a certain heating program, and at the same time nitrogen sulfur codoping and oxidation are adopted to increase the ratio of active sites and the number of surface oxygen-containing function groups, so that the metal-free catalyst possesses relatively activity and selectivity in fixedbed acetylene hydrochlorinate preparation of vinyl chloride. The preparation method is green, and is friendly to the environment; the raw materials are widely available and cheap; the metal-free catalyst can be used for replacing toxic mercuric chloride catalyst; and the application prospect in industrialized production is promising.

Owner:NANKAI UNIV

Nano-zinc oxide-filled diatomite-rubber powder composite modified aging-resistant asphalt and preparation method thereof

InactiveCN108084722AHigh activityImprove mechanical propertiesBuilding insulationsWater bathsWaste rubber

The invention discloses nano-zinc oxide-filled diatomite-rubber powder composite modified aging-resistant asphalt which is characterized in that a preparation method comprises the following steps: calcining diatomite at a high temperature, mechanically grinding and crushing, sieving and then drying; mechanically crushing and sieving a waste tire to obtain a waste rubber powder; adding a silane coupling agent in an alcoholic solution, hydrolyzing, uniformly spraying on the surface of the rubber powder and fully mixing; after microwave treatment, soaking with a sodium hydroxide solution and thendrying in a drying box to obtain the modified rubber powder; dissolving graphene oxide in dimethyl formamide to obtain a liquid A; dissolving nano-zinc oxide in dimethyl formamide to obtain a liquidB; mixing the liquids A and B and organic vermiculite and performing magnetic stirring and water-bath heating to obtain a compound aging-resistant modifier; heating petroleum asphalt to a flow state,adding the materials obtained previously, uniformly stirring, placing in an oil bath pan for heat preservation, cutting and swelling to obtain the aging-resistant asphalt.

Owner:ANHUI HONGSHI OPTOELECTRONICS HIGH TECH CO LTD

Flame-retardant wear-resistant polycarbonate material and manufacturing method thereof

ActiveCN106543680AStrong wear resistance and fire resistanceLarge specific surface areaWaxPolycarbonate

The invention provides a flame-retardant wear-resistant polycarbonate material which is prepared from the following components in parts by weight: 100 parts of polycarbonate, 0.4-0.9 part of anti-ultraviolet agent, 0.5-1 part of antioxidant, 5-7 parts of compatilizer, 0.6-1.1 parts of stabilizer, 0.1-0.6 part of dispersing agent, 1-6 parts of plasticizer, 2-7 parts of toughener, 3-3.5 parts of organosilicon wax and 18-24 parts of modified composite wollastonite fiber. The invention also discloses a manufacturing method of the polycarbonate material. The polycarbonate material provided by the invention has high flame retardancy and wear resistance.

Owner:LIHUAYI WEIYUAN CHEM CO LTD

Preparation method of polymer-coated ardealite composite master batch

PendingCN114316632AImprove dispersionEnhanced interfacial interaction and compatibilityPigment treatment with macromolecular organic compoundsPigment physical treatmentHigh polymerSODIUM SULFATE ANHYDROUS

The invention provides a preparation method of a polymer-coated ardealite composite master batch, and relates to the technical field of hydrophobic modification of inorganic fillers and preparation of composite materials. The method comprises the following steps: calcining ardealite waste residue as a raw material in a gradient furnace, grinding and screening to obtain anhydrous ardealite, treating the anhydrous ardealite with sodium hydroxide and anhydrous sodium sulfate to obtain hydroxylated ardealite, carrying out surface modification on the hydroxylated ardealite with a modifier to obtain modified ardealite, and drying to obtain the modified ardealite. And carrying out in-situ suspension polymerization on the modified ardealite, a vinyl monomer and a reaction aid to prepare the hydrophobic polymer coated ardealite composite master batch. The polymer-coated ardealite composite master batch can be used as a filler in high polymer materials such as plastic or rubber, can significantly enhance molecular winding and interface interaction between the ardealite and a high polymer matrix, and significantly improves the comprehensive performance of a high polymer composite material. Meanwhile, the method has important significance on resource utilization of the ardealite, and the application range of the ardealite can be widened.

Owner:GUIZHOU UNIV

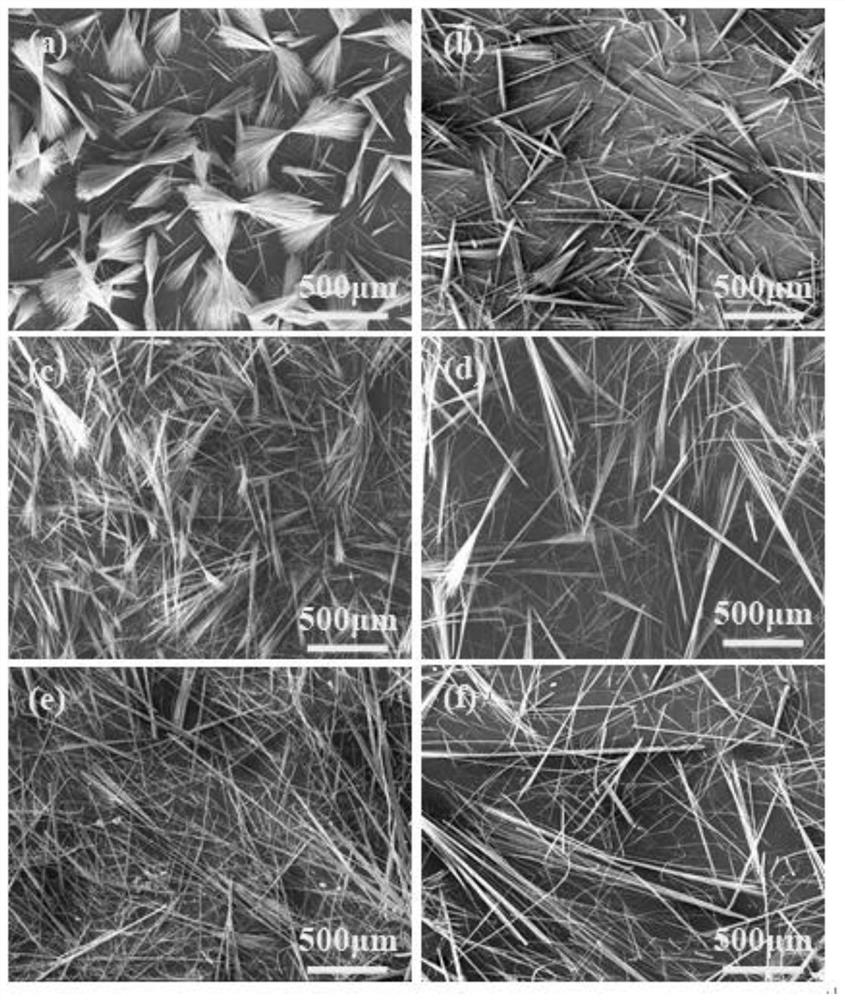

Basic magnesium sulfate whisker with high length-diameter ratio and preparation method thereof

