A kind of preparation method of nano-carbon fiber special for epoxy resin composite conductive material

A nano-carbon fiber, composite conductive technology, applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of difficult to achieve dispersion, complex operation, poor compatibility of polymer matrix, reduce carrier gas and high temperature conditions, and simplify the process. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

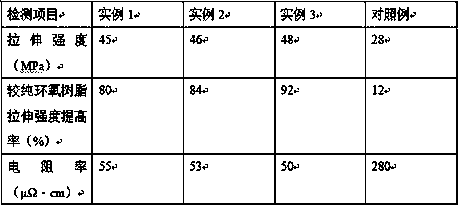

Examples

example 1

[0026] In parts by weight, 50 parts of potassium nitrate, 70 parts of calcium nitrate, 10 parts of ammonium phosphate, 25 parts of magnesium sulfate, 10 parts of ferric chloride and 300 parts of deionized water were weighed to obtain a hydroponic nutrient solution, and the plant height was selected as The 10cm cress is immersed in the hydroponic nutrient solution and cultivated for 15 days until a large number of white root hairs grow from the root of the cress, and the pretreated cress is obtained; the cobalt ion concentration is 500mg / L, and the iron ion concentration is 400mg / L. For the metal salt solution, inject the metal salt solution into a culture tank with an aeration device at the bottom and a size of 10m×10m×0.5m, take a polystyrene foam board with a side length of 1m, and use a puncher to spread the water evenly on the surface of the foam board. Make 25 holes with a diameter of 3 cm, and then pass the root hairs of the above-mentioned pretreated cress through the ho...

example 2

[0028] In parts by weight, 55 parts of potassium nitrate, 73 parts of calcium nitrate, 13 parts of ammonium phosphate, 28 parts of magnesium sulfate, 13 parts of ferric chloride and 350 parts of deionized water were weighed to obtain a hydroponic nutrient solution, and the plant height was selected as The 13cm cress is immersed in the hydroponic nutrient solution and cultured for 18 days, until a large number of white root hairs grow from the root of the cress, and the pretreated cress is obtained; the cobalt ion concentration is 650mg / L, and the iron ion concentration is 500mg / L. For the metal salt solution, inject the metal salt solution into a culture tank with an aeration device at the bottom and a size of 10m×10m×0.5m, take a polystyrene foam board with a side length of 1m, and use a puncher to spread the water evenly on the surface of the foam board. Make 28 holes with a diameter of 4cm, and then pass the root hairs of the above-mentioned pretreated cress through the hole...

example 3

[0030] In parts by weight, 60 parts of potassium nitrate, 75 parts of calcium nitrate, 15 parts of ammonium phosphate, 30 parts of magnesium sulfate, 15 parts of ferric chloride and 400 parts of deionized water were weighed to obtain a hydroponic nutrient solution, and the plant height was selected as The 15cm cress is immersed in the hydroponic nutrient solution and cultivated for 20 days until a large number of white root hairs grow from the root of the cress, and the pretreated cress is obtained; a mixture with a cobalt ion concentration of 800mg / L and an iron ion concentration of 600mg / L is prepared. For the metal salt solution, inject the metal salt solution into a culture tank with an aeration device at the bottom and a size of 10m×10m×0.5m, take a polystyrene foam board with a side length of 1m, and use a puncher to spread the water evenly on the surface of the foam board. Make 30 holes with a diameter of 5 cm, and then pass the root hairs of the above-mentioned pretreat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com