ActiveCN114134574ALow purityReduce concentrationPolycrystalline material growthFrom normal temperature solutionsAqueous ethanolSodium hydroxide

The invention belongs to the technical field of inorganic functional materials, and particularly discloses a high-length-diameter-ratio basic magnesium sulfate whisker and a preparation method thereof.The preparation method comprises the following steps that a sodium hydroxide solution is slowly dropwise added into a magnesium chloride solution, a sol-gel reaction is conducted at the constant temperature, and magnesium hydroxide sol is obtained; dissolving magnesium sulfate in an ethanol-water solution to prepare a magnesium sulfate alcohol-water solution; adding sodium ethylene diamine tetracetate into a magnesium sulfate alcohol-water solution, and stirring for dissolving; mixing the obtained magnesium hydroxide sol with a magnesium sulfate alcohol-water solution, and uniformly stirring to obtain a basic magnesium sulfate whisker precursor; and quickly transferring into a high-pressure reaction kettle, carrying out hydrothermal crystallization reaction, then cooling to room temperature, and carrying out suction filtration, washing and drying to obtain a basic magnesium sulfate whisker product. The basic magnesium sulfate whisker prepared by the method has the advantages of good crystallinity, high length-diameter ratio, good dispersity and the like, the yield of the whisker can reach 90%, the length can reach 500-1000 microns, the length-diameter ratio reaches 150-300 or above, and the basic magnesium sulfate whisker can be applied to various flame-retardant high polymer materials.

Owner:SHANXI UNIV

Preparation method of soil-loosening humectant

InactiveCN107629803AIncrease the number of hydroxyl groupsIncrease infiltration rateOrganic fertilisersSoil conditioning compositionsAlcoholSoil remediation

The invention relates to the technical field of soil remediation and particularly relates to a preparation method of a soil-loosening humectant. The preparation method comprises the steps of firstly carrying out grape fermentation so as to prepare grape fermentation liquid rich in alcohol, soaking sepiolite powder by virtue of the grape fermentation liquid, carrying out hydroxylation modificationon the surface of the sepiolite powder by virtue of alcohol so as to increase the number of hydroxide radicals on the surface of the sepiolite, extracting supernatant rich in amino acids from fermented bean curds and soybeans which are rich in amino acids, carrying out blending fermentation modification on the supernatant and the hydroxylation-modified sepiolite, introducing amino and hydroxide radicals to the sepiolite by virtue of microorganisms so as to obtain modified sepiolite, and grafting the modified sepiolite to acrylic acid, so as to finally obtain the soil-loosening humectant. According to the soil-loosening humectant, the sepiolite has the property of swelling after water absorption, and the soil-loosening humectant is applied to soil and is capable of swelling after the waterabsorption and opening soil so as to realize a soil loosening effect, so that the hardening of the soil is avoided, water molecules can relatively easily enter the soil so as to improve the moisture absorption of the humectants, and the soil-loosening humectant has wide application prospects.

Owner:常州蓝旗亚纺织品有限公司

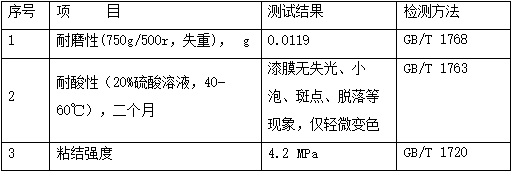

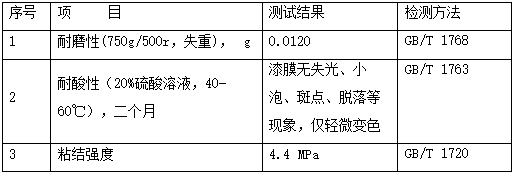

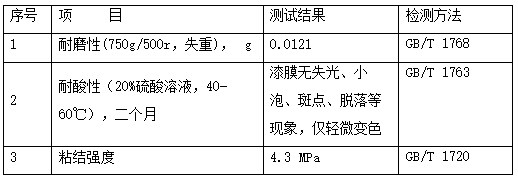

Liquid level coating material of wet-process smelting electrolytic zinc negative plate and preparation method for liquid level coating material

InactiveCN109609009AExtended service lifeImprove protectionAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyElectrolysis

The invention discloses a liquid level coating material of a wet-process smelting electrolytic zinc negative plate and a preparation method for the liquid level coating material. The coating materialis prepared from a component I and a component II in accordance with that OH / NCO=1: 1.1, wherein the component I is polymethylene polyphenyl polyisocyanate, the component II is prepared from the following raw materials in percentage by weight: 16% to 20% of ring-opening epoxy resin, 3% to 5% of maleic anhydride graft-modified SEBS resin, 18% to 22% of chrome oxide green, 6% to 9% of filler, 0.2% to 0.4% of antifoamer and 50% to 55% of mixed solvent A; and the ring-opening epoxy resin is prepared from the following raw materials in percentage by weight: 16% to 18% of octadeca long-chain carboxylic acid, 54% to 56% of powdered epoxy resin, 10% to 12% of xylene and 16% to 18% of mixed solvent B. According to the liquid level coating material and the preparation method therefor, all the components are combined in a specific proportioning ratio to exert a synergistic effect, and thus, the components can be firmly combined to a metal aluminum substrate; the heat resistance and acid resistance are good, the stress corrosion resistance is good, the mechanical properties are excellent, and a paint film has good protection to the metal aluminum substrate, so that the service life of the negative plate can be effectively prolonged.

Owner:中昊北方涂料工业研究设计院有限公司

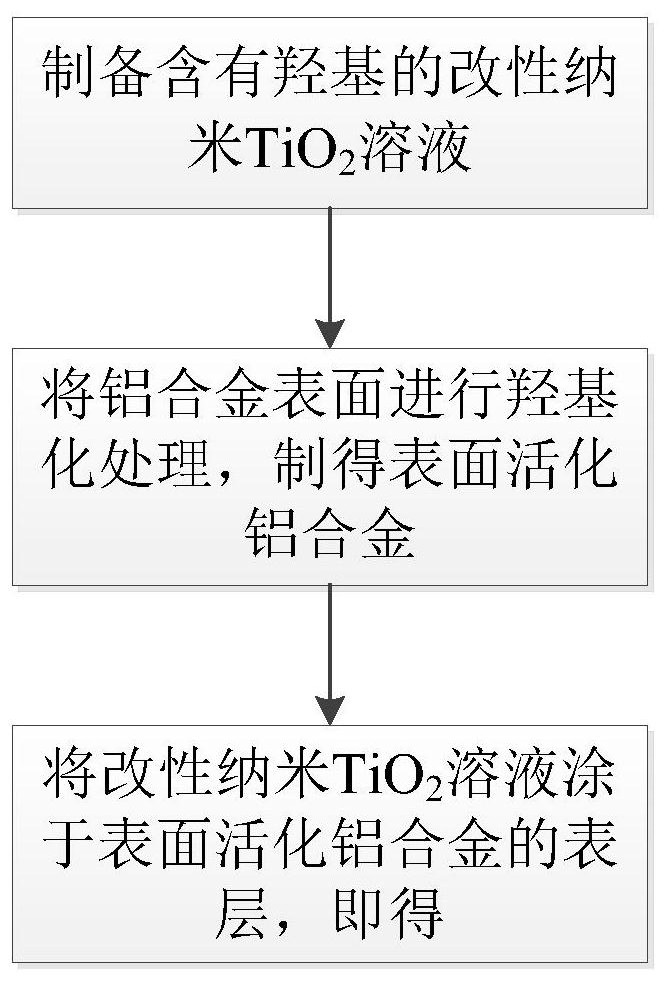

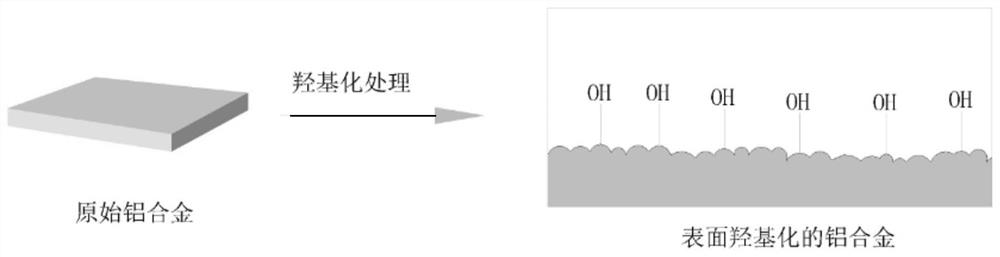

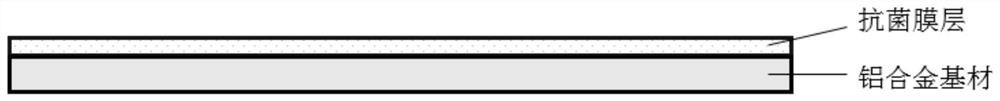

Antibacterial aluminum alloy and preparation method thereof

PendingCN112853431AIncrease the number of hydroxyl groupsImprove bindingAntifouling/underwater paintsSurface reaction electrolytic coatingAnti bacteriaCorrosion resistant

The invention provides antibacterial aluminum alloy and a preparation method thereof. The preparation method of the antibacterial aluminum alloy comprises the following steps that a modified nano TiO2 solution containing hydroxyl is prepared; hydroxylation treatment is conducted on the surface of the aluminum alloy, so that surface-activated aluminum alloy is prepared; and the modified nano TiO2 solution is coated onto the surface layer of the surface-activated aluminum alloy to prepare the antibacterial aluminum alloy. According to the method, hydroxylation treatment is conducted on the surface of the aluminum alloy, nano TiO2 can be chemically grafted onto the surface of the aluminum alloy to form a film layer with the long-acting antibacterial performance, and the antibacterial problem of the surface of the aluminum alloy is effectively solved; and the nano TiO2 can be firmly combined with the aluminum alloy for a long time, and the long-acting antibacterial performance and the service life of the antibacterial film layer are guaranteed. And meanwhile, the corrosion resistance of the aluminum alloy is greatly improved.

Owner:ANHUI HONGCHENG OPTO-ELECTRONICS CO LTD

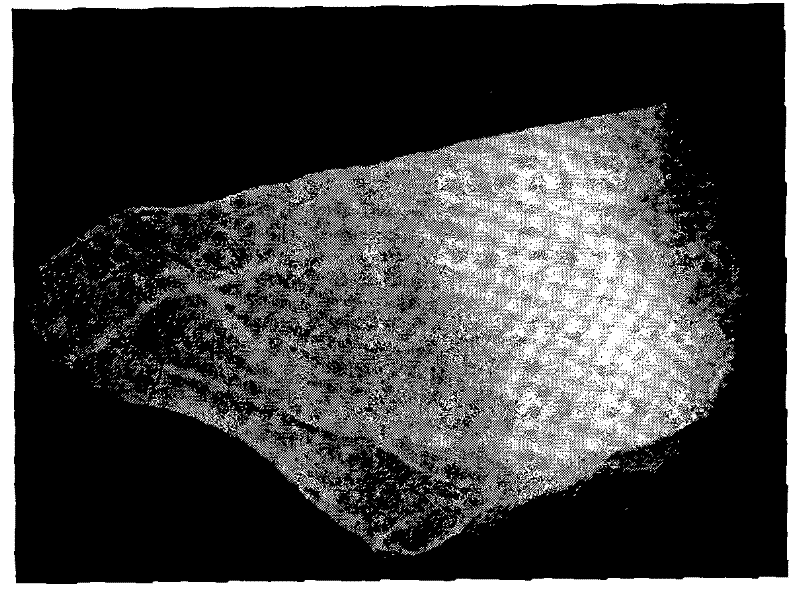

Method for preparing zirconium oxide refractory fibre

The present invention provides a method for preparing a zirconium oxide refractory fiber. The method adopts zirconium oxychloride, aqueous hydrogen peroxide solution, yttrium chloride or yttrium nitrate as raw material, the inorganic zirconium spinnable glue solution is made by reaction and compression, the gelatinous fiber can be obtained by centrifugal fiber forming, and after heat treating sintering the zirconium oxide refractory fiber which has the following advantages can be obtained: crystal phase composition with square phase and / or cubic phase zirconium oxide, purity up to 99.5% above, diameter around 5 mu m, length approximate continuous, soft and flexible property and without slag including sphere. The using temperature of the fiber is above 1600 DEG C, the material can be used as extreme temperature refractory, heat insulation material, protecting material, ablative material, satellite battery separator material and the like, used for the fields of aerospace, war industry and national defense, atomic energy and the like; the fiber can also be used as the flame-proof heat-insulating material of the extraordinary high-temperature electric furnace with temperature 1600 DEGC to 2200 DEG C, the oil or gas burning furnace and other extraordinary high-temperature heating mechanism, and is used for the fields of ceramic sintering, crystal growth, metal smelting, petroleum cracking, scientific researching and the like. The invention totally adopts the inorganic raw material, has the advantages of low cost, no pollution, simple technique and excellent effect.

Owner:山东红阳高温节能材料股份有限公司

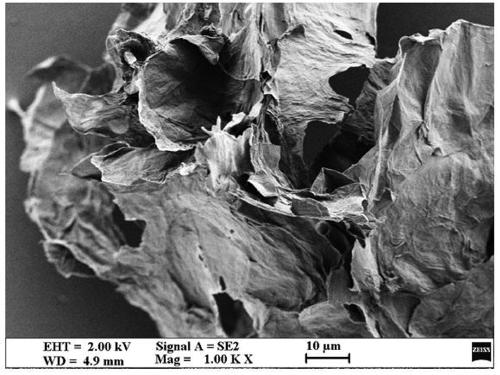

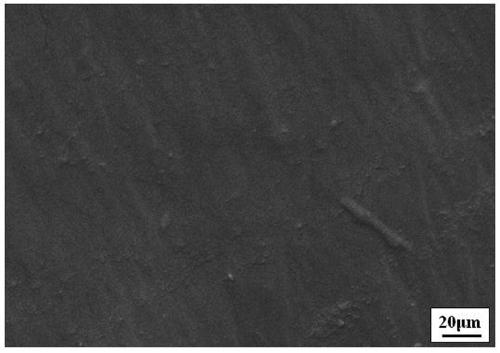

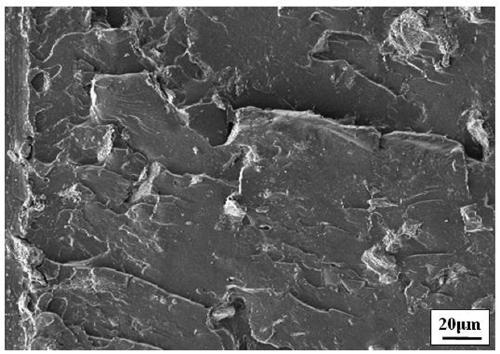

Hydrophobic sponge loaded with carbon nanotubes, preparation method and application of hydrophobic sponge in oil-water separation

ActiveCN113754922AIncrease the number of hydroxyl groupsEasy to modify laterNon-miscible liquid separationPolymer scienceHydrophobe

The invention provides hydrophobic sponge loaded with carbon nanotubes, a preparation method and application of the hydrophobic sponge, which belong to the technical field of oil-water separation. Firstly, polyurethane sponge isoxidized by using a H2O2 / H2SO4 mixed solution, so that the number of hydroxyl groups of the polyurethane sponge is increased, and the polyurethane sponge is convenient to modify; a silane coupling agent is utilized to realize combination of polyurethane sponge and hydroxylated carbon nanotubes, and specifically, hydroxyl groups of the polyurethane sponge and hydroxyl groups of the hydroxylated carbon nanotubes react with the silane coupling agent to obtain the hydrophobic sponge loaded with the carbon nanotubes. On one hand, the carbon nanotubes can increase the roughness of the surface of the polyurethane sponge and improve the hydrophobicity of the polyurethane sponge, so that the oil-water separation efficiency is improved; meanwhile, the carbon nanotubes can also improve the oil absorption rate of the polyurethane sponge, so that the oil absorption efficiency is improved; in addition, long-chain alkyl of the silane coupling agent is grafted to the polyurethane sponge, the hydrophobicity of the polyurethane sponge can be further improved, and then the oil-water separation efficiency is improved.

Owner:SHANDONG UNIV

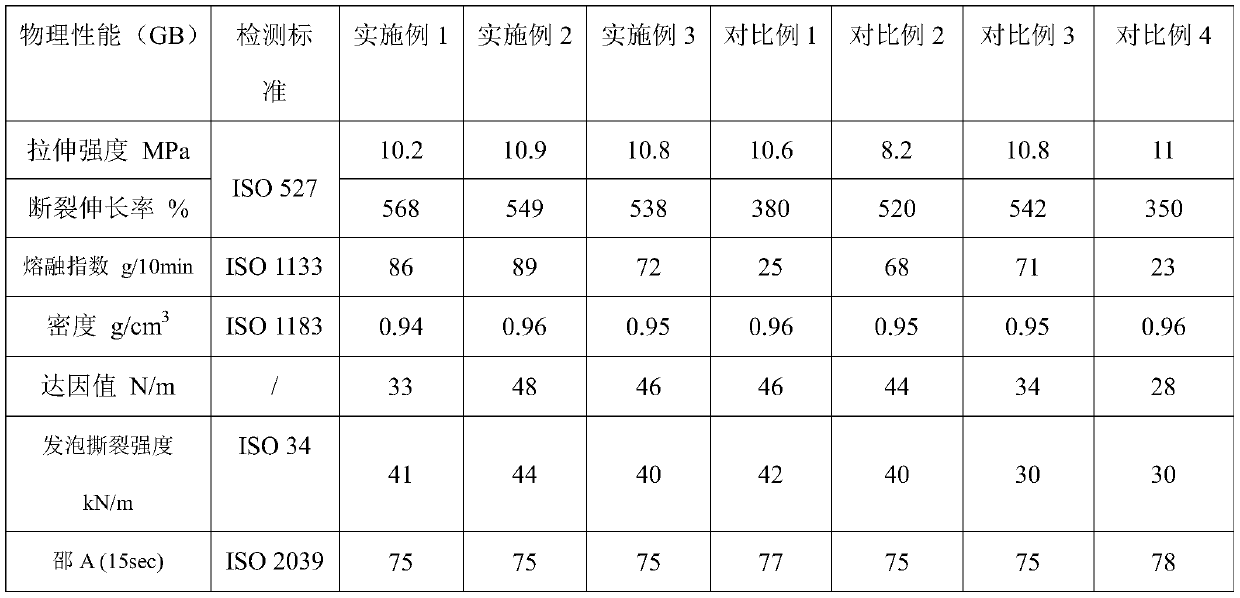

Modified SEBS composite material for automobile injection molding interior decoration, and preparation method thereof

The invention discloses a modified SEBS composite material for automobile injection molding interior decoration, and a preparation method thereof. The material is prepared from, by weight, 50 to 80 parts of a hydrogenated styrene-butadiene segmented copolymer, 20 to 25 parts of a plasticizer, 3 to 8 parts of hydrotalcite, 2 to 5 parts of acetylated SEBS, 5 to 10 parts of hydroxylated SEBS, 0.4 to0.8 part of an antioxidant, 0.3 to 0.6 part of a weather-resistant agent, 0.5 to 1 part of a lubricant and 0 to 3 parts of an auxiliary agent. The dyne index of the material can reach 46 N / m, the tearing strength can reach 36 kN / m, the tensile strength can reach 13 Mpa, and the elongation at break is larger than 500%, so that the material is high in surface dyne index and good in flowing property,and the comprehensive performances of the material are well balanced.

Owner:ORINKO NEW MATERIAL CO LTD

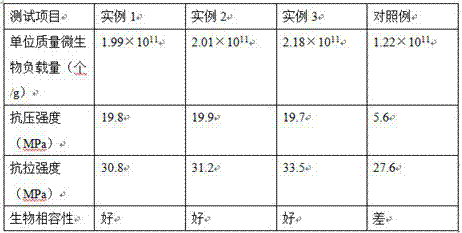

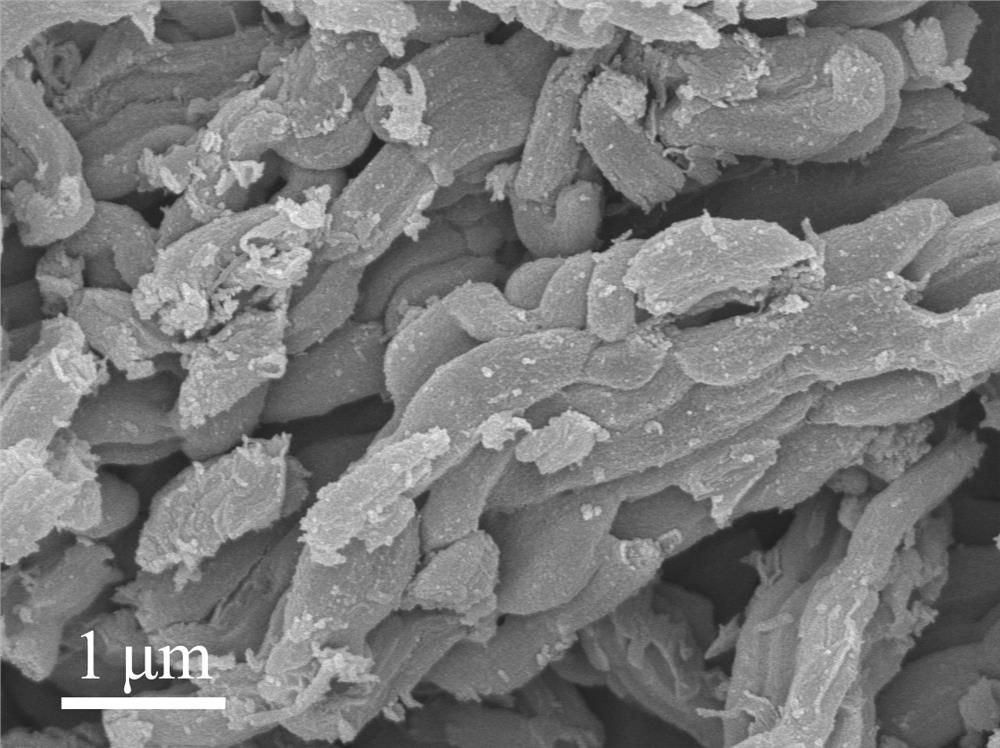

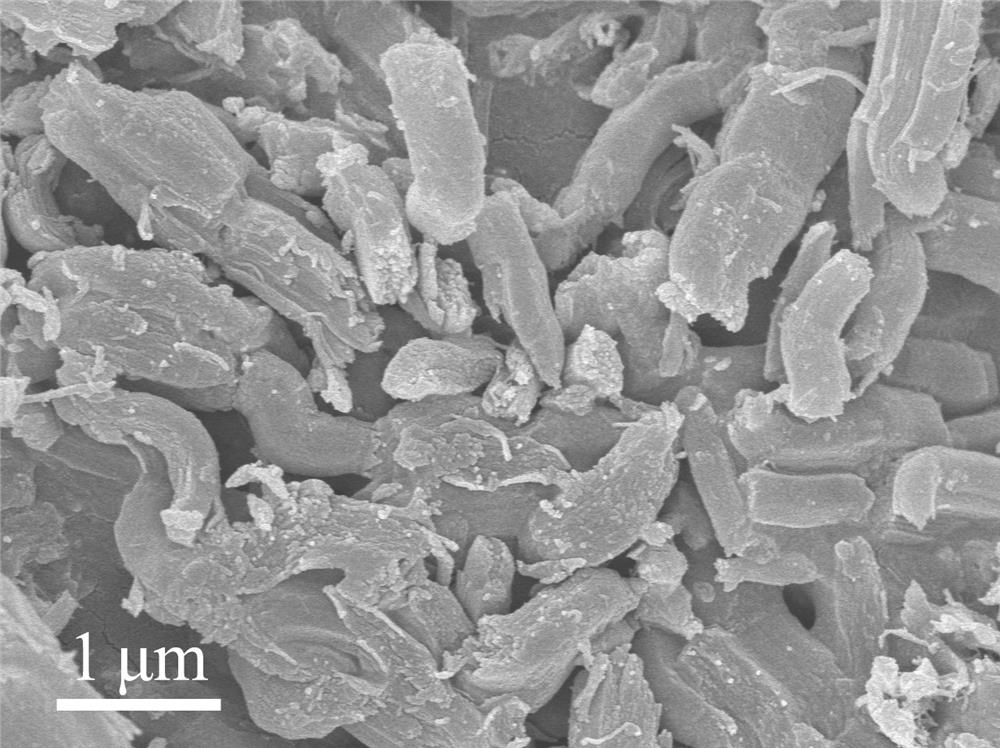

Preparation method for microbial carrier

ActiveCN107267495AIncrease loadBig spaceOn/in inorganic carrierPhosphorus compoundsMicroorganismEthylene diamine

The invention relates to the technical field of microbial immobilization, in particular to a preparation method for a microbial carrier. A porous cotton straw is used as a template, EDTA (Ethylene Diamine Tetraacetic Acid) is taken as a guiding agent to improve the purity of hydroxy calcium phosphate, a porous high-capacity hydroxy calcium phosphate carrier is prepared, mosses are loaded on the surface of the porous high-capacity hydroxy calcium phosphate carrier to provide places and nutrition for the growth of microorganisms, and good mechanical performance and excellent biocompatibility of the hydroxy calcium phosphate are used for finally preparing the microbial carrier with high biological capacity. The defects of poor mechanical performance, low biocompatibility and small biological capacity of a common microbial carrier are eliminated, and the microbial carrier with the high biological capacity has a wide application prospect.

Owner:上海同柏宸科生物技术有限公司

Preparation and use of metal-free catalysts for fixed-bed acetylene hydrochlorination to vinyl chloride

ActiveCN108246340BIncrease contentHigh activityMolecular sieve catalystsPreparation by halogen halide additionPtru catalystFixed bed

The invention relates to a preparation method and an application application method of a metal-free catalyst used for fixed bed acetylene hydrochlorinate preparation of vinyl chloride. Compared with other metal-free catalysts prepared through dipping-calcining method, the metal-free catalyst used for fixed bed acetylene hydrochlorinate preparation of vinyl chloride possesses following advantages:the nitrogen content of the metal-free catalyst used for fixed bed acetylene hydrochlorinate preparation of vinyl chloride is increased through in-suit doping combined ammonia gas treatment; the catalyst specific surface area is increased effectively through calcining of a precursor with polytetrafluoroethylene at a certain heating program, and at the same time nitrogen sulfur codoping and oxidation are adopted to increase the ratio of active sites and the number of surface oxygen-containing function groups, so that the metal-free catalyst possesses relatively activity and selectivity in fixedbed acetylene hydrochlorinate preparation of vinyl chloride. The preparation method is green, and is friendly to the environment; the raw materials are widely available and cheap; the metal-free catalyst can be used for replacing toxic mercuric chloride catalyst; and the application prospect in industrialized production is promising.

Owner:NANKAI UNIV

Finishing method for improving resin finishing wrinkle recovery angle

InactiveCN111826958AImprove permeabilityPenetrate fastWrinkle resistant fibresVegetal fibresFiberPolymer science

The invention belongs to the technical field of textile finishing and processing, and particularly relates to a finishing method for improving the resin finishing wrinkle recovery angle. The finishingmethod for improving the resin finishing wrinkle recovery angle comprises the following steps of (1) pretreating a fabric; (2) padding with a resin finishing liquid; and (3) sequentially carrying outpre-drying, needling, high-temperature baking reaction, water washing, tentering and pre-shrinking on the padded fabric to obtain a finished fabric, wherein the resin finishing liquid is prepared from the following raw material components of 100 to 200g / L of high-temperature resin, 30 to 60g / L of catalyst, 20 to 40g / L of fiber protective agent, 2 to 6g / L of polyvinyl alcohol, 1 to 2g / L of citricacid and the reset of water. The process is simple, the wrinkle recovery performance of the fabric is further improved; the effect that no wrinkle exists on the washed fabric surface is achieved; thewearability and attractiveness of the fabric are improved; the quality is stable; and good popularization prospect is achieved.

Owner:鲁丰织染有限公司

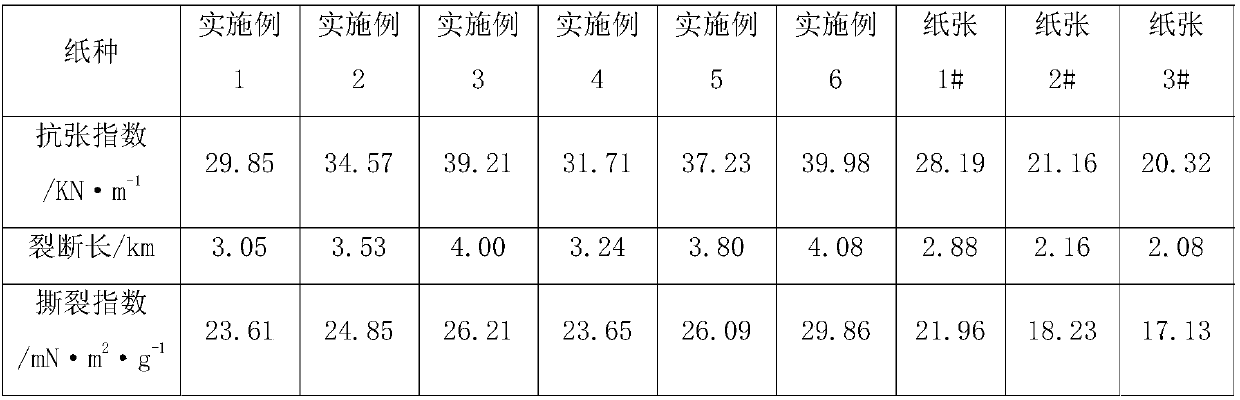

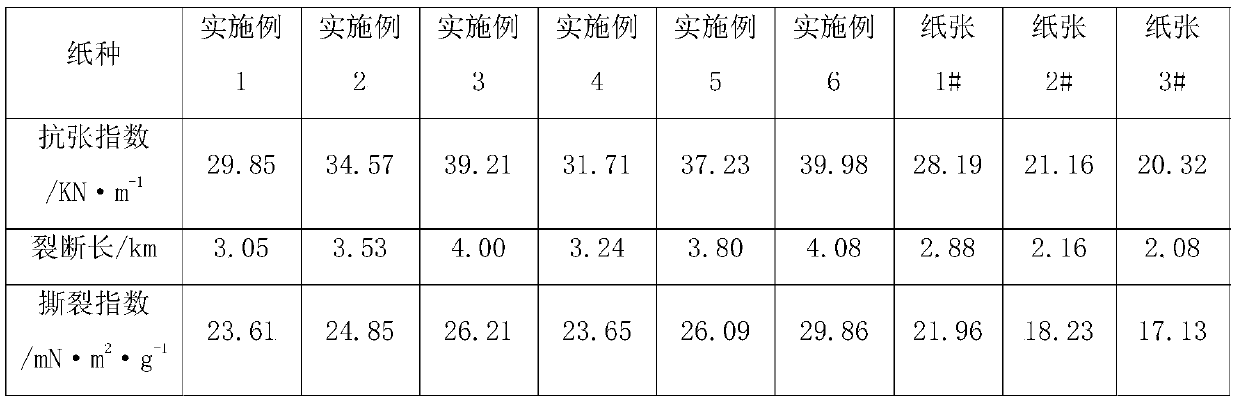

High-strength environment-friendly paper and preparation method and application thereof

ActiveCN107687111AImprove securityImprove stabilityNon-fibrous pulp additionFlexible coversMass ratioChemical polarity

The invention discloses high-strength environment-friendly paper and a preparation method and application thereof. The preparation method of the high-strength environment-friendly paper comprises thefollowing steps: beating a bamboo pulp raw material to obtain SR bamboo pulp with the beating degree of 30-50 degrees; then pretreating the bamboo pulp or PLA fiber in a cationic guar gum solution; making paper from the pretreated bamboo pulp and the untreated PLA fiber, or the untreated bamboo pulp and the pretreated PLA fiber according to an absolute dry mass ratio of 7:3 to obtain the high-strength environment-friendly paper. According to the preparation method, through pretreatment in the cationic guar gum solution, the fiber strength of the bamboo fiber, the chemical polarity on the surface of the PLA fiber and the interfacial compatibility between fibers are improved, and ultimately, the physical properties of the paper are significantly improved. All used materials are environmentally friendly, and the obtained paper has relatively high strength and can be well applied to various fields of daily paper, food packaging paper and the like.

Owner:SOUTH CHINA UNIV OF TECH

A kind of high-strength green environmental protection paper and its preparation method and application

ActiveCN107687111BImprove securityImprove stabilityNon-fibrous pulp additionFlexible coversFood packagingGuar gum

The invention discloses high-strength environment-friendly paper and a preparation method and application thereof. The preparation method of the high-strength environment-friendly paper comprises thefollowing steps: beating a bamboo pulp raw material to obtain SR bamboo pulp with the beating degree of 30-50 degrees; then pretreating the bamboo pulp or PLA fiber in a cationic guar gum solution; making paper from the pretreated bamboo pulp and the untreated PLA fiber, or the untreated bamboo pulp and the pretreated PLA fiber according to an absolute dry mass ratio of 7:3 to obtain the high-strength environment-friendly paper. According to the preparation method, through pretreatment in the cationic guar gum solution, the fiber strength of the bamboo fiber, the chemical polarity on the surface of the PLA fiber and the interfacial compatibility between fibers are improved, and ultimately, the physical properties of the paper are significantly improved. All used materials are environmentally friendly, and the obtained paper has relatively high strength and can be well applied to various fields of daily paper, food packaging paper and the like.

Owner:SOUTH CHINA UNIV OF TECH

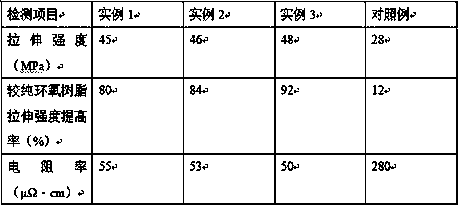

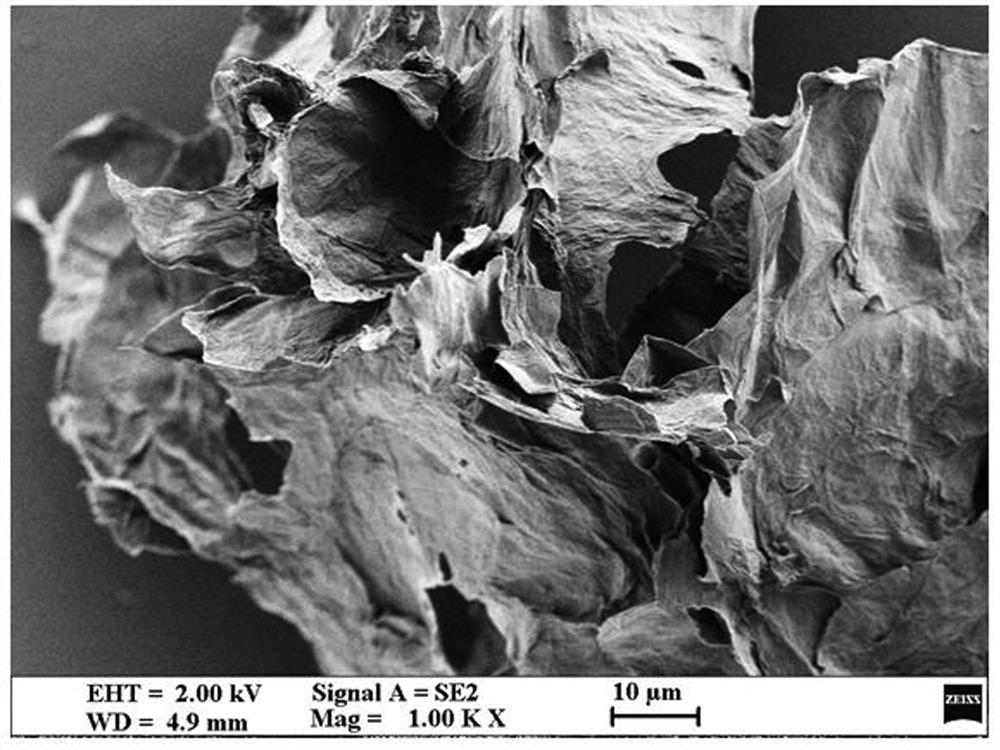

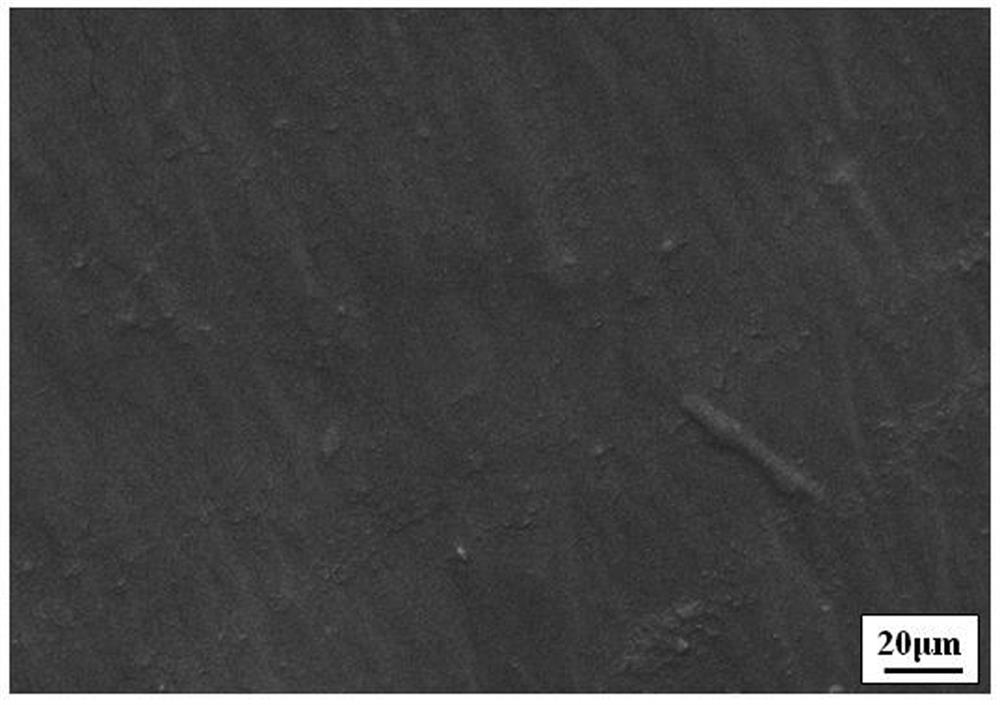

A kind of preparation method of nano-carbon fiber special for epoxy resin composite conductive material

The invention relates to a method for preparing a special nanometer carbon fiber for an epoxy resin composite conductive material and belongs to the technical field of conductive material preparation.The method comprises culturing water fennel to obtain a large amount of roots with excellent adsorption effects, putting the water fennel into a metal salt solution with a citric acid solution, carrying out water planting to convert inorganic transition metal ions into organic metal ions through metabolism of water fennel so that water fennel roots gathering transition metal ions are obtained, mixing the water fennel roots gathering transition metal ions and anhydrous methanol to obtain carbon fuel, carrying out combustion at the normal temperature through a clean glass plate as a nanometer carbon fiber deposition base, scraping the nanometer carbon fibers obtained by the combustion and carrying out hydroxylation and fermentation modification to obtain the nanometer carbon fibers. The method simplifies the process of preparing the catalyst, reduces the carrier gas and high temperature conditions, reduces the cost and has a wide application prospect.

Owner:广西富勒星科技有限责任公司

A kind of preparation method of high strength and high barrier TPU composite material

ActiveCN111138631BIncrease the degree of cross-linkingIncrease the number of hydroxyl groupsPolymer scienceMeth-

The invention discloses a preparation method of a high-strength and high-barrier TPU composite material, which belongs to the technical field of polymer composite material synthesis. In this method, polytetramethylene ether glycol and 4,4'-diphenylmethane diisocyanate are reacted to obtain an isocyanate group-terminated TPU prepolymer, and modified graphene oxide is added to the TPU prepolymer, and 1, 4-Butanediol participates in the in-situ polymerization process together as a compound chain extender to complete the chain extension reaction and obtain a high-strength and high-barrier TPU composite material. Modified graphene oxide increases the number of reaction sites in the reaction system and increases the crosslinking degree of the composite material. There are a large number of covalent bonds and hydrogen bonds in the prepared TPU composite material, which leads to the dispersion of modified graphene oxide in the TPU matrix. Good performance, the interface bonding force with the TPU matrix is enhanced, and the barrier properties and mechanical properties of the TPU composite are improved.

Owner:FUZHOU UNIV

A method of using zeolite and fly ash to strengthen liquefied sand foundation

Owner:上海先科桥梁隧道检测加固工程技术有限公司

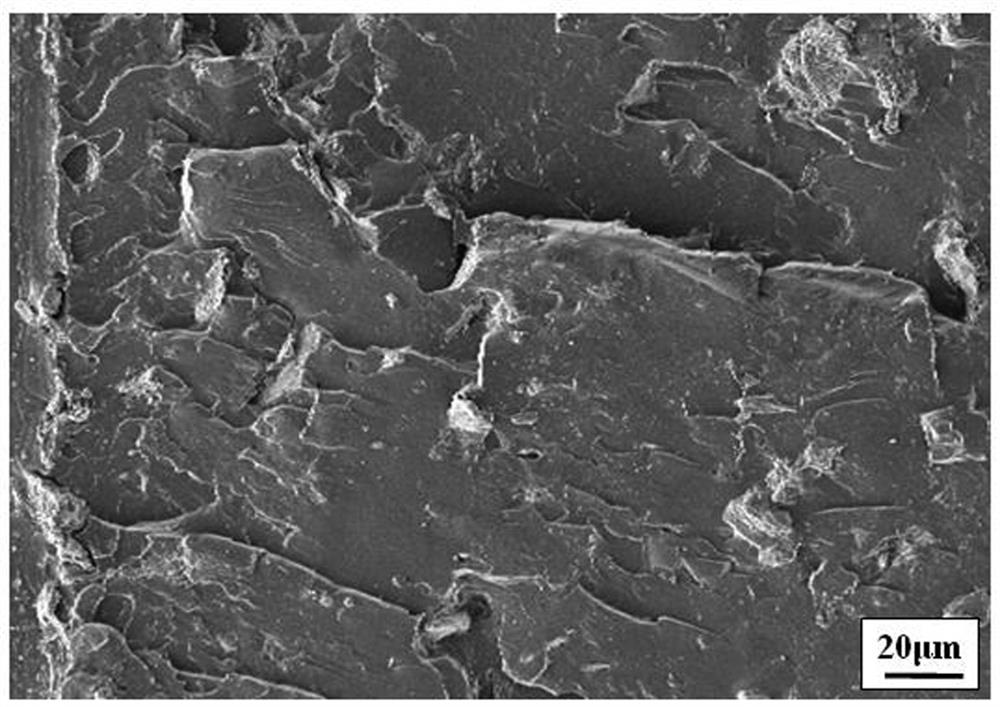

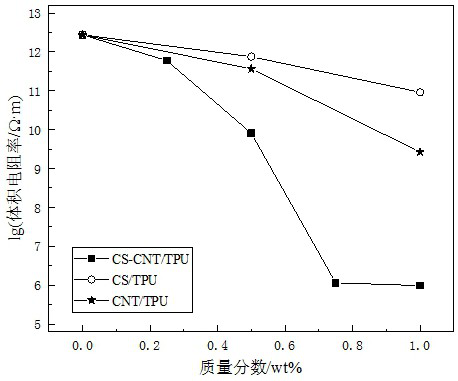

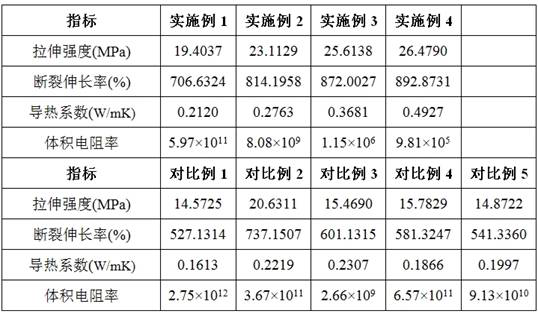

A kind of preparation method of electrical and thermal conductivity functionalized carbon nanotube/tpu composite material

The invention discloses a method for preparing a conductive and thermally conductive functionalized carbon nanotube / TPU composite material. Firstly, the functionalized carbon nanotube (CS-CNT) is obtained by modifying the functionalized carbon nanotube with chitosan, and then combined with 4, 4'-diphenylmethane diisocyanate reaction, then adding polytetramethylene ether glycol, 1,4-butanediol and a catalyst to synthesize the conductive and thermally conductive functionalized carbon nanotube / TPU composite through pre-polymerization-chain extension reaction Material. There are hydrogen bonds and electrostatic adsorption between chitosan and carbon nanotubes in the CS‑CNT molecule, between CS‑CNT, between CS‑CNT and TPU monomer, and between CS‑CNT and TPU matrix A large number of hydrogen bonds and covalent bonds lead to an enhanced binding force with the TPU matrix, an increased degree of crosslinking, and the formation of a complete and dense conductive network and a more efficient heat conduction network. The electrical and thermal conductivity of the TPU composite material have been greatly improved. promote.

Owner:FUZHOU UNIV

A kind of production method of quick-drying bible paper

ActiveCN111691236BImprove water absorptionIncrease the number of hydroxyl groupsSpecial paperWater-repelling agents additionCelluloseFiber

The invention relates to the field of paper manufacturing, in particular to a production method of quick-drying bible paper, comprising the following steps: (1) mixing and stirring fiber raw materials with titanium dioxide, sodium carboxymethyl cellulose, and water; (2) surfing the Forming, pre-dehydration and drying to obtain ultra-thin paper sheets; (3) using adhesives containing silane-based polymers to bond between two ultra-thin paper sheets; (4) polymerizing with branched polyhydroxyl groups Sizing agents, retention aids, and lubricant fillers are double-sided sizing; (5) After dehydration, drying, and calendering, quick-drying Bible paper is obtained. The present invention uses polyhydroxy polymeric sizing agent to sizing the paper, increasing the number of hydroxyl groups on the surface of the paper, improving the water absorption capacity of the paper, ensuring the rapid separation of water and pigment components after the paper absorbs ink, and achieving the effect of quick drying. Hydrogen bonds are formed between the hydroxyl groups on the cellulose on the surface of the paper to increase the strength of the paper; a hydrophobic layer is added in the middle of the paper to ensure that the paper will not show through after absorbing water.

Owner:XIANHE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com